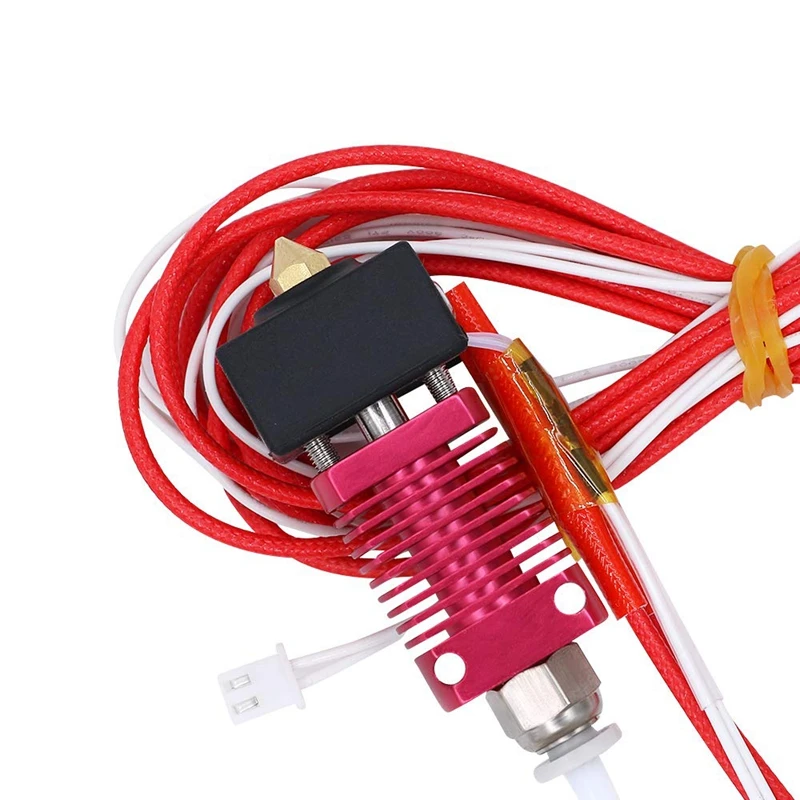

3D printing hot end

E3D v6 Hotends | MatterHackers

Technical Specifications

- Filament Diameters available: 1.75mm and 3.00mm

- Nozzle Diameters available range from 0.15mm with 1.20mm

- When changing nozzles, be sure to have the hotend at operating temperature to avoid damaging either the nozzle or heatbreak.

E3D v6 Hotends

RapidChange Revo

Change nozzles easily and quickly with E3D's revolutionary hotend ecosystem.

Fully Assembled v6 Hotends

Fully-assembled hotends ready to tackle all your 3D printing projects.

v6 Hotend Kits

Hotend kits to assemble that fit almost any 3D printer

Guides & Articles

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

How To Succeed When 3D Printing With PLA Filament

Discover the best practices for 3D printing with PLA filament - from finding the right temperature, to which surfaces to 3D print on, this step-by-step guide will help you succeed with 3D printing PLA.

How To Succeed When Printing With ABS

ABS filament is a versatile material that's a great option for when you need your 3D-printed parts to be strong and heat-resistant. Learn how to print this material like a Pro in this in-depth guide.

Printing Tips & Tricks: ABS Bed Adhesion

ABS: stronger, more durable, and more heat-resistant than PLA. An excellent 3D printing material, but ABS is prone to warp. Stop warping on your ABS prints, and create strong bed adhesion to produce flat prints by following these tips.

Living Hinge: Design Guidelines and Material Selection

Bring your prints to life by adding an additional degree of motion to your designs - living hinges are the foundation of expanded mechanical solutions.

Printing with Bronzefill

Bronzefill filament is made with real bronze powder and offers a unique look and feel for your decorative 3D printed parts

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

3D Printer Troubleshooting Guide

Use this guide to help you identify and solve the most common issues that may occur while 3D printing.

