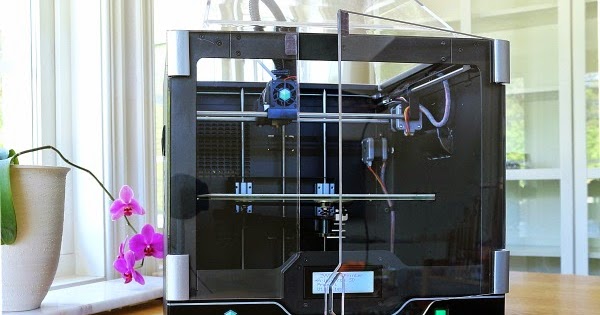

F270 3d printer

Stratasys F270 3D Printer | F123 Series | Stratasys UK

Where are you? Home » Products » 3D Printers - Stratasys, Makerbot, Objet & Metal » 3D Printers » Stratasys F270 3D Printer

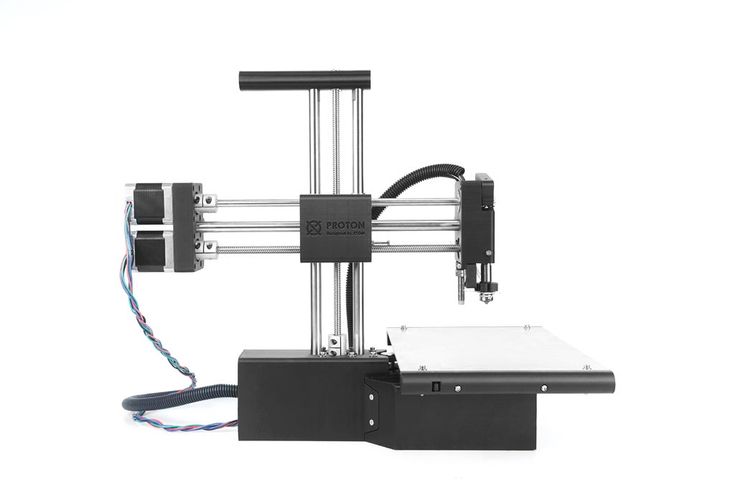

Stratasys F270 3D Printer lets you print everything from fast, low-cost concept models to durable assemblies and offers users the choice of low cost PLA, ABS and ASA from two material bays along with Stratasys easy-to-remove soluble support material . The F270 features 4 material spool bays, 2 for model, 2 for support located in an easy to access drawer at the front of the unit.

Stratasys F270 3D Printer lets you print everything from fast, low-cost concept models to durable assemblies and offers users the choice of low cost PLA, ABS and ASA from two material bays along with Stratasys easy-to-remove soluble support material . The F270 features 4 material spool bays, 2 for model, 2 for support located in an easy to access drawer at the front of the unit.

It’s easy to create complex parts and assemblies with no compromise on accuracy, detail and repeatability. Even for your earliest design iterations, you can expect Stratasys quality and dependability.

Featuring a larger build bay than the F170 you can produce larger models or nest even more smaller parts together.

F270 - Maximum Build Size (XYZ) 305 x 254 x 305 mm (12 x 10 x 12 in)

A variety of the most commonly used CAD file formats can be imported directly into the software. The three printers in the platform, the Stratasys F170, F270 and Stratasys F370, support a broad range of capabilities and budgets for every stage of prototyping.

Minimal setup means you can simply plug and play to give your entire office access to professional 3D printing.

Auto-calibration ensures you spend less time troubleshooting and more time prototyping.

Fast and easy material swaps to help maximize your design team’s productivity.

The Stratasys F123 series features an all-new fast-draft mode to produce initial design concepts quickly and economically. Now you can print twice as fast as standard build mode whilst reducing cost by on average consuming just a third of the material.

Offering a wider choice of materials further efficiency and savings can be gained by using PLA. A thermoplastic made from renewable resources, PLA - gives you the speed of fast-draft mode while keeping material expenses down. Spend less, create more - That’s smarter 3D printing.

