Fastest 3d printers

7 Fastest 3D Printers 2022 In Every Price Range

One of the major gripes with 3D printing is many consider it to be slow. However, over time both the speeds of FDM and resin printers have crept up — and there are now some super-fast options for both technologies.

For industrial printing, there are printers now reaching speeds competitive with traditional manufacturing, aiming to displace injection molding.

But what are the other fastest 3D printers in the world?

We have listed the world’s fastest 3D printers in every price range below, for both FDM and resin printers – but first, let’s explain the factors that affect the speed of 3D printing.

Do Bigger 3D Printers Print Faster?

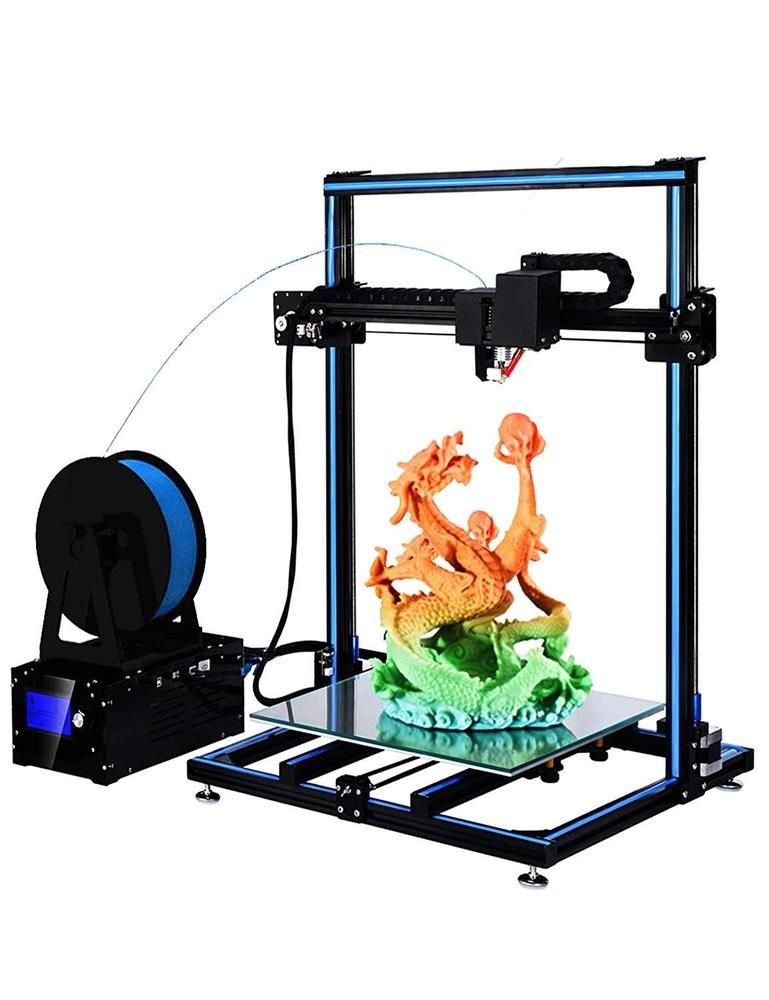

A bigger resin 3D printer does indeed print faster, but this is more in the sense of being more productive. A resin printer cures an entire layer on the XY axes, regardless of size, in one go. This means that the larger the printer, the more productive the printer is.

However, this isn’t the case for FDM printers, which need to deposit filament across the entire layer before moving on to the next.

FAST FDM PICK

Flsun Super Racer200mm/s makes it one of the fastest FDM printers around

Comes 95% pre-assembled

Available at Amazon here

FAST RESIN PICK

Anycubic Photon M3 PlusSuper-fast 100mm/h speed

Larger resin build area for scalable minis prints or larger resin models

Available at Anycubic here Amazon here

SUPER-FAST PICK

Phrozen Sonic Mega 8KExtremely high-res 8K LCD screen

Enormous build area and 70mm/h speed

Available At Phrozen here Amazon here

How Fast is a 3D Printer?

As for the technologies and 3D printers we have now, simply stating the fastest possible 3D printing speeds is difficult.

That’s because – and I know it’s frustrating to read this – it depends on several factors:

Resolution of the 3D printed part: before you start printing, you need to slice your model into layers on a 3D slicer. The more layers, and the thinner each layer, the longer the part will take to print at the same speed. A part printed with 50-micron layers will have twice as many layers as the same part printed with 100-micron layers, and take twice as long at the same speed.

- We also have a guide to high resolution 3D printers.

Quality of print: theoretically you could run a budget 3D printer at an extremely high speed, and it would still print. But the results wouldn’t be anything like how it looked on your slicer. It would be a mess of filament hairs and blobs, because the speed settings were set too fast. Some 3D printers can handle high-speed 3D printing, some cannot.

3D printing technology: how fast a 3D printer prints depends on the technology. Resin 3D printers are significantly faster than FDM 3D printers as they can cure entire layers at once, rather than depositing filament over each part of the layer. The fastest 3D printing technologies include Multi Jet Fusion and resin 3D printing technologies like MSLA.Resin 3D printing technologies are known for being faster than FDM.

Resin 3D printers are significantly faster than FDM 3D printers as they can cure entire layers at once, rather than depositing filament over each part of the layer. The fastest 3D printing technologies include Multi Jet Fusion and resin 3D printing technologies like MSLA.Resin 3D printing technologies are known for being faster than FDM.

Material: some materials are easier to print than others, putting less demand on the printer and leading to a slightly faster print.

Complexity of the model: You will be able to print a cube block far quicker than an intricate 3D printed jewelry piece. This is because you can print larger layers and at a faster print speed without a notable loss of quality, since the cube is a very simple shape with no details.

Size of print: fairly obvious, but a larger print will take far longer than a small one. A full-size vase will take around 12 hours to print in normal detail on most FDM 3D printers, but a small statue may take under an hour.

Nozzle size: for FDM 3D printing, smaller nozzles mean more intricate details can be printed more accurately, but larger nozzles can potentially print faster.

Will 3D printers get faster?

Almost certainly. We’ve already seen a number of major innovations that make 3D printers faster in the last decade. In 2012, the first delta 3D printers started to appear, which print significantly faster than previous Cartesian 3D printers.

Then, new resin 3D printer innovations such as Carbon 3D’s CLIP, and Uniz’s UDP technologies made SLA and DLP faster. Other significant speed innovations include HP’s Multi Jet Fusion technology, and also the huge advances being made in many metal 3D printers such as those by Desktop Metal and Markforged.

The Fastest 3D printers 2022 in Every Price Range

| Name and brand | Build volume (mm) | Max speed | Price | Where to buy |

|---|---|---|---|---|

| Flsun Super Racer | 260 x 260 x 330 | 200mm/s | $499 | Amazon here |

| Anycubic Photon M3 Plus | 197 x 122 x 245 | 100mm/h | $699 | Anycubic here |

| Anycubic Photon M3 Max | 298 x 164 x 300 | 60mm/h | $1099 | Anycubic here |

| Phrozen Sonic Mega 8K | 330 x 185 x 400 | 70mm/h | $2199 | Phrozen here |

| Uniz Slash UDP | 293 x 122 x 200 | 600mm/h | $1,999 | Matterhackers here |

| WASP 2040 Pro Turbo | 200 x 200 x 400 | 500mm/s | $3,400 | Amazon here |

| HP Jet Fusion 5200 | 380 x 284 x 380 | 4115cm3/h | Quote |

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

When you buy through links on our site, we may earn an affiliate commission. Learn more

Flsun Super Racer – Fastest FDM 3D Printer Under $500

- Price — Check latest price at Amazon here

- Technology: FDM Delta

- Max Print Speed: 200 mm/h

- Build Volume: 260 x 260 x 330 mm

True to its speedy name, the Flsun Super Racer is a Delta FDM printer that absolutely gallops with a top print speed of 200 mm/h. It’s an upgraded version of Flsun’s QQ-S, which after some one-on-one time we found to be a competent, worthwhile printer for large projects.