3D Printer Filament Comparison Guide

There are many different kinds of 3D printer filament, and each one has it's own strengths for different projects. Knowing these differences is key to a successful 3D printing experience and so we have created a Filament Comparison Guide with everything you need to know about every type of filament available.

3D Printer Hot-Ends - 3DJake International

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

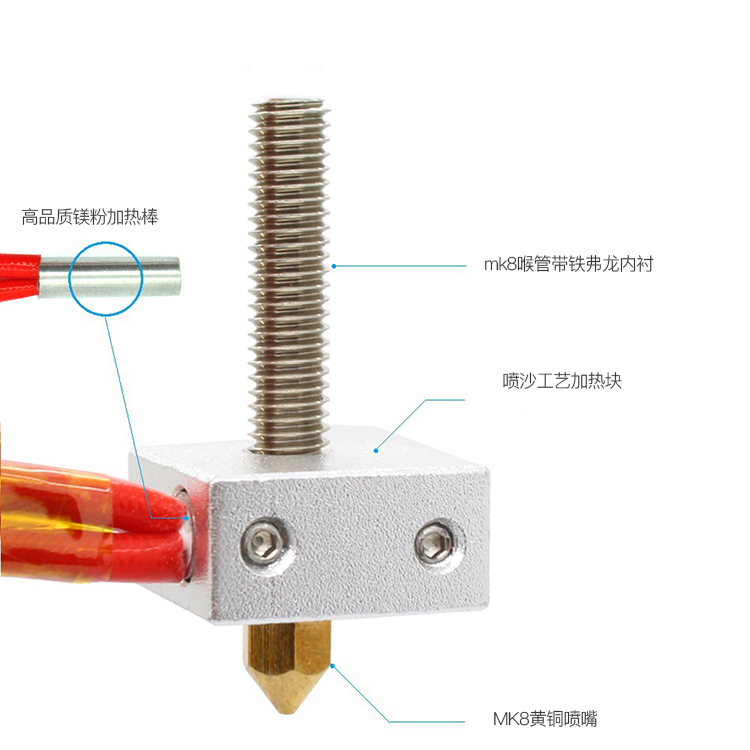

Creality Hotend 23 Model types- Original spare part

- From Creality

-

Micro-Swiss All Metal Hotend Kit for CR-10- All metal

- Better heat dissipation

- No adjustments required

-

Phaetus Dragonfly Hotend BMS- Temperature resistance up to 500 ° C

- All-metal design

- Good heat dissipation

-

BROZZL All Metal Hot-End Upgrade Kit for Ender & CR-10- Easy to use

- Fast assembly

- Precise manufacturing

-

Micro-Swiss Silicone Socks Set for MK7 / MK8 / MK9 1 set- High-temperature resistant

- Set of 3

- Non-stick

-

E3D V6 Plated Copper Heater Block- Good high-temperature performance

- Softening point well over 500 ° C

- Less sticking

-

Micro-Swiss All Metal Hotend Kit for CR-10S Pro- All Metal Hotend

- Better heat dissipation

- Can be used without any modifications

-

Slice engineering Mosquito- Perfect heat transfer

- Temperatures up to 450 ° C possible

- Flexible installation

-

Phaetus Dragonfly Hotend BMO- Temperature resistance up to 500 ° C

- All-metal design

- Good heat dissipation

-

E3D V6 Silicone Socks 1 set- Non-stick surface

- For V6 heating blocks

- Keeps your heating block clean

-

Micro-Swiss All Metal Hotend Kit for the CR-6 SE- Titanium alloy heat break

- Well defined melting zone

- Aluminium heating block

-

E3D Revo Six 2 Model types- Direct replacement for E3D V6 Hotend

- Including a 0.

