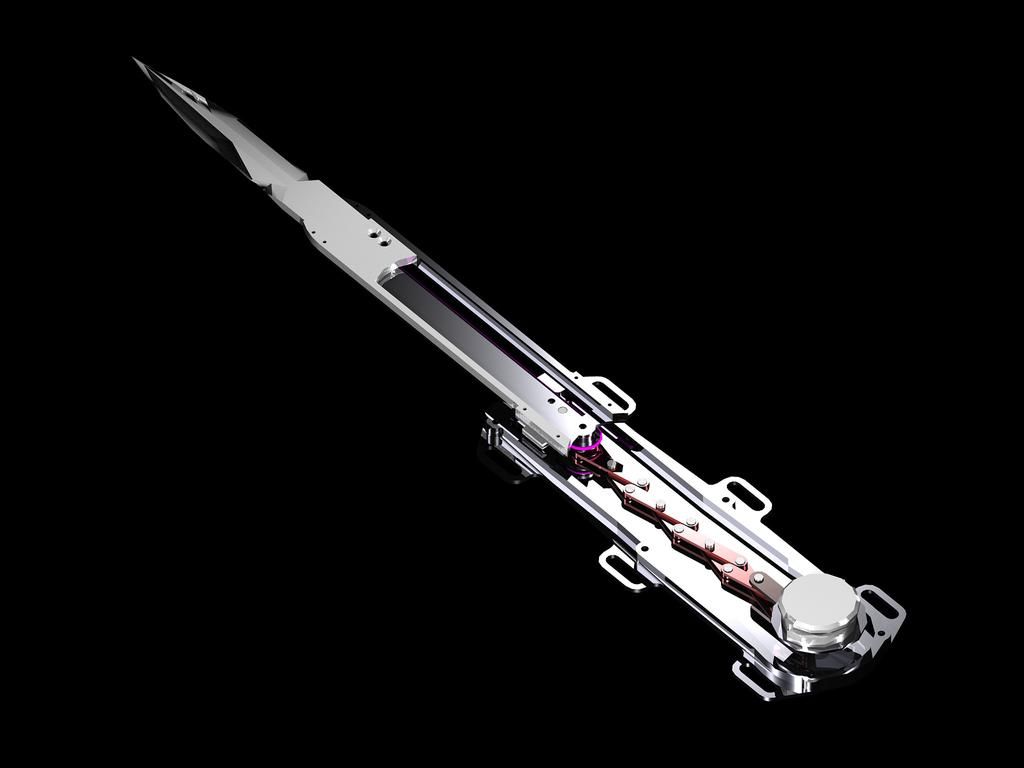

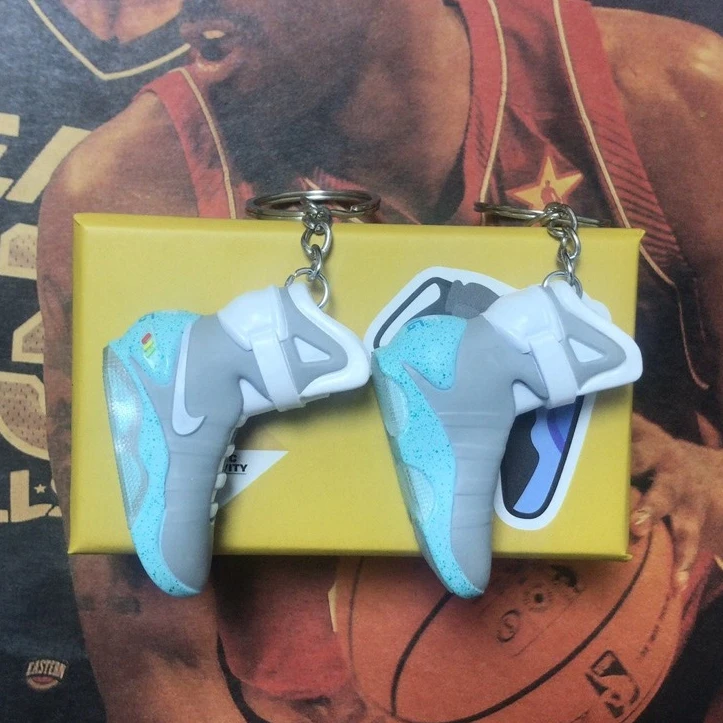

3D printed sneaker keychain

3D SNEAKER KEYCHAIN – customteezstore

3D SNEAKER KEYCHAIN – customteezstoreSkip to content

Filter Filter

Sort SortFeaturedBest sellingAlphabetically, A-ZAlphabetically, Z-APrice, low to highPrice, high to lowDate, old to newDate, new to old

