3D printed sternum

Implantation of a 3D-printed titanium sternum in a patient with a sternal tumor

- Journal List

- World J Surg Oncol

- v.16; 2018

- PMC5769524

World J Surg Oncol. 2018; 16: 7.

Published online 2018 Jan 15. doi: 10.1186/s12957-018-1315-8

,1,2,2 and 2

Author information Article notes Copyright and License information Disclaimer

- Data Availability Statement

Background

Primary malignant or metastatic sternal tumors are uncommon. A subtotal or total sternectomy can offer a radical form of treatment. The issue is to restore the structural integrity of the chest wall.

Case presentation

We report the implantation of an individualized 3D–printed titanium sternum in a patient with a sternal tumor.

Conclusions

We believe that tridimensional print technologies may also change the strategy of chest wall reconstruction.

Keywords: Sternal tumor, Sternectomy, 3D–printed titanium sternum

Primary malignant or metastatic sternal tumors are uncommon. A subtotal or total sternectomy can offer a radical form of treatment. If the sternal tumor has not invaded the mediastinal structure, the sternectomy does not present a surgical technical problem. The issue is to restore the structural integrity of the chest wall. Reports on implantation of autogenous, allogeneic, and prosthetic grafts have been published. Current modern 3D printing technologies bring a change in the strategy of chest wall reconstruction. We report the implantation of an individualized 3D–printed titanium sternum in a patient with a sternal tumor.

