Dishwasher safe 3d printing

Is 3D Printing Filament Dishwasher & Microwave Safe? PLA, ABS – 3D Printerly

While I was 3D printing some PLA objects on my Ender 3, I wondered whether 3D printed items are dishwasher safe. I set out to do some research and find out the answer.

Keep on reading for some basic information on this question, as well as some more key details that you’d want to know.

Is 3D Printed PLA Dishwasher Safe?

PLA is not dishwasher safe due to having a low heat resistance. A standard dishwasher reaches temperatures of 60°C (140°F) and the temperature at which PLA starts to soften is 60-70°C. This will lead to deformation and serious warping. Annealing PLA prints can improve heat resistance.

Most 3D printed items, when washed in hot water or with a dishwasher, undergo deformation. Among the different existing 3D printing filaments, PLA is particularly sensitive to heat, making it very unsafe to use with your dishwasher.

At a glass transition temperature of about 60-70°C, PLA usually softens, leading to destruction.

A glass transition temperature refers to the temperature range where a material turns from its rigid version to a soft (but not melted) version, measured by how stiff the material is. This is different to the melting point, and rather leaves the material in a pliable, rubbery state.

Often, different lists can show slight differences in the transition temperature of PLA depending on the brand and manufacturing technique. Either way, there is usually a range to consider.

According to some lists, the transition temperature for PLA is 57°C, while others quote a range of 60-70°C.

It is important to understand that most dishwashers operate at the household water heater temperature, although some control the heat internally. The household water heater temperature has a range of around 55-75°C.

This range of temperature is where PLA glass transition temperature lies and this makes PLA a risky choice for your dishwasher. You may notice the warping and bending of 3D printed PLA when used with your dishwasher.

For this reason, you may want to avoid placing your 3D printed PLA in your dishwasher if you want it to last.

Annealing, the process of increasing temperature to improve firmness, tensile strength, and heat resistance of a given object, can help improve PLA characteristics.

One user said they use HTPLA from Proto Pasta for mugs. This is only after their annealing process of putting the print in the oven, where the mugs can then safely hold rapidly boiling water without softening.

They said they have used it over a fairly long period of time, while putting it in the dishwasher and there is no sign of damage or degradation. They also used a Alumilite Clear Casting Resin to coat the mugs, a food-safe epoxy (FDA approved).

Is 3D Printed ABS Dishwasher Safe?

ABS has great temperature resistance and many people have used it safely in their dishwashers. One person printed a tea filter cup in generic ABS and washes it just fine in a dishwasher. You wouldn’t want to use ABS for food-related items though because it isn’t food-safe.

As stated by several compatibility charts regarding ABS plastic, ABS is considered fairly resistant to the conditions present in the dishwasher, including the temperatures, organic solvents, and alkaline salts.

According to Hutzler, ABS is dishwasher safe.

ABS has a higher glass transition temperature of about 105°C. This property enables it to withstand much higher temperatures before any form of deformation begins.

This deformation breaks down the material, making it deformed and weaker.

Still, the conditions required for the degradation are much higher than that present in the dishwasher.

ABS is very strong and rigid plastic. Unlike PLA and PETG, it has superior hardness and toughness, which make it dishwasher safe.

Unlike PLA and PETG, it has superior hardness and toughness, which make it dishwasher safe.

One user commented that he successfully uses ABS that has been vapor-smoothed safely in their dishwasher.

Is 3D Printed PETG Dishwasher Safe?

PETG is dishwasher safe in terms of the heat resistance, but it definitely can warp at warm temperatures. It has a glass transition temperature of around 75°C so it may withstand dishwasher temperatures for most households, although some may reach near the heat limit, so do watch out for that.

High-grade PETG material has an excellent chemical resistance with a glass transition temperature of about 75°C.

Compared to PLA, this is relatively higher, which means that compared to PLA, most 3D printed PETG is safe for your dishwasher. You can use most dishwashers to clean printed PETG.

It is also fairly easy to print, having a similar level to printing PLA.

However, it is important to consider the temperature of your household heater. Because of its high melting temperature, PETG would probably survive in dishwashers where PLA would melt.

Because of its high melting temperature, PETG would probably survive in dishwashers where PLA would melt.

Unfortunately, PETG has a glycol modifier and prevents crystallization which is what annealing requires to improve heat-resistance. ABS cannot be properly annealed either.

One user 3D printed some food-safe PETG wheels for their dishwasher since the old ones were worn out, and they are still going strong after 2 years.

What Filament is Dishwasher Safe?

- Annealed High Temperature PLA

- ABS

- PETG – lower temperature dishwasher cycle

You want to avoid putting Nylon filament in a dishwasher because it is very prone to moisture, though a 3D print with thick walls and very high infill can sustain a cool wash in a dishwasher.

HIPS filament will definitely melt in a dishwasher, adding that it is water-soluble and has low temperature resistance.

Definitely avoid placing any kind of carbon fiber 3D prints in a dishwasher because it can warp and clog the moving parts.

Flexible filament isn’t going to stand up well in a dishwasher due to already being really soft and warps under much lower heats.

Best Filament for Microwave Use – Safe 3D Printing

Is PLA Microwave Safe?

PLA is microwave safe depending on the brand and how it was manufactured. One user who ran tests on PLA found that there was no raise in temperature after 1 minute in the microwave, using plain PLA, black PLA, and green-tinted PLA. PLA can absorb water which can then be heated up by the microwaves.

Most people would say to avoid using PLA in the microwave, especially if you are using it for food because it has the opportunity to pick up bacteria through the layer lines and micropores.

Is PETG Microwave Safe?

PETG is transparent to microwaves and has a high enough heat-resistance to sufficiently deal with microwave applications. PETP is the normal plastic within the group that is used for bottles and injection molding, but PETG still holds up very well.