4 mm nozzle

4 mm nozzle

- All-metal hotend

-

E3D Revo Micro Full Kit 2 Model types- Complete set including 4 nozzles

- Compatible with Bowden or Direct Drive setup

- Small & light heat sink

-

Micro-Swiss High Temperature MK8 Heating Block Upgrade- M6 thread size

- Special alloy

- High printer compatibility

-

Creality Heatsink 5 Model types- Original spare part

- From Creality 3D

-

Anycubic Hotend 10 Model types- Original spare part

- By Anycubic

-

E3D V6 All-Metal Hotend Bowden - 1.75 mm 4 Model types- High temperature performance

- All-Metal

- Compact design

-

E3D Prusa V6 Hotend 3 Model types- Replacement hotend

- With V6 parts

- Improved version

-

FLSUN Hotend Thermistor 3 Model types- Original spare part

-

Slice engineering Mosquito Magnum- High printing speed

- Temperatures up to 450 ° C possible

- Flexible installation

-

BondTech BMG-M & Mosquito Magnum Set 2 Model types- Perfect upgrade

- Complete set

- Safe 3D printing process

-

FLSUN Hotend Assembly 3 Model types- Original spare part

- For FLSUN 3D printers

-

E3D Revo CR Full Kit 2 Model types- Simple and quick nozzle change by hand

- Incl.

4 Revo nozzles

4 Revo nozzles

- Increased efficiency & safety

-

Termopasty AG Silver Thermal Paste 4 Model types- Thermally conductive

- Addition of silver compounds

- Fills in micro intolerances

All prices incl. VAT.

