Everything you need to know about 3d printers

Everything you need to know about 3D printing and its impact on your business

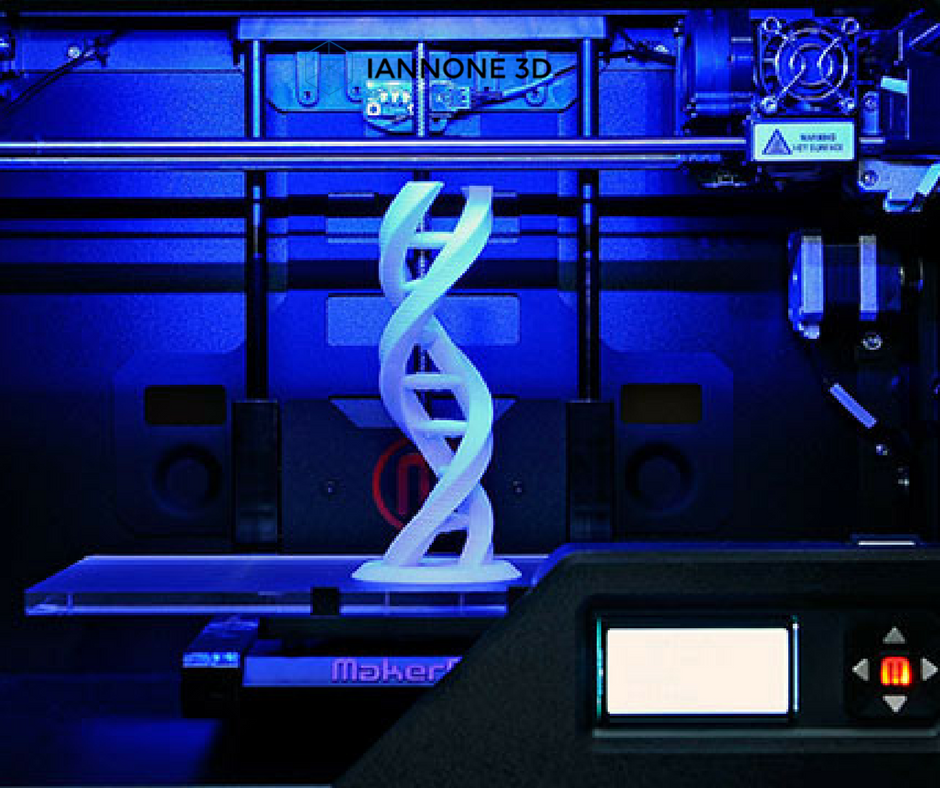

3D printing transforms spools of plastic filament or trays of resin into physical objects. 3D printing is quite literally out of this world. NASA maintains a 3D printer on the International Space Station and astronauts can build custom tools (like this maintenance wrench) without having to fly them into space.

3D printing has been adopted by students, entrepreneurs, hobbyists, and massive factories. Because 3D printing allows for the transformation of a digital design into a tangible object, a wide array of uses have been found.

Also: How Heineken is using 3D printing for on-demand brewery parts

Physicians can print physical models of portions of patient anatomy to better visualize procedures and demonstrate practice. Engineers in factories can create custom jigs and fixtures that both save time and reduce injury during the manufacturing process. Communities foster makerspaces that teach STEM skills and aid in the start-up of new businesses, thereby creating new jobs and local opportunities.

Although mostly used for the creation of plastic objects, 3D printing can also generate metal objects, although this is a much more costly and far less common process than plastic 3D printing.

What is 3D printing? 3D printing is the process of creating a physical object from a digital model. 3D printing is an additive process. Layers of plastic are built up one after the other to create an object.

How does 3D printing impact the economy? 3D printing is a component of the maker movement, which has benefits to communities, education, entrepreneurship, and traditional enterprises. It helps foster the creation of new products and new companies, and teaches skills transferable into a wide variety of technical and professional jobs.

How expensive is 3D printing compared to traditional manufacturing processes? That depends. It's far less expensive and takes far less time to create prototypes, jigs, tools, and fixtures using 3D printing. But once the setup and tooling costs are paid for, traditional manufacturing techniques like injection molding can produce objects in volume more quickly and at lower cost.

How does 3D printing affect the supply chain? 3D printing is ideal for short-run manufacturing and small production jobs. It also allows spare parts to be "stored in the cloud," so physical inventory isn't required until there is a demand for an object. By delivering 3D objects across the globe in digital form and printing locally, the cost and time of shipping can be completely eliminated.

Can 3D printing transform the manufacturing industry? The manufacturing industry is undergoing a vast transformation of which 3D printing is one element. Other factors include a huge increase in data volume and processing, improved analytics, improved human factors, and the automation of various production processes.

3D printing is the process of creating objects (usually plastic, but sometimes metal or composite material) from a digital model. Most 3D printers add material to the object one very thin layer at a time, which is why 3D printers are classified as "additive manufacturing."

How does additive manufacturing work?

The analogy to printing is not perfect. Computer printers generally operate a row at a time. 3D printers work much more like plotters, moving a print head along both the X and Y axis to draw a pattern. In the case of a 3D printer, the pattern is usually drawn with plastic, not ink. What makes the 3D printer three-dimensional is that once a pattern is drawn, the print head moves up (or the print surface moves down), and another pattern is drawn on top of the first.

How does a 3D printer work?

There are several types of 3D printers out there, but we'll be focusing on two: fused-deposition modeling (or FDM) and stereolithography (or SLA).

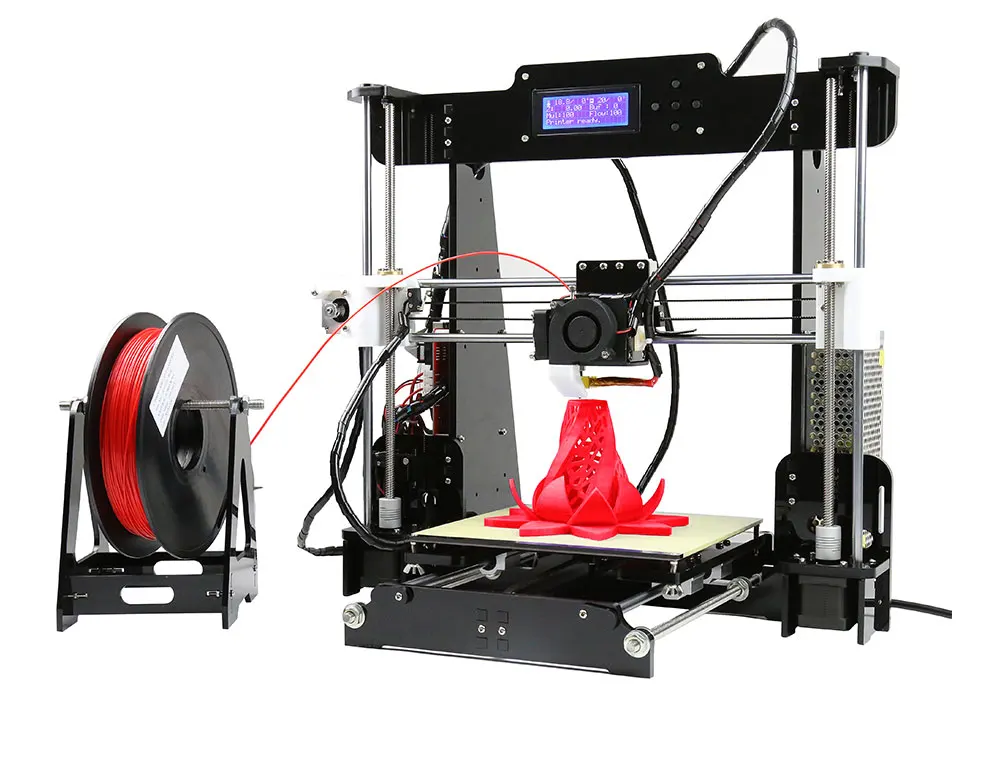

FDM starts with rolls of filament as its source material. These typically come in strands either 1.75 or 2.85 millimeters thick, rolled onto a spindle. An FDM printer heats the filament, squeezes it out through an extruder nozzle, and lays down layers on a build surface. The layers are incredibly thin, and as each molten layer is laid down on top of the previous layer, it partially fuses as it cools.

