3D printed electronics market

3D Printed Electronics Market Size, Trends, Growth, Report 2030

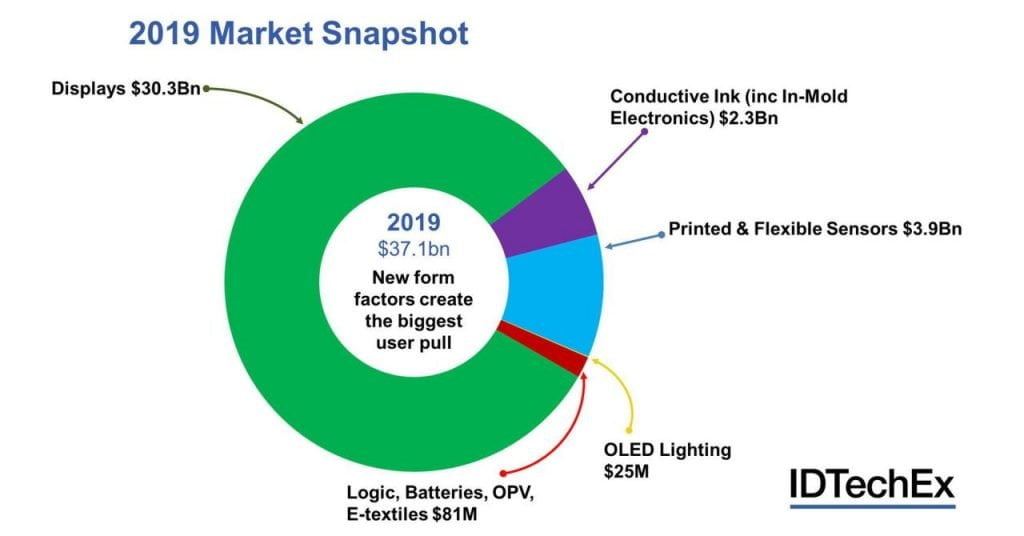

The global 3D printed electronics market size was estimated at USD 10.6 billion in the year 2021 and is expanding around USD 38.2 billion by 2030 with a registered CAGR of around 15.31% during the forecast period 2022 to 2030.

Increased growth of the 3D printed electronics market in various sectors and industries with increased technologies over internet of things are the driving factors pf 3D printed electronics market which extended the market of 3D printed electronics to greater extent. Electronics system integrated with in the gadgets which allows the programming and functioning. Increased focus of 3D printing by using the antennas utilizing connectivity for 3D printed electronics products. With improved techniques and technologies in the 3D printed electronics involves processing of the electronics build components, and material creation and building the complex structure from the number of materials with developed techniques. With increased manufacturing developments and rising production by customizing the parts of the 3D printed electronics required to asset the part in to the electronic component based on the computerized system.

The Increased demand for the machines thinner, tinier machines with improved functions and developments in the 3D printed electronics. Impact of covid-19 affected the market growth which led to decreased production of 3D printed electronics and declined the market revenue share. Wide spread of corona virus across the various regions with imposed rules and regulations and shut down of the nation led to close down of the industries which decreased manufacturing of the 3D printed electronics components.

Faced the challenges for the sale of the 3D printed electronics and manufacturing in the year 2020 and later on solved the issues with developing situation and increased the market growth with increasing demands from the consumers. Electronics gadgets such as cameras, mobiles and number of elements integrated with the electronics systems.

Growth Factors

- Rapid increased and developments in the smart devices and cameras with increased demands from the consumers for the productivity.

- Increased applications for boosting the market of 3D printed electronics with increased efficiency and good productivity for good performance and good productivity.

- Increased 3D printed electronics with increased electrification components in developments in Tv for flexible curved display.

- Increased new technologies and new improved electrical devices.

- The increased technological and advance developments which fuel up the market.

- Large number of markets of electrical with increased demands with new designed features.

- Enhancement of the market rise in upcoming years with new technologies.

Increased manufacturing of the products with low weight, ease of application with improved technology in manufacturing of the electrical components which enhance the market. Enhanced production of the antenna printings, and sensor printings in the 3D form which fuel the market. Rapid acceptance of the newly developed technology in number of sectors and increased demands from the consumers in industries such as health sector, defense, health sector, telecommunication, automobile industry, electrification system, energy utilities, aerospace and other many more industries expected to thrive the market of 3D printed electronics market with increased competition due to the availability of the new arrivals and increased performance. Increased market players with increased investment in the electronics and automobile industry have increased the market rate with increased research and development strives to grow the market during the forecast period.

Enhanced production of the antenna printings, and sensor printings in the 3D form which fuel the market. Rapid acceptance of the newly developed technology in number of sectors and increased demands from the consumers in industries such as health sector, defense, health sector, telecommunication, automobile industry, electrification system, energy utilities, aerospace and other many more industries expected to thrive the market of 3D printed electronics market with increased competition due to the availability of the new arrivals and increased performance. Increased market players with increased investment in the electronics and automobile industry have increased the market rate with increased research and development strives to grow the market during the forecast period.

