Earme 3d printer

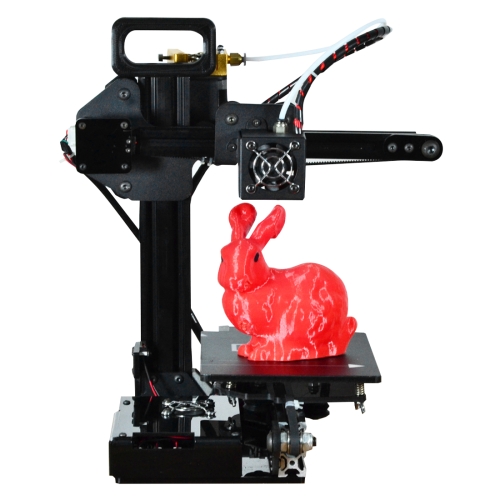

A8 Black UK 3D Printers, 3D Printer Kits Sale, Price & Reviews

Share to:

- Description

- Reviews(0)

- Shipping & Payment

- Wholesale Inquiry

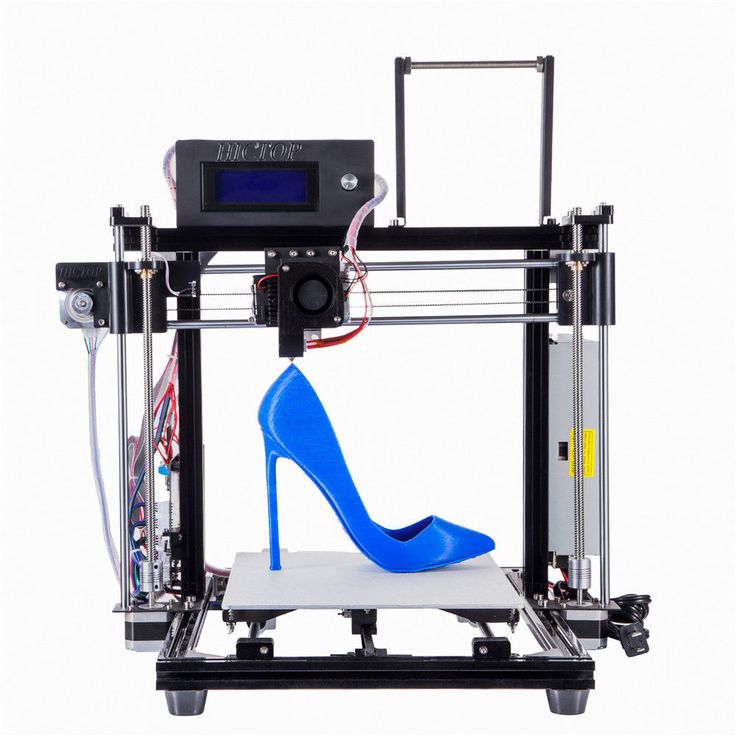

A8 Descriptions

Main Features:

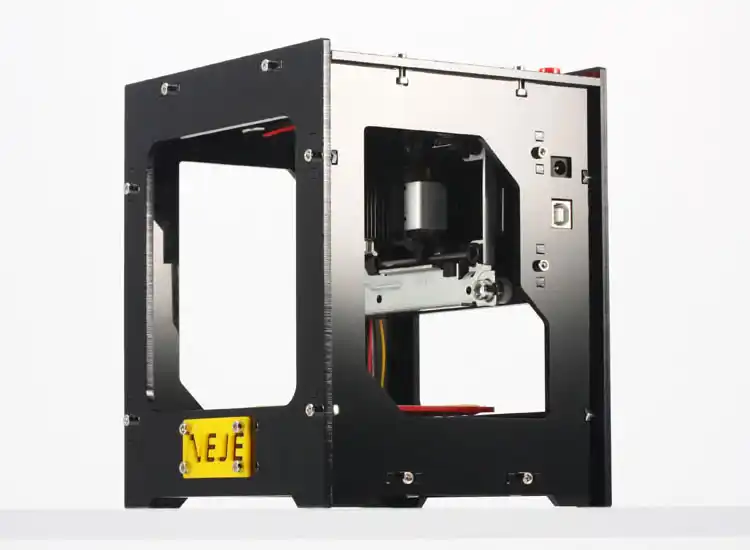

● Engineered to provide redefined usability, quality, performance

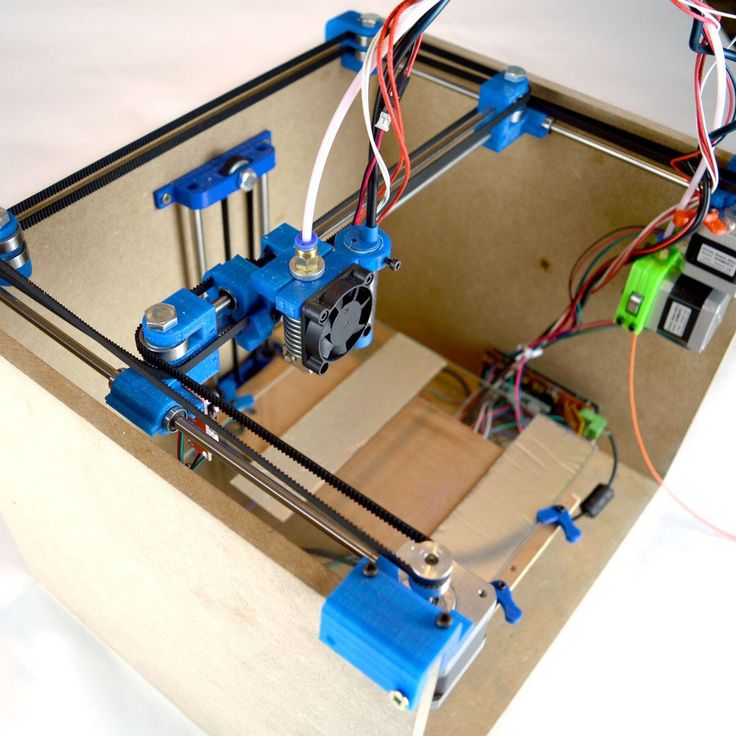

● Made from the piano-black laser-cut acrylic frame. To maintain the garage-built feel and the handmade charm

● It is the unassembled DIY kit, provide you an unforgettable step-by-step learning experience of the 3D printer from scratch. As long as you have a passion for creativity, you can not afford to miss this product

● Suitable for a wide range of customers, young or old, professional or amateur etc.

● Multiple 3D printing filament supportable, support ABS / PLA / wood / nylon PVA / PP / luminescent

●220 x 220 x 240mm printing volume, just right for you

● All metal pulleys for improved functionality and performance

● Quick-release feed gears for faster and fluent filament feeding

● High printing precision, stainless steel rail rods, gears, bearings and connectors for smoother movement

●Operating system: Windows XP / 7 / 8 / 10, Mac, Linux

●Working environment: Temperature: 10 - 30 Deg. C, humidity: 20 - 50 Deg.C

● Firmware version: V1

● Without filament

Performance parameter:

- Engraving area: 220 x 220 x 240mm

- Frame material: acrylic plate

- Platform board: aluminum base

- Nozzle quantity: single

- Nozzle diameter: 0.4mm

- Layer thickness: 0.1 - 0.3mm

- Memory card offline print: SD card ( not included )

- Print speed: 100mm/s

- Supporting material: ABS, luminescent, nylon PVA, PLA, PP, wood

- Material diameter: 1.75mm

- File format: G-code, OBJ, STL

- XY-axis positioning accuracy: 0.012mm

- Z-axis positioning accuracy: 0.004mm

- Voltage: 12V

- Host computer software: cura, repetier-host

Note:

● Because of technology upgrades, accessories may not be the same with the picture, but it does not affect the function

● Because the mainboard is updated, the new system board wiring is opposite with the old wiring. But SD card data did not update ( still the old wiring )

Specification

- All (0)

- Photos (0)

- Videos (0)

- Sort By: All

All Hottest Most helpful Most recent

-

Translate into EngLish

Get G Points! Be the FIRST to Write a Review!

Do you want to bulk buy A8 ? Please submit your wholesale A8 inquiry below. Please note we usually don’t offer free shipping on wholesale A8 orders, but the wholesale price will be a big bargain.

Please note we usually don’t offer free shipping on wholesale A8 orders, but the wholesale price will be a big bargain.

Your Target Price:

Order Quantity:

Country:

Your Name:

Your Tel:

Your E-mail:

Company Name:

Detailed Inquiry Information:

Your Recently Viewed Items

Pre-sale Service

Buy EarMe Anet A8 3D Desktop Acrylic LCD Screen Printer DIY High Accuracy Self Assembly(Not included Filament) Online at desertcart Belize

Brand : Earme

Brand : Earme

Description

- ☑This 3D A8 printer is unassembled DIY kit,it can provide you an unforgettable step-by-step learning experience of 3D printer from scratch. The best gift to your children,the greatest creativity your children will show you..

- ☑This DIY desktop 3d printer support ABS / PLA / Wood / Nylon PVA / PP / Luminescent,support multiple 3D printing filament.

Easy to install,detail install introduction can search "J8tX-Kfb1og"and "EB5Q3_sJ-Tk"on the YOUTUBE..

Easy to install,detail install introduction can search "J8tX-Kfb1og"and "EB5Q3_sJ-Tk"on the YOUTUBE.. - ☑This LCD screen printer has 220 x 220 x 240mm printing volume, just right for you.Made from piano-black laser-cut acrylic frame. To maintain the garage-built feel and the handmade charm..

