3D scanner volume measurement

3D Scanners take Volume Measurement to a New Level

3D Scanners take Volume Measurement to a New Level

Advanced non-contact technology for measuring the volume of solids in silos

There are many devices on the market today for detecting the level of solids and powders in silos. Many devices will only alert when material reaches a particular high or low level in the silo. These point level devices, such as rotaries, are very affordable and reliable. They will prevent overfilling a silo, but do not really provide an accurate inventory. Rather, they simply alert to an impending overfill, so you can stop a process that could create a cleanup nightmare.

Continuous level sensors, such as non-contact radar, guided wave radar, and weight-and-cable or plumb bob type devices only measure the level of material in one location of the silo. Many solid materials tend to pile irregularly and create an uneven topography. As a result, a single measurement point may not depict how much material is on hand, dependent on the measurement location. This result is inaccurate inventory volume.

Solids and powders are difficult materials to measure and manage. Many are dirty and dusty, rendering some types of sensors useless or unreliable when operating in a harsh environment. Some are heavy and lumpy, potentially causing damage to guided wave radar or weight-and-cable sensors. Materials that pile up randomly and do not flow easily make it hard to know what is really remaining in the silo. That is why for calculating inventory, sometimes level data from a single measurement point just isn’t enough.

Today’s 3D scanner technology is a game changer when it comes to inventory accuracy. These sensors measure and map the material surface continually, enabling inventory monitoring in real time. The technology is non-contact, so there is no risk of the sensor being damaged by heavy material. The acoustics-based technology penetrates dust, so it will work reliably in dirty, dusty silos. Plus, 3D technology is far more accurate than any single-point measurement device because it accounts for irregularities in the material surface.

Multiple Point Measurement Really Matters

The advanced, acoustics-based technology used in 3DLevelScanners, also called 3D solids scanners, is very different from other types of level sensors. As the name implies, these devices scan the material surface to take multiple measurements, considering the high and low spots in the silo. Scanning the surface also detects conditions such as cone up or cone down as well as buildup that may be present along the sidewall of the vessel. The data from multiple measuring points is processed using advanced firmware and algorithms, and when combined with the silo’s parameters loaded into the software, a highly accurate volume estimate is provided. Additional data, such as the highest, lowest and average level of the material is also supplied.

Performs Reliably in Heavy Dust

One of the greatest challenges present in silos is the presence of excessive amounts of dust, which can render some types of sensors inaccurate or unreliable until the dust settles. By operating at very low frequencies, a 3D scanner is not bothered by dust and can perform consistently and reliably regardless of the conditions in the vessel. This technology has been proven in many different challenging materials including flour and many foodstuffs and in the power and mining industries to measure materials such as fly ash, ores, alumina powder, carbon black, limestone, manganese, dolomite, bentonite, silica granules, talc powder and all types of sand, including frack or silica sand.

By operating at very low frequencies, a 3D scanner is not bothered by dust and can perform consistently and reliably regardless of the conditions in the vessel. This technology has been proven in many different challenging materials including flour and many foodstuffs and in the power and mining industries to measure materials such as fly ash, ores, alumina powder, carbon black, limestone, manganese, dolomite, bentonite, silica granules, talc powder and all types of sand, including frack or silica sand.

A Great Measure toward Safety

When inventory monitoring is completely automated, there is no need to climb silos to take measurements. This not only saves time but eliminates the risk of falls and the resulting injuries along with the hassles of insurance and paperwork that comes with accidents. Plants today deal with rigorous safety requirements pertaining to climbing and entering silos and risk hefty fines when found in violation. Installing an automated inventory monitoring system allows for material management to be performed from a computer in the safety of an office.

Get a Better Handle on Inventory

A busy plant needs real-time inventory for operational and financial efficiency. This helps improve inventory turnover to make room for deliveries coming into the silos and getting shipments ready for trucks or trains heading to customers. 3D Scanners offer PC-based software that can be accessed from a single location or across an entire enterprise. MultiVision software allows for monitoring the inventory in a single silo or all silos and allows for historical reporting of inventory activity in each vessel.

Self-Cleaning Sensor Minimizes Maintenance

The unique design and materials used to manufacture 3D scanners ensure that the surface resists the buildup of dust particles that are suspended in the air at the top of the silos. Plus, the acoustic pulses emit a “chirping” sound that resonates and creates an almost imperceptible vibration that helps keep the inside of the scanner clean. This way, the sensor stays clean and operational without the need for running an air purge to the top of the vessel, which can be costly.