Report Scope of the 3D Printed Electronics Market

| Report Coverage | Details |

| Market Size in 2022 |

USD 12. |

| Market Size by 2030 |

USD 38.2 Billion |

| Growth Rate from 2022 to 2030 | CAGR of 15.31% |

| Base Year | 2021 |

| Forecast Period | 2022 to 2030 |

| Segments Covered | Printing Technology, Material, Resolution, Applications, End Use Industry, Transport Techniques, and Geography |

| Companies Mentioned | LG Display Co Ltd, Samsung Electronics Co. Ltd, Molex, LLC, Agfa- Gevaert Group, E Ink Holdings, Nova Centrix, BASF, Nissha Co, Ltd, DuPont de Nemours, Inc, Palo Alto Research Center Incorporated, ISORG SA, Sumitomo, Nano Dimension, Hensodt, GSI Technologies LLC, Enfucell, Draper, Eastprint Incorporated, The Cubbison Company, KWJ Engineering Incorporated |

Key Market Drivers

Increased utilization of the 3D printed electronics in the automobile industry widely end-use industry in the 3D printed electronics widely used in the industry with increased features. Increased features such as thinness, flexible, robustness other features such as touch control technique and improved surfaces with increased technologies in the car interior designer. The key market players involved in the 3D printed electronics with new innovation and technologies developed in the 3D printed electronics market with wide demand from the consumers and increased market rate of 3D printed electronics during the forecast period.

Increased features such as thinness, flexible, robustness other features such as touch control technique and improved surfaces with increased technologies in the car interior designer. The key market players involved in the 3D printed electronics with new innovation and technologies developed in the 3D printed electronics market with wide demand from the consumers and increased market rate of 3D printed electronics during the forecast period.

Increased automobile sectors with new manufacturing and developments in the electronic devices includes displays based on OLED, vehicles included with lighting. In automobile industry with wide utilization in displays, touch, sensors, lighting of the monitors. Utilization of sensors, monitor display, lights and many more in the transport automobile industry. Expansion of the 3D printed electronics market in the automobile industry with increased developments and demands strives the market to grow.

Key Market Challenges

3D printing electronics with different techniques available for printing with wide applications of printing technology in the industries. Possessing different factors regarding the selection while printing includes such as selection of material and selection of substrate, selection of the printing pattern, Integrating the hardware design and developed software with new technologies integrated in the system software for developing the 3D printings. Challenging task for integration of the sensors, displays, embedded monitors, circuits, other electrification system involved for integration in to the circuit plays a major task during the utilization of the 3D printing electronic techniques with wide developments.

Possessing different factors regarding the selection while printing includes such as selection of material and selection of substrate, selection of the printing pattern, Integrating the hardware design and developed software with new technologies integrated in the system software for developing the 3D printings. Challenging task for integration of the sensors, displays, embedded monitors, circuits, other electrification system involved for integration in to the circuit plays a major task during the utilization of the 3D printing electronic techniques with wide developments.

- New developing system software which helps to connect the various sensors, electronics devices in building and other electronics components.

- Innovating newly developed connectors which enable to connect the link in rigid hardware and flexible substrate.

- Manufacturing of the small and flexible components which are meant or integrating in to the electronic devices.

- Developed pattern of printing

- Increased selection and understanding of the materials required for integrating in the electronic devices utilized for 3D printing technique.

Key Market Opportunities

3D printed electronics with the improved facilities such as ease of availability, reduced cost of the printing techniques, improved displays, developed sensors, labels are the improved functions in the 3D electronics market.

Increased applications of 3D electronics printing in the health sectors with increased developments of displays, sensors, sounds, connectors and servers with wide demand from the market which helps to boost the market growth. Continuous research and development in the 3D electronics printing with new variations in electronics printing with new improved functions. Printing electronics utilized at home for image printing of the lungs with improved efficacy and market growth. Thin batteries involved in electronic device integrated in the printed plays a major role in the health care sector utilized in medical devices.

Emerging of the under developed nations with the increase developments and innovations and rising demands and continuous new research have increased the demand and strive the market growth.

Segments Insight

Printing Technology Insights

Segmentation of 3D printing electronics based on the printing technology divided in to Ink jet printing includes such as continuous ink jet printing, drop on demand inkjet printing involves Thermal drop on demand inkjet printer, piezo drop on demand ink jet printing, electrostatic drop on demand ink jet printing. Screen printing involves flatbed screen printing, rotary screen printing, flexographic printer, gravure printing, and other such as aerosol printing, reel to reel printing, offset printing, pneumatic printing and many more. Screen printing to be widely used in printings of electronic circuit boards, posters, signage board, sensors, batteries and many more with developed manufacturing and new technologies.

Material Insights

Segmentation of 3D printing electronics based on the materials divided in to different sections such as Inks includes conductive inks involves conductive silver inks, conductive copper inks, transparent conductive inks, silver copper inks, carbon inks, dielectric inks and other inks. Substrate involves organic substrates such as polymers includes polyimides, polyethylene naphtholate, polyethylene terephthalate, papers include polyacrylate, polystyrene, polyvinylpyrrolidone, polyvinyl alcohol. Inorganic substrates involve such as glass and other such as metal and silicon oxides. Ink printers which to be at the top position with increased revenue share and increased the market rate.

