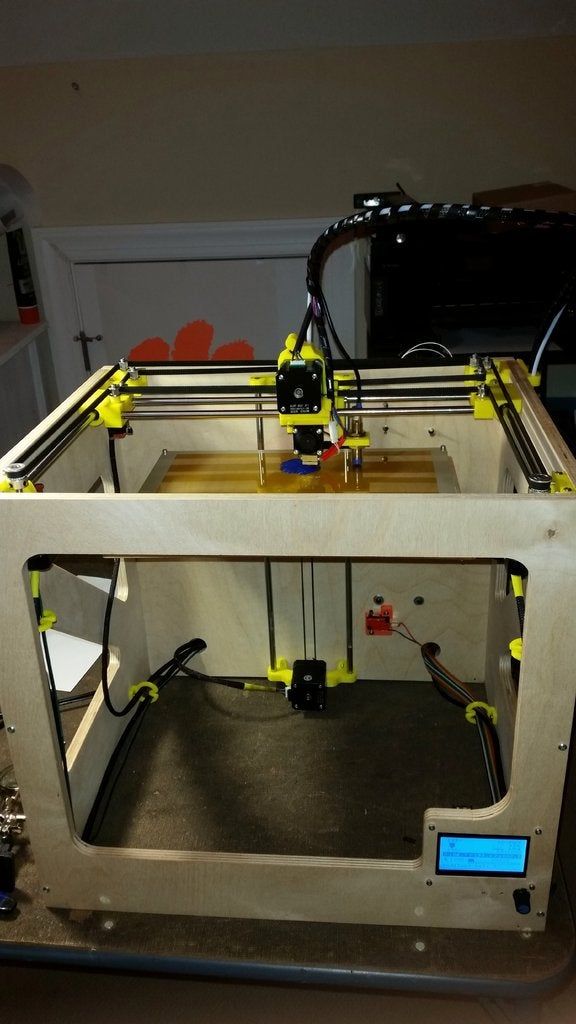

Flm 3d printer

Compare Filament and Resin 3D Printers

The 3D printing and additive manufacturing market has undergone rapid change in recent years. No longer primarily the domain of hobbyists, highly capable desktop machines have developed into essential tools for businesses. After becoming the go-to tool for prototyping and product development, 3D printing use has expanded across manufacturing, dentistry, jewelry, and much more.

Fused deposition modeling (FDM) and stereolithography (SLA) are the two most popular types of 3D printers on the market. Both 3D printing technologies have been adapted and refined for the desktop, making them more affordable, easier to use, and more capable.

In this comprehensive buyer's guide, we take a closer look at FDM and SLA 3D printers (also known as filament and resin 3d printers), and how they compare in terms of print quality, materials, applications, workflow, speed, costs, and more, to help you decide which technique is ideal for your business.