- ☑This printer support Windows XP / Windows 7 / Windows 8 / Windows 10 /Mac / Linux operating system and the Temperature: 10 - 30 Deg.C, humidity: 20 - 50 Deg.C. working environment.

- ☑EARME 3D printer suitable for a wide range of customers, young or old, professional or amateur,the best gift to the people who want to excite his potentiality and creativity.Our printer has one year warranty,3 months refund return..

- Imported from USA (Sizes & Specifications are based on the USA Market).

Noted:There is no instruction in the package,detailed installation instructions in the SD card. Main Features ●Engineered to provide redefined usability, quality, performance ● Made from piano-black laser-cut acrylic frame. To maintain the garage-built feel and the handmade charm ● It is unassembled DIY kit, provide you an unforgettable step-by-step learning experience of 3D printer from scratch. As long as you have a passion for creativity, you can not afford to miss this product ● Suitable for a wide range of customers, young or old, professional or amateur etc. ● Multiple 3D printing filament supportable, support ABS / PLA / Wood / Nylon PVA / PP / Luminescent ● 220 x 220 x 240mm printing volume, just right for you ● All metal pulleys for improved functionality and performance ● Quick-release feed gears for faster and fluent filament feeding ● High printing precision, stainless steel rail rods, gears, bearings and connectors for smoother movement ● Operating system: Windows XP / Windows 7 / Windows 8 / Windows 10 /Mac / Linux ● Working environment: Temperature: 10 - 30 Deg.C, humidity: 20 - 50 Deg.C ● Firmware version: V1 ● Without filament Specification Type: DIY Model: A8 Engraving Area: 220 x 220 x 240mm Frame material: Acrylic plate Platform board: Aluminum Base Nozzle quantity: Single Nozzle diameter: 0.

To maintain the garage-built feel and the handmade charm ● It is unassembled DIY kit, provide you an unforgettable step-by-step learning experience of 3D printer from scratch. As long as you have a passion for creativity, you can not afford to miss this product ● Suitable for a wide range of customers, young or old, professional or amateur etc. ● Multiple 3D printing filament supportable, support ABS / PLA / Wood / Nylon PVA / PP / Luminescent ● 220 x 220 x 240mm printing volume, just right for you ● All metal pulleys for improved functionality and performance ● Quick-release feed gears for faster and fluent filament feeding ● High printing precision, stainless steel rail rods, gears, bearings and connectors for smoother movement ● Operating system: Windows XP / Windows 7 / Windows 8 / Windows 10 /Mac / Linux ● Working environment: Temperature: 10 - 30 Deg.C, humidity: 20 - 50 Deg.C ● Firmware version: V1 ● Without filament Specification Type: DIY Model: A8 Engraving Area: 220 x 220 x 240mm Frame material: Acrylic plate Platform board: Aluminum Base Nozzle quantity: Single Nozzle diameter: 0. 4mm Layer thickness: 0.1-0.3mm Memory card offline print: SD card LCD Screen: Yes Print speed: 100mm / s Supporting material: ABS,Luminescent,Nylon PVA,PLA,PP,Wood Material diameter: 1.75mm File format: G-code,OBJ,STL XY-axis positioning accuracy: 0.012mm Z-axis positioning accuracy: 0.004mm Voltage: 12V Host computer software: Cura,Repetier-Host Packing Type: unassembled packing Certificate: EMC,FCC,LVD,RoHs Packing Contents 1*A8 3D Desktop Acrylic LCD Screen 1xPack of Acce

4mm Layer thickness: 0.1-0.3mm Memory card offline print: SD card LCD Screen: Yes Print speed: 100mm / s Supporting material: ABS,Luminescent,Nylon PVA,PLA,PP,Wood Material diameter: 1.75mm File format: G-code,OBJ,STL XY-axis positioning accuracy: 0.012mm Z-axis positioning accuracy: 0.004mm Voltage: 12V Host computer software: Cura,Repetier-Host Packing Type: unassembled packing Certificate: EMC,FCC,LVD,RoHs Packing Contents 1*A8 3D Desktop Acrylic LCD Screen 1xPack of Acce

Show More

Reviews

Color

3D Printer black

Related Pages

Industrial And Scientific › Additive Manufacturing Products › 3 D Printers

Disclaimer: The price shown above includes all applicable taxes and fees. The information provided above is for reference purposes only. Products may go out of stock and delivery estimates may change at any time. desertcart does not validate any claims made in the product descriptions above. For additional information, please contact the manufacturer or desertcart customer service. While desertcart makes reasonable efforts to only show products available in your country, some items may be cancelled if they are prohibited for import in Belize. For more details, please visit our Support Page.

