Clone wars 3d printer

3d printing a clone trooper helmet

TikTokUpload

For You

Following

mphbricks

Mphbricks (Max)

Here’s how I 3D printed a Clone Trooper helmet from Star Wars! #clone #clonetrooper #starwars #clonewars #3d #3dprinting

3.2K Likes, 47 Comments. TikTok video from Mphbricks (Max) (@mphbricks): "Here’s how I 3D printed a Clone Trooper helmet from Star Wars! #clone #clonetrooper #starwars #clonewars #3d #3dprinting". How to make a 3D Printed Clone Trooper Helmet from Star Wars! | Like and Follow for more!. Republic Clone Army March - Order 66 - Epic Version.

26.4K views|

Republic Clone Army March - Order 66 - Epic Version - Pianistec

theforcecollectors

The Force Collectors

I miss walking into my collection. #starwars #clonetrooper #helmet #starwarshelmet #starwarshelmets #3dprinting

1.4K Likes, 40 Comments. TikTok video from The Force Collectors (@theforcecollectors): "I miss walking into my collection. #starwars #clonetrooper #helmet #starwarshelmet #starwarshelmets #3dprinting". original sound.

8743 views|

original sound - The Force Collectors

the_art_dart

The Art Dart

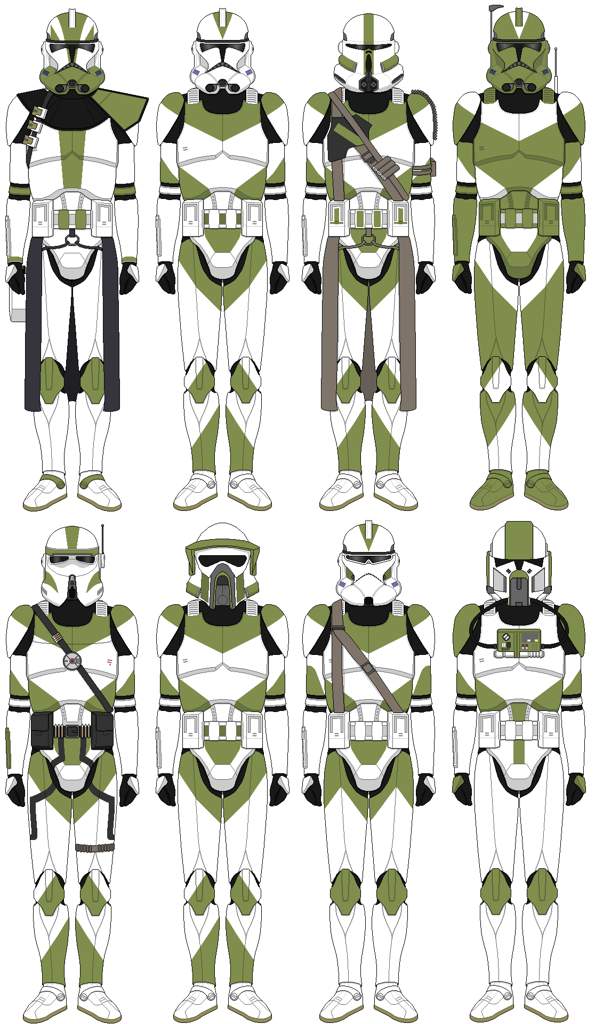

332nd clone trooper helmet build process! #starwars #clonetrooper #clonewars #332nd #LENOVOJUSTBEYOU #starwarsfan #fyp #3dprinting

1.5K Likes, 41 Comments. TikTok video from The Art Dart (@the_art_dart): "332nd clone trooper helmet build process! #starwars #clonetrooper #clonewars #332nd #LENOVOJUSTBEYOU #starwarsfan #fyp #3dprinting". 332nd clone helmet. original sound - Jake Johnson.

332nd clone helmet. original sound - Jake Johnson.

10.4K views|

original sound - Jake Johnson

galacticarmory

Galactic Armory

3D printing a miniature Phase 2 Animated clone trooper helmet! Printed on Elegoo Saturn #starwars #3dprinting #fyp #propmaking #clonewars

2.2K Likes, 32 Comments. TikTok video from Galactic Armory (@galacticarmory): "3D printing a miniature Phase 2 Animated clone trooper helmet! Printed on Elegoo Saturn #starwars #3dprinting #fyp #propmaking #clonewars". The Clone Wars Suite - Cover.

25.1K views|

The Clone Wars Suite - Cover - Samuel Kim

h_hayden_h

h

New 3D printed helmet! #3dprinting #starwars #starwarscosplay #starwarshelmet #clonetrooper #clonehelmet #3dprinter #cosplay #501st #diy #starwarsfyp #starwarstiktok

140 Likes, 9 Comments. TikTok video from h (@h_hayden_h): "New 3D printed helmet! #3dprinting #starwars #starwarscosplay #starwarshelmet #clonetrooper #clonehelmet #3dprinter #cosplay #501st #diy #starwarsfyp #starwarstiktok". original sound.

TikTok video from h (@h_hayden_h): "New 3D printed helmet! #3dprinting #starwars #starwarscosplay #starwarshelmet #clonetrooper #clonehelmet #3dprinter #cosplay #501st #diy #starwarsfyp #starwarstiktok". original sound.

