Do 3d printers need to be vented

How to Ventilate a 3D Printer Properly – Do They Need Ventilation? – 3D Printerly

3D printer fumes and pollutants are usually overlooked by people, but it’s important to ventilate your 3D printer properly.

There are some great ventilation systems that you can make use of to have your 3D printing environment safer and less harmful to people around it.

The best way to ventilate a 3D printer is to put your 3D printer in an enclosure and have a ventilation system that properly tackles the small particulates that 3D printers emit. Make sure you have carbon filters to get rid of the smaller particles that a HEPA filter won’t get rid of.

The rest of this article will answer some key questions on 3D printer ventilation, as well as detail some nice ventilation systems that you can implement yourself.

Do You Need Ventilation for a 3D Printer?

During the printing process, you might have smelled the odor that is produced by the printer. To expel this odor out of the machine and workspace, you can use good ventilation.

However, the quality and smell of odor depends on the type of material that is used for printing purposes. For example, PLA is much safer when it comes to the smell than other filaments such as ABS.

Other than the smell, we also have small particles that are emitted from heating thermoplastics at such high temperatures, the higher the temperature, the worse the particles usually.

It also depends on the chemical makeup of the thermoplastic in the first place. If you are printing with ABS, Nylon or resin material in SLA 3D printers, proper ventilation is highly recommended, along with a mask.

A good enough ventilation system can work very well for ensuring that the surrounding air is clean and not contaminated.

It is said that the average running time for a 3D print can be around 3-7 hours, which is almost a quarter of the whole day when it is producing fumes.

To avoid any kind of harmful effect on your health or body, you seriously need to set up a ventilation system.

Ventilation While Using PLA

PLA is made up of eco-friendly material that produces sweet-smelling fumes that are laced with ultra-fine particles (UFPs) and volatile organic compounds (VOCs).

Technically, these both materials are not harmful to your health according to the research, but exposure to them daily may cause issues, especially to those with respiratory issues.

An open window or air purification system should work well enough for ventilating PLA.

Although many studies and research mention that PLA is safe, it is hard to measure the marginal health risks over time, and they take many years to properly test for. The risk may be similar to other ‘hobby-type’ activities such as woodworking, painting or soldering.

One study did test PLA for its emissions, and they found that it mostly emits Lactide which is known to be quite harmless. You should keep in mind that different types of PLA are created differently.

One brand and color of PLA could be harmless, while another brand and color of PLA isn’t as safe as you may think.

Many of the studies on emissions from 3D printers are in proper workplaces with many things going on, rather than your standard desktop home 3D printer, so its hard to generalize the findings.

Although it may not be completely safe, the studies show that PLA isn’t very risky, especially compared to other activities that we do on a regular basis.

Even going into a big city with all the pollution from vehicles and factories are said to be a lot worse than 3D printers.

Ventilation for ABS

According to the Journal of Occupational and Environmental Hygiene, materials commonly used for 3D printing such as PLA, ABS, and nylon can be a source of potentially dangerous VOCs.

ABS has been shown to result in high VOC emissions when heated at those higher temperatures, the main one being a compound called Styrene. It isn’t harmful in small portions, but breathing in a concentrated amount on a daily basis can be harmful to your body.

The concentration of the VOCs however, aren’t as dangerously high as it requires to have serious negative health effects, so printing in a well-ventilated, large room should be good enough to 3D print safely.

I would recommend not 3D printing ABS in a space where you are occupying for long periods of time. If you are 3D printing in a small room with poor ventilation, the rise of VOC concentration in the air can be troublesome.

The UFPs and VOCs produced by ABS during the 3D printing process contains Styrene. This material is not harmful in small portions; however, breathing in it on a daily basis can harm your body.

This is the reason why ventilation is needed during the printing process with ABS.

I would ensure that you are at least using an enclosure with some type of ventilation, ideally in a larger room.

How to Ventilate a 3D Printer

The best thing you can do to ventilate a 3D printer is to make sure your 3D printer chamber or enclosure is sealed/airtight, then to connect a vent from your chamber to the outside.

Some people use a window fan and put it near a window where your 3D printer is to then blow air out of the house. When printing with ABS, many users do this, and it works well to eliminate noticeable smells.

