Dreamer 3d printer review

Flashforge Dreamer Review 2022 - Why This 3D Printer Is So GOOD!

4.5

See Price

| Printing Area | 230mm x 150mm x 140mm |

| Layer Resolution | 100 to 500 Microns |

| Supported Filament | PLA, ABS, limonene-dissolvable support material, nylon, HIPS, Flex, T-glass, woodFill, copperFill, brassFill |

| Filament Diameter | 1.75mm |

| Extruders | 2 |

| Extruder Diameter | 0.4 mm |

Flashforge has hustled to establish itself as one of the leading consumer brands in today’s saturated 3D printing market. With no less than ten models for sale concurrently, the Chinese giant continues to make waves with a nifty balance of quality and competitive pricing.

Today, we take our magnifying glass to the Flashforge Dreamer, an easy to use printer producing quality prints fit for the home, office, or educational context if we are to go by the marketing pitch. Does it live up to these claims? Let’s find out.

Table of ContentsShow

Design and Features

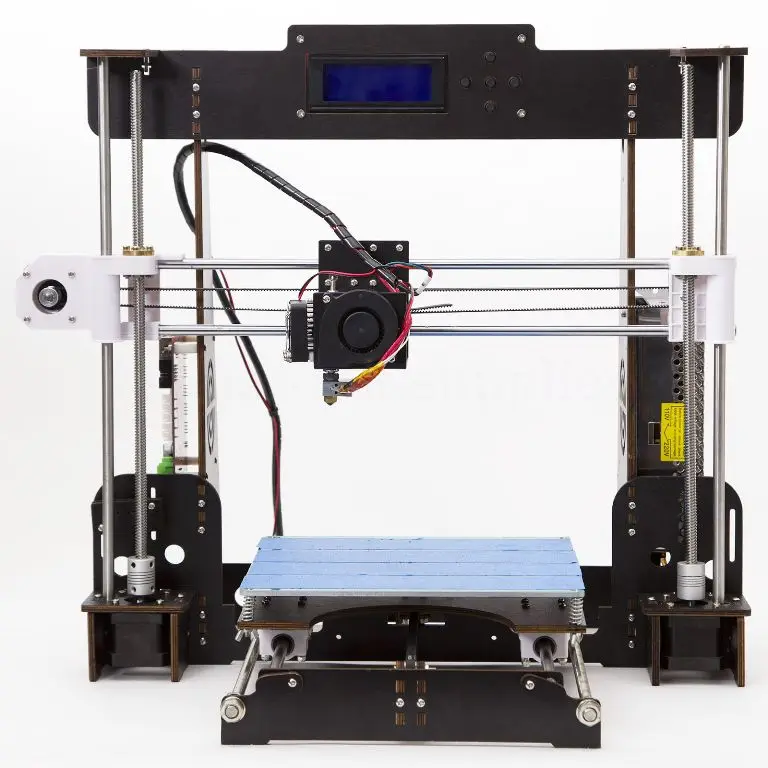

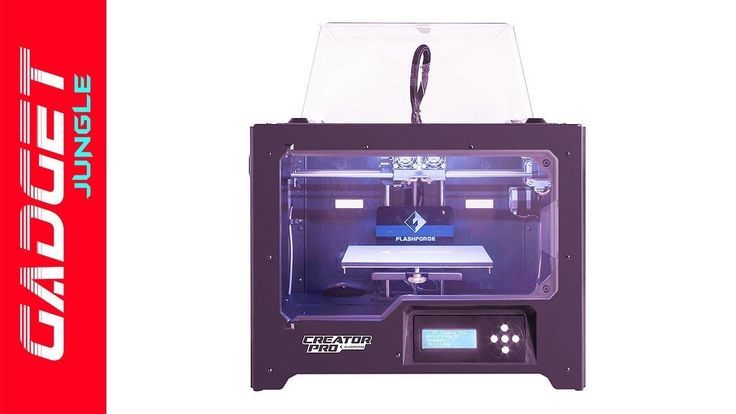

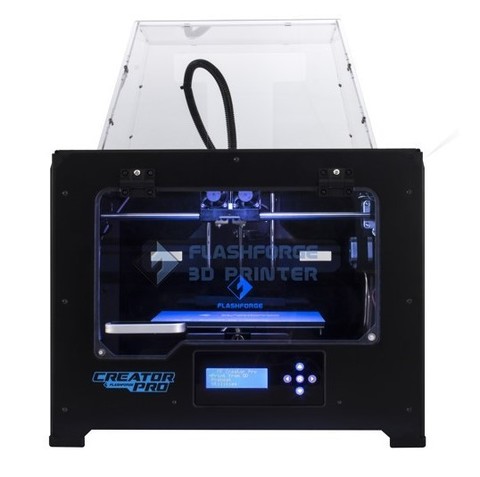

With a look more akin to an MRI machine than one set to energize a workshop with stirring creative juices, the Flashforge Dreamer continues the unfortunate trend of drab, dare we say, ugly 3D printers.

