Electronic 3d printing

What are 3D Printed Electronics? Let us tell you...

Design

The complexity of electronics combined with the capabilities of 3D printing. Heard of 3D printed electronics but want to know more?The ability to 3D print electronics is making waves in an industry plagued by long stints of R&D and a never ending cycle of prototypes and new releases.

But what exactly does this process entail? And how, as a designer, architect, or artist, can it help you? Is it sustainable? What are the dangers? And what should you know about it?

This guide is a useful starting point for you to find out…

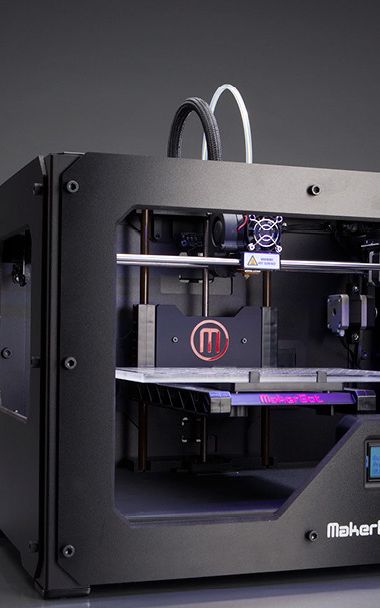

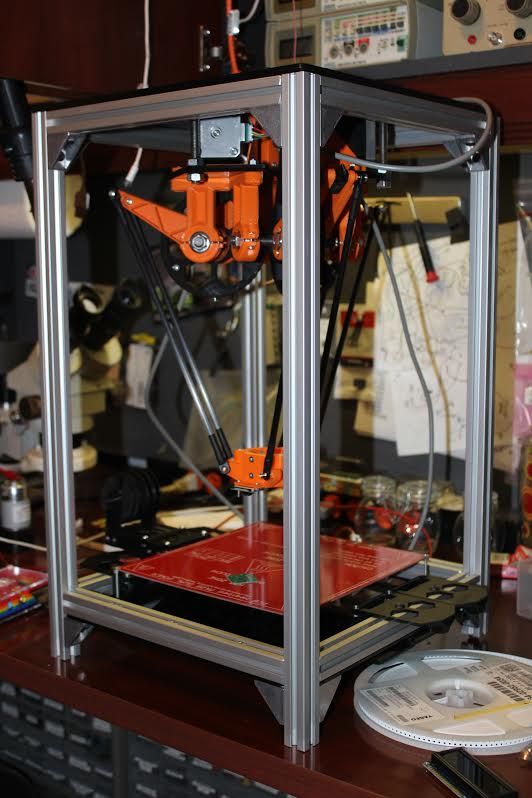

With 3D printing electronics it is possible to make various types of boards that can be programmed and connected to prototypes – ©iakovenko123/Depositphotos.3D Printing objects with electronic functionality is a relatively new concept.

It involves the use of material jetting technology, which is used to jet conductive and insulating inks onto the printing surface.

These inks are applied in lines as thin as a few microns before UV light is used to solidify the inks.

The use of material jetting facilitates multi-material 3D printing, which is particularly useful for the electronics industry.

This means that the different elements necessary in electronics, such as functional circuitry and enclosures, can be manufactured in a single print run.

3D printing electronics involves the use of material jetting technology, which is used to jet conductive and insulating inks onto the printing surface – ©IgorVetushko/Depositphotos.comWhat materials are used when 3D printing electronics?Where systems could typically use just one material in the 3D printing process, recent advancements have enabled the involvement of multiple materials.

This allows manufacturers to merge conductive materials with non-conductive materials.

The thermoplastics used in the 3D printing process are often made with copper, carbon and graphene.

Meanwhile, proprietary conductive and dielectric inks are used simultaneously to build functional circuits and antennas. This expands the range of functions in 3D printed electronics.

Because the process combines multiple materials into the same 3D object it also requires a solvent to ensure their compatibility. The particular solvent used is known as an orthogonal solvent, which is specifically designed not to cause damage to the different components.

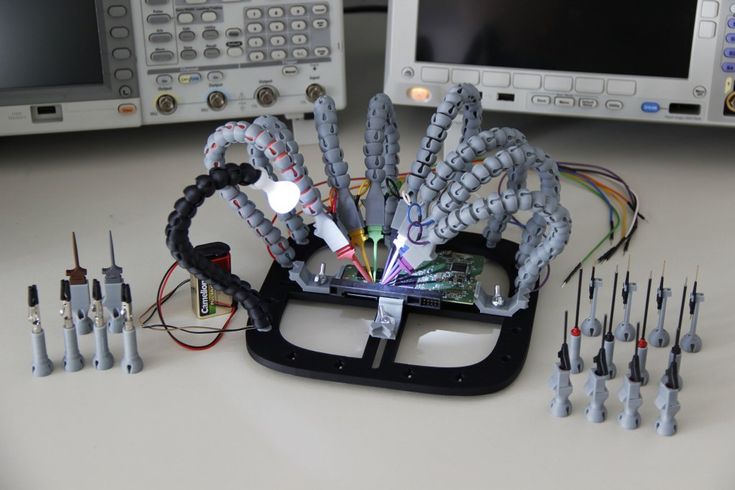

The thermoplastics used in the 3D printing process are often made with copper, carbon and graphene – © Julian Pagliaccio, via Wikimedia CommonsWhat can 3D printing electronics produce?With 3D printing electronics, it is possible to make various types of boards that can be programmed and connected to prototypes.