991 views|

original sound - h

mphbricks

Mphbricks (Max)

*Fake Gun* 😁 Part 2 is out with my build on a fully 3D printed Clone Trooper Armor Set!! Like and Follow for part 3! #starwars #helmet #clonewars #clonetrooper #prequels #ashoka #3dprinting

1.3K Likes, 22 Comments. TikTok video from Mphbricks (Max) (@mphbricks): "*Fake Gun* 😁 Part 2 is out with my build on a fully 3D printed Clone Trooper Armor Set!! Like and Follow for part 3! #starwars #helmet #clonewars #clonetrooper #prequels #ashoka #3dprinting". How I 3D Printed Phase 2 Clone Trooper Armor! Part 2! | *Fake Gun* | Rex! | . ... Duel of the Fates ( Star Wars).

... Duel of the Fates ( Star Wars).

15.6K views|

Duel of the Fates ( Star Wars) - Rob Starr & The Hollywood Singers and Orchestra

lukes_lightsabers

Luke

My 3D printed 332nd Clone helmet! Check out my IG for other helmets and commissions! #starwars #clonetrooper #ahsokatano #clonewars #fyp #3dprinting

16.4K Likes, 201 Comments. TikTok video from Luke (@lukes_lightsabers): "My 3D printed 332nd Clone helmet! Check out my IG for other helmets and commissions! #starwars #clonetrooper #ahsokatano #clonewars #fyp #3dprinting". Covering all print lines and seams with bondo. original sound.

99K views|

original sound - Max Thompson

666st_clone_trooper

Clone trooper

Let‘s go👉 #starwars #3dprinter #clonetrooper #phase1

403 Likes, 5 Comments. TikTok video from Clone trooper (@666st_clone_trooper): "Let‘s go👉 #starwars #3dprinter #clonetrooper #phase1". 3d printing a Phase 1 clone trooper helmet Part3 | So yesterday we finished the back side and now we‘re gonna Print the top | 👉 | .... Love You So.

TikTok video from Clone trooper (@666st_clone_trooper): "Let‘s go👉 #starwars #3dprinter #clonetrooper #phase1". 3d printing a Phase 1 clone trooper helmet Part3 | So yesterday we finished the back side and now we‘re gonna Print the top | 👉 | .... Love You So.

8386 views|

Love You So - The King Khan & BBQ Show

zaliaksmaking

Zaliak's Making

Heavy mode : ON #clonetrooper #starwars #3dprinting #3dprint #clonetrooperhelmet #phase2 #cosplay #propmaker

2.4K Likes, 27 Comments. TikTok video from Zaliak's Making (@zaliaksmaking): "Heavy mode : ON #clonetrooper #starwars #3dprinting #3dprint #clonetrooperhelmet #phase2 #cosplay #propmaker". Aesthetic.

27.4K views|

Aesthetic - Tollan Kim

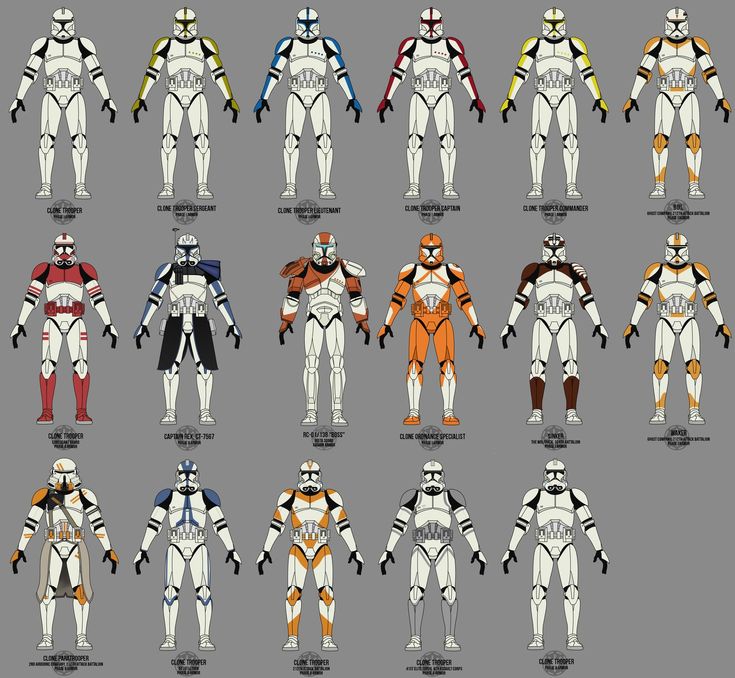

▷ phase 1 clone trooper 3d models 【 STLFinder 】

Star Wars Phase 1 Clone Trooper

sketchfab

Star Wars Phase 1 Clone Trooper with texuter

Phase 1 Clone Trooper Vocoder

thingiverse

I wanted a more detailed vocoder for my Phase 1 (Attack of the Clones) helmet, which is a cast by Sanotized Creations. ...This Vocoder is 23mm wide, and fit my helmet perfectly, but others may require different scale.

...This Vocoder is 23mm wide, and fit my helmet perfectly, but others may require different scale.