Also: 3D printing and robots power largest furniture maker in the world

Over time -- sometimes a lot of time -- an object is built up from hundreds or thousands of these layers.

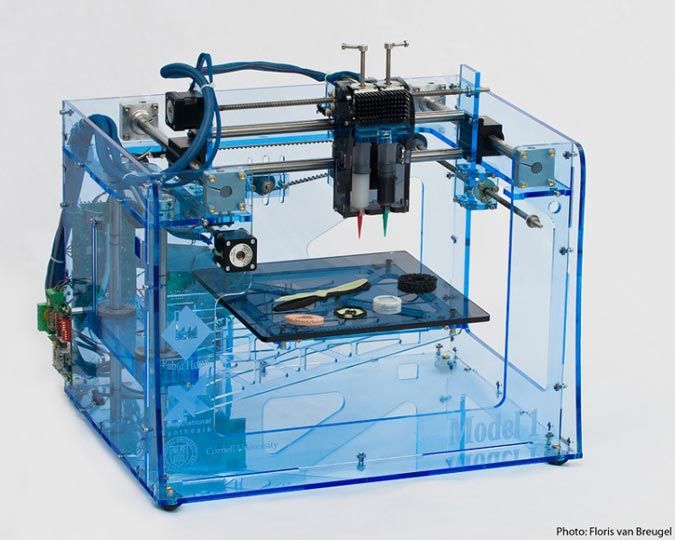

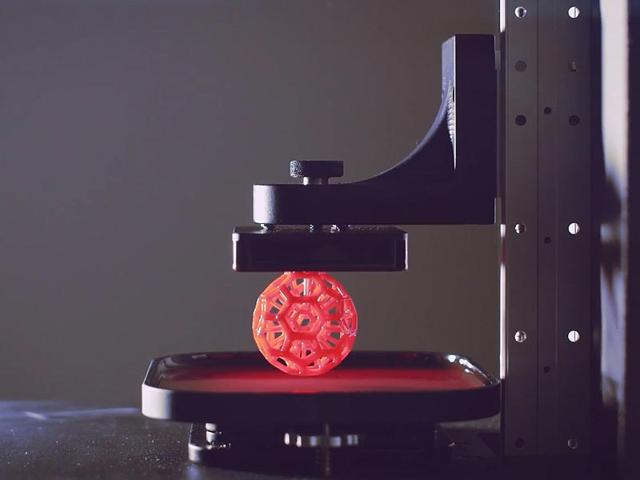

SLA starts with a liquid resin as its source material. A build tray is lowered into the resin (usually upside down) and light (sometimes from an LCD, sometimes from an ultraviolet laser) creates a chemical reaction in the resin that causes it to harden. As each layer is exposed to the light, the printer raises the build platform slightly out of the resin pool, exposing the next layer to light.

Innovation

- Tesla is changing the sensors in its cars. Here is why you should care

- What is the world's brightest flashlight? The top contenders ranked by lumens

- Selling an emotion and a feeling: How these companies see VR as the future of business

- The best affordable EVs and how the federal tax credit can save you $7,500

FDM is the most common form of material extrusion 3D printing. SLA is the most common form of light polymerization 3D printing. These two printing methods have reached a cost level low enough that consumers, hobbyists, educators, entrepreneurs, and small businesses can afford them, but they are generally limited to the production of plastics, plastic composites, and nylon-like materials.

Other forms of 3D printers are available, but at a substantial buy-in cost. These include powder bed 3D printing (which drops powder that is then fused in form), laminated object manufacturing (which glues sheets of material together and then cuts them to form), directed energy deposition (which is kind of like what would happen if a welding machine and an FDM printer gave birth), and electron beam freeform manufacturing (which shoots an electron beam in a vacuum to create molten metal based on a 3D model).

These last forms of 3D printing are generally used to fabricate metal parts, while FDM and SLA are most often used to fabricate plastic objects.

What all of these have in common is that they're creating new objects by incrementally adding and fusing a raw material.

Also: 3D printing: A cheat sheet TechRepublic

What 3D printing is not

3D printers are not Star Trek replicators. As anyone who owns a 3D printer will tell you, as soon as guests see the printer in action, their imagination stirs. Nearly immediately, they'll start calling out the types of objects they'd like to have made. Often these are not even existing items, but entirely new inventions they think can be produced overnight through the magic of 3D printing.

You can't ask one to produce a slice of pecan pie or a perfect, doll-sized replica of Captain Kirk's command chair. While there are 3D printers that actually will create chocolate creations and three-dimensional models of the Captain's chair, 3D printing does have production constraints and design limitations.

Over the next few sections of this guide, we'll dive into the strengths and weaknesses of common 3D printers and what it takes to make 3D prints.

How does 3D printing impact the economy?

In the same way that 3D printing is one element of the larger trend of digital manufacturing transformation, 3D printing is one element of a larger trend economically, the rise of the maker movement.

One exciting aspect of making is that it's all-inclusive and gender neutral. It encompasses everything from doll crafting to robot design, from scrapbooking to making furniture, from leatherworking to 3D printing. It's a word that embraces anyone who makes stuff, pure and simple.

Making is different from manufacturing, although making often leads to manufacturing. When someone designs a product, and builds a prototype, that can be considered making. Once that prototype is in active production, that's manufacturing. Now, combining desktop fabrication with crowdfunding, a very sophisticated prototype can be designed, and then the manufacturing funded by prospective customers.

The National League of Cities' Center for City Solutions and Applied Research has studied the maker movement, and believes that making empowers individuals and improves cities:

The maker movement is centered in cities. And this new, hyperlocal manufacturing environment holds potential not only for individual hobbyists but also for community-wide advances in local entrepreneurship and job creation. Cities have a great opportunity to catalyze this movement as a way to improve our local economies, diversify workforce opportunities, and support the creative economy.

They also believe that 3D printing can lower the barrier of entry for entrepreneurship, stating:

The emergence of makerspaces is effectively lowering the cost of entry for entrepreneurs. Whereas until recently an entrepreneur may have had to spend upwards of $100,000 to produce a prototype for a new product, the operating terrain has changed, and that cost can now range from as little as $2,000 to $4,000.

In short, the cost of developing prototypes has quickly become much more affordable for would-be entrepreneurs.

This cost reduction for prototypes (and by extension jigs, fixtures, and tools) applies to large organizations as well. When you can take an expense and reduce it to just 2-4% of its previous cost, innovation increases because the cost of risk decreases.

According to Paul Heiden, SVP of Product Management for 3D printer maker Ultimaker:

The future of additive manufacturing will not be in the hands of a select few engineers, but rather with any worker who may not have 3D printing experience. Software solutions enable those untrained workers to create parts and tools, closing their own personal skills gap and preparing them for a career in the factory of the future.

One interesting metric is the number of projects and the amount of money pledged through Kickstarter projects. Kickstarter is a crowdfunding platform that enables creators to fund products and projects. In fact, many 3D printer vendors have funded their efforts through Kickstarter.

In fact, many 3D printer vendors have funded their efforts through Kickstarter.

3D Printing

- The best 3D printers: From FDM to resin

- These are the most googled 3D printing questions of 2022, answered

- A 3D printed orthotic device made from castor oil

- This device recycles plastic water bottles into 3D printing filament

As of the moment of this writing, Kickstarter's always-updated stats page shows a cumulative $4.2 billion pledged for 162,912 successfully funded projects. This is directly relevant to 3D printing, because the company no longer allows photo-realistic images for funding pitches and requires an actual prototype be built -- which is often accomplished in part through 3D printing.

Another way to gauge the scope of the maker economy is to look at Etsy, which is fundamentally a marketplace for unique and creative goods. In its 2018 annual report, the company stated that it supports 2. 1 million active sellers, 87 percent of whom are women, and 97 percent who run their creative businesses from their home. According to an economic impact study conducted by ECONorthwest on behalf of Etsy, Etsy sellers...