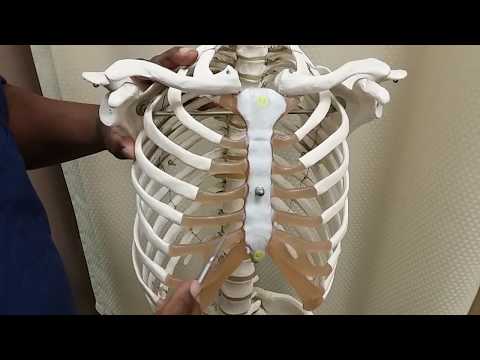

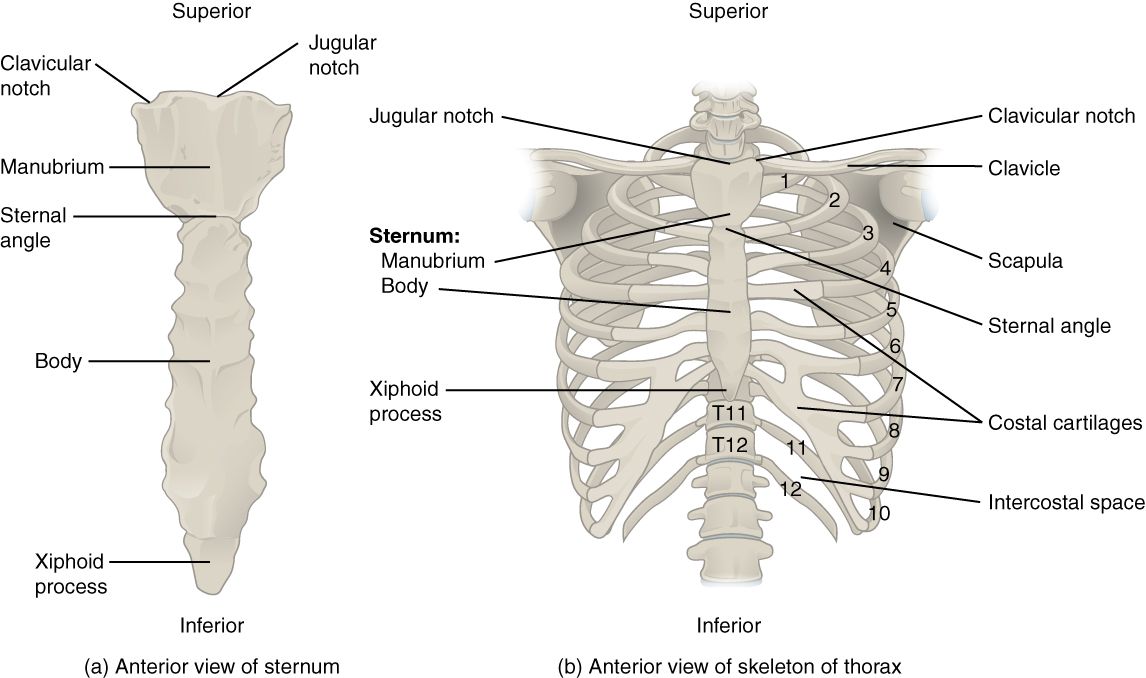

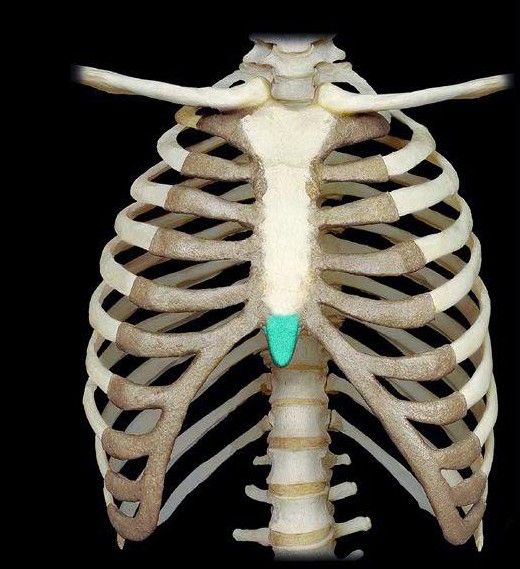

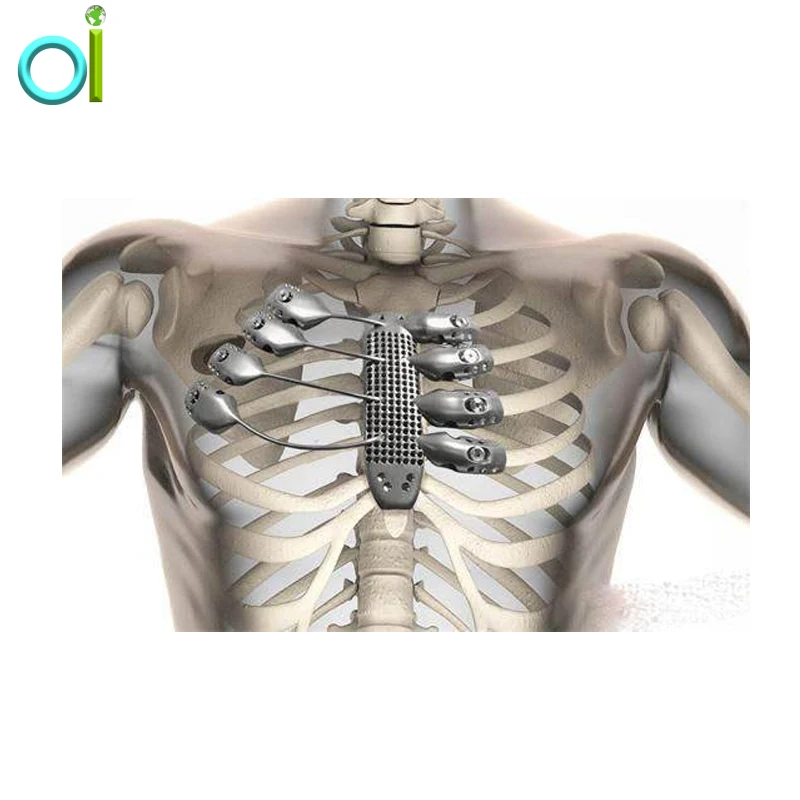

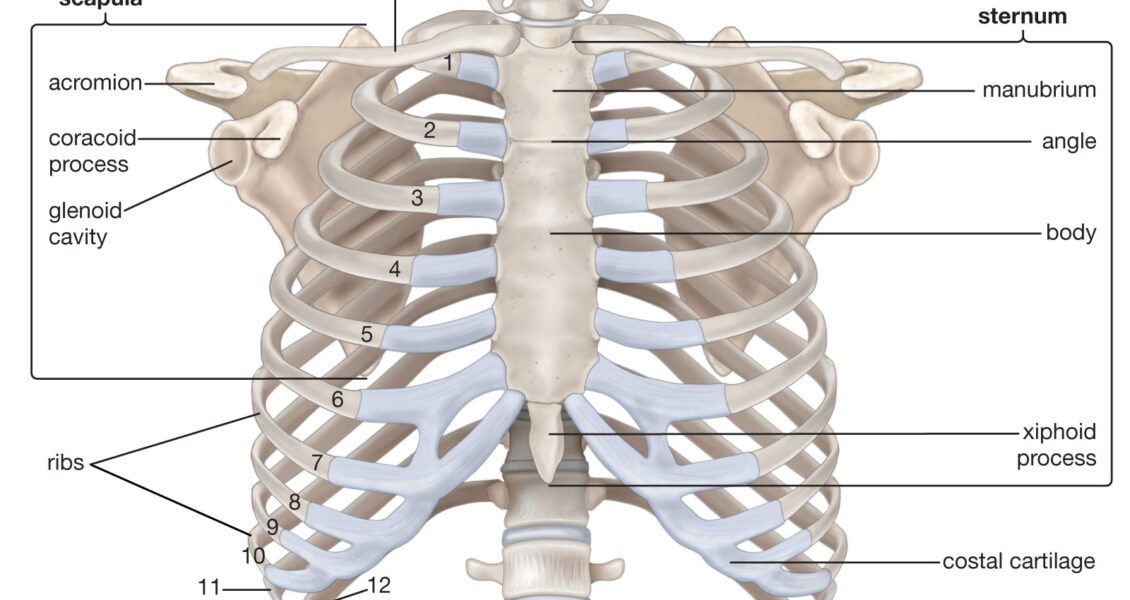

A 70-year-old woman with a history of colorectal and thyroid cancer, after radical operations (colon resection and thyroidectomy), chemotherapy and radioactive iodine therapy was admitted to our clinic with a sternal tumor appearing on computed tomography (CT) (Fig. a, b). A physical examination showed the solid mass of the sternum body. A positron emission tomography (PET-CT) scan revealed the 60 × 50 × 53 mm mass of the sternal corpus, with fluorodeoxyglucose (FDG) uptake and no other sign of local or distant metastasis. The surrounding tissue and mediastinal organs were non-infiltrated by the tumor. The best treatment option was subtotal sternectomy—resection of the sternal body with the adjacent sternocostal cartilage. Sternal reconstruction was discussed with biomedical engineers, who used source CT data and special CAD software Mimics (Materialize, Belgium) and Geomagic Design X (3D Systems, USA) to prepare a digital model of an assembly in 2 weeks (Fig. c), which consisted of a sternal implant and implants for the ribs. Afterwards, the implant (Fig. d) was additively manufactured using DMLS (Direct Metal Laser Sintering) technology (EOSINT M280 machine, EOS GmbH Electro Optical Systems, Germany) with a weight of 53.5 g and a size of 170 × 60 × 105 mm.The patient received a surgical antibiotic prophylaxis. A midline incision was made and the pectoralis major muscles were pushed laterally. We performed en bloc resection of the sternum body with approximately 3-cm pieces of cartilage from the 2nd to 4th ribs, bilaterally (Fig. a). The lines of the