YZY 3D Mini Sneaker Keychain

$25.00

Wother Spoon X AM1 - 3D Mini Sneaker Keychain

$25.00

Up Tempo - 3D Mini Sneaker Keychain

$25.00

Union x AJ1 3D Mini Sneaker Keychain

$25.00

Travis X AJ1 3D Mini Sneaker Keychain

$25.00

Tom Sachs X Mars Yard - 3D Mini Sneaker Keychain

$25.00

Superstar -3D Mini Sneaker Keychain

$25. 00

SUP X Up Tempo - 3D Mini Sneaker Keychain

$25.00

SUP X J5 -3D Mini Sneaker Keychain

$25.00

SUP X Foam Posite - 3D Mini Sneaker Keychain

$25.00

SUP X AF1 - 3D Mini Sneaker Keychain

$25.00

Staple X SB Dunks - 3D Mini Sneaker Keychain

$25.00

Spider X AJ1 - 3D Mini Sneaker Keychain

$25.00

Sold Out

Sean Cliver X SB Dunks - 3D Mini Sneaker Keychain

$25.00

SB Dunks - 3D Mini Sneaker Keychain

$25.00

Sacai Waffle - 3D Mini Sneaker Keychain

$25. 00

00

Sacai Blazer - 3D Mini Sneaker Keychain

$25.00

Play X Converse - 3D Mini Sneaker Keychain

$25.00

OW X SB Dunks - 3D Mini Sneaker Keychain

$25.00

Sold Out

OW X J4 - 3D Mini Sneaker Keychain

$25.00

OW X AJ1 - 3D 3D Mini Sneaker Keychain

$25.00

NMD 3D Mini Sneaker Keychain

$25.00

Neighbor Hood X Super Star - 3D Mini Sneaker Keychain

$25.00

Melody X AJ1 - 3D Mini Sneaker Keychain

$25.00

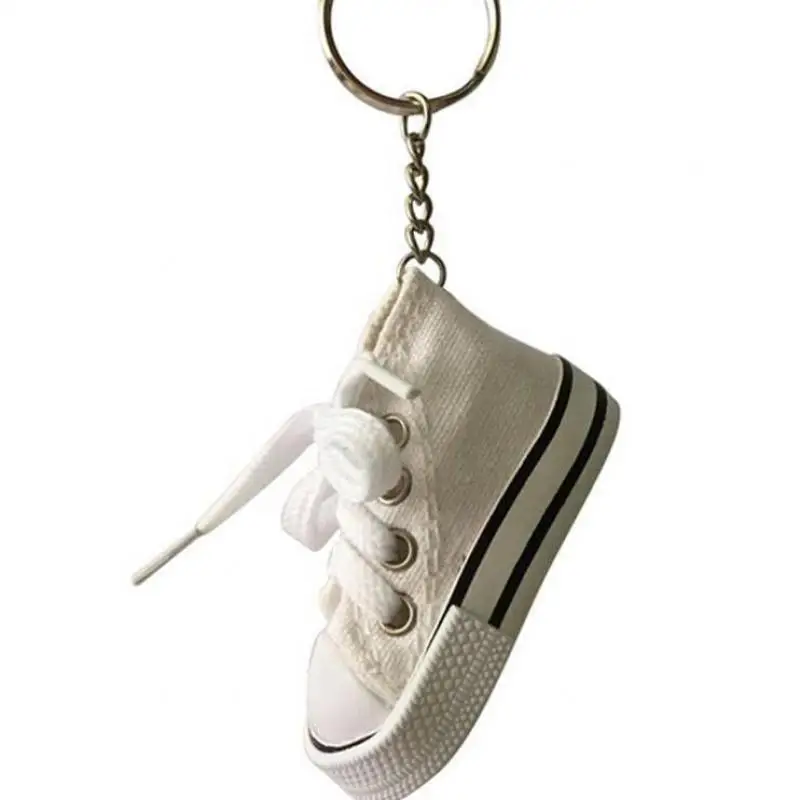

▷ air jordan shoe keychain 3d models 【 STLFinder 】

Air Jordan Keychain

sketchfab

Air JORDAN

Air Jordan Keychain

thingiverse

An Air Jordan keychain. ...I took the Air Jordan logo, extruded it, and added a keychain hole right where the basketball is. ... Enjoy!

...I took the Air Jordan logo, extruded it, and added a keychain hole right where the basketball is. ... Enjoy!

Air Jordan 1 No Keychain

thingiverse

No Keychain Remix

Nike Jordan 1 Shoe with Box (Keychain)

thingiverse

NIKE Jordan 1s Keychain (with hole for ring). Actual shoes were designed by DrydenTheTwig. Link is below: https://www.thingiverse.com/thing:2544793 I used that model but removed a few sections. Box and drawer were designed myself. Easy to...