1 million active sellers, 87 percent of whom are women, and 97 percent who run their creative businesses from their home. According to an economic impact study conducted by ECONorthwest on behalf of Etsy, Etsy sellers...

- Generated more than $1.76 billion in income.

- Contributed $5.37 billion to the U.S. economy, more than double their direct business sales.

- Created 1.52 million jobs in the independent worker economy.

- Produced $3 billion in additional economic value.

Of course, only a small percentage of Etsy sellers use 3D printing, but since many Etsy sellers are candidates for some form of desktop fabrication technology, they are a good proxy for market growth data.

Fundamentally, making in general and 3D printing in specific are transformative drivers for economic growth, helping to train students in tangible skills that produce value, helping entrepreneurs build and test prototypes and engage in initial manufacturing, all of which lead to a potent job-creation force all across the world.

Also:

- Mass production 3D printing? It's coming, and it's a big deal

- 3D Systems integrated into Nokia's Factory in a Box additive manufacturing effort

- Stratasys sheds more light on its metals additive manufacturing plans

Because FDM and SLA printers have become available for both hobbyists and professionals, they are the most common types of 3D printers. Consumer versions are available for a few hundred dollars and professional machines, used for prototyping and jig-making, are priced in the $3,000-6,000 range.

These are the 3D printing technologies in which you're most likely to invest.

FDM printers

FDM was the first mainstream hobbyist 3D printing technology and still leads the market in terms of brands and product offerings, as well as number of units sold.

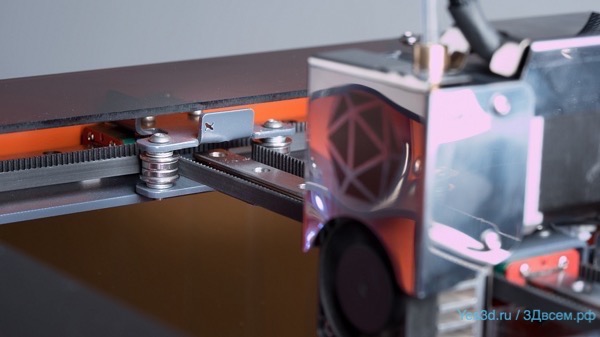

One of the key challenges with 3D printing is getting an object to successfully print. Prints fail because the deposited plastic heats or cools too quickly, because layers don't bond successfully, because the print detaches from the build plate print surface, because filament jams in the extruder, and a wide range of other production gotchas.

Prints fail because the deposited plastic heats or cools too quickly, because layers don't bond successfully, because the print detaches from the build plate print surface, because filament jams in the extruder, and a wide range of other production gotchas.

FDM printers will print in a wide range of plastics. Each plastic has differing characteristics, which can make printing easier or more difficult, and which yield differing characteristics in finished parts.

The most common filament type is PLA (polyactic acid), which is very easy to print, but can be brittle and will deform in sunlight.

Nylon is strong and flexible, but often requires a lot of fiddling to get its print settings to work.

ABS is stronger (it's what LEGOs are made from), but it cools at a rate that often causes the bottom layers to curl up, deforming the entire print. It also has a nasty odor and moderately toxic fumes.

Some vendors infuse the basic plastic (mostly PLA) with other materials, including wood, metals, and carbon fiber.

Each of these change the characteristics of the finished, printed object.

Each of these change the characteristics of the finished, printed object.

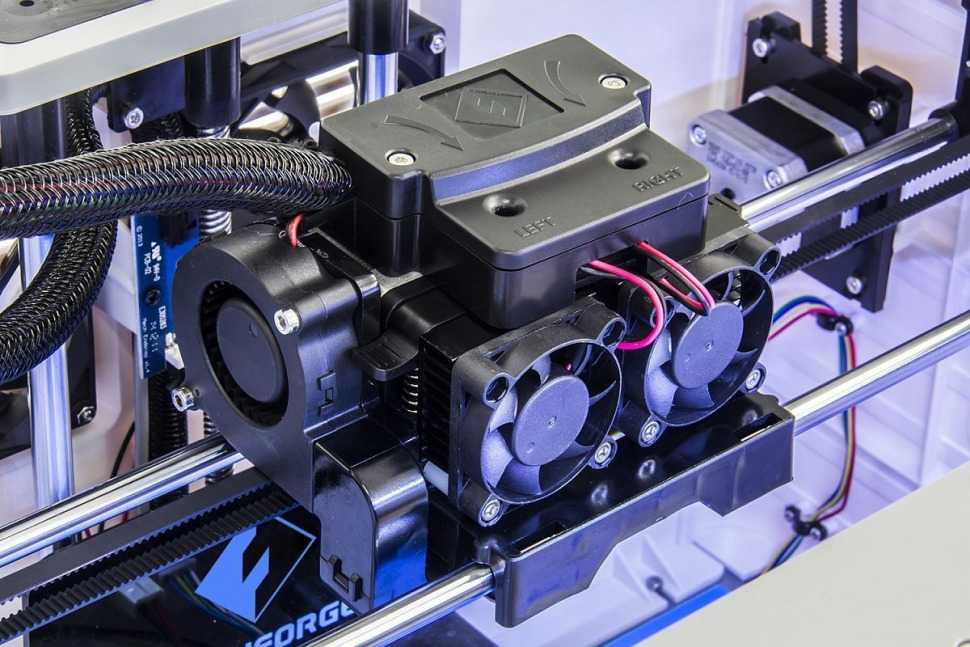

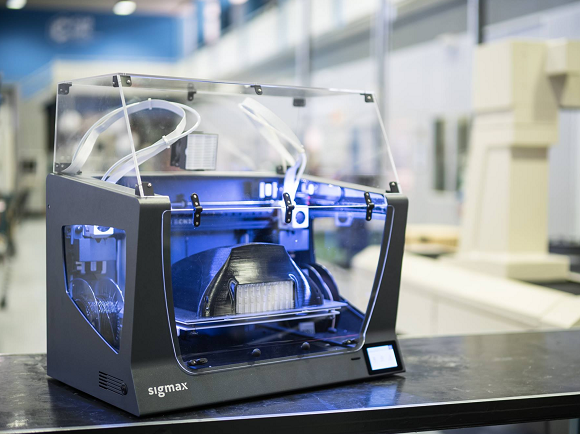

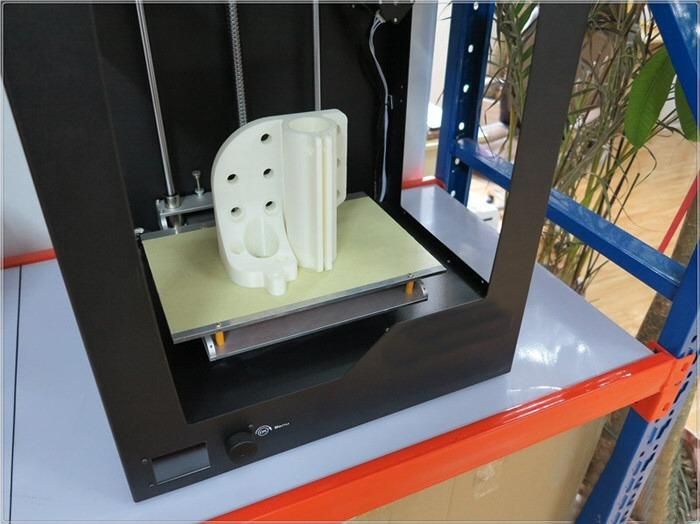

Most FDM printers have a single extruder and can print from a single filament roll at a time. More advanced (and expensive) FDM printers can print two, three, four or more filaments at a time, allowing the printer to mix colors, functional characteristics (like solid plastic with flexible hinges), and dissolvable support materials.

Prints are built up from strings of molten plastic, so overhangs can become an issue. While FDM printers can generally print circles or angles up to 45-60 degrees, they can't print over large air gaps because the molten plastic will simply settle into the gap.