Substrate involves organic substrates such as polymers includes polyimides, polyethylene naphtholate, polyethylene terephthalate, papers include polyacrylate, polystyrene, polyvinylpyrrolidone, polyvinyl alcohol. Inorganic substrates involve such as glass and other such as metal and silicon oxides. Ink printers which to be at the top position with increased revenue share and increased the market rate.

Applications Insights

Segmentation of 3D printing electronics based on the applications involves such as batteries, RFID tags, displays includes such as E-paper display electrochromic displays, electrophoretic displays, other E- paper display. Electroluminescent displays involve such as OLED displays, flexible OLED displays, LCD. Increased utilization in photovoltaic cells includes sensors, touch sensors, gas sensors, humidity sensors, pressure sensors, image sensors, temperature sensors and others. Lighting involves such as electroluminescent lighting, organic light emitting diode lighting and other applications.

End Use Insights

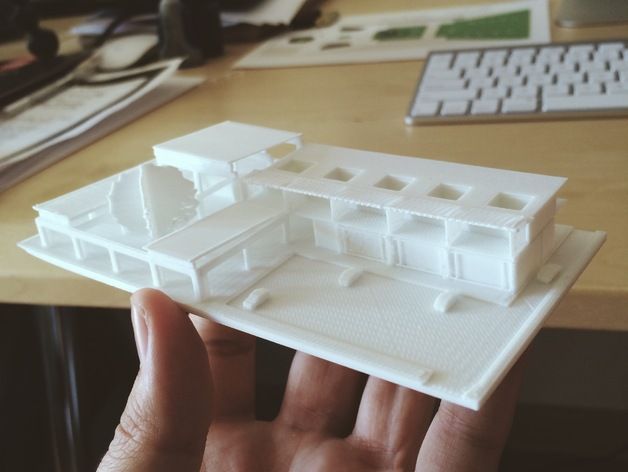

Segmentation of 3D printing electronics based on the end use industry includes automobile and transportation, healthcare, consumer electronics, aerospace and defense, construction and architecture, retail and packaging and other end use industries.

3D Printed Electronics Market Share, By Region, 2021 (%)

| Regions | Revenue Share in 2021 (%) |

| North America | 27% |

| Asia Pacific | 44% |

| Europe | 20% |

| Latin America | 5% |

| MEA | 4% |

Geography Insights

Segmentation of 3D printing electronics based on the geography involves Asia Pacific to hold the largest share of 3D electronics market with increased developments and manufacturing and production of the new technologies with improved performance of the printing technologies with increased demands from the consumers helps to boost the market growth of printed electronics with 3D technology with increased research and development expanded the market growth at a larger extent with increased investment and key market players. Other regions included such as North America, Europe, Latin America, Middle East and Africa also help to drive the market of 3D printing electronics with increased growth rate.

Other regions included such as North America, Europe, Latin America, Middle East and Africa also help to drive the market of 3D printing electronics with increased growth rate.

Recent Developments

- In the year 2021 September, Samsung Electronics Co.Ltd introduced the monitor with the display size of 24inch integrated with webcam over the monitor S4. Model name is S40VA, designed according to the needs of the hybrid workers. Webcam, speakers, microphone integrated and installed in the monitors for easy utilization of the monitor with improved connectivity.

- In the year 2021 July, Acquisition of Laired Performance Materials from the company DuPont. With solutions such as electromagnetic shield and management of the thermal solutions. Which help to boost the electrification system and the industries.

- In the year 2021 January, LG Electronics with improved acquiring with control of stake in TV and measurement. Which provides company with more services and increased content to the customers.

- In the year 2021 April, DATA MODUL and E Ink holdings signing of the agreement a well established company known for the embedded monitors, touch, display, increased selling in US and Europe market.

Key Market Players

- LG Display Co Ltd

- Samsung Electronics Co. Ltd

- Molex, LLC

- Agfa- Gevaert Group

- E Ink Holdings

- Nova Centrix

- BASF

- Nissha Co, Ltd

- DuPont de Nemours, Inc

- Palo Alto Research Center Incorporated

- ISORG SA

- Sumitomo

- Nano Dimension

- Hensodt

- GSI Technologies LLC

- Enfucell

- Draper

- Eastprint Incorporated

- The Cubbison Company

- KWJ Engineering Incorporated

Segments Covered in the Report

(Note*: We offer report based on sub segments as well. Kindly, let us know if you are interested)

Kindly, let us know if you are interested)

