3D laser printers for sale

Your At-Home 3D Laser Printer

Buy today - every US Glowforge Pro & Plus printer ships in 3 days.

Glowforge 3D Laser Printer.

We believe in a future where anyone can create anything. That's why we made Glowforge, the 3D Laser Printer that cuts, engraves, & scores hundreds of materials.

Learn MoreBuy NowFor a limited time: Get 0% APR with Affirm. Ends 8/31

Learn More ➔

A wooden quad-copter made on a Glowforge.

A leather satchel bag made on a Glowforge.

Colorful macarons with unique, personalized names cut into them using a Glowforge.

An intricately decorated mandala laser engraved on the back of a laptop computer using a Glowforge.

An art-deco style lamp made from wood cut on a Glowforge.

A cute little A-frame model made with laser-cut acrylic and laser-engraved wood.

Several leather key-chains and jewelry pieces cut and engraved using a Glowforge.

A slate coaster with an adorable cow, pig, and chicken etched using a Glowforge laser.

See what people are making

Your Glowforge works with hundreds of materials.

Built on laser cutter & engraver technology, Glowforge uses a beam of light the width of a human hair to cut, engrave, and shape designs from a variety of materials.

Features that set Glowforge apart

Live Camera Preview

3D Autofocus

3D Hi-Res Engraving

Laser Precision

Design with just a pen

Cloud simplicity

Automatic Setup

Live Camera Preview

See your design take shape before you print. Onboard cameras show you a preview of your design on whatever material you choose. Place your design with your mouse or finger and position it exactly where you want.

Onboard cameras show you a preview of your design on whatever material you choose. Place your design with your mouse or finger and position it exactly where you want.

Need something outstanding, fast? Catalog designs are the perfect gift.

Print jewelry, toys, leather goods, lighting, containers, art, and more. Designs are thoroughly tested and guaranteed to print perfectly every time. Each comes with detailed photo instructions to make them a snap to finish.

Browse Catalog Designs“…the next wave of computer-aided creativity.”

Real people, real magic. Discover what’s possible.

Glowforge

3D Laser Printer

Glowforge’s powerful desktop laser cuts, engraves, & scores hundreds of materials.

“…the next wave of computer-aided creativity.”

“…the next wave of computer-aided creativity.”

What will you create with Glowforge?

Swipe to see more ⭤

What will you create with Glowforge?

Craft with leather

Design home goods

Make custom signs & maps

Create intricate art

Personalize gifts

Start a side hustle

Customize anything

Bring your ideas to life.

Watch the magic happen.

Customize your prints.

Create with hundreds of materials.

Swipe to see more ⟷

Let's make something together.

Schedule a free virtual demo with a Glowforge Expert & experience the magic of Glowforge in real time.

Schedule a demoMade by creators like you.

Swipe to see more ⟷

Dear Glowforge,

3D laser printers from the top brands | Lowest prices

Filters

- In stock (22)

- Out of stock (7)

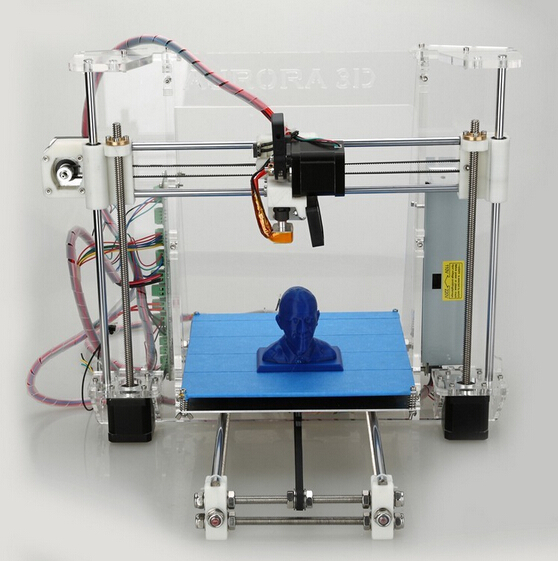

- 3 in 1 3D Printer (1)

- 3D Printer (5)

- Laser Cutter/Engraver (19)

- Comgrow (2)

- Flux (4)

- Gweike Laser (3)

- Lotmaxx (2)

- Makeblock (1)

- Ortur (2)

- Sculpfun (4)

- SnapMaker (3)

- ZMorph (1)

- xTool (3)

Showing 1 - 24 of 25 products

View

Filters

- In stock (22)

- Out of stock (7)

- 3 in 1 3D Printer (1)

- 3D Printer (5)

- Laser Cutter/Engraver (19)

- Comgrow (2)

- Flux (4)

- Gweike Laser (3)

- Lotmaxx (2)

- Makeblock (1)

- Ortur (2)

- Sculpfun (4)

- SnapMaker (3)

- ZMorph (1)

- xTool (3)

voxeljet 3D printers: how a startup becomes a business

Our partners

Disruptive technology articles are almost always a synthetic genre. Synthetic in the sense that it is impossible to separate the history of the company, the features of its business strategy, technologies and specific products. In the field of high, innovative technologies, all this is merged - ideas give birth to a product, the first successful sales attract investors and provide funds for development, commercial success brings money for the development of new ideas, etc. Therefore, the story about the German company voxeljet cannot be reduced to a description its industrial 3D printing systems are definitely unique and very interesting. nine0003

Synthetic in the sense that it is impossible to separate the history of the company, the features of its business strategy, technologies and specific products. In the field of high, innovative technologies, all this is merged - ideas give birth to a product, the first successful sales attract investors and provide funds for development, commercial success brings money for the development of new ideas, etc. Therefore, the story about the German company voxeljet cannot be reduced to a description its industrial 3D printing systems are definitely unique and very interesting. nine0003