To compensate for the problem of large gaps, most printers will generate supports, or temporary towers of plastic that can hold up the bridged areas. Single filament printers use the same material as the object itself, with a variety of settings that can enable the supports to be removed with moderate ease.

Dual filament printers often print with a dissolvable support material like PVA (polyvinyl alcohol) which is pretty much the same material that Elmer's Glue is made from. Once the dual filament print is completed, it's submerged in water for hours (or sometimes days) and the PVA dissolves, leaving an intact print with the open voids the designer intended for the final object.

Because FDM printers print in layers, the orientation of the object being printed can be important. Bonds between layers are often weaker than linear runs of plastic. As such, placement on the bed should take that into account for any objects that are likely to be under stress.

FDM printers come in a variety of sizes. The larger the size, the more challenging the print, because it's often difficult to balance the heat characteristics within the full build area.

FDM printers also offer a variety of nozzle sizes. The larger the nozzle, the more material extruded per minute, but the less refined the final result. The smaller the nozzle, the more detailed the print. Printing with large nozzles or small nozzles will introduce other challenges, often related to supports, bridging, and heat management.

The smaller the nozzle, the more detailed the print. Printing with large nozzles or small nozzles will introduce other challenges, often related to supports, bridging, and heat management.

Also: 3D Printer Reviews CNET

SLA printers

SLA printers have a number of characteristics that have kept them out of the mainstream:

- They use a liquid resin that is quite toxic in its uncured form. If you get it on you, it could cause painful burns or rashes.

- Finished prints need to be processed in a bath and then cured. During this processing time, they are subject to deformation. They also remain toxic.

- Because of the liquid resin and the processing bath, SLA printers are much messier to work with than FDM printers.

SLA printers often have very small build areas, resulting in generally tiny prints. The resin is often specifically formulated for a given printer, so users can be locked into a vendor's offerings, which may limit material and color choices.

Even so, SLA printers have started to grow in popularity, mostly because they are capable of producing prints with very fine detail and few layer lines. This makes them particularly suited for prototyping jewelry designs and molds, small medical and dental designs, and hobbies, like model railroading and gaming miniatures.

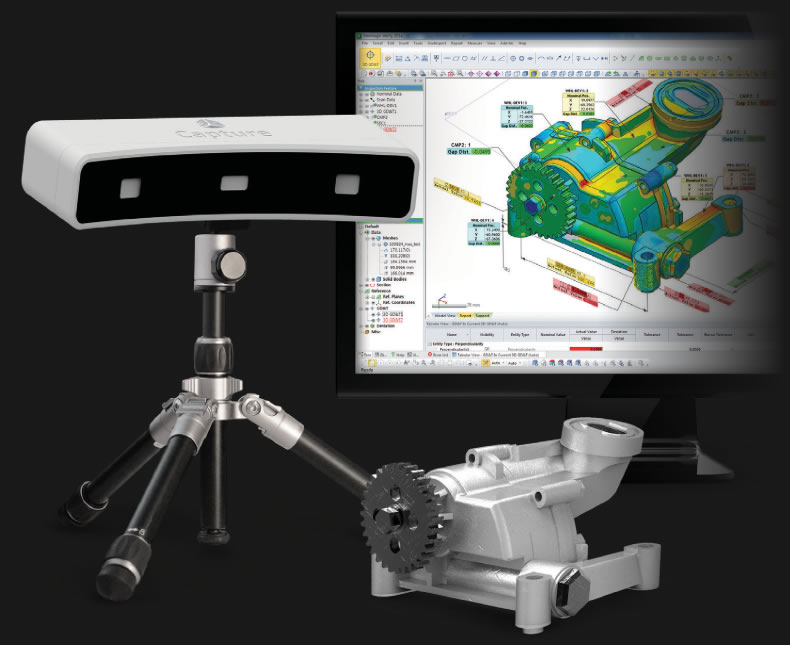

Design and preparation of printsThe process of going from an idea to a 3D-printed object must always pass through two software tool technologies first: 3D-modeling (or CAD) software and slicers.

3D-modeling software

Think of 3D-modeling software, also called CAD (for Computer-Aided Design), as the creation engine for 3D models. In the same way you might use Photoshop to create a graphic, Illustrator to create an illustration, or Word to create an article like this one, CAD software is used to create the design for a 3D model.

There are many CAD programs out there, each best-suited to different tasks. I alternate between TinkerCAD and Fusion 360, depending on whether I need to build a quick part or a more complex design.

TinkerCAD is a very easy-to-use program that's often taught to school kids. It allows for super-quick prototyping of simple designs. Fusion 360 is a full engineering design program with features not only for design, but motion simulation and stress testing as well. There are many other tools, like ZBrush and Meshmixer, that are often used for sculpting in virtual space.

If you can draw a rectangle in PowerPoint, you can use a CAD program to make simple designs. Resources for learning common 3D printing programs are available in many online classes, taught in colleges, and found in abundance on YouTube.

That said, since tools like Fusion 360 can be used to design and virtually test projects like car engines, they can be challenging to master. Often specific-discipline engineering skill is required to understand not only how the tool works, but the physics involved in the operation of the final object.

Slicers

CAD programs produce virtual models of 3D objects. But most 3D printing occurs layer-by-layer, in slices. The process of converting a 3D design into a series of machine movements on a two-dimensional plane (and then moving the plane) is the job of a slicer program.

But most 3D printing occurs layer-by-layer, in slices. The process of converting a 3D design into a series of machine movements on a two-dimensional plane (and then moving the plane) is the job of a slicer program.

Featured

- The best Black Friday and Cyber Monday tech deals still available

- Apple names the 16 best apps and games of 2022, with BeReal taking top honors

- Artemis I mission: Orion spaceship just passed another milestone

- Tech in 2023: 6 new priorities for your shortlist

Most slicers produce G-code, a standard form of numerical control language understood by most computer-aided fabrication devices (not just 3D printers). While G-code is a standard (specifically, "EIA Standard RS-274-D Interchangeable Variable Block Data Format for Positioning, Contouring, and Contouring/Positioning Numerically Controlled Machines"), vendors often add extensions and modifications. This means that G-code usually needs to be generated by the slicer for specific brands and models of numerically controlled devices.

This means that G-code usually needs to be generated by the slicer for specific brands and models of numerically controlled devices.

While some slicers can be operated programmatically by just passing a 3D model file into it and getting G-code output, most slicers today allow for a fully interactive interface. This allows the operator to adjust print orientation and examine the print process layer-by-layer in order to locate potential print problems before a print is sent to the printer.

It's also at this time that different printing settings are configured, ranging from nozzle and build plate temperature, adhesion techniques, infill methods, print speeds, and even custom G-code blocks to account for special procedures, like stopping a print to embed magnets, and then allowing the print to continue.

As with 3D printers and CAD programs, there are many slicers available to choose from. Some of the most popular, like Cura and Slic3r, are open source. There are also robust commercial offerings like Simplify3D.