Exceptional Value

The all-in-one power of the Stratasys F123 series gives you value all around — with expanded capabilities and unprecedented accessibility. New and improved features save time and material. Incredible ease of use with both the hardware and the software means you don’t need special 3D printing expertise. Super quiet and office friendly. Reliable, consistent printing ensures less waste.

More Images

Related Pages

- Stratasys F170 3D Printer

- Stratasys F370 3D Printer

- Stratasys uPrint SE plus 3D Printer

Enquire now

Key Features

- Materials

- PLA, ABS-M30, ASA,

- Build Size

- 305 x 254 x 305mm (12 x 10 x 12 in.

)

) - Perfect for

Design Engineers

Product Designers

Jigs, Fixtures & Tooling

Internal Rapid Prototyping Departments

Small run end use parts

Education Research Institutes/Universities

Contact us with your questions on this product »

Product information

Accuracy: Parts are produced within an accuracy of +/- .200 mm (.008 in), or +/- .002 mm/mm (.002 in/in), whichever is greater.

Material Delivery Options: 4 material spool bays, 2 for model, 2 for support located in a drawer on the front of the unit

Network Connectivity: Wired: TCP/IP protocols at 100 Mbps minimum 100 base T, Ethernet protocol, RJ45 connector, Wireless: IEEE 802.11n, g, or b; Authentication: WPA2-PSK, 802.1x EAP; Encryption: CCMP, TKIP

Software: GrabCAD Print (download):

System Requirements: Windows 7, 8, 8. 1 and 10 (64bit only) with a minimum of 4GB RAM (8GB or more recommended)

1 and 10 (64bit only) with a minimum of 4GB RAM (8GB or more recommended)

Requirements

System Size and Weight: 1626 x 864 x 711 mm, 227 kg with consumables

Noise Specification: 46 dB maximum during build, 35 dB when idle

Altem F270 3D Printers - Altem

Get Smarter Prototyping For Your Entire Office

The Stratasys F123 series combines powerful FDM technology with design to print software for the most versatile and intelligent solution available.

Stratasys F123 Series Key Features

The series of 3D printers allow you to produce fast, effective prototypes for concept development, as well as highly accurate and robust parts for design validation and functional performance:

Maximum Build Size (XYZ):

254 x 254 x 254 mm(10 x 10 x 10 in.)

Easy installation and operation:

You can simply plug and play to give your entire office access to professional 3D printing. Fast, easy material change-out, plus auto-calibration ensures you spend less time troubleshooting and more time prototyping.

Fast, easy material change-out, plus auto-calibration ensures you spend less time troubleshooting and more time prototyping.

Office Friendly 3D Printers:

Ultra low noise level during building – under 46 dB, similar to a residential refrigerator. Fully enclosed system with auto-locking door for safety while building.

Multiple FDM Production Materials

The Stratasys F123 series gives the option of up to four different materials (PLA, ABS-M30, ASA) along with easy-to-remove soluble support material.

Maximum Build Size (XYZ):

305 x 254 x 305 mm

(12 x 10 x 12 in.)

Layer Thickness:

• 0.330 mm (0.013 in.)

• 0.254 mm (0.010 in.)

• 0.178 mm (0.007 in.)

• 0.127 mm (0.005 in.)

PLA in 0.254 mm only

Model Materials:

PLA, ABS-M30, ASA, TPU 92A

Support Method:

Water Soluble Support for ABS-M30 & ASA. Breakaway Support for PLA

System size & weight:

1626 x 864 x 711 mm (64 x 34 x 28 in. ) 227 kg (500 lbs) with consumables

) 227 kg (500 lbs) with consumables

Noise Specification:

46 dB maximum during build, 35 dB when idle

Accuracy:

Parts are produced within an accuracy of +/- .200 mm (.008 in), or +/- .002 mm/mm (.002 in/in), whichever is greater.