Installing Air Purifiers

Air purifiers have become common in major cities to keep the air clean. Similarly, you can use these air purifiers for your places where 3D printing is being performed.

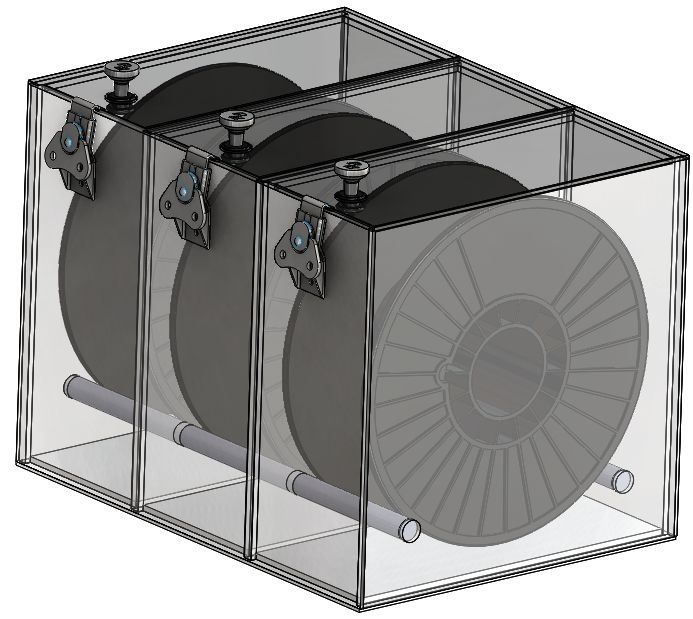

Purchase a small air purifier and install it next to your 3D printer. Ideally you can put an air purifier within an enclosed system that contains your 3D printer so that the contaminated air passes through the purifier.

Look for the enlisted features in an air purifier:

- Have high efficient particulate air (HEPA) filters.

- A charcoal air purifier

- Calculate the size of your room and select the purifier according to it.

Air Extractors

Air Extractors are considered to be one of the best solutions to improve the ventilation of an enclosed room. Its working is explained below for you:

Its working is explained below for you:

- It sucks in the heated air.

- Exchange the heated air with the cool air from outside.

- It uses a fan and suction pipes.

There are two main types of extractors that you can easily purchase from the market, i.e., Twin Reversible Airflow Extractors with and without Thermostats.

Building a 3D Printer Enclosure

You can consider building an enclosure for your printer. It basically involves creating an air-tight enclosure equipped with carbon filters, a fan, and a dry-hose that runs outside your home.

In the enclosure, the carbon filter will trap styrene and other VOCs, while the hose will let the air pass through. This is an effective ventilation process which you can make at home.

This is an effective ventilation process which you can make at home.

