Form 3 3d printer price

Form 3 3D Printer Review: Expensive, But Excellent

Skip to main contentWhen you purchase through links on our site, we may earn an affiliate commission. Here’s how it works.

Excellent prints without a fuss.

Editor's Choice

(Image: © Formlabs)

Tom's Guide Verdict

The Form 3 produces high-quality 3D prints in a variety of materials without fuss, but it is expensive. Artists, designers and professionals who rely on 3D printing will find this cost acceptable for the time it saves, but enthusiasts may seek out cheaper options like SLA printers from Peopoly that can produce similar quality results with tweaking.

Pros

- +

Excellent print quality

- +

Support for range of Formlabs supplied materials

- +

Supports multiple users and printers

Cons

- -

Expensive

- -

Use of third-party resin voids warranty

- -

No major speed increase from older Formlabs models

Why you can trust Tom's Guide Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Today's best Form 3 3D Printer deals

No price information

View at Form Labs

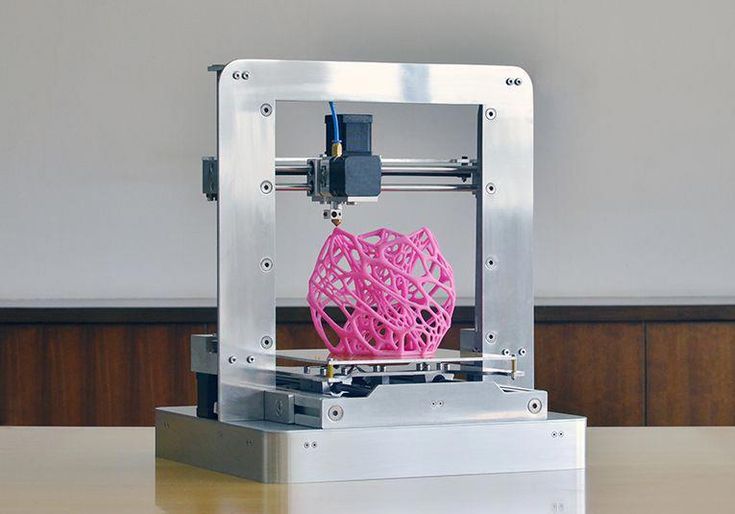

The Form 3 from Formlabs is a high-end Stereolithographic (SLA) printer that uses a laser to zap liquid resin into solid form. It's a sophisticated printer that can produce excellent quality prints with little maintenance or tweaking, making it a great pick for those who want to do a lot of printing without hassle.

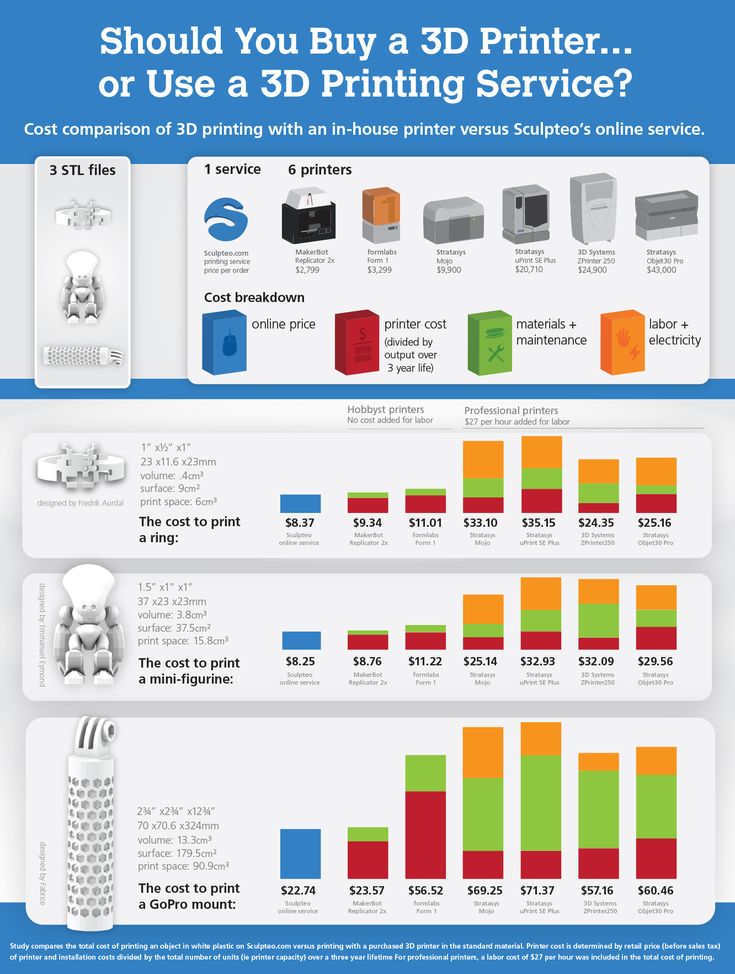

These quality prints don't come cheaply, though — the Form 3 starts at $3,499. That may be a hard price to swallow, especially as rival 3D printer makers developer cheaper SLA models, such as the Peopoly Moai. But budget SLA printers often require a lot of experimentation and maintenance to produce quality prints. The Form 3 requires little of either: It just works. And that's why we include the Form 3 on our list of the best 3D printers you can get right now.

For this review, we tested the $4,999 complete kit that includes the Form 3 printer and the Form Wash and Form Cure devices used for cleaning and finishing prints.

Form 3 3D printer review: Price and availability

Your best bet to buy a Form 3 3D printer is to head directly to FormLabs . There, you'll find the printer available for $3,499 these days, with service plans adding to the cost of your 3D printer.