While desertcart makes reasonable efforts to only show products available in your country, some items may be cancelled if they are prohibited for import in Belize. For more details, please visit our Support Page.

Frequently Asked Questions About Ear Me Anet A 8 3 D Desktop Acrylic LCD Screen Printer DIY High Accuracy Self Assembly Not Included Filament in Belize

Where can I buy Ear Me Anet A 8 3 D Desktop Acrylic LCD Screen Printer DIY High Accuracy Self Assembly Not Included Filament online at the best price in the Belize?

desertcart is the best online shopping platform where you can buy Ear Me Anet A 8 3 D Desktop Acrylic LCD Screen Printer DIY High Accuracy Self Assembly Not Included Filament from renowned brand(s). desertcart delivers the most unique and largest selection of products from across the world especially from the US, UK and India at best prices and the fastest delivery time.

Is Ear Me Anet A 8 3 D Desktop Acrylic LCD Screen Printer DIY High Accuracy Self Assembly Not Included Filament available and ready for delivery in in Belize?

desertcart ships the Ear Me Anet A 8 3 D Desktop Acrylic LCD Screen Printer DIY High Accuracy Self Assembly Not Included Filament to and more cities in Belize. Get unlimited free shipping in 164+ countries with desertcart Plus membership. We can deliver the Ear Me Anet A 8 3 D Desktop Acrylic LCD Screen Printer DIY High Accuracy Self Assembly Not Included Filament speedily without the hassle of shipping, customs or duties.

Get unlimited free shipping in 164+ countries with desertcart Plus membership. We can deliver the Ear Me Anet A 8 3 D Desktop Acrylic LCD Screen Printer DIY High Accuracy Self Assembly Not Included Filament speedily without the hassle of shipping, customs or duties.

Is it safe to buy Ear Me Anet A 8 3 D Desktop Acrylic LCD Screen Printer DIY High Accuracy Self Assembly Not Included Filament on desertcart?

Yes, it is absolutely safe to buy Ear Me Anet A 8 3 D Desktop Acrylic LCD Screen Printer DIY High Accuracy Self Assembly Not Included Filament from desertcart, which is a 100% legitimate site operating in 164 countries. Since 2014, desertcart has been delivering a wide range of products to customers and fulfilling their desires. You will find several positive reviews by desertcart customers on portals like Trustpilot, etc. The website uses an HTTPS system to safeguard all customers and protect financial details and transactions done online. The company uses the latest upgraded technologies and software systems to ensure a fair and safe shopping experience for all customers. Your details are highly secure and guarded by the company using encryption and other latest softwares and technologies.

The company uses the latest upgraded technologies and software systems to ensure a fair and safe shopping experience for all customers. Your details are highly secure and guarded by the company using encryption and other latest softwares and technologies.

10 Benefits of a 3D Printer: Save Time and Money

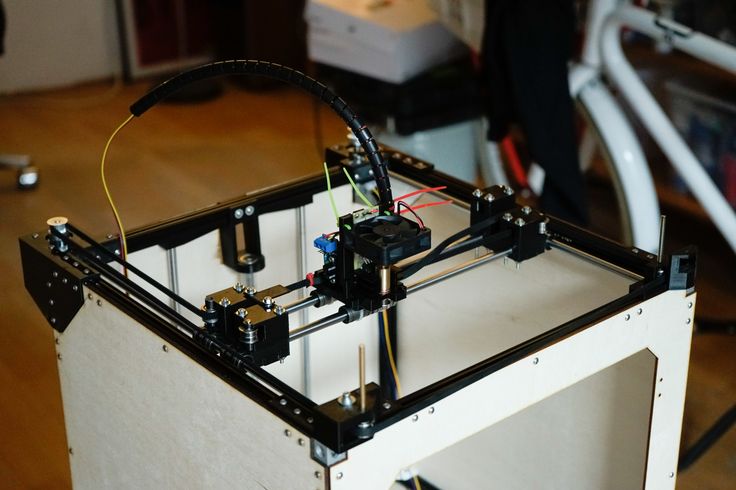

More recently, 3D printing has been viewed as something completely new. The technology was underdeveloped, the hardware was too expensive for widespread use. But only a few years have passed, and the situation has changed radically. Not only did more and more 3D printers begin to appear in stores, but also some enthusiasts began to assemble this equipment themselves.

1. Economy

Although large-scale projects with thousands of 3D printed parts are not cheap, they are still much more profitable than other technologies. Many manufacturers use 3D printing for small runs or for prototyping. Plastic can also be used for injection molding, but casting small batches can require expensive equipment. But even in this case, manufacturers can produce cast 3D parts several times cheaper than using aluminum.

But even in this case, manufacturers can produce cast 3D parts several times cheaper than using aluminum.