Delta printers are known for offering higher speeds than their Cartesian brothers, but Flsun is pushing the boat out to new extremes with the Super Racer. Most standard FDM printers perform best at a comfortable 50-60 mm/h, while the Super Racer delivers solid quality prints at four times that.

With a decently-sized 260 x 260 x 330 mm build volume, the Super Racer is also big on vertical print capacity, ideal for those towering prints that exceed the dimensions of budget FDM printers. Throw in a thoughtful design, quality components, automatic bed leveling, breezy 20-minute assembly, a responsive, easy-to-navigate detachable touch screen, and the Super Racer comes awfully close to a speed freak’s dream 3D printer.

Throw in a thoughtful design, quality components, automatic bed leveling, breezy 20-minute assembly, a responsive, easy-to-navigate detachable touch screen, and the Super Racer comes awfully close to a speed freak’s dream 3D printer.

Now, all this speed does come with a trade-off. Delta printers, the Flsun Super Racer included, lack the accuracy and consistent print quality offered by Cartesian 3D printers. The difference is relatively negligible, but it’s a point to consider before buying for makers that favor quality over speed.

On the filament front, the Flsun Super Racer’s Bowden extruder setup works great for PLA but coughs up the usual Bowden-related jamming and clogging issues with flexibles. For example, if you’re working with TPU, you’re better off sticking to a classic Cartesian printer – ideally with a direct drive extruder.

Anycubic Photon M3 Plus/Max – Fastest Resin 3D Printers Under $1,000

- Price: $699 / $1,099 — M3 Plus Available here / M3 Max Available here

- Technology: MSLA Resin

- Max Print Speed: 100 mm/h / 60 mm/h

- Build Volume: 197 x 122 x 245 mm / 298 x 164 x 300 mm

More than simply an update to the long-running Photon series, the Anycubic Photon M3 machines are turning more than a few heads as the fastest resin 3D printer range around.

In particular, the Anycubic Photon M3 Plus proposes a top print speed of 100 mm/h. The beauty of resin printers is that they cure in layers, regardless of how much space on the build plate that layer takes. Those 100 mm/h apply whether you’re printing a single small miniature or a batch of twelve, which makes the Anycubic Photon M3 Plus exponentially more productive.

The Anycubic Photon M3 Max is no slouch either, offering a respectable 60 mm/h, but does this across a massive 298 x 164 x 300 mm. That’s the largest of any Anycubic resin printer and among the highest capacities found on consumer-grade printers, rubbing shoulders with the hulking Elegoo Jupiter and Phrozen Sonic Mega 8K.

Elsewhere, the Photon M3 duo stands out for offering excellent detail with 34 microns XY resolution on the Plus and 46 microns on the Max. The Max has a 7K LCD, one of the highest pixel counts on the market, while the Plus pushes a 6K LCD – higher than the standard 4K found on comparable printers. Both machines also ship with Anycubic excellent textured checkerboard build plate, which offers superb print adhesion.

Both machines also ship with Anycubic excellent textured checkerboard build plate, which offers superb print adhesion.

Read the full comparison: Anycubic Photon M3 vs M3 Plus vs M3 Max

Phrozen Sonic Mega 8K – Fastest High-Quality Resin 3D Printer

- Price: $2,199 — Available at Phrozen official here

- Technology: MSLA Resin

- Max Print Speed: 70 mm/h

- Build Volume: 330 x 185 x 400 mm

With the Phrozen Sonic Mega 8K, size and speed combine into arguably one of the most impressive mid-range professional resin printers on the market.

The 330 x 185 x 400 mm build volume is the largest available in this price range, and the Sonic Mega 8K darts across this printing expanse at a nippy 70 mm/h. No other printers manage to weave in such a large build volume with such high speeds; it’s always been one or the other.

The Phrozen Sonic Mega 8K allows makers to hone in on all the fine features and intricacies of even the most detailed models and minis thanks to a 43-micron resolution, propped up by a pixel-rich 15’’ 8K LCD. It’s a level of quality that simply isn’t currently available on any other printer in the same printer segment.

It’s a level of quality that simply isn’t currently available on any other printer in the same printer segment.

The build plate comes pre-calibrated, allowing you to print without delay once the Mega 8K lands on your doorstep. A clever dual linear rail design ensures the printer behaves and delivers those sharp details even high up into the upper reaches of the build area.

If you need a mammoth-format printer at a reasonable price to power a small business where time is of the essence, there’s little else out there that comes close to the Phrozen Sonic Mega 8K. If the build volume exceeds what you’ll conceivably ever need, a lower-cost resin printer such as the Anycubic Photon M3 Plus or even the standard M3 is likely a better use of your money. The Phrozen Sonic Mega 8K is a jumbo printer and will be far too much for most amateur makers.

Uniz Slash Plus UDP — Fastest desktop 3D printer

- Max print volume: 293 x 122 x 200 mm

- Price: $1,999 — Available on Matterhackers here

- Fastest 3D printer speed: 600mm/hour in UDP mode

Uniz have made a big impact since their original Kickstarter campaign that raised over $500,000 to produce super-fast resin 3D printers at consumer prices. This quick 3D printer uses Uniz’s Uni-Directional Peel (UDP) technology to print far faster than its competitors, at up to 600mm/hour when in UDP mode.

This quick 3D printer uses Uniz’s Uni-Directional Peel (UDP) technology to print far faster than its competitors, at up to 600mm/hour when in UDP mode.

When not in UDP mode the maximum 3D printer speed is 200mm/hour, but this is still super fast. This is because not all parts are compatible, for example, any parts with cross sections, or fully enclosed parts cannot be printed in UDP mode; and no parts with solid infill can be printed either. You are also restricted as very tall prints cannot be printed in UDP mode, but if your part qualifies then you can print extremely quickly!

Not only is it an extremely fast 3D printer, but it’s also accurate. This SLA 3D printer has an XY resolution of 75 microns, and a minimum layer of thickness of just 10 microns. As a result, parts have very good surface finish and look almost like they have no layers at all. The printer can also calibrate itself, can be operated via your phone or table on the mobile app, and weighs just 12kg. It’s certainly one of the best speedy 3D printers for the price.

WASP 2040 PRO Turbo — Fastest 3D printer in the world

- Price: $3,400 — Available on Amazon here

- Max print volume: 200 x 200 x 400 mm

- Fastest 3D printer speed: 500mm/s recommend (some say it can print even faster!)

Delta 3D printers are known for their speed, and are the fastest FDM 3D printers in the world. The WASP 2040 PRO Turbo is a delta printer that is not only incredibly fast – at up to a recommend 500mm/s – but is also extremely accurate for an FDM printer. The resolution of up to 50 microns means very accurate and low cost prototypes and parts can be produced, and in record time. WASP claim they make the fastest 3D printers in the world for FDM.

WASP 3D printers are known for their reliability, with the Italian company ensuring the printers operate with workhorse-like consistency. It can print 3D printer filaments including ABS, PLA, PETG and Nylon, so if you want to print stronger parts from one of the tougher plastics you still can, and you can use third party filaments if you prefer – the WASP allows for these. and you can choose to buy the WASP 2040 as either a single or dual extruder 3D printer.

and you can choose to buy the WASP 2040 as either a single or dual extruder 3D printer.

Unlike most RepRap 3D printer deltas, the WASP 2040 Turbo comes fully assembled, so those who aren’t masters of DIY do not need to worry. You can also choose to order it either as a single or dual extruder 3D printer based on your printing needs.

It’s the world’s fastest 3D printer for FDM, and also accurate and reliable – what more could you want for under $5,000!

- It also has a variation designed specifically as a clay 3D printer.