By Printing Technology

- Inkjet Printing

- Continuous Inkjet printing

- Drop on Demand ink jet printing

- Thermal drop on demand inkjet printing

- Piezo drop in demand inkjet printing

- Electrostatic drop on demand inkjet printing

- Screen Printing

- Flatbed screen printing

- Rotary screen printing

- Gravure Printing

- Flexographic Printing

- Others

By Material

- Ink

- Conductive Inks

- Conductive silver inks

- Conductive copper inks

- Transparent conductive inks

- Silver copper inks

- Carbon inks

- Dielectric inks

- Other inks

- Substrates

- Organic substrates

- Conductive Inks

- Polymers

- Poluimides

- Polyethylene naphtholate

- Polyethylene terephthalate

- Paper

- Polyacrylate

- Polystyrene

- Polyvinyl Alcohol

- Polyvinylpyrrolidone

- Other

- Organic substrates

- Inorganic substrates

- Glass

- Others

By Resolution

- Less than 100 lines/CM

- 100 to 200 lines/CM

- More than 200 line/CM

By Applications

- Displays

- E paper displays

- Electrochromic displays

- Electrophorectic displays

- Other e-paper displays

- Electroluminescent (EL) Displays

- OLED display

- Flexible OLED display

- LCD

- Battery

- RFID Tags

- Lighting

- Electroluminescent lighting

- Lighting

- Oraganic light emitting diode

- Photovoltaic Cells

- Temperature sensors

- Image sensors

- Pressure Sensors

- Humidity Sensors

- Gas Sensors

- Touch Sensors

- Sensors

- Others

- Other

By End Use Industry

- Retail and Packaging

- Construction and Architecture

- Aerospace and defense

- Consumer electronics

- Healthcare

- Automotive and transportation

- Others

By Transport Techniques

- Roll to roll

- Sheet to sheet

- Sheet to shuttle

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa (MEA)

3D Printed Electronics Market Size Share and Forecast

3D Printed Electronics Market is Segmented By Product (Antennas, Sensors, Printable Displays, PCB, Others), By Application (Production Line, Rapid Prototyping), By End-User (Aerospace and Defense, Consumer Electronics, Medical, Telecom, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) – Share, Size, Outlook, and Opportunity Analysis, 2022-2029

3D Printed Electronics Market Overview

The global 3D printed electronics market reached US$ XX million in 2022 and is expected to record significant growth by reaching up to US$ XX million by 2030, growing at a CAGR of 30.

36% during the forecast period (2023-2030).