The main culprit is the uninspired three-tone color scheme (white, gray, and black) that although clean and clinical, places this model at odds with rival manufacturers who’ve put in a little more time to conjure up alternatives that illicit attraction, and by extension a desire for usage on the part of the owner. Luckily, the look is somewhat bolstered by LED strips that light up the print chamber for a bit more design flair.

The enclosed outer casing is made of high-quality plastic-alloy, which invariably makes things look cheap (not to mention the constant fear that it will melt with the heat of the printing process), while the rest of the components are made of high-quality aluminum and acrylic. Combined, the Dreamer weighs in at a respectable 33.1 lbs, placing it on the lower end of the spectrum and as such easily transportable.

Combined, the Dreamer weighs in at a respectable 33.1 lbs, placing it on the lower end of the spectrum and as such easily transportable.

Both side panels have removable ventilated hatches for maintenance and replacing filament, while the top cover can be lifted off for materials that need cooler temperatures. The acrylic front door also swivels open to access the print bed and is secured by magnetized latches. The enclosed chamber is ideal for stabilizing the inner temperature but also works to limit foreign bodies from tarnishing the layers during the printing process.

As we all know – and this no more true than in the sphere of 3D printing – looks aren’t everything, and the Dreamer conceals quite the assemblage of excellent features hidden under a banal exterior.