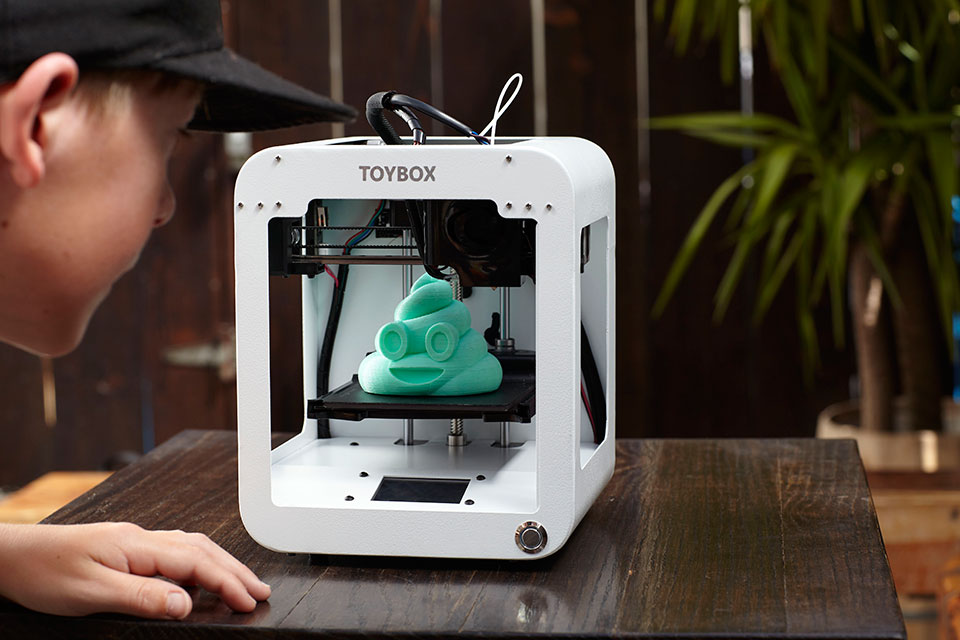

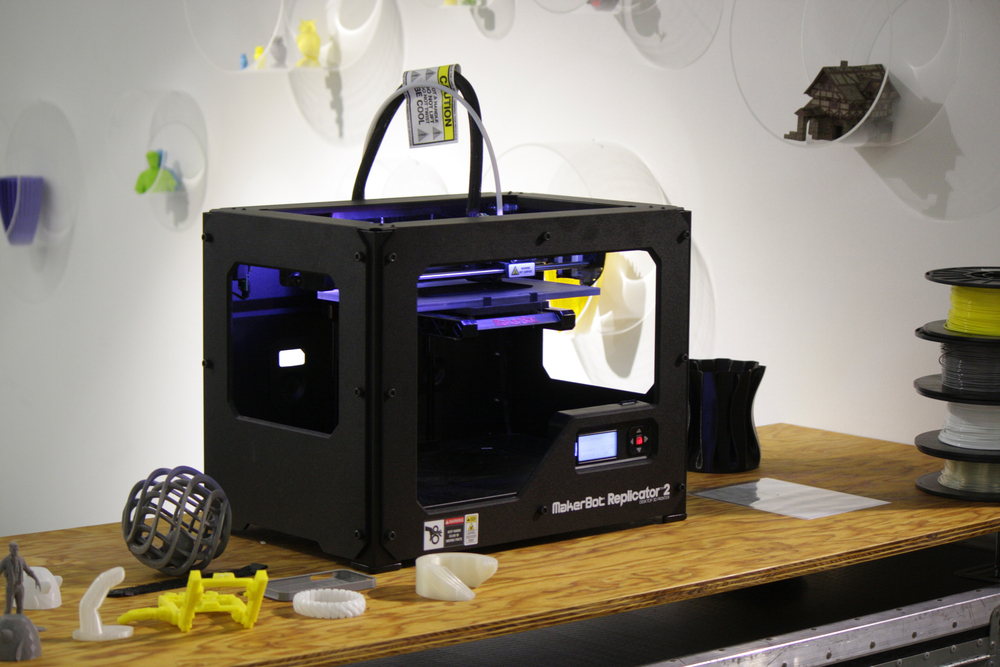

3D Printer with Built-in Filtration

There are very few printers that come with a built-in HEPA filtration. Even the manufacturers are aware of the fumes, but nobody bothers installing a filtration.

For example, UP BOX+ is one of the printers that come with HEPA filtration solutions that filter out tiny particles.

You can choose to get a 3D printer with built-in filtration, but these are usually more expensive so be prepared to pay extra for this feature.

The Elegoo Mars Pro is a good example of this which has a built-in carbon air filter to remove some VOCs and resin odor from the air.

How to Ventilate a Resin 3D Printer?

The best way to ventilate a resin 3D printer is to create a negative pressure enclosure which directs air away the enclosure to a space outside. Long term exposure to resin fumes are unhealthy, even if they don’t smell.

Long term exposure to resin fumes are unhealthy, even if they don’t smell.

Most people don’t have a dedicated ventilation system and are looking for a simple fix to help ventilate their resin 3D printers.

Following the video above should improve your ventilation for a resin 3D printer.

Remember, resins are toxic and can become allergic to your skin, be careful while using them.

Are 3D Printer Fumes Dangerous?

Not all, but some 3D printer fumes are dangerous and can cause serious damage to the health. As previously described, those UFPs are the more dangerous kind of emissions, where they can be absorbed into the lungs, then into the bloodstream.

According to the research done by the Georgia Institute of Technology, 3D printer fumes can negatively impact the quality of indoor air leading to potential respiratory health issues.

The regulations provided by OSHA actually throw light on the fact that 3D printer fumes are dangerous for health and the environment.

According to the research done on 3D printing filament, ABS is considered more toxic than PLA.