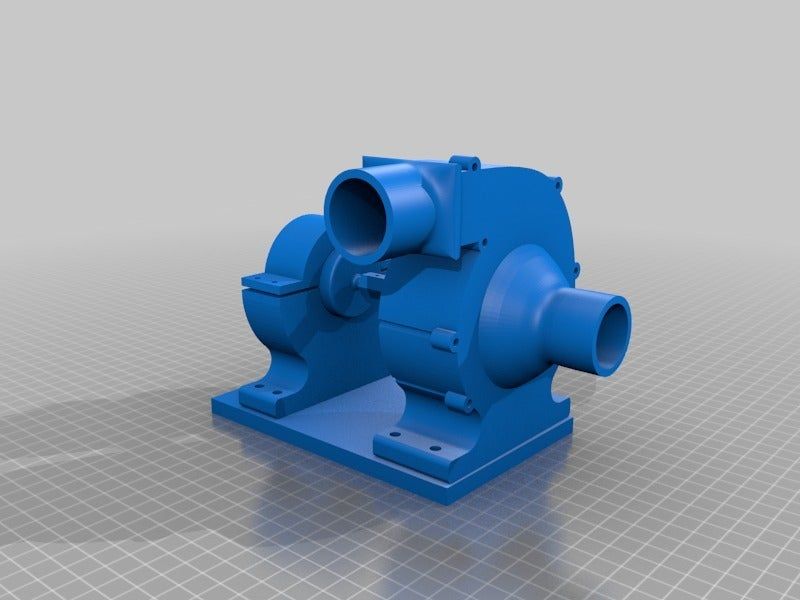

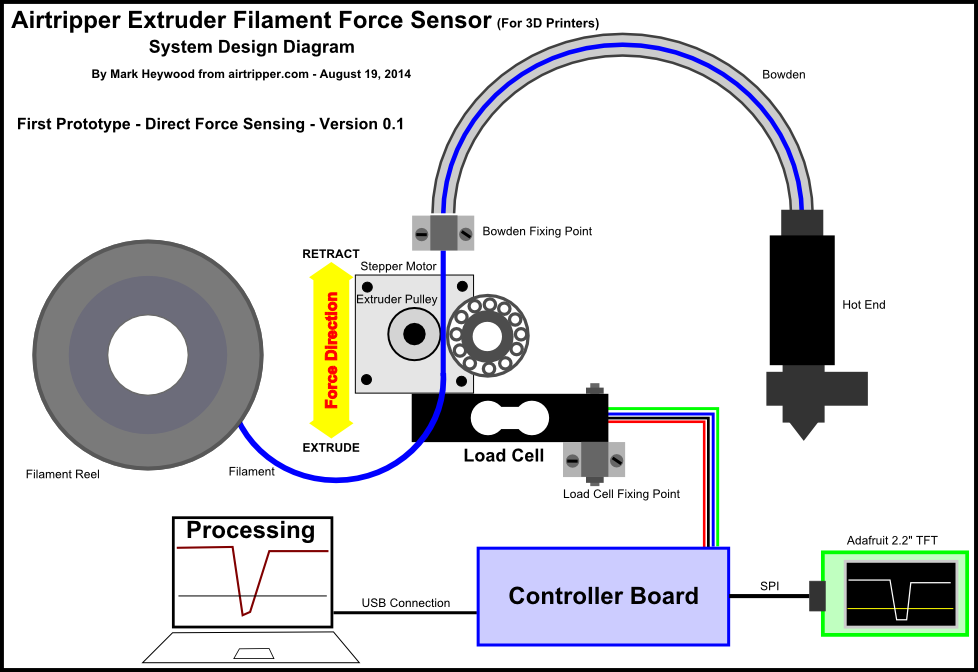

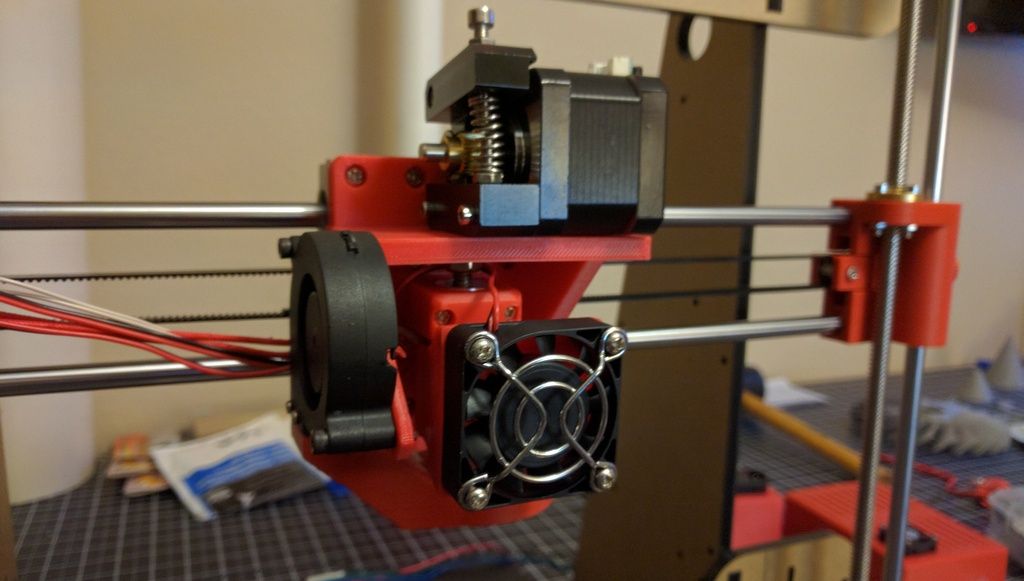

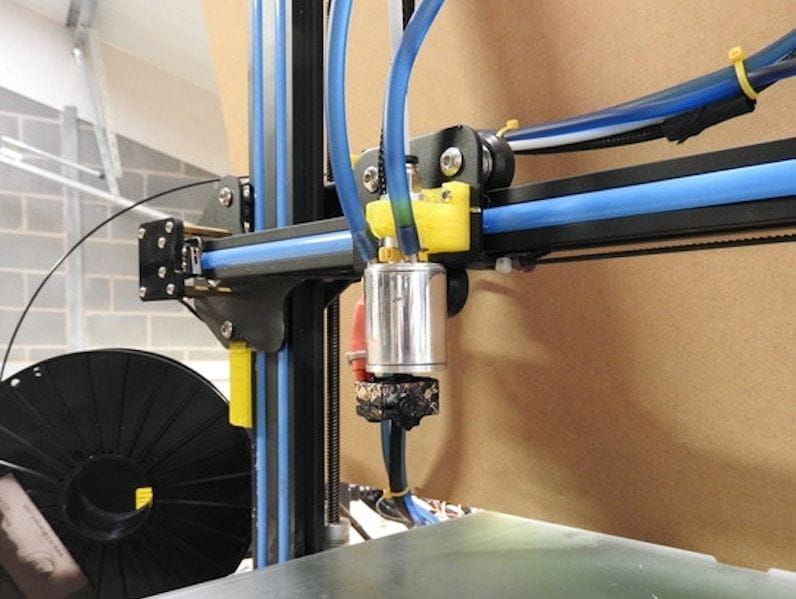

Faberant Cube 3D printer 'hot end', or something about 340°C high temperature extruder and doubling precision on FCoreXY