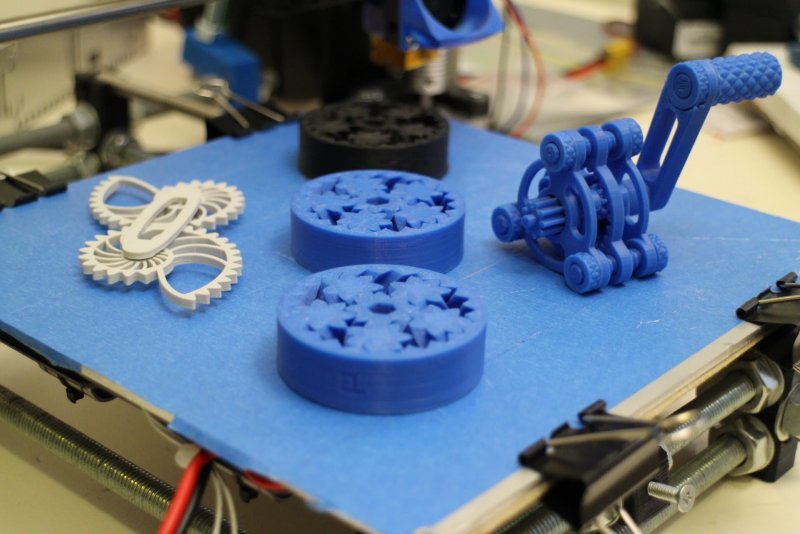

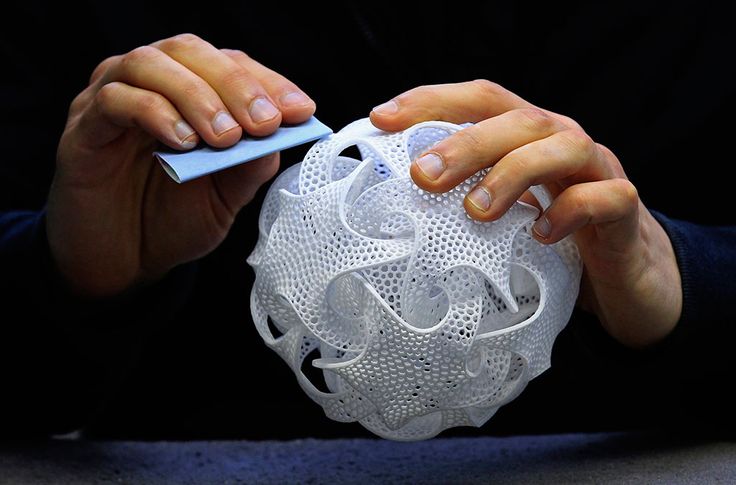

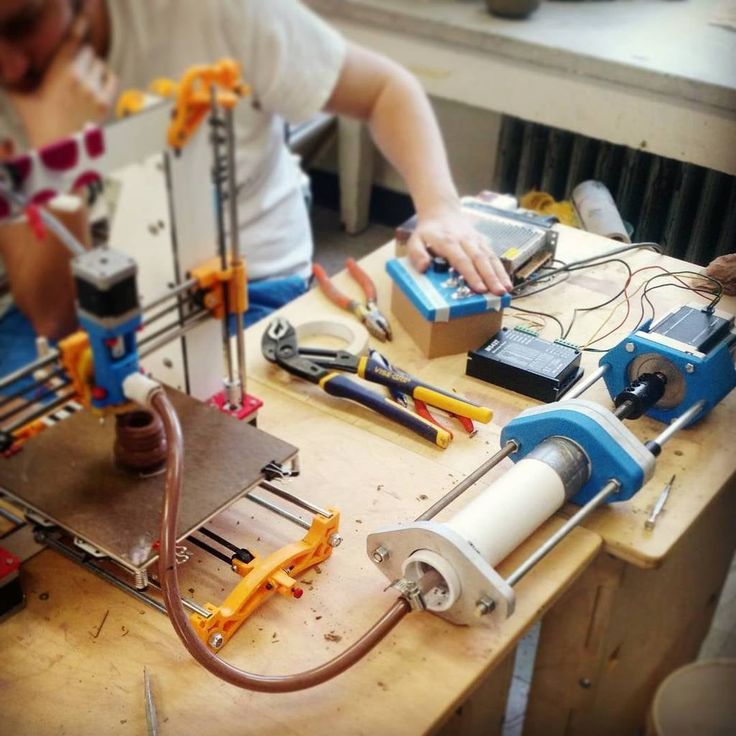

3D printing is a digital manufacturing advanced technology that produces three-dimensional functional objects from its digital prototype. It involves additive processes of laying down successive layers of materials to create the final product. It is finding applications in various industries, from electronics to automotive, aerospace, metalworking and jewelry.

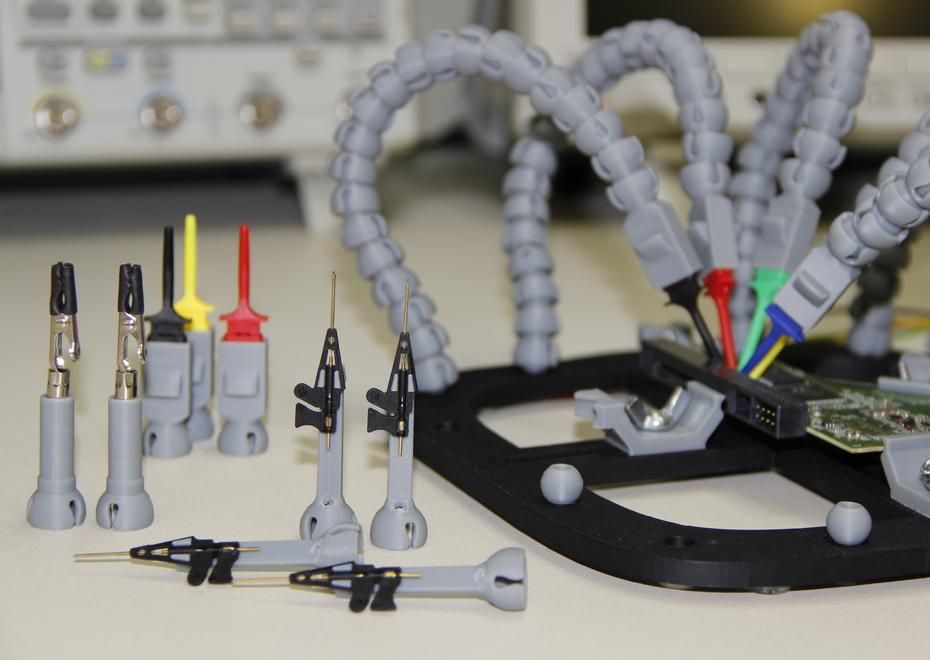

3D printed in electronics is a prototyping tool and offers benefits such as in-house prototyping, design flexibility and customized design. It allows electronic components such as antennas, sensors and displays to be printed directly over base surfaces, reducing overall device size and complexity.

3D Printed Electronics Market Scope and Summary

| Metrics | Details |

Market CAGR | 30.36% |

Segments Covered | By Product, By Application, By End-User, and By Region |

Report Insights Covered | Competitive Landscape Analysis, Company Profile Analysis, Market Size, Share, Growth, Demand, Recent Developments, Mergers and acquisitions, New Product Launches, Growth Strategies, Revenue Analysis, and Other key insights. |

Fastest Growing Region | Asia Pacific |

Largest Market Share | North America |

To Get a Free Sample Click Here

3D Printed Electronics Market Dynamics and Trends

The increased consumption of wearable electronics and the popularity of 3D printing are two main reasons driving the global 3D printed electronics market. However, the cybersecurity risks of 3D printing may restrain market expansion.

Growing consumption of wearable electronicsWearable devices such as smart glasses, smart bands, smart watches and smart clothing monitor real-time fitness, heart rate, sleep statistics and calorie intake to provide valuable health insights. Wearable technology has far-reaching implications in numerous fields, such as education, health and medicine, fitness, gaming and the military. AR technology, when combined with wearables, will be able to provide a much more realistic and immersive environment in real time

Smart glasses are regarded as the next big technological advance in wearables, particularly since Google started the Google Glass project. Unlike other devices, glasses are comfortable to wear and can be used constantly. DataM Intelligence estimates that by 2019, 9.1 million smart glasses will be rolled out in the global wearable electronics market.