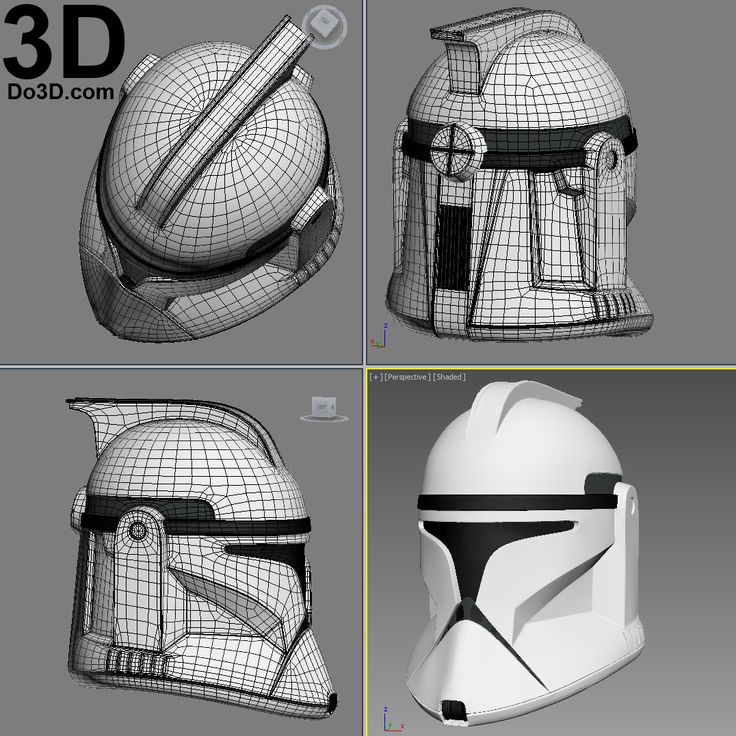

Star Wars Phase 1 clone trooper helmet 3D print model

cgtrader

Star Wars Phase 1 clone trooper helmet

Star Wars Phase 1 Clone Trooper Helmet 3D print model

cgtrader

Star Wars Phase 1 Clone Trooper Helmet 3D-printable model Be sure to scale correctly to proper head size. It is recommended to use 3D Builder to scale and split the model. When printing this Helmet set orientation, splitting, and slicing is up to...

Phase 1 Clone Trooper Helmet Clone Wars version

thingiverse

This is the helmet seen worn by the clone troopers in star wars the clone wars.

Phase 1 Clone Trooper Cosplay Helmet 3D print model

cgtrader

First Generation Clone Helmet The Clone Trooper Phaze 1 Helmet. Be sure to scale correctly to proper head size. Average size of human head is 7x9 just for good measure. (UPDATE) remodeled helmet completely from scratch. This version is more...

clone trooper phase 1

thingiverse

voila une statue d'un clone trooper phase 1 de tres bonne qualité n'hésiter pas a rajouté du support sur les bras car il arrive qu'il sont trop faible pour soutenir les 2 bras

Clone Trooper Phase 1 Helmet

grabcad

Star Wars Clone Trooper Helmet

Clone Trooper Phase 1 Bust

pinshape

Clone Trooper Phase 1 Bust Fan Art 3D print model STL File format *** Update added a Hollow STL For SLA & DLP for save your resin *** Dimension : X : Face length : 8. 2 CM Z : Depth Length : 7.1 CM Y : Height : 15 CM 3D VIEW :...

2 CM Z : Depth Length : 7.1 CM Y : Height : 15 CM 3D VIEW :...

Clone Trooper Phase 1 Visor

thingiverse

I down loaded Killonious's Phase 1 helmet and made it to fit that https://www.thingiverse.com/thing:3486066 I also included an adaption to fit My Captain Rex Suit : ) Just incase. ... https://www.thingiverse.com/thing:2943420 1/5/2021 added an...

Clone Trooper Phase 1 Visor

prusaprinters

Hi Yamoko, I did what I could so hopefully it will work for your project. I down loaded Killonious's Phase 1 helmet and made it to fit that https://www.thingiverse.com/thing:3486066 I also included an adaption to fit My Captain Rex Suit : ) Just. ..

..

Clone trooper phase 1 helmet

thingiverse

Hello everyone. ...I'm a big fan of sci-fi armors and star wars and this helmet was my first creation in fusion 360. I made it based on pictures from the cartoon "clone wars" so there could be some details that isn't perfect.

clone trooper werable phase 1

cults3d

this is a set of clone trooper werable phase 1 for cosplayers

Clone Trooper Phase 1 Helmet Fan Art

pinshape

*** Update Added Shell STL for SLA & DLP 3D Printer system (for save resin) *** STL File format Solid Version Dimension : X : Face length : 75 mm Z : Depth : 86 mm Y : Height : 102 mm Shell Version Dimension (for Toy Scale 1/6 ) : X : Face. ..

..

Star Wars Clone Trooper Phase 1 Magnet

prusaprinters

You can glue a 10 x 1.5 mm round magnet in the base. Print instructionsRecommended infill angle: 0° Low speed and high temperature will create a shiny top surface. There are "holes" inside the model to make some of the top layers more uniform, and...

