Electron 3d printer

The Complete Guide to Electron Beam Melting (EBM) in 3D Printing

Published on October 7, 2019 by Carlota V.

Electron Beam Melting (EBM) is part of the powder bed fusion family. Unlike Laser Powder Bed Fusion (LPBF), it uses, as its name suggests, an electron beam to fuse metal particles and create, layer by layer, the desired part. Marketed by the Swedish company Arcam in 2002, this process enables the creation of complex and highly resistant structures. Note that Arcam was acquired by GE Additive in 2016 and is the only one to market machines based on this process as of today.

The main difference with LPBF technology is therefore the heat source used. Here, EBM technology uses an electron beam produced by an electron gun. The latter extracts the electrons from a tungsten filament under vacuum and projects them in an accelerated way on the layer of metallic powder deposited on the building plate of the 3D printer. These electrons will then be able to selectively fuse the powder and thus produce the part.

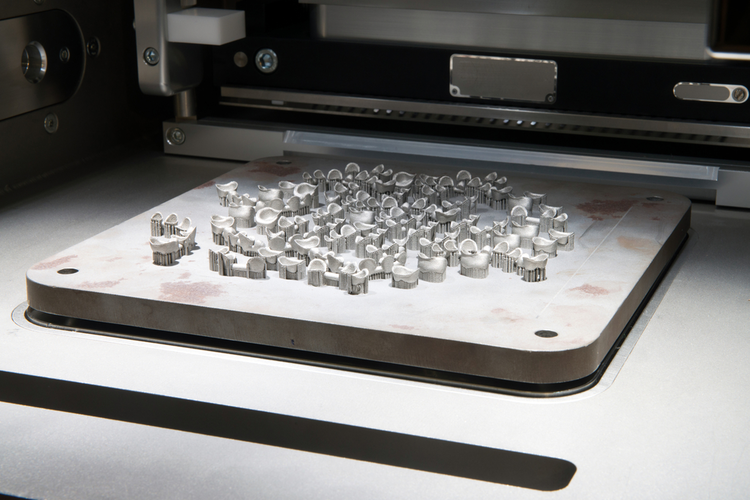

The EBM technology uses an electron beam | Credits: Arcam

The Electron Beam Melting process

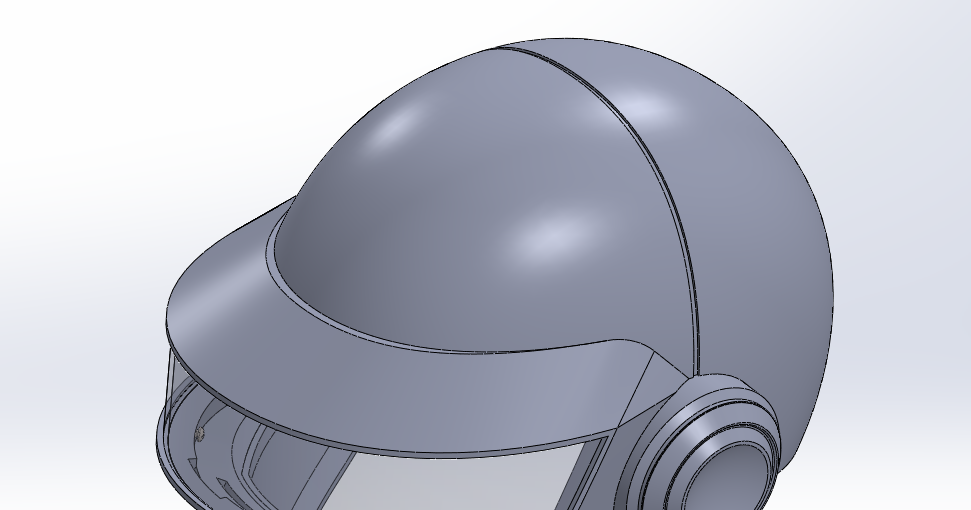

Everything starts with the 3D modeling of the part you wish to create. You can model it using CAD software, obtain it by 3D scanning or download a model of your choice. The 3D model is then sent to a slicing software, also called slicer, which will cut it according to the successive physical layers of deposited material. The slicer will then send all this information directly to the 3D printer, which can then start its manufacturing process. The metal powder can be loaded into the tank within the machine. It will be deposited in thin layers that will be preheated before being fused by the electron beam. In particular, this step provides more support to the cantilever areas of the part being 3D printed. The machine then repeats these steps as many times as necessary to obtain the entire part.