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

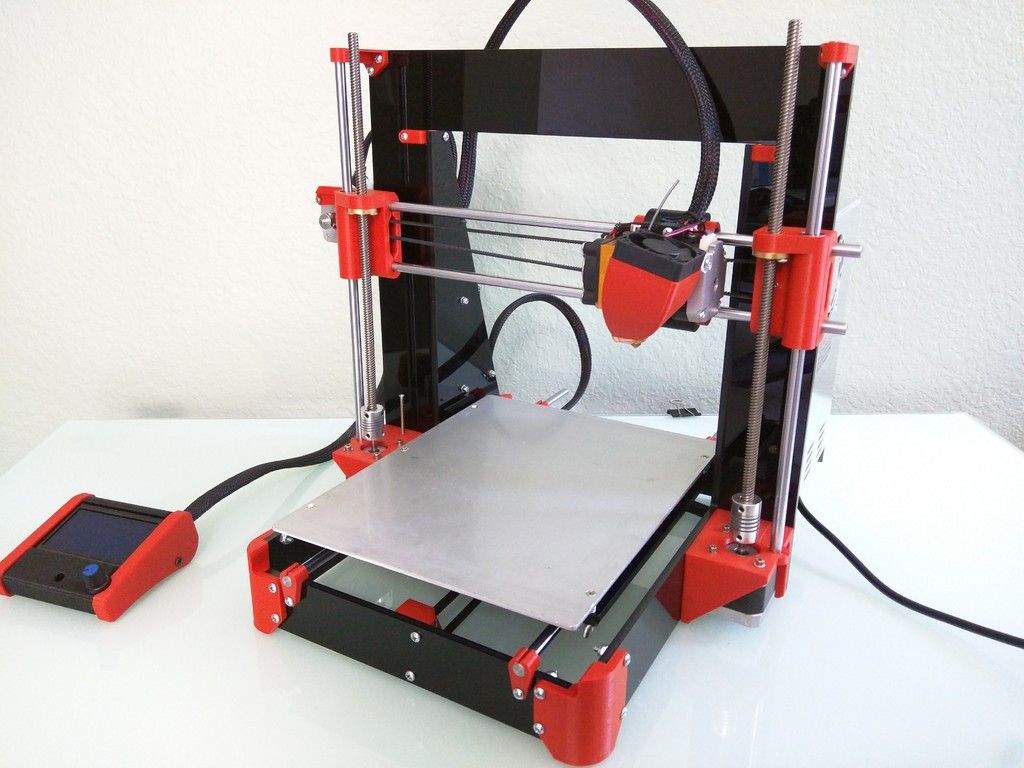

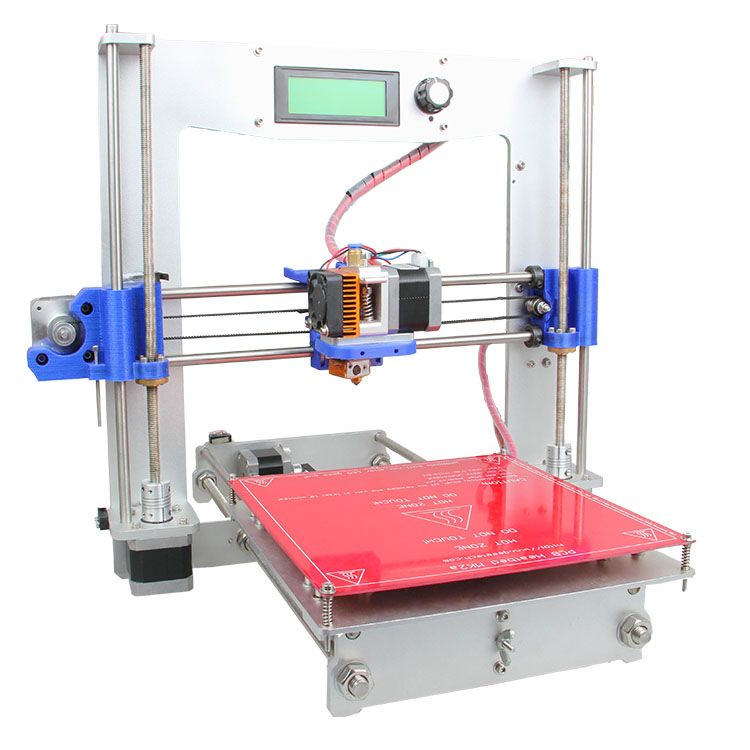

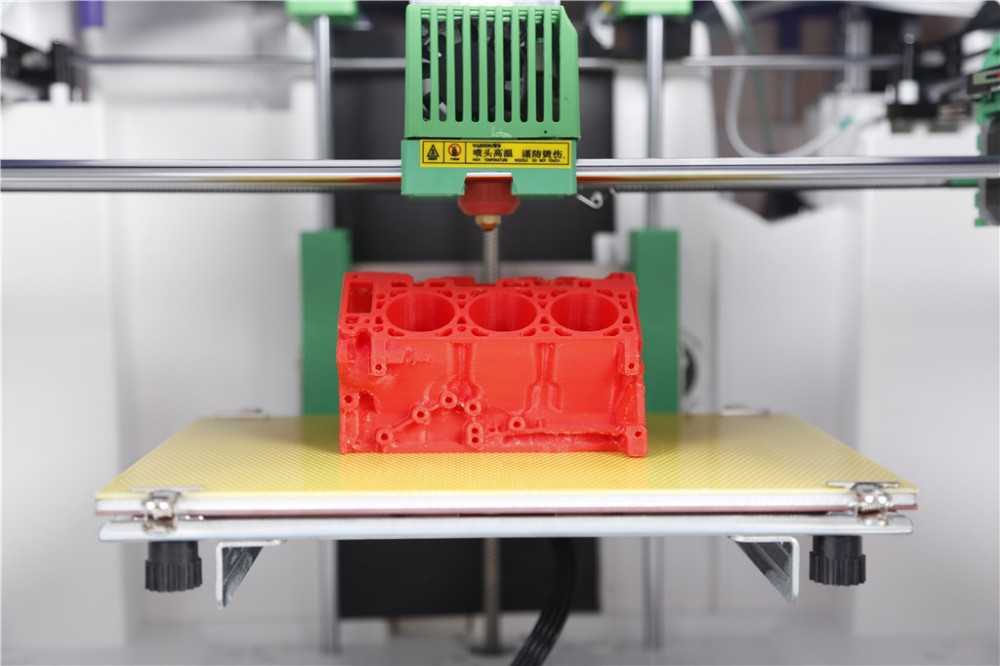

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used type of 3D printing at the consumer level. FDM 3D printers work by extruding thermoplastic filaments, such as ABS (Acrylonitrile Butadiene Styrene), PLA (Polylactic Acid), through a heated nozzle, melting the material and applying the plastic layer by layer to a build platform. Each layer is laid down one at a time until the part is complete.

Watch how FDM 3D printing works.