sternal body resection were 2 cm away from the tumor. Frozen section analysis confirmed the tumor-free sternal margins. The sternal implant was placed and fixed to the manubrium, the distal sternal part and bone parts of the second to fourth ribs bilaterally at additional fixation points (Fig. b). To join single titanium components of thoracic implant, the 18 metric screws M2.0 × 4.0 mm were used. For fixation of thoracic implant components to bone tissue of the patient; to the manubrium, the sternum, and the ribs, the SD2.

Afterwards, the implant (Fig. d) was additively manufactured using DMLS (Direct Metal Laser Sintering) technology (EOSINT M280 machine, EOS GmbH Electro Optical Systems, Germany) with a weight of 53.5 g and a size of 170 × 60 × 105 mm.The patient received a surgical antibiotic prophylaxis. A midline incision was made and the pectoralis major muscles were pushed laterally. We performed en bloc resection of the sternum body with approximately 3-cm pieces of cartilage from the 2nd to 4th ribs, bilaterally (Fig. a). The lines of the sternal body resection were 2 cm away from the tumor. Frozen section analysis confirmed the tumor-free sternal margins. The sternal implant was placed and fixed to the manubrium, the distal sternal part and bone parts of the second to fourth ribs bilaterally at additional fixation points (Fig. b). To join single titanium components of thoracic implant, the 18 metric screws M2.0 × 4.0 mm were used. For fixation of thoracic implant components to bone tissue of the patient; to the manubrium, the sternum, and the ribs, the SD2. 8-L splint screws (MARTIKAN, Slovakia) with defined length for each fixation point were used.

8-L splint screws (MARTIKAN, Slovakia) with defined length for each fixation point were used.