Clone Trooper Phase 1

thingiverse

Remixed from Dylan91. Added thickness, and definition, also adjusted sizing to match what I could find on the internet so that it does fit over the head. ...Sized to fit on CR-10 printer.

Clone Trooper Helmet Phase 1 Star Wars

cults3d

This a Clone Trooper helmet phase 1. Please check us out at : https://www.etsy.com/shop/VillainousPropShop The hole on the bottom to fit your head is way to small with these types of helmets. We added a split version to help fix that. The back...

Please check us out at : https://www.etsy.com/shop/VillainousPropShop The hole on the bottom to fit your head is way to small with these types of helmets. We added a split version to help fix that. The back...

Clone Trooper Helmet Phase 1 Star Wars

thingiverse

This a Clone Trooper helmet phase 1. Please check us out at : https://www.etsy.com/shop/VillainousPropShop The hole on the bottom to fit your head is way to small with these types of helmets. We added a split version to help fix that. The...

Clone Trooper Phase 1 Helmet

grabcad

Made this as a demo for a coworker and figured it was good enough to post here.

Remixed Clone trooper phase 1 helmet (orig by Dylan91)

thingiverse

I imported the stl file from Clone trooper phase 1 helmet by Dylan91 into Blender and added a modifier called Solidify. I used a thickness of 1.6mm and had to adjust some of the vertices on the inside of the helmet at the 'ear' part. They were out...

Clone Trooper Phase 1 Bust Fan Art 3D print model

cgtrader

STL File format *** Update added a Hollow STL For SLA & DLP for save your resin *** Dimension : X : Face length : 8.2 CM Z : Depth Length : 7. 1 CM Y : Height : 15 CM Classic Older :...

1 CM Y : Height : 15 CM Classic Older :...

Clone Trooper Phase 1 Helmet Fan Art 3D print model

cgtrader

*** Update Added Shell STL for SLA & DLP 3D Printer system (for save resin) *** STL File format Solid Version Dimension : X : Face length : 75 mm Z : Depth : 86 mm Y : Height : 102 mm Shell Version Dimension (for Toy Scale 1/6 ) : X : Face Length :...

LEGO - Clone Trooper (Phase 1) (Rigged)

sketchfab

Created in 3DS Max 2019

Clone trooper phase 1 helmet (remix)

thingiverse

This is a remix of a helmet found on Thingiverse (I am uploading it this way because I was unable to find the original Post). I cut it into parts small enough to fit the Anycubic I3 mega. ...I also added little vents on the side and the vent thing...

I cut it into parts small enough to fit the Anycubic I3 mega. ...I also added little vents on the side and the vent thing...

Clone Trooper Helmet Phase 1 Star Wars

thingiverse

just a way bigger head hole! ...thanks for the file Killonious!

Star wars Clone trooper Phase 1 Heavy Low-poly 3D model

cgtrader

It was based on the episode 2 version also inspired by the old battlefront clone heavy trooper . I'll used test render pictures what i got from one of my friend years ago . it isn't rigged ,sorry for that . In the pack are 1 texture folder. I'll hope...

I'll hope...

star wars Clone trooper Phase 1 jungle Low-poly 3D model

cgtrader

... in the zip file . The texture size is 2048x2048. The trooper has 3 materials head(helmet) body leg There are 20 textures 3 base color(albedo) 3 normal 1 emissive 5 metallic (becouse the black cloth) 5 roughness (becouse the black cloth) 3 AO

Clone trooper phase 1 minifig helmet on HF Head

thingiverse

https://www.thingiverse.com/thing:4441076 presented a thumb screw to replace the wing nut on the front-left corner of the BIBO bed. It is too wide for the other two positions. I have created a smaller version to fit the right-front corner and the...

I have created a smaller version to fit the right-front corner and the...

Star wars Clone trooper Phase 1 Low-poly 3D model

cgtrader

The textures are included in the zip file .