Material Delivery Options:

4 material spool bays, 2 for model, 2 for support located in a drawer on the front of the unit

Network Connectivity:

Wired: TCP/IP protocols at 100 Mbps minimum 100 base T, Ethernet protocol, RJ45 connector

Wireless: IEEE 802.11n, g, or b; Authentication: WPA2-PSK, 802.1x EAP; Encryption: CCMP, TKIP

Software:

GrabCAD Print

System Requirements:

Windows 7, 8, 8.1 and 10 (64bit only) with a minimum of 4GB RAM (8GB or more recommended)

Operating Environment

Operating: Temperature: 59-86ºF (15-30ºC), Humidity: 30-70% RH

Storage: Temperature: 32-95ºF (0-35ºC), Humidity: 20-90% RH

Power Requirements:

100–132V/15A or 200–240V/7A. 50/60 Hz

50/60 Hz

Regulatory Compliance:

CE, FCC, EAC, EMC (low-voltage directive), TUV, FCC, RC, RCM, RoHs, WEEE, Reach

GrabCAD Print Software

GrabCAD Print software simplifies the entire 3D printing process with an intuitive CAD-like application anyone on your team can use. Features like detailed reporting and remote monitoring help you easily manage your print jobs from outside the office. Combined with the ability to seamlessly share projects between users, it all adds up to a more streamlined, efficient workflow.

A smooth 3D printing workflow

GrabCAD Print allows you to Print directly from CAD files — even from within Creo 4.0 or the SOLIDWORKS® Add-In. Smart default settings, tooltips, and notifications guide you through a seamless printing process. GrabCAD Print works with detailed views of your model, tray, and slice preview to make necessary adjustments before printing.

Get more from your printers

Helps you maximize print scheduling based on machine availability, estimated job duration etc. Plan and budget by knowing how much material is remaining for each printer and error/complete notifications keep you updated of the process stage.

Print from anywhere

GrabCAD Print is cloud-connected so its gives you access and print capability to any supported printer in your company, even if it’s in a different geographic location from any browser on your device of choice with minimal training.

3D printed prototypes for functional tests

3D printed prototypes for functional testsSupplier of 3D equipment since 2010

[email protected] a call+7 495 646-15-338 800 333-12-82

3D scanners3D printersSoftwareServices

About the companyClients and projectsDemo hallGovernment procurementDeliveryService3D Encyclopedia

BlogContacts

Testing product prototypes, individual components and parts is the most important part of any production chain. With 3D printing, you can quickly obtain high-precision and low-cost samples of future products for various tests and tests.

With 3D printing, you can quickly obtain high-precision and low-cost samples of future products for various tests and tests.

Which tests can you carry out on the received products:

- check the assembly for assembly;

- study the behavior of various materials in the working environment;

- test new design solutions;

- to check strength, wear resistance;

- blow through objects in a wind tunnel.

Which tests can you carry out on the received products:

- check the assembly for assembly;

- study the behavior of various materials in the working environment;

- test new design solutions;

- to check strength, wear resistance;

- blow through objects in a wind tunnel.

Benefits of functional prototyping with 3D printing

- Speed.

You don't have to wait weeks for contractors to build a prototype for you.

You don't have to wait weeks for contractors to build a prototype for you. - High precision. Test samples match your CAD model to within 15-20 microns.

- Low cost.

- Equipment versatility. With the help of 3D printing, you can get not only prototypes for tests, but also solve other production problems.

- Information security. Your know-how will not get to competitors if third-party contractors are not involved in the production chain.

Example: 3D printing for Nascar racing engines

The Ford Nascar racing team is actively using 3D printers to redesign and test new engine, exhaust and fuel system components.

Thanks to 3D printing, our engineers have the unique ability to quickly get full-fledged prototypes of their designs, test them, make changes and implement them in our machines. This allows us to change the characteristics of cars incredibly quickly and prepare for the race.

Victor Martinez, Chief Engineer, Ford Team

Benefits of Functional Prototyping with 3D Printing

- Speed. You don't have to wait weeks for contractors to build a prototype for you.

- High precision. Test samples match your CAD model to within 15-20 microns.

- Low cost.

- Equipment versatility. With the help of 3D printing, you can get not only prototypes for tests, but also solve other production problems.

- Information security. Your know-how will not get to competitors if third-party contractors are not involved in the production chain.

Example: 3D printing for Nascar 9 engines0043

The Ford Nascar racing team is actively using 3D printers to upgrade and test new engine, exhaust and fuel systems.