The Essential Guide to Food Safe 3D Printing

3D printing offers unparalleled design freedom to produce custom parts and complex or organic shapes that would be costly or impossible to manufacture with traditional manufacturing methods.

These benefits can be compelling for a range of food-related applications. However, if 3D printed parts are intended for food contact items, you‘ll have to consider safety practices and regulations to avoid contact with toxic substances and prevent the buildup of harmful bacteria.

Food safe 3D printing is possible and the variety of materials approved as food safe is increasing, but there is a high degree of ambiguity around the workflows and finding the appropriate applicable regulations can be a challenge.

Read on for an introduction to food safety, food safety considerations for 3D printing, and a variety of methods to produce food safe products with common 3D printing processes, including stereolithography (SLA), fused deposition modeling (FDM), and selective laser sintering (SLS).

Please note

No Formlabs resins are food safe unless users take additional steps.

Video Guide

Having trouble finding the best 3D printing technology for your needs? In this video guide, we compare FDM, SLA, and SLS technologies across popular buying considerations.

Watch the Videos

To begin, it’s important to clarify a few key terms:

- Food grade means that the material is either safe for human consumption or permitted to come in contact with food.

- Food safe means that a food grade material meets the requirements determined by the intended use and will not create a food-safety hazard.

- Food contact surfaces include any surface that may come into direct contact with food. These surfaces must be made of nontoxic materials and designed to withstand the environment of their intended use, including exposure to cleaning compounds, sanitizing agents, and cleaning procedures.

Food grading and food safety concern a specific way to ingest parts, called migration. Particles as small as a few nanometers and up to several hundred nanometers may get transferred each time various materials encounter with each other, for example from components of the 3D printer to the 3D printed object, and from the object to the food.

Because migration levels are very low on occasional contact, food grading typically concerns items that are in prolonged contact with food such as containers, straws, utensils, plates, and food molds. Different testing institutions will adhere to different government-imposed risk tolerances and approved substances, which for the US is described by the FDA CFR 21 and for the EU in guidelines 10/2011.

Look for these labels indicating FDA and EU approval. Beware that a material being ‘compliant with’ doesn’t mean that it is explicitly approved by the institutions, so always check the technical datasheets for a certificate.

To be considered food safe according to the FDA Food Code, a material has to meet the following requirements:

- No migration of deleterious substances

- Does not impart colors, odors, or tastes

- Safe under normal use conditions

- Durable, corrosion-resistant, and nonabsorbent

- Sufficient in weight to withstand repeated washing

- Finished to have a smooth, easily cleanable surface without breaks and sharp internal angles

- Resistant to pitting, chipping, crazing, scratching, scoring, distortion, and decomposition

- Accessible to inspection

Any FDA or EU approved material includes not only the raw polymer but also the additives or masterbatch. These might contain components such as plasticizers, impact and heat distortion modifiers, UV-stabilizers, flame retardants, anti-fouling, anti-static, anti-slip, foaming and clarifying agents, anti-oxidants, aromatic nucleators, carbon alloys, phosphorescents, fillers, thickeners, chain extenders, metal deactivators, dyes, and a carrier resin.

These might contain components such as plasticizers, impact and heat distortion modifiers, UV-stabilizers, flame retardants, anti-fouling, anti-static, anti-slip, foaming and clarifying agents, anti-oxidants, aromatic nucleators, carbon alloys, phosphorescents, fillers, thickeners, chain extenders, metal deactivators, dyes, and a carrier resin.

A 3D printed part can turn into a petri dish squirming with bacteria within weeks. Even though some materials will survive the dishwasher, so will dangerous bacteria such as E. coli and salmonella that live in the little nooks and crannies. Some toxic molds find favorable growth conditions on several types of plastic and are hard to remove. Neither cleaning with bleach nor microwaving your polymers is an option for eliminating germs.

While bacteria buildup might not be an issue for disposable items, if you’re planning to create a part for long-term use, using a food safe coating is highly recommended.

The best option to reduce the risk of particle migration and bacteria buildup is by dip coating the 3D printed parts with a food grade epoxy or polyurethane resin, such as Masterbond’s EP42HT-2FG or ArtResin or an FDA approved PTFE (known as Teflon®) to seal their surface.

However, note that coating also doesn’t guarantee food safety for prolonged use as not all of these coatings are dishwasher safe, and they may degrade over time, exposing the original, potentially non-safe surface.

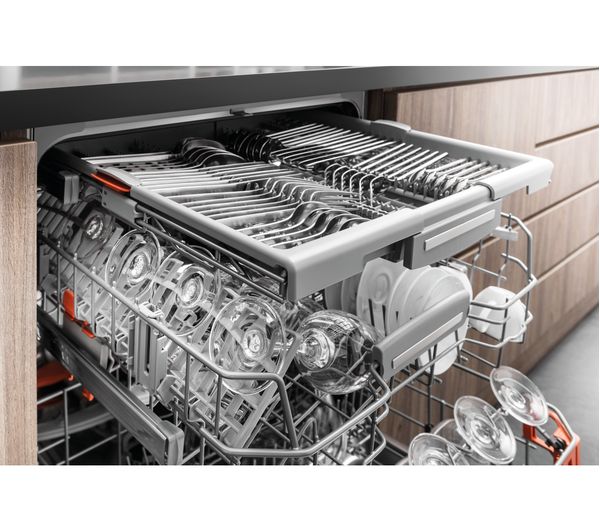

Most 3D printing materials have a low heat deflection temperature (HDT), which means that the 3D printed parts might become brittle and crack, or deform and warp at elevated temperatures. If you’re planning to clean a 3D printed part in a dishwasher, make sure to double check that the material is dishwasher safe and if there are any specific recommendations for washing temperature.

As particles might migrate from components of a 3D printer to 3D printed parts, it is crucial that any components that might come in contact with the 3D printing material or the part are food grade and do not contain or leach harmful chemicals.