HP 3D Jet Fusion 5200 — Fastest Industrial 3D printer

- Price: Requires a quote

- Max print volume: 380 x 284 x 380 mm

- Fastest 3D printer speed: 4115cm3/hour

HP have only been actively involved in the 3D printing industry for the last few years, but have brought such technological advantages in that short space of time. The Jet Fusion 5200 epitomizes this, marking uncharted territory for 3D printing where it is now considered viable for mid-range production.

Multi Jet Fusion has always been known for its fast 3D printing speed, but the Jet Fusion is even faster than its predecessors. With speeds up to 4115cm3/hour, it’s faster than the Jet Fusion 4200 (4000cm3) and the 3200 (2800cm3) – and these were already some of the fastest 3D printers in the world. The high-quality 1200dpi print head resolution allows for extremely accurate parts with smooth surface finishes and crisp, sharp edges.

The Jet Fusion 5200 combines this astonishing speed with low part cost and scalability. Whole layers can be printed at once, rather than tracing each layer as with Selective Laser Sintering, meaning multiple parts can be printed at once without a drop off in productivity. Multi Jet Fusion isn’t known for its versatility of materials, but PA12, PA11 Nylons and TPU are strong materials with good properties for a variety of industries. It’s extremely fast, extraordinarily accurate, and a rare example of 3D printers being competitive in mid-volume part production – very exciting.

Do you really need a fast 3D printer?

Speed is always useful; nobody chooses to wait in a queue longer than they need to. However, with the quickest 3D printers, there are some cases where you can’t take advantage of this speed.

For FDM 3D printers, some materials become volatile and print with imperfections if you don’t slow right down, like PEEK, PC, and others. Printing at 150mm/s+ would just ruin your prints, so the speed is useless here.

Also, if you are printing a very simple object like a cube, speed becomes less useful as you can just use very large layer heights and print quickly anyway.

However, if your business depends on quick production, then absolutely go for a printer that can either print objects very quickly, or multiple objects simultaneously. The ability to rapidly prototype new designs and innovate quicker is invaluable, and other industries like 3D printed jewelry production or hearing aids need to be able to print custom designs at the highest speeds possible.

So, it depends. For hobbyists, speed is great for quality of life and printing all the cool things and useful 3D prints you can. For industry it can be more necessary, and businesses often opt for an industrial 3D printer than can meet their production speed requirements.

How Fast Can PLA Be 3D Printed?

The fastest FDM printers, such as the Flsun Super Racer, can print PLA up to 200 mm/h. However, the most common 3D printers, such as the Ender 3, can print PLA at around 50 to 80 mm/h without sacrificing print quality.

Related articles:

- Best large resin 3D printers (bigger = faster!)

- Best delta FDM 3D printers

- Best FDM 3D printers

The 7 Fastest FDM 3D Printers In 2022 (For Consumers & Professionals)

- Last Updated: November 1, 2022

- Pat Nathaniel

3D printers are a great way to get your part, but if you’re impatient, then you want the fastest on the market. At the same time, you don’t want to waste money or compromise on quality.

At the same time, you don’t want to waste money or compromise on quality.

Don’t worry; this extensive list has you covered.

We will dive into the fastest consumer printers, then take a look at some industrial options. Afterward, we’ll take a look at what print speed is good for a normal printer and why printers can’t go faster.

Let’s take a look at some of the fastest 3D printers available for you to buy today.