Innovative technologies are not limited to one subject area. This is how 3D printing installations, which were originally focused on creating molds, have to do with the electronics industry? However, truly innovative technologies open up completely new opportunities in a variety of directions, allow you to create new products with revolutionary technical and cost characteristics. Therefore, specialists in the field of electronics simply need to know about such technologies. nine0003

nine0003

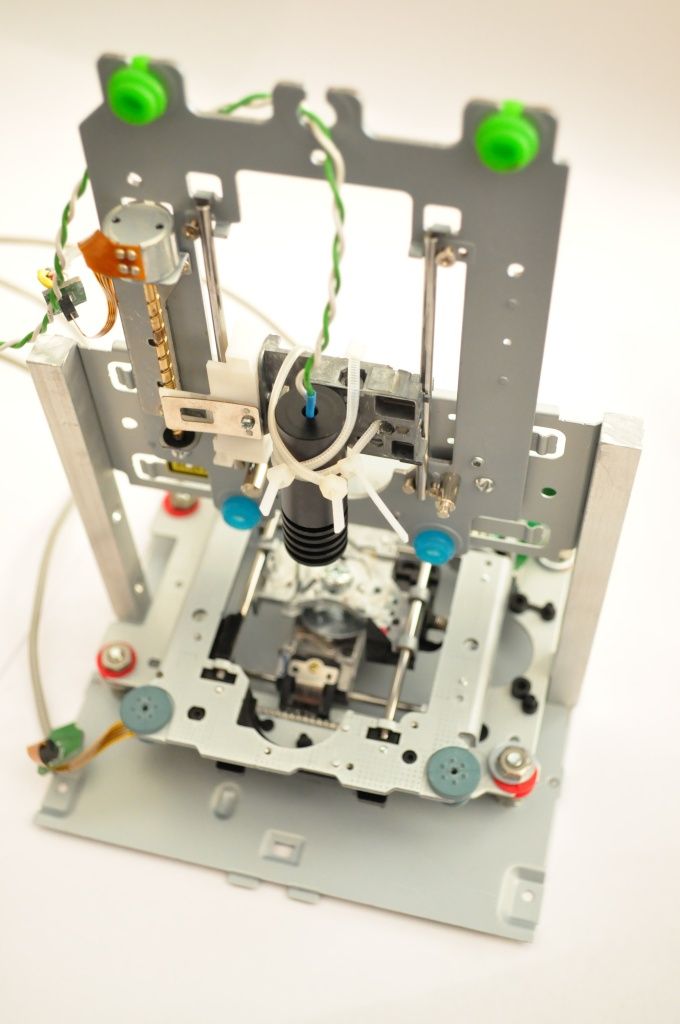

Rice. 1 Principle of voxeljet 3D printing

voxeljet: how startups are born

In the mid-1990s of the last century at the Technical University of Munich, a group of Professor Joachim Heinzl worked on the problem of creating industrial 3D printers. This group included postgraduate student Ingo Ederer, who was writing his doctoral dissertation (PhD), and graduate student Rainer Höchsmann. Professor J. Heinzl, Vice-President of the Technical University of Munich, was already a well-known and very versatile scientist by that time, a recognized specialist in such fields as MEMS, low-noise aerostatic bearings, ultra-precision processing and laser measurements, and a doctorate in 1970 he received in the field of electroacoustics. In the second half of the 70s, J. Heinzl led a division of the central laboratory of Siemens, which was engaged in the development of printers (mechanical, including matrix) and mechanical systems for information storage on punched tapes and magnetic films. It is fundamentally important for us that it was then that J. Heinzl began his work in the field of inkjet printing based on piezoinjection, which ended in 1977 with the creation of the first commercial Siemens PT 80i inkjet printer. Therefore, it is not at all accidental that at 19In 1995, a group led by Prof. J. Heinzl achieved the first successful results in the field of dosing systems for UV-curable polymer resins. It was an important part of the sand mold 3D printer project. Already in 1998, the first sand casting mold was printed at the Technical University of Munich, at the same time the first patent for the invention was received.

It is fundamentally important for us that it was then that J. Heinzl began his work in the field of inkjet printing based on piezoinjection, which ended in 1977 with the creation of the first commercial Siemens PT 80i inkjet printer. Therefore, it is not at all accidental that at 19In 1995, a group led by Prof. J. Heinzl achieved the first successful results in the field of dosing systems for UV-curable polymer resins. It was an important part of the sand mold 3D printer project. Already in 1998, the first sand casting mold was printed at the Technical University of Munich, at the same time the first patent for the invention was received.

On May 5, 1999, J. Ederer, R. Höschmann and Professor J. Heinzl created Generis, the forerunner of voxeljet. At that time there were only four employees. At first, the company was based at the Technical University of Munich, then moved to neighboring Augsburg. In 2000, the young company took part in the business plan competition for start-up projects in Germany and took fourth place among 1261 contestants from all over the country. The company received a cash prize and free annual management consulting services from experts from the world-famous McKinsey & Company. As early as 2002, the first sand mold printers were sold to BMW and Daimler. nine0003

The company received a cash prize and free annual management consulting services from experts from the world-famous McKinsey & Company. As early as 2002, the first sand mold printers were sold to BMW and Daimler. nine0003

In the next year, 2003, very important events took place. On the one hand, the success was so obvious that the company received third-party investments - from the Bayern Kapital venture capital fund and the Augsburg start-up capital fund (Startkapital Fonds Augsburg). Moreover, Rudolf Franz, a professional investor, founder of the investment company Franz Industriebeteiligungen, joined the company.

On the other hand, Generis was divided in 2003: R. Hoeschman left the company to become a co-founder of a competing company. And instead of Generis, voxeljet technology was officially created. voxeljet's Managing Director is Dr. Ingo Ederer (since 2013 - chief executive), and its chief operating officer - Rudolf Franz (since 2013 - financial director). At the same time, a new direction appeared in voxeljet - the provision of services for the production of 3D models and molds from sand and plastic. nine0003

nine0003

Since then, the dynamic development of voxeljet has begun. The development of printing technology from plastic material - polymethyl methacrylate (PMMA) powder has been successfully completed. In 2005, the VX800, the first large-format printer capable of working with PMMA, was sold; two years later, the new VX500 model appeared; concept of "continuous" 3D printing. In 2010, voxeljet changed its location and moved to the technopark in Friedberg near Augsburg, to a new production complex with an area of over 16 thousand square meters. m. nine0003

In 2013, the company took a new step and became a public company (voxeljet AG), after which it successfully completed an initial public offering on the New York Stock Exchange. As a result, its capitalization increased by $64.5 million. The re-issue of shares in 2014 brought the company another $41.4 million. At the same time, a Voxeljet of America branch and service center was opened near Detroit (USA).