Since we first reviewed the Form 3 a few years ago, less expensive SLA printers led by the Peopoly Phenom have come out. And while those devices cost a fraction of what you'll pay for the Form 3, the Formlabs printer remains the standard bearer for SLA models.

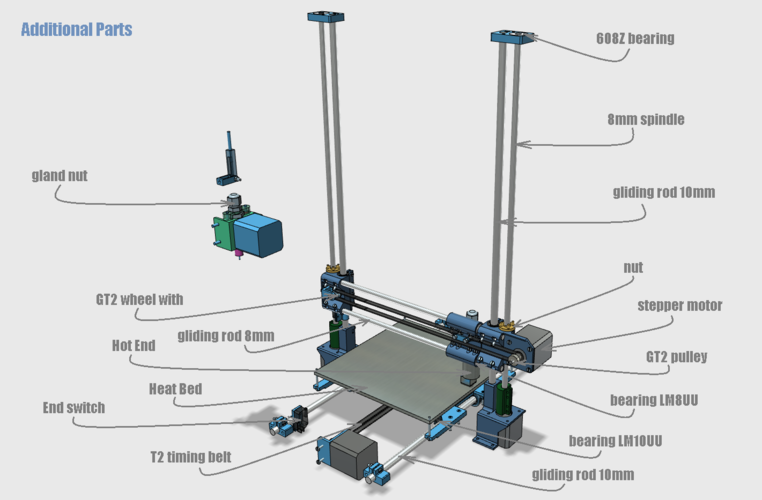

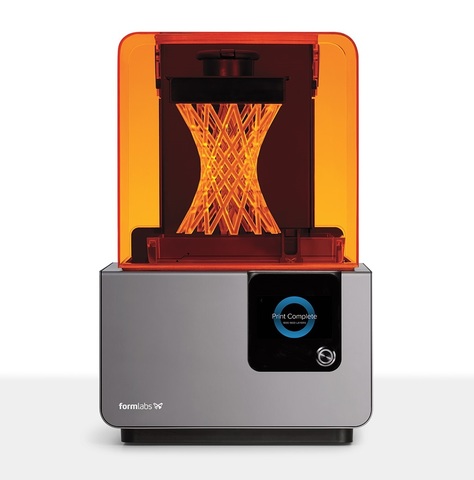

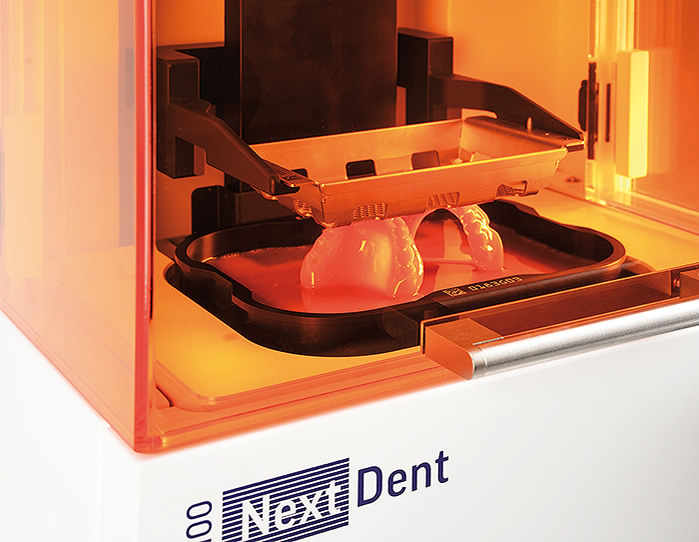

The Form 3 looks much like previous printers from Formlabs, with an orange plastic hood over the printing area and a black plastic base. That's about more than just aesthetics: the UV-blocking orange plastic lets you see what is going on while printing is underway, but without outside lights interfering with the process. This hood folds back to reveal the important parts of the Form 3 — the resin tank and the print platform. Both are a little larger than the previous Form printers, offering a print area of 5.7 x 5.7 x 7.3 inches, or just over 237 cubic inches. A larger model, the Form 3L, ups this to 11.8 x 13.2 x 7.9 inches, a total of 1,230 cubic inches. The Form 3L, which is due to start shipping later this year, will cost you a cool $9,999, though.

This hood folds back to reveal the important parts of the Form 3 — the resin tank and the print platform. Both are a little larger than the previous Form printers, offering a print area of 5.7 x 5.7 x 7.3 inches, or just over 237 cubic inches. A larger model, the Form 3L, ups this to 11.8 x 13.2 x 7.9 inches, a total of 1,230 cubic inches. The Form 3L, which is due to start shipping later this year, will cost you a cool $9,999, though.

We had no failed prints in our Form 3 tests, which is a first for a 3D printer.

The removable resin tank is where the liquid resin sits during printing. The tank's base features a thin, clear plastic layer that the printing laser shines through. To create each layer of the print, the build platform is lowered down to just over this base layer, trapping a thin layer of liquid resin. The UV laser then zaps the liquid, turning it into solid resin, which sticks to the build platform. The printer then lifts the platform, taking the hardened resin with it. The platform lowers again, trapping another layer of liquid resin, and the process repeats. Thus, the Form 3 creates the print layer by layer with layer heights ranging from 0.1mm down to 0.025mm.

The platform lowers again, trapping another layer of liquid resin, and the process repeats. Thus, the Form 3 creates the print layer by layer with layer heights ranging from 0.1mm down to 0.025mm.