This includes taking precautions when using multiple materials, as some materials previously used in the 3D printer might have contained toxic particles and made contact with some components.

Many 3D printing materials are not food safe and might contain toxic chemicals. Only use materials to 3D print parts intended for food contact that are certified for food safety.

As may be expected, the risk of migration is higher if the food is exposed to the 3D printed part for an extended time period. In general, try to limit food contact time and take further precautions for parts that will be in contact with food for longer periods of time.

Think about the reason why you’d like to use 3D printing for a food contact item. If it’s to create custom shapes and forms, in most cases, there are indirect ways to use 3D printing to create these custom parts, for example with molding. See an example in the next section.

SLA 3D printing uses a laser to cure liquid resin into hardened plastic in a process called photopolymerization, resulting in parts that have the highest resolution and accuracy, the clearest details, and the smoothest surface finish of all plastic 3D printing technologies.

Is resin food safe? The answer is no. Substances may migrate from SLA parts which makes none of the resins and printed parts food safe by default. While some resins for dental and medical applications are certified biocompatible, that doesn’t mean that they’re food safe. These materials are certified for specific applications and should not be used for food contact products.

SLA parts have a smooth surface finish that makes it easier to use coatings to seal their surface and prevent the buildup of bacteria. The factors which affect the ultimate smoothness of a part include resin type, layer thickness, build orientation, mesh triangulation resolution of the 3D model, and the curing profile of the SLA resin. Printed parts require washing and post-curing according to the manufacturer's instructions before the coating is applied. However, note that coatings don’t guarantee food safety, as the coating may interact with the resin or degrade over time, exposing the original, potentially non-safe surface.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

Creating custom molds is a common way to leverage the benefits of SLA 3D printing to produce highly detailed custom parts without having the 3D printing parts come into direct contact with food. While SLA 3D prints aren’t suitable for directly molding foods, SLA 3D printers are perfect tools to create mold negatives, which can be vacuum formed using food safe plastic.

The tools and techniques for creating 3D printed food molds are easy to master, and the results are often stunning.

3D printed molds for thermoforming and silicone enabled the creation of unique shapes and designs.

Learn more about creating molds for vacuum forming in our in-depth tutorial.

Electroplating is the process of coating parts with metal using an electric current. The process is most commonly used for decorative purposes or to prevent corrosion by creating a durable surface.

SLA parts are ideal for electroplating due to their smooth surface finish. However, as plastics are nonconductive surfaces, SLA 3D prints have to be rendered conductive by coating with graphite, conductive lacquer, electroless plate, or a vaporized coating.

Food safe metal coatings are available, but as the process involves various chemicals, making sure that the workflow is approved for food contact is the developer’s own liability.

SLA 3D printing offers the unique possibility to produce ceramic parts. After 3D printing, parts can be fired in a kiln to burn out the resin and form a true ceramic part that is strong and heat-resistant. With subsequent food safe glazing, the parts will become more hygienic and resistant to most chemicals.

A variety of food safe glazes are available on the market, but make sure to follow the manufacturer’s instructions in accordance with food safety guidelines.

3D printing in ceramics is ideal for fabricating complex geometries that wouldn’t be possible by hand.