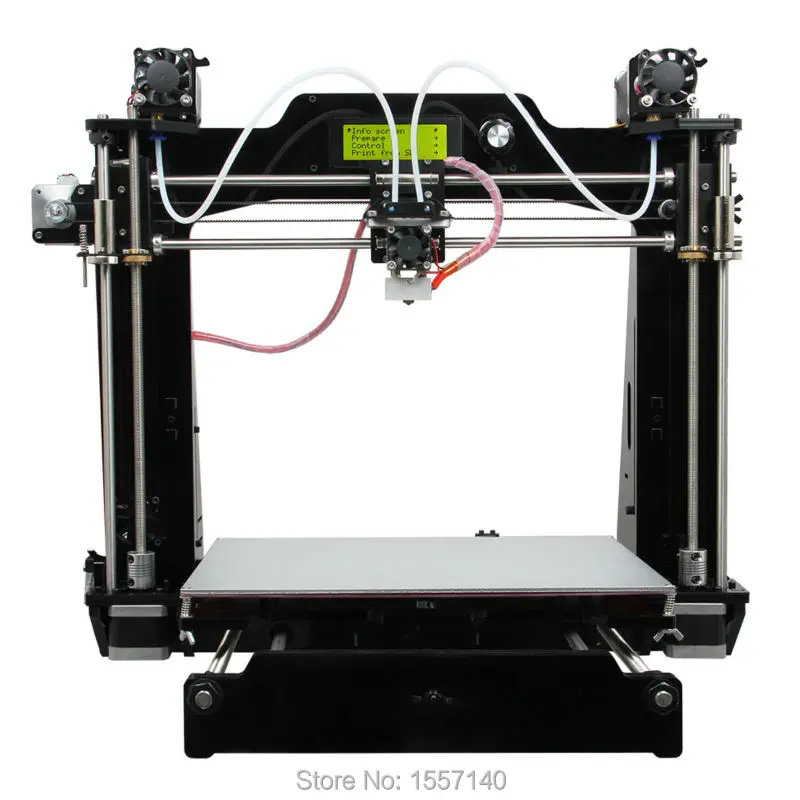

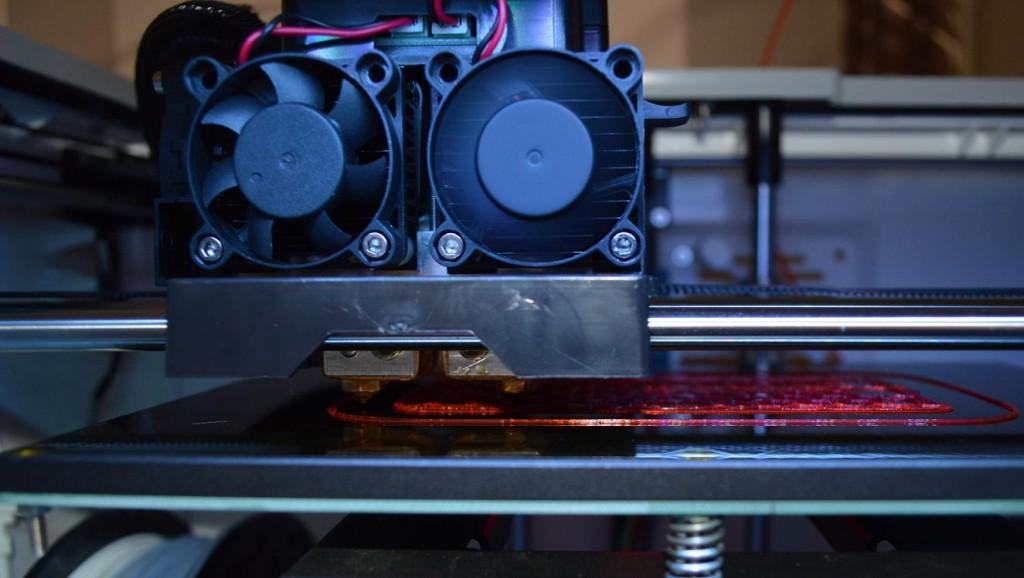

Using FFF (Fused Filament Fabrication) technology, the Dreamer is an XYZ Cartesian style printer that uses a standard dual rod and Moons-manufactured stepper motor setup for both the X and Y axes, with the Z axes running along a threaded rod as well as two classic flush rods.

The print area measures in at a comparatively small 230mm x 150mm x 140mm, but sufficient for the majority of hobbyist projects and ample room to print multiple parts in the same session.

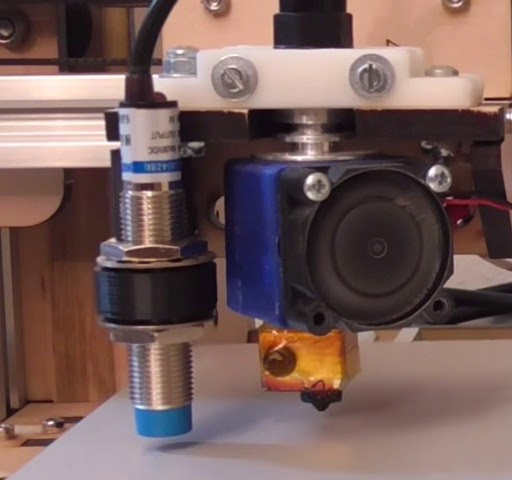

The Dreamer sports a dual direct drive extruder setup with a nozzle diameter of 0.4 mm capable of layer resolutions ranging from 100 to 500 microns. The heated build plate is a chunky 6.3 mm slab of aerospace-grade aluminum for uniform heat distribution that can reach temperatures up to 120 degrees centigrade.

The Flashforge Dreamer is versatile when it comes to materials with support for PLA, ABS, limonene-dissolvable support material, nylon, HIPS, Flex, T-glass, woodFill, copperFill, and brassFill. Filament diameter sticks to the standard 1.75 mm with support for third-party filament spools.

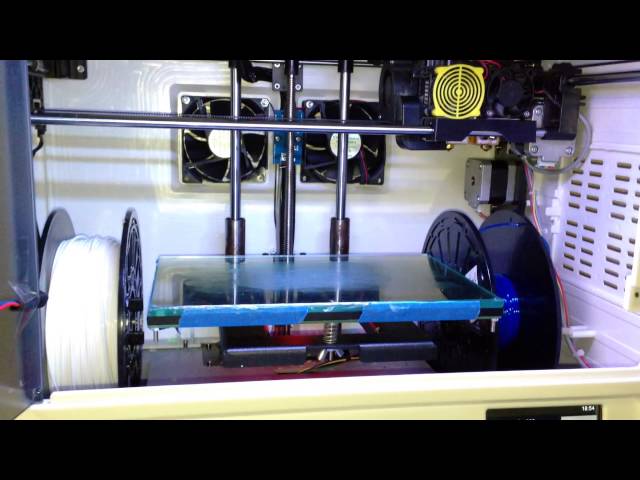

Filament sits inside purpose-designed spool berths (or holders) inside the chamber, which Flashforge argues keeps the filament at a higher temperature thus prolonging the lifespan of the material by removing moisture but is primarily a space saving characteristic.

However, the size of the berths means cartridges are limited to the 0.6 kg variety. Fortunately, the side hatches mean you can also use 1 kg or larger spools by seating them to the sides of the printer.

It’s worth noting that the Dreamer is equally geared towards PLA as it is ABS, unlike countless other models that tend to focus on one with only a handful of cursory arrangements made for the other to be listed as compatible with both materials.

