Et4X 3d printer

ET4X DIY 3D Printer with Resume Printing — Anet 3D Printer

Save $99.00

Original Price $298.00

Current Price $199.00

US / 110V & US Plug - $199.00 EU (VAT included) / 220V & EU Plug - $199.00 EU for UK (VAT included) / 220V & EU Plug - $199.00 CA / 110V & US Plug - $199.00 Brazil / 220V & EU Plug - $279.00 RU / 220V & EU Plug - $199.00 China / 110V & US Plug - $239.00 Vietnam / 220V & EU Plug - $239.00

US

EU (VAT included)

EU for UK (VAT included)

CA

Brazil

RU

China

Vietnam

110V & US Plug

220V & EU Plug

1 2 3 4 5 6 7 8 9 10+ Quantity

Quantity

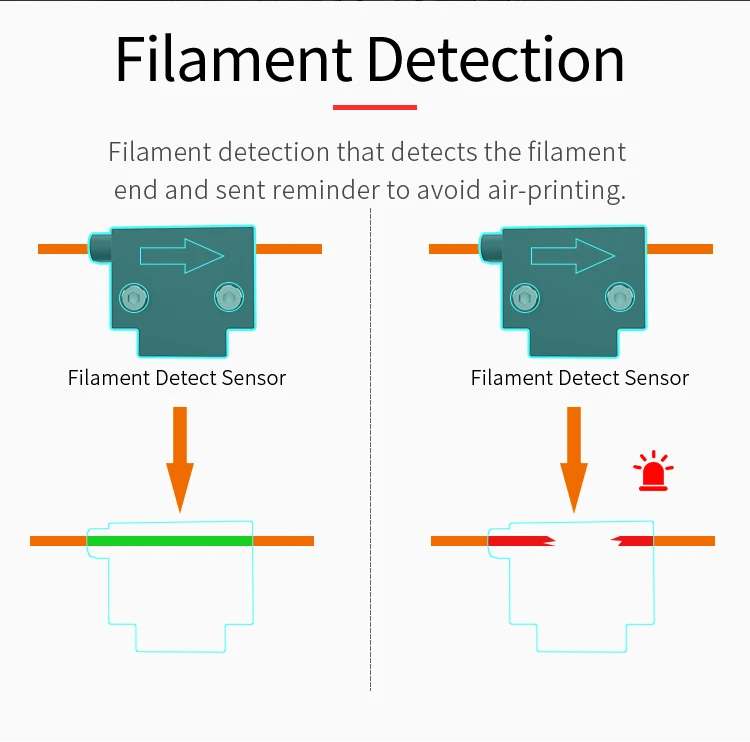

Share this:- Filament detection that detects the filament end and sent reminders to avoid air-printing.

- 2.8-inch full-color touch screen for easy operation.

- You can upload your design and print it online or offline.

- Resume printing and recover from exactly where it left off. No worries about unexpected power outages. Automatic load and unload the filament with a touch screen.

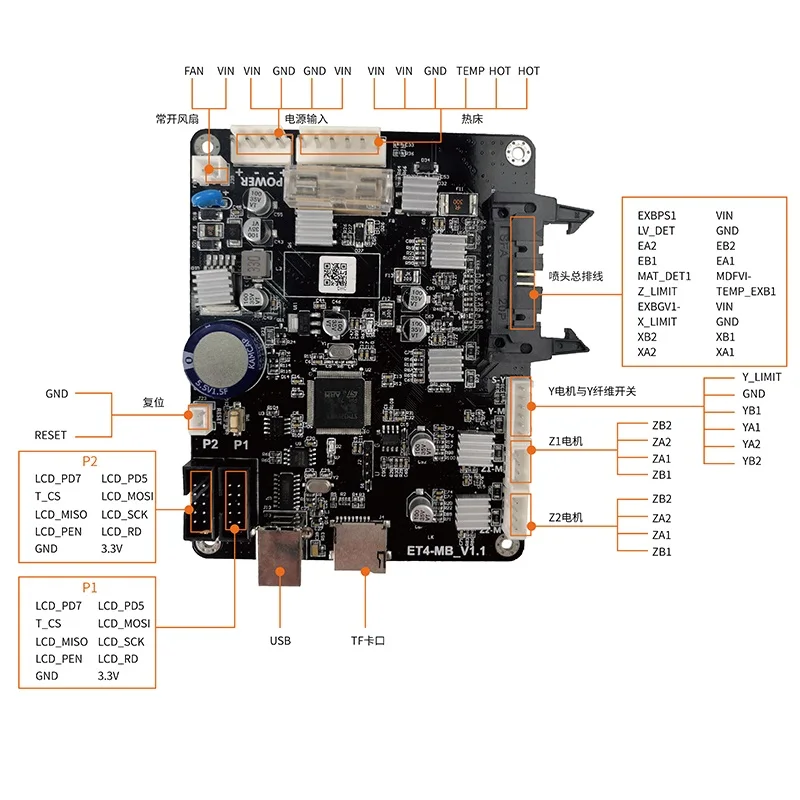

- Terminal pinboard design with integrated connection ports, covered wires and a more sleek appearance.