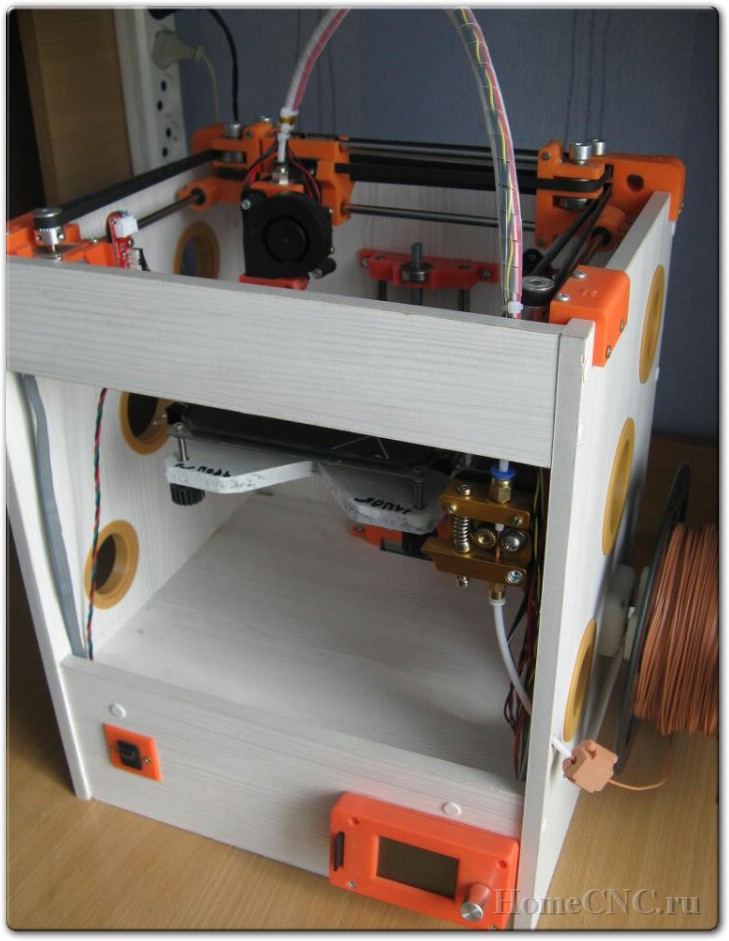

Prototype parts printed on Prusa i3 Bizon 3D printer, layer height 0.1mm, PLA material

2. Faster production cycle

Compared to traditional production methods, the entire process can take weeks or days, and most products are printed in hours. Some manufacturers have even begun to make parts to order, which has also allowed them to optimize their warehouse capacity and resource management scheme, making them more flexible. With this new approach, the manufacturer does not need to store every single part or component, they can simply be printed as needed and immediately put into action.

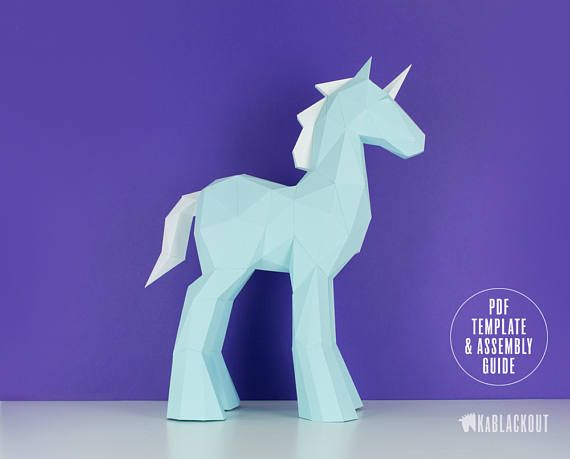

Miniature parts printed by Wanhao Duplicator 7 photopolymer 3D printer, layer height 0.5mm, photopolymer resin material

It not only affects the reputation of the company in its industry, insufficient technical control can lead to injury to employees and customers.

Since 3D printing uses a completely different production method than most machine tool operations, the process has significantly fewer weaknesses and flaws overall.

Since 3D printing uses a completely different production method than most machine tool operations, the process has significantly fewer weaknesses and flaws overall.

Model printed on Picaso Designer X PRO 3D printer, 0.2 mm layer, ABS materials, HIPS

4. Less waste

The press is gaining more and more support in the form of supporters of the "green" movement. Because 3D printing produces significantly less waste than traditional processing, the technology is more environmentally friendly while reducing costs. 3D printing has even made its way into the textile industry, allowing clothing and prototypes to be printed.

Hercules Strong 3D printed yacht steering parts. Details printed in 15 hours with a 0.5 mm nozzle and a layer height of 0.3 mm at a speed of 60 mm/s.

5. Greater customization

3D printed products are also highly customizable. Parts can be printed not only with light plastic, some next-generation models may also have a metal coating. As a result, objects are not only aesthetic, but also functional. In addition, they can acquire thermal and chemical resistance. The existing metallization method can also be used for plastic.