In 2014, voxeljet's turnover was 16. 163 million euros, up 38% on 2013. Moreover, the revenue from sales of printers amounted to 9.057 million euros, and services for the manufacture of 3D parts were provided for 7.106 million euros. But even before that, the company's turnover grew at an average annual rate of 30%. By the end of 2013, 58 voxeljet printers had been installed worldwide, and the company sold seven printers in the fourth quarter of 2014 alone.

163 million euros, up 38% on 2013. Moreover, the revenue from sales of printers amounted to 9.057 million euros, and services for the manufacture of 3D parts were provided for 7.106 million euros. But even before that, the company's turnover grew at an average annual rate of 30%. By the end of 2013, 58 voxeljet printers had been installed worldwide, and the company sold seven printers in the fourth quarter of 2014 alone.

According to the forecast of voxeljet CEO I. Ederer, in 2015 the company's turnover will be from 23 to 24 million euros. Agree that this is a lot for a company that started 15 years ago with four employees. Today, voxeljet employs 125 specialists, and the development of the company continues. So what are the features of voxeljet technology that have allowed it to achieve such impressive results? nine0003

3D printing technologies voxeljet

As in many other 3D printing technologies, parts are formed in layers. A project in the format of any standard design system (CAD) with the help of special software is split into layers of a given thickness. This information is transmitted to the printer, where layer-by-layer printing begins.

This information is transmitted to the printer, where layer-by-layer printing begins.

The fundamental difference between voxeljet printers is the layering technology. It uses powder bonding rather than sintering or printing with liquid polymers like many traditional 3D printers. The essence of the method is that a thin layer of powder material is applied to a flat surface. And then, during the second pass, glue is dosed into the right places, which binds the powder particles. The glue polymerizes in air - at room temperature or by means of IR heating. Then the operation is repeated - again an even layer of powder and a layer of glue - and so on, until the entire object is formed. Then the non-glued powder particles are simply poured out, its excess is blown off (for example, with compressed air), cleaned and reused. nine0003

A remarkable feature of this method is the variety of materials used. Now the company mainly uses fine quartz sand and polymethyl methacrylates (PMMA). However, much attention is paid to the development of new materials, such as casting mixtures based on zirconium and chromite sands, PMMA plastics; silicon carbide; tungsten carbide; wood flour; cement, ceramics, etc. - materials can be very different, it is important to choose the right adhesive component here. For example, organic substances are used for bonding PMMA powders, and special inorganic agents are used for quartz sands. Moreover, instead of traditional furan resins, the company has developed a non-volatile compound that does not emit harmful substances when heated to metal melting temperatures. This is very important in the context of the desire to improve the environmental friendliness of production. More recently, voxeljet announced a new adhesive phenolic resin that opens up new possibilities for printing not only sand molds, but also ceramic molds. nine0003

However, much attention is paid to the development of new materials, such as casting mixtures based on zirconium and chromite sands, PMMA plastics; silicon carbide; tungsten carbide; wood flour; cement, ceramics, etc. - materials can be very different, it is important to choose the right adhesive component here. For example, organic substances are used for bonding PMMA powders, and special inorganic agents are used for quartz sands. Moreover, instead of traditional furan resins, the company has developed a non-volatile compound that does not emit harmful substances when heated to metal melting temperatures. This is very important in the context of the desire to improve the environmental friendliness of production. More recently, voxeljet announced a new adhesive phenolic resin that opens up new possibilities for printing not only sand molds, but also ceramic molds. nine0003

voxeljet

3D printers The stated principle underlies voxeljet 3D printers. The main parts of the printer: powder application system, inkjet printing head with multiple nozzles for dispensing glue and a box with a movable bottom - a working plate. At the beginning of the process, the plate is raised up. Powder RIS 1 is evenly applied to its surface using a squeegee. In this case, the layer thickness can be from 80 to 200 microns for plastics and 300 microns for quartz sand. The dosing head then applies the adhesive as in a conventional plotter. At the same time, resolutions up to 600 dpi (dots per inch) are possible, which is equivalent to 42.3 × 42.3 microns - as in a good printing process. As each layer of powder/adhesive is applied, the plate is lowered down exactly by the thickness of the layer, and all operations are repeated. nine0003

At the beginning of the process, the plate is raised up. Powder RIS 1 is evenly applied to its surface using a squeegee. In this case, the layer thickness can be from 80 to 200 microns for plastics and 300 microns for quartz sand. The dosing head then applies the adhesive as in a conventional plotter. At the same time, resolutions up to 600 dpi (dots per inch) are possible, which is equivalent to 42.3 × 42.3 microns - as in a good printing process. As each layer of powder/adhesive is applied, the plate is lowered down exactly by the thickness of the layer, and all operations are repeated. nine0003

Today, voxeljet offers six different models of 3D printers that allow you to print products ranging in size from 300 × 200 × 150 mm to 4000 × 2000 × 1000 mm with a capacity of 0.7 to 123 liters per hour. , but also the company's focus on creating reliable industrial equipment, which is distinguished by high performance and accuracy.

Table

voxeljet 3D printers| Model | VX200 | VX500 | VXC800 | VX1000 | VX2000 | nine0002 VX4000 |

| Year of issue | 2012 | 2007 | 2012 | 2011 | 2013 nine0003 | 2011 |

| Dimensions of the working area (length × width × height), mm | 300×200×150 | 500×400×300 | 850×500×1500/2000 nine0052 | 1060×600×500 | 2060×1060×1000 | 4000×2000×1000 |

| Permissible layer thickness, microns | 150 | nine0002 80–150 | 300 | 100–300 | 120–400 | 120–300 |

| Print speed (vertically), mm/h | nine0049 15 | 35 | 36 | 21. | 15.4 | |

| Material consumption, l/h nine0003 | 0.7 | 3 | eighteen | 23 | 47 | 123 |

| nine0002 Resolution, dpi | 300 | 600 | 600 | 600 | 200/600 | 600 nine0003 |

| Head width, mm | 21 | 112 | 112 | 112/450 | 520/564 nine0052 | 1120 |

| Number of nozzles | 256 | 2656 | 2656 | 2656/10624 | nine0049 26560 | |

| Installation dimensions (length × width × height), m | 1. | 1.8×1.8×1.7 | 4×2.8×2.2 nine0003 | 2.4×2.8×2 | 4.9×2.5×2.3 | 19.5×7×3.8 |

| Weight, kg | 450 | 1200 nine0003 | 2500 | 3500 | 5000 | — |

| Required production space, m | 3×2.5×2 nine0003 | 3×4×2.2 | 4.8×4×3 | 4.4×7.9×3 | 15×11×3.5 | 25×14×4.8 |