- Industrial grade chipset that allows more accurate, fast print. Protected with safety features like overcurrent protection, overload protection, over-temperature protection, pre-over-temp alarm. Precision rollers on X and Y axis which reduce printing noise and provide ultra-high print resolution.

- Enclosed metal unibody design enables a more stable and reliable structure with compact size. Support personal turn features, including manually set up fan speed, print speed, heated bed, and nozzle temperature.

- Sold out

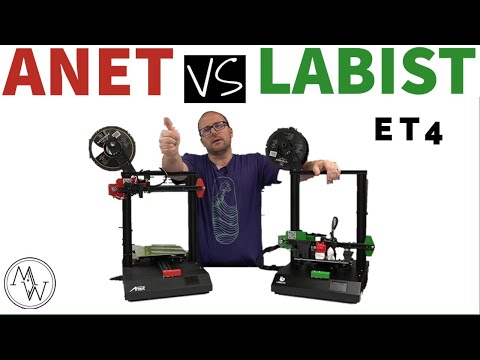

Anet 3D Printer ET4X - Sub-$200 Semi-DIY Kit Review

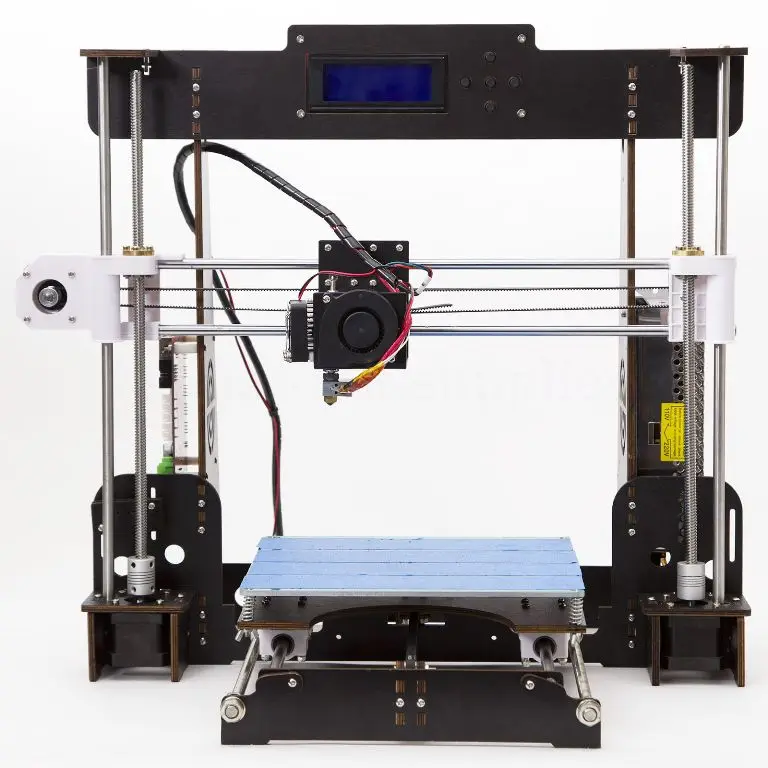

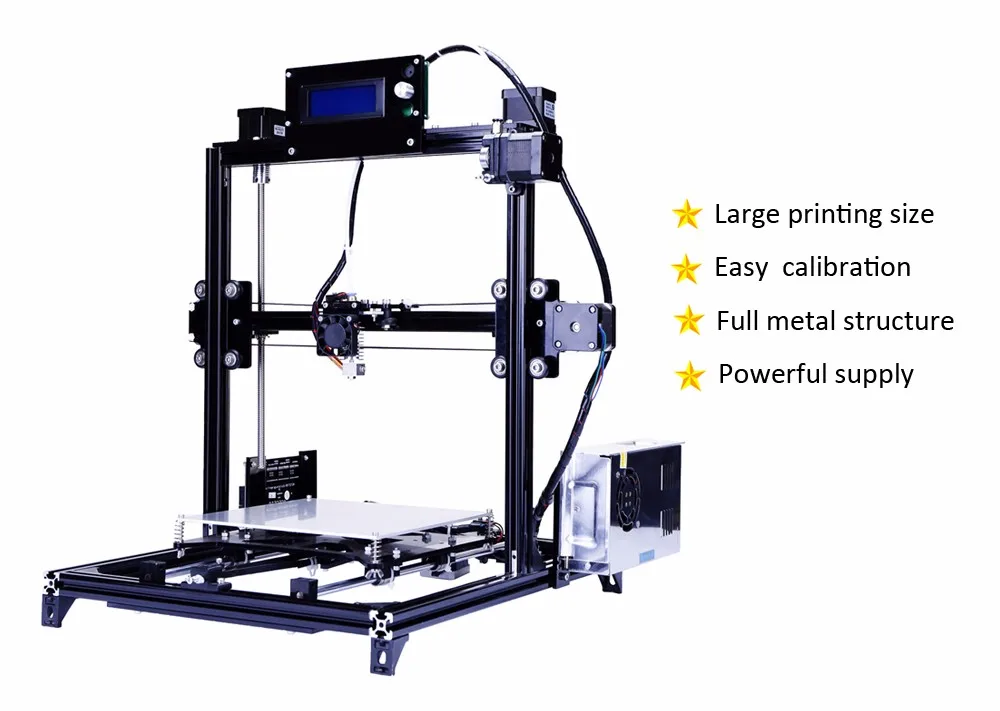

If you’re interested in getting started with 3D printing and your priorities are A) not spending too much money and B) not building a printer from scratch, the Anet ET4X 3D Printer might be a good fit for you. It comes in at under $200 and doesn’t require any electrical wiring knowledge or tools beyond a few allen keys and a screwdriver. The software can be a bit tricky if you’re starting from scratch but if you’re willing to put in the work, this printer will get you up and printing with no additional supplies. Add a filament run-out sensor, a heated bed, and a power outage resume feature and you’ve got a great entry-level machine.

It comes in at under $200 and doesn’t require any electrical wiring knowledge or tools beyond a few allen keys and a screwdriver. The software can be a bit tricky if you’re starting from scratch but if you’re willing to put in the work, this printer will get you up and printing with no additional supplies. Add a filament run-out sensor, a heated bed, and a power outage resume feature and you’ve got a great entry-level machine.

Anet ET4X 3D Printer Review – First Thoughts and Impressions

The Anet ET4X is shipped as a semi-built kit printer, and requires some assembly before you can start printing. The extruder gantry and the hot end assembly come pre-assembled with all wires terminated, so the assembly is generally limited to building the frame of the machine and connecting the wiring.

The gantry needs to be assembled, but the electronics come pre-wired(Image: Andrew Sink)

