3D printer ventilation system

How to Ventilate a 3D Printer Properly – Do They Need Ventilation? – 3D Printerly

3D printer fumes and pollutants are usually overlooked by people, but it’s important to ventilate your 3D printer properly.

There are some great ventilation systems that you can make use of to have your 3D printing environment safer and less harmful to people around it.

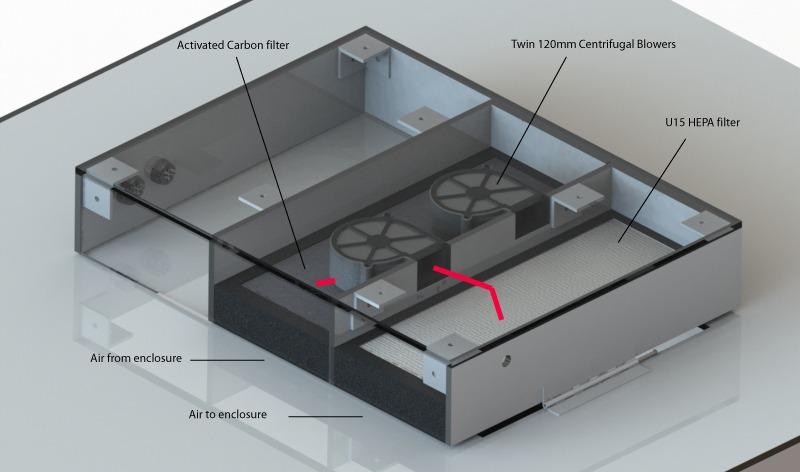

The best way to ventilate a 3D printer is to put your 3D printer in an enclosure and have a ventilation system that properly tackles the small particulates that 3D printers emit. Make sure you have carbon filters and a HEPA filter to tackle odors and smaller particles.

The rest of this article will answer some key questions on 3D printer ventilation, as well as detail some nice ventilation systems that you can implement yourself.

Do You Need Ventilation for a 3D Printer?

During the printing process, you might have smelled the odor that is produced by the printer. To expel this odor out of the machine and workspace, you can use good ventilation.

However, the quality and smell of odor depends on the type of material that is used for printing purposes. For example, PLA is much safer when it comes to the smell than other filaments such as ABS.

Other than the smell, we also have small particles that are emitted from heating thermoplastics at such high temperatures, the higher the temperature, the worse the particles usually.

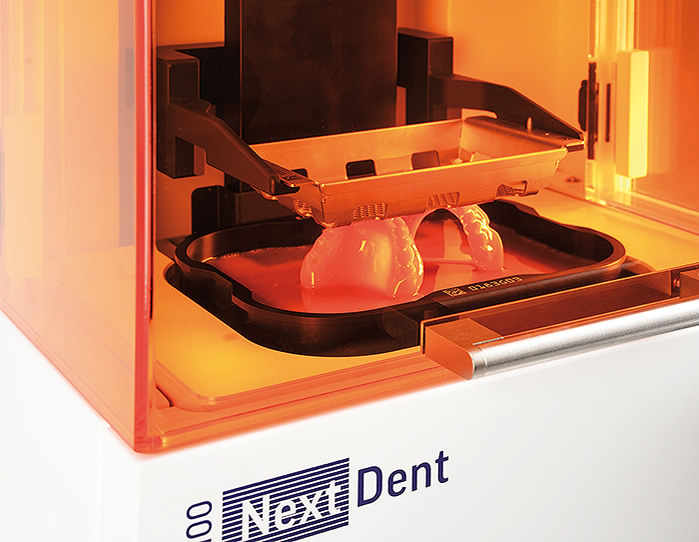

It also depends on the chemical makeup of the thermoplastic in the first place. If you are printing with ABS, Nylon or resin material in SLA 3D printers, proper ventilation is highly recommended, along with a mask.

A good enough ventilation system can work very well for ensuring that the surrounding air is clean and not contaminated.

It is said that the average running time for a 3D print can be around 3-7 hours, which is almost a quarter of the whole day when it is producing fumes.

To avoid any kind of harmful effect on your health or body, you seriously need to set up a ventilation system.

Ventilation While Using PLA

PLA is made up of eco-friendly material that produces sweet-smelling fumes that are laced with ultra-fine particles (UFPs) and volatile organic compounds (VOCs).

Technically, these both materials are not harmful to your health according to the research, but exposure to them daily may cause issues, especially to those with respiratory issues.

An open window or air purification system should work well enough for ventilating PLA.

Although many studies and research mention that PLA is safe, it is hard to measure the marginal health risks over time, and they take many years to properly test for. The risk may be similar to other ‘hobby-type’ activities such as woodworking, painting or soldering.

One study did test PLA for its emissions, and they found that it mostly emits Lactide which is known to be quite harmless. You should keep in mind that different types of PLA are created differently.

One brand and color of PLA could be harmless, while another brand and color of PLA isn’t as safe as you may think.

Many of the studies on emissions from 3D printers are in proper workplaces with many things going on, rather than your standard desktop home 3D printer, so its hard to generalize the findings.

Although it may not be completely safe, the studies show that PLA isn’t very risky, especially compared to other activities that we do on a regular basis.

Even going into a big city with all the pollution from vehicles and factories are said to be a lot worse than 3D printers.

Ventilation for ABS

According to the Journal of Occupational and Environmental Hygiene, materials commonly used for 3D printing such as PLA, ABS, and nylon can be a source of potentially dangerous VOCs.

ABS has been shown to result in high VOC emissions when heated at those higher temperatures, the main one being a compound called Styrene. It isn’t harmful in small portions, but breathing in a concentrated amount on a daily basis can be harmful to your body.

The concentration of the VOCs however, aren’t as dangerously high as it requires to have serious negative health effects, so printing in a well-ventilated, large room should be good enough to 3D print safely.

I would recommend not 3D printing ABS in a space where you are occupying for long periods of time. If you are 3D printing in a small room with poor ventilation, the rise of VOC concentration in the air can be troublesome.

The UFPs and VOCs produced by ABS during the 3D printing process contains Styrene. This material is not harmful in small portions; however, breathing in it on a daily basis can harm your body.

This is the reason why ventilation is needed during the printing process with ABS.

I would ensure that you are at least using an enclosure with some type of ventilation, ideally in a larger room.