Learn More About Ceramics

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

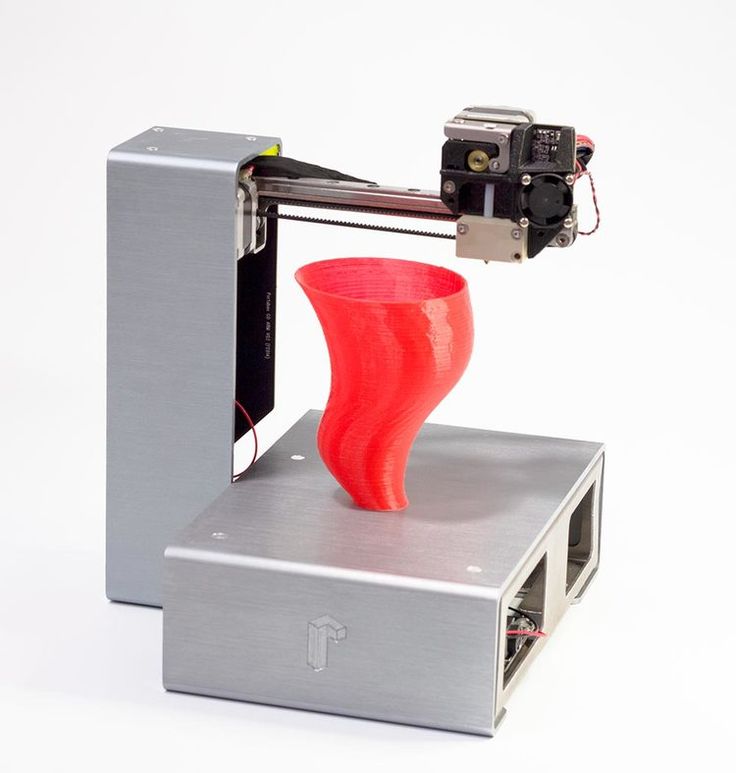

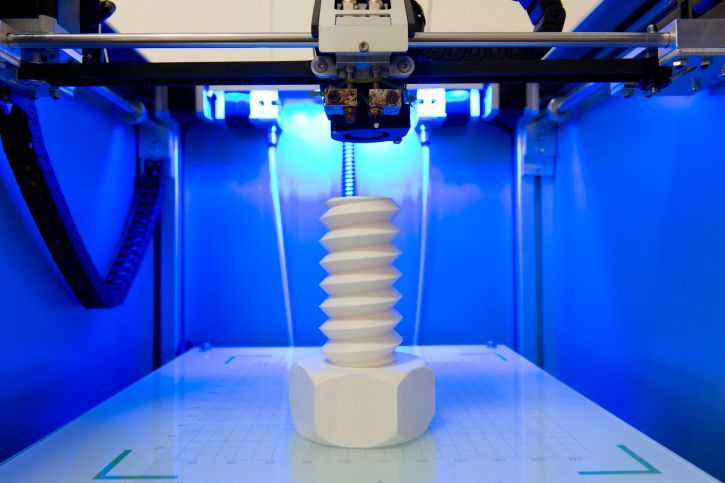

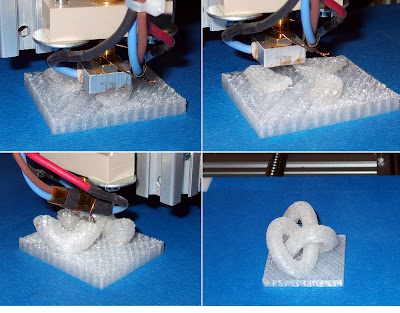

FDM is a 3D printing process that builds parts by melting and extruding thermoplastic filament, which a print nozzle deposits layer by layer in the build area.

The extruded material is circular in cross-section, which leaves very narrow crevices in between layers with a depth directly proportional to layer height. It is recommended in any case to print at the lowest feasible layer height for food safe parts.

Consequently, the main challenge with FDM parts is avoiding the buildup of bacteria. To be truly food safe in the long term, an FDM 3D print needs to have a smooth surface. Chemical smoothing with solvents like acetone, d-Limonene, or ethyl acetate removes many of the irregularities of the print resulting in a smooth, glossy appearance. However, applying a subsequent food safe coating is still highly recommended.

However, applying a subsequent food safe coating is still highly recommended.

Layers showing on FDM (left) and SLA (right) 3D prints.

Food grade filaments do not contain any composite particles so will not wear down the nozzle into the print. Nevertheless, avoid brass nozzles that contain lead and use a dedicated stainless steel nozzle instead for all food contact items.

Always check the compatibility of your 3D printer’s components with the filament. For example, PEI is a material that is FDA compliant and offers great mechanical benefits but needs to be processed at over 300 °C, which requires a specific printer solution.

The most common questions around FDM food safety concern two popular materials. Is PLA food safe? Is ABS food safe? The answer is, it depends.

Food safe 3D printing filaments include PLA, PP, co-polyester, PET, PET-G, HIPS, and nylon-6, as well as some brands of ABS, ASA, and PEI. Having to run parts through the dishwasher rules out PET, nylon, and PLA because these plastics soften and distort around 60–70 °C. For applications involving hot liquids, co-polyester, High Temperature PLA or PEI are most suited.

For applications involving hot liquids, co-polyester, High Temperature PLA or PEI are most suited.

While not reflected in the regulations, some studies suspect that polystyrene may leach styrenes, co-polyesters might cause health concerns and that food grade FDM filaments might lose their safe status due to oxidation and thermal degradation from the printing process.

| Filament | Brand | FDA | EU | Smoothable | Dishwasher safe | Hot liquids |

|---|---|---|---|---|---|---|

| ABS | Adwire PRO | Approved | NA | Yes, acetone | Yes | Yes |

| Innofil3D | Approved except red, orange, and pink | Approved except red, orange, and pink | Yes, acetone | Yes | Yes | |

| ASA | Innofil3D | NA | Compliant | Yes | No | |

| Bendlay | Orbi-Tech | NA | Compliant | Yes, brake cleaner | No | No |

| Biocompound | Extrudr GreenTEC | NA | Compliant | |||

| Co-Polyester | Colorfabb XT | Approved | Compliant | No | Yes | Yes |

| HIPS | Easyfil | Compliant | Compliant | Yes, d-limonene | Yes | No |

| Fillamentum | NA | Compliant | Yes, d-limonene | Yes | No | |

| InnoFil3D | Approved | Approved | Yes, d-limonene | Yes | No | |

| Nylon | Taulman Nylon 680 | Compliant | NA | No | No | |

| PEI | ULTEM® 1000 | Compliant | NA | Yes | Yes | |

| PET | InnoPet EPR | Approved except red and orange | Approved except red and orange | Yes, ethyl acetate | No | No |

| Refil | Approved | NA | Yes, ethyl acetate | No | No | |

| Taulman T-Glase | Approved | NA | Yes, ethyl acetate | No | No | |

| Verbatim | Compliant | NA | Yes, ethyl acetate | No | No | |

| PET-G | Extrudr MF | NA | Approved | Yes, ethyl acetate | No | No |

| HDGlass | Approved | Approved | Yes, ethyl acetate | No | No | |

| PLA | Filaments. ca TrueFS ca TrueFS | Approved | NA | No | No | No |

| Fillamentum | NA | Compliant | No | No | No | |

| Innofil3D | Approved except red, orange, pink, apricot skin, grey, and magenta | Approved except red, orange, pink, apricot skin, grey, and magenta | No | No | No | |

| Copper3D PLActive Antibacterial | Approved | Compliant | No | No | No | |

| Makergeeks | Approved | NA | No | No | No | |

| Purement Antibacterial | Approved | Approved | No | No | No | |

| PLA-HT | Makergeeks Raptor | Approved | NA | No | Yes | Yes |

| Makergeeks Raptor | Approved | NA | No | Yes | Yes | |

| PP | Centaur | Compliant | Compliant | No | Yes | Yes |

| InnoFil3D | Approved | Approved | No | Yes | Yes | |

| Nunus | Compliant | Compliant | No | Yes | Yes | |

| Verbatim | Compliant | NA | No | Yes | Yes | |

| SBS | Filamentarno | NA | Approved only in Russia | Yes, d-limonene | Yes | Yes |

Selective Laser Sintering is a 3D printing process that use a high-powered laser to fuse small particles of polymer powder. The most common material for laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties.