The boards are all clearly marked, so this is a straight-forward process. The most important step is making sure the wiring harness attached to the X gantry is secured to the mounting plate with zip ties, to prevent the connectors from coming loose during printing. This seems to be a common issue, with many negative reviews calling out this step specifically as being easy to miss which could allow damage to occur to the printer.

This seems to be a common issue, with many negative reviews calling out this step specifically as being easy to miss which could allow damage to occur to the printer.

(Image: Andrew Sink)

Anet ET4X Features

The ET4X has a 2.8” color touch screen which makes performing tasks like loading/unloading filament and calibrating the bed an intuitive and simple process. In addition, the extruder and heated bed temperature, print speed, and fan speed can all be controlled during printing via the touch screen. The firmware that ships on this printer does not have the ability to utilize baby-stepping, so all Z adjustments need to be made using the four wheels under the bed to control the overall calibration. The bed is heated, so PLA sticks well to it without any glue or other adhesives.

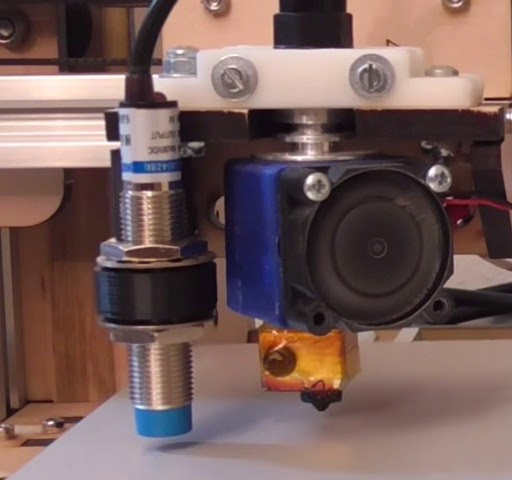

The filament run-out sensor and extruder assembly(Image: Andrew Sink)

Filament Run-out Sensor

The filament run-out sensor is positioned in-line with the aluminum extruder assembly, and has a small printed bracket that makes it fully aligned with the extruder gears. I tested it a few times, and it successfully registers when filament is no longer present, and will bring the printer to a paused state to allow you to insert new material. I thought it was a cool touch that the riser bracket was printed; the perfect example of how 3D printing likely saved the day during manufacturing!

I tested it a few times, and it successfully registers when filament is no longer present, and will bring the printer to a paused state to allow you to insert new material. I thought it was a cool touch that the riser bracket was printed; the perfect example of how 3D printing likely saved the day during manufacturing!