Unlike other devices, glasses are comfortable to wear and can be used constantly. DataM Intelligence estimates that by 2019, 9.1 million smart glasses will be rolled out in the global wearable electronics market.

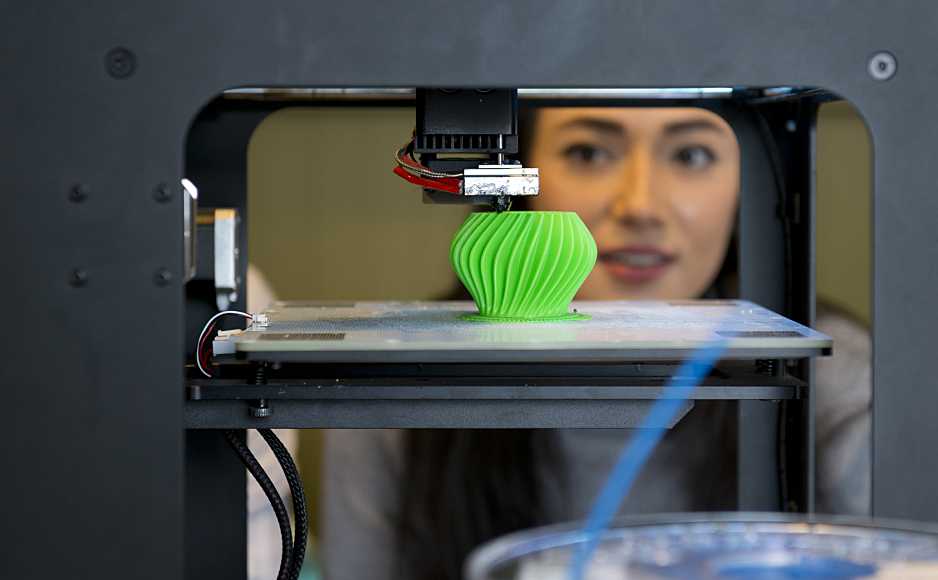

A suitable 3D printing technology is selected from the available ones to carry out the process. Implementing this process across as many industry verticals as necessary is the last phase. The deployment includes providing installation services, advisory services, customer support and addressing copyright, licensing and patenting-related issues. Manufacturers benefit from 3D printing in terms of prototypes, designing the structure and finished goods, modeling and speed to market. Companies can sell superior products for less money because of the huge reduction in production costs. These benefits are projected to increase demand for 3D printers in the coming years.

Risks related to cybersecurityRisks related to cybersecurity are rising in the electronics manufacturing sector due to the use of additive manufacturing. Since 3D printing includes the production of devices from a digital layout, there is a considerable danger of design theft, intentional component failure and design theft. With a rising number of medical, consumer and wearable electronics applications, the security issues associated with 3D printing in production and assembly processes are increasing. For instance, prosthetics and implants made in 3D

Since 3D printing includes the production of devices from a digital layout, there is a considerable danger of design theft, intentional component failure and design theft. With a rising number of medical, consumer and wearable electronics applications, the security issues associated with 3D printing in production and assembly processes are increasing. For instance, prosthetics and implants made in 3D

COVID-19 Impact on 3D Printed Electronics Market

The global market for 3D printed electronics was adversely affected by the spread of COVID-19 when lockdowns were enacted. Due to the decrease in demand from electronic OEMs for functional components, the market has seen the effects on the demand side.

However, the variety of materials has continued to expand even before the effects of COVID-19, with major makers of 3D printer equipment investing a lot of money in bringing new materials to market. Before the pandemic, the range of materials suitable for 3D printed electronics kept growing as customers requested better products with more options and flexibility. It increased the market demand for the product.

It increased the market demand for the product.

3D Printed Electronics Market Segmentation Analysis

By product, the global 3D printed electronics market is antennas, sensors, printable displays, PCBs and others.

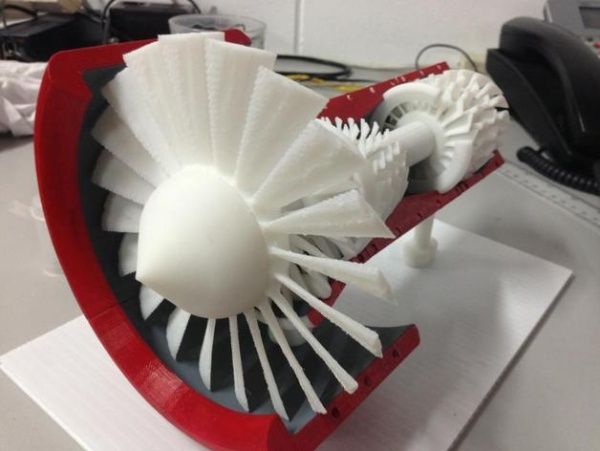

Unique properties of antennas to drive its growth3D printing has been increasingly used to design 3D electromagnetic structures owing to advantages such as smaller form factor, lighter weight, lower cost and more bio-friendly. There are new multi-dimensional printers on the market that can print both metal and dielectric materials, enabling the 3D printing of antennas

Recently, RUAG Space, a major European space industry supplier, designed and built antenna support using 3D printing technology for an Earth observation satellite. In addition, researchers are developing a new kind of capacitively coupled patch antenna array using 3D printing technology. These antennas have high gain and wide coverage, suitable for future 5G smartphone applications.