How to Ventilate a 3D Printer

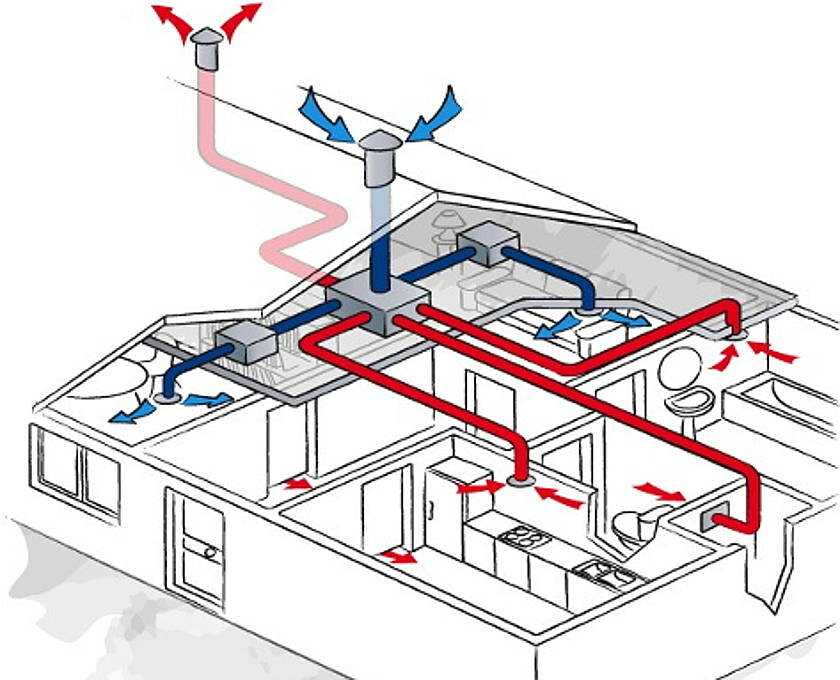

The best thing you can do to ventilate a 3D printer is to make sure your 3D printer chamber or enclosure is sealed/airtight, then to connect a vent from your chamber to the outside.

Some people use a window fan and put it near a window where your 3D printer is to then blow air out of the house. When printing with ABS, many users do this, and it works well to eliminate noticeable smells.

Installing Air Purifiers

Air purifiers have become common in major cities to keep the air clean. Similarly, you can use these air purifiers for your places where 3D printing is being performed.

Purchase a small air purifier and install it next to your 3D printer. Ideally you can put an air purifier within an enclosed system that contains your 3D printer so that the contaminated air passes through the purifier.

Look for the enlisted features in an air purifier:

- Have high efficient particulate air (HEPA) filters.

- A charcoal air purifier

- Calculate the size of your room and select the purifier according to it.

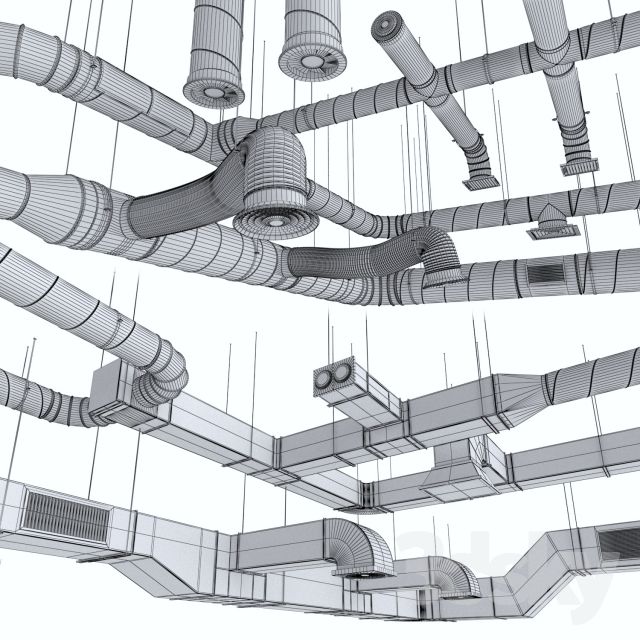

Air Extractors

Air Extractors are considered to be one of the best solutions to improve the ventilation of an enclosed room. Its working is explained below for you:

Its working is explained below for you:

- It sucks in the heated air.

- Exchange the heated air with the cool air from outside.

- It uses a fan and suction pipes.

There are two main types of extractors that you can easily purchase from the market, i.e., Twin Reversible Airflow Extractors with and without Thermostats.