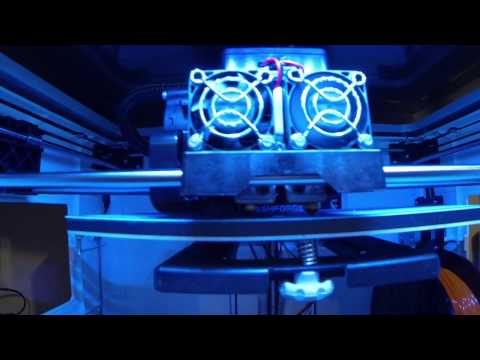

A dual fan setup is fitted to the back panel that works in unison with the triple extruder fans to cool PLA by extracting the warm air. Equally, the Dreamer is equipped with a meter that monitors the ambient temperature to make sure the enclosed chamber is consistently warm enough to avoid ABS warping and cool enough to avoid PLA stringing.

A 3.5-inch full-color HD IPS touchscreen is integrated into the front panel of the Dreamer. We found it particularly responsive and easy to navigate. It features the ability to trigger prints, monitor and preheat extruder and platform temperatures, load/unload filament, activate the bed-leveling wizard, axes homing, update the firmware, and an array of other settings. The touchscreen has support for English, German, Dutch, Polish, French, Korean, and Japanese languages.

The touchscreen has support for English, German, Dutch, Polish, French, Korean, and Japanese languages.

The Dreamer has both an SD card reader slot and a USB-to-PC port, in addition to Wi-Fi connectivity for untethered use. The USB feature is uncommon in that the Dreamer itself has 4GB of onboard memory to store prints of the device itself. If the PC crashes or shuts down unexpectedly, the printer still has access to model details to continue a job uninterrupted.

Flashforge recommends using the Dreamer with its proprietary FlashPrint slicing software, but the printer remains open-sourced so you can use all manner of third-party slicers such as Cura, Simplify3D, and the like.

Flashprint supports Mac, Linux, and PC. Overall, it is incredibly easy to use and walks the user through loading in a model file (STL, OBJ), converting it to Gcode, tweaking a few temperature/slicing/build quality options or using one of the many presets, then triggering the print. When printing, FlashPrint provides a visible progress model, material usage, and finish time estimates.

Advanced opinions allow for support integration, print speed adjustments, first layer thickness tinkering, scheduled pause options, splitting models into several parts, and a feature to convert 2D pictures into 3D models.

Assembly

The packaging is the usual mix of styrofoam cut outs, zip ties, and plastic bubble wrap, which is more than adequate and the printer arrived in perfect condition. The only real issue is that the extruders are housed in a cardboard box that sits inside the printer yet are attached to the printer, so some care needs to be taken when removing the box not to yank out the extruders while doing so.

The package includes official documentation, quick start guide, the printer itself, power cord, USB cable, a tool kit (2GB SD card, tweezers, graver, scraper, two wrenches, grease, Allen key, Phillips screwdriver, unclogging pin tool, PTFE tube, screws, and leveling knob), two spools of filament (PLA and ABS), spool holders, leveling card, extruders, top cover, either a roll of blue painter’s tape or a handful of print bed sheets, a set of screws, and side hatches.

The Flashforge Dreamer arrives pre-assembled and full setup was a matter of minutes. The extruder casing needs installing via a set of three screws. The process is detailed concisely in the quick start guide and involves placing the extruder in the extruder seat, aligning the extruder to the bolt holes, securing the bolts, and finally attaching the turbofan baffle in the same manner.

Although the Dreamer has no auto-calibration feature, the assisted build plate leveling process is easy enough thanks to instructions from the touchscreen. The manual movement of the build plate is assured by a rotating knob that moves the plate up and down. The process is the usual process of establishing the right gap between the plate and the nozzle using the leveling card.

Next, we installed the filament cartridges by feeding the spool holder through the center and snapping them into place. Finally, feeding the filament into the tubing was simple enough before we had to trigger the gearing to grip the material via the touchscreen. Once the extruder was heated, we fed the filament into the extruder by pressing down on the gear button simultaneously. From here onwards, we encountered no issues feeding filament, and it worked beautifully every time.

Once the extruder was heated, we fed the filament into the extruder by pressing down on the gear button simultaneously. From here onwards, we encountered no issues feeding filament, and it worked beautifully every time.

Printing

What can we say? Its questionable exterior belies a versatile beast capable of systematic quality prints. Contours were smooth, layers were almost unnoticeable, and imperfections so rare they aren’t even worth mentioning.

For the price of the Dreamer, there isn’t an equivalent that offers both out of the box functionality and such a high quality of prints regardless of whether you go for rapid, low-resolution prototyping or high-resolution detail-oriented ornaments.

The dual extruders work well, especially when it comes to supports that quelled any fears we had of botched jobs due to insufficient support. Additionally, the Dreamer is a pretty nifty little printer as well, finishing up jobs in entirely respectable times even at higher resolutions.

The cherry on top is that the Dreamer is a relatively silent printer even with the top cover and hatches off.

