Envision one 3d printer cost

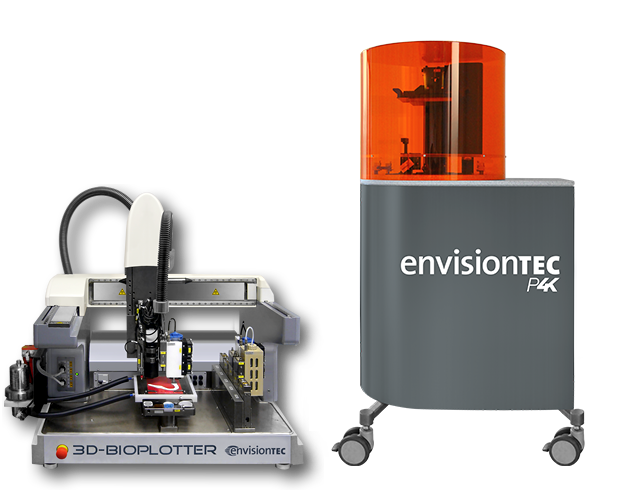

Best Dental 3D Printer: Envision One cDLM

New 3D printing technology is revolutionizing many industries – and dental is no exception. The Envision One cDLM dental is the best dental 3D printer on the market. This printer has best-in-class accuracy and uses patented advanced DLP technology to produce prints with a beautiful smooth finish. Plus, with the ability to use a variety of materials, this printer can be used for a range of dental applications include models, castables, restorations, and appliances.

Not sure if the Envision One cDLM is right for you?

Try our 3D printer selection wizard to find the right printer for your needs.

Launch

Envision One cDLM Dental Details

Features and Benefits

The Envision One cDLM Dental printer uses advanced DLP technology that makes it possible to print bigger and smoother parts, faster than traditional DLP or SLA methods. It also prints at an extremely high resolution. These elements together mean prints require no post-processing – tasks that can quickly diminish all of the productivity improvements offered by 3D printing in the first place.

The advanced features in the Envision One cDLM Dental provide numerous benefits:

- Incredible printing speeds make it possible to print 6 orthodontic arch models in 15 minutes and 10 dentures in an hour

- Require 75% less supports compared to traditional DLP printers

- Utilizes a high-resolution industrial projector with UV optics

- Domeless technology makes it possible to have the highest accuracy in Z

- Layerless technology provides an incredibly smooth finish

- The LED light source wavelength allows for higher accuracy on clear parts and crisper details overall

- Dual linear slides increase stability during the building process – removing any risk of part shift

Specs

| Build Size | 180 x 101 x 85 mm (7.09 x 3.98 x 3. 35 in.) 35 in.) |

| Build Speed | Up to 45 mm/hour* |

| Native XY Resolution | 93 µm |

| XY Resolution with Contour Gray Scaling | 60 µm |

| Dynamic Z Resolution | 50 µm to 150 µm* |

| Price | Starting at $20,000 |

*material dependent

The Envision One cDLM dental creates parts with incredible detail and a smooth finish that eliminates the need for post-processing.

Best Dental 3D Printer Materials

The best dental 3D printer will obviously be supported by state-of-the-art materials. The Envision One cDLM Dental is compatible with:

- ABS Tough

- E-Guard

- E-Guide

- E-Guide Tint

- E-Gum

- E-Model

- E-Model HS

- E-RigidForm

- KeySplint Soft for EnvisionTEC

- NextDent C&B MFH

- NextDent Denture 3D+

- NextDent Tray

- Press-E-Cast

Applications

The Envision One cDLM can be used for a variety of both dental and orthodontic applications. Depending on design and material, users can quickly create:

Depending on design and material, users can quickly create:

- Models

- Castables

- Direct crowns and bridges

- Bite splints

- Nightguards

- Indirect bonding trays

- Surgical drill guides

- Flexible gingiva masks

- Denture bases

- Diagnostic wax-ups

Lower Costs and Increase Competitiveness with the Envision One cDLM Dental

Adding the best dental 3D printer to your dental business gives you a competitive edge. Dentists can decrease overall costs, provide more convenient care, and have more control over treatment. Dental labs have an opportunity to produce more work faster to increase competitiveness and re-shore production. Starting at just $20,000 the Envision One cDLM Dental is worth the long-term investment for your practice or lab.

Support your dental business with the best dental 3D printer – the Envision One cDLM dental.

Ready to purchase the best dental 3D printer?

Buy Now

Have questions? Just fill out the form below.