PLA is made up of eco-friendly substance, thus it is less harmful. This is one of the reasons why PLA is so commonly used, especially over ABS, because of its safety and non-smelling properties.

Should All 3D Printers Be Ventilated? 5 Things To Know – Printing It 3D

3D printers give off very harmful resin fumes. The effects of these eco-friendly thermoplastics do not show immediately but become dangerous over a long period.

All 3D printers should be ventilated to avoid inhaling toxic materials. Ventilation prevents safety disasters and health issues that can occur in the long run. Always purchase the right 3D printer and use eco-friendly materials to avoid fatal disasters.

Every printer is different and uses its fuels, ventilation, and materials to print. Read on to learn about preventing the inhalation of toxic fumes from your 3D printers and why you should purchase a 3D printer that meets your ventilation standards. Ventilation saves you from dangerous emergency room visits.

Ventilation saves you from dangerous emergency room visits.

Things To Know About 3D Printers

3D printers can create a 3-dimensional figure from just a digital file. Unfortunately, these helpful machines have several safety concerns. The dangerous burning plastic smell called volatile organic compounds (VOCs) can cause cancer.

These safety risks go unnoticed because buyers are unaware of how life-threatening they are. Below you will learn the most important things about 3D printer ventilation so you can keep yourself safe.

Before purchasing your 3D printer, there are a few things you should know:

- Fumes From Your 3D Printer Can Be Hazardous

The fumes from 3D printing can be hazardous to your health. These fumes are called volatile organic compounds (VOCs). Although you may not feel the effects of VOCs immediately, breathing in resin fumes for too long can have severe impacts on your health.

You might recognize VOCs from household products like acetone, formaldehyde, and benzene. These all have different toxicity levels. Long-term, unprotected exposure can cause serious health issues like cancer.

These all have different toxicity levels. Long-term, unprotected exposure can cause serious health issues like cancer.

In any case, using proper ventilation like enclosures that immediately filtrate the air around your 3D printer is the only way to avoid these hazards.

- ALL 3D Printers Require Ventilation

Proper ventilation prevents you from breathing in toxic fumes like styrene, a chemical that can be harmful to your upper respiratory system. The ventilation process makes the air around your 3D printer breathable.

Overexposure to resin fumes can be fatal. Without ventilation, the air around your 3D printer would not be safe to breathe and may end up making you ill. To prevent this from happening, 3D printer owners use vents to detoxify the air before it reaches the human respiratory system.

There are many types of ventilation systems available for your selection. The most effective method for ventilating your 3D printer is using an enclosure. Enclosures instantly purify the harmful, ultra-fine plastics surrounding your 3D printer and make the air around it breathable.

- The Location of Your 3D Printer Is Important

The place that you put your 3D printer will have a significant impact on your health and safety. The location of your 3D printer includes the room, the amount of airflow, the material you place your machine on, and much more.

If you do not consider the location of your machine, it can overheat and cause a fire. Consider the following about your 3D printer location:

- The more airflow, the better.

- Avoid placing your printer in high-traffic areas.

- Do not place your machine on wood.

- Your office is not an ideal printing space

- The Type of Printing Materials Used Can Affect Your Health

Consider what materials you are going to use wisely. The resins used have a significant impact on the environment and your health. The type of resin used to print 3D models include the following:

- Poly Lactic Acid (PLA). A biodegradable plastic made from corn starch.

It varies in color and is perfect for beginners just starting on their 3D printing journey. According to an Illinois Institute of Technology study, PLA filament fumes are sweet and are mostly harmless.

It varies in color and is perfect for beginners just starting on their 3D printing journey. According to an Illinois Institute of Technology study, PLA filament fumes are sweet and are mostly harmless.

- Acrylonitrile Butadiene Styrene (ABS). A durable and flexible petroleum-based plastic. This synthetic material has a much higher heat resistance than polylactic acid (PLA). VOCs emitted from ABS during the 3D printing process are harmful to your health and even cause cancer.

- There Must Be a Way for Your Heat To Escape Your Enclosure

Temperature control is a critical element for owning a 3D printer. If the heat from your machine gets trapped in your enclosure, the plastic parts in your 3D printer may melt.

One of the most common problems that occur when a 3D printer overheats is plastic parts melting. Melting plastic occurs because printing takes a long time which can change the temperature quickly. If plastic overheats, this can cause the rest of the machine to catch on fire.