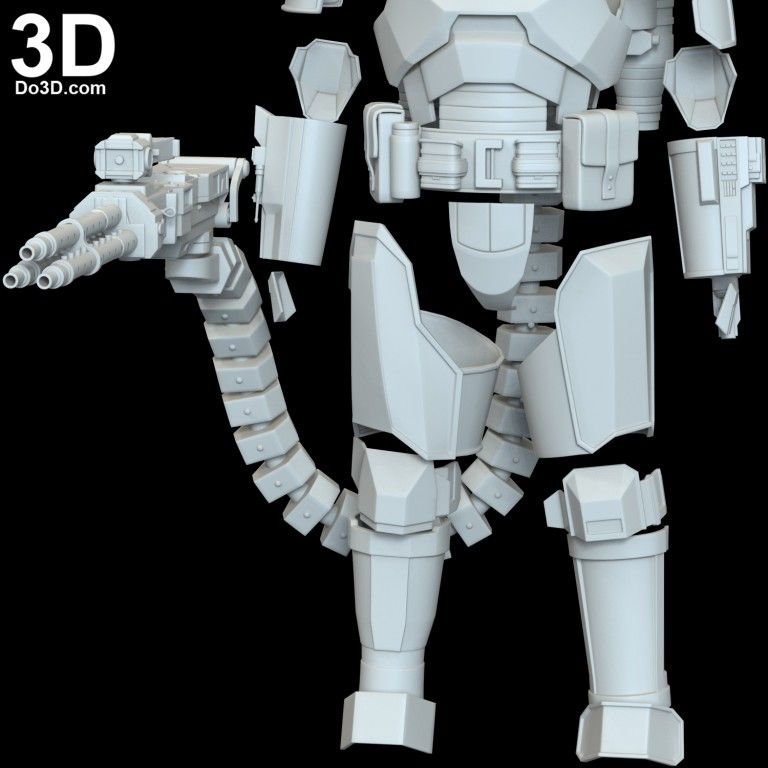

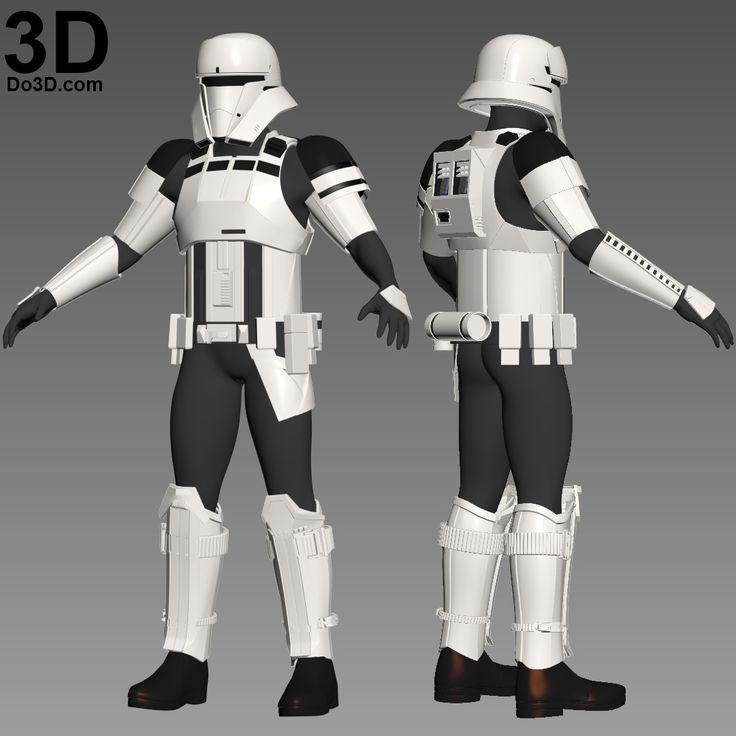

Star Wars Clone Trooper phase 1 Full Armour 3D print model

cgtrader

Be sure to scale it to the right size. It is recommended to use 3D Builder to scale and split the model. When printing this armour set orientation, splitting, and slicing is up to you. Please, Do not share/resale the 3d model, for private use...

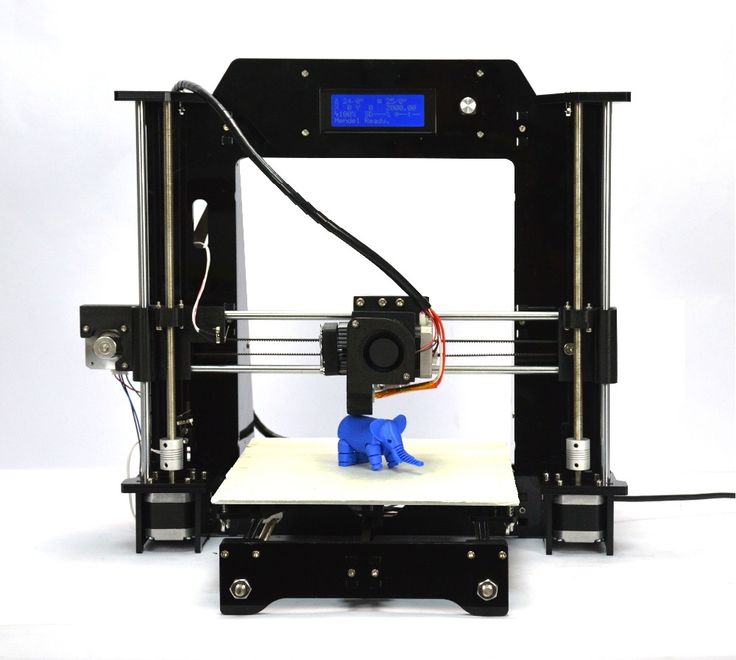

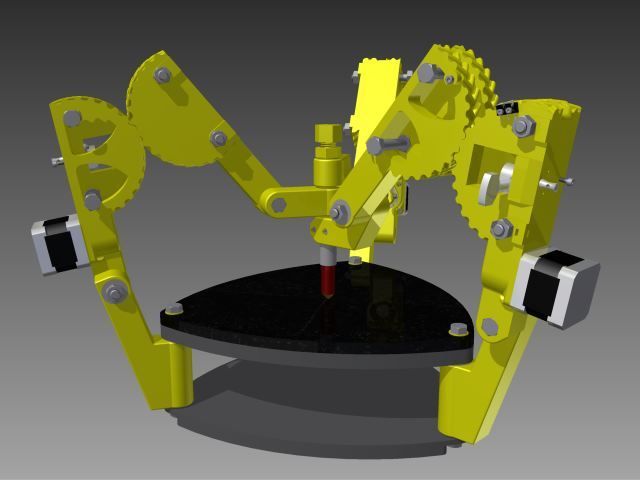

3D printers.