Jordan 1 Left shoe for Shoe box keychain

thingiverse

https://www. thingiverse.com/mostafa5chehadeh made an amazing keychain with tiny shoes inside but there is only a right shoe in the files. ...I used TinkerCAD to mirror the image to create a left shoe as well

thingiverse.com/mostafa5chehadeh made an amazing keychain with tiny shoes inside but there is only a right shoe in the files. ...I used TinkerCAD to mirror the image to create a left shoe as well

Nike Air Jordan 4 What The Shoe 3D model

cgtrader

Iconic Jordan shoe with a sleek new colourway. ...The Jordan 4 What The combines four of the most popular colourways into one pair of sneakers that aim to make you say What the?

Nike Air Jordan 4 Retro Bred Shoe 3D model

cgtrader

2021 update. ...Shoe is now closer material wise to the real Jordan 4 Bred. Some minor model improvements have also been made. ...The original files are still here in their entirety if you prefer the look of that model

Some minor model improvements have also been made. ...The original files are still here in their entirety if you prefer the look of that model

jordan KeyChain

cults3d

Jordan keychain basketball

Air Jordan I Keychain

thingiverse

That's my first sneaker project. ...If you want more - follow my profile !

Jordan Air Nike Shoe low poly PBR Low-poly 3D model

cgtrader

Shoes were just shoes for the first 80-some-odd years of the 20th century. ...Then in the mid-1980s, Nike released a pair of basketball shoes featuring a certain ex-Tarheel. The Air Jordan was born, and the rest, as they say, is history.

...Then in the mid-1980s, Nike released a pair of basketball shoes featuring a certain ex-Tarheel. The Air Jordan was born, and the rest, as they say, is history.

air jordan shoes Low-poly 3D model

cgtrader

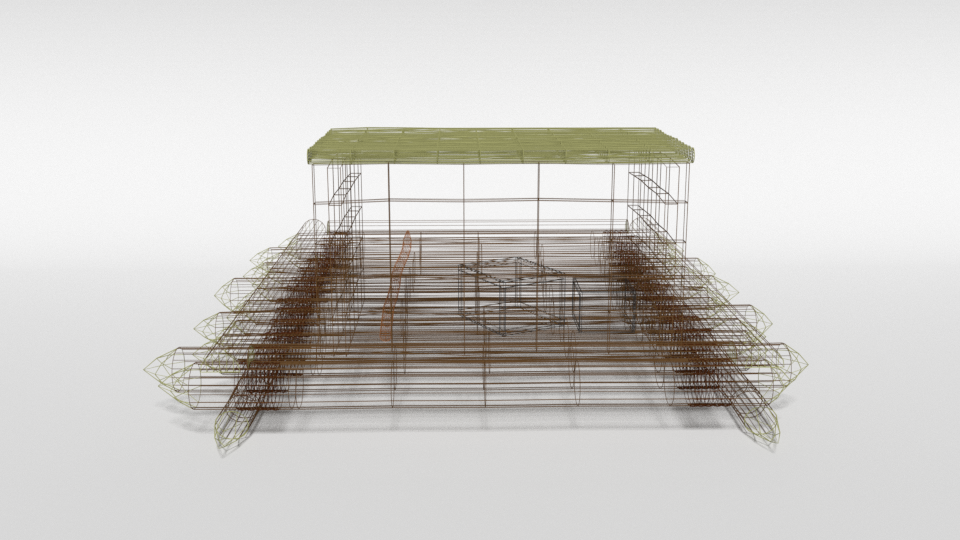

this is low poly air jordan shoes, very simple wireframe

Jordan Keychain

thingiverse

... http://www.thingiverse.com/thing:117519 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=117519 Instructions Using the following options: Text_Size = 9 Text_Rotate = 0 Text_Font = write/Letters.dxf Your_Text = Jordan

Jordan Keychain

thingiverse

. .. ...http://www.thingiverse.com/apps/customizer/run?thing_id=52734 Instructions Using the following options: flat_bottom = 2 font_thickness = 5 font_size = 10 Font = write/Letters.dxf stick_thickness = 3 hole_radius = 2 stick_width = 8 message = Jordan

.. ...http://www.thingiverse.com/apps/customizer/run?thing_id=52734 Instructions Using the following options: flat_bottom = 2 font_thickness = 5 font_size = 10 Font = write/Letters.dxf stick_thickness = 3 hole_radius = 2 stick_width = 8 message = Jordan

Jordan Keychain

thingiverse

http://www.thingiverse.com/apps/customizer/run?thing_id=739573 Instructions Using the following options: ruler_unit = 10 bar_shift = 0 lug_width = 6 outlineextruder = extruder1 border_width = 1.2 font_weight = 0 bar_length_trim = 0 font_with_style =...