Open in a separate window

a Axial chest computed tomography of the sternal tumor. b Sagittal computed tomographic reconstruction of the sternal tumor. c Digital model of the implant. d Titanium implant ready for insertion

Open in a separate window

a Resected sternal tumor. b Intraoperative photograph of the implanted titanium-printed prosthesis

For insertion of SD2.5-L splint screws, the D121 screwdriver (MARTIKAN, Slovakia) was used. The medial margins of the pectoralis major muscles were sutured together to cover the implant. A redon tube was inserted into the mediastinum and was then removed 6 days after the operation. The length of surgery was 150 min and blood loss was 200 ml. Postoperatively, the patient had no chest paradoxical motion, experienced minimal pain, and had no limitation and no regional effusion. A routine postoperative chest x-ray demonstrated no pathology. The patient was discharged on the 10th postoperative day. Histopathology revealed low-grade chondrosarcoma.

A routine postoperative chest x-ray demonstrated no pathology. The patient was discharged on the 10th postoperative day. Histopathology revealed low-grade chondrosarcoma.

The principle of sternal resections and reconstructions is an adequate radical resection associated with the maintenance of chest stability for lung function as well as an acceptable cosmetic result [1]. A critical point in anterior chest wall reconstruction is a suitable prosthetic replacement that is able to restore the rigidity of the chest and prevent paradoxical motion [1]. Today, no consensus exists on which is the ideal prosthesis material and the optimal technique to reconstruct chest wall defect, and the decision still remains on the surgeon’s choice [1].

Synthetic materials such as polypropylene mesh, polyester mesh, polytetrafluoroethylene mesh, expanded polytetrafluoroethylene mesh, polyglactin 910 mesh can be used to reconstruct the chest wall defect after resection. They are relatively cheap and have high affinity for tissue growth, but its lack of rigidity in patients with extensive defects may result in paradoxical motion of the chest wall [2].

Methylmethacrylate is an interesting prosthesis material. It can be used alone or incorporated between two layers of polypropylene mesh in a sandwich fashion. Methylmethacrylate is lightweight, versatile, with minimal cost, and penetrable by x-rays. Loosening with dislocation and fracture of a chest wall sandwiched methyl methacrylate prosthesis were reported [3].

The biomimetics used with CAD modeling are pursued by respecting the anatomy, preserving function, selecting adequate reconstructive materials and integrating multidisciplinary efforts for complex reconstructions [4]. An individualized approach is necessary in modern chest wall reconstructive surgery. Technological advances in tridimensional printing using the principles of biomimetics enable production of 3D–printed titanium sternum. Recently, three modern case studies have been published on the application of a custom made titanium implant after anterior chest wall resection [5–7].

The titanium alloy and 3D technology used have practically unlimited possibilities in terms of the desired shape and size of the individualized implant, based on the specific patient anatomy. The prosthesis material is characterized by high strength while maintaining low weight and excellent biocompatibility, which guarantees minimal potential complications. The risk of migration or dislocation is limited by optimal planning of the number and location of fixation points. Preoperative individualized modeling of the implant enables easy insertion and fixation, which reduces the operation time. The short-term results were excellent: postoperative pain was minimal; the functions and stability of the chest remained unchanged; the cosmetic effect was fine and there was no regional seroma. Our recent and published data are insufficient to assess the long-term outcomes.

The prosthesis material is characterized by high strength while maintaining low weight and excellent biocompatibility, which guarantees minimal potential complications. The risk of migration or dislocation is limited by optimal planning of the number and location of fixation points. Preoperative individualized modeling of the implant enables easy insertion and fixation, which reduces the operation time. The short-term results were excellent: postoperative pain was minimal; the functions and stability of the chest remained unchanged; the cosmetic effect was fine and there was no regional seroma. Our recent and published data are insufficient to assess the long-term outcomes.

A 3D-printed titanium implant meets the criteria for an ideal prosthesis: user-friendliness in its placement and in adaptation by the patient’s body, without significant functional limitations and with an adequate cosmetic effect, biocompatibility, minimal risk of infection, high strength with minimal possibility of mechanical failure, low weight and ideal individualized material for fixing with preoperative planning of fixation points. The technology of individualized 3D printing is very well applicable for the reconstruction of chest wall defects. It reduces morbidity and brings benefits for the patient in terms of optimal function and structural chest configuration after resection.