Clone Wars. Part 1.

Clone Wars. Part 1.

Article applies to printers:

MakerBot Replicator 2X WANHAO Duplicator 4S FLASHFORGE Creator ProHello everyone! Today we would like to tell you about 3 models of 3D printers with two extruders. But after thinking, we decided that it was not interesting to write three reviews about similar printers. Popular wisdom says - " Truth is known in comparison ". We decided to listen to the words of an unknown author and tried to find the truth.

And today we will compare MakerBot Replicator 2X , Wanhao Duplicator 4S , FlashForge Creator Pro.

A little about the manufacturers.

- MakerBot - is an American company founded in 2009. Actively engaged in the popularization and promotion of 3D printing technology. At the initiative of MakerBot, the Thingiverse portal was created, in 2014 it was acquired by Stratasys.

- Wanhao is a Chinese manufacturer of 3D printers.

The company's history is quite interesting. Three students, dorm roommates, chipped in and bought a MakerBot Replicator. Impressed by him, they decided to create their own 3D printer.

The company's history is quite interesting. Three students, dorm roommates, chipped in and bought a MakerBot Replicator. Impressed by him, they decided to create their own 3D printer.

- FlashForge is a Chinese company Zhejiang Flashforge 3D Technology Co., Ltd. Established in 2011 and today is one of the largest in China.

These printers are not chosen by chance.

- MakerBot is essentially the original based on which Wanhao and FlashForge Creator Pro were made.

- Wanhao Duplicator 4S is one of the best selling printers in Russia

- FlashForge Greator Pro is the highest rated printer on the 3DHUBS 3D printing enthusiast website

According to the manufacturer's specifications, these printers are almost twins. All have a closed body, two extruders. Only the MakerBot stands out with a slightly larger printable area, while the FlashForge comes with a PLA fan shroud.

Unpacking.

The theater starts with a hanger, and the first impression of a printer from the box)

Wanhao and FlashForge fit in one box. The MakerBot has a separate printer and a separate top cover.

The printers are packaged securely and neatly. MakerBot has made the printer the safest to transport. All carriages and moving parts were fixed with ties with special linings.

Wanhao - the most disassembled. All acrylic parts will have to be assembled - the top cover, sides and door.

With MakerBot, the entire assembly consisted of just installing the top cover.

FlashForge in installing the cover and screwing the extruders to the carriage.

Knowing our shipping companies, I would be wary if my printer is shipped in individual boxes like MakerBot. But when ordering a printer from us, you can not worry, we always additionally pack a second box in order to avoid damage. FlashForge turned out to be the most compact box.

FlashForge turned out to be the most compact box.

Complete.

MakerBot turned out to be not very rich in equipment.

- 1 spool of ABS plastic 0.5 kg.

- PTFE-based grease

- Business card - gauge for setting the gap between the nozzle and the table.

- Flash drive

- 2 spool holders

- Hexagon set

- Plastic spatula for easy application of film on the table

- 3 kapton foils

- USB-A to USB-B cable

- Mains cable

- Instruction in Russian and warranty card

- Tubes for guiding the thread

Wanhao was the most generous.

- 2 kg spools of plastic (PLA/ABS).

- Spare bolts.

- Flash drive

- USB-A to USB-B cable

- Mains power cable

- Top cover assembly tool kit (hexagons, bolts, even larger screws than needed)

- Platform holder kit (paper clips)

- Kapton self-adhesive thermal film

- Table glass

- Printing tape

- 2 spool holders

- Instruction in Russian and warranty card

- Thread guide tubes

Forge

Forge - 2 plastic spools (ABS/PLA)

- PLA blower hood

- Flash drive

- USB-A to USB-B cable

- Allen key set

- Spare table cover.

- 2 spool holders.

- Mains power cable

- Instructions in Russian and warranty card

- Tubes for guiding 3D filament

It is quite logical that MakerBot only comes with an ABS plastic spool. The manufacturer's website states printing only with ABS plastic.

Looking ahead, I will say that we will carry out printing tests with ESUN plastic. The 1kg plastic spool (the hole diameter of the spool is 51 mm) didn't fit on the FlashForge and MakerBot holders. For them, you will have to print the holders for the coils.

Appearance.

At first glance, the printers look like brothers and differ only in shape.

I did not find a single printed part in them, all plastic parts are molded. The body of all is essentially the same - a metal frame with panels of composite and acrylic.

The body of all is essentially the same - a metal frame with panels of composite and acrylic.

In terms of build quality, Wanhao turned out to be a good average. There are no obvious gaps. Acrylic side panels can be quickly and conveniently removed by unscrewing just 4 screws. I think this will be a good advantage when printing PLA. The door fits snugly, but does not lock in the open position. This means that if you need to do something inside the printer (for example, calibrate the stage or remove the finished product), you will have to remove the door or do all the actions with one hand.