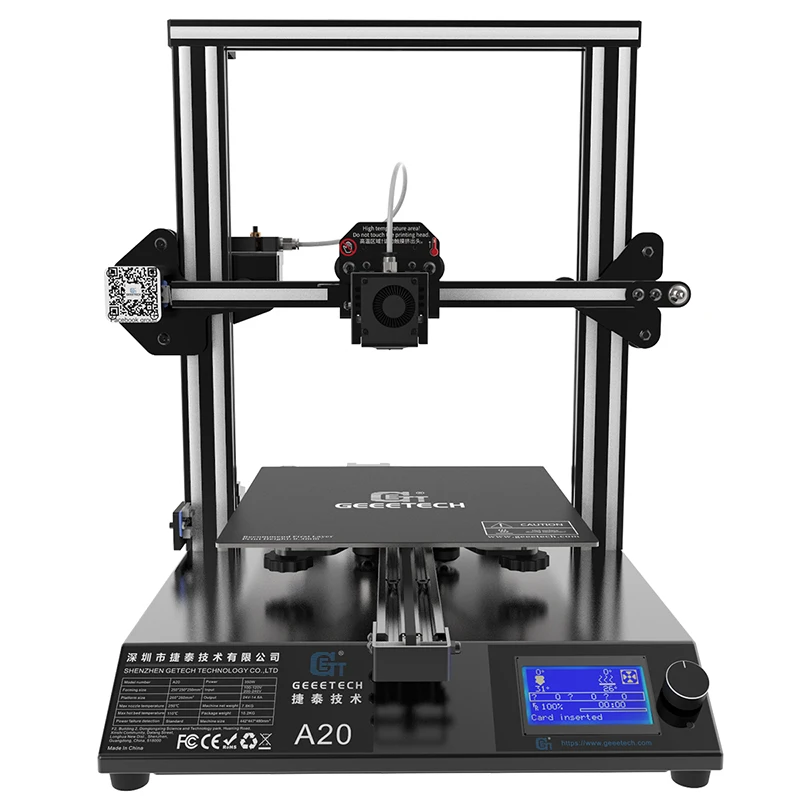

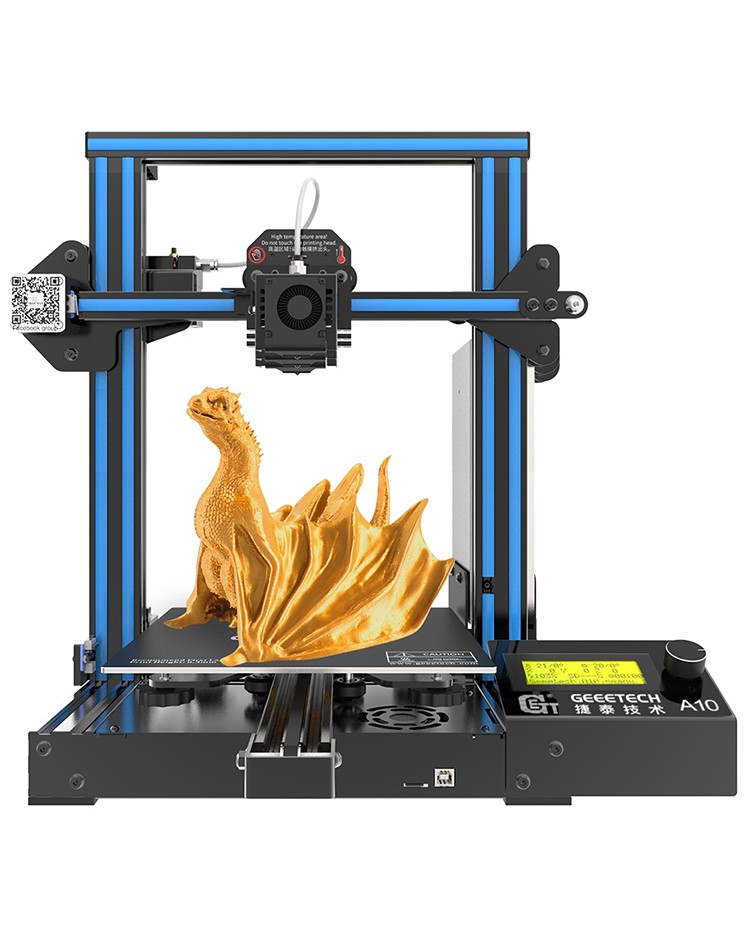

Anycubic Mega S

Click For Best Price

Check Latest Price

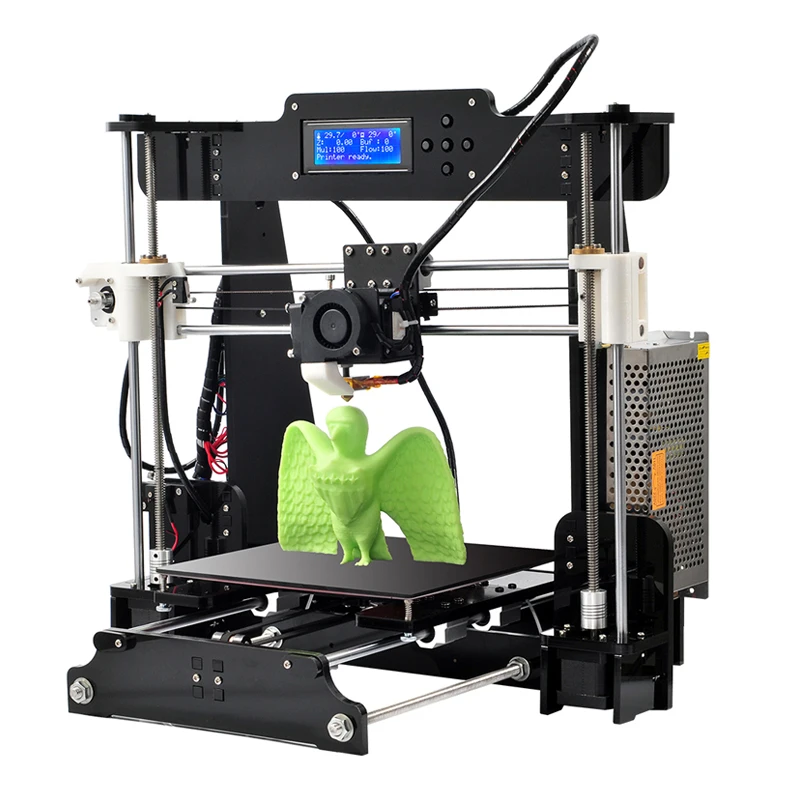

FLSUN QQ-S

Check Latest Price

Wasp 2040 PRO Turbo

Check Latest Price

Table of Contents

- Quickest 3D Printers For Consumers

- 1. Anycubic Mega S (Best Value)

- 2. FLSUN QQ-S (Quietest / Editor’s Choice)

- 3. Delta WASP 2040 Turbo 2 (Fastest / Premium Choice)

- 4. Uniz Slash Plus UDP

- 3D Printers For Industrial Use

- 5.

Cincinnati Incorporated BAAM

Cincinnati Incorporated BAAM - 6. Massivit 1800

- 7. HP Jet Fusion 5200

- 5.

- What is a Good Print Speed for 3D Printers?

- Relationship Between Speed and Quality

- Limiting Factors for Speed

- Cooling the Plastic

- Tiny Motors Driving the Motion

- 3-Axis Setup

- How to Make a 3D Printer Faster

- Conclusion

Quickest 3D Printers For Consumers

These are consumers printers that focus on speed. You’ll get your part back fast, and you won’t have to pay an arm and a leg to print them with an industrial printer.

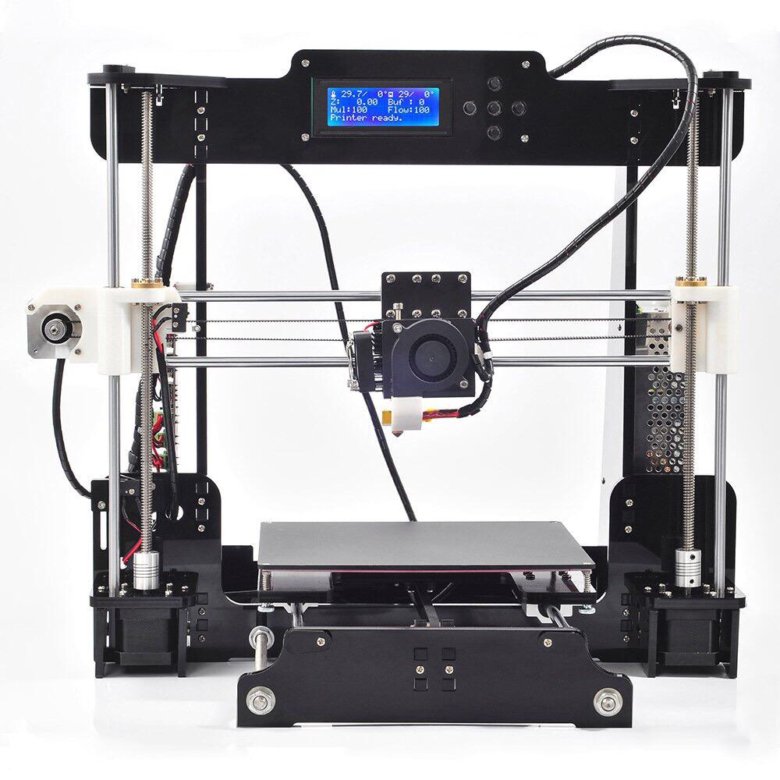

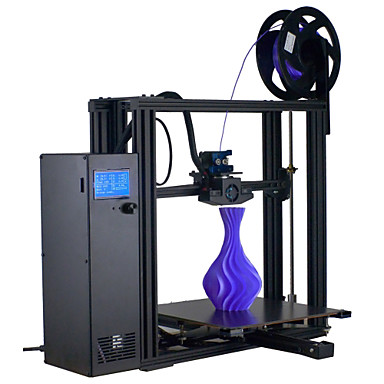

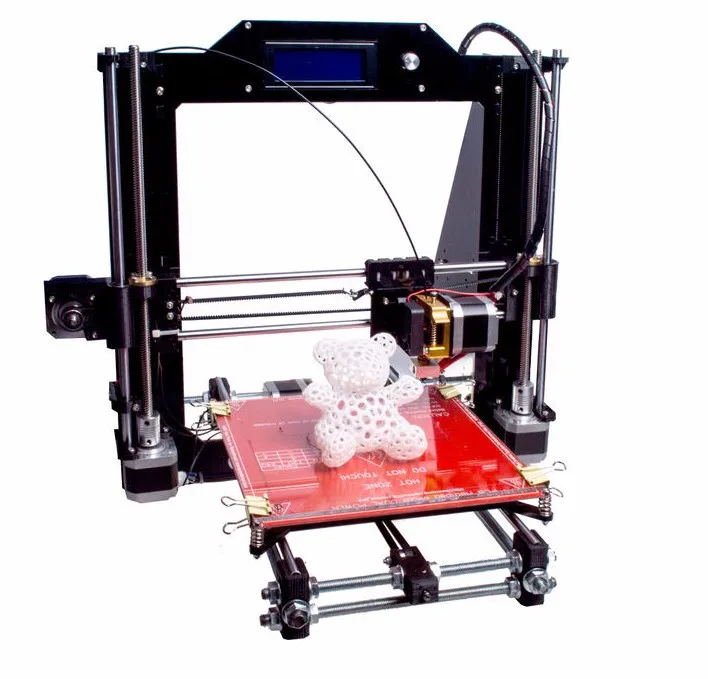

1. Anycubic Mega S (Best Value)

Build volume: 210 x 210 x 210 mm | Layer Resolution: 200 mm/s | Max Print Speed: 100 mm/s

For the price, the Mega S delivers great results. The accuracy, build volume, and printing speeds are rare gems in this price category.

It comes with a touch screen to make things easier for you, and the UI is clean.

The noteworthy thing about the Mega S is how many features they added while still keeping the price low:

- The frame is metal, which means better results for you.

- The build plate is heated, and the hot-end gets hot enough to print a ton of different materials.

- A filament sensor will tell you when you’re out of material and it will automatically pause the print. When it detects new filament is loaded, it will resume right from where it stopped. You can use third-party filaments as well.

Out of the box, you’ll have to make a few connections before you can start printing. Also, the filament is side-mounted, which typically leads to some reliability issues.