One of the innovations here is the flexible plastic on the bottom of the layer, which means that the Form 3 can use less force in pulling the hardened layers up. Formlabs calls this Low Force Stereolithography, and claims that it makes printing more reliable. Formlabs isn't the first printer maker to use this technique (it's available as an upgrade feature for printers like the Peopoly Moai), but it definitely seems to be effective. We had no failed prints in our Form 3 tests, which is a first for a 3D printer.

The Form 3's laser and optics are found under the resin tank, located in a sealed package called the Light Processing Unit (LPU). This, Formlabs claims, makes the printer more reliable as dust can't get in to block the path of the laser. It also makes the LPU easier to replace, as the whole unit can be easily removed and replaced by the user.

The Form 3 produced excellent quality prints, with fine details and smooth, organic curves and surfaces, even when we used the fastest print settings.

The Resin cartridge in the rear of the Form 3 holds the liquid resin. The printer automatically fills the resin tank: You never need to touch the resin or fill the tank yourself, which is a plus because it is nasty, stinky stuff. The resin tank and cartridge are removable so you can swap out different printing resins without having to clear out the whole printer. The tanks can be cleaned out and reused, but the resin cartridges can't be reused. It is possible to fill a cartridge with a third-party resin, but Formlabs stresses that this might void the warranty of its printer. If you aren't using the printer for a few days, Formlabs recommends that you remove the print tank and store it in the airtight shipping container it came in to prevent it hardening in place.

Form 3 3D printer review: Controls

The Form 3 includes an excellent touch screen that allows you to control the printer directly, accessing all of the features and stopping or starting prints. Most users will turn to the PreForm software and the online printing dashboard to operate the Form 3, though.

Most users will turn to the PreForm software and the online printing dashboard to operate the Form 3, though.

SLA printers typically require a lot of tweaking, calibration and other fiddling to get good results. The Form 3 just works.

PreForm is the software that prepares your print, loading a 3D model (standard .stl and Wavefront .obj formats are supported) and slicing the model for printing. Available as a free download for Mac and Windows, PreForm is straightforward to use, with a helpful one-touch printing feature that automatically prepares the print, creating the supports that hold it in place while printing and sending the file to the printer. If you want to tweak the process yourself, PreForm allows you to scale, move, spin and otherwise mess with 3D models, as well as arrange several models for printing at one time (a process called plating).

(Image credit: Formlabs)The printing dashboard is an online service that manages the Form 3. It's aimed more at users who operate multiple Form printers or those who share a single printer between multiple users. This dashboard allows you to queue and schedule prints, monitor print progress and pause or cancel printing. The dashboard can also notify you through your cellphone when a print is complete or when a printer has a problem or requires maintenance.

It's aimed more at users who operate multiple Form printers or those who share a single printer between multiple users. This dashboard allows you to queue and schedule prints, monitor print progress and pause or cancel printing. The dashboard can also notify you through your cellphone when a print is complete or when a printer has a problem or requires maintenance.

MORE: How to Buy a 3D Printer

Since there's no camera inside the Form 3 to monitor the prints, you generally don't know if a print has failed until it is complete, unless you take a look during the printing process. The Form 3 isn't unique in this, though: The way that 3D printers like this work, with a large print platform obscuring the printing area, makes it harder to see how the print is progressing.

Form 3 3D printer review: Performance

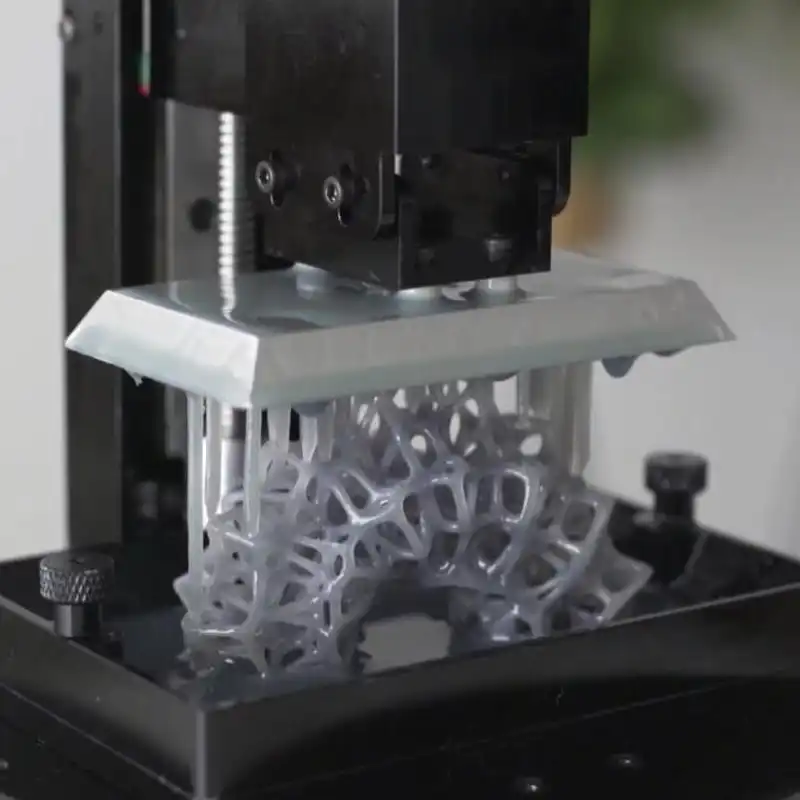

In our tests, the Form 3 produced excellent quality prints, with fine details and smooth, organic curves and surfaces, even when we used the fastest print settings. Our test models had smooth, even detail with barely detectable layers.

Our test models had smooth, even detail with barely detectable layers.

Our first test model is a 3D scan of Rodin's The Thinker sculpture. The resulting prints looked excellent. We appreciated the curves on the sculpture's shoulders and arms and excellent detail on its face.