Because heat can be so overbearing, keep all electronics outside your enclosure. Keeping electronics and power supplies outside of the 3D printer enclosure further mitigates interactions between you and VOCs.

Checkout some enclosures for your 3d printer here

How Much Ventilation Does a 3D Printer Require?

3D printers require constant ventilation as they print to keep the air toxin-free. Leave the ventilation system running after the machine has stopped printing to continue circulating the air inside your enclosure.

Ventilation keeps the air free of dangerous microparticles. Without this step, you can accidentally cut your life short because you exposed yourself to toxic chemicals.

There are a few key features that all 3D printers should include:

- Ductless ventilation

- Enclosed cases

- Environment control (temperature, moisture, etc.)

When purchasing your 3D printer, find a ventilation option that works for you and that satisfies your printing needs. Remember, your 3D printer requires constant ventilation to purify the air.

Remember, your 3D printer requires constant ventilation to purify the air.

You might also be interested in purchasing an additional air purifier for the room. This way, any fumes that somehow go unpurified will be given another clean.

Final Thoughts

Whether you are a small business looking to manufacture goods or an entrepreneur trying to create a prototype of your next great invention, 3D printers are the way to go.

These innovative machines are moveable, eco-friendly devices that can print massive designs in less time than it takes to get a good night’s sleep!

The fumes from 3D printing can be very hazardous. Ventilating your 3D printer is critical for your health. Without ventilation, you will breathe in harmful resin fumes that can be cancerous to your upper respiratory system.

Phrozen Sonic Mini 8K - the first honest review from a user in RuNet

Good afternoon, colleagues!

I present to your attention a review of my new friend - Phrozen Sonic Mini 8K 3D printer. This is the first review from a user - all the others were copy-paste of a promotional review from the manufacturer. Read and enjoy!

This is the first review from a user - all the others were copy-paste of a promotional review from the manufacturer. Read and enjoy!

The review turned out to be too emotional and extensive - if it seemed to you that the bookoff is too much - just scroll down to a short summary with the advantages and disadvantages of the printer.

A bit of history - for several years I printed on a workhorse from 3DArtel - a very successful, reliable and fast printer. In principle, it completely suits me, but ... in the era of 4..8K, be content with a grain of 67 microns? In the era of mono screens, be content with RGB? And, most importantly, you can’t buy a screen for it anymore ... This means that after the current screen fails, my printer will turn into a pumpkin ... No, I know that Chita releases upgrade kits and has already ordered a frame, a monoscreen and a motherboard … But all this will still have to be placed somehow.. Well, the last argument is that “slow” resins, designed specifically for monochrome printers, have been in fashion lately, it is uncomfortable to print on RGB with such resins - the speed is low.

Considered a lot of options - there were even offers to buy a discounted printer after repair at the "manufacturer" ...

In principle, with my print volumes (rare, small), I don’t need especially sophisticated and expensive models ... But the amphibian showed non-standard behavior and, as it were, whispered - “try 8K, try COB”. You know yourself - a toad, it often turns out to be stronger than us ...

In general, I made up my mind. Bought through OZON - there is a convenient delivery. And the price is the lowest ever.

Features ? And why - on any site there is ... well, copy-paste:

Printer size - 290x290x420 mm

Printer weight - 15 kg

Construction area - 165x72x180 mm

Pixel size - 22 µm

Here come HE, handsome man!

Photo 1. Printer.

Handsome! After it, I realized that everything I had printed on before was pathetic Chinese. The printer made an impression on everyone - both with a rigid construction, and with a double rail along the Z axis, and with a thick acrylic cap. Both beauty and design.

Both beauty and design.

Standard equipment - a pair of spatulas, hexagons, side cutters, a funnel, etc. Well, the world is not without unnecessary details.

Photo 2. Complete set. A metal spatula and a funnel are included, but left behind the scenes...

Alas... it is absolutely impossible for me to print on such beauty - when you live in a sunny region on the sunny side of the house - a transparent cap is evil. Especially in winter, when the sun is low - the sun's rays hit the entire length of the room. I had to seal all this beauty with foil and hang with cardboard.

Photo 3. Printer at his workplace.