Non-Contact Sensor Will Not Get Damaged

With an acoustic sensor, there is nothing that comes into contact with the material, making it very reliable when it is used in heavy, lump materials. There is no risk of equipment being stuck in deep material or becoming detached and potentially damaging structure or equipment in the bottom of the silo. There is no need to replace probes or cables that can wear out over time. Eliminating contact with material helps ensure long life with minimal preventive maintenance or cost.

Models for Either Level & Volume Measurement

3D Scanners – like most other measurement devices – come in a variety of models and offer a wide range of options to tailor the device to the application. To select the right model for an application, it is extremely important to communicate expectations of the technology and how you plan to use the data that you get from the device. Many plants are focused upon having a very high level of inventory accuracy. Accuracy of the 3D scanner is driven by several variables, starting with information about the size of the vessel, the presence of structure inside of it, and the material that is being measured. The installation location is also important as scanner technology measures multiple points, so the device needs to have a clear view of the material surface.

Accuracy of the 3D scanner is driven by several variables, starting with information about the size of the vessel, the presence of structure inside of it, and the material that is being measured. The installation location is also important as scanner technology measures multiple points, so the device needs to have a clear view of the material surface.

The most basic and most affordable model of a scanner is referred to as an RL, which is short for reliable level. This model measures material in a narrow beam directly below the device, penetrating high levels of dust and performing where other types of non-contact level sensors become unreliable or inaccurate. This model is most often used when highly reliable level measurement data is needed on a continual basis. This model is frequently applied in applications that are less prone to excessive buildup and in narrow or smaller silos.

The M model takes measurements from a broader 70° beam angle making it appropriate for larger diameter silos and silos with uneven material topography. It also generates additional data including the lowest, highest and average distances based upon multiple measurements. Due to its ability to scan the material surface and take into account irregularities, it can provide a very high level of volume accuracy in silos up to about 45’ in diameter.

It also generates additional data including the lowest, highest and average distances based upon multiple measurements. Due to its ability to scan the material surface and take into account irregularities, it can provide a very high level of volume accuracy in silos up to about 45’ in diameter.

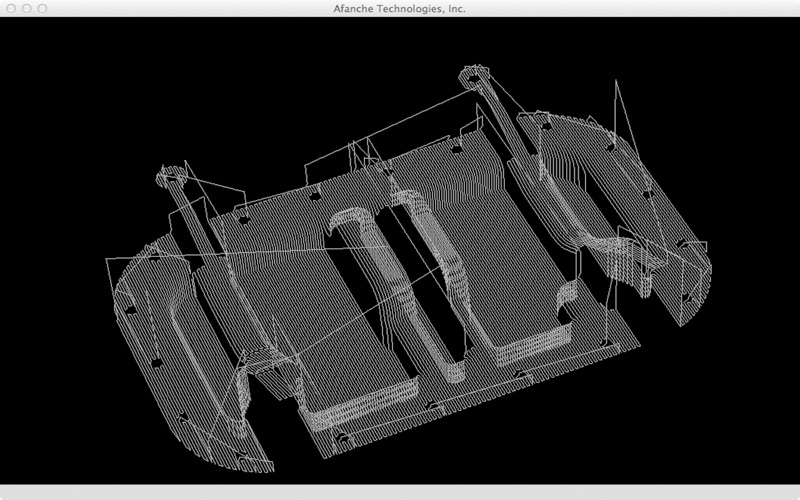

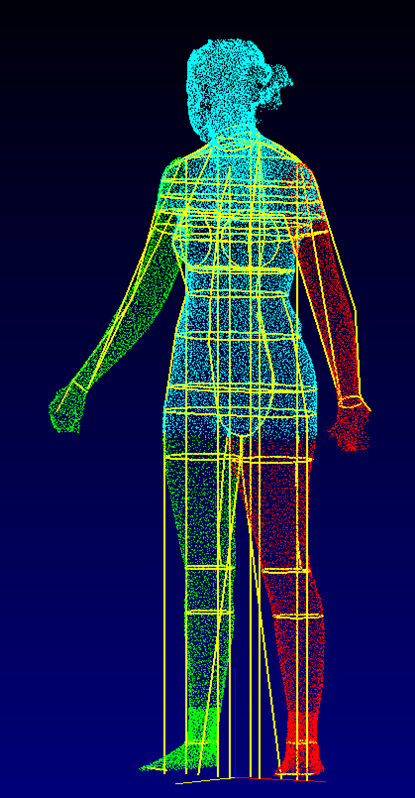

At the top of the model spectrum is the model MV, which does everything the M does, plus adds a unique visualization feature. Using complex algorithms and a lot of processing power, this model generates a 3D image that indicates where the high and low spots are in the silo, shows if the cone is up or down, and detects sidewall buildup. This additional feature can be used to help manage filling and emptying points as well as detect if maintenance is needed to clean out buildup. This model is often used in large silos where materials tend to pile up unevenly.