As a result, objects are not only aesthetic, but also functional. In addition, they can acquire thermal and chemical resistance. The existing metallization method can also be used for plastic.

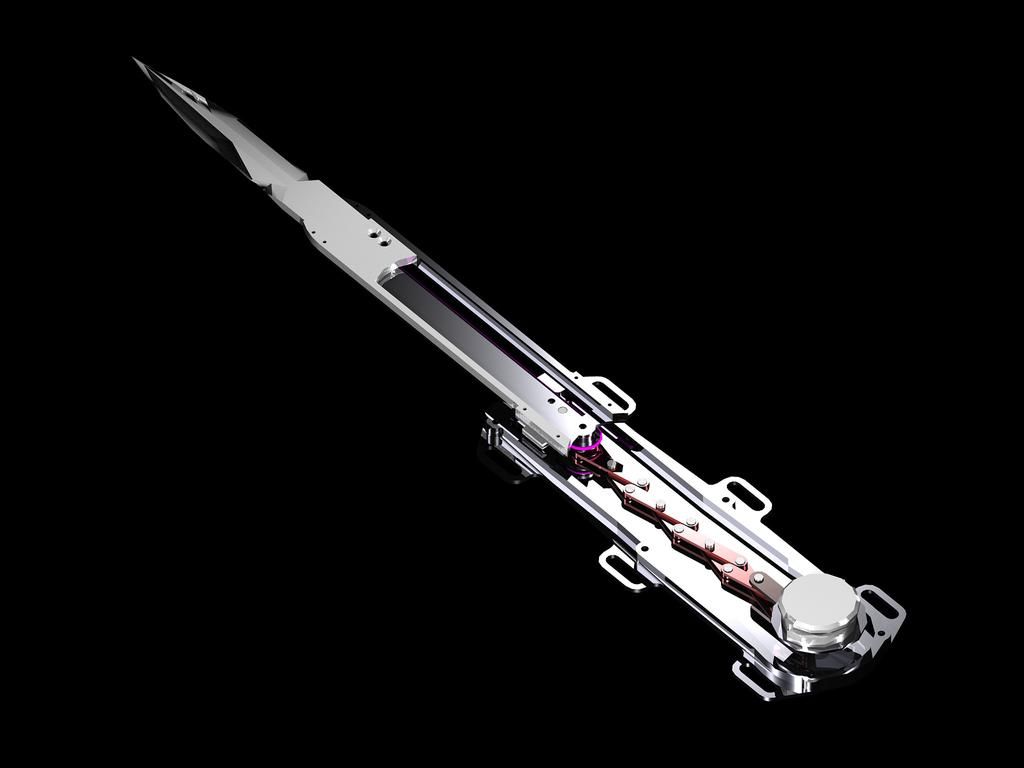

Functional parts printed on Hercules. Material ABS, nozzle diameter 0.5 mm, layer height 150 µm, filling 100%. The model consists of 3 parts: the body and 2 halves of the latch, after printing and processing, the parts were glued together with acetone.

6. Customer Accessibility

If some craftsmen set up small mechanical workshops, for example, in garages, then most of us cannot afford such a luxury. 3D printing allows you to bring a significant part of the manufacturing process directly into the home, made possible by the availability of user-grade 3D technology. While it turns out to be quite expensive for one-off projects, the price of 3D printers and consumables is dropping rapidly.

Technical wing caps in REC RUBBER or REC FLEX. The models are printed on a Prusa i3 Steel 3D printer.

The models are printed on a Prusa i3 Steel 3D printer.

7. High complexity

In most cases, when it comes to complex parts and elements, the manufacturing process imposes certain limitations. Techniques used in casting and finishing objects may not be subtle enough for sophisticated design details. 3D manufacturing processes make it possible to realize almost any design solution, regardless of its complexity, and in a reasonable time. This not only eliminates the extra assembly steps required by traditional methods, but also provides more freedom to create future-proof designs.