Previous

|

Next

Get in touch!

Have a question? Want to learn more? Ready to Buy Now? Contact us.

Our support team will get back to you within 1 business day.

Subscribe to Digital Transformation Digest:

- Email*

Search for:

EnvisionTEC One/Vida vs. Formlabs Form 3/3B

Skip to Main Content

Scale prototyping and production as your business grows with the Form 3+ and the Form 3B+, affordable, easy to use, and industrial-quality 3D printers.

Request a Free Sample PartBuy Now

Printer

Price

Starting at $3,500

Transparent pricing with no hidden fees. Buy directly from Formlabs via sales or the online store, or locally from a worldwide partner network.

Starting at $17,000

Complicated and opaque pricing, requires multiple quote requests and negotiation.

Technology

Low Force Stereolithography (LFS)™

This new generation of stereolithography (SLA) 3D printing uses lasers to cure liquid resin into hardened plastic to produce high-accuracy, isotropic, and watertight prototypes and parts with a smooth surface finish.

Continuous Digital Light Manufacturing (cDLM)

cDLM is a type of Digital Light Processing (DLP) 3D printing. It works similarly to SLA, but uses a digital projector screen to flash an image of a layer across the entire platform, curing all points simultaneously. There’s a direct trade-off between resolution and build volume, and as a result, EnvisionTEC printers offer a small build volume to retain a resolution close to what SLA can achieve.

Build Volume (W × D × H)

Form 3+/3B+:

14.5 × 14.5 × 18.5 cm

5.7 × 5.7 × 7.3 in

One cDLM:

18 x 10.1 x 17.5 cm

7.09 x 3.98 x 6.89 in.

Vida cDLM:

14.5 x 8.1 x 10.0 cm

5.7 x 3.2 x 3.94 in

Resolution

Accurate, repeatable prints with a smooth surface finish

25-200 microns Z resolution

25 micron XY resolution

Accurate, repeatable prints with a smooth surface finish

25/50-150 micron Z resolution

76/93 micron XY resolution

Materials

30+ functional resins

A wide range of materials for prototyping from soft silicone-like to flexible, tough, durable, and rigid varieties. Specialty materials for high-temperature applications and castable patterns. A variety of dental resins, including biocompatible materials.

Specialty materials for high-temperature applications and castable patterns. A variety of dental resins, including biocompatible materials.

25+ functional resins

A wide range of materials for prototyping from soft silicone-like to flexible, tough, durable, and rigid varieties. Specialty materials for high-temperature applications and castable patterns. A variety of dental resins, including biocompatible materials.

Setup and Requirements

Plug and print

Contact-free delivery and online or in-person training for the entire team. Compact, desktop size, with no special facility requirements. Quiet operation.

Involved

Setup and training with on-site installation recommended. The printer requires an air compressor, which is too loud for an office environment. The full solution takes up considerably larger space.

Ease of Use

Simple

Easy workflow empowers anyone at your company to use the system independently after less than one hour of training.

Complex

From having to manually refill materials to the lack of automated post-processing solutions, each step of the workflow is more labor-intensive, less user-friendly, and has a steeper learning curve.

Software

Free and easy to use

Formlabs' free print preparation software, PreForm, automatically suggests optimal orientation, supports, and layout, with the ability to manually refine as needed. Try it now. You can also use the online Dashboard to manage printers, materials, and teams.

Paid updates

EnvisionTEC’sOne RP print preparation software offers a range of basic and advanced features, but very limited options for fleet management and job tracking. New software updates (even bug fixes) require a paid service contract.

Service

Pro and Dental Service

Premier support service with fast response time, customized training, replacement printer, and extended warranty—all for an affordable price. Free email support without a service plan. Customized dental service by a dedicated team of certified dental specialists for dental customers.

Free email support without a service plan. Customized dental service by a dedicated team of certified dental specialists for dental customers.

Mandatory contract

An expensive service contract is in effect required to have access to service and software maintenance. Service plan doesn’t include replacement printer. Without a plan, there’s only paid support beyond the warranty period and no updates.

Company

Formlabs adapted the SLA technology to the desktop in 2011 and has since become the market leader, selling more than 70,000 printers as of today.

EnvisionTEC primarily offers industrial 3D printers that are limited to large companies due to their high price.

Do you have more questions about the differences between these solutions?

The Industry-Leading Desktop 3D Printer, Powered By Low Force Stereolithography

Learn More

A Next-Generation Dental 3D Printing Ecosystem and Certified Workflows From the Leader in Dental 3D Printing

Learn More

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

We’ll ship a free sample part to your office.