A very wide range of inks can be utilized enabling a full range of printed electronics functionality: conductors, semiconductors, dielectrics, resistors and more.

The process can be used to manufacture electronic components such as resistors, capacitors, antennas, sensors, and thin film transistors.

Using the 3D printing process, it is also possible to rapidly 3D print fully functional electronic circuits that contain electrically-conductive metallic inks and insulating polymeric inks, which could be useful for medical devices, radio frequency shielding surfaces and novel structures for harvesting solar energy.

Today, however, it’s main applications include printing electronics for use in prototypes for upcoming products, prosthetics and more complexly shaped electronic products.

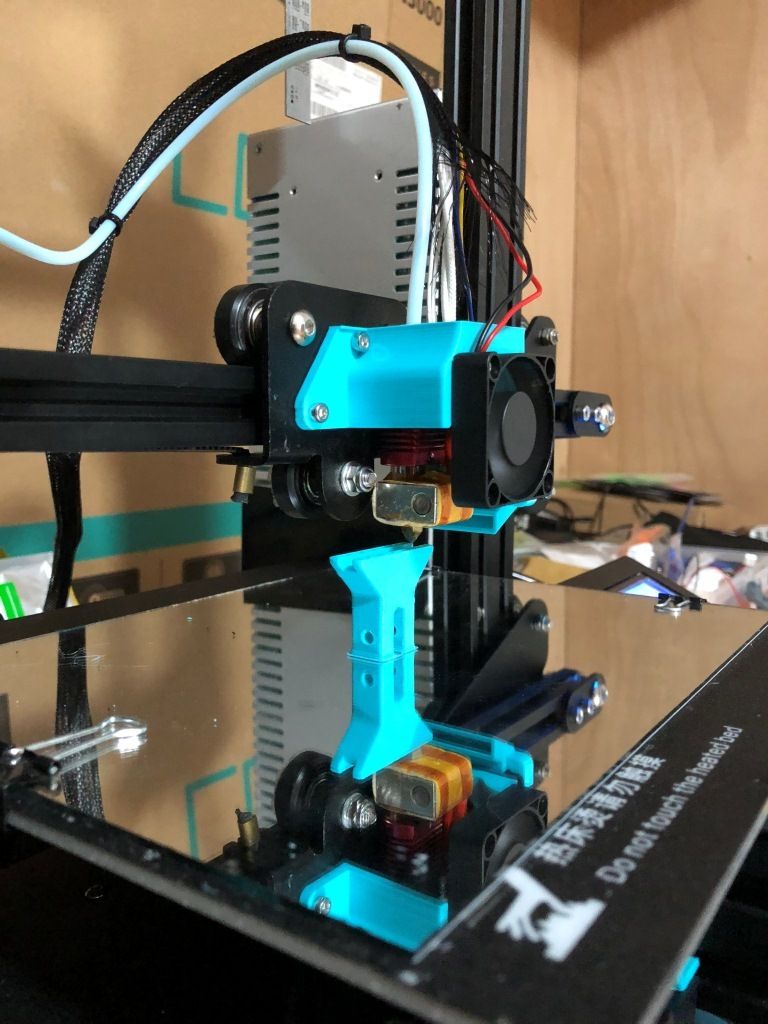

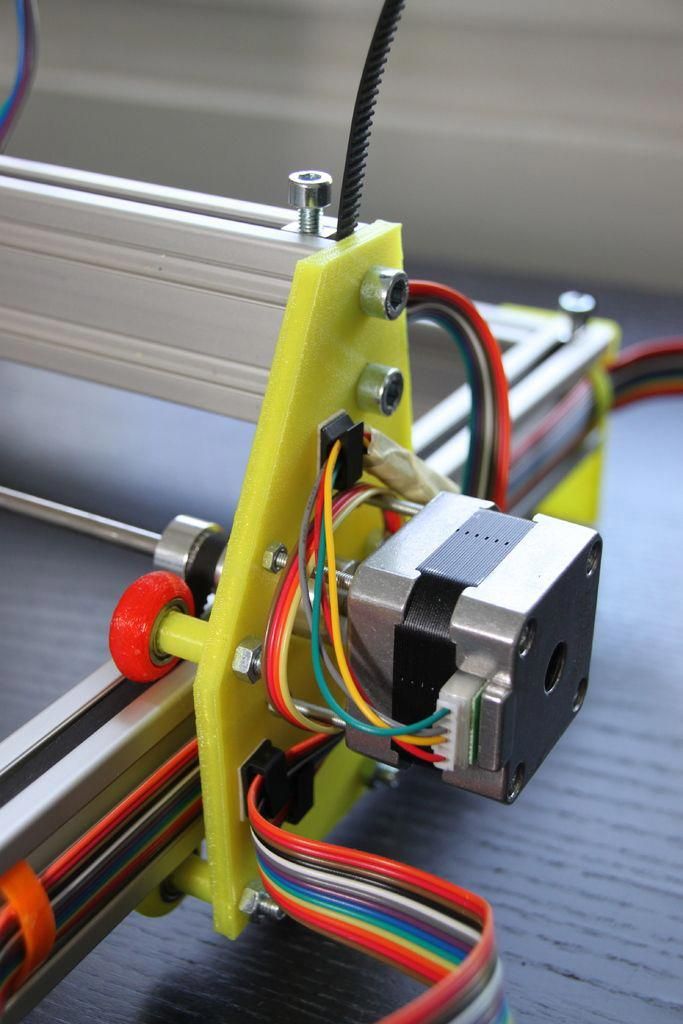

Give me a step-by-stepWhile several methods exist for 3D printing electronic components, they typically mirror the various steps utilised in regular 3D printing. The main difference is the use of a dual-material fused filament process with conductive thermoplastic filaments.