MakerBot is a bit disappointing - the composite does not fit snugly at the bottom of the body, there is a small but unpleasant gap. And the door does not close completely due to ill-conceived holes for the hinges (the manufacturer says that it is necessary for ventilation). The hinges are tight and the door can be easily fixed in the open position. Acrylic sidewalls can be removed, but it will be inconvenient to do this, because they are unscrewed only from the inside.

Acrylic sidewalls can be removed, but it will be inconvenient to do this, because they are unscrewed only from the inside.

FlashForge pleased with a very high-quality and solid assembly. Externally, the printer looks very solid. There are handles on the side for easy carrying of the printer. The door is not up, but to the side. This means that it does not have to be held when manipulating inside the printer. The closed door "snaps" on 2 small magnets, this ensures that it does not open during printing.

The top covers are also different.

- The MakerBot has a one-piece lid. The lid at the base has a small "skirt" in which there are holes. These holes align with the bolts on top of the printer. Due to this, the cover does not roll around the printer and can be easily removed.

- Wanhao's cover is assembled and not fixed in any way. It just sits on the printer.

- FlashForge also has a one-piece lid and is rigidly fixed on top of the printer.

It takes some effort to get it off.

It takes some effort to get it off.

All printers have screens with control buttons on the front panel. But even here there are slight differences.

- The MakerBot has a recessed screen and buttons. The buttons are rubber. Very easy to press.

- Wanhao has plastic buttons recessed into the case. When pressed, they click nicely.

- FlashForge has a 45 degree screen and buttons in relation to the body. To look at the screen, you don’t have to bend over if the printer is on a pedestal at waist level. A trifle, but nice.

Mechanics

The kinematics and layout inside the housing are exactly the same.

Two motors for feeding plastic are located on the “head” of the printer. In theory, this increases the weight, and consequently the inertia. But on the other hand, this layout allows you to print with soft types of plastic without problems.

The Y-axis motor is attached to the carriage.

X-axis motor mounted on the body. Nothing dangles anywhere and does not play. The straps are well tensioned.

Trapezoidal screw and 2 shafts mounted on the Z axis. Wanhao and MakerBot do not have a screw on top, unlike FlashForge.

There are handy wide screws for calibrating the stage. MakerBot and FlashForge are calibrated with three points, Wanhao with four.

Extruders.

We will not analyze the design of extruders in detail. Wanhao and FlashForge have similar designs. MakerBot has its own extruder design.

Electronics

Wanhao and FlashForge have internal power supplies. MakerBot has an external one. I think this is more of a plus than a minus.

MakerBot has very well shielded wires. Drivers signed.

Wanhao and FlashForge boards are very similar. The visible difference is different driver models.

The visible difference is different driver models.

Totals:

In fact, these three printers are really very similar. Although they leave behind a different impression. That's how I rated them on a 10 point scale.

Never printed with MakerBot. It will be very interesting to see what he can do.

Wanhao stood out with a rich bundle, it's nice to get a bunch of pleasant little things in addition to the printer. But I've heard very mixed reviews about it.

Outwardly, I liked FlashForge the most. It looks strong and reliable. I hope he will be able to please me not only in appearance.

Of course, judging a printer by appearance alone is stupid. Therefore, in the following parts, we will compare printer software, interface, calibration complexity and, of course, conduct print tests.

Well, a little advertising)

Buying equipment in our company, you get 10 benefits:

1. Opportunity to use the Trade In program.

Opportunity to use the Trade In program.

2. Warranty - 12 months

3. Instruction in Russian

4. Technical support throughout the entire operation period

5. You buy a Wanhao 3D printer from the official Wanhao distributor in Russia

6. Free shipping.

7. Free training in our office.

8. Opportunity to buy a printer on credit through TKS, OTP, Renaissance banks.

9. 10% discount on plastic forever.

10. An opportunity to get acquainted with the printer in our demo room.

Review prepared by Anna Panfilova, 3D printing specialist at Tsvetnoy Mir.

Subscribe to our Facebook and VK groups to keep abreast of the latest events.

https://www.facebook.com/groups/cvetmir3d/ https://vk.com/cvetmir3dhttps://www.youtube.com/channel/UCnfeyFh4TKIVpMCMi1zd0fA

3D printers. Clone Wars. Episode 3.

The article applies to printers:

MakerBot Replicator 2X WANHAO Duplicator 4S FLASHFORGE Creator Pro Hi all.

Finally, we moved on to the most important thing - printed tests. You can talk for a long time about the design, appearance, convenience of the slicer, but the result is important.

For MakerBot, we used the Maker Bot slicer. For Wanhao and FlashForge we used Flash Print.

I understand that any printer can print well, the only question is how much time it will take to refine and configure. We evaluated the printer more from the point of view of a novice user, so the printer had 1 attempt to print the model.

But first, I will answer questions that came across in the comments to the previous parts.

'Where's the quality/speed comparison? Ease of maintenance / plastic replacement? Reliability after all!After all, the printer is not bought to stand on the table and joyfully beep / shine with lights.'