Dear readers! Some of you have heard of the Faberant Cube doubling precision 3D printer, but most of you are not aware of what this machine is and what it can do. Now we, its developers, are starting a series of articles about this 3D printer.

So, let us recall that the Faberant Cube is a Russian-designed 3D printer that has been produced since 2018. The printer has a fully enclosed chamber, which allows you to print durable heat-resistant parts made of Polycarbonate and Nylon. Also supported are Polypropylene, Polyurethane, ABS, PLA, FLEX, Rubber, HIPS, PVA, SBS, PETG. Heating of the table up to 170°C, all-metal extruder up to 340°C. nine0003

Body made of 2 mm thick steel. The XYZ motors are taken out of the print chamber and, together with the electronics, are located in a separate cooled compartment. The print area is 200x200x245 mm. The original doubling-precision movement system, FCoreXY, is used. The printer is designed for long-term commercial use, while it is successfully used in educational institutions, as well as for personal use.

Faberant Cube 3D printers are constantly improving. The developer monitors user requests for various improvements, the latest developments in the field of 3D printing, and is constantly working to improve the technical characteristics, quality and convenience of printers. For example, in this price segment, only this printer has a bed as high as 170°C, and an all-metal extruder (hot end) up to 340°C, which allows you to print almost all range of plastics, including high-temperature nylon and polycarbonate. nine0003

For example, in this price segment, only this printer has a bed as high as 170°C, and an all-metal extruder (hot end) up to 340°C, which allows you to print almost all range of plastics, including high-temperature nylon and polycarbonate. nine0003

Why heat the table so much? The fact is that the higher the melting temperature of the plastic, the more the table and the surrounding air in the chamber must be heated, otherwise the product will peel off the table during printing due to shrinkage and the printing will be interrupted. So, for polycarbonate, the temperature of the extruder during printing can reach 310 ° C. If small details can be printed at a table temperature of 130°C, then medium ones are already from 150°C, and large ones can be kept on the table only at 170°C.

Heating table for Faberant Cube 9 3D printer0014

The extruder uses an original thermal barrier that does not need to be unscrewed from the heatsink when changing the nozzle, just loosen one screw and the entire heating unit can be easily pulled out for quick replacement. Also, for the convenience of the user, in addition to the automatic change of plastic, manual feed is provided using the side handle. This greatly simplifies printer maintenance.

Also, for the convenience of the user, in addition to the automatic change of plastic, manual feed is provided using the side handle. This greatly simplifies printer maintenance.

Faberant Cube 3D printer heating unit

Faberant Cube 9 3D printer extruder unit0014

The printer was originally designed as a closed printer, so it does not have wires and tubes sticking up, and there is no 'aquarium' on top that increases the volume of the camera, like other manufacturers.

Printer closes at the top and front with quick release doors. When using a large number of printers, it is possible to stack them on top of each other to create 'print walls'.

Faberant Cube 3D printers in one of the colleges in Novosibirsk.

As far as kinematics is concerned, the Faberant Cube uses its own original development - the double precision movement system - FCoreXY.

The classic CoreXY outperforms the H-Bot type kinematics used in most of these printers, due to the fact that it completely compensates for the 'skew' of the axes during movement. Due to distortions in the H-Bot, such printers can only print well when assembled on expensive linear guides. Printers on CoreXY print perfectly on more affordable cylindrical rails. By the way, this printer uses high-quality SKF guides from Sweden. nine0003

The complexity of implementing systems on the classic CoreXY is that, due to the design features, the two belts must cross. So that they do not touch each other during operation, different solutions are used.