3D Printed Electronics Market Geographical Analysis

The increasing demand for innovative consumer electronics in Asia-PacificAsia-Pacific dominates the global 3D printed electronics market, accounting for the largest market share in 2021. China’s increasing defense budget and increasing demand for innovative consumer electronics products in China are leading to the growth of the 3D printed electronics market in the region. The large population base & demand, low price of raw materials, availability of skilled & cheap labor and favorable government policies are the primary factors propelling the country's 3D printed electronics market growth.

Chinese companies have made rapid technological advances in the 3D printed electronics sector. In May 2017, China’s first large passenger jetliner, C919, which featured 3D printed electronic components, made its maiden flight. The 3D-printed electronic components installed in C919 helped reduce its weight and shorten the delivery schedule.

3D Printed Electronics Market Companies and Competitive Landscape

The 3D printed electronics market is fragmented, with numerous players holding a significant share. With technological advancements, the demand for 3D printed electronics will likely evolve rapidly in the coming years. As a result, the market players focus on strengthening their product portfolio by adopting several strategies such as partnerships, mergers & acquisitions and new product developments.

Major global 3D printed electronics market companies include Nano Dimension, Optomec, Inc., Zortrax, Novacentrix, Ceradrop, Neotech AMT, EoPlex Technologies, nScrypt Inc., Cartesian Co. and BotFactory Inc.

Nano DimensionOverview: The company is a leading additive electronics provider of precision 3D printed electronics that is disrupting, reshaping and defining the future of functional and connected products. The company products combine three advanced technologies that include 3D inkjet, 3D software and associated nanomaterials. The company's primary products include the development of 3D printers dedicated to printing multilayer PCBs (printed circuit boards) and advanced nanotechnology-based conductive and dielectric inks. Nano Dimension's printer integrates advanced functional nanomaterials (polymers and metals) in the same print process to make rapid prototyping of multilayer circuit boards an easy in-house process.

The company's primary products include the development of 3D printers dedicated to printing multilayer PCBs (printed circuit boards) and advanced nanotechnology-based conductive and dielectric inks. Nano Dimension's printer integrates advanced functional nanomaterials (polymers and metals) in the same print process to make rapid prototyping of multilayer circuit boards an easy in-house process.

Product Portfolio: The company provides the DragonFly 2020 Pro 3D printer. It is used for Aerospace and Defense purposes. Its dual-material system lets users 3D-print prototype multilayer printed circuit boards (PCBs), saving time and supporting more design explorations. It offers a build volume of 20 x 20 x 0.3 cm inside a unit that sits on the floor and measures 140 x 80 x 180 cm.

Key Development: In January 2022, Nano Dimension announced the acquisition of UK-based Inkjet Systems Ltd. for nearly US$ 18.1 million. The acquisition strengthens Nano Dimension's offerings in the 3D printing hardware market.

The global 3D printed electronics market report would provide access to an approx. 61 market data table, 52 figures and 212 pages.

Frequently Asked Questions

What is the Growth Rate of the 3D printed electronics market?

Grow at a high CAGR of 12.23% during the forecast period (2022-2029)

What Companies Are Included in the 3D printed electronics market?

Nano Dimension, Optomec, Inc., Zortrax, Novacentrix, Ceradrop, Neotech AMT, EoPlex Technologies, nScrypt Inc., Cartesian Co., BotFactory Inc., Notion Systems GmbH, Pulse, a Yageo company, and ChemCubed. Pivotal market.

Trending Topics

Augmented Reality (AR) and Mixed Reality (MR) Market

Educational Robot Market

IoT in Education Market

Other pages - Page not found

Ratings and awards Management Expert Council Licenses and accreditations Reviews and thanks Sustainability Management and ESG Cooperation Corporate venture fund

About company >

Accompanying the conclusion of the SPIC Anti-crisis consulting Tax consulting Audit of RAS / IFRS Financial advisory due diligence Investment consulting and valuation HR consulting Management consulting Legal consulting Accounting consulting Transition to FSB Intellectual Property Management Attracting investments

Services and practices ›

Oil and gas Construction and development Mining and exploration Medicine and pharmaceuticals Energy Transport and logistic Food industry and agriculture infrastructure construction mechanical engineering Metallurgy IT industry Retail Light industry Financial sector Science and innovation Management companies Telecommunications and communications Chemical industry Timber industry and woodworking Production

All industries ›

company's news Legislative news Expert Publications Analytical studies

Press Center ›

Jobs Command Internship Alumni

Career >

Send a message and our managers will contact you as soon as possible

We use cookies to improve the site and its user experience. By continuing to use the site, you consent to the use of cookies.

By continuing to use the site, you consent to the use of cookies.

Accept

nine0000 NANO DIMENSION LEADS THE 3D PRINTED ELECTRONICS MARKET WITH AME TECHNOLOGYYou are here

Home

Since launching its own technology and industrial 3D printer in 2014, OEM Nano Dimension has made a name for itself in the additively manufactured electronics (AME) world.