Thanks to 3D printing, our engineers have the unique ability to quickly get full-fledged prototypes of their designs, test them, make changes and implement them in our machines.

This allows us to change the characteristics of cars incredibly quickly and prepare for the race.

Victor Martinez, Ford 9 Team Chief Engineer0066

Example: 3D repair of a prototype of the step motor for conducting tests

Example: 3D-tobate a prototype of the step motor for conducting tests

3D-printers for printing functional models

Stratasys F370

9 9000 9000 -Z AnyForm 650 PRO

3DLAM Mid

0106

3DLAM MID

UnionTech RSPRO 800

- +7 495 646-15-338 800 333-12-82

2012-2022, GLOBATTEC (GLOBATEC ). All rights reserved.

Privacy policy and personal data processingPrices on the site are for reference only. Not an offer.

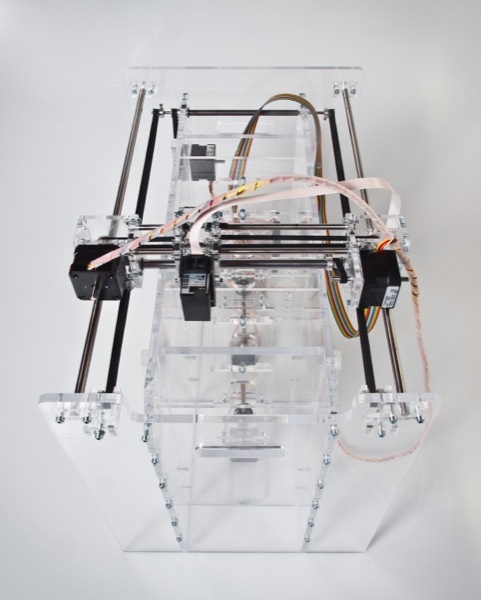

3D printing services on the Stratasys Connex3 Objet260 printer

Intrasoft JSC offers 3D printing services on the Stratasys F270 and Stratasys Connex3 Objet260 printers

The Stratasys Connex3 Objet260 3D printer is optimal for the rapid development of any type of product with high requirements for prototype detail and texture. For parts that require a wide range of mechanical, optical or thermal properties (for example, multi-layer casting, the production of transparent covers, flexible joints or heat-resistant surfaces).

For parts that require a wide range of mechanical, optical or thermal properties (for example, multi-layer casting, the production of transparent covers, flexible joints or heat-resistant surfaces).

The Objet260 Connex3 professional resin 3D printer can use a wide range of materials in a single job to create realistic prototypes without the need for unnecessary assembly and post-processing.

Applications Objet260 Connex3

- Instrumentation - for making molds using inserts with complex internal cooling channels;

- Architecture and design - to quickly create accurate and visual models, layouts and compositions;

- Industry (aerospace, defense, automotive industry) - modeling and high-precision prototyping of various samples, parts, improvement of drawings, innovative developments;

- Advertising, marketing - creation of mockups, three-dimensional models, samples of commercial products;

- Education - the creation of test, educational and training products that most accurately repeat the physical and geometric properties of real objects.

Characteristics of Objet260 Connex3 3D printer

Print technology:

PolyJet Matrix Layer-by-layer deposition of photopolymer materials, with the possibility of simultaneous use of two modeling materials with different properties.

Supported materials

3D printing base materials:

Vero family color opaque materials:

- VeroGray (RGD850) 90

- VeroBlue (RGD840) (blue)

- VeroBlackPlus (RGD875) (black)

- VeroCyan (blue)

- VeroMagenta (Purple)

- VeroYellow (yellow)

- VeroBlack (black)

- VeroWhitePlus (white)

- Vero PureWhite, a brilliant white 20% brighter than VeroWhitePlus and half as transparent

Digital materials:

- Hundreds of composite materials can be made on the job, including:

- Bright mixed colors of hard and opaque material

- Translucent color shades

- Elastic materials with a variety of hardness values Shore

- Digital ABS materials for durability, including blends with rubber

- High temperature resistant polypropylene materials

Construction area size (maximum size of the resulting model): 255 × 252 × 200 mm

T layer thickness: 16.

.jpg)