Once the manufacturing process is complete, the operator removes the part from the machine and ejects the unmelted powder with a blowgun or brush. Following this, it’s possible to remove the printing supports (if any have been used) and to detach the part from the build plate. The post-printing steps can include machining of surfaces in contact with other parts, polishing, etc. In some cases, it may be necessary to heat the part in an oven for several hours to release the stresses induced by the manufacturing process.

Following this, it’s possible to remove the printing supports (if any have been used) and to detach the part from the build plate. The post-printing steps can include machining of surfaces in contact with other parts, polishing, etc. In some cases, it may be necessary to heat the part in an oven for several hours to release the stresses induced by the manufacturing process.

Note that all manufacturing must take place under vacuum to properly operate the electron beam. This also prevents the powder from oxidizing when heated. At the end of the production process, a large part of the unmelted powder can be reused almost directly. It is easy to understand the interest that this represents for manufacturers, particularly in the aeronautics sector where it often happens that only 20% of the purchased material is actually used to produce the final part, the rest being removed by machining and sent for recycling.

Materials and Applications

As the process is based on the principle of electrical charges, the materials used must be conductive. Without this, no interaction can occur between the electron beam and the powder. The manufacture of polymer or ceramic parts is therefore technically impossible with an electron beam and only metals can be used. Today, titanium and chromium-cobalt alloys are mainly used – Arcam has restricted the range of compatible materials. In fact, to be allowed to use or test another material, users must undertake paid training and obtain an authorization to use the machine as they see fit.

Without this, no interaction can occur between the electron beam and the powder. The manufacture of polymer or ceramic parts is therefore technically impossible with an electron beam and only metals can be used. Today, titanium and chromium-cobalt alloys are mainly used – Arcam has restricted the range of compatible materials. In fact, to be allowed to use or test another material, users must undertake paid training and obtain an authorization to use the machine as they see fit.

EBM technology is mainly used in aeronautics and medical applications, particularly for implant design. Titanium alloys are particularly interesting because of their biocompatible properties and mechanical properties, they can offer lightness and strength. The technology is widely used to design turbine blades, for example, or engine parts. Electron Beam Melting technology will create parts faster than LPBF technology, but the process is less accurate and the finish will be of lower quality because the powder is more granular.

3D printed implants using an Arcam machine | Credits: Arcam

Laser or Electron Beam?

The question is regularly asked by manufacturers who are interested in metal 3D printing. The answer depends mainly on what applications you are interested in, because each process comes with benefits and limitations.

Strengths- Manufacturing speed. The electron beam can separate to heat the powder in several places simultaneously, which significantly speeds up production. On the other hand, a laser must scan the surface point by point.

- Pre-heating the power before it melts limits the deformations and thus reduces the need for reinforcements and supports during manufacturing.

- Precision. At the powder level, the electron beam is a little wider than the laser beam, which reduces the accuracy.

- The size of the parts that can be manufactured. Arcam’s largest build volume (on the Q20 machine) represents a diameter of 350 mm for a height of 380 mm.

On the other hand, laser machines (such as the X-Line of Concept Laser) offer manufacturing volumes at least twice as high.

On the other hand, laser machines (such as the X-Line of Concept Laser) offer manufacturing volumes at least twice as high.

Arcam is the only manufacture of EBM 3D printers

Did you find our Electron Beam Melting (EBM) guide helpful? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

What is Electron Beam Melting (EBM)?

What is Electron Beam Melting (EBM)?

What is Electron Beam Melting (EBM)?