The main difference is the use of a dual-material fused filament process with conductive thermoplastic filaments.

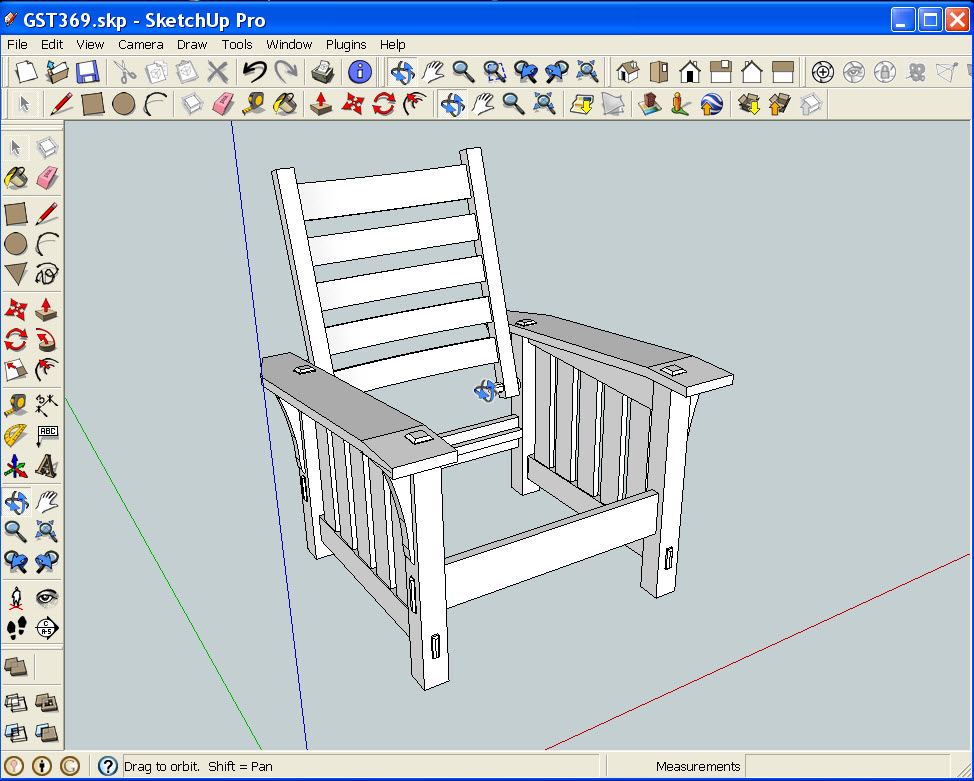

As with all 3D printing, a digital CAD model of the desired part is designed, which serves as the printer’s instruction model.

When the printing process begins, a trace or “fingerprint” is created, and then the requisite materials needed for that specific part are added in layers.

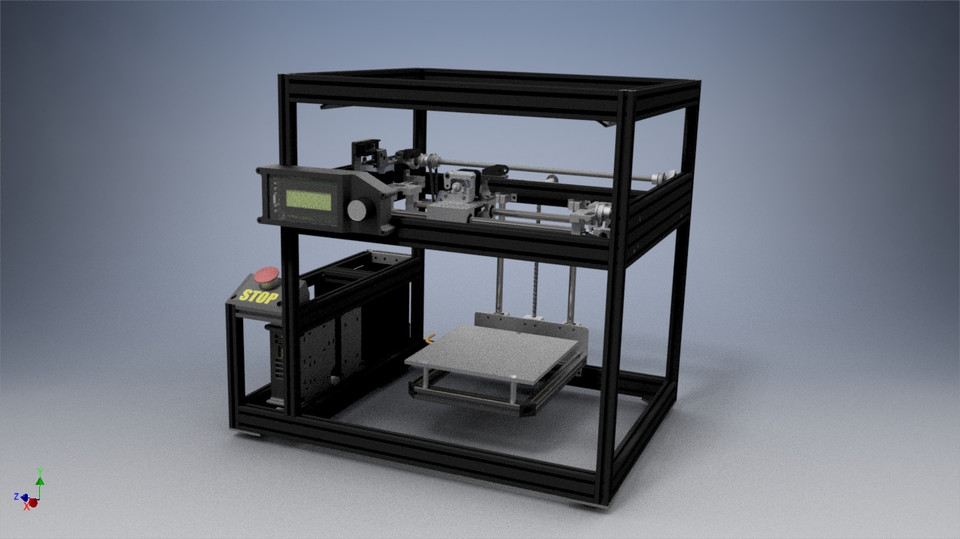

The process flow of the 3D systemWhat machinery is used when 3D printing electronics?Specialised machinery is required which integrates a precise inkjet deposition printer with dedicated nano-inks and software capable of printing electronic circuits such as printed circuit boards (PCBs), antennas, capacitors and sensors.

Can I do it at home?Due to the complexity of the process, it is not possible to replicate it at home unless you have the capability of manufacturing your own 3D printer.

With the relevant machinery, it is possible to 3D print electronics at home.

Find out more about manufacturing processes, don’t miss What is Explosive Forming? Let us tell you…

The benefits of 3D printing electronics range from faster time-to-market, greater freedom of design and customizationWhat are the pros & cons of 3D printed electronics?At the core of every electronic device is a Printed Circuit Board (PCB) which is difficult to produce. Luckily, with the advent of 3D printing, manufacturing these circuit boards is less challenging.