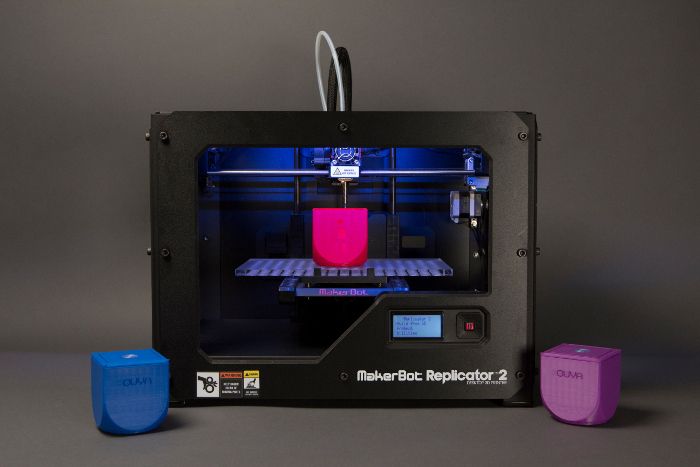

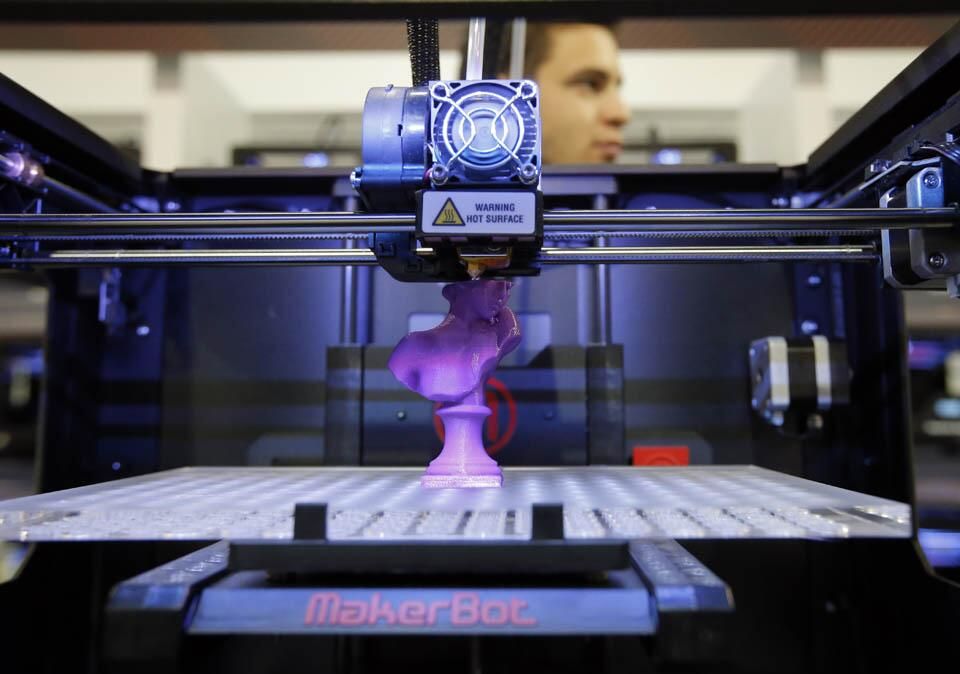

Additionally, some vendors (like Zortrax and MakerBot) have created their own proprietary slicers tied to their individual hardware. As you might imagine, there are some benefits in this approach for tight machine integration, but the lock-in often means that operators who own multiple brands of 3D printers can't standardize on one slicing tool if they use these machines. Some machines with custom slicers ship with incomplete software, which tends to reflect poorly on the product's design and usability.

3D printing and manufacturingFor those organizations used to traditional production processes, 3D printers can save a tremendous amount of time. One example is Volkswagen Autoeuropa. In a discussion with 3D printer maker Ultimaker's president back in 2017, I was told:

The company [Volkswagen] turned to desktop 3D printing to create custom tools and jigs that are used daily on the assembly line, replacing an old process that required outsourcing and long lead times.

Not only did 3D printing introduce a more cost-effective way to produce the tools, it gave time back to the company. The seemingly minor change saved $160,000 in just one plant in 2016, and it's projected to save $200,000 this year.

3D prints can take hours or days to print. I built a set of custom adapters that go between my shop dust collection system and the dust port for each of my tools. Printing each adapter at low resolution took about three hours. A detailed model of the Star Trek starship USS Discovery took a few days to produce as did a scale model of a Ford engine block.

I was able to create a custom adapter system perfectly tailored to my specific needs. 3D printing allowed me to make one-off objects at a material cost in pennies each. Because I was able to do my own design, I incurred no design cost.

Also: HP's new 3D printer has 3D-printed parts

How expensive is 3D printing compared to traditional manufacturing processes?

Adapters like these, built using traditional methods, would have required custom machining, and take weeks from design to delivery. Costs would have been thousands of dollars more than I paid. Because the turnaround from idea to object was so short, and because the out-of-pocket cost was so low, I was able to avail myself of a productivity-improving custom solution I might not otherwise have had.

Costs would have been thousands of dollars more than I paid. Because the turnaround from idea to object was so short, and because the out-of-pocket cost was so low, I was able to avail myself of a productivity-improving custom solution I might not otherwise have had.

This is another benefit of 3D printing: because the cost is so low, there's very little cost barrier to innovation, and as such, more innovation happens.

The thing is, comparing 3D printed objects to traditionally manufactured objects can't necessarily be quantified by cost. Traditionally manufactured objects often have a huge upfront expense necessary to build molds, fixtures, and even factories. But once those expenses have been incurred, the individual unit cost and time to delivery can be nearly instantaneous.

A tangible comparison

LEGO bricks (which are produced from ABS plastic) are made in astonishing quantities. The company reports:

- 19 billion LEGO elements are produced every year

- 2.

16 million LEGO elements are molded every hour

16 million LEGO elements are molded every hour - 36,000 are created every minute

Also: Stratasys launches F120 3D printer for $11,999; V650 Flex

I downloaded a classic 4x2 (four studs by two studs) rectangular LEGO brick model from 3D object sharing site Thingiverse. This is an exact fit-compatible version, which gives us an ideal comparison of production processes. We're comparing the exact models using the same plastic.

On my Ultimaker S5 (which is the same machine used in the Ford and Volkswagen factories), it would take 29 minutes to 3D print one brick, or about two an hour. Filling the large build plate, it's possible to print 65 bricks at once, but the process will take one day, seven hours, and 39 minutes to complete.

In the same 31 hours it takes to produce one plate of 65 bricks, LEGO produces 66.96 million. In other words, you'd need roughly one million 3D printers running full time to produce what LEGO produces in its factories.

Each brick produced by a 3D printer takes about 3g of filament (about half a meter). 3D printing costs about $0.06 per gram of filament for PLA or ABS. Not counting the cost of power, labor, maintenance, and real estate, each brick costs roughly $0.18. By contrast, LEGO sells its bricks to consumers for an average of 10.4 cents.

While it might be possible to produce LEGO bricks in volume via 3D printing, it's neither practical nor cost-effective. On the other hand, when LEGO wants to prototype and test new brick models, at about $0.18 per prototype, the hands-on design and testing process is certainly wildly cost-effective.

How does 3D printing affect the supply chain?

3D printing is also ideal for low volume or short run manufacturing. While some companies need to churn out products in the thousands or millions, other companies need to produce a relatively small number of units or produce units on-demand.

Low-volume production is needed in a variety of applications:

Production for in-house use: A small number of internal departments or users can benefit from the build.

Jigs and frameworks fit this need perfectly.

Jigs and frameworks fit this need perfectly. Test market production: A limited number of units are produced at a manageable cost to test for either suitability for sale, or functionality and performance of features. If buyers respond well, more units can be produced using traditional production means.

On-demand production: Units needed rarely, or in a back catalog can be "stored in the cloud" and produced only when needed. This allows a large warehouse of parts to be stored virtually, and yet made available to customers as needed.

Entrepreneurial ventures: Small numbers of units can be produced as proof-of-concept for crowdfunding or to provide to influencers and reviewers to create initial press and awareness of a product before full funding has been closed.

It's this low-volume, on-demand capability that 3D printing provides that can be transformative to industry overall, not just manufacturing. By being able to quickly and inexpensively create and test new objects, it's possible to innovate at a pace impossible with traditional means.

By being able to quickly and inexpensively create and test new objects, it's possible to innovate at a pace impossible with traditional means.

Additionally, 3D printing promotes the idea of "think global, make local" in the sense that designs for objects can be shared internationally, but new units can be printed out wherever they are needed.

Take, for example, a fixture used in Ford's pilot plant in Cologne, Germany. The company has a small-scale manufacturing line which tests production of new vehicles. As part of this process, engineers use 3D printers to create jigs, tools, and fixtures.

Once tested and confirmed to be effective, delivering fixtures and jigs to other plants around the world would take shipping time, cost for international express shipping, as well as possible customs or other international transit paperwork. But if engineers at the AutoAlliance plant (a joint venture between Ford and Mazda) in the Rayong province of Thailand wanted to use a jig developed in Cologne, all they would need to do is download the digital file and print it.