Refilling plastic is quite convenient. Go to menu-Utilities-Filament Loading. There are 4 items Load / Unload right and Load / Unload left (load / unload the right extruder, load / unload the left extruder). Select the desired item. The printer heats up the desired extruder, turns on the motor and loads/unloads the bar. But the extruder only heats up to 230 degrees. In the FlashForge and Wanhao menus, you can change the heating temperature for Preheat and manually push the bar. I did not find such an item in MakerBot. It is inconvenient to shamanize loading PLA, PVA and other types of plastic with a lower extrusion temperature compared to ABS.

Go to menu-Utilities-Filament Loading. There are 4 items Load / Unload right and Load / Unload left (load / unload the right extruder, load / unload the left extruder). Select the desired item. The printer heats up the desired extruder, turns on the motor and loads/unloads the bar. But the extruder only heats up to 230 degrees. In the FlashForge and Wanhao menus, you can change the heating temperature for Preheat and manually push the bar. I did not find such an item in MakerBot. It is inconvenient to shamanize loading PLA, PVA and other types of plastic with a lower extrusion temperature compared to ABS.

Printer reliability is a very relative item. More dependent even on the private instance of the printer. I have all 3 printed without problems. Only Wanhao once had to disassemble the "head" and clean the nozzle.

For tests, we used Esun ABS, PLA, PVA, HIPS plastic. When switching from one type of plastic to another, the extruder was cleaned with Esun cleaning plastic (By the way, a good and convenient thing. It is very economical. A standard 100 gr package turned out to be quite large).

It is very economical. A standard 100 gr package turned out to be quite large).

Print ABS

The first thing we tested was ABS, of course. On the move, it turned out such a boat. (15% infill, Standard quality)

Maker Bot did it in 1h 19m, Wanhao in 1h 35m, FlashForge in 1h 15m.

Still, when printing ABS in a closed chamber, it is desirable to blow it. On small details (pipe of a boat) this is especially noticeable.

This became more noticeable in printed tests. (15% coverage, High quality)

MakerBot completely refused to print bridges. And Wanhao was very pleasantly surprised by the test. Print time for MakerBot is 1h 32m, Wanhao is 2h 15m, FlashForge is 1h 46m.

ABS small test (15% infill, High quality)

Corner bending is not ABS deformation when it cools, it is an attempt to tear the part away from the platform. Print time MakerBot - 46m, Wanhao - 1h, FlashForge - 52m.

- At Wanhao we printed on glass + glue.

- MakerBot Kapton film.

- FlashForge has its own coverage. And if usually the problem is to stick the first layers to the table, then this coating has a problem tearing the part off the table. Seriously. It is generally unrealistic to tear off the cooled ABS table.

ABS printing in two colors.

Here already MakerBot showed its best side. Almost no snot on the model and color mixing. This is more the merit of the slicer. MakerBot Desktop builds a cleaning fence with two nozzles, Flash Print prints a fence around the model with only one nozzle - this was not enough. Print time for MakerBot is 2h 17m, Wanhao is 2h 27m, FlashForge is 2h 22m.

Printing PLA

"If a printer can print ABS, it can print everything else)"

Let's check this statement. We decided to print the same models only with PLA plastic.

We decided to print the same models only with PLA plastic.

After the very first boat, it became clear that Wanhao and MakerBot with the maximum open cameras cannot print objects from PLA. Not at all. We decided to cheat a little and set to print two boats at once and two tests at once. FlashForge printed 1 test at a time.

Large and small test

Bicolor boat.

As can be seen from the tests, these printers are more suitable for printing ABS. Even FlashForge clearly lacks airflow for good PLA printing.

And of course, the most interesting thing in my opinion is the printing of models with soluble supports.

PLA + PVA

Especially for Wanhao and MakerBot, we came up with a model blowing system)

It turned out very well with blowing.

PVA turned out to be quite capricious and very fluid material. MakerBot was the only one able to print the PVA raft. Wanhao and FlashForge started chewing on the bar.

MakerBot was the only one able to print the PVA raft. Wanhao and FlashForge started chewing on the bar.

Wanhao, in spite of the maximum retract set in Flash Print, managed to "puff up" the second PVA model.

After rinsing off support.

MakerBot was unable to print small fangs on the model. Wanhao printed both fangs. FlashForge printed only one fang on the blower side.

ABS + HIPS

Here the printers were in their element.

The model was larger than a boat and all the printers did an excellent job.

Half washed.

Here MakerBot was the best because of the slicer. Flash Print considered that the thin septum in the nose was a design error.

Print speed test.

The dice test was not very revealing.

The first and last cube.

Airflow becomes necessary at high speeds. I did not notice that the printer would shake very strongly at high speeds. Perhaps this is because we printed small models.

I did not notice that the printer would shake very strongly at high speeds. Perhaps this is because we printed small models.

Results

Let's evaluate the print quality on a 10-point scale.

Let's summarize all 3 parts.

Average scores for packaging, assembly, slicer and of course printed tests.

Maker Bot turned out to be a good workhorse. A decent printer with a very thoughtful slicer. When printing did not cause any problems. The only negative is the lack of airflow, which is still required for printing small ABS products.

Wanhao is a printer with great potential. With a little tweaking, it can print very decently. I think it will suit a person with straight arms who will be interested in modifying the printer.

FlashForge is a very high quality and well-made printer. I was very pleased with the quality of printing, the material of the table and the presence of airflow.

We believe there are no bad printers.