The benefits of 3D printing electronics range from faster time-to-market, greater freedom of design and customisation.

This is because with the advent of 3D printing electronics manufacturers can create prototypes of circuits and circuit birds in-house, reducing procurement expenses and eliminating concerns about IP infringement.

3D printing also opens up opportunities to design complex shapes and components. For example, multilayer circuits can now be 3D printed on non-flat, flexible surfaces, which would not be possible with traditional manufacturing techniques.

Components can also be printed onto 3D surfaces eliminating the need for a separate substrate and reducing the size, thickness and weight of the end product.

However, there are several limitations when it comes to 3D printing electronics, not only because it is limited in the types of parts it can produce.

Whilst the recyclability of 3D printed electronics is an area being explored by various researchers, it remains a con due to what is currently possible.

Another downside to 3D printed electronics, and in fact, all 3D printed products is their structural integrity.

Whilst printed layers adhere together in some cases, and under certain stresses or conditions, they can delaminate.

Another major downside to 3D printing as a whole is its increasing popularity and accessibility. On one hand, it democratises the manufacturing processes but it also makes it easier to fake and counterfeit products.

I want to know if it’s sustainable…Whilst 3D printing electronics can minimise the manufacturing footprint by localising production, the difficulty in recycling the various components means it can’t be considered a sustainable process.

There are several resources that are useful when it comes to building your knowledge around 3D printed electronics.

If you want to learn more check these out:

- A visual demonstration of the 3D printing process used to manufacture electronics.

- An explanation of the various capabilities of 3D printing electronics.

- A paper detailing the evolution of 3D printing electronics.

- A breakdown of the various benefits and current systems employed when 3D printing electronics

- A detailed research into the future of 3D printing electronics and its benefits when used for prototyping.

Fascinated by 3d printing? Don’t miss 3D printing ceramics: Interview with Hilda Nilsson.

3D printing electronics: Transforming the electronic industry

3D Learning Hub

See all categories

Contents:

- Introduction

- What are the advantages of 3D printing for electronics?

- 3D printing with electrostatic discharging properties

- Conductive 3D printing offering new opportunities

- 3D printed electronics: What is possible?

- What about the future of 3D printing in the electronics industry?

Introduction

What are the advantages of 3D printing for electronics?

3D print the perfect prototype

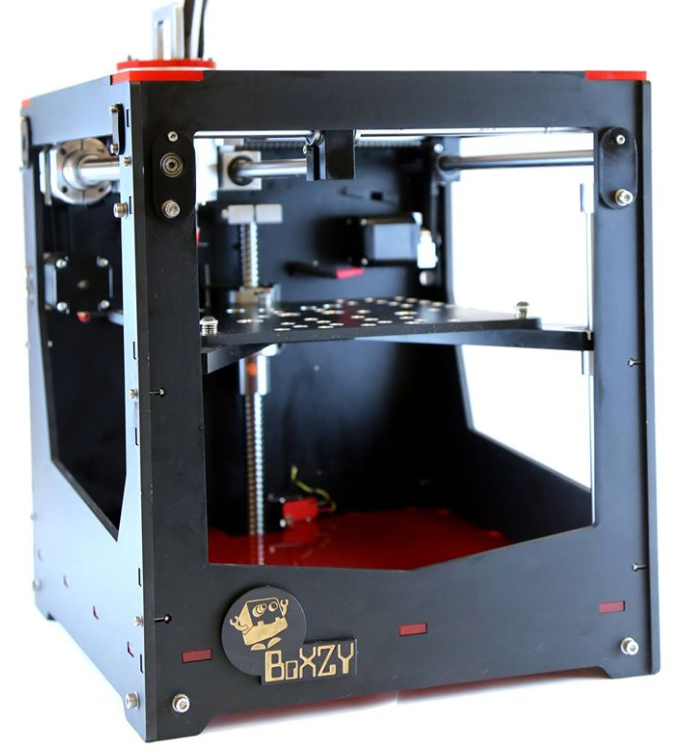

3D printing helps you get from the idea to the product in a matter of days. Thus, 3D printing electronic devices appears to be really interesting. The professional 3D printers used by Sculpteo’s online 3D printing service allow you to create high-quality casings for your devices with the highest level of details. They will perfectly match your electronics components such as a circuit board. Rapid prototyping is also made easy thanks to the 3D printing process and will allow you to build the best product designs.

Thus, 3D printing electronic devices appears to be really interesting. The professional 3D printers used by Sculpteo’s online 3D printing service allow you to create high-quality casings for your devices with the highest level of details. They will perfectly match your electronics components such as a circuit board. Rapid prototyping is also made easy thanks to the 3D printing process and will allow you to build the best product designs. Launch your first series

Moreover, the electronics industry can truly benefit from additive manufacturing. No stock, no minimum number of units and short turnaround are the key upsides of using Sculpteo’s 3D printing service for your electronic devices, regardless of where they are in product life cycle management. Electronic production is made easy thanks to our 3D printing technology and will improve and simplify your whole supply chain management! 3D printing and electronics are strongly linked. Online 3D printing allows you to create a new kind of relationship with your clients. You can easily produce small series, limited editions and spare parts in a small batch. Whether you’re looking for just a prototype or a thousand units, your 3D printing product will benefit from our experience and know-how to achieve the best quality.