FDM 3D printers are well-suited for basic proof-of-concept models, as well as quick and low-cost prototyping of simple parts, such as parts that might typically be machined.

Stereolithography was the world’s first 3D printing technology, invented in the 1980s, and is still one of the most popular technologies for professionals. SLA 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization.

SLA 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization.

See how SLA 3D printing works.

SLA resin 3D printers have become vastly popular for their ability to produce high-accuracy, isotropic, and watertight prototypes and parts in a range of advanced materials with fine features and smooth surface finish. SLA resin formulations offer a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

Resin 3D printing a great option for highly detailed prototypes requiring tight tolerances and smooth surfaces, such as molds, patterns, and functional parts. SLA 3D printers are widely used in a range of industries from engineering and product design to manufacturing, dentistry, jewelry, model making, and education.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

When additive manufacturing processes produce parts layer by layer, each layer also introduces an opportunity for inaccuracy. The process by which layers are formed affects the surface quality, level of precision, and the accuracy of each layer, and consequently, the overall print quality.

FDM 3D printers form layers by depositing lines of molten material. With this process, the resolution of the part is defined by the size of the extrusion nozzle and there are voids in between the rounded lines as the nozzle deposits them. As a result, layers may not fully adhere to one another, layers are generally clearly visible on the surface, and the process lacks the ability to reproduce intricate details that other technologies can offer.

In SLA 3D printing, liquid resin is cured by a highly-precise laser to form each layer, which can achieve much finer details and is more reliable to repeatedly achieve high-quality results. As a result, SLA 3D printing is known for its fine features, smooth surface finish, ultimate part precision, and accuracy.

As a result, SLA 3D printing is known for its fine features, smooth surface finish, ultimate part precision, and accuracy.

Accuracy, precision, and tolerance in 3D printing are complex and often misunderstood terms. Learn more about their meaning to better understand 3D print performance.

SLA parts have sharp edges, sleek surfaces, and minimal visible layer lines. This example part was printed on the Formlabs Form 3 desktop SLA 3D printer.

The use of light instead of heat for printing is another way SLA printers guarantee reliability. By 3D printing parts at close to room temperature, they don't suffer from thermal expansion and contraction artifacts, which can happen during the FDM printing process.

Thanks to the highly precise laser, SLA 3D printers are better for manufacturing complex parts (FDM part on the left, SLA part on the right).

While FDM printers produce a mechanical bond between layers, SLA 3D printers create chemical bonds by cross-linking photopolymers across layers, resulting in fully dense parts that are water and airtight. These bonds provide high degrees of lateral strength, resulting in isotropic parts, meaning that the strength of the parts does not change with orientation. This makes SLA 3D printing especially ideal for engineering and manufacturing applications where material properties matter.

These bonds provide high degrees of lateral strength, resulting in isotropic parts, meaning that the strength of the parts does not change with orientation. This makes SLA 3D printing especially ideal for engineering and manufacturing applications where material properties matter.

The difference in quality is less visible on relatively simple parts. However, SLA parts are dense and isotropic, which makes them better suited for many engineering and manufacturing applications (FDM part on the left, SLA part on the right).

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

Plastic extrusion 3D printers work with a range of standard thermoplastic filaments, such as ABS, PLA, and their various blends. The popularity of FDM 3D printing in the hobbyist space has led to an abundance of color options. Various experimental plastic filaments blends also exist to create parts with wood- or metal-like surface.

Engineering materials, such as Nylon, PETG, PA, or TPU and high-performance thermoplastics like PEEK or PEI are also available, but often limited to selected professional FDM printers that support them.

FDM filaments and blends offer various color options. (source: All3DP.com)

SLA resin materials have the benefit of a wide range of formulation configurations: they can be soft or hard, heavily filled with additives like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance. Various resin formulations offer a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

SLA 3D printers offer diverse materials for engineering and manufacturing applications.

In some cases, it’s this combination of versatility and functionality that leads to companies to initially bring SLA 3D printing in-house. After finding one application solved by a specific functional material, it’s usually not long before more possibilities are uncovered, and the printer becomes a tool for leveraging the diverse capabilities of various materials.

Some material properties that are unique to SLA include:

SLA is the only 3D printing technique that can produce transparent parts on the desktop. Ideal for getting visibility into complex assemblies, (micro)fluidics, mold making, optics, lighting, and any parts requiring translucency.

Learn More

Parts printed in this material look and behave like a molded silicone part, and are durable enough to use for multiple cycles.

Learn More

Offers a heat deflection temperature (HDT) of 238 °C @ 0.45 MPa, the highest heat resistance of any material in desktop 3D printing.

Learn More

A 20% wax-filled material for direct investment casting and pressing for dental and jewelry applications.

Learn More

Specialized materials for dental applications like biocompatible surgical guides, splints, fixed patterns and models, clear aligner models, and full dentures.