The technology of individualized 3D printing is very well applicable for the reconstruction of chest wall defects. It reduces morbidity and brings benefits for the patient in terms of optimal function and structural chest configuration after resection.

None.

Funding

The presented article was supported by the project ITMS 26220220038 Creation and Technological Support in Diagnostics of Parts and Nodes by Computed Tomography and the project APVV-14-0294 – Production and Testing of Custom Made Hard Tissues Substitutions from Hydroxyapatite (HA).

Availability of data and materials

All relevant data are within the paper.

| CT | Computed tomography |

| DMLS | Direct metal laser sintering |

| FDG | Fluorodeoxyglucose |

| PET | Positron emission tomography |

AD performed the surgery, designed the report, collected the material, and wrote the manuscript. RH revised the manuscript. RP, JZ, and RH prepared the digital model and manufactured the implant. All authors have read and approved the final manuscript.

RH revised the manuscript. RP, JZ, and RH prepared the digital model and manufactured the implant. All authors have read and approved the final manuscript.

Ethics approval and consent to participate

Ethics approval and consent to participate is not required. In our institution (Jessenius Faculty of Medicine in Martin, Comenius University in Bratislava, Slovakia), a case report does not require ethical approval from the Institutional Ethical Committee.

Consent for publication

Written informed consent has been obtained from the patient for the publication of this case report and accompanying images.

Competing interests

The authors declare that they have no competing interests.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

1. Mansour KA, Thourani VH, Losken A, Reeves JG, Miller JI, Jr, Carlson GW, et al. Chest wall resection and reconstruction: a 25-year experience. Ann Thorac Surg. 2002;73:1720–1725. doi: 10.1016/S0003-4975(02)03527-0. [PubMed] [CrossRef] [Google Scholar]

Ann Thorac Surg. 2002;73:1720–1725. doi: 10.1016/S0003-4975(02)03527-0. [PubMed] [CrossRef] [Google Scholar]

2. Matsumoto K, Sano I, Nakamura A, Morino S, Yamasaki N, Tsuchiya T, et al. Anterior chest wall reconstruction with titanium plate sandwiched between two polypropylene sheets. Gen Thorac Cardiovasc Surg. 2012;60:590–592. doi: 10.1007/s11748-012-0048-9. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

3. Lardinois D, Muller M, Furrer M, Banic A, Gugger M, Krueger T, et al. Functional assessment of chest wall integrity after methylmethacrylate reconstruction. Ann Thorac Surg. 2000;69(3):919–923. doi: 10.1016/S0003-4975(99)01422-8. [PubMed] [CrossRef] [Google Scholar]

4. Rocco G. Chest wall resection and reconstruction according to the principles of biomimesis. SeminThorac Cardiovasc Surg. 2011;23:307–313. [PubMed] [Google Scholar]

5. Demondion P, Mercier O, Kolb F, Fadel E. Sternal replacement with a custom-made titanium plate after resection of a solitary breast cancer metastasis. Interact Cardiovasc Thorac Surg. 2014;18:145–147. doi: 10.1093/icvts/ivt456. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

Interact Cardiovasc Thorac Surg. 2014;18:145–147. doi: 10.1093/icvts/ivt456. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

6. Turna A, Kavakli K, Sapmaz E, Arslan H, Caylak H, Gokce HS, et al. Reconstruction with a patient-specific titanium implant after a wide anterior chest wall resection. Interact Cardiovasc Thorac Surg. 2014;18:234–236. doi: 10.1093/icvts/ivt408. [PMC free article] [PubMed] [CrossRef] [Google Scholar]

7. Aranda J, Jiménez M, Rodriguez M, Varela G. Tridimensional titanium-printed custom-made prosthesis for sternocostal reconstruction. Eur J Cardiothorac Surg. 2015;48:e92–e94. doi: 10.1093/ejcts/ezv265. [PubMed] [CrossRef] [Google Scholar]

Articles from World Journal of Surgical Oncology are provided here courtesy of BioMed Central

Sternal Reconstruction Using Customized 3D-Printed Titanium Implants

Case Reports

. 2020 Jun;109(6):e411-e414.

doi: 10. 1016/j.athoracsur.2019.09.087. Epub 2019 Nov 23.

1016/j.athoracsur.2019.09.087. Epub 2019 Nov 23.