The Anycubic Mega S delivers great performance and a healthy build volume that won’t break the bank.

In its price category, it is the fastest 3D printer, and it’s a great choice for people who are looking for a budget 3D printer.

- Good build volume

- Hotend and build plate heat up to high temp

- Added features are great

- Clean UI

- Great user experience, easy to use

- Some assembly required

- Side-mounted filament

Click for Best Price

Check Latest Price

2.

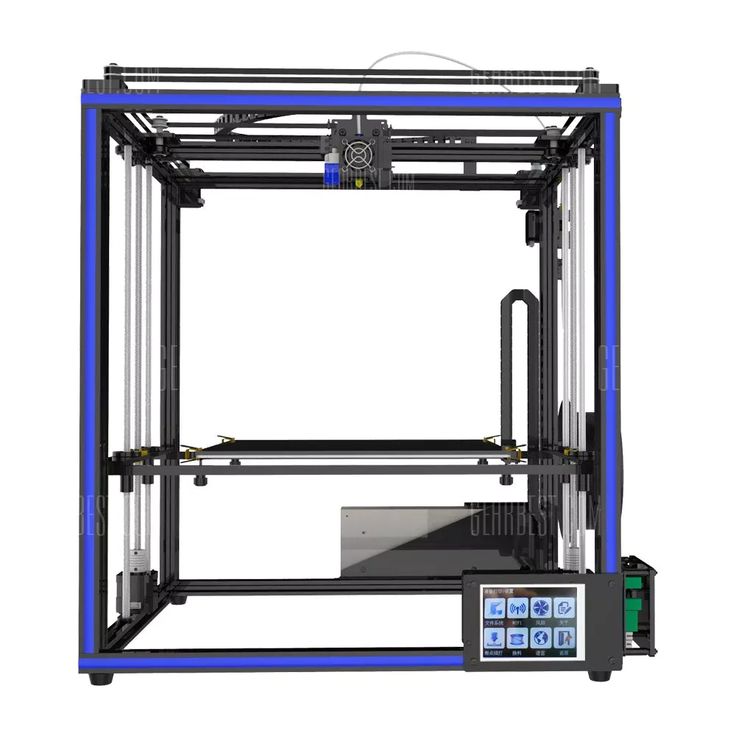

FLSUN QQ-S (Quietest / Editor’s Choice)

FLSUN QQ-S (Quietest / Editor’s Choice) Build volume: 255 x 255 x 360 mm | Layer Resolution: 50 micron | Max Print Speed: 300 mm/s

Next on the list is the QQ-S by FLSUN.

It’s hard to know what all the letters stand for, but it’s a good guess that the S stands for “silent.” This unit’s claim to fame is the whisper that it prints at.

This printer’s default running speed is 60 mm/s, however, it can go up to 300 mm/s. And some users even reported higher speeds with a bit of tweaking.

The build volume is the largest on this list on the consumer side.

This printer also will resume a print after it’s paused or stopped. Out of the box, it takes about a half-hour to finish the assembly and set up before you can start printing. The filament is top-fed, which is great for space savings so you can put it in your office.

Another great feature is its unique lattice build plate, which makes it easy to remove prints.

While we don’t recommend the QQ-S for beginners, overall this 3D printer is our choice for a fast, delta 3D printer with the right price.

- Large build volume

- Accurate

- Super silent

- Can print with most filament types

- Auto-leveling bed

- Unique build plate

- Intuitive touchscreen

- High-speed printing

- Takes time to fully assemble unit

- Manufacturer support is underwhelming

- Not ideal for beginners

Check Latest Price

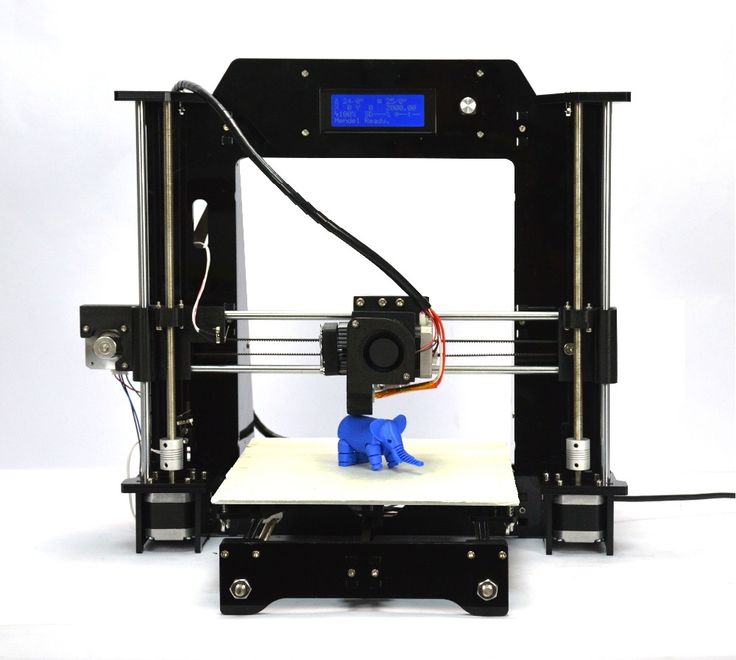

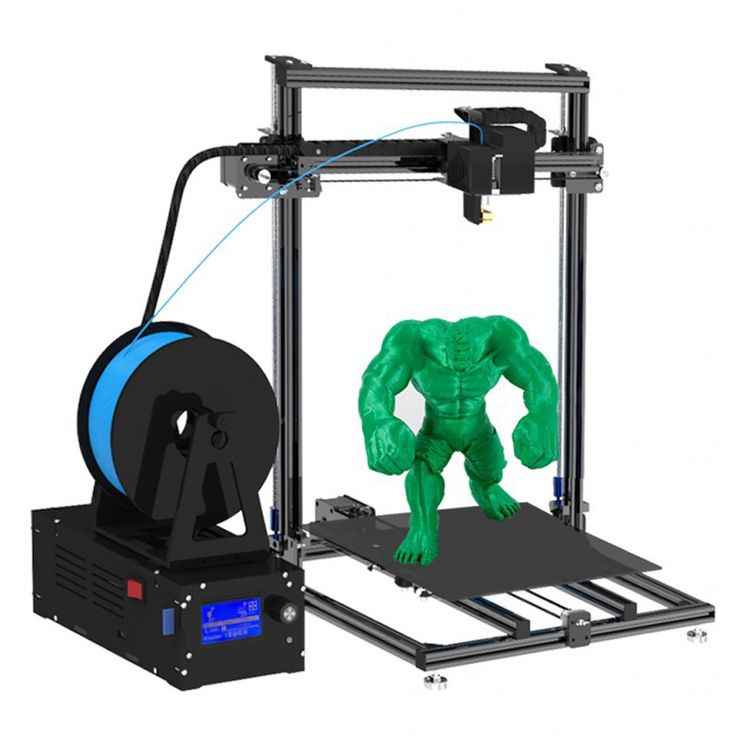

3.

Delta WASP 2040 Turbo 2 (Fastest / Premium Choice)

Delta WASP 2040 Turbo 2 (Fastest / Premium Choice) Build volume: 200 x 200 x 400 mm | Layer Resolution: 50 mm/s | Max Print Speed: 500 mm/s

You might recognize the Delta WASP 2040 from our best delta 3D printer review; the Turbo 2 is that and more.

This printer can be bought with a single or dual extruder. Either one will print at speeds up to 500 mm/s and travel up to 1,000 mm/s.

You won’t find numbers like this for an FDM printer anywhere else.

Even more impressive is the final print quality. That was the main area of improvement that his printer has over its predecessor.

If you blink during the printing process, you’ll miss it, but you’ll be left with a beautiful part.

The build volume also has a huge height dimension. You can print skyscrapers on this printer in the blink of an eye.

The framework is really sturdy. This means fewer vibrations for your print, which results in a more reliable printer. This also helps achieve better accuracies.