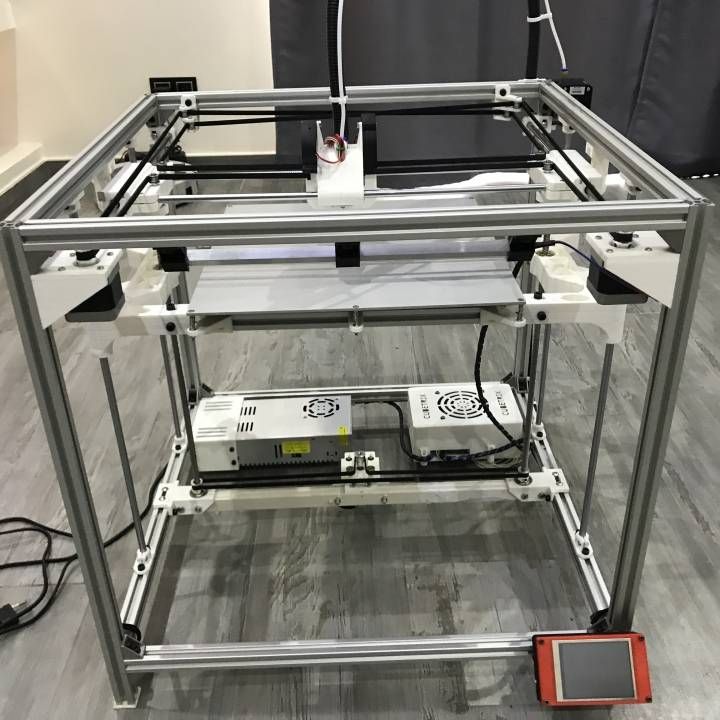

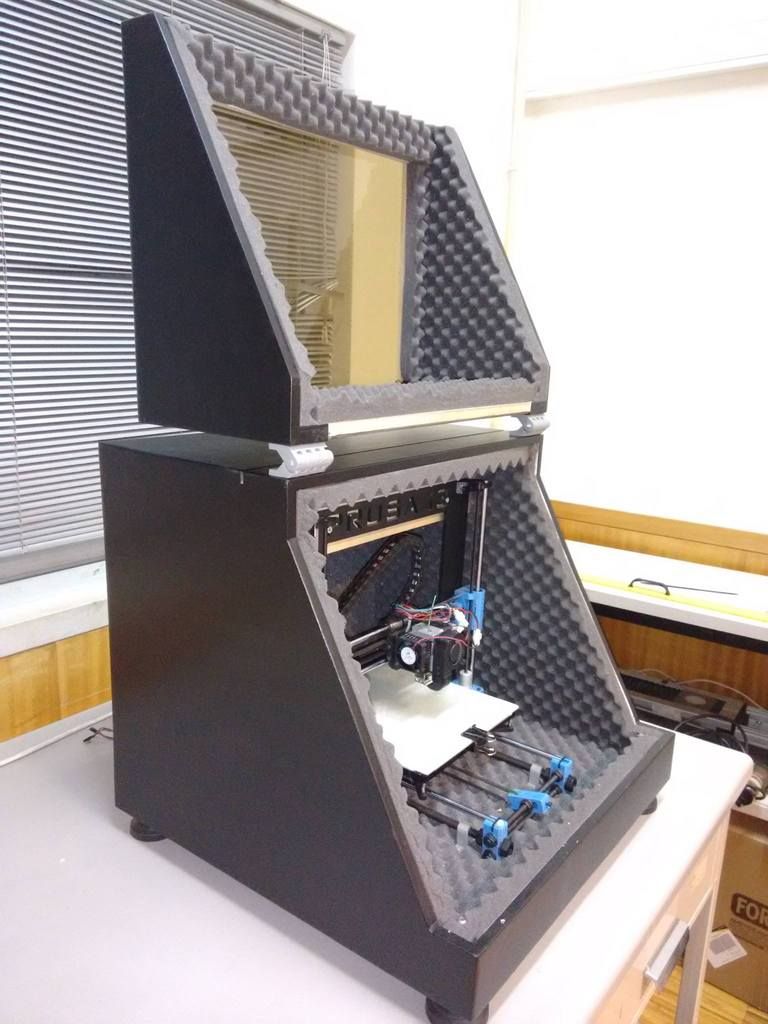

Building a 3D Printer Enclosure

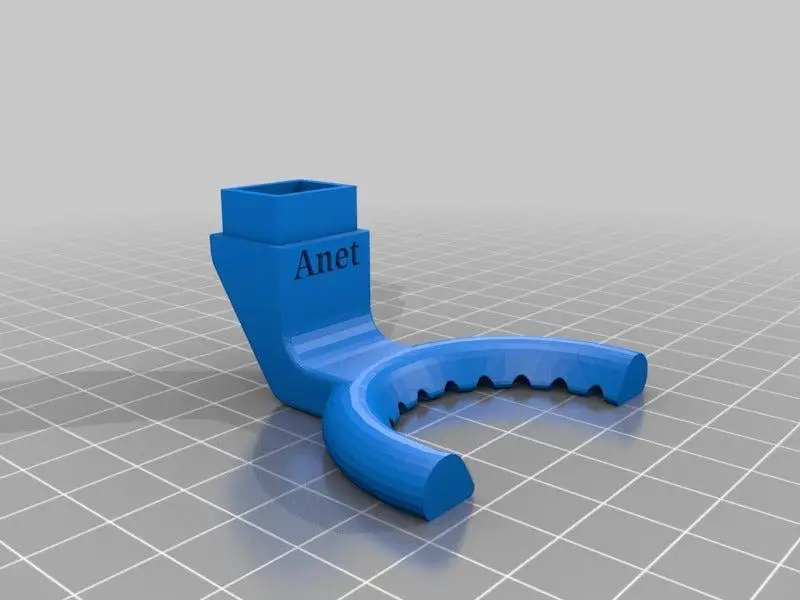

You can consider building an enclosure for your printer. It basically involves creating an airtight enclosure equipped with carbon filters, a fan, and a dry-hose that runs outside your home.

In the enclosure, the carbon filter will trap styrene and other VOCs, while the hose will let the air pass through. This is an effective ventilation process which you can make at home.

This is an effective ventilation process which you can make at home.

3D Printer with Built-in Filtration

There are very few printers that come with a built-in HEPA filtration. Even the manufacturers are aware of the fumes, but nobody bothers installing a filtration.

For example, UP BOX+ is one of the printers that come with HEPA filtration solutions that filter out tiny particles.

You can choose to get a 3D printer with built-in filtration, but these are usually more expensive so be prepared to pay extra for this feature.

The Elegoo Mars Pro is a good example of this which has a built-in carbon air filter to remove some VOCs and resin odor from the air.

How to Ventilate a Resin 3D Printer?

The best way to ventilate a resin 3D printer is to create a negative pressure enclosure which directs air away the enclosure to a space outside. Long term exposure to resin fumes are unhealthy, even if they don’t smell.

Long term exposure to resin fumes are unhealthy, even if they don’t smell.

Most people don’t have a dedicated ventilation system and are looking for a simple fix to help ventilate their resin 3D printers.

Following the video above should improve your ventilation for a resin 3D printer.

Remember, resins are toxic and can become allergic to your skin, be careful while using them.

Are 3D Printer Fumes Dangerous?

Not all, but some 3D printer fumes are dangerous and can cause serious damage to the health. As previously described, those UFPs are the more dangerous kind of emissions, where they can be absorbed into the lungs, then into the bloodstream.

According to the research done by the Georgia Institute of Technology, 3D printer fumes can negatively impact the quality of indoor air leading to potential respiratory health issues.

The regulations provided by OSHA actually throw light on the fact that 3D printer fumes are dangerous for health and the environment.

According to the research done on 3D printing filament, ABS is considered more toxic than PLA.

PLA is made up of eco-friendly substance so it is less harmful. This is one of the reasons why PLA is so commonly used, especially over ABS, because of its safety and non-smelling properties.

For people struggling with various 3D printing issues, you might want have wanted more guidance towards getting ideal 3D printing results. I created a course that's available to get called Filament Printing 101: Beginner's Guide to Filament Printing that takes you through some of the best 3D printing practices early on, so you can avoid those beginner mistakes.

DIY Ventilation and Filtration for 3D Printing

This 4D Filtration resource is user-supported by donations, affiliate links, and/or ads.