(Image credit: Tom's Guide)The layers of the print were barely visible, even on the fastest 25-micron printing setting.

(Image credit: Tom's Guide)With the layer height on the minimum 0.025mm setting, the layers are barely visible on the shoulders of The Thinker.

(Image credit: Tom's Guide)Our second test creates complex set of planetary gears, to see how well the printer can produce interlocking parts. The Form 3 produced excellent quality prints here, too, handling complex details like the screw thread and gear teeth. The parts fit together without any hassle, with screws fitting tightly into other parts and gears meshing together cleanly.

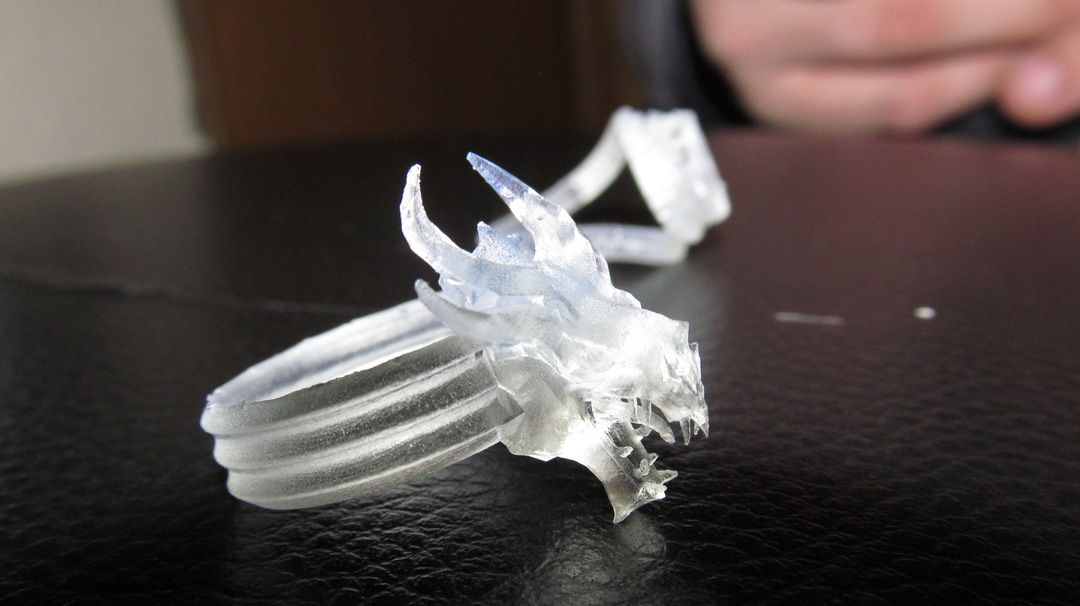

Finally, we use a geometric sculpture as a test of how well the printer can reproduce sharp edges and points. Again, we found excellent results here, with the many angled surfaces of the sculpture coming out with clean, smooth edges and sharp points that almost look like they could draw blood.

Form 3 3D printer review: Speed

The Form 3 is not a particularly fast printer, taking between 10 hours and 17 hours and 21 minutes to complete our standard 4.5-inch Thinker test print, depending on where we set the layer height. SLA printers are not generally very fast, and the Form 3 doesn't buck the trend. These times are comparable to other SLA printers like the Peopoly Moai, which took between 7 hours and 20 minutes and 18 hours to produce a similar print.

(Image credit: Formlabs)One thing to note, though: while our tests were done with the standard gray and clear resins from Form, the company offers a special resin called Draft Resin, which can be printed in layers 0. 3mm thick. That would make printing significantly quicker, but less detailed. That resin wasn't available for us to test.

3mm thick. That would make printing significantly quicker, but less detailed. That resin wasn't available for us to test.

Form 3 3D printer review: Print materials

The Form 3 is designed to work with parts and materials only from Formlabs. You have to buy the resin tanks and cartridges from the printer maker. A new resin tank will cost you $149, while a cartridge that contains a liter of resin costs $149 for the standard resin, $175 for the tough resin and $299 for the castable wax resin that jewelers and artists use to create molds.

(Image credit: Formlabs)It is possible to use third-party resin with the Form 3 by filling one of the printer's cartridges with another supplier's, but Formlabs claims that this could void the Form 3 warranty. For reference, we got seven fairly large prints out of a single cartridge of the gray resin, so each print cost about $21.

Form 3 3D printer review: Verdict

The Form 3 is a real plug-and-play 3D printer. We didn't have to do any tweaking or fiddling around to get printing — we just plugged in the Form 3 loaded it up and started printing. The whole process was clean and generally hassle free, which is a lot different from typical SLA printers that require a lot of tweaking, calibration and other fiddling to get good results. The Form 3 just works.

The whole process was clean and generally hassle free, which is a lot different from typical SLA printers that require a lot of tweaking, calibration and other fiddling to get good results. The Form 3 just works.

At $3,499 and up, though, the Form 3 is also one of the most expensive 3D printers we have tested, and it is expensive to run. For professionals and anyone else who relies on 3D printing, that won't be an issue. The Form 3 will cost a lot up front, but will be worth it for the easier printing it offers. For enthusiasts and amateurs, it's trickier, as you can get equally good results from a much cheaper printer like the $1,999 Peopoly Phenom if you are prepared to take the time to tweak the printer and develop a workflow for cleaning and hardening prints afterward.

Still, if 3D printing is a critical part of your workflow, you'll be pleased with the ease of use and quality results you'll get by the Form 3.

Richard Baguley has been working as a technology writer and journalist since 1993. As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

As well as contributing to Tom's Guide, he writes for Cnet, T3, Wired and many other publications.