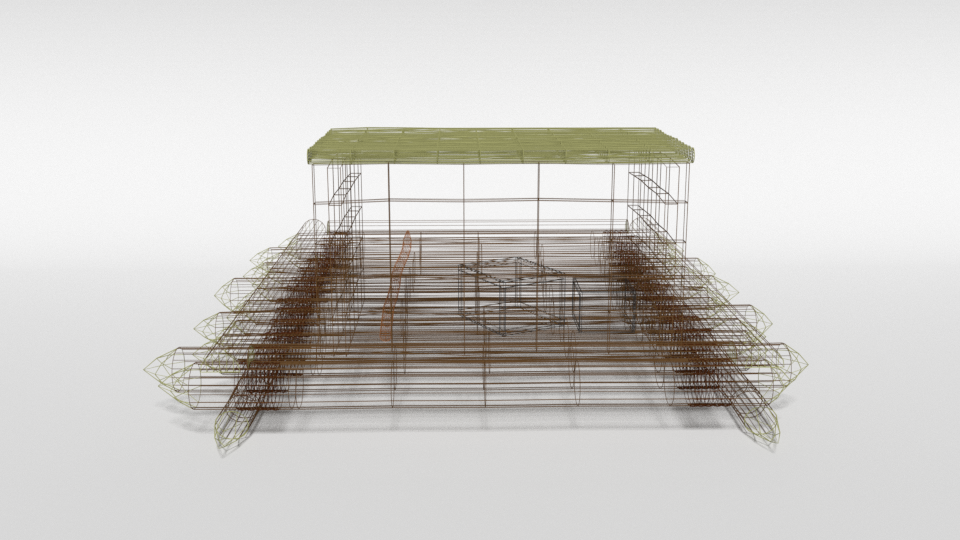

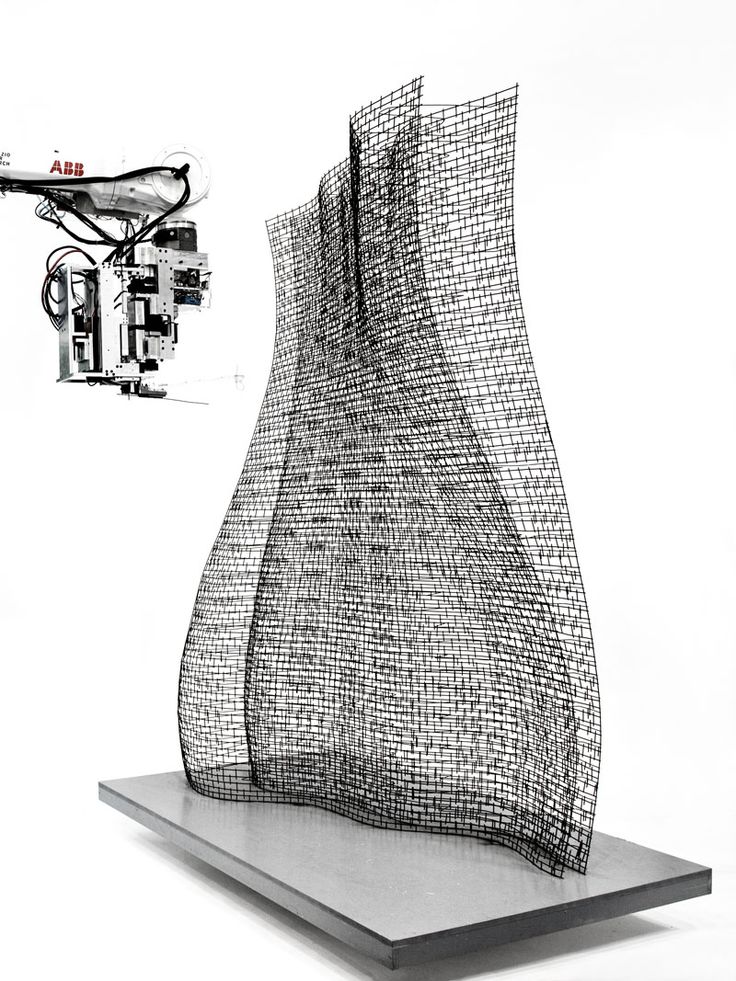

Zenit 3D Printing Big Details From Engine 3D Printer

8. Less risk

While there are inherent risks associated with these new technologies, in terms of day-to-day business, 3D printing risks are significantly lower than with traditional manufacturing methods. Not only is 3D printing much cheaper when it comes to testing a new design or product, the printed prototypes themselves can stir up investor and customer interest and get them to decide whether to proceed with mass production of a product, whether it is worth the time and effort required.

Wanhao Duplicator i3 3D Printer Miniature Printing

9. Variety of materials

The materials used in today's 3D printers are much more diverse than most raw materials in traditional production methods. 3D printing also provides the ability to mix different substances, a luxury that is not always available with conventional methods. Although many 3D printer manufacturers offer their own, very limited set of sources, 3D printers can work not only with original materials, allowing you to simulate ceramics, metal, glass and more.

Wanhao D6 3D Printer PEGT, ABS-PC, PLA, SBS

The manufacturer not only needs to clearly understand what the customer wants, the manufacturer must also be able to explain what he himself can. Drawings, diagrams, diagrams are all good, of course, but there is nothing better than a real prototype that you can hold, look at and study. The fact that the materials are inexpensive, coupled with the short prototyping time on today's 3D printers, helps a lot during the prototyping phase, keeping all stakeholders connected.