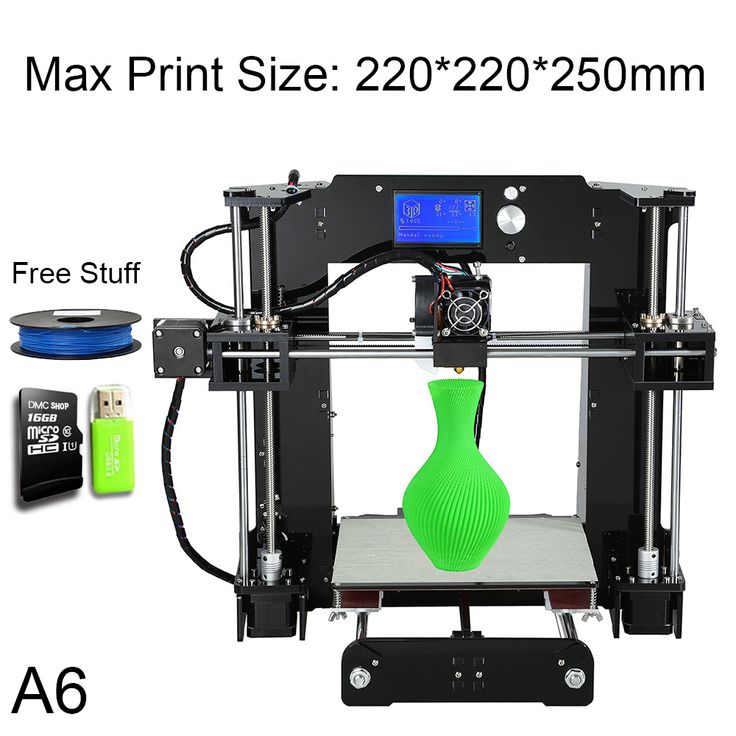

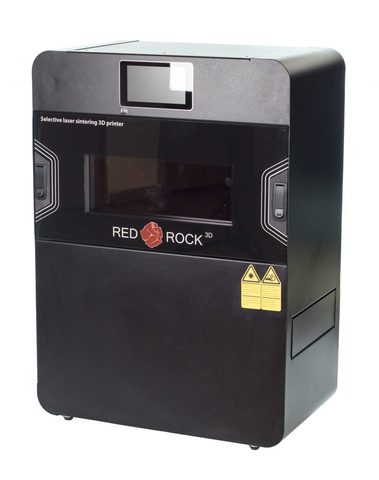

The very first printer sold today was the VX500, introduced in 2007 FIG. 2. This compact model, with a working space of 500 x 400 x 300 mm, provides the ability to work with various materials with layer thicknesses up to 80 microns. Print resolution - 600 dpi, productivity - up to 15 mm / h vertically, that is, about 19from to layer. The dimensions of such an installation (length × width × height) are 1.79 × 1.85 × 1.66 m, weight is 1.2 tons.

The dimensions of such an installation (length × width × height) are 1.79 × 1.85 × 1.66 m, weight is 1.2 tons.

Rice. 2 VX500 printer

Even more compact is the entry-level model VX200 with a working space of 30 x 20 x 15 cm FIG. 3. It handles 150 µm thick layers, 300 dpi dosing head resolution, and 12 mm/h (0.7 l/h) throughput . Installation dimensions - 1.7 × 0.9 × 1.5 m, weight - 450 kg. Although this is the simplest voxeljet model, it was one of the last to be introduced, in 2012. Therefore, it implements all the technologies and capabilities that are characteristic of larger installations, including reliability and quality. The very fact of creating such an installation speaks of the company's desire to be represented in the widest possible range of different applications. nine0003

Rice. 3 VX200 entry-level printer

The dimensions of the formed parts are limited by the dimensions of the box. It is not easy to increase the base plate - after all, the thickness of the powder layer is from 80 to 300 microns, while all movements must be precise. However, the company does offer a range of printers with moveable bases up to 2 x 1 m and box heights up to 1 m. - for the VX1000 printer FIG. 5. Both of these printers are equipped with interchangeable boxes that can be simply lifted on a forklift. However, the VX1000 can be equipped with a special 450 mm wide printhead with 10,624 individually controlled nozzles. This allows you to print a single layer in just two passes (at 40cm/s) for a throughput of up to 36mm/h (23 l/h). nine0003

However, the company does offer a range of printers with moveable bases up to 2 x 1 m and box heights up to 1 m. - for the VX1000 printer FIG. 5. Both of these printers are equipped with interchangeable boxes that can be simply lifted on a forklift. However, the VX1000 can be equipped with a special 450 mm wide printhead with 10,624 individually controlled nozzles. This allows you to print a single layer in just two passes (at 40cm/s) for a throughput of up to 36mm/h (23 l/h). nine0003

Rice. 4 VX2000 printer. In the foreground - a replaceable work box

The VX2000 is the latest voxeljet printer. Its working space is 2060 × 1060 × 1000 mm, dimensions are 4.9 × 2.5 × 2.3 m, weight is 5 tons. Like the VX1000, this is a serious industrial plant designed for continuous round-the-clock operation. Its capacity is 21.6 mm/h (47 l/h), layer thicknesses are from 200 to 400 microns.