Mohamed K Kamel 1 , Ann Cheng 1 , Bruna Vaughan 1 , Brendon Stiles 1 , Nasser Altorki 1 , Jason A Spector 2 , Jeffrey L Port 3

Affiliations

Affiliations

- 1 Division of Thoracic Surgery, Department of Cardiothoracic Surgery, Weill Cornell Medicine-New York Presbyterian Hospital, New York.

- 2 Division of Plastic and Reconstructive Surgery, Department of General Surgery, Weill Cornell Medicine-New York Presbyterian Hospital, New York.

- 3 Division of Thoracic Surgery, Department of Cardiothoracic Surgery, Weill Cornell Medicine-New York Presbyterian Hospital, New York. Electronic address: [email protected].

- PMID: 31765620

- DOI: 10.1016/j.athoracsur.2019.09.087

Case Reports

Mohamed K Kamel et al. Ann Thorac Surg. 2020 Jun.

. 2020 Jun;109(6):e411-e414.

doi: 10.1016/j.athoracsur.2019.09.087. Epub 2019 Nov 23.

Authors

Mohamed K Kamel 1 , Ann Cheng 1 , Bruna Vaughan 1 , Brendon Stiles 1 , Nasser Altorki 1 , Jason A Spector 2 , Jeffrey L Port 3

Affiliations

- 1 Division of Thoracic Surgery, Department of Cardiothoracic Surgery, Weill Cornell Medicine-New York Presbyterian Hospital, New York.

- 2 Division of Plastic and Reconstructive Surgery, Department of General Surgery, Weill Cornell Medicine-New York Presbyterian Hospital, New York.

- 3 Division of Thoracic Surgery, Department of Cardiothoracic Surgery, Weill Cornell Medicine-New York Presbyterian Hospital, New York. Electronic address: [email protected].

- PMID: 31765620

- DOI: 10.1016/j.athoracsur.2019.09.087

Abstract

In this report, we describe the use of custom-designed 3D-printed titanium implants to reconstruct the anterior chest wall, including the sternum and adjacent ribs, in two patients. These cases are the first to be reported in the United States, and they are among a handful performed around the world.

These cases are the first to be reported in the United States, and they are among a handful performed around the world.

Copyright © 2020 The Society of Thoracic Surgeons. Published by Elsevier Inc. All rights reserved.

Similar articles

-

Three-dimensional (3D)-printed titanium sternum replacement: A case report.

Wang W, Liang Z, Yang S, Feng Q, Nie X, Su G, Yuan W, Han Y. Wang W, et al. Thorac Cancer. 2020 Nov;11(11):3375-3378. doi: 10.1111/1759-7714.13655. Epub 2020 Oct 5. Thorac Cancer. 2020. PMID: 33015990 Free PMC article.

-

Chest-wall reconstruction with a customized titanium-alloy prosthesis fabricated by 3D printing and rapid prototyping.

Wen X, Gao S, Feng J, Li S, Gao R, Zhang G.

Wen X, et al. J Cardiothorac Surg. 2018 Jan 8;13(1):4. doi: 10.1186/s13019-017-0692-3. J Cardiothorac Surg. 2018. PMID: 29310677 Free PMC article.

Wen X, et al. J Cardiothorac Surg. 2018 Jan 8;13(1):4. doi: 10.1186/s13019-017-0692-3. J Cardiothorac Surg. 2018. PMID: 29310677 Free PMC article. -

Chest Wall Mechanics In Vivo With a New Custom-Made Three-Dimensional-Printed Sternal Prosthesis.

Oswald N, Senanayake E, Naidu B, Khalil H, Bishay E. Oswald N, et al. Ann Thorac Surg. 2018 Apr;105(4):1272-1276. doi: 10.1016/j.athoracsur.2017.11.005. Ann Thorac Surg. 2018. PMID: 29571330

-

Closing the cleft over a throbbing heart: neonatal sternal cleft.

J AR, G M, K M, P R. J AR, et al. BMJ Case Rep. 2014 Jul 4;2014:bcr2014204529. doi: 10.1136/bcr-2014-204529. BMJ Case Rep. 2014. PMID: 25100810 Free PMC article. Review.

-

[Current development in therapy of congenital funnel chest].

Ji K, Luan J. Ji K, et al. Zhongguo Xiu Fu Chong Jian Wai Ke Za Zhi. 2012 Dec;26(12):1516-8. Zhongguo Xiu Fu Chong Jian Wai Ke Za Zhi. 2012. PMID: 23316649 Review. Chinese.