The most common material for laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties.

While some SLS powders are graded food safe, the particles on the surface of printed parts might not fuse completely, resulting in parts that are inherently porous and do not deal well with moisture and mold growth. Even though the nylon 12 powder can be steam cleaned in an autoclave, it is best to coat SLS parts with food safe coatings to seal their surface.

A common post-processing step for SLS parts is dying. But note that after an SLS part has been dyed, the dye may leach into the printed part which renders the item not food safe.

White Paper

Looking for a 3D printer to create strong, functional parts? Download our white paper to learn how SLS printing works and why it's a popular 3D printing process for functional prototyping and end-use production.

Download the White Paper

Food safety with 3D printing is not a simple matter that will boil down to a clear yes or no answer. Producing 3D printed parts for food contact items requires careful consideration of the risks depending on their intended use.

Producing 3D printed parts for food contact items requires careful consideration of the risks depending on their intended use.

For further information on food safety and 3D printing, we recommend reading the following:

- FDA Regulations CFR 21

- EU Guidelines 10/2011

- Risk Assessment of 3D Printers and 3D Printed Products

- The Tricky Business of Choosing Plastic for Food Contact Applications

11 Fun Facts About Food-Safe 3D Printing

Printing things that are cool and useful is incredibly cool. It never gets boring. However, when making fun-designed kitchen utensils or mugs, you might well be wondering: how safe is 3D printing for objects that come into contact with food and drink every day? For example, is PLA filament harmless in this sense? What about ABS?

Such a statement of the question is quite reasonable. Both FDM and SLA technologies use active mixtures of chemicals that are heated during the printing process. And this suggests the idea: is the resulting resin food-friendly?

And this suggests the idea: is the resulting resin food-friendly?

If it contributes to the risk of poisoning by toxic substances or harmful microbes, it is important to know about it. Below we provide a guide to food-safe 3D printing, highlighting the most important issues and techniques to minimize the risks.

1. Bacteria buildup

This is the biggest food safety hazard in 3D printing because even if the print looks flawlessly smooth, it still has microscopic cracks and cavities in which microorganisms can accumulate and grow.

Microscope photo of print surface

If you are printing a disposable cup, plate or kitchen utensil, this should not be a problem. But if you plan to use such an item repeatedly, you should seriously consider whether 3D printing is appropriate here at all.

2. Treat printout with food safe sealant

Use food safe epoxy or a suitable sealant to seal cracks where microorganisms can accumulate. For PLA, ABS/, SBS or HIPS, polyurethane is a good choice. Care must be taken to ensure that the model does not come into contact with raw meat and eggs, which pose the greatest potential threat in terms of “collecting” microbes.

For PLA, ABS/, SBS or HIPS, polyurethane is a good choice. Care must be taken to ensure that the model does not come into contact with raw meat and eggs, which pose the greatest potential threat in terms of “collecting” microbes.

3. Chemicals in the filament

In general, ABS filament is considered unsafe to create any objects that come into contact with food. The fact is that ABS contains extremely toxic chemicals that can contaminate products and cause harm to humans.

Natural PLA is made from corn starch and is generally considered food safe. Here, however, things are not so simple. Most manufacturers add components to the filament - for color, strength, or other purposes - that make it an undesirable "food". Some PLA filaments are specifically designed to be food safe, but if this is not stated, check with the manufacturer.

4. Toxic Particles During Printing

According to a 2015 study by the Illinois Institute of Technology, desktop FDM printers emit extremely large amounts of so-called ultra-fine particles when printing ABS and PLA. These particles can deposit on the surface of the printed object and, if inhaled or swallowed, can cause serious health problems.

These particles can deposit on the surface of the printed object and, if inhaled or swallowed, can cause serious health problems.

Again, ABS is more dangerous than PLA, but in both cases it is recommended to work in a well ventilated area. And don't snack in front of the 3D printer! Research in this area is still ongoing, but with a high degree of certainty it can be argued that just as you should not inhale ultrafine particles, you should not eat food that is contaminated with them.

5. Forget the dishwasher

Let's go back to the issue of microbial buildup and ask ourselves: can't we just wash the printed object thoroughly every time? Unfortunately no. If you wash a 3D print in warm water, or even in a dishwasher, the object will gradually deform and warp.

In particular, PLA is very sensitive to heat and is definitely not safe to put in the dishwasher. If the object is fragile, it can break into a thousand pieces during the washing process, which can lead to breakage of the machine itself.

6. Use warm water and antibacterial soap

This does not mean that 3D printed objects cannot be washed at all. You can - but not in the dishwasher, but in slightly warm water and with a mild antibacterial detergent, and immediately after use. This will reduce the risk of the printout melting and will also remove bacteria from the surface of the printout.

7. Copper nozzles may contain lead

FDM printer extruders vary. Some are made of steel, some are made of aluminum and some are made of copper or brass. In the latter case (copper/brass), they may contain lead, and ingestion of lead can lead to very serious health problems. Check your 3D printer carefully to see what type of nozzle it has and whether it can be easily replaced.

8. Use a food safe hot end/extruder

To avoid contamination from the extruder, a stainless steel hot end that is considered food safe should be purchased. If you're going to be printing a plate or two, this might seem like overkill, but if you're serious about threats or planning to fill your kitchen with homemade creations, this kind of upgrade is definitely worth considering.

9. Limit the contact time of printed objects with food

Another aspect to pay attention to when talking about food safety is what exactly the printed object will be used for. Different kinds of knives and cake cutters or cutters do not come into contact with food for too long, so they can be considered safe even if non-certified filament was used. However, if the coffee cup or food container is in contact with food for a long time, additional precautions should be taken.