Electron Beam Melting (EBM) is a 3D manufacturing process in which a powdered metal is melted by a high-energy beam of electrons. An electron beam produces a stream of electrons that is guided by a magnetic field, melting layer upon layer of powdered metal to create an object matching the precise specifications defined by a CAD model. Production takes place in a vacuum chamber to guard against oxidation that can compromise highly reactive materials. Electron Beam Melting is similar to Selective Laser Melting (SLM), as they both print from a powder from the 3D printer’s powder bed, but EBM uses an electron beam instead of a laser.

Electron Beam Melting is similar to Selective Laser Melting (SLM), as they both print from a powder from the 3D printer’s powder bed, but EBM uses an electron beam instead of a laser.

EBM builds high-strength parts that make the most of the native properties of the metals used in the process, eliminating impurities that may accumulate when using casting metals or using other methods of fabrication. It is used to print components for aerospace, automotive, defense, petrochemical, and medical applications.

EBM Printing Advantages and Disadvantages

Electron beam melting technology is proprietary and EBM printers require skilled technicians to run them. Though EBM can be much faster than SLM (selective laser melting), SLM produces smoother, more accurate parts.

In 1993, Arcam collaborated with Chalmers University of Technology in Gothenburg in filing an application for a patent on the principles of EBM. The process was developed with the goal of creating 3D objects by melting an electrically conductive powder, layer by layer, with an electric beam. In 1997, Arcam AB was founded and the company has continued to develop EBM and commercialize EBM printing.

The process was developed with the goal of creating 3D objects by melting an electrically conductive powder, layer by layer, with an electric beam. In 1997, Arcam AB was founded and the company has continued to develop EBM and commercialize EBM printing.

What is the difference between electron beam melting (EBM) vs selective laser melting (SLM)? Electron Beam Melting is similar to SLM in that they both print from a powder from the 3D printer’s powder bed, but EBM uses electrons rather than the photons used in the SLM process. In EBM, a high-energy electron beam melts layers of powdered metal to create a form within a vacuum. In SLM, a laser beam emitting photons bonds or sinters layers of powdered metals to solidify the metal. SLM does not require a vacuum environment.

What temperatures are required for EBM? As EBM often is used on metals with a high melting point, temperatures as high as 2,000 degrees Celsius have been measured in the electron beam melting process.

Why does the EBM process take place in a vacuum? Treating metals at a high heat tends to increase oxidation which can make the final product brittle. Since the EBM process takes place in vacuum, allowing for a high temperature in a non-oxygenated environment, it relieves internal stresses and resulting in more resilient, flexible parts.

How does an electron beam gun work? An electron beam gun has a tungsten filament that, when superheated, emits a stream of electrons that, in a vacuum, accelerate to roughly half the speed of light.

Can EBM be used on plastics, metals and ceramics? Since EBM relies on electrical charges and extremely high temperatures, it can only be used on conductive materials like metals.

Which is the better choice for rapid prototyping: SLS or EBM? Because an electron beam is wider than a laser beam, EBM may produce a less precise part than SLS but is faster in producing larger objects.

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

3D technology for the sake of art. Applications for 3D devices in the theater and museum

Not surprisingly, a 3D printer is a versatile tool for creating everything that can be made from plastic. Other 3D technologies - lasers, milling cutters, scanners, etc. - are joining the same line. However, have you ever thought that the scope of these devices is not limited to industry and trinkets for the soul?

And there are enough applications. And not only in theory, but those that are already being used in practice. Specifically, here we will talk about the use of 3D technologies in art - theater, museum, cinema. nine0003

Specifically, here we will talk about the use of 3D technologies in art - theater, museum, cinema. nine0003

Applications of 3D technologies in theater and museums

3D technologies are broadly divided into two categories of use - scanners and object manufacturers. Let's start with the first.

3D Scan

These devices are used to convert a physical object into a digital format - an electronic 3D model. After that, the model is ready for use both in the creation of 3D games or films, and for prototyping on a 3D printer, for example. nine0003

There are many different scanners, both in design and in the principle of operation, but the most popular format is an installation with a rotating platform and a fixed reading device (laser, camera, etc.), which “reads” the shape of an object on the surface and writes it in the form of an electronic 3D models.