Tom's Guide is part of Future US Inc, an international media group and leading digital publisher. Visit our corporate site .

© Future US, Inc. Full 7th Floor, 130 West 42nd Street, New York, NY 10036.

Formlabs Form 3 review | TechRadar

TechRadar Verdict

The Form 3 shouldn't be your first choice if you're new to 3D printing given its lofty price, but if you have a business that requires consistent results and fantastic support then we can't recommend it enough. This industrial-grade machine is ideal for engineers, designers and even those in the medical and dental industry thanks to its selection of approved materials, and it's one-click print option takes all the confusion out of printing.

TODAY'S BEST DEALS

Pros

- +

Professional results and build quality

- +

Incredible customer support

- +

One-click print saves time and energy

Why you can trust TechRadar Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

Find out more about how we test.

Formlabs Form 3 3D printer two-minute review:

The Formlabs Form 3 is a resin-based 3D printer that sits firmly within the premium category of the market, offering high-end features and unbeatable build quality that you can’t find on more budget-friendly machines created for hobbyists. Instead, this is a commercial-grade printer for businesses that utilize 3D printing that won’t have time to play around with settings to ensure that you get the best possible results.

There’s an expectation of ‘learn by doing’ with many 3D printers, and if things break you’d order the required spare parts from the printer manufacturer or a third-party retailer and learning how to install them yourself. This is a far cry from what Formlabs is offering with the Form 3, which instead offers fantastic customer service and expert care, with some aspects of the machine being modular and disposable. In that sense, if something like the Elegoo Saturn was a kit car, the Form 3 would be a Mercedes with a premium service package.

As you’d expect, that level of care comes with a pretty steep price tag. The Form 3 starts at $3,499 (£3,299 / AU$4,800), though recommended extras to clean excess resin from and fully cure the models pushes the price even higher. Our review unit came with the Form 3 Finish Kit which retails for $100 (£90 / around AU$140) excluding VAT, though Formlabs also offers the Form Wash and Form Cure that cost $499 (£455 / around AU$690) and $699 (£625 / around AU$950) minus VAT, respectively.

(Image credit: Future)You can also purchase service plans to keep the machine in top working condition, which is why we would recommend these for enterprise customers rather than anyone just getting started with a printing hobby, but there’s absolutely nothing to stop everyday consumers from picking one up.

Image 1 of 2

(Image credit: Future)The resin washing station for the Formlabs Form 3

(Image credit: Future)The resin washing station for the Formlabs Form 3

Our only critique in that respect would be that in the years since Form 3 was released, hobby-grade 3D printers have become far cheaper, making them more appealing if you’re tight on cash and willing to put some work in.

Everything from the machine itself to the software you’ll need to start printing feels like it was created to make 3D printing as efficient and simple as it can possibly be, without losing a sense of luxury. If you have a business that requires consistent results from 3D printing and you want the process to be as convenient as possible, look no further than the Form 3.

The Formlabs Form 3 printer itself is gorgeous and manages to stand out against rival offerings from brands such as Elegoo and AnyCubic, despite sharing many of the same principles. The base of the machine that contains most of the mechanisms is black, with an illuminated Formlabs logo located on the bottom left corner. There’s an orange hood to keep fumes from the curing resin from traveling too far, and this also appears to double as additional UV protection against sunlight.

The hood actually folds up using a hinge rather than lifting away from the machine entirely as you typically see with hooded printers. You get an easy handle to grab to maneuver this into place, and the hood won’t fall down without being manually closed, so there’s no risk of you slamming your hand in it.

You get an easy handle to grab to maneuver this into place, and the hood won’t fall down without being manually closed, so there’s no risk of you slamming your hand in it.

Strangely, there’s no manual off/on button located on the machine, so the only way to power down is to unplug the kettle cable from the rear, or switch it off directly at the power source. This is likely because this is intended more as an industrial printer and therefore likely to be running on a near-daily basis, but this still feels a tad wasteful if you’re energy conscious.

Image 1 of 2

(Image credit: Future)(Image credit: Future)The control panel located on the front of the machine is hands down the best we’ve ever tested on a 3D printer, being incredibly responsive and well designed. There are various options to help you keep your printer running at its best with minimal confusion, and each option will walk you through what needs to be actioned with clear, easy-to-read instructions. If the Form 3 runs into an issue during set up or midway through a print, a diagram of the printer will display exactly what is causing the problem, and how you can fix it, such as if the resin tank has become uncoupled.

The resin tank for the Form 3 is an innovative cartridge that can be reused as many times as required and then disposed of if it becomes damaged. These also contain a wiper that runs through the vat when full, mixing the liquid resin and keep the bottom of the tank clear from debris. These tanks can be stored in their original shipping boxes when not in use, even if they’re still full of resin as they come with a UV-protective lid and stack well on top of each other.

There’s a thin sheet of plastic on the base of the tank where UV light will shine through to cure your prints layer by layer, something that comes with a risk of perforation. On other printers, this will require you to take apart the tank and manually replace the film, which can be time-consuming and generally just a nuisance, but you can simply dispose of the damaged Form 3 tank and replace it with another.

Image 1 of 2

(Image credit: Future)(Image credit: Future)While this isn’t great if you’re trying to reduce your waste, resin is a toxic substance and many aspects of it will require you to use disposable equipment like nitryl gloves which means this was never going to be zero-waste in the first place. Tossing a defective tank also means you can replace it with a brand new one, reducing the likelihood of your next batch of prints going awry by trying to fix the issue yourself.