Support

Flashforge offers a standard 180-Day manufacturer’s warranty for the Dreamer, although extensions of up to 12 months are available by buying the ProCare Extended Warranty.

The Flashforge website is packed with instructional videos, walkthroughs, troubleshooting articles and more. The customer support from the company is of the highest quality with a team intent of finding solutions to the rare problems you may face.

Verdict

Although we weren’t enamored with the aesthetic design of the Flashforge Dreamer, we were incredibly impressed by what it hides under the hood as well as the high quality of the prints. It’s a reliable printer that will suit first-timers and daily users alike. You can trust it to complete prints, and it isn’t a model you need to babysit or tinker with merely to get it working. If you haven’t already guessed, we love the Dreamer.

Flashforge Dreamer NX Review - ToBuyA3DPrinter.com

8.0 Great

Flashforge have a reputation for user-friendly 3D printers that make 3D printing as painless as possible. With that in mind, the Flashforge Dreamer NX appears to follow suit, touting a ton of high-tech features to make your life easier while keeping all the hardware tidy and enclosed. Does it make the grade, though? How does it compete with other printers in the sub-$500 price category? Find out in today’s Flashforge Dreamer NX review.

The Dreamer NX starts with a modest build volume measuring 9” x 5.9” x 5.5”. That’s a bit above average, though the printer itself is much larger, measuring 19” x 13.5” x 20.8”. Keep this in mind when planning desk space for this machine.

More Details ❯

This printer achieves layers as small as 50-microns and prints at speeds as high as 200mm/s. This gives you the freedom to make finely detailed pieces, quick test prints, or anything in between. Choose from a variety of filaments, too, including PLA, ABS, TPU, and PETG. Connectivity options are equally broad, allowing you to choose from cabled USB, WiFi, and SD card.

Choose from a variety of filaments, too, including PLA, ABS, TPU, and PETG. Connectivity options are equally broad, allowing you to choose from cabled USB, WiFi, and SD card.

Achieving high precision prints involves a lot of factors. Print resolution must be high, the extruder must be accurate, temperature control is imperative, and setting a good foundation is key. The Dreamer NX excels in each of these areas, allowing you to make high-quality models right out of the box.

To start, the Dreamer NX goes down to 50-micron layer resolution. That’s twice as small as most 3D printers that only achieve 100-micron layers. Next, this printer uses a dependable extruder for smooth, even filament extrusion no matter what plastic you use. Importantly, this extruder setup is capable of printing flawlessly with flexible filaments like TPU and PETG as well.

More Details ❯

Finally, temperature control within this unit is exceptional. The heated print bed is quick to warm up and provides even heat distribution across the entire platform. Meanwhile, the extruder itself has a patented fan system that keeps filament at the right temperature as it prints, leading to fewer blemishes and a smoother finish. There’s even live temperature monitoring within the enclosed build space. If your print environment gets too hot, fans automatically start circulating fresh air into the system. All these factors combine for highly detailed models with less tinkering from the user.

The heated print bed is quick to warm up and provides even heat distribution across the entire platform. Meanwhile, the extruder itself has a patented fan system that keeps filament at the right temperature as it prints, leading to fewer blemishes and a smoother finish. There’s even live temperature monitoring within the enclosed build space. If your print environment gets too hot, fans automatically start circulating fresh air into the system. All these factors combine for highly detailed models with less tinkering from the user.

More Details ❯

Flashforge are a long-standing brand within the 3D printer market. Part of their success comes from excellent customer service. Although their responses may contain some broken English, the company is quick to respond to tickets and they don’t give customers a hard time about repairs or replacements. If you plan to purchase the Dreamer NX, rest assured that Flashforge is no fly-by-night company. Additionally, the Dreamer NX includes a 1-year warranty for peace of mind.

Additionally, the Dreamer NX includes a 1-year warranty for peace of mind.

We’re shocked to see that the Dreamer NX, for all its smart design and quality craftsmanship, does not include some very simple quality-of-life features. For example, the Dreamer NX will not automatically pause printing if your filament runs out, meaning your project is ruined if this happens. There’s not automatic bed leveling, either, which can be a pain considering that this is a fully enclosed printer. The WiFi connection also isn’t the best, so although it is technically a feature of this machine, we recommend using a USB or SD card connection instead.

Flashforge Dreamer NX Review VerdictMore Details ❯

This is a solid 3D printer for beginners and experienced users alike. With all the filament options most people need, high-quality prints, and friendly customer service, what more can you ask for at this price point? To boot, the Dreamer NX is an attractive machine with a simple and intuitive user interface that makes it feel like a proper modern appliance.