The result would be the transferring of a custom-made tool across the world in hours, not days, for pennies, not hundreds or thousands of dollars, and with none of the paperwork hassle normally involved in international shipping.

How can 3D printing transform the manufacturing industry?

According to Ultimaker's Heiden: "3D printing continues to evolve within the manufacturing sector, and factory workers have led the adoption of the technology. As their skills continue to develop, the impact of 3D printing will continue to grow in every aspect of the manufacturing process."

That said, 3D printing is not necessarily suited to volume manufacturing. Because prints can take hours or days, once a prototype is developed, you may want to move to a faster production process for your final sale products.

On the other hand, 3D printing is ideal for creating molds, so you can design your object in a CAD program like Autodesk's Fusion 360, print out a prototype, and refine it until it meets your needs. Filament producer Polymaker, for example, has created a special ash-free filament called PolyCast. This filament can produce investment-casting objects that can be placed inside mold shells and then burnt out, creating a mold with no ash, ready for metal casting.

Filament producer Polymaker, for example, has created a special ash-free filament called PolyCast. This filament can produce investment-casting objects that can be placed inside mold shells and then burnt out, creating a mold with no ash, ready for metal casting.

But if you look at manufacturing solely through the lens of 3D printing, you'll be missing a much larger trend, that of "Industry 4.0." McKinsey estimates that the global manufacturing sector is worth roughly $10 trillion per year. The consulting firm contends there are four vast disruptions that will drive change in industrial processes and goods manufacturing:

Data volume and compute capacity: It's not just big data, it's the tremendous flow of data, the increase in computational power, and ubiquitous connectivity. McKinsey specifically calls attention to the impact of low-power, wide-area networks common among Internet of Things.

Analytics: Between AI and big data, the opportunity to subject every process to detailed examination and optimization based on advanced business analytics will drive supply chains that can be both dynamically reactive to worldwide events and micro-changes, as well as predictive based on accumulations of analytical resources from global sources.

New user interfaces: McKinsey believes that touch-interfaces, augmented-reality systems, and other forms of human-machine interaction will drive change in the manufacturing sector. You can consider 3D printing a new user interface as well, because the opportunity to hold a design concept in your hand can transform how you understand an object at a visceral level.

Digital numerical control: McKinsey describes this as "improvements in transferring digital instructions to the physical world," which is, in effect, G-code. But it's actually more than that. It's not only the transfer of instructions, which we've had for years. It's the technologies (ranging from 3D printing to robotics) capable of acting on those instructions that are proving to be transformative.

In looking at how manufacturing is transforming, it's necessary to look beyond just basics of production to transformations in asset management, labor (human, robot, and hybrid solutions), inventory management, quality (via advanced process control, machine vision, and business intelligence), supply chain management, time-to-market, and even after sales service.

Also: Despite growth, 3D printing represents only 0.1% of global manufacturing TechRepublic

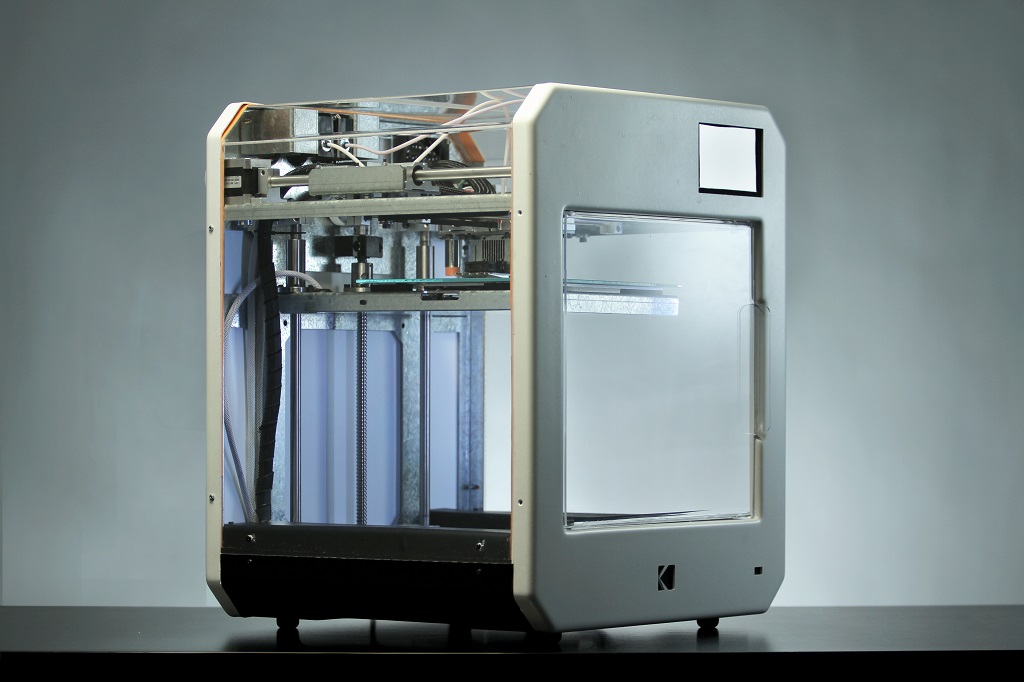

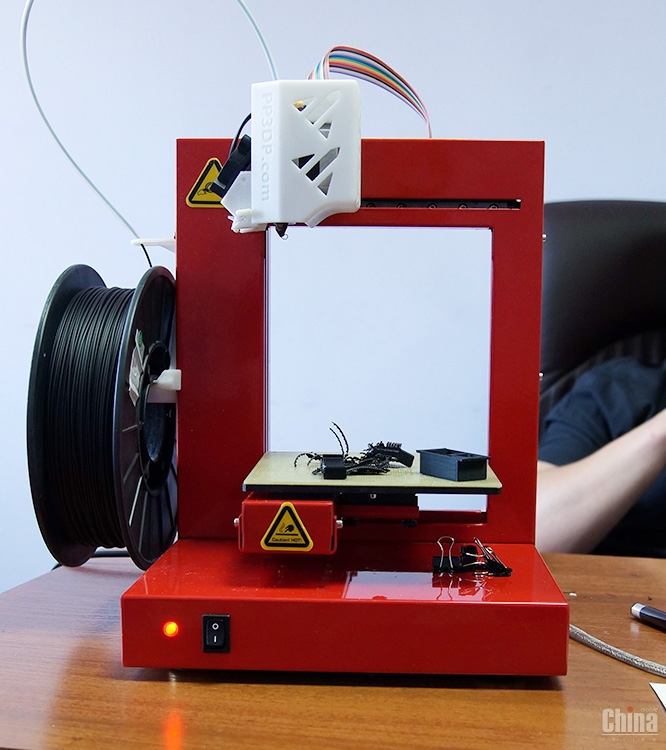

Hands-on with 3D printingIf you're curious about 3D printing, perhaps the best way to understand how it might impact your business is to buy a 3D printer. Consumer-level 3D printers can be had for under $500, and excellent professional printers like those from Ultimaker, LulzBot, and MakerBot are available from about $3,000 to $6,000.

Here at ZDNet, we have run an extensive 3D Printing Discovery Series, with a whole range of articles, reviews, and hands-on video guides. Feel free to read and watch this series. In doing so, you'll be able to quickly and easily develop an in-depth understanding of 3D printing processes and potentials.

Now, go out there and make something great!

Related stories:

- HP sees 3D printing potential in transforming APAC manufacturing

- Dell Technologies using 3D printing to transform prosthetics

- 3D printing guns at home: Does new technology change America's gun control debate?