Last Updated: January 27th, 2023

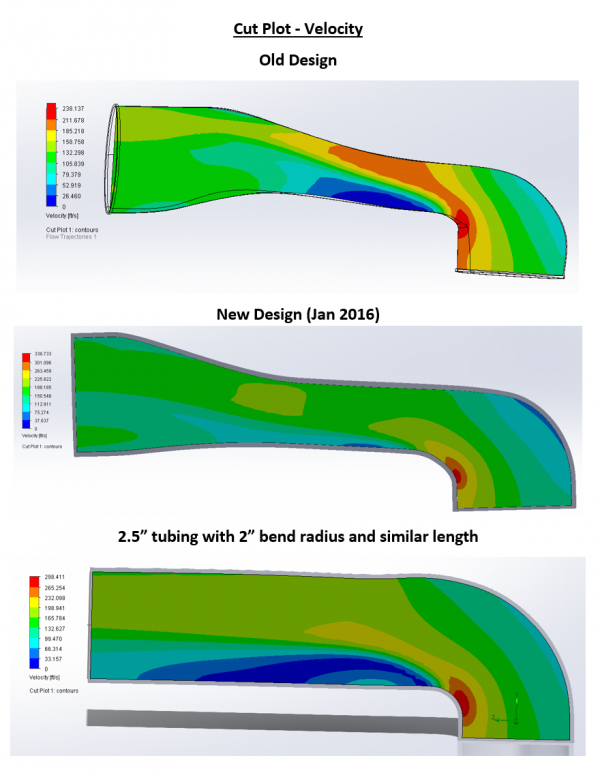

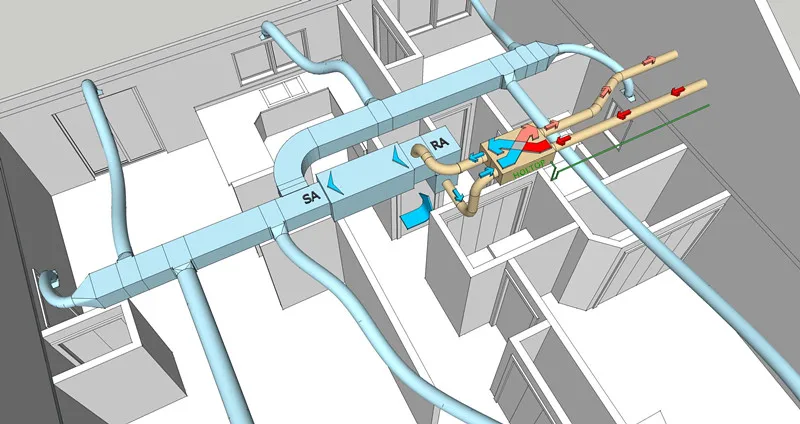

The following simulations are intended to provide a comparison between common ventilation setups for 3D printers. The animations represent the behavior of the particulates and VOCs that are suspended by airflow. The exact concentrations present during printing are not represented, only the behavior.

The animations represent the behavior of the particulates and VOCs that are suspended by airflow. The exact concentrations present during printing are not represented, only the behavior.

When it is available, we recommend placing resin printers in a location outside of your home, such as a garage. Resin printers can be indoors but they should be enclosed and vented. Grow tents are an affordable and effective option to vent or keep the heat in for both FDM and resin printers.

Duct from fume extractors can easily attach to a grow tent - this is ideal for FDM printers. For resin printers, grow tents can be used to enclose the printer and vent the fumes out a window - this is occurs when you do not have access to a work area outside the residence (ie: garage, shed, etc).

We transformed a room specifically for resin printing and documented how we implemented an enclosure, heating, ventilation, filtration, and cleaning equipment.

Table of Contents

- Worse Case: Indoors With No Ventilation

- Best Case: Outdoors

- Ideal Case: Garage or Separate Room, No Enclosure

- Ideal Case: Garage or Separate Room, Grow Tent Enclosure

- Using Filtration For Mitigation & Secondary Defense

Assumptions

- The small resin printer is simplified to a 20" cube.

- Air temperature is 90°F (32°C), and there is an external wind speed of 5 mph (2.2 m/s).

- The room size is 12x16' (3.7x4.9 m).

- The airflow is represented by transparent brown arrows; the particles are the spheres, colored by the legend dependent on their velocity or temperature.

Worst Case Scenario - No Ventilation

Sealed Room With No Ventilation

A completely sealed room allows for the particle concentration to increase. Resin that off-gasses will eventually spread to the rest of your home.

The mixture remains suspended by free convection that is powered by heat from electronics, sunlight, and artificial light.

Best Case Scenario - Outside The Home

Balcony or Patio With 5 mph Wind

While not always practical, placing the printer outside allows for particles to be swiftly carried away by a light wind.

The goal of ventilation is to attempt to reach this behavior while the printer is indoors.

Garage or Indoor Ventilation

Garage or Room With Box Fan

Perhaps the cheapest garage or indoor solution, the good ol' plop a fan in the window method will move a lot of air but will gradually expose the entire room to the external temperature.

In a garage, this could work when it is warm outside, but the cool winter air can result in print failures. A small heater will be needed in this case.

The simulated box fan is rated at 1,800 CFM and ≈0.10 inH2O.

Garage or Room With Box Fan & Cracked Window

Slightly opening a window allows for air to enter the room, ensuring that there are no stale pockets of air. The static pressure experienced by the fan is lowered, thereby increasing the flow rate.

This case will be common for most rooms due to air leaking in through cracks, ducts, and under doors.

Garage or Room With Box Fan & Open Window

Fully opening a window or door maximizes the circulation and ventilation of the air-particle mixture.

Remember that this showcases the particle behavior and not the concentration.

Garage or Indoor Ventilation via Enclosure

Grow Tent Enclosure With Ventilation

This is an ideal solution for ventilation since the particles are contained and there is minimal impact on the air temperature of the residence.

The simulated enclosure is a grow tent that lets air in through the zipper and small cracks. The ventilation is provided by a 120mm fan with a meager 40 CFM and 0.11 inH2O.

Smaller fans prevent excess heated/cooled indoor air from being lost during printing. However, when the enclosure is opened, the small fan is not able to extract the fumes to the extent that a tube-axial (inline) fan could.

Grow Tent Inspiration

The reasons why grow tents are widely used in resin printing is that they are affordable, easy to setup, and sturdy.

A 30 x 18 x 36 inch grow tent retails between $70 to $100. It can comfortably fit a small or medium resin printer + a heater + resin/equipment. This size can fit two printers, but it will be cramped with a heater.

This size can fit two printers, but it will be cramped with a heater.

Always make sure to check the printer's dimensions and pick an appropriate grow tent. If you have the space, a larger grow tent can be useful to store multiple printers, cleaning equipment, resin, and other supplies.