Basic motion system FCoreXY

Red and blue lines are belts.

The new FCoreXY system uses a two-level solution where the belts run parallel one above the other and do not cross. Some pulleys in this design are also arranged in two levels on top of each other on the same axis and take up less space than in the classic CoreXY. nine0003

nine0003

An important difference of FCoreXY was that the developers turned the motors with their axes in a horizontal plane, which made it possible to improve the layout of other elements. At the same time, the XYZ engines are taken out of the print chamber and hidden in the technical compartment with forced ventilation. It is worth noting that almost all other printers have these motors in the print chamber and can overheat. This will not happen in the Faberant Cube 3D printer.

To improve accuracy, the FCoreXY system uses additional blocks that can be placed very compactly without significantly increasing the size of the entire structure. The displacement equations show that the accuracy of the FCoreXY system can be 4 times higher than classical systems (see the displacement equations in the diagram). nine0003

For example: when the belts are moved by motors ΔA and ΔB by 10 cm each, in total 20 cm, we get a movement of the printer's extruder ΔX by only 5 cm, i.e. 4 times smaller, which means more accurate.

While conventional printers print with 0.1 mm accuracy in XY axes, FCoreXY printer can print with 4 times higher accuracy - 0.025 mm in XY axes.

FCoreXY implementation for Faberant Cube 3D printer

Y-axis uses thick guides with a diameter of 10 mm,

thinner X-axis with a diameter of 8 mm

As a result of using the system on FCoreXY, the Faberant Cube 3D printer can print very precisely geometrically, and since the layers are stacked with high precision in XY, the visible side surface of the products formed by the perimeters of the layers , it turns out visually very even, and the product is of high quality.

In addition to the improved kinematics along the two XY axes, the third Z axis has also been upgraded. So, in order to obtain layers that are as even as possible in height and the maximum print quality, a special gearbox for the Z axis with a ratio of 1 to 2.5 was developed for the Faberant Cube 3D printer. This means that the height of the layers when printed will be 2.5 times more accurate than on other printers without a gearbox. nine0003

This means that the height of the layers when printed will be 2.5 times more accurate than on other printers without a gearbox. nine0003

And now examples of how can Faberant Cube be printed:

Printing PLA material from stimplast

Printing PLA material

Printing PLA material

9000 S mix once. PLA from Strimplast

Printing with UltraPET from Strimplast

Printing with soft FLEX material from Strimplast

Printing with Polypropylene from PrintProduct

This is not all that I wanted to show and tell about the printer! If you didn't have enough details about the 'hot end', then next time we will tell you about the next improvements in the latest version of the Faberant Cube 3D printer, and believe me, there are a lot of them! New electronics, upgraded extruder and more are already in production!

If you are interested in this printer, we inform you that the new model is already being sold by pre-orders, those who wish can queue for production on order, or wait for the availability of printers. nine0003

nine0003

The Faberant Cube 3D printer is guaranteed for 1 year.

The price of the Faberant Cube 3D printer can be found on the manufacturer’s website. An order for a 3D printer can be sent to developers by mail (in free form) [email protected] An article for those who are ready to dive into technical details and find out how it was designed Faberant Cube. Read more about why you need a heating table and a closed chamber. For specialists - an article about printing with polypropylene on Faberant Cube. Please send questions, wishes, comments to the manufacturer's mail (in free form) [email protected] You can follow the project here:

www.faberant.ru | VKontakte | YouTube | Instagram Thank you for your attention!