This also helps achieve better accuracies.

This is a Delta-style printer, which means it moves differently than a standard Cartesian 3D printer. It makes it even more fun to watch the printer move around, has better accuracy, and can achieve quicker speeds.

The Delta WASP 2040 Turbo 2 is a much-welcomed sequel. It’s fast, accurate, and has a large build volume. It’s the fastest FDM printer that’s commercially-available, and it’s not as expensive as you might think.

- Sturdy frame

- Reliable, great accuracy, good precision

- Generous build volume

- Expensive for beginners, but you get a lot for the price

- Delta printers are hard to mechanically troubleshoot and fix

Check Latest Price

4.

Uniz Slash Plus UDP

Uniz Slash Plus UDP Build volume: 192 x 120 x 200 mm | Layer Resolution: 200 mm/s | Max Print Speed: 1,000 cm3/hr

Let’s take a look at the Uniz Slash Plus UDP.

You might recognize the name from their Kickstarter campaign. They raised over $500,000 with the mission of creating a super-fast commercial-grade 3D printer. Mission accomplished.

This is the fastest commercial-grade 3D printer on the market. This is largely due to the fact that it’s an SLA-type printer.

The other good news about it being an SLA printer means you get to enjoy a better accuracy and precision with your prints.

The price is high for this unit because you are getting a great piece of machinery. It achieves a great printing speed and doesn’t have to sacrifice performance or accuracy at all.

The build volume is pretty good, but it’s small for the price.

Uniz also put a lot of effort into keeping maintenance low for this printer. They say you can go 1,000 hours of printing without touching the screen, and there won’t be any issues.

They say you can go 1,000 hours of printing without touching the screen, and there won’t be any issues.

There are also a lot of great features built into the printer. You can remotely monitor your print to make sure everything is going smoothly.

You can start the print remotely via WiFi printing. To make things easier, the printer will automatically calibrate before each print.

The Uniz Slash+ is not only quick, but there’s a lot of ease-of-use and features built-in. It’s a great choice for a commercial printer if you care about accuracy, speed, and don’t mind the price tag.

- User interface is smooth and easy to use

- Final print quality is amazing

- SLA offers a lot of benefits over FDM

- High price tag for beginners

- Length of the build volume is small

Check Latest Price

3D Printers For Industrial Use

If you’re looking for the titans of the space, and price is not an issue, you will love these next few printers.

These guys are designed specifically for industrial use. They’re faster, bigger, and badder than any commercial printer you’ll find on the market.

They are all hundreds of thousands of dollars, but they are also revolutionizing the 3D printing industry and what can be achieved.

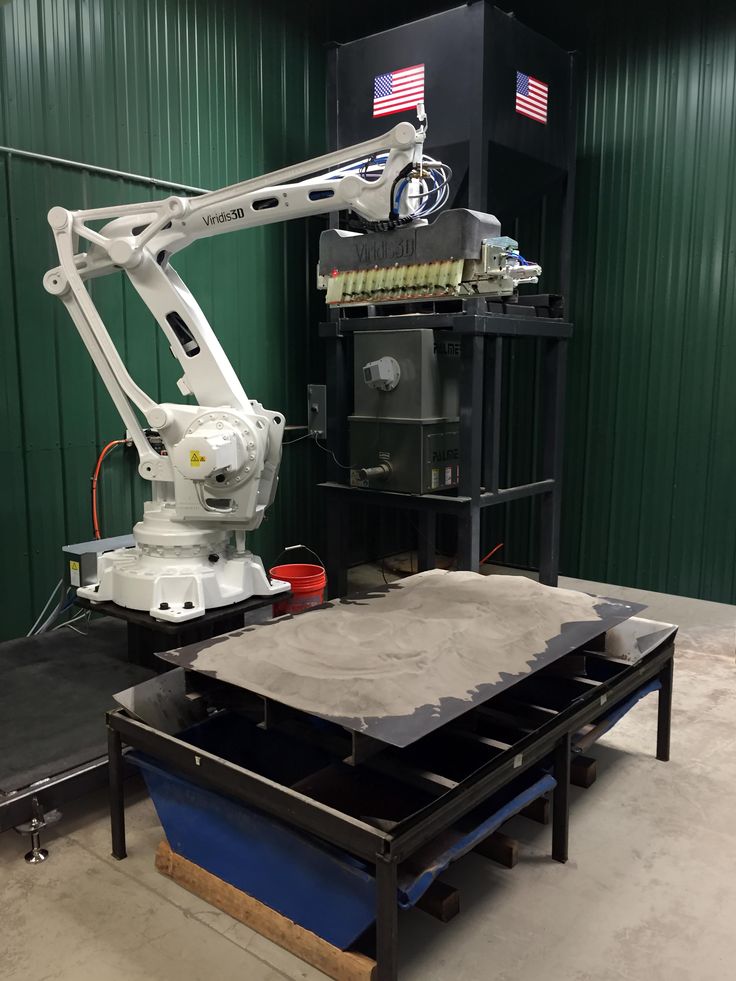

5. Cincinnati Incorporated BAAM

Build volume: 6,000 x 2,300 x 1,900 mm | Layer Resolution: 1,250 mm/s | Max Print Speed: 80 lbs/hr

The first speedy printer for industrial use is the BAAM.

That stands for Big Area Additive Manufacturing. This might come as a shock, but it’s an additive manufacturing machine that has a big area. A really big area.

This printer looks like a small room filled with magic. The creators realized that if you want a massive build volume, you need an impressive printing speed.

The print speed is 80 pounds per hour.

The BAAM has printed a ton of big items in the past. A kayak, an electric car, and a replica F-22 to name a few.

A kayak, an electric car, and a replica F-22 to name a few.

The extruder gets hot enough to handle a lot of different materials.

The printer is built within a steel frame, which means vibrations won’t disturb your massive prints.

Though the company won’t release the retail price, they do offer quotes to print your project on the massive BAAM machine. Serious buyers can reach out to BAAM to get a price on the machine as well.

This printer is the best option if you’re looking to print massive objects quickly. This comes with a big price tag, but it’s easy to overlook when you realize what the BAAM can produce.

- Massive build volume

- Steel framework

- Touchscreen

- Can print a wide range of filament materials

- Company won't release the price

- Takes up a lot of space (obviously)

- Low resolution

Check Latest Price

6.

Massivit 1800

Massivit 1800 Build volume: 1,800 x 1,500 x 1,200 mm | Layer Resolution: 500 mm/s | Max Print Speed: 1,000 mm/s

Massivit 1800 is another heavy-hitting printer you want to take a look at.

This printer was made specifically for visual communication. It can make large signs, props, and displays.

It opts for Gel Dispensing Printing rather than FDM. This results in a better finished product and a more aesthetically pleasing print.

You’ll see this printer used to make movie props, art exhibits, and different sculptures.

The 1800 definitely has the required build volume to make large props. It also prints at a speed of a meter a second which is one of the fastest in the industry.

Purchasing this unit will set you back about a quarter of a million dollars. You can also get a quote to use one of the company’s 3D printers for your needs.

You can also arrange the unit to be a dual extruder printer, which opens the door for even more possibilities.

The designers also made the printer really easy to use. A few clicks of a button and you’re on your way. The UI is smooth and provides troubleshooting feedback.

The Massivit 1800 is the leader in the visual communication space. The prints are highly detailed, smoothly contoured, and they’re done really fast.

- Great print quality

- Huge build volume

- Easy to use

- Very expensive

- GDP technology is trickier to troubleshoot

Check Latest Price

7. HP Jet Fusion 5200

Build volume: 380 x 284 x 380 mm | Layer Resolution: 1,200 dpi | Max Print Speed: 4,115 cm3/hr

The HP Jet Fusion 5200 is a modern marvel in the industrial 3D printing world.

This is the fastest printer currently on the market.