Grow tents can be used:

- outdoors to block wind, sun, rain, and critters on a patio or balcony

- indoors to vent directly outside

- in a garage to help contain heat and optimize venting

- with a fume extractor before being vented

- to fit a printer + a wash & cure station if wide enough

- as a fume hood if using a strong inline fan

Separate & Sealed Room

Garage

Patio

Balcony

Vivosun Grow Tent

$80+

(15% Off)

We use the 30x18x36" size with two resin printers

VivosunAmazon

AC Infinity Grow Tent

$90+

Tall grow tents can be used sideways if needed

Amazon

Gorilla Grow Tent

$120+

The 24x24x32" size provides plenty of space

Amazon

Install Filtration as a Secondary Defense

Installing ventilation should always be the primary focus, with filtration acting as a secondary defense. In the event that ventilation is not possible then fume extractors can be utilized so long as they are maintained and the filters replaced regularly. For FDM printers, installing filtration is often a necessity since the vast majority of filaments are temperature sensitive and their enclosures are not vented.

In the event that ventilation is not possible then fume extractors can be utilized so long as they are maintained and the filters replaced regularly. For FDM printers, installing filtration is often a necessity since the vast majority of filaments are temperature sensitive and their enclosures are not vented.

Even if ventilation is installed, you may feel more comfortable with the extra layer of defense provided by an air cleaner. For FDM printers, the focus will be split on removing both particulates and VOCs, whereas SLA will be primarily VOCs.

Particulates can be efficiently removed with MERV 11-16 or HEPA filters. HEPA filters are not always the best option since they often have a lower flow rate compared to a MERV filter, but they perform well for fume extraction.

The efficient removal of VOCs will require a bed of activated carbon granules or pellets. Impregnated foam is not recommended since it is not as efficient nor as long-lasting as granules.

The capture efficiency of professional/industrial activated carbon systems can be 92-98%, but smaller units with a carbon thickness of 1-2 inches can have an efficiency of 40-60%. The capture efficiency of carbon will vary depending on the chemicals, impregnation, thickness, temperature, air speed, and etc. The efficiency will decrease when the carbon surpasses a saturation threshold dependent on the thickness of its mass transfer zone.

Filtration - Fume Mitigation

These small air cleaners are designed to be placed inside the cover of a resin printer.

The units only use activated carbon so they be able to capture an estimated 40-60% of fumes until they become saturated. Particulates will not be captured to any meaningful extent.

The P Mini air cleaner's files are free to download, it uses a blower fan with a higher static pressure, the extra battery capacity gives hours of additional use, and the thick carbon bed will have a longer life and higher capture efficiency.

4D Filtration - P Mini

DIY

Battery: 5,000 mAh

Carbon: 50 g

Dimensions: 53x53x133 mm

4D FiltrationPrintablesThingiverse

Anycubic - AirPure

$30

Battery: 2,000 mAh

Carbon: 13.6 g

Dimensions: 46x46x115 mm

AnycubicAmazonAliExpress

Elegoo - Mini Air Purifier

$30

Battery: 2,000 mAh

Carbon: 13.6 g

Dimensions: 44x44x107 mm

ElegooAmazonAliExpress

Filtration - Fume Extractors

Fume extractors are designed to remove the majority of containments from the air leaving an enclosure.

The Promethean air cleaner is offered as an affordable alternative that can be hooked up using duct, be inside an enclosure, or next to the printer - the higher flow rate allows it to act similar to a normal air cleaner.

The BOFA fume extractors utilize HEPA media, have a thicker carbon bed, and are a more quiet - the downside is the price bump. Fume extractors are ideal for resin and FDM.

Fume extractors are ideal for resin and FDM.

4D Filtration - Promethean

DIY or $200

MERV Filter: $15

Activated Carbon: $15

Airflow: 11-27 cfm

Noise: 41-68 dB

Protection: Particulates & VOCs

via MERV & Activated Carbon Granules

4D Filtration

BOFA - Print Pro 2

$770

Combo Filter: $260

Airflow: 26.5 cfm

Noise: <44 dB @ "typical"

Protection: Particulates & VOCs

via HEPA & Activated Carbon Granules

BOFAMatterHackers

BOFA - Print Pro 3

$1,200

Combo Filter: $260

Airflow: 88 cfm

Noise: <57 dB @ "typical"

Protection: Particulates & VOCs

via HEPA & Activated Carbon Granules

BOFAMatterHackers

Sample Size = 178

Ultimate Resin Guide - compare resin printers, resin material, and equipment

Preparing for Resin Printing - setting up an enclosure, heating, ventilation, filtration, and cleaning equipment

FDM Printers Guide - comparison table and top picks for filament printers

Resin Properties or Filament Properties - comparison table and top picks for materials

Disclaimer: You assume all responsibility and risk for the use of, but not limited to, the resources, advice, and opinions of 4D Filtration or its employees. 4D Filtration or its employees do not assume any liability or create any warranty for the use of any information. 4D Filtration may receive commissions for referral links. Prices are approximated for simplicity and they may fluctuate due to sales or markdowns. Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon's link redirect system will take you to a different product.

4D Filtration or its employees do not assume any liability or create any warranty for the use of any information. 4D Filtration may receive commissions for referral links. Prices are approximated for simplicity and they may fluctuate due to sales or markdowns. Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon's link redirect system will take you to a different product.

Did we miss anything or do you have any information worth an update? Let us know!

Like the resources? Consider supporting us via donation, referral links, or purchases!