G_Air_Jordan_Logo

thingiverse

Air Jordan Logo

Nike Air Jordan

sketchfab

Nike Air Jordan

AIR JORDAN BOX LED

thingiverse

Boitier air jordan led

Air Jordan XIII

thingiverse

This is just the air jordan 13 that benben made without the keychain :)

Air Jordan logo

thingiverse

This is the GOAT! . ..Air Jordan!

..Air Jordan!

AIR JORDAN SHOES POLYMER CLAY CUTTER

cults3d

3 model best of jordan sneakers. ... AIR JORDAN SHOES POLYMER CLAY CUTTER You can make cookies from these molds or clay decoration! ... Sizes: 100mm or you can scale for individual size

Air Jordan Renew 2022

thingiverse

An update for Air Jordan I, - Sole included - Sholelace enhancement

air jordan ornament

thingiverse

Its an ornament with a detachable air Jordan logo.

Air Jordan Tag

thingiverse

This is the accessory for the Air Jordan keychain. ...Printing Scale: Length - 25mm Print Settings Printer Brand: MakerBot Printer: ...

Air Jordan VIII

thingiverse

Hi guys, a good news to all sneaker addicts! ...I drew the series of Air Jordan Retro in Keychain Version, now you can simply download and share all to your friends ! Enjoy ! ...(By Rhinoceros)

Air Jordan IX

thingiverse

Hi guys, a good news to all sneaker addicts! . ..I drew the series of Air Jordan Retro in Keychain Version, now you can simply download and share all to your friends ! Enjoy ! ...(By Rhinoceros)

..I drew the series of Air Jordan Retro in Keychain Version, now you can simply download and share all to your friends ! Enjoy ! ...(By Rhinoceros)

Air Jordan XII

thingiverse

Hi guys, a good news to all sneaker addicts! ...I drew the series of Air Jordan Retro in Keychain Version, now you can simply download and share all to your friends ! Enjoy ! ...(By Rhinoceros)

Air Jordan I Revised

thingiverse

This was a repair and re-post of the following Air Jordan I. I wanted some small Air Jordans for my Spider-man figure, but the laces would not print in a smaller scale. I noticed that the laces were not resting on the tongue of the shoe, so I. ..

..

Air Jordan 6 Retro

sketchfab

Air Jordan 6 Retro PBR Ready Air Jordan 6 Retro was created with real world scale.i hope you like it.

PS5 Air Jordan 1

sketchfab

Air Jordan 1 inspired by the PS5 design. ... Made by RTFKT Studios

Air Jordan VI

thingiverse

I drew the series of Air Jordan Retro in Keychain Version, now you can simply download and share all to your friends ! Enjoy ! ...(By Rhinoceros) Print Settings Printer Brand: MakerBot . ..

..

Perm Terminator John Henry performed at the technology festival in Moscow

You are here

Home

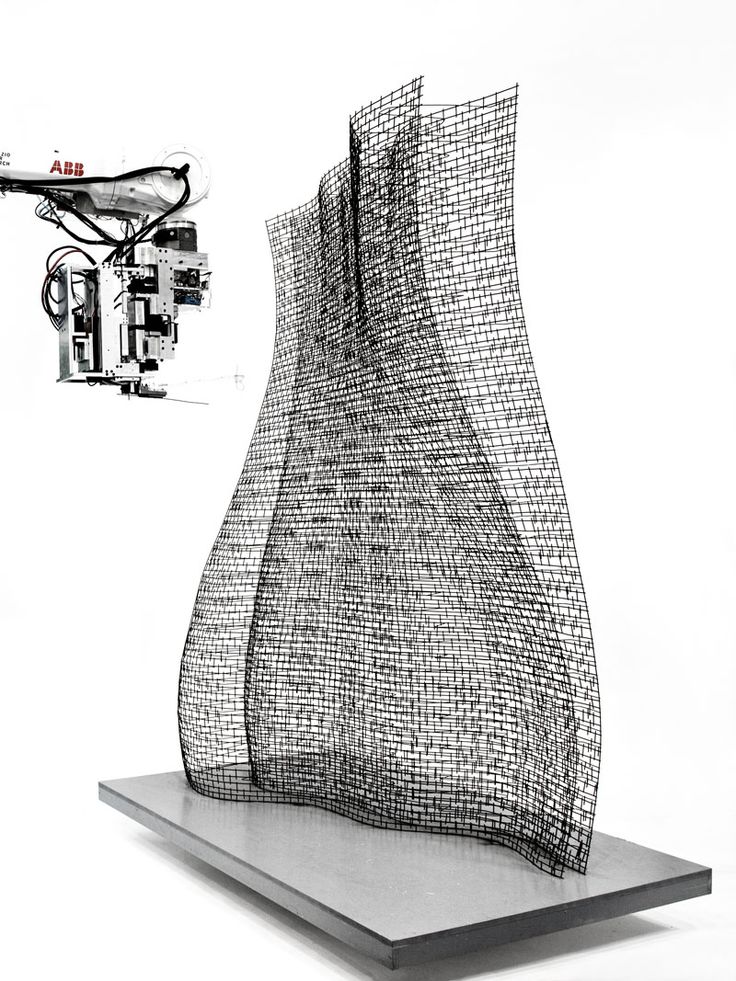

Terminator from Prikamye conquered the capital. Robot John Henry, who was created by Kunguryak Alexander Osipovich, performed at the Technosreda festival in Moscow. The android printed on a 3D printer independently told about itself to the guests of the exhibition and federal journalists.