Nothing is perfect, not even the Dreamer NX, but we can forgive this printer’s shortcomings. Flashforge dropped the ball on filament detection and bed leveling, but those features may have cut into the Dreamer NX’s affordable price point. It may not be the biggest 3D printer under $500, but the print results and ease-of-use make up for an average build volume. We haven’t loved everything out of Flashforge lately, but the Dreamer NX is a step back in the right direction for this company.

Share. Twitter Facebook Google+ Pinterest LinkedIn Tumblr Email

Overview of 3D printer Flashforge Dreamer

3d printing has been my passion for the last 2-3 years. I purchased a Makerbot Replicator 2 3D printer a little over a year and a half ago and have since printed everything from Christmas ornaments and necklaces to toys for my son. I eventually got used to my Replicator 2, although at first I had some difficulty setting it up, loading it, leveling the desktop, and keeping all the settings up and running. When I was asked to review a new 3d printer, I admittedly hesitated a bit with the answer. nine0003

When I was asked to review a new 3d printer, I admittedly hesitated a bit with the answer. nine0003

First impression

When I first unpacked the Flashforge Dreamer, I thought "they must have sent me the microwave by mistake". The new 3D printer in appearance reminded me of a small microwave oven, and even guests sometimes asked why I have a microwave in my office. It weighs about the same as the Replicator 2. It really looks good, so you're not afraid to put it in a prominent place in the house. I have seen quite a few 3d printers that are ugly on the outside. and Flashforge Dreamer is definitely not one of them, and the reason is primarily in a completely closed chamber. It looks good and seems solid enough. The only slight complaint about the appearance is the plastic surfaces of the case, which add a sense of cheapness to its appearance. But after a while, I changed my mind. The design of the case is made so that you can see most of the parts of its design that make it work.

Installation

As I found out later, all 3d printers are similar, but not quite. It seemed to me that my experience with the Replicator 2 would be enough, but unfortunately this was not the case. Installation went quickly and without difficulty. I took it out of the box, secured the extruder with two screws, turned on the power, and loaded the plastic. The model I tested had two extruders and came with a spool of red PLA plastic and white ABS. Loading took place on time to spit. There were buttons for loading and unloading filament on the touch screen. I pressed the button, waited for it to warm up and loaded the plastic through the hole on top. Just 30 seconds and the printer was ready to go. nine0003

The first stupidity

Without reading the instructions, I immediately downloaded a few files and decided to print them. This was a big mistake. I forgot to level the platform before starting to print. In short, as a result, the extruder was clogged, and I had absolutely no idea how to clean it..jpg) I wrote a message to the support service and within an hour I received detailed instructions for disassembling the extruder and clearing the blockage. The whole process took me 20-25 minutes.

I wrote a message to the support service and within an hour I received detailed instructions for disassembling the extruder and clearing the blockage. The whole process took me 20-25 minutes.

First print.

I finally set up my printer and printed a little frog. I decided to start small, just to make sure everything was in order with the settings. The result was great. The frog looked flawless even though it was printed without support. The next model was a spinning wheel toy car that was printed in one go. I tried to print it on other 3d printers, but the result was worse every time.

I expected similar results from the Flashforge Dreamer , but to my surprise the ABS printed car came out almost perfect. Spoiled the impression of a small defect on one side. But the wheels turned, and I could roll it without difficulty, just like any of my son's other cars.

Resolution and print quality.

I was surprised by the print quality. It was commensurate with the quality of my Replicator 2, and in some cases even higher than I'm used to. nine0003

Dual Extruder

I've never used a 3d printer with two extruders before. They allow the support to be printed in a material that is different from that of the main model. It also makes it possible to print in two colors, and get more vibrant 3d objects. Colors add charm to any object, whether it's a toy car, a pretty box, or a piece of jewelry. I probably don't want to go back to a printer with a single extruder anymore. nine0003

Software.

One of the most time-consuming and complex processes in 3d printing is, of course, the cutting of layers of objects, and the process of generating a gcode that is sent to the printer in order to control the printing process. The Flashforge software proved to be easy to use. I just installed it, loaded the object and hit print. I was offered several options for slicing, the choice of extruder and printing temperature. I left most of the parameters by default, since they were in the values I needed. A couple of minutes after pressing "OK", the printer began to print. This was probably the fastest print submission I have ever made. Yes, this printer gives you the choice of settings you need, and it's great for beginners and advanced users alike. nine0003

I was offered several options for slicing, the choice of extruder and printing temperature. I left most of the parameters by default, since they were in the values I needed. A couple of minutes after pressing "OK", the printer began to print. This was probably the fastest print submission I have ever made. Yes, this printer gives you the choice of settings you need, and it's great for beginners and advanced users alike. nine0003