You can easily produce small series, limited editions and spare parts in a small batch. Whether you’re looking for just a prototype or a thousand units, your 3D printing product will benefit from our experience and know-how to achieve the best quality. Design freedom

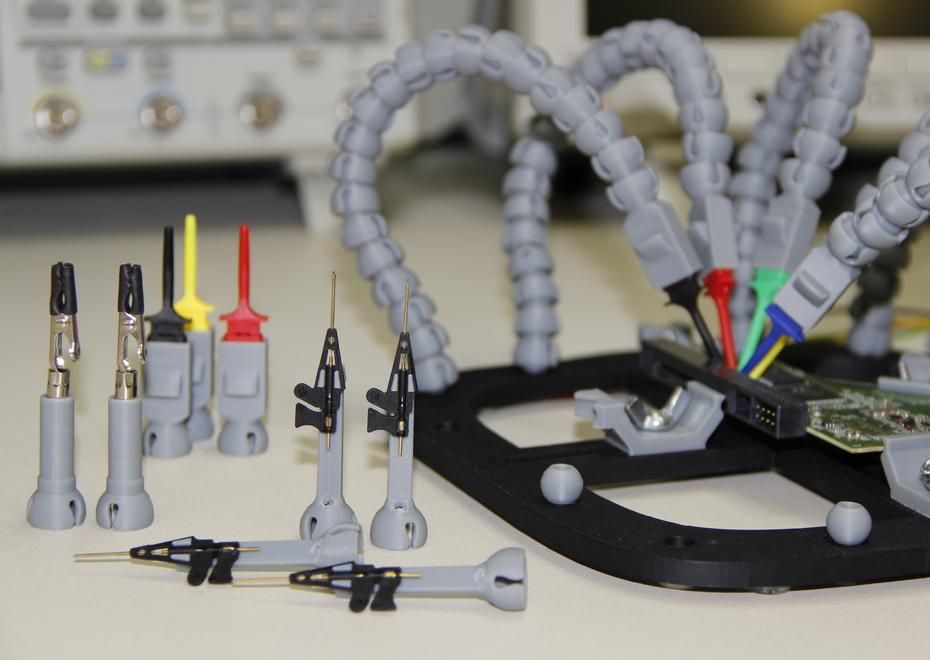

Electronic components production can now be thought in terms of 3D design and not only 2D, with new ways of stacking the circuits. It opens new possibilities to design for electronics, that are new to explore! Customization is becoming a big asset while using additive manufacturing for the creation of your products: you can create parts perfectly adapted to a circuit board or any electronic device. 3D printing can be used to create personalized electronic enclosures, USB stick cases, and keyboards, for example. Using additive manufacturing also offers you flexibility in the creation of your design. More than a perfectly adapted device, you can also elaborate complex geometries impossible to make with other traditional manufacturing techniques. With 3D printing, you can also make the most of parts that don’t require any assembly process!

With 3D printing, you can also make the most of parts that don’t require any assembly process! 3D printing with electrostatic discharging properties

What is an electrostatic discharge?

What is called “electrostatic discharge” (ESD) is the flow of electricity between two electrically charged parts causes by contact. Static electricity often causes ESD through a process known as tribocharging. This static electricity can arise when surfaces rub together and this results in an excess of electrons on one surface and a deficiency on the other. The ESD occurs when differently-charged objects are brought close together or when the dielectric between them breaks down, often creating a visible spark. Electrostatic Discharges are a real problem and can damage sensitive electronic components. It can also lead to the alteration of magnetic media and set off fires, explosions in flammable environments! ESD is a big concern for the electronic industry, and being able to manufacture ESD-safe part is a real advantage to avoid any problem.

Focus on: Ultrasint PA 11 ESD

At Sculpteo, we are now offering you the possibility to manufacture your ESD-safe parts. If you are prototyping or producing a project where electrostatic discharging safety is critical, our Ultrasint® PA11 ESD material will be a perfect choice. Ultrasint® PA11 ESD is a bio-derived material, appearing to be a perfect choicel for increased process safety in advanced applications. With its interesting mechanical properties, this material offers new possibilities for a wide range of new applications, especially for the electronics sector. Indeed, with its low resistivity, Ultrasint® PA11 ESD is reducing the risk of electrostatically induced damage or failures, the material does not accumulate static electricity and can come in contact with electronic components without running any risk. The surface resistivity of Ultrasint® PA11 ESD is lower than traditional electrostatic dissipating materials. You can now make the most of the advantages of both additive manufacturing and electrostatic discharge properties. For electronic housing, electronic jigs and fixtures, this material is perfectly adapted. PA 11 ESD also as other advantages and interesting mechanical properties such as high tensile strength and elasticity, which could help you create efficient tools. What are you waiting for? With this material, you can create parts combining superior mechanical and thermal characteristics with outstanding electrostatic discharging properties. Get your parts 3D printed with Ultrasint® PA11 ESD by uploading your 3D file on our 3D printing service right now. It will only take a few clicks and you will get an instant quote.

For electronic housing, electronic jigs and fixtures, this material is perfectly adapted. PA 11 ESD also as other advantages and interesting mechanical properties such as high tensile strength and elasticity, which could help you create efficient tools. What are you waiting for? With this material, you can create parts combining superior mechanical and thermal characteristics with outstanding electrostatic discharging properties. Get your parts 3D printed with Ultrasint® PA11 ESD by uploading your 3D file on our 3D printing service right now. It will only take a few clicks and you will get an instant quote.