Rice. 5 VX1000 printer nine0003

In 2011, voxeljet introduced the VX4000 RIS 6 with a 4m x 2m board and up to 1m part height. It is the largest industrial 3D printer in the world with an 8m3 workspace. However, the design of this printer is different from other models. In it, the plate is fixed, and the head moves vertically. And the head is also unique. At 112 cm wide, it has 26,560 glue nozzles and delivers up to 600 dpi resolution at a travel speed of 50 cm/s—a layer is printed in two head passes. At the same time, the productivity of the printer reaches 15.4 mm / h (123 l / h). The printer itself has impressive dimensions - 19.5 × 7 × 3.8 m, in fact, this is a separate production complex. But it also allows you to solve very serious tasks.

It is the largest industrial 3D printer in the world with an 8m3 workspace. However, the design of this printer is different from other models. In it, the plate is fixed, and the head moves vertically. And the head is also unique. At 112 cm wide, it has 26,560 glue nozzles and delivers up to 600 dpi resolution at a travel speed of 50 cm/s—a layer is printed in two head passes. At the same time, the productivity of the printer reaches 15.4 mm / h (123 l / h). The printer itself has impressive dimensions - 19.5 × 7 × 3.8 m, in fact, this is a separate production complex. But it also allows you to solve very serious tasks.

Rice. 6 VX4000 system

In 2012, the company introduced another printer with a new, revolutionary "continuous" printing technology, the VXC800 RIS 7. It allows you to produce objects of theoretically unlimited length.

The system is called "continuous" printer. In it, the printed layer is located not horizontally, but at an angle. The first layer is applied on an inclined plate mounted on a conveyor. The angle of inclination of the plate is chosen so that the powder does not crumble from it. Then the conveyor moves forward one step (corresponding to a layer thickness of 300 microns) and the process is repeated for as long as desired. It is clear that the plate is needed only at the very beginning of the process, then the inclined surface is formed each time by the powder application system. This method allows you to print parts continuously - at one end of the printer, the formation of blanks begins, at the exit of the working chamber, the powder falls off, and the finished parts leave the conveyor. The dimensions of the working chamber of the printer are 58 × 50 cm, the possible height is 1.5 or 2 m. It is clear that these dimensions do not limit the length - theoretically, it is possible to print a sample of any length, as long as the dimensions of the conveyor and workshop are enough. At the same time, the print resolution is 600 dpi, the layer thickness is 300 microns, and the productivity is 35 mm/h (18 l/h).

The angle of inclination of the plate is chosen so that the powder does not crumble from it. Then the conveyor moves forward one step (corresponding to a layer thickness of 300 microns) and the process is repeated for as long as desired. It is clear that the plate is needed only at the very beginning of the process, then the inclined surface is formed each time by the powder application system. This method allows you to print parts continuously - at one end of the printer, the formation of blanks begins, at the exit of the working chamber, the powder falls off, and the finished parts leave the conveyor. The dimensions of the working chamber of the printer are 58 × 50 cm, the possible height is 1.5 or 2 m. It is clear that these dimensions do not limit the length - theoretically, it is possible to print a sample of any length, as long as the dimensions of the conveyor and workshop are enough. At the same time, the print resolution is 600 dpi, the layer thickness is 300 microns, and the productivity is 35 mm/h (18 l/h). It is obvious that for all its apparent simplicity, the creation of the VXC800 system had to solve many complex engineering problems, for example, to provide precise control of the conveyor. nine0003

It is obvious that for all its apparent simplicity, the creation of the VXC800 system had to solve many complex engineering problems, for example, to provide precise control of the conveyor. nine0003

Rice. 7 VXC800 Continuous Printer

Thus, the company has created a line of printers covering the widest range of tasks. Moreover, the technology embedded in them allows you to create objects that are inaccessible to other methods. For example, you can make two parts nested one inside the other, but not connected in any way - for example, a ball inside a hollow sphere, two knots with an inseparable swivel joint, etc. Moreover, many parts can be made at once in one box - as identical, and completely different. A special program helps to tightly arrange the parts in the volume of the box, with allowable gaps of up to 2 mm. This greatly increases the speed of voxeljet units and makes their nominal output (in mm/h) quite realistic. For example, a VX500 printer box can accommodate 484 parts with dimensions of 115 × 34 × 30 mm FIG. 8, 9. The VX1000 prints 780 two-stroke engine mold blanks in just 23 hours! And there are many such examples. Therefore, the large workspaces of voxeljet printers are not only large-sized parts, but also high productivity, virtually continuous mass production.

8, 9. The VX1000 prints 780 two-stroke engine mold blanks in just 23 hours! And there are many such examples. Therefore, the large workspaces of voxeljet printers are not only large-sized parts, but also high productivity, virtually continuous mass production.

Rice. 8 Example of dense packing of various parts in the box space: a 484 parts with dimensions of 115 × 34 × 30 mm in a VX500 printer box, b 780 parts (78.3 × 58.6 × 75.5 mm) in a VX1000 printer box nine0003

Rice. 9 Program for dense nesting of parts in the box

3D Parts Manufacturing Services: Fast and Affordable

The voxeljet company not only manufactures printers, but also continues to produce 3D parts to order, that is, it acts as a contract manufacturer. At the same time, PMMA plastics with various dyes and sand (quartz, zirconium, chromite, etc.) are used as materials. Large voxeljet equipment provides two unique features in the market - large part sizes and/or high productivity at an affordable cost and high quality. In other words, the company provides the speed of order fulfillment and flexibility typical of 3D printing, but at the same time the price of services corresponds to traditional technologies, if there is such an alternative. nine0003

In other words, the company provides the speed of order fulfillment and flexibility typical of 3D printing, but at the same time the price of services corresponds to traditional technologies, if there is such an alternative. nine0003

Rice. 10 All this is printed on voxeljet printers

Not surprisingly, voxeljet's customers include representatives from a wide variety of industries. These are architectural models of various structures, and ready-made architectural details of buildings (column capitals, gable decorations, etc.), various design solutions (armchairs, chandeliers, even sanitary ware), statuettes of famous people, movie heroes, etc. FIG. 10. The company is especially proud of the fact that it was the company that ordered the model (in 1:3 scale) of the legendary James Bond car Aston Martin DB5 for filming one of the most successful Bond films “007. Coordinates: Skyfall FIG. 11. However, voxeljet's focus remains on mold making—for cast iron, as well as steel, aluminum, and copper alloys. So let's talk about them in more detail. nine0003