The ET4X also has the ability to resume a print after a power outage. I tested this by unplugging the printer during a print, and then plugging it back in. After being prompted to continue the print, the ET4X will rehome the X/Y axis, so the print will continue even if the print head has moved on the X/Y. While you might have calibration issues when printing with higher-temp materials due to shrinkage, this function worked as expected when printing with PLA.

3D printer touch screen(Image: Andrew Sink)

First Prints – Choosing Slicer Software

Unfortunately, if you’ve never used any 3D printer slicing software before, the Anet ET4X can be a little tricky to set up. Anet recommends using Cura as a slicer for this machine, and offers a downloadable profile that you can get from within Cura. This profile has a number of questionable parameter decisions (including printing infill before perimeters) which can make your first print come out with noticeable defects. I opted to create a profile with PrusaSlicer along with some custom start g-code to create an initial purge line, and have been very happy with the software experience since. If you’re planning on using Cura with the ET4X, I would highly recommend taking your time and getting your profile dialed in before you start any large or ambitious prints.

Anet recommends using Cura as a slicer for this machine, and offers a downloadable profile that you can get from within Cura. This profile has a number of questionable parameter decisions (including printing infill before perimeters) which can make your first print come out with noticeable defects. I opted to create a profile with PrusaSlicer along with some custom start g-code to create an initial purge line, and have been very happy with the software experience since. If you’re planning on using Cura with the ET4X, I would highly recommend taking your time and getting your profile dialed in before you start any large or ambitious prints.

(Image: Andrew Sink)

Manual and Automatic Bed Leveling Systems

To level the bed before printing, I adjusted the four bed adjustment screws at each corner of the bed while tramming the nozzle until they were all equally offset from the bed. It pays off to be very careful and precise during this process, especially if you are going to be printing directly on the glass bed and want an even first layer.

Both Anet ET4 PRO and Anet ET5 PRO 3D printer models have automatic bed leveling systems.

Silent Mode 3D Printing with TMC2208 Stepper Driver

One of the first things you’ll notice while printing is the sound of the stepper motors. The Anet ET4X uses A4988 stepper drivers, which can create a high buzzing sound during rapid travel moves. If you’re printing large objects with long print times this noise can get pretty old, pretty quickly. The upgraded ET4 Pro uses TMC2208 stepper drivers, which are significantly quieter and allow for a more peaceful printing process. I personally have the printer on the other side of my office while I’m working, so the noise is less intrusive.

- Anet 3D Printers on Amazon (affiliate link)

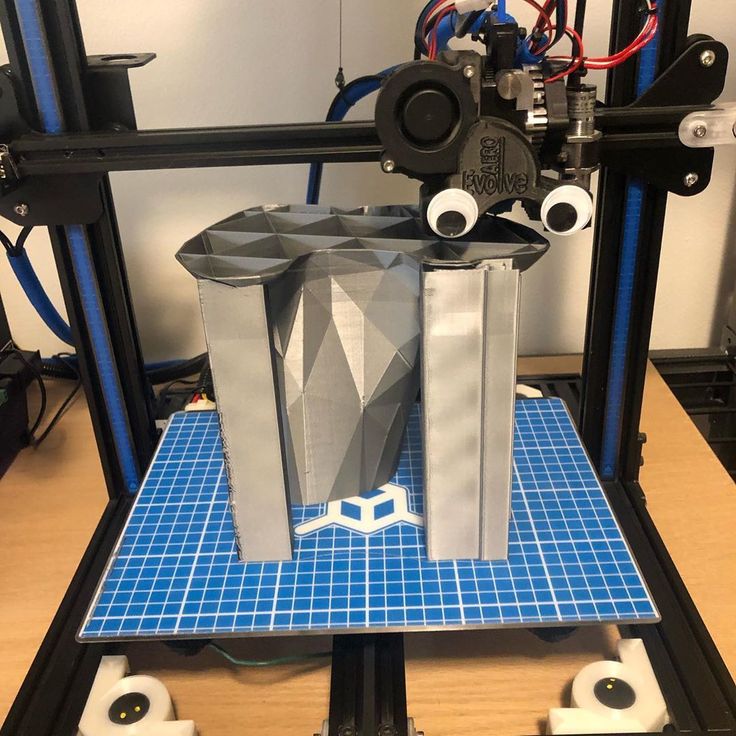

I printed several 20mm calibration cubes to test the accuracy of the machine, and they were generally accurate to +/- .04mm (or 0.0015”) on the X,Y, and Z axis. I didn’t test this accuracy on larger parts (or large parts with small features), but it certainly shows a good deal of promise for printing small, accurate parts.