- Photos: 26 weird and useful things to 3D print for your desk TechRepublic

- Scientists build a 3D printer that turns goo into solid objects CNET

- Best 3D Printer of 2020 CNET

Everything You Need To Know About 3D Printing

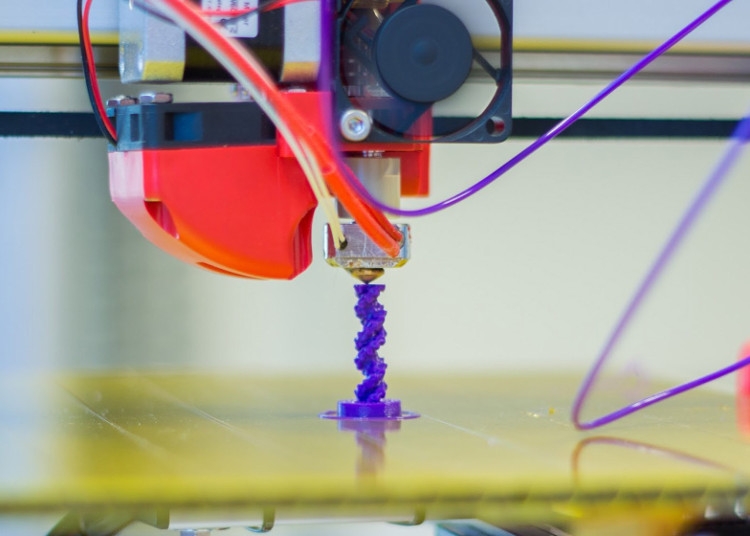

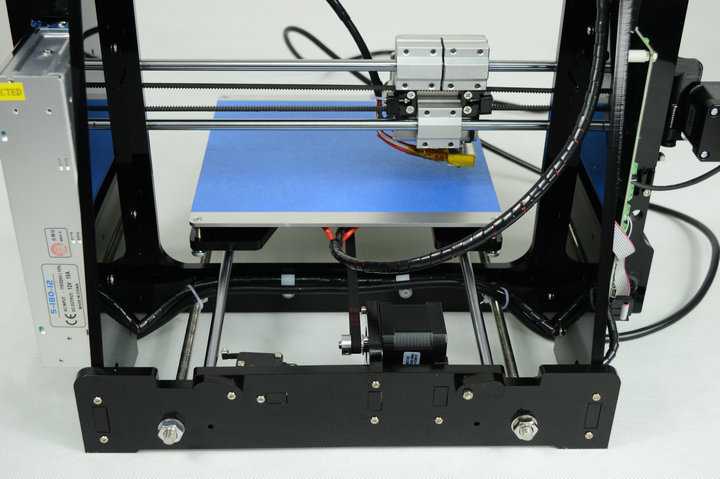

Above: FFF 3D printing technology (representation purpose)/Image Credit: 3D Hubs

3D printing/additive manufacturing is where three-dimensional models are constructed from digital files prepared in 3D modelling software. Currently, this technology isn’t restricted to one technology like it was when it was first created, rather it now covers a variety of technologies that involves layer-by-layer fabrication.

Currently, this technology isn’t restricted to one technology like it was when it was first created, rather it now covers a variety of technologies that involves layer-by-layer fabrication.

3D printing is not a new invention, though it only gained popularity in recent years. But it has been known for a long time in the industry. This technology began as a method of prototyping for large industries, but later on, manufacturers began creating budget-friendly 3D printers meant for hobbyists and small businesses.

Contents

- 1 DIFFERENCE BETWEEN ADDITIVE AND SUBTRACTIVE MANUFACTURING

- 2 PROCESS OF 3D PRINTING

- 2.0.0.0.1 Above: Tutorial on 3D printing in SelfCAD/Video Credit: SelfCAD/YouTube

- 3 3D PRINTING TECHNOLOGIES

- 3.0.1 Fused Deposition Modelling (FDM) / Fused Filament Fabrication (FFF)

- 3.0.2 Digital Light Processing (DLP)

- 3.0.3 Stereolithography (SLA)

- 3.

0.4 Selective Laser Sintering (SLS)

0.4 Selective Laser Sintering (SLS) - 3.0.5 Selective Laser Melting (SLM)

- 3.0.6 Laminated Object Manufacturing (LOM)

- 4 REVOLUTION OF 3D PRINTING

- 5 MASS PRODUCTION USING 3D PRINTING

- 6 USES OF 3D PRINTING

- 6.0.1 1. Professional Use

- 6.0.2 2. Entertainment Industry

- 6.0.3 3.Healthcare System

- 6.0.4 4. Automotive industry

- 6.0.5 5. Education

Above: Additive Manufacturing complements Traditional Manufacturing/Image Credit: AMFG

Though both additive and subtractive manufacturing processes are used hand-in-hand due to their overlapping range of applications, they differ. Additive manufacturing creates objects by adding materials layer-by-layer. Subtractive manufacturing, on the other hand, creates parts by removing materials.

Subtractive manufacturing begins with metals, solid blocks, or other materials that can be shaped by drilling, cutting, boring, or grinding. These processes can be performed by CNC machines or manually. This process is usually used to create parts in metals or plastic meant for prototyping, end-user parts, as well as manufacturing tooling. Processes used in subtractive manufacturing includes laser cutting, water jet cutting, and electric discharge machining.

These processes can be performed by CNC machines or manually. This process is usually used to create parts in metals or plastic meant for prototyping, end-user parts, as well as manufacturing tooling. Processes used in subtractive manufacturing includes laser cutting, water jet cutting, and electric discharge machining.

Additive manufacturing, on the other hand, adds materials layer by layer, and each successful layer is bonded to the preceding later till the parts of the design are completed. The 3D printer deposits the materials, then it’s melted, and the powder is then fused. The parts 3D printed usually requires some finishing and cleaning in order to achieve the final products. It’s applied in manufacturing industries, engineering, prototyping, and also the production of complex products that are hard to achieve in other manufacturing processes.

PROCESS OF 3D PRINTINGAbove: CAD Model of the Statue of Liberty/Image Credit: SelfCAD

The process of 3D printing usually depends on the technology being used. The Fused Deposition Modeling process is the most popular technology that creates parts by heating the material and creating layers of the material. Another technology that is much used is Laser sintering. This technology uses lasers or projectors to fuse plastic and metal powder.

The Fused Deposition Modeling process is the most popular technology that creates parts by heating the material and creating layers of the material. Another technology that is much used is Laser sintering. This technology uses lasers or projectors to fuse plastic and metal powder.

3D printing usually begins with the design of a 3D model by the use of a 3D modeling software. There are various types of 3D modelling software that are used in the creation of 3D models, each of them meant for a specific niche.

Above: Tutorial on 3D printing in SelfCAD/Video Credit: SelfCAD/YouTube

Besides designing 3D models, there are other ways you can get models that you can customize and even 3D print. A good example is Thingiverse, Myminifactory, Cults3D, etc. Once you download them, you can import them to programs like SelfCAD then slice them. You can also hire a 3D designer to help you design your model.

Once you download them, you can import them to programs like SelfCAD then slice them. You can also hire a 3D designer to help you design your model.

After you’ve got your 3D model, you now need to slice them. Slicing is the process of splitting the model into layers that the 3D printer will be able to print. The purpose of slicing a 3D model is to generate the G-Code, which contains the instructions for the 3D printer. The G-Code has instructions relating to where the 3D printer should begin from, where to move to, and also where to conclude the 3D printing process.

The next step in the process is to upload the G-Code file into the 3D printer for actual production.

3D PRINTING TECHNOLOGIESThere are a good number of 3D printing technologies available. Let’s have a look at some of the most common ones.

- Fused Deposition Modelling (FDM) / Fused Filament Fabrication (FFF)

FDM/FFF is the most popular and widely used 3D printing technology. It uses a solid material in filament form that is heated to a liquid form and deposited onto the build platform in a layer-by-layer process to form the complete object.

It uses a solid material in filament form that is heated to a liquid form and deposited onto the build platform in a layer-by-layer process to form the complete object.

- Digital Light Processing (DLP)

DLP is a 3D printing technology that uses light to solidify the model. The conventional light source is usually controlled by mirrors when it’s moved across the resin.

- Stereolithography (SLA)

SLA uses liquid thermoset polymers to create solid objects. The liquid is placed on the vat and laser traces the geometric pattern as defined by the G-Codes. The laser cures or hardens the liquid material wherever it flashes and thus the object is built layer by layer.