Robot John Henry:

- My body is 3D printed. Made in the image and likeness of the T-800 robot from the movie "Terminator". The legs are not yet functional. All parts of the body are driven by servos.

Cannot walk yet, but recognizes faces, sex and age of interlocutors well, identifies objects, synthesizes speech. And Kungursky John Henry parodies his prototype well. At an exhibition in Moscow, he quoted the T-800 in the original language.

John Henry robot:

- I am a terminator. Cyberdyne systems. Model 101. I need your clothes, your boots and your motorcycle. My mission is to protect you. Come with me if you want to live.

The Kama android is not averse to philosophizing. He does not dream of becoming a man - this is a step back. He himself claims that he is already much more perfect than the two-legged. By the way, they showed great interest in John Henry. The robot was interviewed by journalists from a number of federal media. But John Henry aroused greater enthusiasm among the younger generation of techies.

Alexander Osipovich has been improving the android robot for more than 10 years. In the evenings, after working at a local poultry farm, he finishes his offspring. Recently, the Terminator took up arms - learned how to hold them. And now, like the prototype in the first part of the trilogy, its mission is to protect - the creator jokes.

Alexander Osipovich, creator of the Kungur Terminator:

- Its main function is to protect the house.

I live in the city of Kungur in the private sector. Everyone keeps an angry dog, and I have an angry terminator.

In his spare time from his main mission John Henry from Kungur performs at exhibitions. By the way, the video about his trip to the Moscow "Technosreda" overtook the video about another Permian robot - Alyosha, who also conquered the capital at the robofest.

Source

Other materials:

- COVESTRO AND ENVISIONTEC CREATE SOLUTION FOR 3D PRINTING TOOLING

- TÜV SÜD RELEASES PROCESS GUIDE FOR STABLE PRODUCTION OF 3D PRINTED MEDICAL DEVICES

Fundamentals of 3D modeling. Printing 3D models on a 3D printer.

Educational workshop

for teachers

Topic: Basics 3D modeling. Printing 3D models on a 3D printer.

Purpose: formation and development intellectual and practical competencies in the field of creating spatial models.

Tasks:

- to form a positive attitude towards 3D modeling algorithms;

-form ability to navigate in three-dimensional space;

- give an idea of three-dimensional modeling, appointment, development prospects;

- modify, change objects or their individual elements;

- create simple three-dimensional models;

Shape conducting:

students with teachers;

- lecture with presentation elements, practical work.

Registration:

- presentation on the theme of the master class.

Materials and tools for work: computer, projector, 3D printer, plastic ABC

Structure master class:

1. Introductory part. Announcement of the theme and purpose of the MC. The content of MK in as a whole and individual components.

2. Theoretical and demonstration part.

The main stages of the project.

The main stages of the project. 3. Practical part. Basic implementation techniques.

4. Reflection of MK participants. Summarizing.

Master course

1. Organizing time.

Hello, Dear guys and colleagues! Glad to see you all at our master class.

The theme of our master class: Fundamentals of 3D modeling. Printing 3D models on a 3D printer

Purpose of the master class: formation and development of intellectual and practical competencies in the field creation of spatial models.

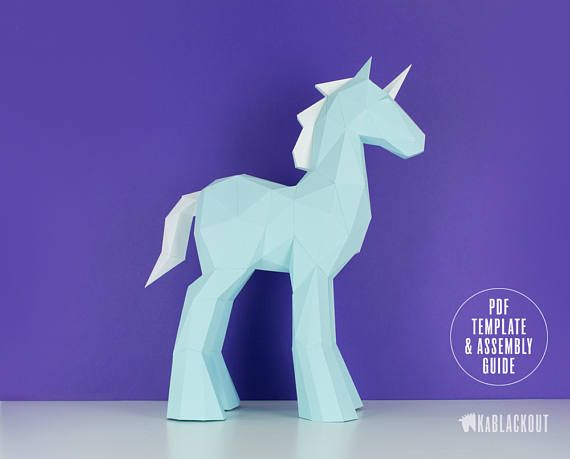

In the course of our creative activity, you will consolidate and master the basics of modeling using online Tinkercad program and make a "Keychain" model.