EinScan-SE 3D scanner

Props and props using 3D technologies

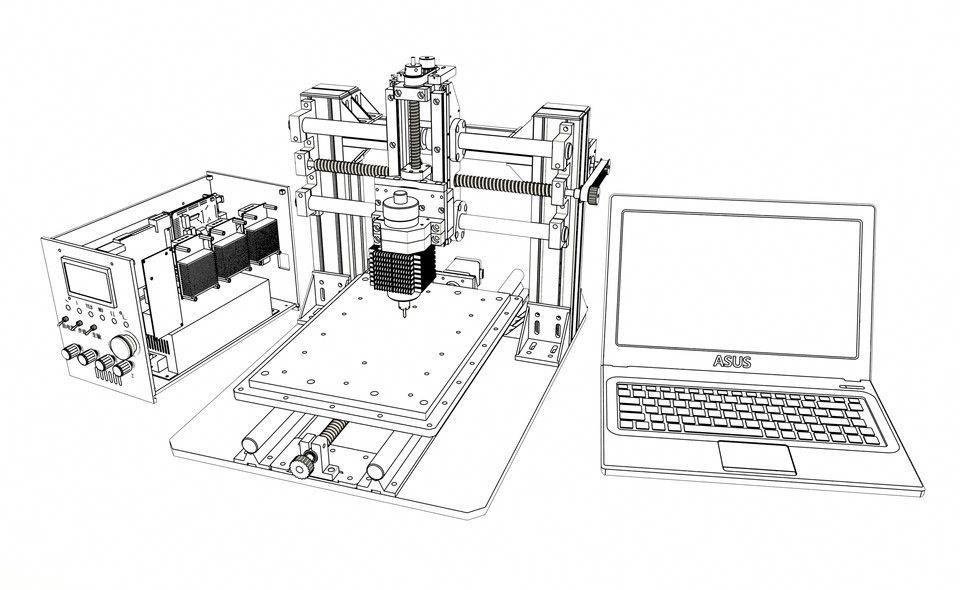

There are many 3D technologies for creating various objects and details. We wrote about different types of 3D printers here, but besides them, there are various CNC machines - lasers, milling machines, engravers, etc., so they can be used in any idea. You can safely use both plastic and metal powder, and if your heart desires, then make objects from wood, stone, metal using a blank on a CNC machine. nine0003

We wrote about different types of 3D printers here, but besides them, there are various CNC machines - lasers, milling machines, engravers, etc., so they can be used in any idea. You can safely use both plastic and metal powder, and if your heart desires, then make objects from wood, stone, metal using a blank on a CNC machine. nine0003