(Image: Andrew Sink)

I also tested the printer’s ability to print a large object using the “Spiralize Outer Contour” setting in Cura and printed out the ‘‘Curved honeycomb vase’ by eggnot from Thingiverse. The printer performed well with no hiccups, and the printed model looked great.

Due to the continuous toolpath that had very few large travel moves, this printing mode was a good deal quieter than the standard printing mode.

3D Printed in Vase Mode – Honeycomb Vase by eggnot(Image: Andrew Sink)

Should you be interested?

Coming in at under $200 shipped to your door from Amazon, the Anet ET4X is an attractive option for someone getting started in 3D printing who doesn’t mind tinkering or building their machine themselves. For the price, the Anet ET4X offers a lot of value and most beginners will come to appreciate the extra features built into this machine over time. For more advanced users who want features like an auto-leveling bed, TMC2208 silent stepper drivers, or a smaller amount of assembly, Anet also offers a Pro version of the ET4 platform that has those features in a more print-ready machine.

- Anet A8, ET4, ET5 Series 3D Printers on anet3d.com

Anet 3D Printers

- Anet A8 – 220x220x240mm Volume – Full DIY Desktop FDM 3D Printer

- Anet A8 Plus – 300*300*350mm Volume

- Anet ET4X – 220*220*250mm Volume – Semi-DIY

- Anet ET4 PRO – 220*220*250mm Volume – Silence Printing, Auto-Leveling

- Anet ET5X – 300*300*400mm Volume – Semi-DIY

- Anet ET5 PRO – 300*300*400mm Volume – Silence Printing, Auto-Leveling

Choose a desktop 3D printer that is right for you. Build volume, FDM or SLA, well-known brand or a start-up – all to consider. Choose a desktop 3D printer that is right for you. Build volume, FDM or SLA, Kit or Plug-and-Play, well-known brand or a start-up – all to consider. The table helps to compare and make a comprehensive decision. It is regularly updated and maintained.

It is regularly updated and maintained.

Review of Anet ET4 3D printer after using

3DPrintStory Reviews Review of the Anet ET4 3D printer after use

Chinese 3D printer manufacturer Anet has made a name for itself in the world of 3D printing over the past few years with the highly successful Anet A8. The low price and competitive quality of 3D printing made it very attractive to many enthusiasts and it became very popular in a short time. But sometimes being cheap can be expensive in the long run, and the Anet A8 dream turned into something of a nightmare when some users reported that their 3D printers started to catch fire. But that's in the past. This year, a new improved A8 plus appeared on the market, in which the manufacturer thought about security. In addition, a new promising 3D printer has appeared on the market - Anet ET4, which will be discussed below. nine0005

In addition, a new promising 3D printer has appeared on the market - Anet ET4, which will be discussed below. nine0005

What do I want from a 3D printer? I am a designer, and first of all, the quality of 3D printing, stability and ease of use of the printer are important for me. I don't want to know much about how 3D printers work, software tricks and workarounds. I need a reliable machine with good print quality that won't give me too much trouble.

Anet ET4 3D Printer General Information

ET4 is a DIY desktop 3D printer that needs to be assembled after purchase. Thanks to the modular design, it doesn't take long to start 3D printing. When you open the box for the first time, assembly is mostly intuitive. It doesn't have many parts, most of it is made up of 3 separate blocks that can be put together with a few screws. I just had to check the instructions a couple of times. Unpacking, setting up and getting to your first 3D print is generally very easy. nine0005

I like that this 3D printer is built on an all-metal frame. It's an aluminum frame that isn't hard to move because it's not too heavy. This 3D printer model gives a solid feel and has a compact design that makes it quite rigid and resistant to vibrations. While, as we mentioned earlier, the Anet A8 made us feel a little uncomfortable, it does feel like leaving the ET4 without close supervision is entirely possible.

It's an aluminum frame that isn't hard to move because it's not too heavy. This 3D printer model gives a solid feel and has a compact design that makes it quite rigid and resistant to vibrations. While, as we mentioned earlier, the Anet A8 made us feel a little uncomfortable, it does feel like leaving the ET4 without close supervision is entirely possible.