Learn More

3D print parts with a stone-like finish and fire them to create a fully ceramic piece.

Learn More

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

See how to go from design to 3D print with the Form 3+ SLA 3D printer. This 5-minute video covers the basics of how to use the Form 3, from the software and materials to printing and post-processing.

The workflow for both FDM and SLA 3D printing consist of three steps: designing, 3D printing, and post-processing.

First, use any CAD software or 3D scan data to design a model, and export it in a 3D printable file format (STL or OBJ). 3D printers then require print preparation or slicer software to specify printing settings and slice the digital model into layers for printing.

Low-cost FDM or SLA 3D printers are not really user friendly and often require many hours of tweaking and experimenting to dial-in the correct print settings. Still, the results might change with each new design or material and the chance of failed prints remains high. This not only delays projects, but can also lead to messy failures that require a lengthy cleanup process.

Still, the results might change with each new design or material and the chance of failed prints remains high. This not only delays projects, but can also lead to messy failures that require a lengthy cleanup process.

Professional SLA 3D printers, like the Form 3, and some other professional FDM printers come with their own proprietary software and predefined settings for each material that have been thoroughly tested to ensure the highest print success rate.

Setting up prints with advanced print preparation tools like PreForm is plug and play. PreForm is a free download, try it now.

Once the 3D printing process begins, most 3D printers can run unattended, even overnight, until the print is complete. Advanced SLA 3D printers like the Form 3 offer a cartridge system, that refills the material automatically.

The final step of the workflow is post-processing. SLA parts require rinsing in isopropyl alcohol (IPA) or alternative solvents to remove any uncured resin from their surface. Using the standard workflow, this involves first removing parts from the build platform, then manually soaking them in a bath of solvent to clean off excess resin.

Using the standard workflow, this involves first removing parts from the build platform, then manually soaking them in a bath of solvent to clean off excess resin.

Professional solutions such as the Form Wash automate this process. Parts can be transferred directly from the printer to Form Wash, which agitates the solvent around the parts to clean them and automatically raises parts out of alcohol bath when the process is finished.

After rinsed parts dry, some SLA materials require post-curing, a process which helps parts to reach their highest possible strength and stability.

The FDM process has the benefit that it doesn’t require cleaning; unsupported finished parts are ready for use or further post-processing once the printing process is complete.

Both FDM and SLA processes use support structures to facilitate 3D printing more complex geometries and their removal represents the last step in post-processing.

Supports on FDM parts need to be manually torn away or dissolved in water, depending on the support material.

Supported FDM prints require additional post-processing to achieve a high-quality finish (source: 3D Hubs).

Support removal for SLA parts requires cutting away the support structures and lightly sanding the parts to remove support marks. Formlabs’ Low Force Stereolithography (LFS)™ technology offer light-touch supports, which allow an entire object to be torn away from its support base in seconds, leaving minimal markings and reducing time spent post-processing.

When further post-processing is required, both FDM and SLA parts can be machined, primed, painted, and assembled for specific applications or finishes. FDM parts, however, require additional sanding before priming or painting and need higher infill levels to be machined or bored.

Webinar

In this webinar, Matt Lewis and Ricky Hopper walk you through an overview of the improved SLA line, and give a hands on demo of the new products.

Watch the Webinar Now

How much does an FDM or SLA 3D printer cost and how much time and cost can you actually save with it for your business? Calculating cost per part requires accounting for the costs of equipment ownership, material, and labor. It’s helpful to understand the factors that influence each of these cost components, and the questions to ask to evaluate alternative production methods and uncover hidden costs.

It’s helpful to understand the factors that influence each of these cost components, and the questions to ask to evaluate alternative production methods and uncover hidden costs.

One of the main selling points for FDM 3D printers is the low machine cost. With entry-level FDM printers available for only a few hundred dollars, hobbyists and small businesses can try FDM to see if 3D printing is something worth adding to their toolset. For those unsure of where to start, the lower cost of an entry-level FDM machine is often persuasive enough to justify a purchase. However, these low-cost FDM printers can be unreliable and often require an expert to keep running in the long term.

Professional desktop FDM printers are easier to use and more tailored to businesses, with prices ranging from $2,000-$8,000. These 3D printers generally provide better reliability, higher print quality, and larger build volumes. While these machines are suitable for producing functional parts, competition at this price point is fierce, as SLA machines offer a wider range of applications and better quality prints.

SLA 3D printers start around $3,750 with Formlabs offering the only accessible large SLA 3D printer solution starting at $11,000.

In terms of materials, FDM filaments are also relatively low cost compared to materials for other 3D printing technologies. Common FDM materials like ABS, PLA, and their various blends generally start around $50/kg, while specialized FDM filaments for engineering applications can be $100-150/kg. Soluble support materials for dual extrusion FDM 3D printers sell for $100-200/kg. In comparison, most standard and engineering resins for SLA 3D printers cost $149-$200/L.