So let's talk about them in more detail. nine0003

Rice. 11 1:3 plastic model of the legendary James Bond car Aston Martin DB5 for the film “007. Coordinates: "Skyfall" printed on VX1000

voxeljet 3D printing technologies for molds

The most widespread metal casting technology is based on the use of sand molds. These molds are made from special sand casting mixtures. The manufacturing technology of such molds is laborious and difficult to automate. Both the models for such molds and the molding processes themselves are complex, require manual labor, often complex molds are assembled from many parts, casting cores, sprues, etc. are mounted separately in them. Actually, they started working on this problem more than 20 years ago founders of the voxeljet company. 3D printing technology from fine sand, with inorganic adhesives, turned out to be an almost ideal solution. The company produces sand casting molds for a wide variety of applications on request of customers, and immediately with an integrated sprue system fig 12. The main customers are manufacturers of engines and power units. Molds are produced for marine diesel cylinder blocks, manifolds, powerful pump casings (weighing up to 800 kg), radial-axial turbine impellers, casting cores for water radiator jackets, etc. FIG. 13. Of course, which molds are disposable, but voxeljet produces them on an industrial scale, which turns out to be cheaper, better and faster than traditional approaches. nine0003

The main customers are manufacturers of engines and power units. Molds are produced for marine diesel cylinder blocks, manifolds, powerful pump casings (weighing up to 800 kg), radial-axial turbine impellers, casting cores for water radiator jackets, etc. FIG. 13. Of course, which molds are disposable, but voxeljet produces them on an industrial scale, which turns out to be cheaper, better and faster than traditional approaches. nine0003

Rice. 12 Casting based on voxeljet 3D printed sand molds

Another mass type of metal casting, primarily precision casting, is casting into crust (shell) molds according to lost-wax or burnt-out models. This method is mainly used for parts of complex shape. Its essence: an exact master model of the part is made (from wood, gypsum and other easily processed materials), a matrix is made according to the master model - a mold for the investment model. It is carefully processed, the surface is polished. Such a mold is used to make investment models from wax, paraffin, or polymer low-melting foam materials (usually polystyrene). The finished model, to which the sprue system is added, is immersed in a liquid molding sand (ceramic suspension) and dried. The inner model is melted with hot water, the mold is placed in an oven, where the ceramics are sintered and the organic residues of the model are removed, and the mold for precision casting is ready. nine0003

The finished model, to which the sprue system is added, is immersed in a liquid molding sand (ceramic suspension) and dried. The inner model is melted with hot water, the mold is placed in an oven, where the ceramics are sintered and the organic residues of the model are removed, and the mold for precision casting is ready. nine0003

Rice. 13 Samples of voxeljet 3D-printed products - from complex design structures and designer aluminum chairs to engine assemblies

A similar technology is used by voxeljet, only in a much simpler version of FIG. 14. A model is immediately made from PMMA powder on a 3D printer (no need for a master model). To achieve a perfectly smooth surface, it is dipped in melted wax and/or coated with epoxy. Further, as in the classical technology, the model is immersed in a liquid molding sand and/or sprinkled with molding sand, which is sintered in an oven at a temperature of about 800 °C. At the same time, the PMMA model burns out without residue - a finished shell mold for precision casting is formed. This technology is used, for example, for casting cylinder heads, turbine impellers, etc. nine0003

This technology is used, for example, for casting cylinder heads, turbine impellers, etc. nine0003

Rice. 14 The process of casting in crust molds according to burn-out patterns 25

It would seem that the problems of casting power plant parts are far from electronics. But the automotive industry, engine building in general, is just an example of mass production. And voxeljet solutions have already proven their effectiveness in this kind of tasks. In the field of creating radio-electronic systems, there are many problems associated with the mass production of complex structures, both serial and at the level of single samples and pilot batches. Not to mention the fact that electronics is not a self-sufficient area, any electronic unit must be inserted into any structure - be it a cell phone, an airplane or a phased antenna array. And therefore, advanced industrial technologies for creating complex structures, including foundries, are extremely important for the electronics industry. Voxeljet solutions may be especially relevant in combination with other technologies, for example, technologies for direct formation of circuits on three-dimensional surfaces (for example, 3D-MID). And here the possibilities of precise and technological casting can be extremely in demand. nine0003

Voxeljet solutions may be especially relevant in combination with other technologies, for example, technologies for direct formation of circuits on three-dimensional surfaces (for example, 3D-MID). And here the possibilities of precise and technological casting can be extremely in demand. nine0003

We asked Tobias King, director of applications and planning, to talk about the development of the company's business, including in Russia.

Tobias, in which areas are voxeljet products most in demand?

The advantages of the 3D printing method compared to traditional production methods lie primarily in cost reduction. In turn, this decrease is due to a decrease in the number of technological steps required to create a particular product. And with the increase in printer productivity, and hence the ability to manufacture large batches of parts, this trend will only continue. Our company focuses on industrial applications. Therefore, it is not surprising that among our customers are such industrial giants as BMW, Daimler, Ford, MAN B&W Diesel and many others. In addition, voxeljet cooperates with the aviation industry, with the energy industry, with heavy engineering, technical universities, etc. As a result, we are one of the largest suppliers of sand foundries in Europe, our printers consume up to 200 tons of sand per month. And this is fundamental - everyone associates 3D printing with piecework, and therefore expensive production. We can, in a day, in one cycle, make 780 models for molds for single-cylinder two-stroke engines on the VX1000 printer. Due to the size and performance of our equipment, we provide mass production services. nine0003

In addition, voxeljet cooperates with the aviation industry, with the energy industry, with heavy engineering, technical universities, etc. As a result, we are one of the largest suppliers of sand foundries in Europe, our printers consume up to 200 tons of sand per month. And this is fundamental - everyone associates 3D printing with piecework, and therefore expensive production. We can, in a day, in one cycle, make 780 models for molds for single-cylinder two-stroke engines on the VX1000 printer. Due to the size and performance of our equipment, we provide mass production services. nine0003