THE PAST, PRESENT AND FUTURE OF 3D PRINTING

Despite a relatively slow start, the concept of 3D printing is finally gaining momentum and popularity among manufacturers and customers. We already see a lot of benefits of 3D printing, including shorter production cycles, more complex designs and improved quality, and the peak of the popularity and functionality of this technology is yet to come.

What material does the 3D printer print with? Plastic for 3d printer.

Layer-by-layer printing of three-dimensional models is made from a variety of materials, be it plastic, concrete or metal, and even hydrogel, chocolate and living cells.

For 3D printing, the use of ABS plastic is most optimal. Acrylonitrile butadiene styrene (official name ABC plastic ) is valued for its lack of foreign smell, toxicity, in addition, it is impact resistant, flexible and elastic. The material begins to melt from 240 to 248 degrees Celsius. Plastic goes on sale in a powdered state, or in the form of bobbins with plastic threads wound around them. Despite the fact that plastic does not tolerate direct sunlight, models made from it are famous for their durability. Plastic for a 3D printer can be bought in our online store.

Plastic goes on sale in a powdered state, or in the form of bobbins with plastic threads wound around them. Despite the fact that plastic does not tolerate direct sunlight, models made from it are famous for their durability. Plastic for a 3D printer can be bought in our online store.

Unlike ABC plastic, which models are opaque, acrylic is used to create transparent objects. But acrylic is more capricious in the process of use: the melting point of acrylic is reached later, which means that it will take more time and energy to heat up, and at the same time it quickly cools and hardens. The very process of manufacturing the product is laborious, since heated acrylic contains a lot of air bubbles that can distort the finished product.

Concrete applied for 3D printing , improved, and has a formula that differs from the formula of conventional cement by 5%. The “printing” of a residential building with an area of 230 m2 on a 3D printer will take no more than 20 hours, during which it carefully “lays out” building blocks and structures from concrete.

The use of hydrogel for 3D printing was successfully tested by scientists from the University of Illinois, who used a 3D printer to print miniature (5-10 mm) biorobots. Living cells isolated from the tissue of the heart muscle were placed on them, which, spreading through the hydrogel, set the biorobot in motion. The speed of such a biorobot is 236 µm/s. As planned by scientists, in the future, with the help of such biorobots, tumors and toxins in the body will be detected and neutralized, and they will also be used to deliver medications to diseased human organs.

There are 3D printers that use ordinary office paper as a material. Pre-cut layers of paper are applied one on top of the other and attached with glue. Paper models are cheap enough that they are accessible to users, but at the same time, paper models are not durable and not aesthetically pleasing. Models created in this way are ideal for prototyping in computer projects.

Gypsum used for 3D printing is a fragile, short-lived material, but at the same time it has a low cost. Therefore, models made of plaster are mainly suitable for presentations, perfectly conveying the shape, structure and size of the original product. The resistance of gypsum to heat treatment makes it possible to use it in the foundry as samples for casting.

Therefore, models made of plaster are mainly suitable for presentations, perfectly conveying the shape, structure and size of the original product. The resistance of gypsum to heat treatment makes it possible to use it in the foundry as samples for casting.

Fans of natural wood and products made from it will also enjoy 3D printing, as there is a specially designed “wood” fiber that contains wood and a polymer, and its properties are similar to polyactide (PLA). Outwardly looking like natural wooden models with the smell of fresh wood, they are quite strong and durable. Currently, the material can only be used in the RepRap self-replicating printers.

3D printing with ice is perhaps the most exotic way of making small figures today. The temperature at which the figures are printed is quite low and is -22 degrees Celsius, and the printing material is water and methyl alcohol heated to 20 degrees Celsius.

The pleasant soft sheen and high strength of the metal are far ahead in quality of any plastic used in 3D printing, therefore light and precious metal powders are successfully used in this area. Copper, aluminum and its alloys, gold and silver in powder form are used for printing, adding fiberglass and ceramic inclusions to them.

Copper, aluminum and its alloys, gold and silver in powder form are used for printing, adding fiberglass and ceramic inclusions to them.

Nylon printed parts are similar in many ways to ABS plastic parts, but are softer and more practical. Nylon manufacturing technology is more capricious, in particular, it has a longer curing period, the printing temperature reaches 320 degrees Celsius, and it is more toxic.

3D printers of the near future will be able to print shaped chocolate molds, which should be in high demand in restaurants and pastry shops.

It is also impossible not to mention polycaprolactone, the most popular consumable for 3D printing. This material is so valued for its excellent physical properties and the possibility of being used in various printing technologies.

Of the plastic materials for printing, it is also worth highlighting polycarbonate (hard plastic), polylactide material obtained from biomass, sugar beet or corn silage, polypropylene, polyphenylsulfone, which came from the aviation industry, and an unsurpassed leader in the field of 3D printing, used in any of its areas - polyethylene low pressure.