Tossing a defective tank also means you can replace it with a brand new one, reducing the likelihood of your next batch of prints going awry by trying to fix the issue yourself.

The resin itself is also part of a closed system from Formlabs. The unique design of each bottle includes a perforated rubber seal, that allows the printer to fill itself with resin and keep topping up where required. As expected, this is a feature that also doesn’t come cheap, as a single 1ltr bottle of Grey resin will cost you $149 (£120, around AU$205 ), and specialist resins are even higher, but there are many different varieties to choose from, including dental, BioMed, flexible and castable wax that can be used by jewelers and artists to create molds.

You can even customize the color completely to your needs with a special resin that requires you to use a selection of syringes filled with a color additive to mix and create your desired shade. These come with a mixing guide that gives you exact measurements for each syringe to achieve specific colors, though you’ll need to mix up an entire bottle of the base resin in that shade.

Image 1 of 3

(Image credit: Future)(Image credit: Future)(Image credit: Future)There’s nothing stopping you from refilling the empty resin bottles with another manufacturer's liquid resin as they all cure using the same 405 nm UV wavelength, but this will void the Formlabs warranty, so isn’t advisable.

While expensive, this also is one of the safest systems we’ve seen for loading resin into a 3D printer if you want to avoid a literally toxic mess. Loading a fresh cartridge into the printer also means that you can have the machine ready to go at a moment's notice, even if you’re away from the printers itself.

The print platform itself provides a build volume of 5.7 x 5.7 x 7.3 inches / 145 × 145 × 185 mm. This may seem on the small size, but resin-based printers are typically restricted by size as they require the resin tank to be large enough to submerge the entire build plate into. As such, larger files will need to be sliced into sections and printed in stages to be reconstructed together at a later date.

Features:

(Image credit: Future)The Formlabs Form 3 uses Stereolithographic (SLA) technology to create a model within a vat of liquid resin using UV light that will cure whatever file you’ve loaded into the machine layer by layer. This results in much finer detail than what can be achieved in another style of 3D printing, fused deposition modeling, where a spool of filament is melted and then piped into shape on a moving axis.

The tech isn’t exclusive to Formlabs, but the company has made some impressive adjustments to it for the Form 3 Printer. Where most SLA printers use a fixed laser and mirrors to bounce UV light around, the Form 3’s Low Force Stereolithography (LFS) uses a single galvanometer and actually works with the flexible film on those disposable tanks to reduce the forces exerted on parts during the print process.

The proprietary slicing software used by the Form 3 is PreForm, which is much cleaner and easier to use than other options like Chitubox. Specific features that allow you to change the actual file you’re about to print are tricker to locate or absent entirely though, so if you want to hollow out or cut up the model you’re working on, this is better done while you create the model in CAD or a sculpting software.

Specific features that allow you to change the actual file you’re about to print are tricker to locate or absent entirely though, so if you want to hollow out or cut up the model you’re working on, this is better done while you create the model in CAD or a sculpting software.

That said, it does include a feature that you’ll struggle to find elsewhere: one-click print, which can be found at the top-left hand side of the application. This will place the model onto the best position on the build plate, rotate and automatically add supports where needed and start the printing process with a single action, saving valuable time. Having tested the feature, it’s pretty reliable, with only a single unsupported model failing out of our batch of tests.

PreForm also allows you to set up and start your print remotely as the Form 3 can be connected to the internet via either WiFi or ethernet. This adds a great deal of convenience to the system, so while it is possible to connect the printer to a laptop or PC for updates, you’d be missing out on one of the best features that Formlabs has provided.

This also ties in with another feature that allows you to track the progress of your print and the general health/status of the printer remotely via the Formlabs dashboard. Here, you can track if the machine is experiencing issues, how long is left on the progress of a print, how much resin has been used and even the ID number of the cartridge and tank currently in use for you to keep records.

The dashboard will record the data for every print, including those you mark as failed (which the printer will prompt you for after a print has finished), which helps you keep track of specific orders for your business, as well as easy bookkeeping if you want to check how much resin has been used within a certain timeframe.

Performance:

Image 1 of 2

(Image credit: Future)(Image credit: Future)For the Formlabs Form 3 printer, there are four layer-thicknesses you can choose from in the PreForm software. This may feel restrictive, but it’s incredibly difficult to detect the difference with the naked eye unless you have a model that’s especially detailed.

The available options are 0.100mm (the fastest but lowest detail), 0.050mm and 0.025mm (highest detail, but slow printing speed), with an ‘adaptive layer thickness’ option in public beta that can automatically calculate what layer thickness is needed at different stages of the print to maximize both print quality and speed.

Image 1 of 3

(Image credit: Future)*Please note* Images were taken is a place protected from direct UV light. Please do not open the hood of a resin printer in direct sunlight.

(Image credit: Future)*Please note* Images were taken is a place protected from direct UV light. Please do not open the hood of a resin printer in direct sunlight.

(Image credit: Future)A criticism we have with the Form 3 is that it’s much slower than more affordable printers on the market. It took the Form 3 around 11 hours and 10 minutes to print this dragon figurine from PrintMyMinis, while the Phrozen Sonic Mini 8K managed the same file in 6 hours 12 minutes, despite being set to a higher layer count. That said, you’re not getting the same build quality and post-purchase care with printer marketing towards hobby users, and speed isn’t everything if you’re concerned about quality.

That said, you’re not getting the same build quality and post-purchase care with printer marketing towards hobby users, and speed isn’t everything if you’re concerned about quality.