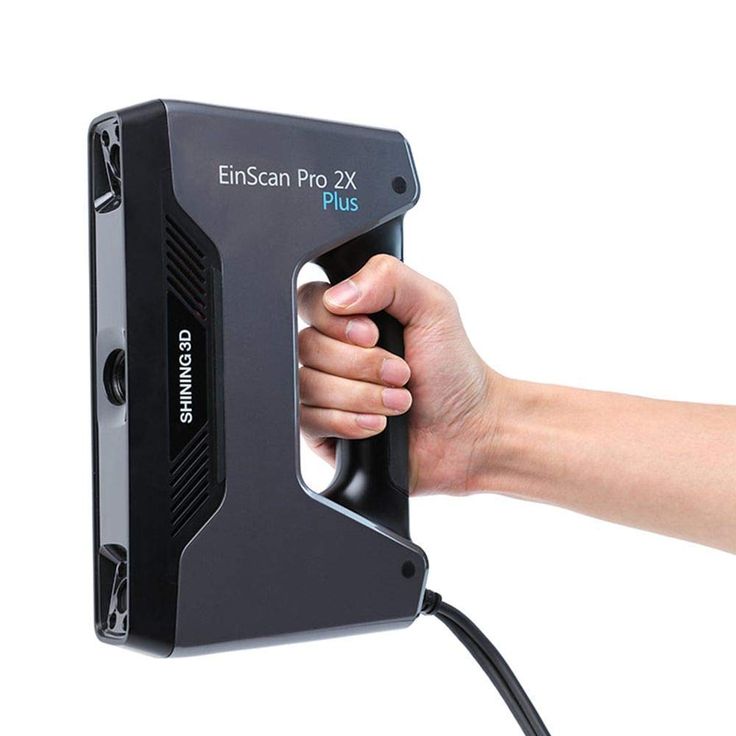

In addition to mass serial orders, we are often contacted if you need to produce any unique parts for replacement. For example, turbine impellers - they often work in installations for 50-60 years, and no technological documentation or drawings have been preserved for them. And they need to be replaced. We take such an impeller, scan it in a 3D scanner, create a CAD project and print a casting mold on a 3D printer. And here another feature of 3D printing manifests itself - the preparation time for production is minimal and does not require serious costs. nine0003

And here another feature of 3D printing manifests itself - the preparation time for production is minimal and does not require serious costs. nine0003

Completely unexpected market niches are opening up before us - for example, the production of props for the film industry. Three years ago, we were contacted by the English company Propshop Modelmakers, which produces fake models. They had to create a model of a James Bond car for the movie 007. Coordinates: Skyfall. After all, no computer graphics can replace the realism of scenes where a real car or its model explodes or crashes into a wall. And our technology has allowed filmmakers to save a lot of money. Moreover, the entire Aston Martin DB5 model printing project, from order receipt to shipment, took us only five days. Of these, the actual printing on the VX1000 printer took 25 hours. There are other areas of film production where our services are in demand. For example, they scan an actor, make a 3D model of him, and then select clothes, etc. In general, this direction turned out to be so interesting for us that in early 2014 voxeljet acquired Propshop Modelmakers, now it is voxeljet UK, our subsidiary In Great Britain. nine0003

In general, this direction turned out to be so interesting for us that in early 2014 voxeljet acquired Propshop Modelmakers, now it is voxeljet UK, our subsidiary In Great Britain. nine0003

We have a lot of orders from other areas, in particular, our models are used in the development of Formula 1 cars. In the field of architecture, these are building models that are made from PMMA. They can be viewed from all sides and divided into component parts. From sand materials, copies of statues and architectural details are made. In medicine, with the help of 3D models, they plan and prepare operations. In the field of consumer products, 3D printing is very useful in the manufacture of chairs, lamps and other objects of exotic shape - the list is long. Recently, we were approached by FIFA, they needed to make full-length figures of famous football players. We have completed this order. Then the figures are painted and can be used in wax museums around the world. Moreover, we can talk about the emergence of a separate direction - from several photographs of a person from different angles, you can build his 3D model and print it on a printer. nine0003

nine0003

We receive requests from a variety of customers, more and more new markets are opening up for us. The company's products are successfully distributed all over the world with the help of 35 distribution partners. Among them is our Russian distributor, Ostek.

Which line of business - manufacturing services or equipment sales - is most important for voxeljet's business?

The company earns most of its profits from the sale of printers, but the provision of services is no less important to us, since this is usually the beginning of cooperation with customers. In addition, manufacturing services is a highly profitable business, and we allocate revenue in this area to the creation of new technologies and printers. And they, in turn, allow you to provide new services. So these two directions are interconnected and complement each other. nine0003

What are your plans for business development in Russia?

In Russia, as elsewhere in the world, we follow our business model, which provides for development in two directions - the provision of services and the sale of installations. Now we are in contact with promising customers, demonstrating the capabilities of our 3D printers. It all usually starts with the fact that customers order certain parts (there are already such customers in Russia), then they begin to increase the volume of orders and eventually mature to the acquisition of their own printer. This is the most effective way, minimizing all risks. nine0003

Now we are in contact with promising customers, demonstrating the capabilities of our 3D printers. It all usually starts with the fact that customers order certain parts (there are already such customers in Russia), then they begin to increase the volume of orders and eventually mature to the acquisition of their own printer. This is the most effective way, minimizing all risks. nine0003

Can customers only use materials supplied by voxeljet?

Of course not. Users can buy materials for making parts themselves, as it is often much cheaper locally. voxeljet has a list of powders and adhesives that are tested and approved for use with each specific 3D printer. But, in principle, the range of powders and adhesives can be expanded, just each specific case must be specially tested on specific voxeljet devices. nine0003

And we are always open for cooperation in terms of developing technologies for new materials. Even if they come to me tomorrow and say: "We need a printer for chocolate powder", I will answer: "No problem, let's start researching and searching for a sugar-based adhesive. " And there are also two possible ways. First, the client can purchase a small, inexpensive printer and experiment with it. Or we ourselves can look for a solution that is adaptable to our industrial systems. There are no restrictions here! nine0003

" And there are also two possible ways. First, the client can purchase a small, inexpensive printer and experiment with it. Or we ourselves can look for a solution that is adaptable to our industrial systems. There are no restrictions here! nine0003

Additive technologies in Ostec

3D printing technologies are actively developing in the world market. Their unique capabilities are used both by leaders in the industrial production of products and equipment for the mass production of complex parts, and by scientific organizations and universities - for rapid prototyping of three-dimensional models in scale or life size.