10. Completely food safe

As you may have realized by now, in reality it is quite difficult to make a 3D print that can be certified as 100% food safe. In this sense, for an object to have a food safety certificate and to be completely safe are not the same thing. It's not the same thing - to get poisoned from a printed cup or plate once or twice. As with everything, the main thing here is not to overdo it.

11. Choose material wisely

Choosing the right material is important for 3D printed objects. PLA for a coffee mug may be a food-safe choice, but the plastic is too soft for hot drinks and can melt in the dishwasher. ABS may be stronger here, but it is not certified as food safe and contains chemicals that are potentially toxic to humans, but do not despair - PLA and ABS are not a wedge of light. A good substitute could be SBS, PETG, PP

PLA for a coffee mug may be a food-safe choice, but the plastic is too soft for hot drinks and can melt in the dishwasher. ABS may be stronger here, but it is not certified as food safe and contains chemicals that are potentially toxic to humans, but do not despair - PLA and ABS are not a wedge of light. A good substitute could be SBS, PETG, PP

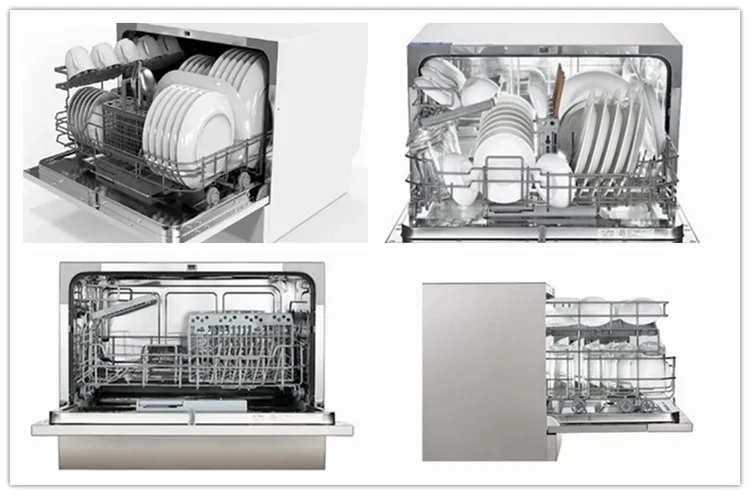

Dishwasher - pros and cons: Do you need a dishwasher at home

There is an endless debate about how best to wash dishes. Do you need a dishwasher at home? Or is it better to wash the dishes the old fashioned way, by hand? And in what case is the dishes cleaner and less water is used?

We decided to survey our users from eight countries: Russia, Italy, Spain, France, Japan, USA, UK and Australia. Through surveys and discussions on Houzz, we tried to understand what we can learn from representatives of other cultures about this dilemma. This is how the issue of dirty dishes is solved all over the world.

Corynne Pless

Dishwashers are getting more popular, but it's not that easy

As it turned out, 60 to 70 percent of respondents in every country except Japan, where the vast majority prefer to wash dishes by hand, answered that they use a dishwasher. For example, Valerie from France explains: “I can't live without a dishwasher. It saves a huge amount of time and is much more environmentally friendly. Plus, it makes my hands look better!”

In the US, 67 percent of our survey participants said they preferred a dishwasher. US user nnigrt writes in the comments: “Sometimes I want to mop the floors instead of vacuuming, bake my own bread, and not go to the supermarket. But I never get the urge to do the dishes by hand!”

But it cannot be said that everyone has abandoned hand washing. In each country, 30 to 40 percent of those surveyed prefer this particular method. Lorella Dia, an Italian Houzz user and owner of Milan Chic Chandeliers, says she understands why large families with lots of unwashed dishes after dinner prefer to use dishwashers. But if the family consists of two, then washing dishes by hand is easier and perhaps even more romantic. “You can use the time spent washing dishes to talk to each other,” says Lorella. “Like in old romantic movies!”

But if the family consists of two, then washing dishes by hand is easier and perhaps even more romantic. “You can use the time spent washing dishes to talk to each other,” says Lorella. “Like in old romantic movies!”

Let's take a look at what people usually say about each method to understand why some people can't live without the time-saving dishwasher, while others like to wash dishes by hand. So, washing by hand or dishwasher: pros and cons.

1. Saving water

It is believed that: the dishwasher saves water

Reality : yes, but the same can be said about effective washing

According to the study 20009year among UK users, conducted in 2009 by the University of Bonn (Germany), those who wash dishes by hand use an average of 49 liters of water, while a dishwasher uses only 13. In 2011, the US Natural Resources Conservation Council (NRDC) supported results of this study, stating that new dishwashers that meet Star Energy standards use an average of 14 to 23 liters of water. If we compare these figures with the amount of water, which, according to the Council's charter, is economical when washing dishes by hand and is 36 liters, then dishwashers would seem to win, but everything is not so simple.

If we compare these figures with the amount of water, which, according to the Council's charter, is economical when washing dishes by hand and is 36 liters, then dishwashers would seem to win, but everything is not so simple.

First of all, you need to find the answer to the question of what can be considered effective washing dishes by hand. According to Waterwise, a non-profit organization dedicated to reducing water consumption in the UK, the amount of water flowing from a faucet in one minute while washing dishes can range from 2 to 25 liters.

Also according to Waterwise, water used in the kitchen makes up 8 to 14 percent of a home's total water consumption, and kitchen faucet aerators can significantly reduce water flow. Also, if you soak your dishes in a sink filled with soapy water, you can cut your water consumption by 50%. But if you choose the best approach and, for example, use one container for washing dishes and another for rinsing, then you can reduce the amount of water used to the indicators of the newest dishwashers.

According to the Natural Resources Conservation Council, each person washing dishes at an open tap uses about 123 liters of water. Horror! Let's not do that again.

However, do not forget that the amount of water consumed by the dishwasher depends on the dishwasher model. Not everyone has new machines that usually use less water and energy. Older dishwashers, according to Waterwise, can use as much as 50 liters per wash, while modern machines use only about 10 liters.