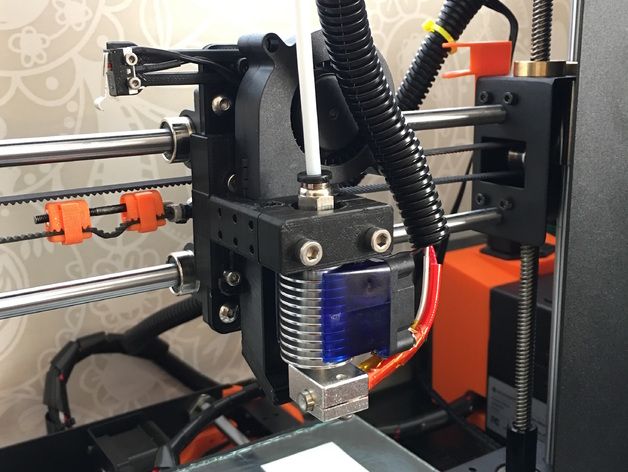

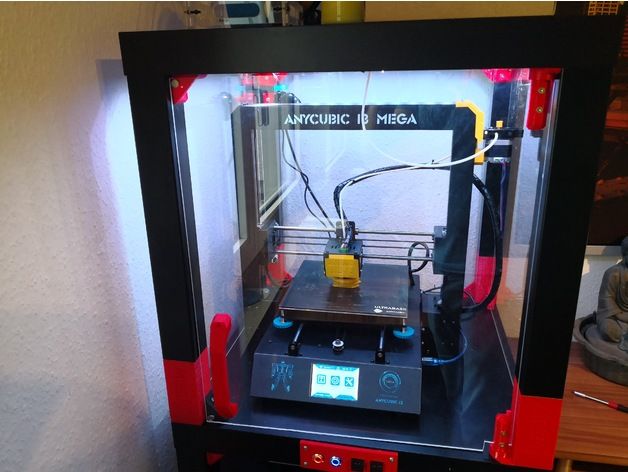

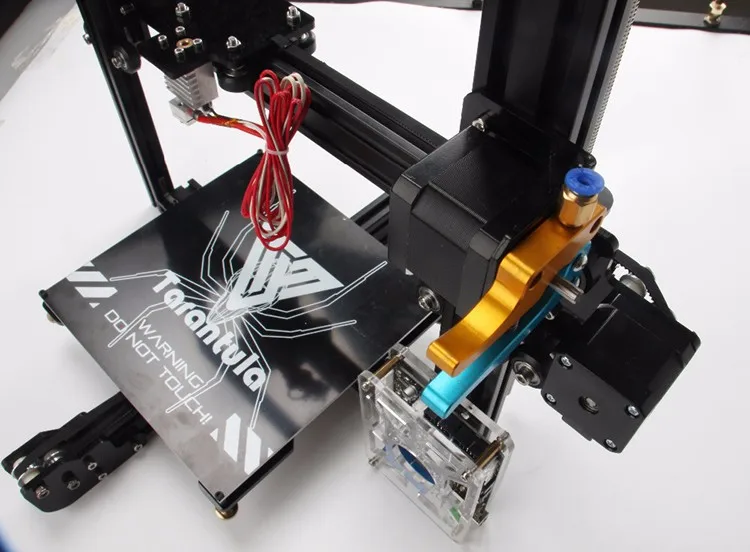

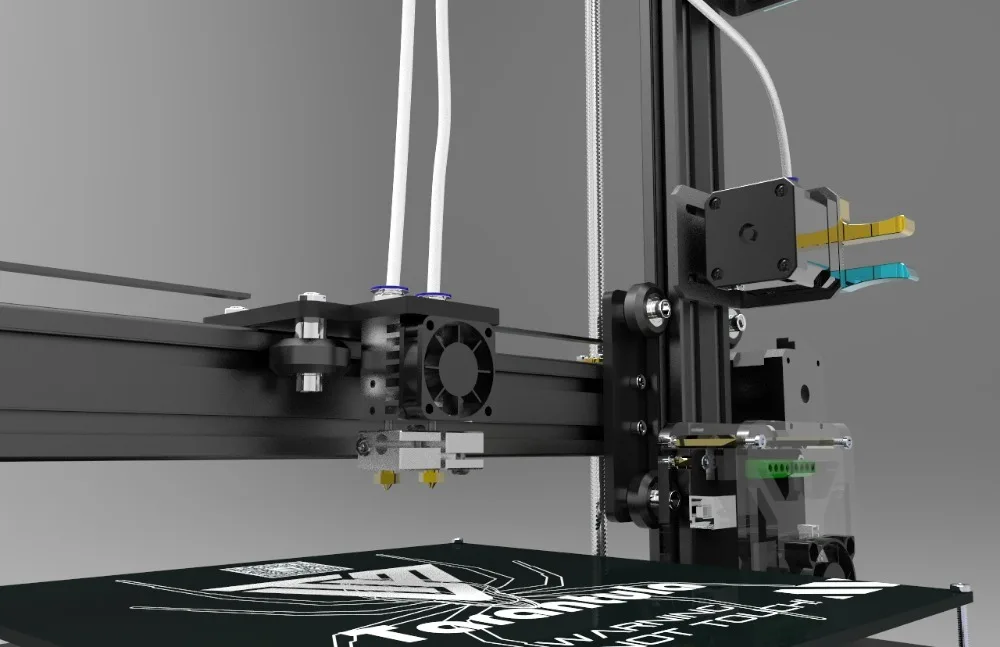

Wanhao Duplicator I3 mini 3D printer

Specific examples of using 3D devices

The purpose of 3D devices is quite clear - digitization or the creation of a real object. But let's not be unfounded - we look at the real use of these devices.