Request a Free Sample Part

Buy a fleet of 4-8 Form 3+s or Form 3B+s or 1-2 large-format Form 3Ls for the price of a single EnvisionTEC printer to scale your throughput, be able to print different materials simultaneously, and have peace of mind to avoid downtime.

Buy Now

Reduce costs, iterate faster, and bring better experiences to market with our advanced 3D printing materials designed to deliver beautiful final parts for a wide range of applications.

Printer

Material

Print Time

Print Cost

Buy Now

3D printing cost calculation

Although I posted the link in the discussion of the parallel topic of comrade 3D_MPL (Cost of 3D printing. Calculator for calculating from 3D-MPL), I thought it would be better to make a separate post to get feedback.

So please make constructive (!) suggestions. I will answer any questions on the topic.

.

So.

Again and again the question arises of how to calculate the payment of your labor as correctly as possible. Although some of the details seem simple, they often require a lot of brain effort, which MUST be paid. Well, the time spent too. nine0003

.

Some people think that it is enough to take into account the weight of the part - I think this method is simply fundamentally wrong, because, for example, printing a vase / box with a 1mm nozzle and a 0.6mm layer will be faster than printing some highly detailed bracket in a car or a souvenir with a 0.2mm nozzle and a 0.05mm layer. So, with the same weight, the time can be many times (tens of times) longer! Yes, and draw a different bracket, you must be able to!

Moreover, we want our many hours of work to be adequately paid. nine0003

A typical example from my practice is a kettle handle.

The detail is shapeless, you don't know how to approach it in order to draw it. The result - 7 hours of modeling, 4 hours of printing, an hour of post-processing, 57 (total!) Grams of plastic. And now, imagine, a customer comes to you, 'Why is it so expensive??? It's only 57 grams!!!'. And you lost a whole day (work shift).

The result - 7 hours of modeling, 4 hours of printing, an hour of post-processing, 57 (total!) Grams of plastic. And now, imagine, a customer comes to you, 'Why is it so expensive??? It's only 57 grams!!!'. And you lost a whole day (work shift).

.

So, I think that the main resource that should be paid for is time!

.

And here, in fact, is the table. nine0003

Link to Yandex Disk: https://yadi.sk/i/oy1r3v_dA-8E1w

.

By the way, I update the table from time to time! I recently discovered an inaccuracy in the calculation of the cost of the material, corrected it. So follow the link and check it out.

.

Some characteristics:

Time is written conveniently - in hours and minutes.

Modeling and post-processing cost per hour.

Separately, the weight and cost of the coil are written - no need to calculate the cost of a kilogram (for lazy people). nine0003

The so-called 'difficulty factor' is missing from the table. The complexity itself will be formed from: modeling time (mostly), printing time (necessary detailing), post-processing time (picking out supports from hard-to-reach places, painting, etc.).

The complexity itself will be formed from: modeling time (mostly), printing time (necessary detailing), post-processing time (picking out supports from hard-to-reach places, painting, etc.).

Substitute the values that are convenient for you. I don't insist on these. Columns 'Prices' and 'Costs'.

The white numbers in the 'Total' column are reference numbers, just for convenience.

Depreciation is calculated from the time of direct operation of the printer (more work - more wear). I take half a dollar. nine0003

The price of the first part differs from the subsequent ones only by taking into account the simulation time.

Printer power is taken to the maximum - pennies still come out.

Currency - rubles. You can change to yours.

When you write the price for a reel, you must also take into account the cost of delivery! (In our outback, the delivery of one coil is 500 rubles!) I can add the 'delivery' item for convenience, if you want.

.

I advise you not to show this table to the client. Unless if he thinks that it is too expensive, it must be recalled that he would not agree to work for 100 rubles / hour (or how much you put). And you yourself know that the client wins if he buys one spare part instead of a whole expensive unit. See for yourself. nine0003

Sometimes, on the contrary, it is possible to raise the price for the same reasons)))

.

Let me add a little about the cost of the actual filament.

Even the most expensive filament does not affect the final cost so much. Substitute in the table, for example, Bestfilament PLA (1350 rubles / kg) or Filamentarno CF-5 (3300 rubles / kg).

Here is a well-known detail. Bosch meat grinder safety clutch:

Its weight is 9 grams.

Calculate the cost of material only:

Bestfilament PLA - 7 rubles. (don't make such a thing out of it! :o)

Filamentafno CF-5 (as in the photo) - 30 rubles.