The screen was covered with something thick. Protective film for shipping or protective film for printing? I didn’t understand, but since the thickness was significant and it was pasted over the adhesive tape, I tore it off and covered the screen with lavsan from the baking sleeve - just in case.

Photo 4. Screen after applying lavsan for protection.

Screen after applying lavsan for protection.

Yes, by the way - if you pay attention - no fans blowing into the printing area - you can safely print without fear that the ventilation will spread the aromas throughout the apartment. I don’t know what kind of gloomy genius came up with ventilating the print space, but this printer is devoid of this idiocy.

The platform is covered with some strange engraving. Supposedly to improve adhesion. The meaning is not clear to me - those polymers with which I print are already perfectly fried to the platform. But not to grind?

Photo 5. Engraving on the platform.

Fixation of the platform during calibration - "ears" for 4 screws. On the one hand, it is much less convenient and much less reliable than a ball joint. On the other hand, on a hard printer, you have to calibrate once a year, or even once a lifetime. And on my artel, I didn’t even recalibrate the platform after changing the screen. Although . .. I'm afraid that the efforts during printing can disrupt the calibration - screws, this is not reliable, no matter how you tighten it. Well, the operation will show what's what ...

.. I'm afraid that the efforts during printing can disrupt the calibration - screws, this is not reliable, no matter how you tighten it. Well, the operation will show what's what ...

Bath - with "legs", which allows you to accurately fix the bath and put it on the table without fear of damaging the film. Convenient ... With a collapsible frame - the film is pre-fixed in the frame, then the frame is fixed on the bath - I think many are familiar with this design.

Photo 6. Bath "with legs". The size of the film for stretching into the bath.

Okay... it's time to start typing. Unlike other “frozens”, it does not have “its own” slicer and the print is prepared in a regular “chitoobox” - this is convenient for me personally, but some people like protoprietary slicers.

And here is the first surprise - if slicing is fast enough, then writing the print file - my laptop frankly hangs, I need to close all programs and stop secondary processes and wait 10 minutes, or even more . .. All the same, 8K is not a joke ... so, the first conclusion is that this beast also needs a powerful computer to comfortably prepare the file for printing.

.. All the same, 8K is not a joke ... so, the first conclusion is that this beast also needs a powerful computer to comfortably prepare the file for printing.

Printing. Everything is on film... I set the exposure time longer - the same thing. I set the time as on my "aretle" - a normal print. I try to reduce the exposure time - and here is disappointment - the printer is frankly "slow" - the exposure time is only about 1.3..1.5 times less than en RGB artels. Yes, I understand everything - my "Artel" is very fast for RGB, but I bought a printer because of the new "monochrome" resins ... And if you also take into account very slow accelerations and the fact that you print with a 22 micron grain in thick layers ( thicker than 30 microns) - not very smart, you know - I got a slower printer than I had ...

In general - sadness ...

Interestingly, in reviews of fine-grain printers, no one dared to demonstrate the 3DSLA cube. I'm demonstrating:

Photo 7. 3DSLA cube printed on the corners of the screen.

3DSLA cube printed on the corners of the screen.

Not impressive? Naturally… ordinary, albeit highly pigmented resin, screen corner (COB is not parraled). On a special resin in the center of the screen, if you jerk off, you can probably get an ideal cube ... Although ... I highlighted two points in red - this can only be obtained on a small pixel. But what I'm interested in is the standard quality that I can expect from the resins I use. In general, I was once again convinced that if you print on "ordinary" resins and do not wrap with ideal settings - that the grain is 75 microns, that is 22 - there is not much difference in resolution. Those. a pixel of 22 microns is not about “accuracy”. And about what?

See for yourself:

Photo 8. The same part printed on a "regular" printer (right, brown) and Frozen 8K (left, black).

No pixel moire when using anti-aliasing on black resin. More precisely, there are no miracles, but it is so small that it is perceived as a natural velvety or matte surface. That is, 22 microns is not about accuracy, it's about surface quality. For those who print small things and do not want to suffer with skinning or fill everything with a thick layer of primer-paint, this is it. There is nothing better.

That is, 22 microns is not about accuracy, it's about surface quality. For those who print small things and do not want to suffer with skinning or fill everything with a thick layer of primer-paint, this is it. There is nothing better.