Unsuccessful

If you still talk about the negative sides of this 3d printer, because it should be an honest review. I would like a little more volume. Of course, the 9.1” x 5.9” x 5.5” volume is sufficient for printing small objects, but I am used to the larger volume of my Replicator 2. I have not yet had to print an object that was larger than the maximum possible, but I feel that in one fine day I may need extra centimeters. The cheap appearance of the extruder, made of powder-coated steel, did not immediately convince me of the high quality of the 3d printer. But at the same time, the printer mechanism was made of high quality and executed with high accuracy, and this is what matters when printing. nine0003

But at the same time, the printer mechanism was made of high quality and executed with high accuracy, and this is what matters when printing. nine0003

Specifications

- Interfaces: Wi-Fi, USB, SD

- Positioning accuracy: 0.1 mm - 0.2 mm

- Layer thickness (resolution): 100 - 500 microns

- Print volume:

- ” x 5.5”

- Nozzle diameter: 0.4 mm

- Print speed: up to 200 mm/s

- Platform temperature: 120°C maximum

- Power: 100 – 240V, 50/60Hz Wattage:

- W

- Overall size: 19 x 16 x 13 inches / 485 x 400 x 335mm

- The size of the box: 25 x 23 x 19 months / 565 x 535 x 430mm

- Brutto weight: 32LBS

- Weight Net: 27LBS

Software 9000

- File type: STL / X.

- OS: Windows, OS x, Linux

- Software: FlashPrint

Consumables

- Materials: ABS, PLA, PVA, etc.

30082 Body colors, black, yellow, red, blue, green, transparent

30082 Body colors, black, yellow, red, blue, green, transparent - Filament diameter: 1.75 mm - 1.80 mm

Features

- 3.5” multi-touch capacitive LCD 9 extruder with built-in fan provides instant cooling of printed objects

- ARM Cortex M4 processor provides fast and stable processing performance

- 4 GB internal memory

- FlashPrint software (included)

- A aviation alloy platform provides maximum stability against deformation

- Support for print ABS, PLA, PVA, Nylon, etc.

- 12 LEDs cover the print chamber

Conclusions 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 printer Flashforge Dreamer for those who are looking for a medium-sized device capable of printing at high resolution.

The printer is very stable, and leaving it to print for several hours in my absence, I was not at all afraid. I have spoken to many 3d printer owners and have heard many stories about how often models that were left to print turned out to be unsuccessful. I left it again with no problem. nineHello everyone. Today we have prepared a review of two models of 3D printers - FlashForge Dreamer and FlashForge Creator Pro.

The printer is very stable, and leaving it to print for several hours in my absence, I was not at all afraid. I have spoken to many 3d printer owners and have heard many stories about how often models that were left to print turned out to be unsuccessful. I left it again with no problem. nineHello everyone. Today we have prepared a review of two models of 3D printers - FlashForge Dreamer and FlashForge Creator Pro. - FlashForge is a Chinese company Zhejiang Flashforge 3D Technology Co., Ltd. Established in 2011 and today is one of the largest in China. Last year, the company produced 30 thousand 3D printers and ranked 4th in terms of sales of 3D printers in the world. nine0083 The

- FlashForge Dreamer and FlashForge Creator Pro is a top 10 printer on the 3DHUBS 3D printing enthusiast site.

3DHUBS has a lot of positive feedback from both beginners and advanced users. These printers are valued for their very good value for money.

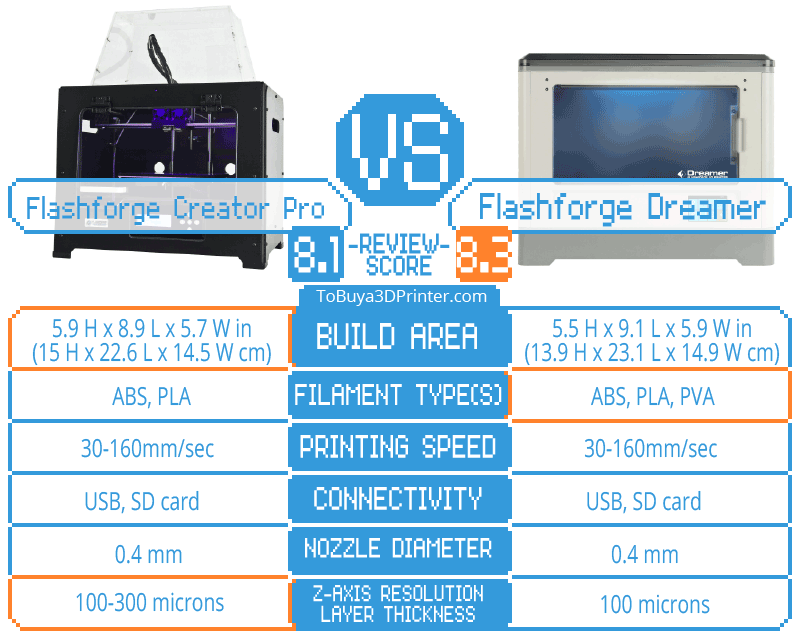

Specifications

As you can see from the technical specifications, the printers are almost the same. Unless Dreamer is a newer and more advanced model, with a bunch of small improvements that may be useful to the user. nine0003

Unless Dreamer is a newer and more advanced model, with a bunch of small improvements that may be useful to the user. nine0003

Appearance.