2. Theoretical demo part

To continue our wizard class guys will introduce you what is 3d modeling and 3d printing in general terms and we will smoothly move on to our practical parts

3D printing technology.

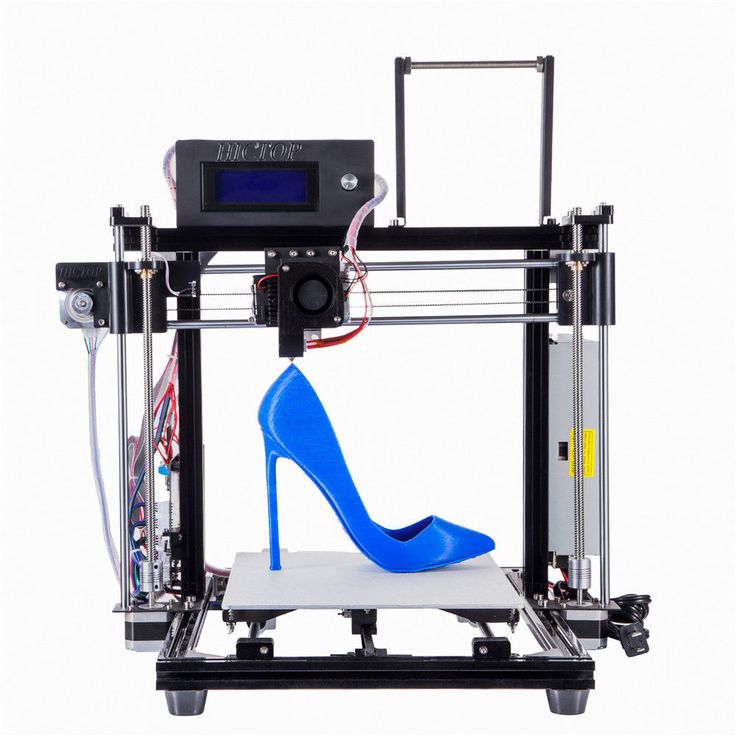

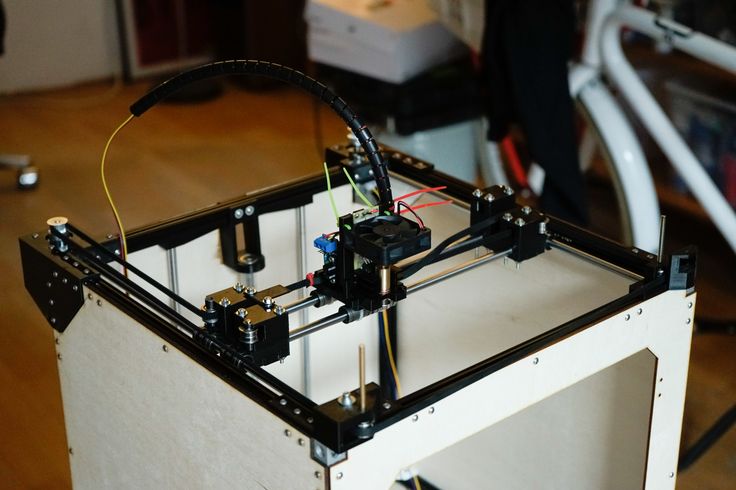

3D or 3D printing is a layer-by-layer creation of a physical object based on virtual 3D model.

Printing comes from several hundred and even thousands of layers on a special device - a 3D printer. 3D printer is called three-dimensional data output device, it is from a conventional printer that outputs two-dimensional information on a sheet, in that it allows you to display three-dimensional information (immediately in three dimensions) according to the principle of layer-by-layer growth The physical model is usually bottom-up. In turn, 3D printing is called the process of creating physical objects from 3D digital models created by 3D modeling in any CAD or CAD program.

Printing comes from several hundred and even thousands of layers on a special device - a 3D printer. 3D printer is called three-dimensional data output device, it is from a conventional printer that outputs two-dimensional information on a sheet, in that it allows you to display three-dimensional information (immediately in three dimensions) according to the principle of layer-by-layer growth The physical model is usually bottom-up. In turn, 3D printing is called the process of creating physical objects from 3D digital models created by 3D modeling in any CAD or CAD program. 3D technology printing originated in the middle of the twentieth century, at the same time the first 3D printers that looked more like manufacturing machines than printing devices. The price of such devices ranged from several tens to several hundred thousand dollars. With the development of 3D printing technology printers became smaller and cheaper. The first devices appeared available not only for industrial enterprises and large commercial organizations, but also for small businesses and households.

materials for 3D printing can be very different from the so-called ABC plastic to chocolate.