Labor costs are the final—often forgotten—part of the equation. For simple designs that require no supports to print, FDM requires almost no post-processing. Supported FDM prints and parts that require a high-quality finish, however, require lengthy manual post-processing.

SLA parts require washing and, depending on the material, also post-curing, but both of these processes can be mostly automated with accessories to minimize labor time. Supported SLA prints only require a bit of sanding to remove support marks and achieve a high-quality finish.

Supported SLA prints only require a bit of sanding to remove support marks and achieve a high-quality finish.

As a rule of thumb, FDM 3D printers will create the cheapest parts if you’re printing only relatively simple prototypes in limited numbers. SLA resin 3D printers offer higher resolution, better quality, and a wide variety of 3D printing materials at a slight premium, but the difference quickly diminishes when you print complex designs or larger batches due to the less labor-intensive post-processing.

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

Draft Resin is a fast-printing SLA material that can create parts up to 5-10X faster than FDM 3D printers. With a 200-micron layer height, Draft Resin is accurate enough to meet prototyping needs while enabling faster design iterations. Larger models that take up most of the build volume of an SLA printer (around a 15 cm cube) take only around nine hours to print with Draft Resin. Printing the same part at 200-micron layers on an FDM printer can take 80-90 hours. This is ideal for applications like rapid prototyping, where it allows users to quickly evaluate success and move on to another print or project.

Printing the same part at 200-micron layers on an FDM printer can take 80-90 hours. This is ideal for applications like rapid prototyping, where it allows users to quickly evaluate success and move on to another print or project.

FDM and SLA printing speed becomes comparable when printing parts at similar layer heights with other materials. But note, that a part printed at 100-micron layers on an FDM printer looks vastly different from a part printed at 100-micron layers on an SLA printer, because of the way the layers are built. Achieving comparable quality with FDM parts will require lower layers height —thus two to four times longer printing time— or significant and time-consuming post-processing to improve surface finish.

Webinar

Looking to learn more? Listen to the product managers who helped develop Draft Resin materials in this on-demand webinar.

Watch the Webinar Now

One area where FDM printers traditionally reigned used to be build volume. Due to the differences in technology, developing larger FDM machines is less complex. There are numerous larger FDM solutions on the market for applications that require 3D printing bigger parts.

Due to the differences in technology, developing larger FDM machines is less complex. There are numerous larger FDM solutions on the market for applications that require 3D printing bigger parts.

The inverted SLA process behind desktop SLA printers reduces footprint and cost, but heightened peel forces introduce limitations around materials and build volume, and larger parts require sturdy support structures to print successfully.

With the introduction of the Low Force Stereolithography (LFS) print process that powers the Form 3 and Form 3L, Formlabs has completely re-engineered our approach to resin-based 3D printing to drastically reduce the forces exerted on parts during the print process. Uniform linear illumination and the low forces from the flexible tank mean Low Force Stereolithography technology can seamlessly scale up to a larger print area built around the same powerful print engine.

The first affordable large format resin printer, the Form 3L delivers large parts fast, using two staggered light processing units (LPUs) that work simultaneously along an optimized print path. Delivering a build volume five times larger than current SLA printers, the Form 3L removes size restrictions that sometimes hinder workflows on smaller desktop devices, while maintaining a competitive price point.

Delivering a build volume five times larger than current SLA printers, the Form 3L removes size restrictions that sometimes hinder workflows on smaller desktop devices, while maintaining a competitive price point.

The Form 3L offers five times larger build volume than current SLA printers while maintaining a competitive price point.

Webinar

Want to learn more about the Form 3L and Form 3BL ecosystem, and the new large format post-processing machines?

In this demo, Kyle and Chris will expain how to navigate the Form 3L end-to-end workflow, including post-processing.

Watch Now

Each 3D printing technology has its own strengths, weaknesses, and requirements, and is suitable for different applications and businesses. The following table summarizes some key characteristics and considerations when comparing resin vs. filament 3D printers.

| Fused Deposition Modeling (FDM) | Stereolithography (SLA) | |

|---|---|---|

| Resolution | ★★☆☆☆ | ★★★★★ |

| Accuracy | ★★★★☆ | ★★★★★ |

| Surface Finish | ★★☆☆☆ | ★★★★★ |

| Throughput | ★★★☆☆ | ★★★★☆ |

| Complex Designs | ★★★☆☆ | ★★★★☆ |

| Ease of Use | ★★★★★ | ★★★★★ |

| Pros | Low-cost consumer machines and materials Fast and easy for simple, small parts | Great value High accuracy Smooth surface finish Fast printing speeds Range of functional applications |

| Cons | Low accuracy Low details Limited design compatibility | Sensitive to long exposure to UV light |

| Applications | Low-cost rapid prototyping Basic proof-of-concept models | Functional prototyping Patterns, molds, and tooling Dental applications Jewelry prototyping and casting Modelmaking |