Continuously improving its flagship DragonFly LDM® 3D printer, the company is now doubling its high-performance electronic device (Hi-PED™) 3D printing capacity, and has made significant strides in recent years. Hi-PED™ often cannot be produced using traditional printed circuit board (PCB) manufacturing processes. nine0003

DragonFly LDM 3D printer from Nano Dimension. Photo by Nano Dimension.

Yoav Stern, CEO of Nano Dimension, states: “We are a 3D printing company for customers who need to stay at the forefront of electronics manufacturing. If you are innovating in the field of hardware and electronics design, you need an additive manufacturing solution that will enable you to achieve what no one else has done in the field of electronics design, and do it faster and easier than ever before.” nine0003

If you are innovating in the field of hardware and electronics design, you need an additive manufacturing solution that will enable you to achieve what no one else has done in the field of electronics design, and do it faster and easier than ever before.” nine0003

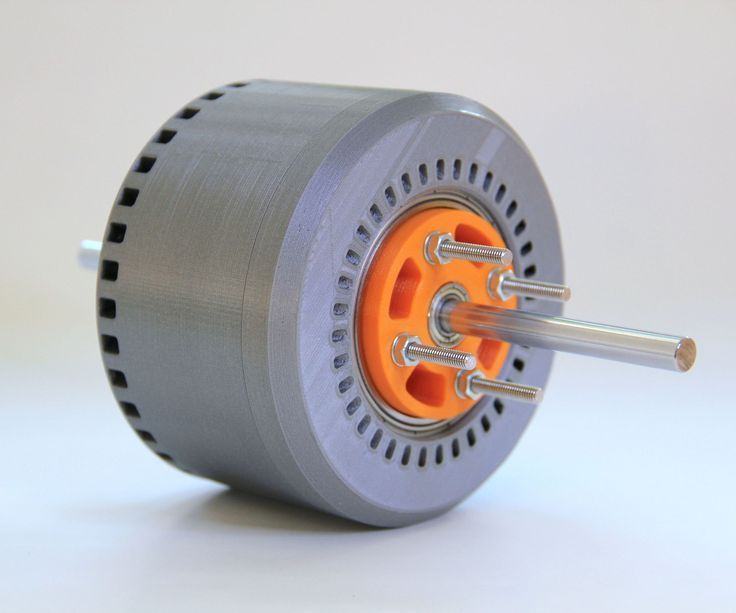

DragonFly LDM

The DragonFly LDM® is the driving force behind AME Nano Dimension's capabilities, combining free-form geometry with built-in 3D electronics. Equipped with two separate print heads, the system can simultaneously apply conductive silver nano ink and dielectric photopolymer ink. The former make up the bulk of the printed circuit connections, while the latter serve to provide mechanical support, thermal resistance, and electrical insulation to the surrounding structure. nine0003

The system is well suited for rapid prototyping and is safe to use both in the office and in the lab. Starting with a Gerber or CAD file, the user can create custom Hi-PED™ such as complex layered circuits with a couple of mouse clicks. The system's AME technology allows the use of many built-in electronic components, including capacitors, antennas, coils, and transducers, to name but a few. In addition, it is possible to install electronics in non-traditional cubic packages, while they are separated from the rest of the printed circuit boards. nine0003

The system's AME technology allows the use of many built-in electronic components, including capacitors, antennas, coils, and transducers, to name but a few. In addition, it is possible to install electronics in non-traditional cubic packages, while they are separated from the rest of the printed circuit boards. nine0003

Stern adds: “Nano Dimension bridges the gap between PCBs and semiconductor integrated circuits. A revolution at the touch of a button - from CAD to a functional and high-performance AME device in a matter of hours, purely through consumables.”

Nano Dimension's AME 3D printing technology works by applying two different types of inks. Image courtesy of Nano Dimension.

AME 3D Printing for ISS

While the AME process has applications in many industries, from medicine to the automotive industry, one project stands out in collaboration with communications technology firm Harris Corporation (now L3Harris). The partners have been working on 3D printing radio frequency (RF) circuitry for transmitting data to and from the ISS. Traditional RF circuit manufacturing is usually a very tedious trial and error process with numerous design iterations. nine0003

The partners have been working on 3D printing radio frequency (RF) circuitry for transmitting data to and from the ISS. Traditional RF circuit manufacturing is usually a very tedious trial and error process with numerous design iterations. nine0003

Dr. Arthur Paolella, Senior Scientist at L3Harris, said: “The application of 3D printing is very broad, touching almost every aspect of research, design and manufacturing. The main goal of this project is to conduct an experiment consisting of an additive manufacturing integrated communication circuit and analyze the RF properties of these materials in the space environment. To the best of our knowledge, this will be the first systematic approach to analyze such a device in space.” nine0003

Using Nano Dimension's AME technology, the partners 3D printed a 101 x 38 x 3mm circuit in about 10 hours. After testing a 3D printed RF circuit with a traditionally made RF circuit, L3Harris determined that they had very similar transmission characteristics.

22 Billion

22 Billion