Main features and functions of Anet ET4

Once enabled, you can control some of the 3D printing functions using the 2.8-inch touch screen located at the base of the 3D printer. I don't want my computer to be connected to the printer all the time, so for me using the screen on the printer is a must as it makes it much easier to manage its operation. It also allows me to check print settings such as nozzle and bed temperature, files to be printed and how long it will take, etc. The controls and software were reasonably easy to use and understand. The user interface is also decent, without unnecessary complications. nine0005

nine0005

Another handy feature is "Resume Print": in the event of a sudden interruption in printing, the Resume Print function allows you to continue 3D printing where it left off. This is very convenient in the event of a power outage or other similar problem. But there are features here. This is true - you can continue printing, but when the 3D printer is turned off, the material, still warm, continues to exit the nozzle onto the part. So it will need to be scraped off. As stated in the specification, the printer's media-out detection works. nine0005

One feature that didn't satisfy me was the automatic calibration. This is fairly common in FDM type 3D printers these days, but in ET4 the implementation has clearly let it down. It has 25 control points along the table, which sounds promising. For my first 3D print, I did a manual calibration, and since then I've tried to use only the automatic one, but it doesn't always work properly. From time to time, you still have to manually calibrate the table, like on the good old Anet A8. The loading and unloading of 3D printing material is well implemented, the feed works well. nine0005

The loading and unloading of 3D printing material is well implemented, the feed works well. nine0005

Another important aspect for me is the level of noise that the 3D printer produces. Anet ET4 is pretty quiet. It is quite possible to do something from another while it works in the background. Although I'm pretty picky about noise. ET4 has a choice between two stepper drivers, A4988 and TMC2208, I bought the version with the second one. And it makes the 3D printer virtually silent. You can get the latest updated driver from their official website. I would definitely recommend spending $15 more on the TMC2208 ET4 version as the noise level will be fundamentally lower. nine0005

3D print quality on Anet ET4 and where to buy

And now one of the most important parts - 3D print quality. For me, this is the most important aspect, and the results pleasantly surprised me. I use 3D printing to make pottery molds and also 3D print finished products, so I need high quality. And using Anet ET4 with the right 3D print settings you can get really great results. The 3D print quality is really good, especially for a printer in this price range. I've also been very happy with the textures that I've had problems with other 3D printers in the past. Sometimes textures can look a bit clunky, or the printer will start making strange noises while making short, quick strokes while printing fine textures. It wasn't here. On Anet ET4 I was able to get very detailed textures for both small and large parts. Yes, the printer is not perfect, but it is a good model for its price. nine0005

And using Anet ET4 with the right 3D print settings you can get really great results. The 3D print quality is really good, especially for a printer in this price range. I've also been very happy with the textures that I've had problems with other 3D printers in the past. Sometimes textures can look a bit clunky, or the printer will start making strange noises while making short, quick strokes while printing fine textures. It wasn't here. On Anet ET4 I was able to get very detailed textures for both small and large parts. Yes, the printer is not perfect, but it is a good model for its price. nine0005

You can buy Anet ET4 3D printer from this link on Aliexpress

After more than 100 hours of printing on ET4, I can say with confidence that if you are thinking about buying a 3D printer and your budget is between 200 and 300 dollars , you may consider purchasing Anet ET4. This is a good choice for an inexpensive desktop 3D printer.

You may not agree with my conclusions, but these personal impressions are made honestly and with a sincere desire to help you buy a decent 3D printer. nine0005

nine0005

the case when "Pro" did not report / 3D printers, machine tools and accessories / iXBT Live

Anet ET4 Pro is 3D printer which I definitely would not recommend to beginners. Before he started typing more or less normal, he drank a lot of blood from me. Table calibration made easy pain. Screws loose during printing, firmware failure, limit switch glitch, not very high quality build. All this you get in full, with the purchase of this models. It took me weeks to get this printer to print more or less bearable. But I still don't trust him to print important models, only drafts, prototypes or parts that do not have requirements for perfect surfaces. But here, rather, the reason is that I have other printers, which out of the box print much better. And all this for $200+. AT in general, right away and at the beginning of the review I can say that this printer is definitely not Suitable for beginners in 3D printing. Although if you tinker a little, then on this printer and you can get normal quality models. But is it necessary to you? This is the question. I personally definitely plan in the future completely remake this printer, leaving only the frame as a base, and on its basis already build a more interesting printer. Perhaps hands will reach and tell about this. But now the review is precisely Anet ET4 Pro in stock condition. nine0005

But is it necessary to you? This is the question. I personally definitely plan in the future completely remake this printer, leaving only the frame as a base, and on its basis already build a more interesting printer. Perhaps hands will reach and tell about this. But now the review is precisely Anet ET4 Pro in stock condition. nine0005

- Model: ET4 PRO

- Print technology: FDM

- Print block type: 1xBowden extruder

- Media Type: plastics PLA, ABS, HIPS and analogues

- Filament diameter: 1.75mm

- Frame material: aluminum

- Print area: 220x220x250mm

- Nozzle diameter: 0.4mm nine0052

- Accuracy: ±0.1mm

- Layer thickness: 0.1-0.3mm

- Model loading options: connection to a computer; off-line with microSD

- LCD display: 2.8 inch color

- Max speed printing: up to 150mm/s

- Recommended speed printing: 30-60mm/s

- Table material (HotBed): aluminum platform + tempered glass or thermal pad nine0052

- Extruder temperature: up to 250°C

- HotBed temperature: up to 100°C

- 3D printer size: 510x485x250mm

- Weight: 7.