Image 1 of 2

Model printed on the Form 3 is on the left, while the model printed using the Phrozen Sonic Mini 8K is on the right (Image credit: Future)Model printed on the Form 3 is on the left, while the model printed using the Phrozen Sonic Mini 8K is on the right

(Image credit: Future)The Form 3 certainly delivers on quality too, having picked up all of the fine details on our test print models. The resin formula also somehow feels higher quality than other bottles of resin we have used across testing other printers, but this is hard to quantify outside of feeling tougher and more durable.

Image 1 of 4

(Image credit: Future)(Image credit: Future)(Image credit: Future)(Image credit: Future)Above, you can see the level of detail achieved on the bust of Zombie Captain America from the Marvel 'What If?' series (credit to Fotis Mint ), with even the pattern of the fabric around his neck being picked up, something you have to bring your face close to the model to detect by eye.

Similarly, the model of Loona from Helluva Boss (credit to Printed Obsession ) also has a great amount of detail, and is sturdy enough to survive being knocked around and off surfaces without shattering or breaking in any way.

Image 1 of 2

(Image credit: Future)(Image credit: Future)We ran into a few small issues during the testing process that after some digging around online, appear to not be unique to us, such as the printer refusing to start filling the tank with resin as it couldn’t recognize it.

This is remedied by manually pouring a little resin into the tank before loading the resin cartridge into the printer, which isn’t ideal, but it was also the solution that others experiencing the same problem came to. We only ran into this issue with one resin tank so it’s hard to predict how much of an issue this could be.

The resin cartridges also needed some help, as the rubber seal wasn’t perforated enough to let the room-temperature resin flow. The solution to this was to carefully make this larger with a craft knife, which again, worked first time.

Should you buy the Formlabs Form 3?

Buy it if...

You run a business:

The Form 3 is an industrial-grade printer, so while anyone can buy one, it's commercial customers that will make the most out of its features. This is an expensive machine, but you really do get what you paid for.

You value after-service and customer care:

The aftersale support and build quality of the Form 3 are top of its class, which is ideal if you need a 3D printer that will provide consistent results. If anything goes wrong, there's a team of experts on hand to advise you and get you back up and running again.

You want high quality with minimal fuss:

The PreForm 'one-click print' feature really is impressive, and the ability to check the status of your printer and its current job remotely takes most of the stress out of 3d printing.

Don't buy it if...

You're on a tight budget:

Again, this is a commercial-class 3D printer so it has a lot features that bump up the price to a lofty height. If you don't have bucket of cash to spare, there are much cheaper options for resin-printers available.

If you don't have bucket of cash to spare, there are much cheaper options for resin-printers available.

You're new to 3D printing:

The Form 3 certainly takes a lot of pressure away from resin-based printing, but this is a pricey purchase if you have no prior experience. It may be best to buy a cheaper product first to experiment with before jumping into using such a professional piece of hardware.

FormLabs Form 3: Price Comparison

No price information

Check Amazon

powered by

Jess is a former TechRadar Computing writer, where she covered all aspects of Mac and PC hardware, including PC gaming and peripherals. She has been interviewed as an industry expert for the BBC, and while her educational background was in prosthetics and model-making, her true love is in tech and she has built numerous desktop computers over the last 10 years for gaming and content creation. Jess is now a journalist at The Verge.

Jess is now a journalist at The Verge.

Desktop 3D printers for the home

Anet Anycubic Creality3D CreatBot Dremel Elegoo Felix FlashForge FLSUN Flying Bear Formlabs IBRIDGER imprinta MakerBot Peopoly Phrozen PICASO 3D QIDI Raise3D Tiertime Ultimaker Uniz Voxelab wanhao XYZPrinting ZENIT Zortrax

Availability

In stock

Manufacturer

Phrozen Raise3D Creality wanhao FlashForge

PICASO 3D Anycubic Formlabs Tiertime Flyingbear QIDI Uniz CreatBot Dremel DigiLab Felix Zortrax XYZprinting Ultimaker imprinta Elegoo MakerBot Anet FLSUN iBridger Peopoly snapmaker Voltera Voxelab ZENIT

Delivery

Assembled printer Assembly kit

Application

Architecture For large objects For beginners The medicine Education

Orthopedics Production prototyping Reverse engineering Advertising, exhibitions Sculpture Dentistry Hobby jewelry

Print technology

DLP/LCD/SLA FDM/FFF LFS

Thread diameter

1. 75 mm 2.85 mm 3.00 mm

75 mm 2.85 mm 3.00 mm

Material type

ABS PLA PETG Photopolymers Flex

Nylon (Nylon) ASA Carbon HIPS PC PEEK PP TPU other Metal (Ultrafuse 316L, Ultrafuse 17-4PH)

Number of extruders (print heads)

Heating table

Yes Not

Wi-Fi or other wireless network

Yes Not

Country of origin

China Russia USA Taiwan Hong Kong

Netherlands Poland

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220 x 220 x 250 mm |

| Number of extruders (print heads) | 1 |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| On order/Transit | Goods in transit |

| Construction area size | 235x235x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220 x 220 x 250 mm |

| Number of extruders (print heads) | 1 |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 220x220x250 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| On order/Transit | Goods in transit |

| Construction area size | 220x220x270 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| On order/Transit | Goods in transit |

| Construction area size | 200x200x200 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| Construction area size | 300 x 300 x 400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Flyingbear |

| Construction area size | 255x210x210 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| On request/Transit | Goods in transit |

| Construction area size | 250x250x400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | Creality |

| On order/Transit | Goods in transit |

| Construction area size | 350x350x400 mm |

| Number of extruders (print heads) | 1 |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 102x57x165 mm |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 134x75x130 mm |

| Country of origin | Taiwan |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Anycubic |