The Waterwise experts offer the following tips to save water.

- Choose small dishwashers. If you live alone or alone, then you should stop by a car designed not for 12, but for 9 sets of dishes.

- Use the Eco mode in your car, which uses less water and energy.

- Do not use pre-rinse, which is not required by modern detergents.

Lisa Gabrielson Design

2. Save time

It is believed that: the dishwasher saves our time

Reality: yes, but it depends on the circumstances

According to our users, saving time is the main advantage of the dishwasher. Many owners of dishwashers do not understand how they used to live without them. For most, it's more than just a dishwashing device. “You can throw anything into them,” writes the American user dahupaylo. - Including pet bowls, keys, baseball caps, toys, plastic containers, empty peanut butter cans, dish brushes. And then come back in an hour, and everything will shine with cleanliness!”

Many owners of dishwashers do not understand how they used to live without them. For most, it's more than just a dishwashing device. “You can throw anything into them,” writes the American user dahupaylo. - Including pet bowls, keys, baseball caps, toys, plastic containers, empty peanut butter cans, dish brushes. And then come back in an hour, and everything will shine with cleanliness!”

However, the advantages of washing in the dishwasher are not obvious to everyone. Many people who have washed dishes by hand for a long time and bought a dishwasher in one day are surprised to learn that they have to work hard first, loading the machine. You still need to clean the plates of leftover food and rinse them. You also need to refuel the car correctly: wait until the car has washed a batch of dishes, and only then pull it out. All this takes time, although not as much as a hand wash.

According to a study by the University of Bonn, loading and unloading a dishwasher takes 60 minutes for those who usually wash dishes by hand, and only 9 for those who are accustomed to this process. .

.

According to the American organization Consumer Reports, which tests and evaluates various products, one dishwasher cycle usually takes from two to those hours. This time can be spent on a bunch of different things instead of standing at the sink. “When you have a lot of household chores, any way to save time is welcome,” says Susan Redman, our user from Australia.

But not everyone thinks that a dishwasher saves time. “Washing dishes is not my favorite activity, but I like the result of hand washing much more,” says another user from Australia, Janine Feris. “No scratched dirty glasses for you. Plus, loading, unloading, and drying plastic that never fully dries out takes the same amount of time as washing dishes by hand.”

Although both loading and unloading the dishwasher take time, 67 percent of US users surveyed said they prefer to load the dishwasher. One of the reasons is that many people are used to doing certain things in a specific way and cannot trust this process to anyone else. “No one but me loads the dishwasher correctly, so every time I have to redo everything,” says our US reader Whitney Wadsworth. “It's a form of mania, what can I say! But I really don't like unloading the dishwasher. I do not know why".

“No one but me loads the dishwasher correctly, so every time I have to redo everything,” says our US reader Whitney Wadsworth. “It's a form of mania, what can I say! But I really don't like unloading the dishwasher. I do not know why".

Of course, when you wash dishes by hand, you either have to put them on the dryer, or wipe them with a towel and put them in cupboards, which also takes time. In the US, 72 respondents said they preferred using a dryer rather than wiping dishes with a towel.

Australia and Italy have a similar situation. But in Italy, dryers are not like those used in the US or the UK. Most Italians, along with the French and Russians, use a rack with a dryer over the sink, as shown in this photo, where water drains from the dishes, after which they are placed on cabinets and shelves.

Jennifer Young

3. Disinfection

It is believed that: In the dishwasher, the dishes is better than disinfected are : Yes, but this is not always the case of

in dishwasher 60 in dishes degrees by Energy Star standards, which means it's more effective at killing bacteria than hand washing. But this is not always the case, and it does not necessarily give a positive result. “Washing dishes in a dishwasher at a very high temperature will certainly help you kill bacteria, but the problem is that microbes can also be beneficial,” explains Jonathan Eisen, professor of microbiology at the University of California at Davis.

But this is not always the case, and it does not necessarily give a positive result. “Washing dishes in a dishwasher at a very high temperature will certainly help you kill bacteria, but the problem is that microbes can also be beneficial,” explains Jonathan Eisen, professor of microbiology at the University of California at Davis.

He points to a Swedish study published in the journal Pediatrics in early 2015, which found that washing dishes by hand could reduce the risk of allergies, asthma and eczema in children.

“With this less effective method, it is possible to enhance immunity – through interaction with microbes,” write Bill Hesselmar, Anna Hikke-Roberts and Goran Wennergreen in conclusion. Aizen agrees with these conclusions: “We must stop the widespread belief that all microbes need to be destroyed. Plenty of evidence shows that excessive cleanliness is unhealthy. This is especially true for children.

If you wash dishes by hand, rinse and leave to dry, you get rid of all harmful organisms and leave useful ones. A dishwasher is needed only for convenience and saving water in some cases.

A dishwasher is needed only for convenience and saving water in some cases.

Christine F. Interiordesign as

4. The remains of dirt

It is believed that: The dishwasher does not completely wash the dish

Reality often this is not so

Lucyl. Science often hears that consumers don't use the different modes and functions of their dishwashers. However, thanks to them, you can make the cycle longer for such specific dishes as slides and pans, and, conversely, shorten it for small things.

Lucinda advises to read the manual. A lot of new technologies have come out in recent years, so it's worth making sure you're using your dishwasher in the best and most efficient way to save time and money. The instructions also often explain how to properly load the machine, including manipulating the racks that will allow you to optimally arrange the dishes.

A 2015 study by the University of Birmingham (UK) analyzed water trajectories to determine the most efficient way to load the machine: the plates should be laid out in a circle, while the dirtiest plates should be placed closer to the center, where the water pressure is stronger , and less dirty - to the periphery, where the pressure is less. For many, this approach to loading may seem complicated, since the design of the machines is not adapted for it, but it's worth a try.