As I said above - this Frozen is not paralyzed, but COB with a mirror - there is nothing to measure the uniformity of the screen illumination, but judging by the photographs - very good. No overexposure-underexposure at the edges of the lenses. All in a bunch. If I decide to buy a Chitov radiometer, I will take measurements, but for now, believe the photographs.

Photo 9. Frozen screen photo, and Frozen light scheme.

One more unanswered question remains - what about perspective distortions? Dear dagov, according to the appollone method, did not intend anything on the "halot", but how is it here? Well, let's face it, if it's not paraled, then there should be perspective distortions, both on the halot and on the Frozen with COB. It's just that appolone developed its methodology for old terrible printers, now the situation is better. So I just printed three calibration sleepers - two at the edges of the screen, one in the center.

It's just that appolone developed its methodology for old terrible printers, now the situation is better. So I just printed three calibration sleepers - two at the edges of the screen, one in the center.

If they are combined:

Photo 10. Combination of calibration sleepers printed in different places on the screen.

As you can see, there are distortions, but they are so small that I won't even undertake to evaluate them. About tenths of a%. Approximately 0.5% of the distance at the corners of the screen is larger than in the middle. The sleeper in the center of the screen is 0.2% longer than the sleeper at the edge of the screen. Is it a lot or a little? How critical is it? I don't know.. everyone has their own requirements. For someone, 0.5 ... 0.2% is nothing at all. And it’s critical for someone ... But, I think, most users of this Frozen will not even notice any distortion. Well, for those for whom this is critical, “paralled” has no alternative so far.

What else is left to tell? Film…. And pain and joy. The kit comes with an excellent nFEP-film, no worse than Hardlight. This is good. But with the replacement of the film - very bad. The length of a piece of film should be 210mm, at worst - 207mm, and "standard" pieces for 6 ... 5 inch printers sized 200x140mm do not fit ... You need to buy A4 sheets and cut them in half. Well, or order a roll on Ali.

Drivers. I don’t know which ones, I didn’t climb, didn’t open, didn’t look, but they are quiet. Really quiet.

The combination of high-quality mechanics and quiet drivers, low accelerations and high-quality film, good fans gives almost silent printing - almost no stepper songs, no tear-off sound, no fans are heard. I have a printer in a closet, if you close the cabinet doors - you can't hear the printer's operation - you can print at night and sleep in the same room.

Well, that's all... I hope I didn't bore you with my story. It's time to sum up.

So...

Advantages of the printer:

Handsome!

Robust, rugged construction.

Foot bath

Excellent print surface without pixel moiré.

Virtually silent printing (quiet drivers, quiet fans).

There is no fan in the print area. There are no carbon filters and other unnecessary advertising bells and whistles.

Uniform screen illumination

Supplied with high quality FEP film.

Disadvantages:

Slow.

Slight perspective distortion

Features:

Calibration with screws, not a hinge (I don’t like it, but there are fans of this particular calibration method)

7 inch diagonal - longer than 5-6 inch printers, but not essential.

Long bath - standard pieces of film 200x140mm will not work, you need to order either films specifically for it, or cut the A4 format at random.

Transparent removable hood (I personally find hoods more convenient, but there are also door lovers)

Comfortable cutting of files requires a powerful computer (this is probably a feature of all 8L printers).

To achieve accuracy and maximum resolution, special resins are required, on "regular" resins the resolution is not higher than that of a "regular" printer.

No protoprietary "Frozen" slicer

Who might be interested in this printer?

First of all, for those who need a high-quality surface - modelers, puppeteers, lovers of printing various miniatures, souvenirs, etc.

Is it suitable for jewelers? I do not know their surface requirements. But I think it should.

Dentists? Probably, there are perspective distortions, but they are small.

In general, it's worth paying extra for 8K or "regular" quality is enough for you - it depends on your tasks and requirements. I personally liked the printer, and I am satisfied with the purchase.

That's all for now.

Happy printing!

How a 3D printer works, what can be printed on a 3D printer

The 3D printer is a technology that allows you to create real objects from a digital model. It all started in the 80s under the name "rapid prototyping", which was the goal of the technology: to create a prototype faster and cheaper. A lot has changed since then, and today 3D printers allow you to create anything you can imagine.

It all started in the 80s under the name "rapid prototyping", which was the goal of the technology: to create a prototype faster and cheaper. A lot has changed since then, and today 3D printers allow you to create anything you can imagine.