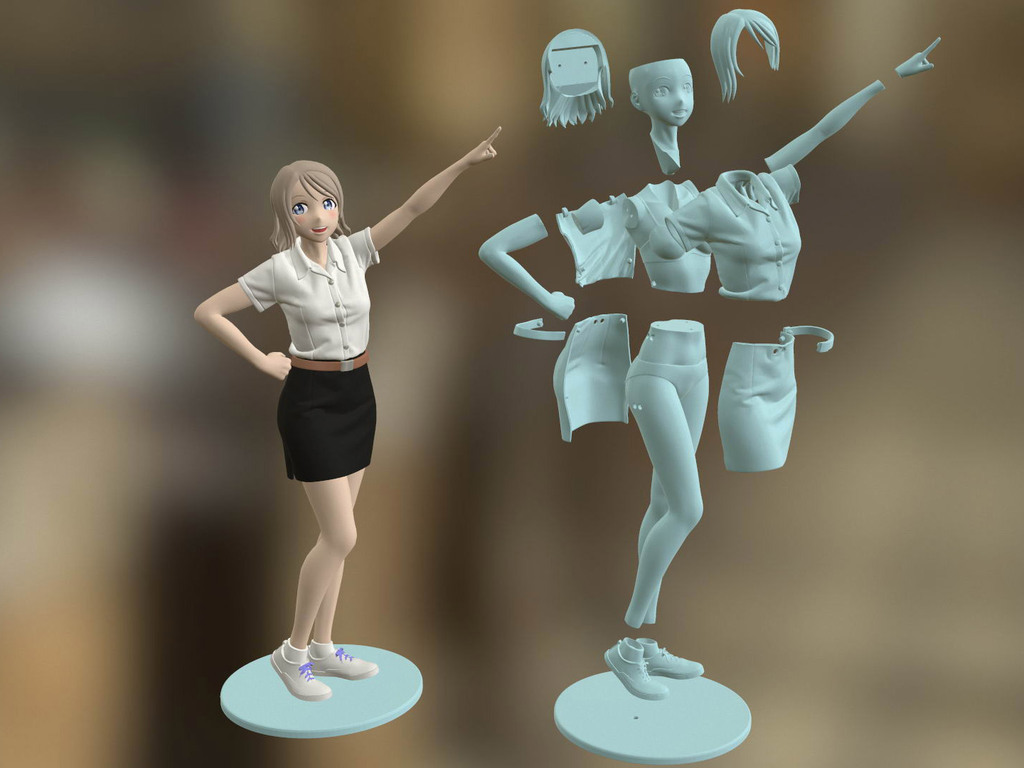

Free 3D file compact hot end・3D printed object to download・Cults

Wall mount TP link deco

2 €

Lighter Holder

Free

Ender 3 Fan Cover

Free

Magnetic box Child lock

Free

Barbed screwdriver

Free

Moroccan seamless pattern

Free

mobile phone stand with credit card

free

Tiny Gate

Free

The best files for 3D printers in the Tools category

Lola Animatronic Dryod

Free

Fortnite LLama

0. 95 €

95 €

BIG SPOOL (3Kg) IKEA Skadis spool holder with bearings

Free

nine0117 DIY Safety Galvanic Isolation Transformer2.69 €

topper FATHER'S day

Free

60 NeoPixel Ring Camera Mount

Free

Sandpaper holder [Shuttlecraft]

Free

SCREW ORGANIZER

Free

nine0004Bestsellers in the Tools category

Paint stand with scissors

5,25 €

Cut-Man - PET bottle cutter with handle!

€3.49

Fast print paint bottle rack (6 sizes)