Other Measures to Improve Accuracy

If a silo is very wide or large, two or more scanners can be combined into a multiple-scanner system. By adding a controller that synchronizes the measurements from all the scanners on a silo, the MVL model can provide very high-volume accuracy in very wide diameter silos. The number of scanners needed on the silo is determined by how large the silo is and the desired level of accuracy. The MVL also generates a 3D visualization of the material surface from the measurements taken from all scanners.

By adding a controller that synchronizes the measurements from all the scanners on a silo, the MVL model can provide very high-volume accuracy in very wide diameter silos. The number of scanners needed on the silo is determined by how large the silo is and the desired level of accuracy. The MVL also generates a 3D visualization of the material surface from the measurements taken from all scanners.

Silos can be challenging structures to measure and often they come with some surprises that need a little “work around”. For example, sometimes there is structure in the top of the silo, so a measurement device might try to measure the structure instead of the material. Neck extensions have been designed for scanners that allow them to clear structure and see beyond it to get an accurate measurement of the material. Angled mounting flanges are designed to keep the device level, while angled mounting adaptors can be used when it is necessary to aim the device in a problematic silo.

Measure Material Piled in Domes

Not only for silos, scanners are the only type of level sensor technology today that can provide inventory information for dome structures. Due to their vast size, multiple filling and emptying points, and irregular piles of material, there just has not been a way to automate inventory management for these vast storage applications. Using multiple scanners strategically located above the material to span the entire surface is an innovative way to estimate inventory in storage domes. Advanced software combines all measurements from multiple scanners and maps them three-dimensionally to estimate the volume of material.

Due to their vast size, multiple filling and emptying points, and irregular piles of material, there just has not been a way to automate inventory management for these vast storage applications. Using multiple scanners strategically located above the material to span the entire surface is an innovative way to estimate inventory in storage domes. Advanced software combines all measurements from multiple scanners and maps them three-dimensionally to estimate the volume of material.

Caption: 3D Scanners with multiple-point measurement technology used in frack sand dome.

Summary

3D acoustics-based level sensors are revolutionizing inventory management by adding the ability to accurately estimate the volume in a silo without ever leaving the safety of an office. The data derived from these devices improves operations in so many ways by allowing for timely replenishment and purchasing, reducing safety stock, and making inventory valuation far more accurate. For plant personnel, the 3D Scanner has been a game changer, keeping personnel safe from climbing silos and making them more efficient. Scanners truly have taken volume to a new level.

For plant personnel, the 3D Scanner has been a game changer, keeping personnel safe from climbing silos and making them more efficient. Scanners truly have taken volume to a new level.

Contributed by Jenny Christensen, MBA, Vice President of Marketing, BinMaster Level Controls

Side Bar #1

How 3D Scanners Measure

The measuring range starts at 19” below the threads on the process connection (upper dead zone). Unlike any other technology, the 3DLevelScanner takes measurements from multiple points within the silo. These points detect irregular material topography to determine the volume of material in the bin. Measurement points are not simply averaged to calculate bin volume. Instead, an advanced algorithm assigns each point a “weight” to determine the true volume of material in the bin.

Side Bar #2

PROS

- Multiple point measurement

- Continuous level measurement

- Non-intrusive, non-contact technology

- Measures uneven solid material surfaces

- Detects cone up, cone down, and sidewall buildup

- Provides minimum, maximum, and average distances

- Performs in extreme levels of dust

- Calculates highly accurate silo volume due to mapping multiple measuring points on the material surface

- Measuring range up to 200 feet

- Self-cleaning with minimal maintenance

- Models for high temperature applications available

- Automatic compensation for temperature changes

- Analog and digital communication options

- Network PC software available for multiple vessel monitoring

- Generates a 3D representation of material surface

- Wireless interfaces available to reduce the need for cabling

- Approved for hazardous locations

- Not affected by material characteristics or low dielectric constants

CONS

- Elevated background noise can impact performance of acoustics technology.