Ostec is ready to provide a wide range of professionals with the opportunity to get acquainted with the latest technology, not only to understand “how it works”, but also to get physical access to the equipment and try to test their ideas on real samples or evaluate the possibilities of 3D printing for their own production. nine0003

In our demo hall, a whole section of additive technologies is deployed on the basis of partner equipment - VoxelJet AG. Our experts will help evaluate the feasibility of your models in practice, possible difficulties and ways to overcome them, and get the material embodiment of your ideas. In the process of communication, you will be able to independently understand the technology and capabilities of the equipment, choose the most effective solution that will allow your company to move to a qualitatively new level of production, reducing time and money costs along the entire chain from a CAD model to a real product. nine0003

Our experts will help evaluate the feasibility of your models in practice, possible difficulties and ways to overcome them, and get the material embodiment of your ideas. In the process of communication, you will be able to independently understand the technology and capabilities of the equipment, choose the most effective solution that will allow your company to move to a qualitatively new level of production, reducing time and money costs along the entire chain from a CAD model to a real product. nine0003

We invite you to a conversation! And the topics for conversation can be different: from reversing the details of old, but quite working equipment, to creating models, prototypes or injection molds with huge linear dimensions of 4000 × 2000 × 1000 mm, inaccessible to any other technologies while maintaining maximum accuracy.

Fantasy should have no limits. Only the one who dreams and tries reaches those peaks that looked unapproachable just yesterday. And we will try to make this path as short and correct as possible! nine0003

Detailed information on the website www. ostec-3d.ru

ostec-3d.ru

materials, equipment and technologies for advertising production

- Product catalog

Product catalog

Go to expanded catalog

PDF catalogs

CONSUMABLES

- Silk-screen materials

- Advertising and decorative lighting

- Chemistry (adhesives, paints, varnishes, special chemicals, cleaners) nine0527

- Mounting and packaging materials

- Aluminum and plastic profiles

- Materials and equipment DTF

- Digital printing ink

- POS materials and equipment, Joker, Uno and Tritix systems

- Mobile stands, Flagpoles, Pavement signs, Fencing posts

- Rigid sheet materials

- Colored self-adhesive films

- Materials for printing and lamination

- Reflective materials nine0527

- Thermal transfer materials

- Souvenir and premium products

- Clothes and accessories for labeling

- CRAFT materials and equipment

EQUIPMENT AND TOOLS

- Printers for advertising production

- Printers for printing and transfer printing

- 3D printers

- Equipment for nesting and cutting

- Milling and engraving equipment and laser engravers nine0527

- Fabric printing equipment

- T-shirt printers

- Laminators

- Thermopresses

- power tool

- Aluminum ladders and ladders

- Equipment for the production of liquid acrylic letters

- Trimmers, abrasives, film tools

- Eyelets and tools for their installation

- Knives, blades, scissors, mats

- Silk-screen equipment nine0527

- Spare parts, add.

hardware and software

hardware and software

New Year

- Zenon Academy

- videos

- Articles

- Webinar Plan

- About us

- About company

- Our staff

- News nine0513

- News

- Stock

- New

- Seminars

- Exhibitions

- Congratulations

- Webinars nine0527

- Signboard calculation

- Service

- Shipping

- Payment

- Events

- videos

WE ARE 30 YEARS OLD!

ZENON-KURSK is already working! nine0003

Write to manager option

New site section: SALE

ZENON News Digest is published again on Tuesdays and Thursdays

Recordings of webinars

are already available on our websiteSublimation mugs with color border

Zenon Company Happy New Year 2023 to everyone!

nine0002 GONGZHENG TJ AW1804UV, I3200-4H Large Format UV Roll PrinterNuances of processing poster click profiles on the example of ALU-POSTER 25 (part 1)

ZENOTOOLS

Transfer Tape Application SystemInfinilite LED Bar

Welcome to the website of Zenon - Advertising Supplies - the Russian leader in the production and supply of materials, equipment and technologies for the production of advertising. Here you can get acquainted with all areas of the company's activities, get comprehensive information about the structure of the supplied products and prices, learn about new products in the advertising technology market, and be aware of the current commercial activity of our company. If you are a professional advertising maker, this site will help you in your day to day work, making it much easier to place orders, receive up-to-date news and additional information, which will allow you to be half a step ahead of your competitors. We hope you will be fine with us. nine0003

article

Subscribing to the newsletter

A confirmation email has been sent to the email you specified.

Please follow the instructions in the letter.

Sorry, an error has occurred, please try the service later.

To subscribe to the newsletter, please fill in ALL fields of the form

Subscription regions

- Moscow - Golyanovo nine0527

- Moscow - Losiny Ostrov

- Moscow region - Odintsovo

- Moscow region - Podolsk

- Arkhangelsk nine0514 Barnaul

- Belgorod

- Vladivostok

- Vladimir

- Volgograd nine0527

- Voronezh

- Yekaterinburg

- Izhevsk

- Irkutsk

- Kazan nine0527

- Kaliningrad

- Krasnodar

- Krasnoyarsk

- Kursk

- Lipetsk nine0527

- Nizhny Novgorod

- Novosibirsk

- Omsk

- Orenburg

- Penza nine0527

- Permian

- Pyatigorsk

- Rostov-on-Don

- Ryazan

- Samara nine0527

- St.

Petersburg

Petersburg - Saransk

- Saratov

- Simferopol

- Smolensk nine0527

- Sochi

- Stavropol

- Tambov

- Tolyatti

- Tomsk nine0527

- Tula

- Tyumen

- Ulyanovsk

- Ufa

- Khabarovsk nine0527

- Cheboksary

- Chelyabinsk

- Yakutsk

- Yaroslavl

I AM agree for the processing of personal data nine0044

Application for goods:

You can submit this product request form, or contact us by phone or by email , informing the manager of the article .

6

6  7×0.9×1.5

7×0.9×1.5