€2. 83

83

Ender 3 S1 BEST cable guide - vertical

€2.50

Business card embossing system

3 €

Bit holder Spartan 4 mm Hex

1,80 €

PRECISE DIAL INDICATOR 3D PRINT DIY

1.91 €

'ELEGANCE' Bambu lab set and general 3d printers

5 €

nine0117 Tool holder for 3D printer V3.01.05 €

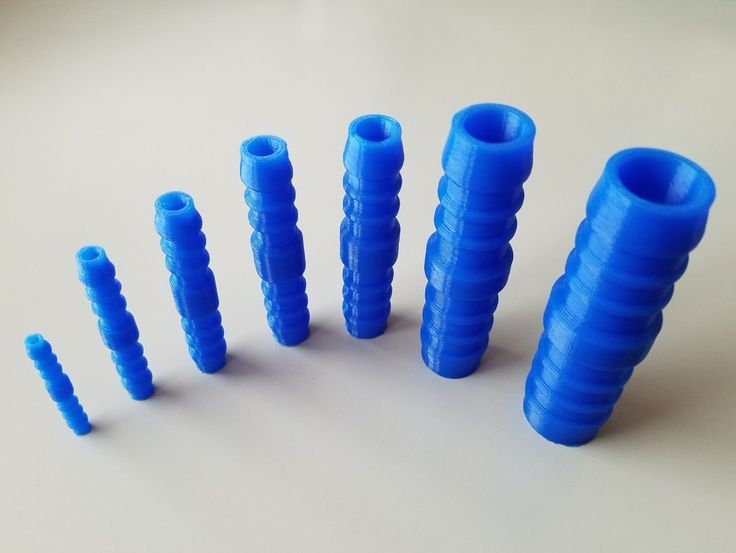

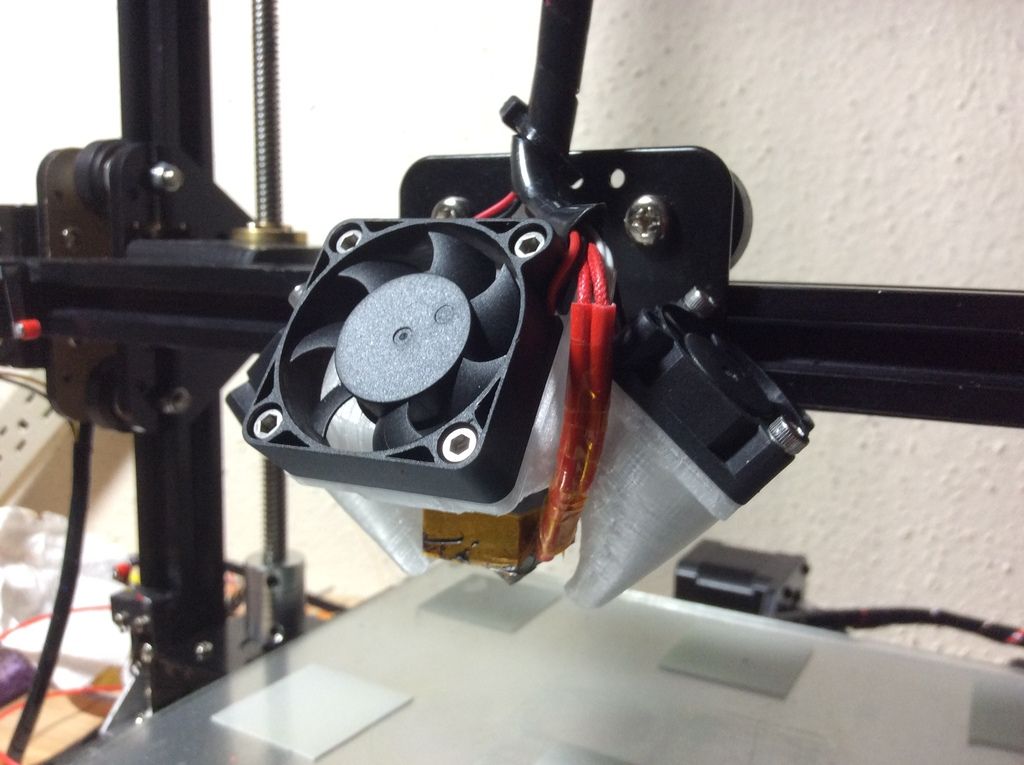

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. No support required for printing

1.58 €

Phone holder

2.46 €

Quick Print Stackable Parts Containers / Storage Boxes

2. 83 €

83 €

ENDER 3 S1, S1 PRO, SPRITE, HOT END DUCT 4020 OR 5015 FAN, PROBE NO Y OFFSET

€2.28 -20% 1.83 €

SUPERBOX

1,50 €

Armadillo - flexible wire conduit

1.69€

Display holder FLSUN v400

€9.99 -50% 4.99 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us at maintaining the activities of and creating future developments of is very simple.