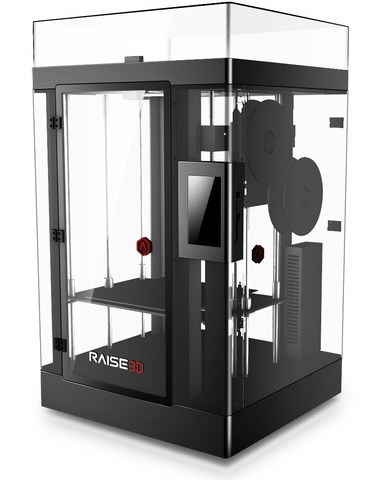

materials for 3D printing can be very different from the so-called ABC plastic to chocolate. Fig. 1.1. - Modern compact 3D printer

Modern 3D printing devices have learned to create not only household items and clothing, but also own parts, food, human tissues and organs.

3D printing has its own history since 1948, when the American Charles Hull developed the technology layer-by-layer growth of physical three-dimensional objects from photopolymerizable compositions (FPK).

Patent for own the author received the invention only at 1986, the same year he founded the company 3D System and started developing the first industrial device for 3D press, which was presented to the public a year later, in 1987. So since the term "3D printer" has not yet been introduced into circulation, the apparatus of Charles Hull received the name "installation for stereolithography".

3D features print. Methods for obtaining three-dimensional models.

3D printing capabilities are limitless.

With the help of a 3D printer, you can create a variety of things: from shoes to jewelry, from plastic phone cases to implants spine, which are made of medical grade titanium.

With the help of a 3D printer, you can create a variety of things: from shoes to jewelry, from plastic phone cases to implants spine, which are made of medical grade titanium. 2008 - Objet Geometries announced the creation of a revolutionary rapid prototyping system Connex500™. It was the first system in the world to allow the production of 3D parts. using different materials at the same time.

November 2010 - Urbee the first prototype of a printed car was presented. This is the first a car whose body was printed by a giant 3D printer. All external components - including glass panel prototypes - were created using Dimension 3D Printers and 3D Systems Fortus.

In 2011, the company Lockheed demonstrated at the British air show in Farnborough a large an unmanned aircraft, most of which was made using the 3D print. The Polecat aircraft is a flying prototype designed to show performance of new 3D printing technology. To the merits of such parts manufacturing is not only speed, but also relatively low the cost of such parts, and this is the main goal.

Production methods 3D models. 3D scanner.

As mentioned Previously, three-dimensional (3D) printing consisted of printing three-dimensional three-dimensional models hundreds or even thousands of layers.

Three-dimensional model, which will need to be printed can be obtained in three ways:

download the finished model, for example, from the Internet;

draw from scratch full 3D model;

scan existing object.

3D models from ABS plastics are durable, but do not tolerate direct sunlight. By using only opaque models can be obtained from such plastic.

Acrylic. Acrylic used in 3D printing to create transparent models. Using acrylic, the following features must be taken into account: for this material you need higher melting point than ABS and cools very quickly and hardens. In heated acrylic, a lot of small air bubbles appear. bubbles that can cause visual distortion of the finished product.

Concrete. B At present, trial samples of 3D printers for printing with concrete have been made. These are huge printing devices that painstakingly, layer by layer, “print” concrete construction details and structures. This 3D printer can in just 20 hours to "print" a residential two-story house with a total area of 230 m2.

For 3D printing an improved grade of concrete is used, the formula of which is 95% the same with the formula of ordinary concrete.

Hydrogel . Scientists from the University of Illinois (USA) printed using a 3D printer and hydrogel biorobots 5-10 mm long. Cells were placed on the surface of biorobots heart tissue that spread through the hydrogel and began to contract, driving the robot. Such hydrogel robots are able to move with speed of 236 micrometers per second. In the future, they will be launched into the body human to detect and neutralize tumors and toxins, as well as to transportation of medicines to the destination.

Paper. B Some 3D printers use plain paper as the print material. A4 paper. Since paper is an affordable and inexpensive material, paper models are inexpensive and accessible to users. Such models are printed in layers, with each subsequent layer of paper cut out printer and pasted on the previous one. Paper models print quickly, but cannot boast of strength or aesthetics. They are ideal for rapid prototyping of a computer project.

Plaster. B gypsum materials are widely used in modern 3D printing. models, made of gypsum, short-lived, but have a very low cost. Such models are ideal for the manufacture of objects intended for presentations. They can be shown as a sample to customers and customers, they perfectly convey the shape, structure and size of the original product. Because plaster models are characterized by high heat resistance, they are used as casting samples.

Wood fibre. Inventor Kai Parthi has developed a special wood fiber for 3D printing.

Fiber consists of wood and polymer and is similar in properties to polyactide (PLA). The combined material allows to obtain durable and solid models, which outwardly look like wooden products and have the smell of freshly sawn tree.