See all similar articles

Cited by

-

Fused Deposition Modeling PEEK Implants for Personalized Surgical Application: From Clinical Need to Biofabrication.

Wang L, Yang C, Sun C, Yan X, He J, Shi C, Liu C, Li D, Jiang T, Huang L. Wang L, et al. Int J Bioprint. 2022 Sep 9;8(4):615. doi: 10.18063/ijb.v8i4.615. eCollection 2022. Int J Bioprint. 2022. PMID: 36404782 Free PMC article. Review.

-

Customized three dimensional printed prosthesis as a novel intercalary reconstruction for resection of extremity bone tumours: a retrospective cohort study.

Zhang Z, Shi Y, Fu J, Liu D, Zhu D, Liu X, Dang J, Fan H. Zhang Z, et al. Int Orthop. 2022 Dec;46(12):2971-2981. doi: 10.1007/s00264-022-05559-y. Epub 2022 Sep 9. Int Orthop. 2022. PMID: 36083497

-

Commentary: Acellular porcine mesh for chest wall reconstruction.

Weksler B. Weksler B. JTCVS Tech. 2022 Feb 19;13:261-262. doi: 10.1016/j.xjtc.2022.02.015. eCollection 2022 Jun. JTCVS Tech. 2022. PMID: 35711218 Free PMC article. No abstract available.

-

A Review on Development of Bio-Inspired Implants Using 3D Printing.

Raheem AA, Hameed P, Whenish R, Elsen RS, G A, Jaiswal AK, Prashanth KG, Manivasagam G. Raheem AA, et al. Biomimetics (Basel). 2021 Nov 19;6(4):65. doi: 10.

3390/biomimetics6040065. Biomimetics (Basel). 2021. PMID: 34842628 Free PMC article. Review.

3390/biomimetics6040065. Biomimetics (Basel). 2021. PMID: 34842628 Free PMC article. Review. -

Commentary: Three-dimensional printing and customizable implants: The future is now.

Weksler B. Weksler B. JTCVS Tech. 2021 May 14;8:216-217. doi: 10.1016/j.xjtc.2021.05.006. eCollection 2021 Aug. JTCVS Tech. 2021. PMID: 34401859 Free PMC article. No abstract available.

Publication types

MeSH terms

Substances

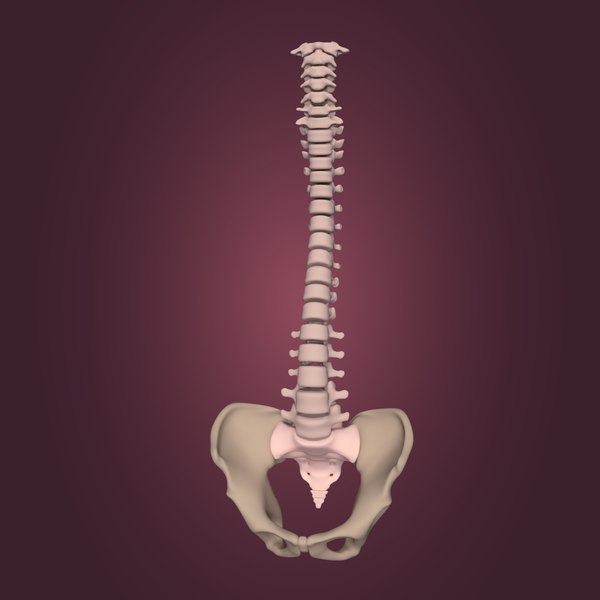

3D printed titanium endoskeleton

Andrey Vasilkov

September 11, 2015

Specialists from the Australian State Association for Scientific and Applied Research (CSIRO) made a large fragment of a human skeleton from titanium. A 54-year-old man from Spain will be the first to have an exact titanium replica of the missing bones implanted.

A 54-year-old man from Spain will be the first to have an exact titanium replica of the missing bones implanted.

Treatment of patients with oncological diseases is aimed primarily at improving their quality of life. An important direction here is prosthetics, since surgeons have to remove tissues and organs affected by tumors, including entire bones.