- Selective Laser Sintering (SLS)

SLS is a powder-bed fusion 3D printing technology. It uses powdered polymer material. A roller is used to place layers on top of each other and then a laser is used to solidify the powder.

- Selective Laser Melting (SLM)

SLM is almost similar to SLS but they only differ when it comes to the type of material being used. SLS uses powdered polymer material while SLM uses powdered metal materials.

- Laminated Object Manufacturing (LOM)

In this technology, the materials being used are coated with adhesives that have been fused with layers of materials. The materials are fused using heat and pressure and a laser is then used to cut the final product.

REVOLUTION OF 3D PRINTINGAbove: 3D Printing is revolutionising how things are being manufactured/Image Credit: Sika Group/Twitter

As mentioned in the introduction of this article, 3D printing isn’t a new technology despite its popularity in recent years. In the past 3D printing wasn’t very popular. It was only used for prototyping purposes. 3D printing name wasn’t existing, rather, it used to be called rapid prototyping and it was only restricted to only engineers.

But as technology continued to advance, many people showed an interest in 3D printing. Prices of 3D printers become affordable and easy to use 3D modelling software continues to be developed. Hence everyone can now get started in 3D printing with ease.

MASS PRODUCTION USING 3D PRINTINGAbove: BMW to use 3D printing for automotive series production under IDAM project/Image Credit: BMW Group

It will take long before additive manufacturing replaces the traditional method of manufacturing. However, 3D printing is helping companies to bypass certain issues in traditional manufacturing. For example, 3D printing allows companies to work on geometries that were previously hard or impossible to work on in traditional means.

Many companies are investing in buying large and powerful 3D printers that can make it easier to 3D print large volumes of 3D prints. And we believe, in the near future, more advances are going to be made in this field, and even if it won’t completely replace the traditional method of manufacturing but it will solve issues that come along with 3D printing complex designs.

It’s used in creating prototypes. 3D printing is flexible in terms of speed and it reduces the costs that companies could have used in prototyping and testing.

Above: Vase prototype designed in SelfCAD/Image Credit: SelfCAD

2. Entertainment Industry

3D modelling software is used in creating 3D models for movies and films, TV shows as well as games. Artists no longer have to spend many hours manually designing the designs.

3.Healthcare System3D printing is used in creating various healthcare designs like prosthetics based on the patients’ requirements. It’s also used in printing organs like the heart by the use of the human cells and this helps in avoiding transplant rejection and patients don’t have to wait for people to donate organs.

4. Automotive industryThe creation of customized parts is easier and this helps reduce cost and time. It’s also the most efficient method of getting parts that cannot be found in the shops unless imported.

It’s also the most efficient method of getting parts that cannot be found in the shops unless imported.

It allows engineers, scientists, and designers to test ideas in real life. Also, introducing 3D printing to students when they are still learning makes them be familiar with the technology that they will later use in their careers.

(NOTE: This was originally posted on SelfCAD and readers can read it HERE)

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn.

Everything you need to know about 3D printing

Home

3D printing technologies. Fundamentals of 3D printing. Overview of materials and manufacturers for 3D printing. Varieties of 3D printers. Tips for choosing a 3D printer

Fundamentals of 3D printing. Overview of materials and manufacturers for 3D printing. Varieties of 3D printers. Tips for choosing a 3D printer

Overview of 3D printing technologies

Category: 3D printingAuthor: Editor 0

layer of consumables, shifting the desktop down by

How to use pla plastic in 3d printing projects

Category: 3D printingBy Editor 0

Let's look at the advantages and disadvantages of using popular PLA materials in 3D printing projects.

3d printer abs plastic

Category: 3D printingAuthor: Editor 0

ABS plastic is one of the most popular and sought-after consumables for 3D printing. Its price is tempting, which is very affordable, as well as

Tweaking 3d printer settings, flow and extruder settings

Category: 3D printingBy Editor 0

A bit of math in print settings. The article describes 3 interesting settings that are calculated using formulas.

The article describes 3 interesting settings that are calculated using formulas.

The ultimate guide to polycarbonate 3d printing

Category: 3D PrintingBy Editor 0

Do you know what is Polycarbonate 3D Printing? The Ultimate Guide to will tell you everything.

Printing of blood vessels or 3D bioprinting of organs

Heading: 3D printingAuthor: Editor 0

3D printing of blood vessels - a technology with promise or another experiment with consequences? About a new technology for growing cell material

How to choose a filament for 3d printing. abs or pla?

Category: 3D printingBy Editor 0

What is better PLA or ABS? What material to choose for 3D printing?

3D printing with polypropylene PP: temperature, speed, 3D printer settings

Category: 3D printingAuthor: Editor polystyrene), PETG, SBS, Flex, Nylon, PC, Wood, Metal, bioFila, Conductive, Ceramo, Carbon Fiber, PMMA, PP

Overview of high temperature fdm plastics for industrial 3d printing

Heading: 3D printingBy Editor 0

The scope of application of additive technologies is wide: on one extreme - desktop printers "only PLA", for decorative use, on the other - installations for direct printing with metals, between them -. ..

..

Possibilities of modern 3d printing

Heading: 3D printingAuthor: Editor 0

Learn more about 3D printing methods and areas of its use. Possibilities of modern 3D-equipment, overview of popular technologies.

3d printer: what is it and how does it work?

Heading: 3D printingAuthor: Editor 0

How does a 3d printer work and what is it - definition, characteristics. Description of the capabilities of a 3D printer, who invented it - GeekBrains experts say.

3d figurines from a photo

Category: 3D printingAuthor: Editor 0

3d figurines from a photo It is possible to create your own small copy or another person who would like to give an original gift.

6 3D printing technologies that will increase the competitiveness of your business

Category: 3D printingBy Editor 0

3D printing and additive manufacturing: read an overview of the main technologies in one article! Pros and cons, industries, materials, implementation examples. Additive technologies in production can significantly reduce time

Additive technologies in production can significantly reduce time

Programs for preparing a 3d model for printing on a printer

Heading: 3D printingAuthor: Editor 0

We talk about programs for a 3D printer in Russian and English, paid and free versions.

anycubic vyper 3d printer review

Category: 3D printingBy Editor 0

We're back with another review of AnyCubic 3D printer. Last time we reviewed Mono X, one of AnyCubic's MSLA Printers. This time we tried

Prusa i3

Category: 3D-pacifier: Editor 0

Original Printer In-Depth ReView 9000 Capricat: 3D-sheet: EDDITOR 0

Is the Original PRUSA SL1 worth it? Discover this 3D printer's features, quality, and pros and cons in our detailed review to know more.

What is a 3D printer, what can it do and why is it needed at all? Take 3D printing for example! It's time to understand how the 3D printer works

Configuring the marlin firmware for the creality3d cr-10s 9 printer0003

Category: 3D printingAuthor: Editor 0

Marlin Firmware for Anet A8 org from https://github.com/MarlinFirmware/Marlin - GitHub - cyclemat/Marlin-2.0.0-for-Anet- A8-: Marlin Firmware for Anet A8 org from https://github.com/MarlinFirmware/Marlin

Overview of 3D Printing Consumable Manufacturers

Category: 3D PrintingAuthor: Editor 0

Brief Overview manufacturers of polymer filaments for 3D printing: Rec, SEM, BestFilament, PP3DP and ESUN.

How to dry the filament. do-it-yourself dryer for plastic

Category: 3D printingAuthor: Editor 0

How to dry the filament. DIY plastic dryer

DIY plastic dryer

Guide to choosing the right filament for 3d printing

Category: 3D printingBy Editor 0

their low price and ease of handling..

Homemade extruder for a 3d printer (works on granules)

Heading: 3D printingAuthor: Editor 0

Types of extruders for 3D printers and how they work. How and from what you can make individual extruder blocks with your own hands

Speed, acceleration and jerks of 3D printing: 3D printer settings, possible defects

How to clean the head of epson, canon, hp and other printers: working methods for cleaning nozzles (nozzles)

Sensor bltouch electrical circuit