.

PS: The table is not designed for big business, but rather for a part-time job/money hobby.

.

Everything for everyone!

up to 10 materials per model / Sudo Null IT News

MIT has developed a 3D printer that can print ten materials at once. The company wants the device to be able to print fully functional objects such as printed circuit boards soon. nine0095

Article Mary-Ann Russon from Ibtimes.co.uk translated for you by Top 3D Shop .

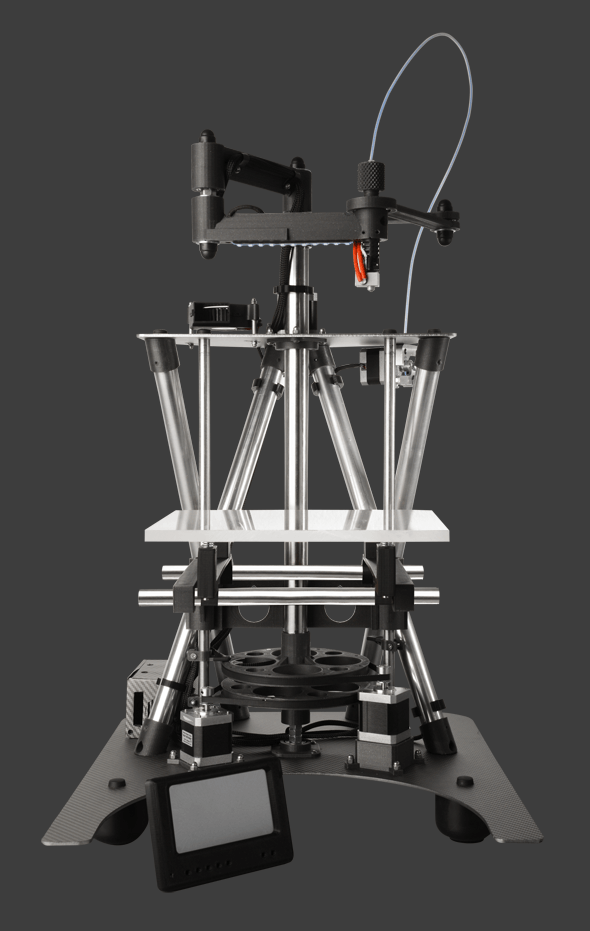

Researchers at the MIT Computer Science and Artificial Intelligence Laboratory (CSAIL) have made a breakthrough in 3D printing by developing a prototype 3D printer that can use up to 10 different materials simultaneously on a single object.

At the moment, most 3D printers can print only one material during one process, many can already print two, and very rare models can print three or five. Multi-material 3D printers have existed before - Stratasys launched the world's first full-color multi-material 3D printer in January 2014. He was able to print rubber and plastic objects, but his problem was the extremely high cost ($250,000). Another disadvantage of this solution is that it still required human intervention in the printing process. nine0003

He was able to print rubber and plastic objects, but his problem was the extremely high cost ($250,000). Another disadvantage of this solution is that it still required human intervention in the printing process. nine0003

MIT's new 3D printer, the MultiFab, doesn't have these drawbacks. It's a $7,000 all-in-one system that can quickly print multi-material objects with no operator intervention required.

How MultiFab works

During printing, the printer monitors the progress of work, for this it uses three-dimensional machine vision.

The data received from optical sensors allows the 3D printer computer to independently calibrate the device and correct errors that occur. nine0003

Specialized components such as electronic components can be added to the model during printing. The device will continue to print around these components, including them in the final product.

“With MultiFab, we have combined two worlds – traditional manufacturing and 3D printing. We will be able to make a number of new objects that were impossible to create until recently.

We will be able to make a number of new objects that were impossible to create until recently.

Right now, 3D printers are mainly used for prototyping, creating injection molds and other types of blanks, but MultiFab will create full-fledged functional objects by combining several materials with different properties,

said Javier Ramos, research engineer with CSAIL and co-author of the research paper.

Modern electronics in the future

LED lenses that were 3D printed using MIT MultiFab.

So far, CSAIL researchers have already succeeded in printing LED lenses, a plastic metal blade holder, and smartphone cases that are printed right around the gadget. The developers believe that MultiFab will find its application in the production of consumer electronics, medical imaging and telecommunications. nine0003

The next step for researchers is to 3D print objects with built-in motors and actuators. If the finished products can function, it will open up opportunities for 3D printing in advanced electronics such as building robots.