| Price | Budget printers and 3D printer kits start at a few hundred dollars. Higher quality mid-range desktop printers start around $2,000, and industrial systems are available from $15,000. Higher quality mid-range desktop printers start around $2,000, and industrial systems are available from $15,000. | Professional desktop printers start at $3,750, large-format benchtop printers at $11,000, and large-scale industrial machines are available from $80,000. |

| Print Volume | Up to 300 x 300 x 600 mm (desktop and benchtop 3D printers) | Up to 300 x 335 x 200 mm (desktop and benchtop 3D printers) |

| Materials | Standard thermoplastics, such as ABS, PLA, and their various blends. | Varieties of resin (thermosetting plastics). Standard, engineering (ABS-like, PP-like, flexible, heat-resistant), castable, dental, and medical (biocompatible). |

| Training | Minor training on build setup, machine operation, and finishing; moderate training on maintenance. | Plug and play. Minor training on build setup, maintenance, machine operation, and finishing. |

| Facility Requirements | Air-conditioned environment or preferably custom ventilation for desktop machines. | Desktop machines are suitable for an office environment. |

| Ancillary Equipment | Support removal system for machines with soluble supports (optionally automated), finishing tools. | Washing station and post-curing station (both can be automated), finishing tools. |

After comparing the two technologies, we can conclude that FDM and SLA printers both have similar, often complementary features. But the two types of 3D printers are not always competing; many businesses use both as FDM and SLA 3D printers alongside one another. This can mean the best of both worlds: low-cost rapid prototyping coupled with high quality, functional parts for a wider range of applications.

A few practical examples:

-

In product development, FDM parts, or SLA printing with Draft Resin are both ideal for basic proof of concept models and rapid iterations. As a project moves forward in the development, SLA 3D printing is ideal for detailed concept models or functional prototypes might require better quality and materials with different properties.

-

Both FDM and SLA 3D printing are commonly used in manufacturing to create jigs, fixtures, and other tooling. FDM is better for large, simple parts, while SLA is a better solution for complex jigs, highly accurate tooling, and molds.

-

The education industry has seen success in deploying both FDM and SLA machines. Many education institutions start with FDM printing as its low cost is ideal for students who need quick drafts and some hands-on experience with the technology. SLA is the preferred choice for many technical schools, universities, research institutes, and in dental and jewelry education due to the higher quality and wider range of applications.

The University of Sheffield Advanced Manufacturing Research Centre (AMRC) uses a fleet of 12 SLA 3D printers for most engineering and manufacturing applications and reserve five industrial FDM printers for larger parts.

Download our white paper for a detailed overview of SLA ecosystems and the step-by-step 3D printing workflow.

Curious to see the SLA quality firsthand? Pick from our list of applications and request a complimentary sample part to find a material that meets the requirements for your project.

Request a Free Sample Part

Take on FLM 3D Printing in the 2015 3D Printer Challenge from RepRap Central - 3DPrint.com

Back in 2005 when Dr. Adrian Bowyer, a lecturer in mechanical engineering at the University of Bath, created the RepRap, or Replicating Rapid Prototyper, the goal of his project was to create a self-replicating device, in this case a 3D printer, that would be so useful it could ensure its own evolution and distribution.

Bowyer retired in 2012 to concentrate on the RepRap Project and his company, RepRapPro Ltd.

The RepRap Printer can print a percentage of its component parts, and as such Bowyer says he hopes that this ‘Portable Factory’ concept will bring on a new era of personal manufacturing.

Now RepRap Central are calling on developers and engineers to push the project on to the next level with their 2015 3D Printer Challenge.

RepRap Central sells 3D printers, 3D printer kits, and accessories from their offices in West Sussex and Cornwall, UK, and the challenge they’ve thrown open for this year is a call for entrants to build their own FDM 3D Printer.

Dr. Adrian Bowyer

But it’s about more than simply building a printer, it’s about building a printer to “revolutionize the 3D Printing revolution itself.”

They’re calling on entrants to the challenge to create an “FLM” 3D Printer. So what is an “FLM” printer? They say it stands for Fused Layer Manufacturing, a term they coined to describe a 3D printer capable of printing a complete layer at a time.

“Imagine the benefits of this type of 3D Printer. Very rapid build times, super smooth vertical operation, a level of accuracy yet to be experienced and super quiet operation,” states the challenge release. “What could this look like? We’ll we think it would only need a (Vertical) Z Axis. Gone are the mechanics of the current X and Y Axis used today in most if not all existing 3D Printers.

”

The idea is that some sort of innovative ‘active extruder’ would be central to the design which could fill the width and depth of the entire X and Y build area. They’re looking for a device which may mix technologies from 3D printing and injection molding which can be controlled at high resolution layer levels.

“We hope you’ll play a part, whether it’s to critique the proposal, put forward ideas, come up with designs or even build an FLM prototype.” they say. “The challenge is open to anyone, individual or business, and the winning design or designs will be announced later in the year.”