Theater

Costumes and props in theaters are not limited to cloth costumes and household items.

In the theater, the use of a 3D printer and other devices is beneficial and in demand, because, unlike cinema, it is impossible to use 3D graphics in theaters for obvious reasons, so making real props and props is a must. With the use of 3D devices, this process becomes faster and easier, and as a result, durable and no less high-quality things are obtained. nine0003

nine0003

Ekaterinburg Puppet Theater 3D-printed figurines

Cinema

Yes, cinematography often uses 3D graphics instead of creating real props, but no one will argue with the fact that real objects have always been and will look like in the frame is much more impressive and realistic than the elements of the environment and interaction drawn in the editor.

3D printed Iron Man suit

But no one has abolished 3D graphics, and that's where 3D scanners are used.

For example, in the film The Girl with the Dragon Tattoo, the stuntman's head was "replaced" by actress Rooney Mara using 3D scanning in the stunt scene.

The process of "replacing" the stuntman's head in the frame

Museum

In the museum business, objects of interest are exhibits. But the bust of Nefertiti and the statue of the Virgin Mary exist only in one copy, and you want to look at them, even copies. Here they show themselves on the good side of 3D technology. nine0003

Bust blank, machined from foam. Do not be embarrassed by the strange appearance, the model is still at the manufacturing stage 🙂

By the way, 3D scanners will be indispensable for prototyping exhibits, which will help create an accurate and high-poly electronic model, for example, a sculpture or a bas-relief.

CNC machines are good at making exact copies of objects. It is very handy when copying

Cosplay

Cosplay (English costume play) - the embodiment of any image from cinema, animation, video games, etc., that is, the repetition of the costume and appearance of the character, his behavior, facial expressions, etc.

Cosplay is like theater. Here, too, props and acting are needed, but still, in cosplay, you need not only to create a costume, but to make it as similar as possible to the original source.

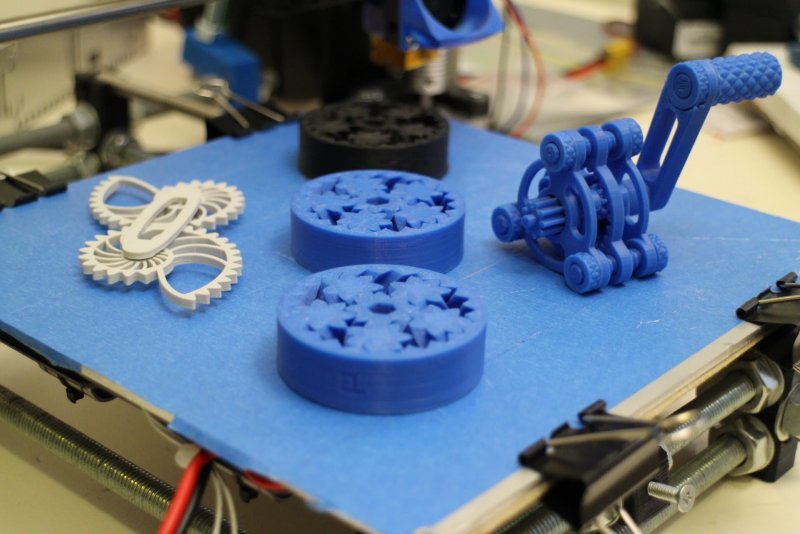

Awesome suit. The parts are made using a 3D printer, which is why they have such a realistic "factory" shape

The parts are made using a 3D printer, which is why they have such a realistic "factory" shape

What equipment is best for creating props

In the theater, cinema and cosplay, 3D printers will be the most in demand. On our website, we can get a decent option even with a small budget, for example, Creality3D Ender 3.

If you need to make smaller parts and the best quality and shape of the final model is important, the Anycubic Photon Mono photopolymer printer will suit you.

If you want to look for another option, here is a link to the catalog 🙂

CNC machines are needed to process finished workpieces made of wood, metal, etc. To create bas-reliefs and similar decorative elements, we recommend taking a milling machine. A good option would be Scotle 6040.

3. Conclusion

The convenience and indispensability of 3D technologies in theater, museums and other areas of art is understandable and justified.