| Construction area size | 197 x 122 x 245 mm (print volume 5. 9 l) 9 l) |

| Country of origin | China |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen |

| Construction area size | 165x72x180 mm |

| Country of origin | Taiwan |

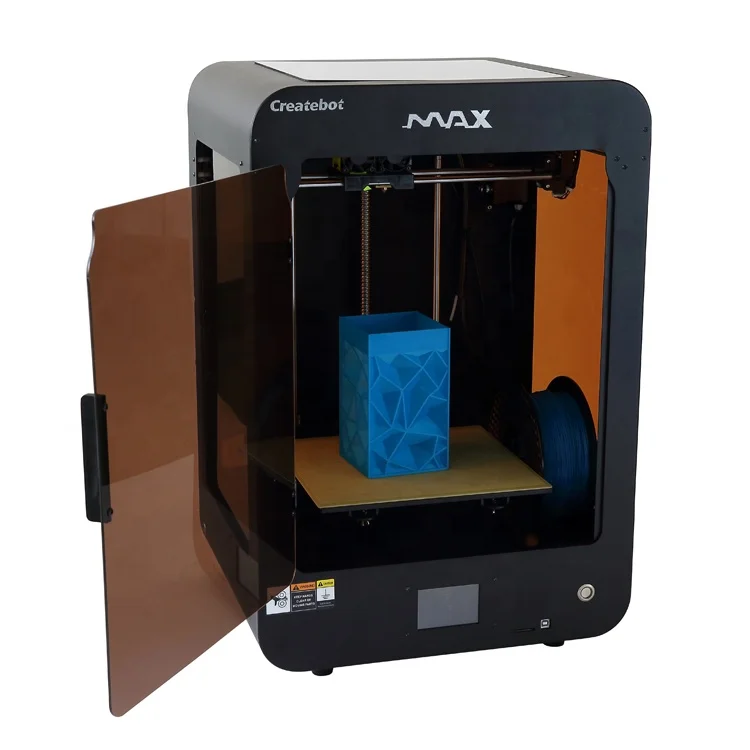

3D printing is one of the most promising areas of technological development in the 21st century. Having gone a long way from bulky and heavy boxes to compact desktop devices, 3D printers have ceased to be something inaccessible to a wide range of users. The era of mass additive manufacturing has already arrived, and every home can now house a real desktop factory.

You can buy a 3D printer capable of printing small models and prototyping of medium complexity today at the price of an entry-level laptop. The price of PLA or ABS plastic, which acts as a consumable, also no longer seems exorbitant. In a word, if you have long dreamed of getting to know the world of 3D printing and joining the ranks of makers, the right moment has come!

To save you time and make it easier to select equipment, we have collected in one section all desktop 3D printers optimized for home and office use. These are the real "workhorses" with the perfect balance of functionality, quality and price. Even a beginner can understand the settings, mount and calibrate a 3D printer, and as he gains experience, he will be able to print more and more complex three-dimensional models.

These are the real "workhorses" with the perfect balance of functionality, quality and price. Even a beginner can understand the settings, mount and calibrate a 3D printer, and as he gains experience, he will be able to print more and more complex three-dimensional models.

AMT construction 3D printers / Construction 3D printers from the manufacturer AMT

AMT is an expert in construction printing

Construction printer manufacturer No. 1

Construction 3D printing allows you to build faster, cheaper, better, more environmentally friendly.

-

Material savings

-

Cost savings

-

Maintenance personnel

-

Time savings

0002 We manufacture professional equipment for the real world. - The first residential 3D house in Europe (Yaroslavl, Russia. 1 floor 3 m high, area 298.5 sqm)

- The first 3D office building in Europe (Copenhagen, Denmark. 1 floor 5 m high, area 50 sq.m.)

- The world's first 3D fountain (Palekh, Russia. Diameter 26 m, depth 2.2 m)

- One of the houses in the village near the city of Yaroslavl (Yaroslavl, Russia. 1st floor, built-up area 64 sq.m)

- "Summer Pavilion" - a complex architectural building serving as a summer kitchen (Yaroslavl, Russia, 1st floor, area 23 sq.m)

- Construction printers for printing low-rise buildings 1-2 floors

- Construction printers for printing multi-storey buildings (up to 80 m high)

- Construction printers for landscaping, outdoor furniture, landscaping, landscaping, architectural decoration

- Warranty and post-warranty service

- Staff training, installation supervision of equipment

- Consulting and technical support in the implementation of projects

- Heavy duty professional equipment

- Real working equipment manufactured in the factory.

Not a prototype in a single copy, assembled in a garage

Not a prototype in a single copy, assembled in a garage - Our printers do not require special blends. All types of concrete and local materials can be used

- We use only reliable suppliers and high quality components. Printers are certified in Russia and the European Union

- Training, warranty, technical support

-

The company "AMT" launches a promotion for the construction 3D printer S-300!

In order to promote a new printer model, we are launching a campaign for a construction printer S-300 and offer our participation in the promotion of technology.

10% discount on the S-300 printer, free shipping in Russia. The promotion is valid until the end of 2021.

More -

AMT presents the world's first complex architectural object printed on a construction 3D printer!

The AMT company, a resident of the Skolkovo Foundation, on October 19, 2021 in the city of Yaroslavl presented a pavilion of complex architectural form.

Learn more

AMT construction printers

AMT is the first company to launch mass production of 3D construction printers.

More than 150 units of construction printers have been sold since 2015.

Please ask the other "leading" companies how much they have sold.

Our equipment printed such iconic buildings as:

We offer a turnkey solution

When you choose us, you choose solutions from an expert and market leader:

Our strengths

News / Articles