RepRap Central says more information on the challenge is coming soon, and they add that there’s a plan to “provide an environment where we can all share ideas and contribute thoughts and designs.”

Do you have the skills to take on the RepRap Central FLM Printer Challenge? Let us know what you think about the idea in the 2015 3D printer Challenge forum thread on 3DPB. com.

com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: challenge • Dr. Adrian Bowyer • FLM 3D printer • flm 3d printing • fused layer manufacturing • reprap • RepRap Central • RepRap Challenge • uk

Please enable JavaScript to view the comments powered by Disqus.

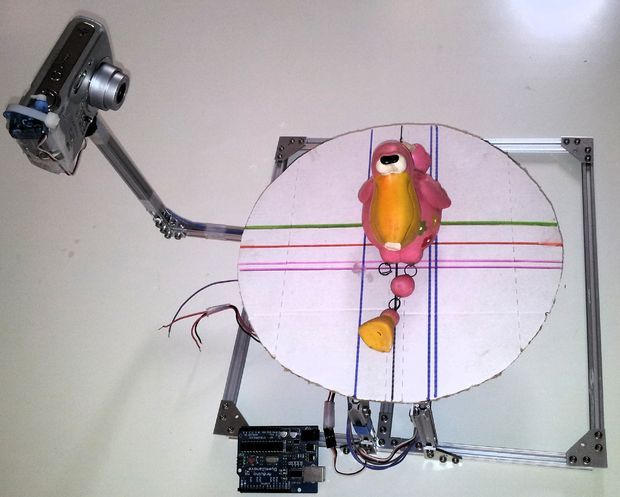

The designer made a film camera on a 3D printer

A camera on a 3D printer

Contrary to expectations, digital technologies in photographic equipment could not completely replace the classical methods of shooting, although they considerably surpassed them in popularity. Film photography is now a rarity, something like an unusual hobby that maintains its position in certain circles no matter what.

Someone will say that analog photography will never die, another will start arguing the opposite with fervor, and a third will start looking for ways to preserve the technology. This is exactly what a designer named Amos Dudley did, who wants to preserve the authenticity of the art of photography at all costs. And he did a very unusual thing for this: he printed a film camera on a 3D printer.

This is exactly what a designer named Amos Dudley did, who wants to preserve the authenticity of the art of photography at all costs. And he did a very unusual thing for this: he printed a film camera on a 3D printer.

He solved this problem with the help of innovative 3D printing technology, thus combining established traditions and current techniques. The goal was to produce a film camera that would be fully functional and not inferior in performance to similar devices.

According to Dudley, additive manufacturing and film photography complement each other perfectly, forming a new, unique device at the intersection of design and photography. It may seem that making a camera on a 3D printer can be problematic, but Amos approached the problem with all seriousness. The designer has been interested in 3D printing for a long time, having appreciated the possibilities of this technique. In his own words, the 3D printer transforms ideas and thoughts into real forms, making it the ideal working tool for a variety of creative projects. One of them, bold and unusual, is today's news.

One of them, bold and unusual, is today's news.

3D printed camera

Amos faced a difficult task - the decision to use 3D printing to create each element of the camera on the one hand limited, and on the other hand facilitated the search for new solutions. The 3D printed camera was supposed to be the quintessence of the traditional and the innovative. To begin with, Dudley compiled a list of all the parts of a 35mm film camera, including the film winder, shutter, diaphragm, light-tight camera body, and even the lens. To simplify the task, the designer decided to optimize the camera body in order to speed up the 3D printing process and reduce material consumption. The camera on the 3D printer was supposed to be as simple as possible, but to perform all the necessary functions.

This was followed by a long process of 3D modeling, at various stages of which Dudley created prototypes of the future camera. Upon reaching the most suitable variant of the design of the device, it was possible to start printing. As a working tool, the designer used a Formlabs SLA 3D printer and several different types of resins for individual parts of the camera. This decision was caused by the type of elements that differ in strength and flexibility, which required different approaches for their manufacture. In order to properly align the parts in the finished device, they were printed with a tolerance of ±0.75 mm and gaps of 0.25 mm. This ensured the smooth running of all moving parts.

As a working tool, the designer used a Formlabs SLA 3D printer and several different types of resins for individual parts of the camera. This decision was caused by the type of elements that differ in strength and flexibility, which required different approaches for their manufacture. In order to properly align the parts in the finished device, they were printed with a tolerance of ±0.75 mm and gaps of 0.25 mm. This ensured the smooth running of all moving parts.

3D printing of the camera lens

The hardest part of the whole project was the 3D printing of the camera lens. The desired result cannot be achieved using a standard FDM printer, and in the case of using a device with SLA technology, a long processing of the printed parts will be required. Since there was no other way out, the designer armed himself with a set of fine polishing pads and 12000 sandpaper. It took Amos about six hours to grind each lens, but the result still did not satisfy him.