6 kg

6 kg

The printer comes in a large, heavy box, already half-assembled. form:

We take out two substrates, one contains the lower part of the printer, and into the second gantry of the Z axis. There are also various accessories between the frame. I also come with the printer was a 1kg PLA plastic spool, but it did not get into the photo. nine0005

I also can't help but show how the box with the printer was damaged, and the presence of soft foam material is clearly not superfluous here. After all, our mail probably it can, as in a joke: when delivering two iron balls from a bearing, one was lost and the other was broken. There was such a hole in the sidewall of the box:

We admired the hole, now let's admire the printer. Let's start with lower part. The motherboard, power supply and one motor are inside the metal body, which is also reinforced from the inside with an additional profile. Heating table implemented from a sandwich in the form of a retaining plate, on which there is an aluminum plate with heating and glass on top. Also included is a sticker for table, which I naturally pasted. The case itself is well made. With on the right side it has a switch, a hole for the power cord, MicroSD card slot and Type-B port for connecting the printer to the computer. There is also a grille motherboard

Also included is a sticker for table, which I naturally pasted. The case itself is well made. With on the right side it has a switch, a hole for the power cord, MicroSD card slot and Type-B port for connecting the printer to the computer. There is also a grille motherboard

On the left side there is a cooler grill through which the printer blows air:

If you turn the base over, you can see the power supply, a little wires, which are fixed with plastic holders and the Y-axis motor

Now let's take a closer look at the heating table. As I wrote above, this sandwich made of X-shaped plate, aluminum plate and glass:

It is good that during assembly the manufacturer abandoned unreliable plug connections. Here the heater wire is rigidly fixed with a plastic clamp and soldered to the contact site:

But not happy that the heating plate has no insulation. Though To be honest, the table heats up quickly enough. Up to 60-70 degrees it heats up in about 1-2 minutes. This is enough for printing by most popular filaments.

This is enough for printing by most popular filaments.

As for the sticker, it definitely needs to be glued. And not in order to improve the adhesion of the filament, but in order not to crush the glass with a nozzle table. This is easier to do than it seems.

After a couple of test prints, during the calibration process, I have a sticker immediately damaged:

But I'm already getting ahead of myself. Now consider the portal of the Z axis. It has a classic construction. The Z axis moves vertically with a single motor with fixed on it with a rigid hitch pin. The pin itself at the top is not has a latch. This is a plus for some and a minus for others. I personally never I fix the stud on top of the frame, and I think that it is not necessary to do this.

Interestingly, I can also note the presence of an adapter board on the Z axis, which also serves for beauty, and for reliability:

One cable comes from the motherboard, and on this board there is already connection of all necessary elements.

X and Y axis mechanical limit switches:

Extruder in Bowden printer. There is a filament end sensor. But they are not placed very conveniently, and replacing plastic you understand.

The print head itself is separate. It moves along the profile due to the wheels in the V-slot profile. When assembling, you need to put it on the frame, place the belt and tension it with the X-axis motor

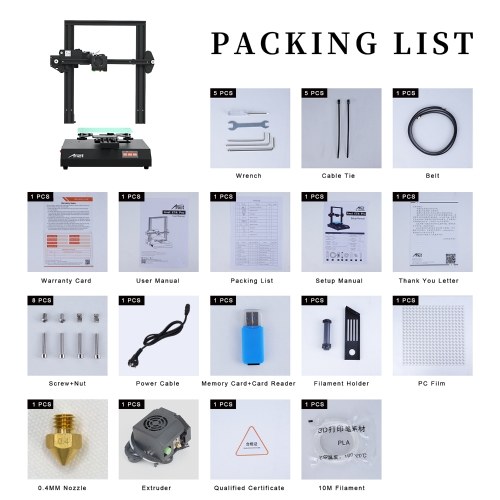

Now that we have looked at the details, we can start assembling. For Assembly included with the printer has all the necessary tools. Kit hexagons, a wrench for adjusting the table sensor and an open end wrench. And yes, in In the kit there is also a card reader and a non-named MicroSD card. ( by the way, the card turned out to be buggy. At first it lost files, and then completely died )

Assembly is actually not difficult. First of all, you need to twist both half of the frame with four supplied screws, as well as connect all the plugs in connectors

The second step is to put the print head in place, tighten the belt and connect the cable from the motherboard to the distribution board:

We clamp the cords with ties:

coil holder. Here the manufacturer did not reinvent the wheel, and, as in most printers just put in a kit a metal leg with a plastic tube:

Here the manufacturer did not reinvent the wheel, and, as in most printers just put in a kit a metal leg with a plastic tube:

And on this the printer is ready to go. Sort of. But it's really worth checking out. tightening absolutely all screws, tighten the eccentric nuts on all axles to remove backlash ( and they are here and decent ). My printer is just up between the bedside table and the table where he will work:

And if you think that now you can definitely print, then you are mistaken. Now we need set the automatic table sensor. He's a capacitive ABL. First we need a sheet of paper. On sensor there is a screw that needs to be tightened until it stops when the sensor react to the table, but will react to the inserted sheet. Then you can make automatic calibration, and tighten the screws of the table to level it. I got the following:

Real table curve, and no matter how I tried, the photo shows the best calibration that I could receive. By the way, I don’t know if these are jambs of my printer, or everyone has it, but in fact the printer does not remember and does not take into account the nervousness of the table. He is not writes these measurements to memory and does not use them when printing. And this is a joint. Therefore, you can simply use the usual calibration, and then set the desired us the amount of clearance of the Z axis.

He is not writes these measurements to memory and does not use them when printing. And this is a joint. Therefore, you can simply use the usual calibration, and then set the desired us the amount of clearance of the Z axis.

Well now you can start printing. But before that, let's get acquainted with the printer software. nine0005

Printer has 2.8 inch color touch screen. The sensor is resistive, and reacts not only to the finger, but also for other things.

Power on printer, the user sees a splash screen with the manufacturer's logo:

Loading printer is quite fast, it turns on in 15 seconds. This is what the main looks like menu:

Here you can immediately try to select the language we need, but, unfortunately, the Russian language was not delivered:

In the Prepare menu are axis settings and calibration, as well as the menu for changing the filament:

In the Settings menu, you can perform manual calibration, view information about the printer and firmware and also update the firmware from a flash drive:

And like this looks like the Print menu. At pressing it opens the contents of the flash drive, where you can select a file for printing:

True, there is One obvious jamb of the firmware. The file that we need to print must be selected with the arrows up and down. It would be logical to just click on the file name to choose but no. You must first scroll through, and click on the desired selected file OK button. nine0005

After selected a file for printing, we see this menu:

Here, right away, so to speak, on the fly, you can adjust the temperature of the table and nozzles, as well as adjust the fan speed. Come on and stamp on pause or stop it altogether.

Upon completion of printing, the printer displays this window with information about that printing is complete:

And now about printing. As I said above, the printer loves to fail. For example, he can completely forget the gaps, and start pushing the nozzle into the table, or lose limit switches and their directions. At any moment, one or the other can unwind screw, and as a result, one of the axes will loosen. And as a result, left without An oversight print might look like this:

And as a result, left without An oversight print might look like this:

Or like this:

Or like this:

Which, of course, does not add joy. And sometimes it can print two details in a row, but one of them will look normal, and the second not so. As here:

Although if you sit over the printer and watch, you can do quite good details. Here, the same hooks as in the photo above, but this time he decided that he was ready for work:

But, by the way. If you still calibrate the printer before printing, everything will check several times, make sure that the temperature is set correctly, and the gaps did not run away, then you can get normal models. Here are examples:

And this fitting and adjustment before each print, frankly, very annoying. Sit and think, print or not. How to play the lottery.

Either he prints well, then some bug will come out.

In general, you understand. It's pretty nerve-wracking.

Conclusion

To be honest. AnetET4 Pro 3D printer I definitely do not recommend for purchase. Look like that's it smartly done, but poorly implemented. I personally keep this printer only in as a backup printer when my two primary printers are busy printing. Suddenly you urgently need to print something else, and this is something not very complicated and the customer will have no complaints about the quality, only then I start printing. I can to forgive such a printer if it cost 100-130 bucks. But the price of this the printer is now 230-270 bucks. What kind of product is just a frank overprice. For example, I have a Kywoo3D Tycoon Max 3D printer (my review), its price is about $300 and it fully justifies its price. And here is the printer not that he does not pull on his price, he also requires dancing with a tambourine around him. It's better to buy folk Ender, than this share. nine0005

AnetET4 Pro 3D printer I definitely do not recommend for purchase. Look like that's it smartly done, but poorly implemented. I personally keep this printer only in as a backup printer when my two primary printers are busy printing. Suddenly you urgently need to print something else, and this is something not very complicated and the customer will have no complaints about the quality, only then I start printing. I can to forgive such a printer if it cost 100-130 bucks. But the price of this the printer is now 230-270 bucks. What kind of product is just a frank overprice. For example, I have a Kywoo3D Tycoon Max 3D printer (my review), its price is about $300 and it fully justifies its price. And here is the printer not that he does not pull on his price, he also requires dancing with a tambourine around him. It's better to buy folk Ender, than this share. nine0005

I personally plan to rebuild this printer. Already looked at the linear guides, but have not yet decided on the motherboard.