Air pollution in 3D printing

Main page

Articles

Smoke from a 3D printer

Smoke from a 3D printer

Introduction How does a printer pollute the air How does a BOFA filter

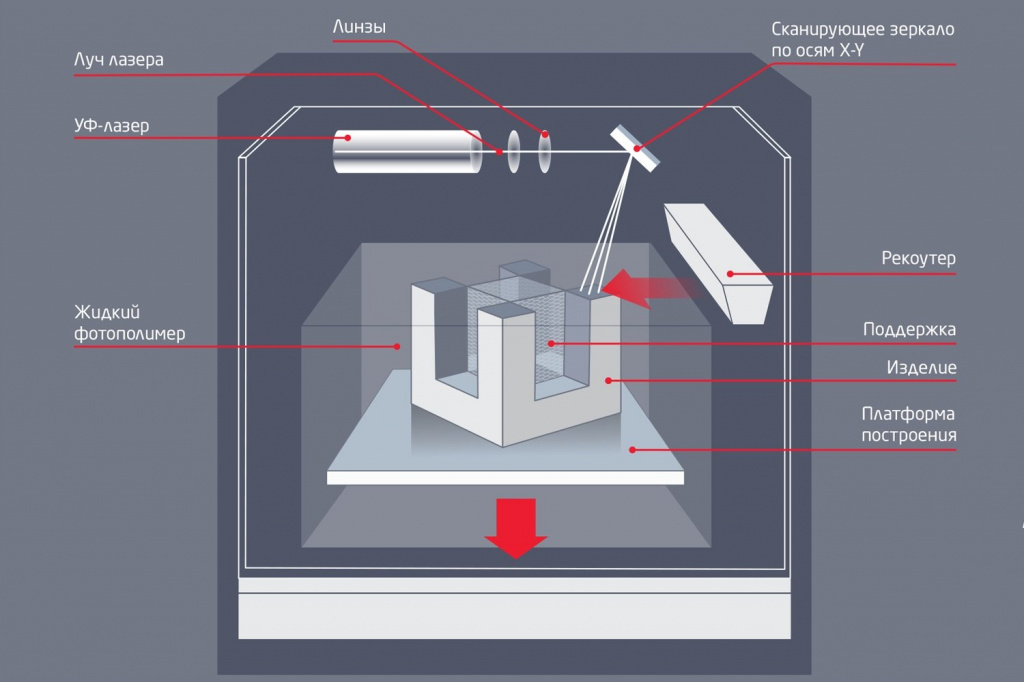

What is 3D printing

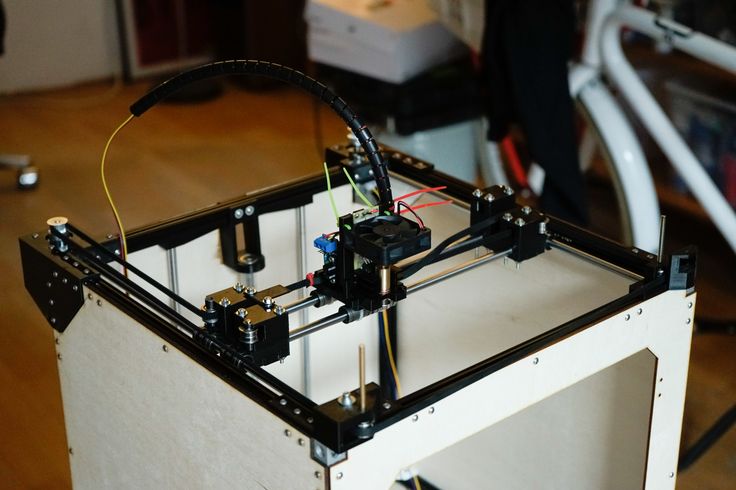

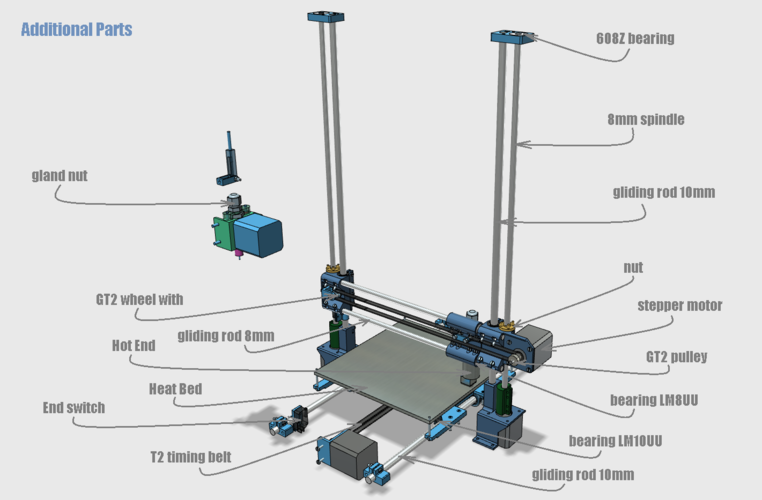

3D printing is also known as additive manufacturing. This means that the product is created by adding material in layers. The process is controlled by a coordinate XYZ robot with digital control. Printers work with plastic or metal. The material is fed to the deposition point in the form of wire or powder. The printer is melting the material. Then it connects to the previously applied base.

The process is controlled by a coordinate XYZ robot with digital control. Printers work with plastic or metal. The material is fed to the deposition point in the form of wire or powder. The printer is melting the material. Then it connects to the previously applied base.

A 3D printer will produce objects of complex shape. This favorably distinguishes the additive process from the subtractive one, when excess is removed from a large piece of material. Machining, laser processing, soldering or welding generate more contamination. And a lot of material is wasted. 3D printing does not consume a lot of extra material. It appears to be a clean process, but it still pollutes the air.

Anyone using 3D printing needs to be aware of the health risks. The 3D printer seems safe. But it can generate toxic fumes and hazardous substance particles. Technological processes that transform the material pollute the air in the workplace. This applies to cutting, engraving, thermal decomposition in a laser machine, soldering with a toxic flux, etc. Molten metals and polymers are no exception.

Molten metals and polymers are no exception.

Why is a 3D printer dangerous?

Ultrafine particles

Heating a substance causes the release of solid particles, droplets and vapors. They may be harmful if inhaled.

European scientists are gradually revealing the dangers of 3D printing to health. According to the 3D Printer Emissions Report , plastic melting releases small nanoparticles of material into the air. They cannot be seen without special equipment. But that doesn't mean they are safe.

PLA plastic nanoparticles are used in pharmaceuticals as a means of delivering drugs to various organs, including the brain. Cosmetics use the same effect. Ultrafine particles penetrate the skin. By themselves, PLA particles are not toxic. But no one knows about the consequences of accumulation in human organs. Nanoparticles condense into relatively large formations. It is known for certain about the harmfulness of soot nanoparticles from automobile exhausts . They are associated with degenerative brain diseases, such as Alzheimer's disease.

They are associated with degenerative brain diseases, such as Alzheimer's disease.

ABS plastic is toxic when melted. Nanoscopic ABS particles are just as toxic. These particles are very small. During inhalation, they enter the brain through the olfactory nerve. They spread throughout the body through the bloodstream. Most organs can get rid of them naturally, but the brain and lungs become clogged for a long time.

In fact, particles as small as 10-200nm easily enter the bloodstream through the lungs. Their toxic action differs from the original substance in the usual shapes and sizes. According to study by the Italian Institute of Health and Consumer Protection nanoparticles are deposited in the lungs in greater quantities than e-cigarette smoke.