Contents:

- What is 3D printing?

- How does a 3D printer work?

- What can be printed?

The 3D printer allows you to create objects that are almost identical to their virtual models. That is why the scope of these technologies is so wide.

What is 3D printing?

3D printing is an additive manufacturing process because, unlike traditional subtractive manufacturing, 3D printing does not remove material, but adds it, layer by layer - that is, it builds or grows.

- In the first step of printing, the data from the drawing or 3D model is read by the printer.

- Next is the sequential overlay of layers.

- These layers of sheet material, liquid or powder are bonded together to form the final shape.

With limited production of parts, 3D printing will be faster and cheaper. The world of 3D printing does not stand still and therefore there are more and more different technologies competing with each other on the market. The difference lies in the printing process itself. Some technologies create layers by softening or melting the material, then they provide layer-by-layer application of this same material. Other technologies involve the use of liquid materials, which acquire a solid form in the process under the influence of various factors.

In order to print something you first need a 3D model of the object which you can create in a 3D modeling program (CAD - Computer Aided Design) or use a 3D scanner to scan the object you want print. There are also easier options, such as looking for models on the internet that have been created and made available to other people.

Once your design is ready, all you have to do is import it into Slicer, a program that adapts the model into codes and instructions for a 3D printer, most of the programs are open source and distributed free of charge. The slicer will convert your project into a gcode file ready to be printed as a physical object. Simply save the file to the included SD card and insert it into your 3D printer and hit print.

The slicer will convert your project into a gcode file ready to be printed as a physical object. Simply save the file to the included SD card and insert it into your 3D printer and hit print.

The whole process can take several hours and sometimes even days. It all depends on the size, material and complexity of the model. Some 3D printers use two different materials. One of them is part of the model itself, the other acts as a prop that supports parts of the model hanging in the air. The second material is subsequently removed.

How does a 3D printer work?

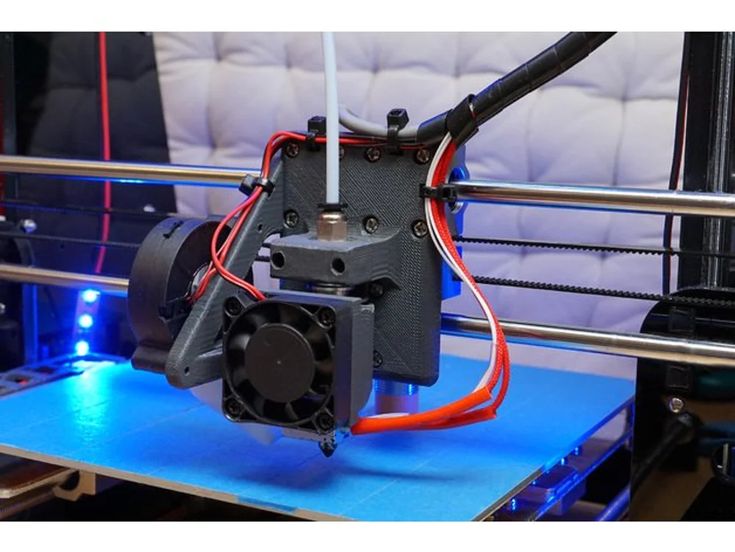

Although there are several 3D printing technologies, most create an object by building up many successive thin layers of material. Typically desktop 3D printers use plastic filaments (1) which are fed into the printer by the feeder (2) . The filament melts into the print head (3) which extrudes the material onto the platform (4) creating the object layer by layer. Once the printer starts printing, all you have to do is wait - it's easy.

Once the printer starts printing, all you have to do is wait - it's easy.

Of course, as you become an advanced user, playing with the settings and tweaking your printer can lead to even better results.

What can be 3D printed?

The possibilities of 3D printers are endless and they are now becoming a common tool in fields such as engineering, industrial design, manufacturing and architecture. Here are some typical use cases:

Custom Models

Create custom products that perfectly fit your needs in terms of size and shape. Do something that would be impossible with any other technology.

Rapid Prototyping

3D printing allows you to quickly create a model or prototype, helping engineers, designers and companies get feedback on their projects in a short time.

Complex geometry

Models that are hard to imagine can be easily created with a 3D printer. These models are good for teaching others about complex geometry in a fun and useful way.