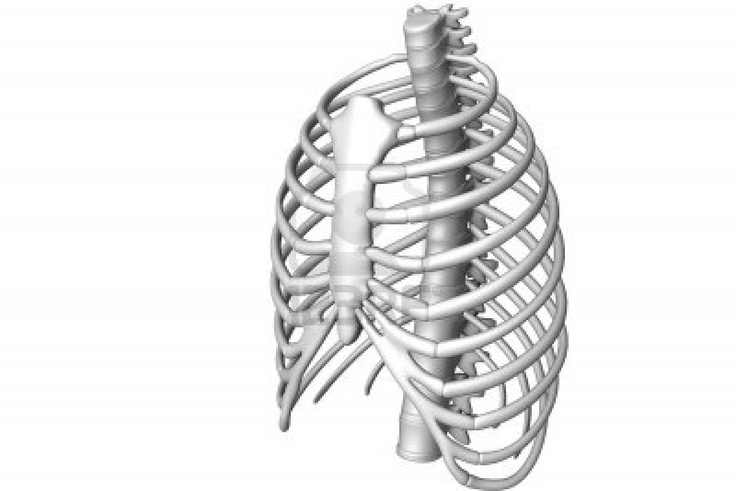

Titanium sternum and rib prosthesis (photo: Anatomics).A 54 year old Spanish patient was operated on for chest sarcoma. It would be too difficult to prosthetize it with classical methods due to the many removed bones and their complex geometry. Excursion of the chest occurs with each breath, and traditional prostheses do not allow you to achieve the necessary mobility. In addition, laminar implants lose their shape and elasticity over time.

Based on the results of computed tomography and other methods of radiation diagnostics, the most accurate three-dimensional model of the patient's thoracic region was created. It was used both for printing a prosthesis, and for precise localization of the tumor and coordinating the volume of surgical intervention.

It was used both for printing a prosthesis, and for precise localization of the tumor and coordinating the volume of surgical intervention.

The surgical team of the University Hospital of Salamanca in Spain asked their colleagues about the possibility of making a prosthesis of the sternum and associated ribs from titanium. 3D printing techniques already make it possible to make exact copies of individual bones, but this is the first time such a complex prosthesis has been requested. Suitable technology and experience in the production of complex parts were found only in Australia.

CSIRO uses a variety of additive printing techniques to produce strong, complex parts. Jet turbines, custom-made helmets - all of this has already been made to order. Now it is the turn to make a large part of the endoskeleton. However, the existing equipment was either designed for smaller parts or did not meet the requirements for implantable structures.

Especially for this task, a new 3D printer based on electron beam melting (EBM) technology, worth about a million dollars, was purchased from the Swedish company Arcam AB. Together with Anatomics from Melbourne, a titanium sternum (along with the xiphoid process) and eight ribs were printed on it in 3D printing laboratory No. 22.

3D printer manufactured by Arcam AB with electron beam melting technology (photo: CSIRO). The prosthesis was delivered by air, put together and checked the accuracy of manufacturing on the existing model. After the operation, the patient was observed for 12 days and was discharged with improvement. The success of biomedical applications of 3D printing was announced in a speech by Australian Minister for Industry and Science Development Ian Macfarlane. He noted that in recent years, 3D printing techniques have gone through a huge stage of development. If earlier they were used exclusively for rapid prototyping, now they have become the basis for the production of any structures of complex shape - from those experiencing strong mechanical and thermal loads to those implanted in the human body.

If earlier they were used exclusively for rapid prototyping, now they have become the basis for the production of any structures of complex shape - from those experiencing strong mechanical and thermal loads to those implanted in the human body.

Please enable JavaScript in your browser to participate in the discussion.

In Spain, for the first time in world surgery, a patient was transplanted ribs printed on a 3D printer. Spain in Russian

Subscribe to our newsletter and be the first to know about all offers

News

For the first time in world surgery, Spanish doctors transplanted titanium ribs and sternum, printed on a 3D printer, to an oncological patient. The transplant implants were designed and manufactured in Melbourne.

The transplant implants were designed and manufactured in Melbourne.

A 54-year-old man suffered from a chest wall sarcoma (a type of tumor that grows in and around the chest) and needed to have his sternum and part of his chest replaced.

As you know, these organs are difficult to recreate with prosthetics due to the complex geometry and structure of the bone tissue. And the surgical team of the University Hospital of Salamanca decided that the best option in this situation could be the sternum and chest, completely made by 3D printing.

They approached Melbourne-based medical device company Anatomics, which designed and manufactured the implant using a CSIRO 3D printer.

After delivery to Spain, the prosthesis was implanted in the patient. The patient was discharged from the hospital 12 days after the operation due to improvement in his condition.

RK

Need help in Spain? The center of services for life and business "Spain in Russian" is more than 100 types of services in the native language in any region of Spain.