Gases or vapors

Molten ABS gives off a particularly unpleasant odor. Other plastics including nylon, HIPS and HDPE emit the same toxic fumes but have less odor.

Polymer materials can vaporize some of their constituents. Dioctyl phthalate is often added to them for flexibility and mold resistance. During high heat or laser treatment, benzene is released in hazardous quantities. And while working with PVC, HCl aerosol condenses in the air.

The high temperature in the area of the printer head causes the air to expand. Vapors quickly spread in the work area along with plastic particles. Thermal degradation products of polymers are shown in the diagram below.

How does BOFA work?

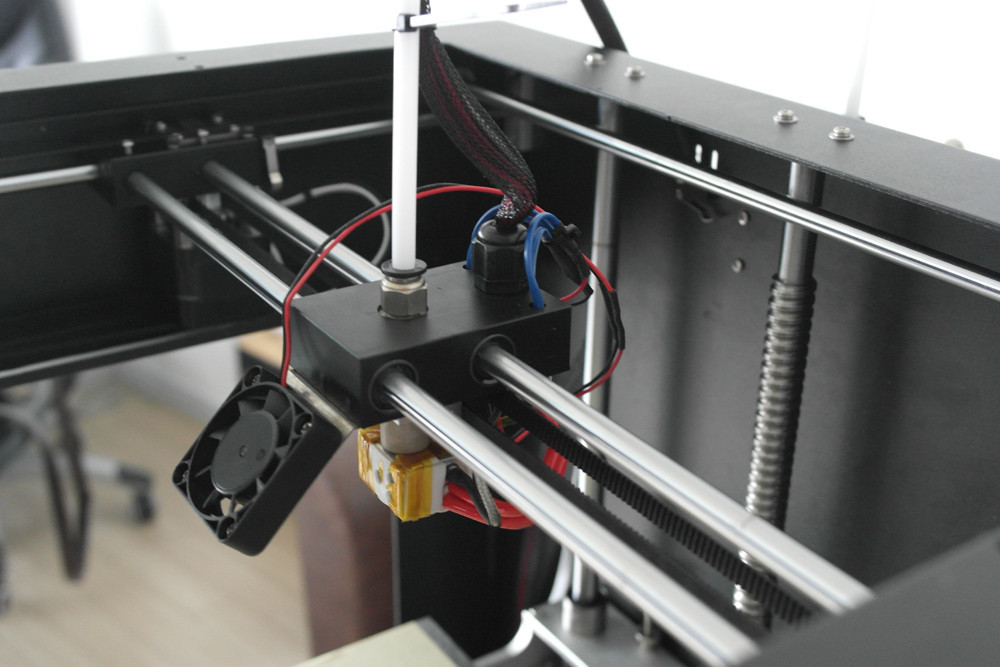

A smoke extractor is an extractor hood with filters placed in one device. She got her name at the time when she removed the smoke of a soldering iron or a laser engraver. But these same devices with special filters are also suitable for a three-dimensional printer. The smoke extractor block for the printer is not much different from the soldering block.

3D printing is sensitive to changes in air temperature. Therefore, he is afraid of drafts. If you are using a small open printer, then the polluted air can be removed with a conventional smoke extractor. In order not to disturb the climate in the printer, select the minimum air suction speed.

Therefore, he is afraid of drafts. If you are using a small open printer, then the polluted air can be removed with a conventional smoke extractor. In order not to disturb the climate in the printer, select the minimum air suction speed.

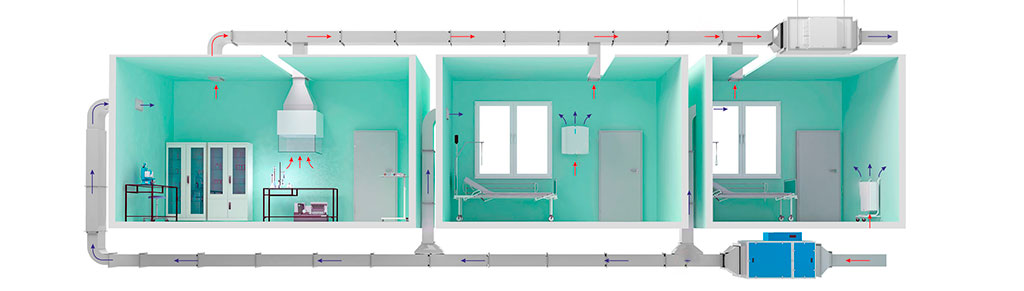

If your 3D printer model is closed, there is a protective cover, then you can install a cleaning curtain. During operation, while the printer window is closed, it can be turned off. But it will clean the outgoing air when you open the box to take out the finished product.

If your printer is large and completely enclosed, then it will most likely have built-in pipes for connecting the hood. They can be connected to a smoke extractor with large filters. It can operate continuously or turn on at the command of the printer. The fume extractor captures dirty air and returns it back to the printer so as not to change the air temperature during the printing process.

3-stage filtration

A complete smoke extractor is equipped with three filters. The first is the pre-filter. It does not let in coarse dust, so as not to clog the main fine filter with it. The fine filter is HEPA. Particles of all sizes, including aerosols and nanoparticles, settle on its fibers. The gas filter completes the cleaning. It consists of densely packed activated carbon granules with interlayers of fiberglass. Activated carbon traps VOCs and nanoparticles that HEPA missed.

The first is the pre-filter. It does not let in coarse dust, so as not to clog the main fine filter with it. The fine filter is HEPA. Particles of all sizes, including aerosols and nanoparticles, settle on its fibers. The gas filter completes the cleaning. It consists of densely packed activated carbon granules with interlayers of fiberglass. Activated carbon traps VOCs and nanoparticles that HEPA missed.

Smoke extractor against exhaust

The cheapest way to remove smoke is a duct fan and air ducts. The emission of polluted air through the window is prohibited by SanPin standards. And the smoke extractor has advantages.

- Good air purification from all kinds of solid particles and aerosols

- There will be no odors from melted plastic or metal in the room

- You will be sure that your health will not suffer

- The microclimate in the 3D printing machine will be stable

- Supply ventilation with heating or air conditioning is not needed, as for the extract through the window

Eliminate the harmful agent

The hood with filters will solve the problems with harmful emissions from 3D printing with polymers and metal powder. Without proper filtration, ultrafine particles cause skin and eye irritation. Nanoparticles accumulate in internal organs and lead to systemic disorders, heart and vascular diseases, and Alzheimer's disease. The smoke extractor is suitable for household and professional models of printers. Extractor hood with filter, recirculation and airflow adjustment minimally affects the air temperature inside the printer. BOFA will take care of you and the world we live in.