For many, this approach to loading may seem complicated, since the design of the machines is not adapted for it, but it's worth a try.

Esther Hershcovich

5. Silver load

believes that: Silver cutlery is better loaded with a slide down

Reality : The 9000,

around this argument is not always hot around this argument. The opinions of participants in surveys conducted in the UK, Australia and the US were divided equally. The first half states that appliances should be loaded handle down. “It seems to me that in this position, the appliances are washed better,” writes armipeg , our US user. The other half loads them with the handle up to make it easier to unload the machine and not touch the part of the cutlery that comes into contact with food.

Most interviewees agree that sharp knives should be washed by hand, placed in the horizontal cutlery drawer (as pictured above) in the dishwasher, or loaded with the handle up to avoid cuts or even fatal wounds. According to The Guardian, in 2003 a young woman died after slipping in the kitchen and falling on a knife blade protruding from a dishwasher. Six years earlier, a 12-year-old boy had died under the same circumstances.

According to The Guardian, in 2003 a young woman died after slipping in the kitchen and falling on a knife blade protruding from a dishwasher. Six years earlier, a 12-year-old boy had died under the same circumstances.

Studio 3 kitchens

6. Noise level

It is believed that: the dishwasher is too noisy

Validity : Old models can be really noisy 9002 depending on the model 9002 If you want to watch a movie or talk with friends in peace and quiet, then you should turn on the car later. With newer machines, noise is kept to a minimum so that you may not even notice whether the machine is on or not, which can be considered both a plus and a minus.

Design Platform

7. Old kind romance

It is believed that: washing is a manually with a conversation

Reality : Yes, but also saved dishwasher, we can use the same conversation 9000 9000 9000 9000 received comments from people who have given up using the dishwasher, preferring to spend their time washing dishes by hand talking to family members or friends. After all, while washing dishes, you can talk, play, dance

After all, while washing dishes, you can talk, play, dance

“In the past, washing dishes, wiping them and putting them in their places meant spending time with the family,” writes our user from Australia sjp777 . “It was a family activity that everyone did together. Unfortunately, it seems that this ritual is gradually disappearing, but in our family we still keep it.”

Mark, a US Houzz user, shares this sentiment: “We live in a wonderful home and can afford the best kitchen equipment, but you never see a dishwasher in our kitchen. It may sound strange, but we really love spending time together and sharing how our day went while washing dishes. We look forward to this moment, which we cut out from a busy schedule. We throw wet towels at each other like when we were young. I would never trade this joy for a dishwasher.”

But many people have other plans for the time they save with a dishwasher. “We have two small children, and we prefer to spend the time saved by washing dishes with them. In addition, we can clean up the rooms that the kids managed to smash, ”writes Michelle Morton from the UK.

In addition, we can clean up the rooms that the kids managed to smash, ”writes Michelle Morton from the UK.

Australian user mcxu8 agrees: “Since I started working, I find it too tiring to spend half an hour at the sink. Thanks to the dishwasher, I have extra time to relax after a hard day at work.”

That is, both the minuses and pluses of the dishwasher are different for everyone.

8. Washing frequency

It is believed that : it is best to wash dishes after each meal

Reality : yes, for most people, when it is worth washing dishes

The only time users are willing to make an exception is during holidays and parties when there are guests in the house. In this situation, it is best to clear the table, serve coffee and continue the conversation with the guests, and wash the dishes and silverware when everyone has left.

In this situation, it is best to clear the table, serve coffee and continue the conversation with the guests, and wash the dishes and silverware when everyone has left.

Torie Jayne

8. Meditation

It is believed that: washing dishes by hand calms

Reality : yes, but not all work can be a kind of therapy, we already wrote a kind of therapy

“While washing dishes, you can think about many things and solve many problems,” writes Laura Tallarida from Italy. Robert Herget of Houzz Germany agrees: "It's very comforting." Our US user mirador echoes this point: “I love washing dishes by hand. It is a simple and satisfying process during which one can reflect.”

According to a study conducted at the University of Florida in October 2015 and published in the journal Mindfulness, focusing while washing dishes (on the smell of soapy water, its temperature, the shape of the plates) stimulated the brain and reduced nervousness among focus group participants.

Read also ...

Order in the house: Homework that will help you defeat the spleen

LIB Contents

9. Manual Washing - for expensive dishes

It is believed that: Weapy more watering more. suitable for tableware with gilding, hand-painted, etc.

Reality: everything is correct

It is hard to argue with this statement. Try to find someone willing to load their grandmother's china into the dishwasher. Naturally, we treat the dishes we value with more care and trust them only to our own hands. This applies to good knives as well.

In Japan, where dishes are most often made of clay and varnished, which means they cannot be washed in a dishwasher, the vast majority of users who participated in the survey prefer hand washing. “I never wash Japanese lacquerware and expensive glasses in the dishwasher,” writes Miki Anzai, a Japanese journalist. “I can say the same about cutlery, dishes with gold and silver trim.”

“I can say the same about cutlery, dishes with gold and silver trim.”

Yukiko Tahara, owner and designer of LiB Contents Tokyo, says that about 70 percent of customers ask for a dishwasher in their renovated kitchen. About 15 percent believe that they don’t need a car at all at home, and the remaining 15 percent, after some thought, nevertheless refuse a dishwasher, since it takes up a lot of space. “The average size of Japanese kitchens is noticeably smaller compared to American kitchens,” says the designer.

LiB contents

According to Yukio, in addition to the fact that Japanese earthenware and lacquerware cannot be washed in the dishwasher, the Japanese also prefer to eat from bowls, and "dishwashers do not do well with them."

But perhaps there is a reason related to the cultural characteristics of Japan. “I think the Japanese really like to wash dishes,” says Yukio. — As far as I know, this is the first housework task taught to children.