There are more differences in appearance. Dreamer has become more compact compared to Creator Pro.

Plastic spools stow away inside the printer instead of hanging outside. On the one hand, this allows you to additionally dry the plastic inside the printer chamber, on the other hand, it will be problematic to shove a spool of 1 kg or more. And if you “start” the plastic from the outside, you will have to remove the cover.

FlashForge Creator Pro does not have this problem. You can hang the spools on the case or print the spool holder. The lid has a space for feeding plastic outside the chamber. nine0003

Mechanics.

The kinematics of the printers is similar and made according to the most popular scheme. Nothing new here.

The head moves along the X and Y axes, the platform moves along the Z axis. The printer prints without problems not only ABS and PLA, but also more whimsical, softer types of plastic.

The printer prints without problems not only ABS and PLA, but also more whimsical, softer types of plastic.

Or say Woodforce from Fiber Force.

By the way, plastic turned out to be very interesting. The nozzle does not clog and smells like wood. Very easy to skin. nine0003

The most interesting thing is the Dreamer airflow. In appearance, the blower casing is only on the left nozzle. And there are no more differences from the same Flash Forge Greater Pro.

The main difference was noticeable on the first print. At the back of the printer are 2 fairly large fans. They blow air out of the chamber.

There are ventilation grilles on the sides that draw air into the printer.

It turns out that air is constantly circulating inside the camera during printing. Surprisingly, this turned out to be a great solution for PLA printing. Airflow occurs from all sides of the printed part. Even small details are excellent, without “streaks”. nine0003

nine0003

Creator Pro cannot boast of such stability. In hot weather, small PLA products may lack airflow.

FlashForge Dreamer is equipped with a convenient touch screen and Wi-FI.

Slicer.

It is proposed to use FlashPrint as a slicer. A fairly convenient program with a pleasant interface, also partially Russified. This can be a big plus for beginner printers. nine0003

The program has several rather useful functions. For example, the ability to cut the model.

The cutting plane can be set with the mouse or along one of the axes.

The ability to place supports manually is what I so often missed in Cura. There are 2 types of support.

Tubes (they are by default)

And bollards.

BUT the most interesting feature in my opinion is the ability to convert drawings into three-dimensional bas-reliefs. nine0003

The program has quick print settings. (low - 0.30mm standard - 0.18mm and high - 0.14mm. When choosing PLA plastic, the best print quality appears is a layer of 0.08mm.). It will be convenient for beginners during the first steps.

(low - 0.30mm standard - 0.18mm and high - 0.14mm. When choosing PLA plastic, the best print quality appears is a layer of 0.08mm.). It will be convenient for beginners during the first steps.

There are also advanced settings to fine-tune print settings. To enable advanced settings, you need to open the file tab - settings and switch from Basic Mode to Expert Mode.

Retract settings, support print speed, wall width for nozzle cleaning when printing with two types of plastic and much more. nine0003

Print tests

And of course the review would not be complete without the print tests.

FlashForge Creator Pro

ABS from ESUN, layer 0.15.

PLA from ESUN, layer 0.15.

And the most interesting thing is printing with supports.

ABS+HIPS

PLA+PVA

FlashForge Dreamer

ABS+HIPS from ESUN, layer 0.15.

PLA+PVA

CARBON FIBER from NYLFORCE, layer thickness 0. 15

15

PLA, Bronze, Esun, layer thickness 0.14

Woodforce plastic from Fiber Force and blue PLA from ESUN, layer thickness 0.18

Ninjatek Soft Cheetah Post-apocalyptic duck, 0.18 layer thickness, 0% infill

0.18 layer, Flashforge Dreamer printer. Esun eCopper and eAlfill plastic.

Results

Both printers surprisingly give a very decent print result “out of the box” without any “finishing” and shamanic settings. nine0003

FLASHFORGE Creator Pro keeps up with its older brother FlashForge Dreamer in print quality. The maximum that you can find fault with is the insufficient airflow of small PLA models in the Creator Pro.

Visually, FlashForge Dreamer, in my opinion, is more of a "home" printer. Neat, compact. Plus the ability to connect via WI-FI so as not to pull extra wires. But here everyone will decide for himself whether it is worth overpaying for aesthetics and comfort or not.

Traditionally, a minute of advertising)

Buying equipment from our company, you get 10 advantages:

1.