Without proper filtration, ultrafine particles cause skin and eye irritation. Nanoparticles accumulate in internal organs and lead to systemic disorders, heart and vascular diseases, and Alzheimer's disease. The smoke extractor is suitable for household and professional models of printers. Extractor hood with filter, recirculation and airflow adjustment minimally affects the air temperature inside the printer. BOFA will take care of you and the world we live in.

Smoke extractor catalog PDF

You can familiarize yourself with the models on our website in the section Smoke detectors for 3D printers

During business hours, a showroom or showroom is open in our office. Popular BOFA smoke extractors are on display here.

Watch our video

Visit our YouTube channel where you can get a closer look at the manual editing methods we offer: www.youtube.com/user/ARGUSXvideo

How 3D printing is helping to tackle the ventilator shortage

Amid the growing shortage of medical equipment, a number of organizations and enterprises have taken up the design and manufacture of ventilators, relying on rapid production using 3D printing technologies. We share examples and links.

We share examples and links.

The first news about 3D printed ventilators, apart from the Italian hospital valve story, came from Spain. Here we are talking about the so-called "Ambu bags" - temporary, hand-held fans, commonly used in the field, for example by ambulance workers. The mechanically driven 3D printed version was developed by a consortium led by Leitat Technology Center in Barcelona, with contributions from the Catalan Health Service, the Barcelona Free Trade Zone, Hewlett Packard and Sabadell University Hospital, home to the Faculty of Medicine of the Autonomous University of Barcelona.

Designed by Leitat Senior Engineer Magy Galindo, testing by Dr. Louis Blanche, Director of Innovation at the University Hospital. Based on the test results, a decision was made to immediately start production and in parallel develop an improved version in accordance with the recommendations of the national regulator - the Agency for Medicines and Medical Products of Spain. The aerospace concern Airbus and the Spanish shipbuilding company Navantia volunteered to help with production, having the necessary additive equipment, including industrial 3D printers. The additive power is enough to 3D print 50-100 field respirators per day.

The aerospace concern Airbus and the Spanish shipbuilding company Navantia volunteered to help with production, having the necessary additive equipment, including industrial 3D printers. The additive power is enough to 3D print 50-100 field respirators per day.

The Polish company Urbicum, which manufactures FDM 3D printers, went further and launched an open source project called VentilAid to create a complete, but as simple as possible mechanical ventilator in terms of design, with extensive use of 3D printed parts.

The company's engineers have already demonstrated a working prototype of the electrically powered device. The developers take into account various points: like standard, certified equipment, the project provides for the possibility of adjusting the humidity of the incoming air, filtering the air at the inlet and outlet, synchronization with the patient's breathing and pressure control to prevent lung barotrauma. The 3D printed parts of the prototype took approximately fifteen hours to produce. The pilot system uses homemade PLA, ABS and TPU components, but also includes factory parts such as an actuator and a pneumatic limit switch.

The pilot system uses homemade PLA, ABS and TPU components, but also includes factory parts such as an actuator and a pneumatic limit switch.

The project is open under a non-commercial license, but has not yet been fully clinically tested, and therefore is offered as a last resort. The authors invite engineers, doctors and medical technicians to cooperate in order to improve the system. Work on an improved, standalone version is already underway, and up-to-date information is published on the official website of the project.

While Spanish engineers are working on manual fans, and Polish engineers are working on automated ones, American colleagues are busy with a transitional option. Researchers at the Massachusetts Institute of Technology (MIT) offer a solution in case there are no problems with the lack of Ambu bags, but mechanical ventilation systems are urgently needed. That is, the idea is to remake a hand tool into a more or less autonomous ventilator.

Development began long before the pandemic: in 2010, university students presented a project to convert the Ambu bag into a portable fan, but then the matter ended with the construction of a prototype. Now the institute is urgently finalizing the project to meet at least the minimum safety requirements. The developers focus on caution, as the device is inferior to certified devices in terms of efficiency, reliability and safety, and therefore is to be used only in clinical conditions, only under the supervision of specialists, and only in case of emergency.

All developments on this project will be made publicly available on the official website of the project. The available results have already been submitted to the US Food and Drug Administration (FDA) for approval to use makeshift equipment in exceptional circumstances.

By the way, the US Department of Health and Human Services sets an example for the global bureaucracy: back in February, the department exempted developers, manufacturers and medical personnel from legal liability for the use of emergency solutions to combat the coronavirus epidemic, except in cases of intentional, knowing harm. FDA approval for the use of such products, created in a hurry and not fully clinically tested, is still required, but applications are processed quickly, and after official approval, there is no fear of criminal prosecution or lawsuits. If the patient is harmed without malicious intent, the state will pay monetary compensation.

FDA approval for the use of such products, created in a hurry and not fully clinically tested, is still required, but applications are processed quickly, and after official approval, there is no fear of criminal prosecution or lawsuits. If the patient is harmed without malicious intent, the state will pay monetary compensation.

Of course, these are not all examples. Thus, Volkswagen temporarily suspended the work of a number of enterprises, including in Mexico, the USA and Brazil, but at the same time donated industrial respirators from its own stocks to the German healthcare system and expressed its readiness to participate in the development and production of 3D printed ventilators. Volkswagen has about 125 3D printers at its disposal, including industrial additive systems that print both polymer and metal powders. In the UK, three consortiums are working on emergency development and mass production of fans, consisting of enterprises in the automotive, aerospace and additive sectors, including Airbus, Maggit (manufacturer of aviation oxygen equipment), McLaren, Nissan, Renishaw (manufacturer of industrial 3D printers), GKN and Thales. Task: to produce five thousand fans in the shortest possible time, and thirty thousand devices in the long term.

Task: to produce five thousand fans in the shortest possible time, and thirty thousand devices in the long term.

Enthusiasts also contribute. We already talked about the emergency 3D printing of venturi valves for ventilators in an Italian hospital, but the heroes of this story continue to offer solutions to combat the shortage of medical equipment: the other day, Christian Fracassi shared a 3D model of an adapter that allows you to turn diving masks into individual CPAPs -masks for connection to hospital ventilators.

This particular product is designed for use with masks from the French brand Decathlon, who readily provided the original drawings, but can be modified to fit other masks. The developers have issued a protective patent, but only so that no one steals the original design and breaks the price. You can find all the necessary files and instructions, as well as participate in the project on a non-commercial basis (at your own peril and risk, subject to local laws) at this link.