HP (yes, it’s that HP) has only been in the 3D printing world for a few years, but they’ve made some huge players in the space. Who knew that paper printing was so akin to 3D printing?

Their 5200 is the top of the Jet Fusion line they have, and it’s the fastest model. It prints at a staggering pace of 4,115 cm3/hr or 1,143 mm3/s.

The print speed isn’t measured in mm/s due to the speed of the technology used.

It uses Multi Jet Fusion, which is a different printing technology than SLA or FDM, which you might be familiar with. MJF lets you print whole layers at a time rather than tracing the layer line by line, as FDM printers do.

The resolution of the printer is super crisp.

The build volume isn’t as big as the other industrial printers, but that isn’t the focus of this printer. The 5200 will get you your print faster than any other printer around.

For reference, if you make a single part that’s as large as the build volume (380 x 284 x 380 mm), it will complete the print in as low as 10 hours – this is strikingly fast.

You’ll need to get a quote for pricing on this machine, but the manufacturer hints that the sticker price is over $250,000.

This might be the first 3D printer that can compete with other manufacturing methods for mid-volume part production.

The HP Jet Fusion 5200 is a super-fast 3D printer that gives you accurate, precise, and crisp parts faster than any other printer around. It’s the newest of their three-machine lineup, and it’s worth every penny.

- Fastest printer on the market

- Accuracy, reliability, and resolution are incredible

- Final print quality is excellent

- The first viable option for mid-volume part production

- Pricey unit

- Build volume could be bigger

- MJF technology has steep learning curve compared to FDM

Check Latest Price

What is a Good Print Speed for 3D Printers?Source: Youtube The Technology ManA good print speed really depends on what you’re using your printer for, and it’s all about personal preference.

For a recreational printer that you’re just using for fun, realistically nothing’s wrong with 1 mm/s – it’s just going to take a lot of patience.

3D printer manufacturers know that we aren’t patient, so they upped that number a lot.

As you look around the market, you’ll find that a lot of commercial printers can hit 40-60 mm/s comfortably.

For a little more money, you can hit 100 mm/s on a commercial printer. The higher-end units will run around 150 mm/s.

Manufacturers suggest running at 60% of the max speed so you get a higher quality.

But how is quality related to speed?

Relationship Between Speed and QualitySpeed and quality seem to be related in every industry – if your mechanic is the fastest in the world, you’re going to be sitting on the side of the road a lot.

3D printers are the same in this sense, but for a technical reason.

The actual speed of a printer moving in a straight line doesn’t affect the print a ton. It’s the change in speed that does.

It’s the change in speed that does.

When you’re in a car and you stomp on the gas or brake pedal hard, your body will lurch. When a 3D printer suddenly accelerates or slows down, the same thing happens.

When the 3D printer lurches, the print quality suffers. You’ll get stringers, wobbly sections, fuzzy exterior walls, and an inconsistent build.

A ton of effort has to go into ramping the printer up to speed and decelerating it without hurting the print.

There are other reasons why the speed can hurt the quality of print.

Limiting Factors for SpeedDon’t let this list fool you, a majority of printers on the market are painstakingly slow in comparison.

So what slows down 3D printers? Why can’t ever printer churn out speeds like the WASP or the HP Jet Fusion 5200?

Let’s look at the answer in terms of FDM printers.

If you recall, FDM printers work by laying down hot plastic from an extruder head that moves on a 3-axis setup, driven by tiny motors. Every step of this process limits how fast you can print

Every step of this process limits how fast you can print

The first thing that limits how fast you print is how long it takes the hot plastic to cool.

Since you’re building on top of previous layers, the first layer has to be solidified enough before adding the second layer.

Imagine you’re painting a wall, but you don’t wait for the primer to dry before applying the first coat of paint. The result is similar to 3D printers.

The layers will drag, deform, and might get caught on the extruder nozzle. In other words, your final print will be unrecognizable.

Tiny Motors Driving the MotionIf you want a 3D printer to be small, quiet, and inexpensive, you need tiny motors to run the operation.

- Check out our review of the smallest 3D printers here

This is fine because the extruder isn’t heavy either, so you don’t need a lot of power.

If you want the printer to move faster, you need bigger, heavier, stronger motors. This would call for a complete redesign of how 3D printers look, and the added weight would be a huge problem.

This would call for a complete redesign of how 3D printers look, and the added weight would be a huge problem.

The tiny motors are another limiting factor to the speed.

3-Axis SetupThe 3-axis setup (or gantry) is the final big hurdle.

It’s tough to understand how this limits speed without a deep explanation, but it works for the same reason that trains run on a single track.

Single-axis motion is really easy to speed up and predict the outcome. When you add the y- and z-axes, things become more unpredictable, and more vibration affects the process.

Your 3D printer relies on predictability and few vibrations. That’s the secret sauce to get good quality on your final print.

That’s why the printers have to take it slow on a 3-axis gantry, so the final prints turn out good.

Let’s see what can be done to make 3D printing faster.

How to Make a 3D Printer Faster3D printers can be faster by getting rid of the limiting factors described above.

- Get rid of the jerk associated with quickly getting up to speed and slowing down.

- Use materials that cool a lot quicker or don’t require cooling.

- Step away from the tiny motors used to drive 3-axis printers.

- Lastly, get rid of the 3-axis setup altogether.

The way printing companies achieve this is by getting away from FDM altogether. They’ll opt for SLA, GDP, or MJF technologies which eliminate one or all of these limiting factors for speed.

Unfortunately, the way to make a 3D printer faster is to get away from FDM printers and move to another technology of printer.

ConclusionIf you want to print quickly, there aren’t a lot of printers that can do so without hurting the final print quality. This shortlist of printers can manage to do it successfully, but it comes at a price.

You’ll be shelling out more cash and potentially getting a smaller build volume. You have to consider which is the most important for your application and go from there.

You have to consider which is the most important for your application and go from there.

When it comes to true speed, the printers on this list stand in a league of their own.

Related Articles:

- Best CoreXY 3D Printer review

- Best DIY 3D Printer Kit review

- Best 3D Printer under 200 review

Pat Nathaniel

Pat is the editor-in-chief at Printing Atoms. He has a BS in Mechanical Engineering from the University of Florida and wants to spread the word on 3D printing. When he's not writing, he likes to tinker with his Ender 3 Pro, test filament brands, and scuba dive.

Fastest SLA 3D Printer - SLASH 3D Printer

Description

Fastest 3D Printer

The SLASH 3D printer is a novelty that has shaken up the 3D printing market. What is special about this device? Quite simply, this is the fastest SLA 3D printer available today. Let's list its features:

High speed printing . Just imagine, this desktop 3D printer allows you to create products at a speed of up to 200 mm/hour;

Just imagine, this desktop 3D printer allows you to create products at a speed of up to 200 mm/hour;

High print precision . The fastest 3D printer SLASH did not let us down with the accuracy of 3D printing. The minimum available layer thickness is 10 microns, which not all professional devices can boast of;

Large plot area . This 3D printer is also distinguished by a large build area for equipment of its class - as much as 192x120x200 mm. This is not just enough, it is more than enough even for non-standard tasks;

Powerful software . Specialized software turns the fastest 3D printer into one of the most functional 3D printers due to numerous flexible 3D printing settings;

Large selection of materials available . Manufacturers have developed a range of specialized photopolymers to work with the fastest 3D printers. With them, each user will be able to realize any ideas.

SLASH 9 3D printer0003

SLASH 3D printers are a revolutionary development of UNIZ in the field of 3D printing, which uses stereolithography technology to build objects from photopolymer resin. As a polymerization factor, the printer uses light from the LED array and the LCD module that forms the layer mask. Incredible print speed in the printers of this series became possible due to the implementation by the company's engineers of a unique cooling system for the print area. The construction zone is cooled using a special liquid module - a heat exchanger. To fully exploit the unique capabilities of SLASH and SLAH+ printers, UNIZ has developed a series of unified photopolymer formulations. The SLASH model, thanks to its patented technological innovations, has reduced the cost of printing equipment to the level of 3D printers using FDM technology, and even surpassed them in terms of the speed of building objects.