Conductive 3D printing offering new opportunities

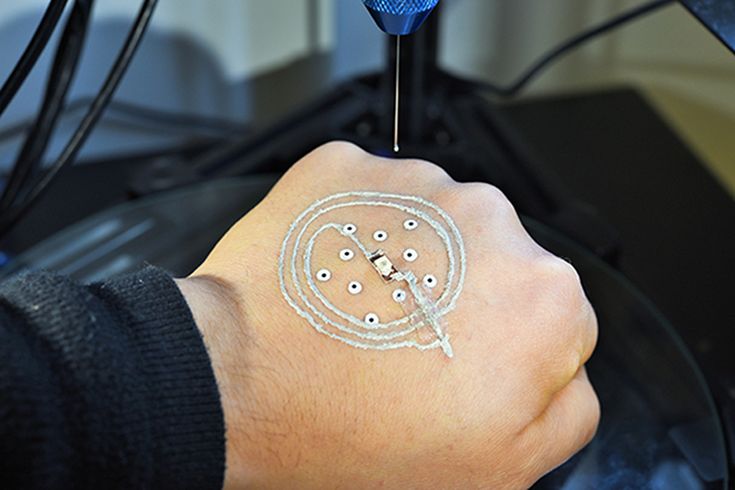

3D printing complex electronic components could go even further with conductive 3D printing. The creation of electronic devices with conductive features using 3D printing can particularly be useful to develop IoT (Internet of Things) projects. This innovative technology could allow creating 3D printed devices like LED, or touch sensors. But this ability to 3D print conductive devices could be involved in bigger projects, in soft robotics, 3D electronics, and also for communication devices such as 3D printed Near Field Communication (NFC) antennas.

But this ability to 3D print conductive devices could be involved in bigger projects, in soft robotics, 3D electronics, and also for communication devices such as 3D printed Near Field Communication (NFC) antennas.

3D printed electronics: What is possible?

As you will see, this 3D technology can be used for various applications in the electronics industry. Get inspired by these innovative electronic devices made using additive manufacturing!

3D printed circuit board by Nano Dimension and Harris Corp: 3D Printed Circuit Boards

Nano Dimension is known to work actively on 3D printed electronic devices The Nano Dimension’s DragonFly™ system is used to 3D print functional electronics prototypes and complex multi-layer Printed Circuit Boards (PCBs). But that is not all.

Nano Dimension and Harris Corp partnered to develop 3D printed electronic devices to create a radio frequency (RF) amplifier. They now work to go further and create hardware for the International Space Station. Their goal is to optimize the 3D printing process for RF components for flight studies aboard the ISS. Using additive manufacturing is a solution for them to find new ways to create radio frequency and circuit boards to find new innovative techniques.

Their goal is to optimize the 3D printing process for RF components for flight studies aboard the ISS. Using additive manufacturing is a solution for them to find new ways to create radio frequency and circuit boards to find new innovative techniques.

The Simusolar project

At Sculpteo, some of our customers are working on solar energy using 3D printing. On the blog, we already told you about Simusolar, a company created in 2014 and looking to bring solar energy to the rural population of Tanzania. They develop and implement small-scale sustainable solutions to help local people in their everyday life.

They decided to use 3D printing because they needed a lot of custom made parts, for a low price. Their clients are farmers, fishers, or rural residents looking for various equipment powered by solar energy.

Optomec developing the Aerosol Jet Technology

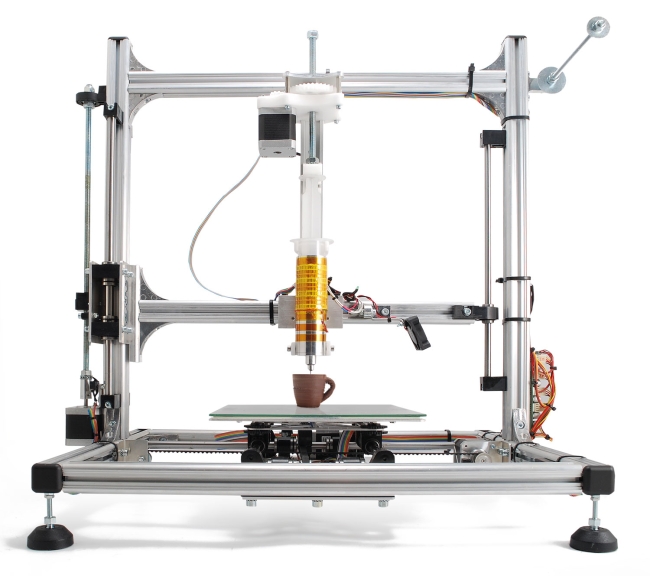

Optomec announced that their Aerosol Jet Technology will be printing embedded electronics at the micron scale. The innovative process relies on both local deposition and local curing. This way, electronics parts are more affordable and require less waste of materials, and all of this with a superior resolution.

The innovative process relies on both local deposition and local curing. This way, electronics parts are more affordable and require less waste of materials, and all of this with a superior resolution.

Start 3D printing enclosures!

3D printing enclosures are one of the most common uses of 3D printing for the electronic industry. Solidity, quality, customization, and accuracy, this is what you will make the most of while 3D printing your electronics enclosures.

If you are interested in 3D printing your own enclosure, you can follow our 3D printed enclosure design guide!

What about the future of 3D printing in the electronics industry?

What if in a few years, we could be able to create fully-functional smartphones or multi-material products using additive manufacturing? If these ideas are still dreams today, the innovations related to conductive 3D printing and electronic devices are now showing new opportunities. It might be time to rethink the way we conceive enclosures, circuit boards, and electronic components. From your prototyping process to the production and the management of your supply-chain, additive manufacturing could help you go through new challenges.

From your prototyping process to the production and the management of your supply-chain, additive manufacturing could help you go through new challenges.