To solve this problem, Dudley built his own grinder from scratch. Its work is based on the principle of industrial polishing devices complete with a special abrasive suspension. The final processing of the lenses took some more time, after which the next question arose: “How to design a shutter?”. The designer revised and discarded several different designs before settling on the 1885 camera mechanism. Yes, it turned out that the design of almost two centuries ago is ideally suited to the modern version of the film camera. Thus, a camera on a 3D printer combined several technologies at once, from the origins to the present.

Its work is based on the principle of industrial polishing devices complete with a special abrasive suspension. The final processing of the lenses took some more time, after which the next question arose: “How to design a shutter?”. The designer revised and discarded several different designs before settling on the 1885 camera mechanism. Yes, it turned out that the design of almost two centuries ago is ideally suited to the modern version of the film camera. Thus, a camera on a 3D printer combined several technologies at once, from the origins to the present.

After some improvements, the 3D model of the shutter has been completed and is ready to be played. The assembled camera on a 3D printer pleased the creator with full compliance with all expectations and a pleasant picture. From the shots taken on a homemade 3D-printed camera, it breathes something fabulous and mysterious. Slightly blurred images, although not particularly clean, have a special charm, fully justifying the efforts of the designer. Indeed, the finished camera not only impresses with its full functionality, but also allows you to fully experience the full power of 3D technology.

Indeed, the finished camera not only impresses with its full functionality, but also allows you to fully experience the full power of 3D technology.

https://skfb.ly/NMxr

Back to main page

18-year-old student converted a film camera to digital using 3D printed parts

There are two types of people in the world of photography: those who only use film cameras, and those who have fully embraced the glitz and glamor of digital photography. Recently, however, an 18-year-old physics student found a way to combine the best of both worlds.

Ollie Baker from Brighton, UK successfully converted a Konica Auto S3 1970s release into a digital camera using parts from a Sony NEX-5 and 3D printed parts he designed himself. It is not only the end result that is striking, but the process of transformation itself.

Now called the FrankenCamera, the idea came about last year when Baker was awarded a generous amount by the Arkwrite Scholarship Fund, one of the UK's most prestigious scholarship schemes. Ollie decided to invest in his personal project to "digitize" traditional film cameras.

Ollie decided to invest in his personal project to "digitize" traditional film cameras.

He chose the Konica Auto S3 analog camera, originally released in 1973 and known for its excellent rangefinder. In those days, she was considered one of the best. According to Baker, the Konica was the ideal choice because of its fixed 38mm f1.8 lens with non-contact internal leaf shutter. And the rangefinder mechanism allowed the camera to be small, unlike SLR cameras, which require a fairly large mirror. One of the downsides of Konica is that there is no built-in diopter adjustment for eyeglass wearers, but Baker cut one of his lenses out of old glasses and inserted it into the viewfinder as a diopter adjustment to solve the problem.

For a digital camera that would need to be dismantled and integrated into the Konica frame, Baker needed a balance between image quality, cost and appropriate size. Ultimately, he chose the Sony NEX-5, a small SLRless camera. Since Sony was only being used as a "donor", he decided which parts would be absolutely necessary, narrowing down the list to the board, sensor, SD card slot, battery slot and screen. In addition, Baker had to use a motor and connecting teeth to adjust the shutter to avoid annoying "camera errors" on the screen.

In addition, Baker had to use a motor and connecting teeth to adjust the shutter to avoid annoying "camera errors" on the screen.

The design process followed and Baker created a completely 3D printed new back to house the digital components and attach them to the film camera. To do this, he used Solidworks CAD software, as well as a caliper to take measurements. The top of this new part contains the screen and buttons, while the bottom contains the SD card slot, sensor, motor, screws, and battery. The main board is in the middle.

Baker originally intended to use his school 3D printer, but the detail quality was poor. So he sent his files to the SLS company in London for printing. After some adjustments, Baker got a strong, precise and flexible nylon print that fit perfectly with the original camera, with a hinge at one end and a clasp at the other that matched Konica's own locking mechanism. All it took was a small piece of black leatherette to match the design of the Konica 19. 70 years.

70 years.

Photo of Baker's first 3D print

Photo of the second and final 3D print of the back

CAD file design, wiring and soldering, to ON/OFF mechanism design and trigger replacement. But the grandest thing is that the camera does not just work, but takes good pictures. As the videos show, the FrankenCamera works just like the original Konica, including a bright flash. The only difference is the digital image sensor, the high screen resolution, and the SD card instead of the old-fashioned film. As you can see from the photos below, the results are incredibly convincing.

Then there was what happens to almost all postings on the Internet, Baker got negative comments: "Why ruin a wonderful Konica camera?" He was even accused of forgery (which he took as a compliment). However, the young creator claims that his goal was not to make a commercial product. Rather, he wanted to realize his personal vision by creating something new, interesting and, above all, exciting.