Features:

- The relatively low price of this series of printers is comparable to FDM printing equipment.

- The use of a unique combination of LED array and LCD module provides a faster build speed than FDM printers and the quality inherent in stereolithography.

- Unique resin cartridge system for economical resin usage and easy storage.

- Steel-reinforced frame to ensure the build area is dimensionally stable and prevents the device from deforming, which could affect print quality.

SLASH 3D printer

Specifications

| 3D printing technology | LCD Stereolithography |

| Construction area | 192 x 120 x 200 mm |

| XY Resolution | 75 micron, WQXGA [2560 × 1600] |

| Precision | 50 micron |

| Layer thickness (Z-axis) | 10, 25, 50, 75, 100, 150, 200, 300 micron (adjustable) |

| 3D printing speed | Up to 200 mm/h Up to 1000 cm 3 /h |

| Resin level control | Automatic |

| Assembly | Fully enclosed body, adjustable build platform |

| Optical system | Blue LED array (5000 Lux blue LED array) Liquid cooling |

| 3D printer bath cover | Original polymer coating, up to 100 times stronger than PDMS |

| Operating temperature | 18-28°C |

| Interface | USB, WiFi, Ethernet |

| System requirements | Windows 7 sp1 or higher (64-bit only), Mac OS X 10. 7 or higher (64-bit only), 2 GB RAM, OpenGL 2.1 7 or higher (64-bit only), 2 GB RAM, OpenGL 2.1 |

| Compatible formats | STL, OBJ, UNIZ |

| Compatible systems | iPhone, iPad, Android phone |

| Power supply | 100-240V, 3A @ 50/60Hz, 240W |

| Dimensions | 350 x 400 x 530 mm |

| Weight | 12 kg |

| Warranty | 1 year |

Back to main page

8 nuances worth paying attention to

Sooner or later, everyone will learn about 3D printing. And only a few lucky people, imbued with the opportunities that 3D printing opens up, catch themselves thinking that they want to purchase a 3D printer. The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems?

Tip 1 : Decide on 3D printing technology

The first step is to decide on the technology of 3D printing. There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

Nuance 2: Evaluate your needs

Of course, you always want to get all the best and with maximum opportunities. Do you need all this to solve your current problems? What can be cited as an example? For example, the size of the working area of the FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

Nuance 3 : Decide on the complexity of the products

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles of more than 30 degrees.

Point 4: Decide on the list of materials to be used.

Another important point. You must immediately determine for yourself a list of possible materials with which you are going to print. This primarily applies to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends.

In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

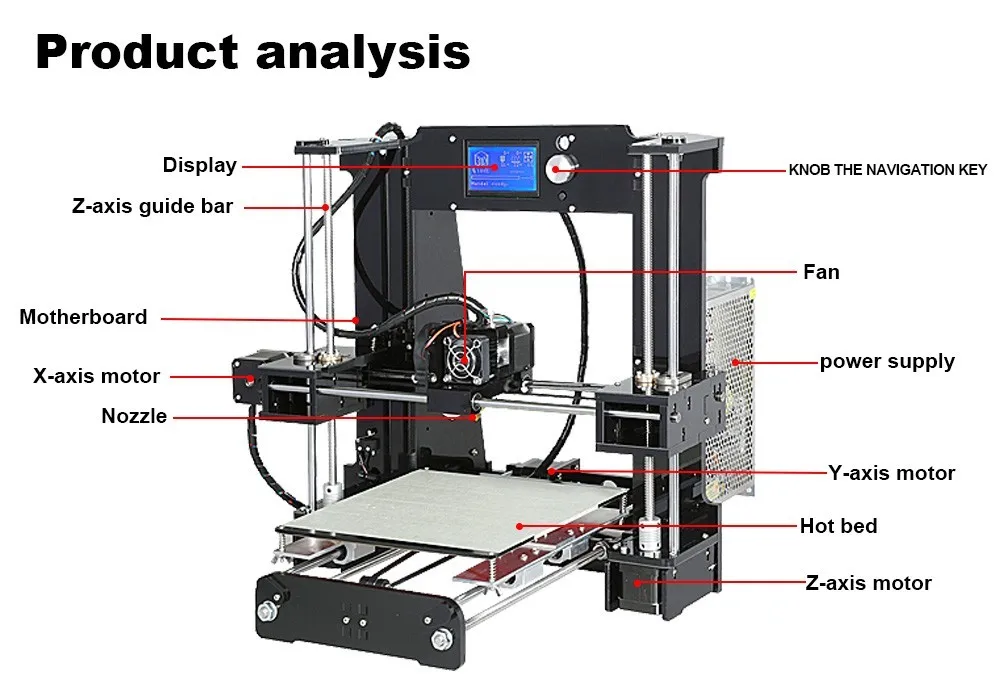

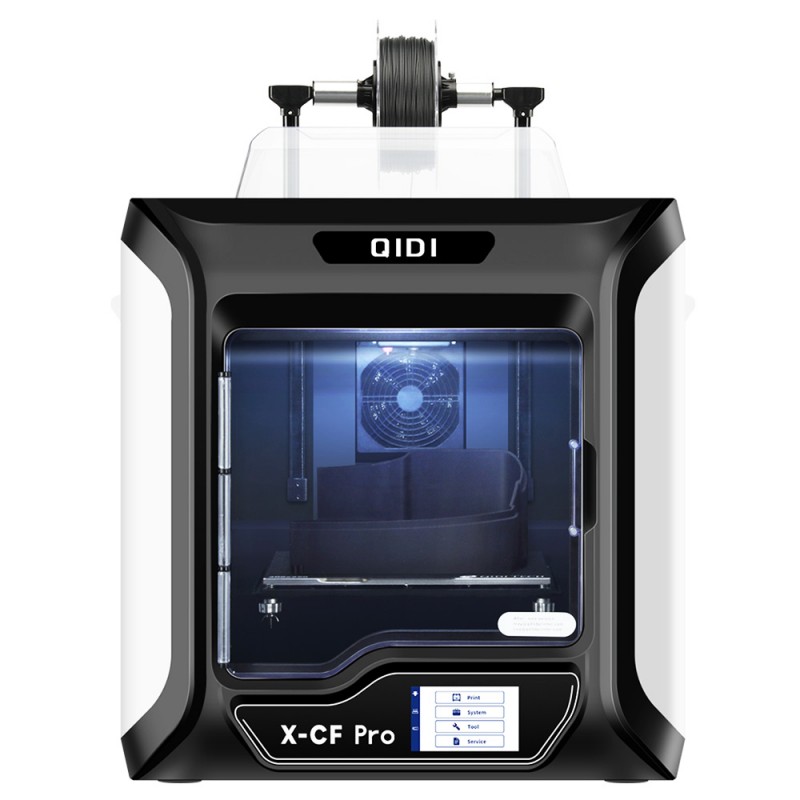

Nuance 5: Construction and kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say? Printers with an open design, usually have kinematics with a horizontally moving table (based on Prusa 3D printers). This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

Nuance 6: Diameter and changeable nozzle

Most 3D printers on the market come with 0. 3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

Nuance 7: Print thickness

It is important to understand that most models on a 3D printer are printed with a layer of 0. 1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

Nuance 8: Extruder type

Today there are two main types of extruder. This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube. What are the advantages and disadvantages of each type of extruder? Bowden extruder, due to the lack of a motor on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types.

And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types. Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

In our assortment you can always find 3D printers for your tasks:

1) Budget 3D printers

2) 3D printers for business

3) Large area 3D printers

4) SLA and DLP 3D printers

Do you have any questions?

Call: +7 (495) 324-07-90 (Moscow) and 8 (800) 775-86-69 (toll-free in the Russian Federation) or write to the mail: sales@3dtool.