As you can see additive manufacturing has a lot to offer for electronics. It could become quite common to 3D print electrical elements. If you have an electronic project, but you don’t know what software you could use to start it: here is our selection of the best CAD software for electronics. Then, don’t hesitate to try out our online 3D printing service. You will just have to upload your 3D file, we will take care of it and send you your 3D printed objects in a few days.

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

how to optimize design and speed up production

Rapid prototyping

Experts recommend

Author: Viktor Naumov

Author: Viktor Naumov

Benefits of 3D Printed Cases | Developing custom electronics cases: what material to choose for 3D printing? | How to design enclosures for 3D printing | Access to components | The strength of the 3D printed case | Quality and precision | Order a 3D printing service

Implementing additive manufacturing can bring more value to your business than you might think. The production of electronics requires a lot of effort, but thanks to 3D printers, this process can be simplified. We will look at one particular detail: the body of an electronic device. How can it be improved and thereby optimize the entire production process? This will be discussed in the article.

The production of electronics requires a lot of effort, but thanks to 3D printers, this process can be simplified. We will look at one particular detail: the body of an electronic device. How can it be improved and thereby optimize the entire production process? This will be discussed in the article.

Scalable Electronics Manufacturing

The manufacture of electronic devices is associated with certain difficulties. How can the creation of electronics cases affect the success of related projects and business as a whole?

See the benefits of scalable and adaptable enclosures. When designing electronic devices, you must keep pace with changing market demands, including record-breaking project turnaround times. This is made possible by an optimized and scalable manufacturing process. Implementing Just-In-Time principles in part manufacturing can also be a huge business benefit.

In the electronics industry, additive manufacturing opens up many opportunities. Consider the example of a plastic case. This is where 3D printing technology can bring significant benefits. The introduction of 3D printing is a solution that can speed up production processes and increase competitiveness. But that's not all. Additive technologies will also enable innovation and improved hull design.

Consider the example of a plastic case. This is where 3D printing technology can bring significant benefits. The introduction of 3D printing is a solution that can speed up production processes and increase competitiveness. But that's not all. Additive technologies will also enable innovation and improved hull design.

iQB Technologies Experts Recommend Article: 14 Frequently Asked Questions About FDM Production Printing

Benefits of 3D Printed Cases

Adaptability

Additive manufacturing provides almost limitless freedom of action. In the manufacture of cases on a 3D printer, it is possible to provide for latches, locking connections, threaded connections and flexible hinges. Thanks to thoughtful functionality, the case will become more versatile.

3D printing provides design flexibility not available with injection molding. Indeed, it is almost impossible to make changes to the design of the finished mold. If you want to change the project, you will have to start all over again.

With 3D printing, everything is different: you just need to make changes to the 3D file, which will not stop the manufacturing process for a minute. The ability to quickly adjust workflows increases production agility at no extra cost. Thanks to 3D files, there is no need to worry about the service life of the body structure or other part. Changes can be made at any time as needed.

Another significant advantage of additive manufacturing is mass customization. You can customize the work files according to the client's needs. Making several iterations of the case on a 3D printer will not increase the cost of production!

Prototype laser housing 3D printed by TWIZE

3D printer: ProtoFab SLA600 DLC

Material: photopolymer Formula W

Layer thickness: 100 microns

Print time: 12 hours

The result of the work: a laser body suitable both for checking the assembly and as a master model for casting in silicone

Want to try 3D printing prototypes or functional products? Test service is free!

Order a 3D printing service

Innovations

Additive manufacturing provides an opportunity to innovate and improve designs. With 3D printing, you can focus on what you want to create, rather than what you can, given the limitations of traditional manufacturing. Experiment and improve your designs with cutting-edge technology.

With 3D printing, you can focus on what you want to create, rather than what you can, given the limitations of traditional manufacturing. Experiment and improve your designs with cutting-edge technology.

You can take into account all the functional features of the part and integrate them directly into the device.

Acceleration of production processes

Speeding up processes drives business growth. When creating an electronic device, the design and ergonomics of the case are just as important as its performance. This requirement is easily implemented due to the ability to create complex forms very quickly. 3D printing is the fastest prototyping technology: unique prototypes can be produced without a mold, resulting in low part cost.

With 3D printing, the price does not depend on the number of parts, but on the amount of material used. By making multiple iterations of the same case, 3D printing will be a much more sustainable and sustainable manufacturing method than traditional ones. Using a 3D printed prototype, you can check the ergonomics, material features, as well as the fit of internal components or additional elements. With a wide range of 3D printing materials, you can evaluate their benefits and build quality based on project requirements.

Using a 3D printed prototype, you can check the ergonomics, material features, as well as the fit of internal components or additional elements. With a wide range of 3D printing materials, you can evaluate their benefits and build quality based on project requirements.

3D printing is ideal for making plastic cases. Whether you need to customize a product or follow Just-In-Time principles, the benefits of this technology for your business are undeniable.

iQB Technologies Experts Recommend Article: From Aircraft Prototype to Biomedicine: Sharebot Unleashes New Opportunities

Development of customized electronics enclosures

Which 3D printing material to choose?

What is the best material for case making? To develop a project and start 3D modeling, you must select the material and take into account the design parameters.

Plastic enclosures for electronics can be developed through additive manufacturing using adapted materials. Nylon-based materials such as Nylon PA12 or Nylon PA11 are especially suitable for 3D printing plastic cases. These are low-cost materials that can be used to make prototypes, as well as small or large series. Photopolymers with a variety of mechanical properties are also suitable for printing prototypes and finished products.