Fiber consists of wood and polymer and is similar in properties to polyactide (PLA). The combined material allows to obtain durable and solid models, which outwardly look like wooden products and have the smell of freshly sawn tree. Ice. B 2006 two Canadian professors received a grant for the development of 3D technology ice figure prints. In three years, they learned how to create using 3D printers small ice objects. Printing proceeds at a temperature of -22 ° C, as consumables are water and methyl ether, heated to temperature 20oC.

Metal powder. Not a single plastic can replace metal with its pleasant soft gloss and high durability. Therefore, in 3D printing it is very often powder from light and precious metals is used: copper, aluminum, their alloys, as well as gold and silver. However, metal models do not have sufficient chemical resistance and have high thermal conductivity, therefore, in metal printing powder add fiberglass and ceramic additives.

Jewelry from metal powder printed by a 3D printer.

Nylon . Nylon printing has a lot in common with ABS printing. Exceptions are higher printing temperature (about 320oC), high ability absorb water, longer curing time, need to pump out air from the extruder due to the toxicity of the nylon components. Nylon is enough slippery material, for its application it is necessary to equip the extruder with spikes. Despite these shortcomings, nylon is successfully used in 3D printing, since parts from this material are not as rigid as from ABS plastic, and sliding hinges can be used for them.

Polylactide (PLA). Polylactide is the most biocompatible and environmentally friendly material for 3D printers. It is made from biomass residues, sugar beet silage or corn. Having a lot of positive properties, polylactide has two essential disadvantage. Firstly, the models made from it are short-lived and gradually decompose under the influence of heat and light.

Secondly, the cost of production polylactide is very high, which means that the cost of models will be much higher similar models made of other materials. Used in 3D printing technologies: SLS and FDM.

Secondly, the cost of production polylactide is very high, which means that the cost of models will be much higher similar models made of other materials. Used in 3D printing technologies: SLS and FDM. Chocolate. British scientists presented to the public the first chocolate 3D printer that prints any chocolate figurines ordered by the operator. The printer inflicts each next a layer of chocolate on top of the previous one. Thanks to the ability of chocolate to quickly harden and harden when cooled, the printing process proceeds quite quickly. In the near future, such printers will be in demand in confectionery and restaurants.

what I expected was that houses would not just be built, but printed on 3D printer. The Chinese were able to think of this, and as it turned out, it turned out to be very reasonable.

The fact is that 3D the printer builds a house from industrial waste, fiberglass and cement, which is, in fact, slag concrete, which is both environmentally friendly and cheap.

In addition, absolute automation eliminates costly manual builder's work. As a result, the cost of the finished house is $ 4800, which is negligible.

In addition, absolute automation eliminates costly manual builder's work. As a result, the cost of the finished house is $ 4800, which is negligible. Teacher : Demonstration by the teacher of the operation of the 3D printer "Anet8". Printing 3D models. -------------------------------------------------- ---------------

Teacher's story about the benefits of 3D printing:

B why is it needed for educational purposes?

3D printers in education are a great opportunity to develop spatial thinking and creative skills. Practical modeling radically changes the way children think about various objects and makes the process of teaching such sciences as more accessible and understandable programming, design, physics, mathematics, natural science. Besides, creating something with your own hands will help to cross the threshold of the usual of our society of passive consumption of typical goods to the realization of their ideas into reality.

On 3D printer can print:

§ visualization of complex structures, objects and even formulas;

§ layout of a chain reaction or physical process;

§ imitation of a fragment of a human body or organ;

§ reconstruction of historical, archaeological or geographical significance of objects.

Beyond creative development students gain practical experience in prototyping, educational the program is supplemented with new subjects - the basics of design, engineering, design and modeling.

3. Practical part.

We have fixed and familiarized ourselves with basics of 3d modeling, 3d printing and 3d printers. Now let's move on to our practical part. We will break into groups as follows 1 student + teacher. The guys will be tutors today, will guide you, help you master the Tinkercad online 3d modeling program and At the end, we will print the design keychain you received on our 3d printer

The keychain will consist of from the details that you choose yourself because it is designer, which means flight your imagination is unlimited and then 3D printed.

go online editor like this it looks like on the right all forms what you can use on the left field on which we edit our model. Let's get started.

go online editor like this it looks like on the right all forms what you can use on the left field on which we edit our model. Let's get started. 4. Printing

Connect the printer to network, select the type of plastic and temperature. We insert a thread of plastic into the hole, located near the power input. I draw your attention to the fact that The end of the thread must be cut evenly. Then click on the download button plastic (left arrow). It is important that the plastic thread is not tangled, do not press on the nozzle and do not touch it with your hands, to stop the flow of plastic, press and hold down the plastic feed button (left arrow).

5. Reflection.

Our master class has come to an end. I hope you liked it and the knowledge acquired today and skills you can apply in your future work. I I thank you for your patience, activity and wish you health, success and professional optimism! Please complete the feedback sheet.

Learn more