Nylon-based materials such as Nylon PA12 or Nylon PA11 are especially suitable for 3D printing plastic cases. These are low-cost materials that can be used to make prototypes, as well as small or large series. Photopolymers with a variety of mechanical properties are also suitable for printing prototypes and finished products.

How to design enclosures for 3D printing

Before you start modeling a case, it is recommended that you start designing with the components that it will contain. This way you can place components and make sure everything fits, as well as provide clearance for connectors or cables. To ensure that all components will fit, we recommend leaving a gap of 0.5mm between the components and the 3D printed elements.

Access to components

The first thing to think about when designing a case is what to put in it and how to access it later. If access to the components is not required, you can design special fasteners or use adhesive during assembly of the case to completely seal it.

If access to the components of the case is necessary, the following mechanisms can be used:

-

semi-rigid eyelets;

-

sliding panels;

-

screws;

-

conventional and flexible hinges;

-

prefabricated structures.

Eyelets, slots and flanges help with assembly and alignment of parts. In addition, if the minimum dimensions of these elements are observed, they can increase the strength of the hull.

Durability of 3D printed case

The main thing to consider is the thickness of the walls of the case. This parameter determines the weight, stiffness, strength and possible applications of the hull. Even if the 3D printer is capable of printing small parts and thin walls, we recommend keeping the minimum wall thickness of 2mm. This value provides structural strength while keeping the weight of the part light. The optimum thickness can also be determined using the design guide for the material used.

However, be careful, because depending on the length of the casing, the 2 mm thick walls can bend, which can lead to some shrinkage.

Corner rounding is a key feature of 3D printing because hard corners can be printed poorly. Roundings are necessary both inside the case and outside.

Roundings avoid sharp corners and reduce stress

For external corners, a slight rounding (1 or 2 mm) can be used on the housing surface.

Inside the case, the corners can be reinforced with thickenings and roundings. A very small radius simplifies 3D printing and reduces stress concentration at corners.

Thickening and rounding inside the body reduce stress around the hole

3D printed housing: quality and precision

If the design contains gaps or holes for fasteners, select a material that provides the desired accuracy. 3D printing plastic provides high precision, but we recommend drilling or punching holes after printing with special tools.

If you slightly increase the diameter of the holes for the fasteners, the result will be better.

At the same time, for a tighter connection of the fasteners with the body, the diameter of the holes should be reduced.

Small walls and thin-walled elements are often added to the housing to hold components. These elements must meet the minimum thickness of the material used, and in addition, we recommend adding structures such as corners or stiffeners, which will make the element more durable and ensure correct 3D printing.

Corners and stiffeners reduce stress and make thin-walled elements and the case itself stronger

Finally, remember that in addition to rapid iteration and prototyping, 3D printing can be used to mass-produce cases.

The article uses materials from Sculpteo

Article published on 03/25/2021, updated on 06/15/2022

Industrial micro 3D printing in microelectronics

Table of Contents

Introduction

Constant development of the technical process results in electronics being smaller, more densely packed and subjected to more stringent conditions. Miniaturization, the growing number and density of electronic components, and higher data rates that generate more heat are just some of the challenges electronics designers face today.

Miniaturization, the growing number and density of electronic components, and higher data rates that generate more heat are just some of the challenges electronics designers face today.

Regardless of component size, engineers need electronic connectors that connect securely and retain their thermal and mechanical properties. If a smartphone or avionics connector does not meet the requirements for form, fit, and function, product launch may be delayed.

During the design process, engineers need prototypes that are as close to production quality as possible. During testing, it is very important to meet well-defined requirements. The electronics industry also needs a smooth market entry and support for faster production and efficient assembly.

Issue

Traditionally, manufacturers have used micro-injection molding to produce electronic components such as connector bases, chip sockets, and fiber array brackets.

Unfortunately, casting has two significant drawbacks, because this process requires a lot of time and financial costs. Making a tooling can take anywhere from 10 to 12 weeks. Moreover, if the final design changes, then all the created technological equipment for casting will simply not be needed, which will lead to additional costs.

Making a tooling can take anywhere from 10 to 12 weeks. Moreover, if the final design changes, then all the created technological equipment for casting will simply not be needed, which will lead to additional costs.

Solution

3D printing eliminates the need for injection molding tooling and can reduce time to market across multiple design iterations and test cycles. However, most 3D printers for creating small parts force engineers to compromise between production speed, part accuracy and surface quality.

Boston Micro Fabrication offers a one-stop solution for all the industry's challenges and challenges. BMF's Projection Micro-Stereolithography (PµSL) technology allows you to quickly print small electronic components with the exact specifications required for parts such as electronic connectors. Today BMF offers a unique micro 3D printing solution that matches precision injection molding in terms of resolution, size and tolerances. PμSL supports electronics manufacturing in other ways as well.

Result

Electronic components printed using PμSL technology use photopolymer resins with reliable thermal and mechanical properties. This is important in applications where 5G products are exposed to high temperatures, need to be securely connected, and ensure efficient assembly. During PCB assembly, for example, reflow soldering exposes surface mount components to high temperatures. In IC sockets, integrated circuit (IC) pins must provide reliable but solderless connections. Both methods require reliable components that withstand the test and achieve the required volumes.

LGA chip package

Approximately 2500 trapezoidal holes. Each hole has a raised structure

Length 75 mm ± 25 µm / Printing time: 3 hours / 1 piece ( S 140)

Microchm panel

(376 holes / Ø 0.2mm / distance ± 0.025mm) 9000

The foundation of the detachment of the detachment of the detachment0180

(Minimum hole diameter 0.

Learn more