- Setup requires care in mounting the sensor in the proper location and accurately mapping the vessel dimensions

- Time required to process multiple pulse echoes limits the sample rate

- Corrugation on small vessel walls can cause false echoes

- Not recommended for materials with a bulk density under 11 lb./cu. ft. due to absorption of the acoustic pulse

https://magazine.processindustryinformer.com/books/moqf/#p=99

SMARTTECh4D|3D Scanners|SMARTTECh4DDUAL VOLUME

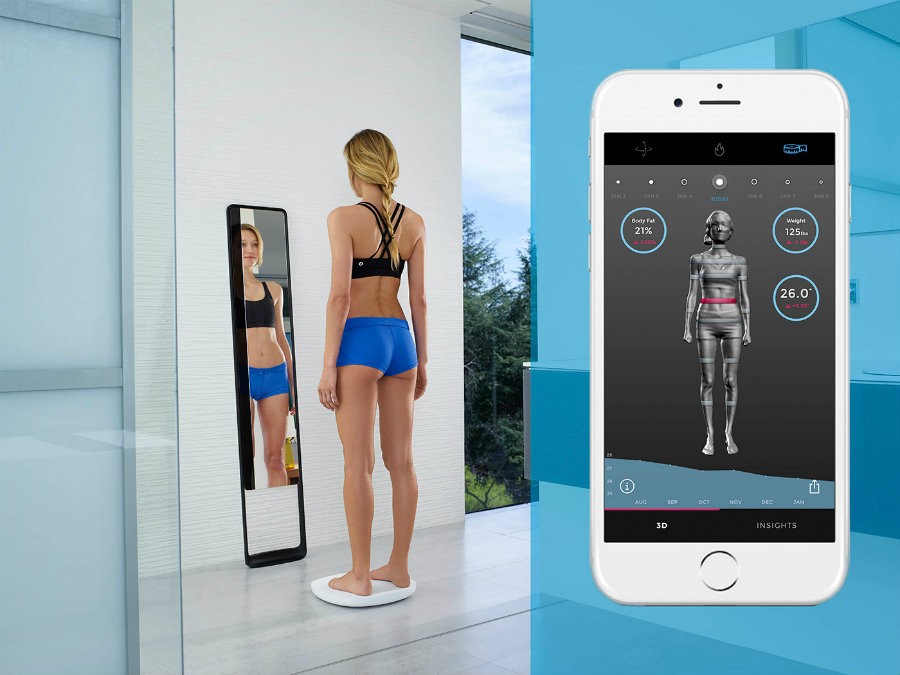

SMARTTECh4D DUAL VOLUME

The SMARTTECh4D DUAL VOLUME is a precise contactless measurement device which, thanks to the latest LED light and GigaBit Ethernet communication technologies, enables a rapid performance of complex measurements. As a professional tool for metrology each 3D scanner is certified according to the VDI / VDE 2634 standard and its accuracy can be confirmed by independent accredited metrology lab resulting in a certificate. The SMARTTECh4D DUAL VOLUME has two independent measurement volumes characterised by different work space, accuracy and measurement resolution. The large measurement volume allows for an automated measurement of overall dimensions using markers that are then merged into a single point cloud. The small volume, on the other hand, allows for the replication of even the smallest of details of the object and in a high-resolution mode (up to 1500 points/mm2).

The large measurement volume allows for an automated measurement of overall dimensions using markers that are then merged into a single point cloud. The small volume, on the other hand, allows for the replication of even the smallest of details of the object and in a high-resolution mode (up to 1500 points/mm2).

All professional 3D scanners produced by SMARTTECH are factory-calibrated “plug&scan” devices ready to work within seconds after being launched. As part of the standard equipment, a SMARTTECH 3D scanner is provided with everything you need in order to begin the 3D scanning process: lasers enabling easy positioning of the object within the measurement volume, a tripod with tilt and swivel head, a trolley for an even more user-friendly scanning and professional transport cases. The 3D scanners can operate in two scanning modes (PRECISE & FAST) for each of the measurement volumes, allowing for an additional hardware reduction of the resolution when the maximum sampling density is not required. Due to all of the abovementioned characteristics and the ability to acquire a certificate of accuracy from an accredited laboratory, our clients often call these systems optical coordinate measuring machines (CMM).

Features:

• Fast and intuitive change of the measurement volume. The end user is not required to change optics and perform a complicated process of calibration.

• Changing the field of view takes literally two pushes of a button – you just turn off the previous mode and turn on the new one. It allows us to assure a certified accuracy of the device and doesn’t force the customer to carry large calibration plates.

• Several camera configurations, ranging from 1,3 MPix up to 10 MPix allow us to find a perfect solution for the customer’s needs and budget.

• The SMARTTECh4D DUAL VOLUME operates based on the most up-to-date computing algorithms implemented in the latest SMARTTECH software - SMARTTECh4Dmeasure v2018. It allows you to perform a measurement using a 3D scanner as well as edit gathered measurement data. The implemented automation module allows us to fully automate the process of transforming the point cloud into a triangle mesh without involvement of the user and limiting his actions to placing the examined object in the 3D scanner’s field of view.

It allows you to perform a measurement using a 3D scanner as well as edit gathered measurement data. The implemented automation module allows us to fully automate the process of transforming the point cloud into a triangle mesh without involvement of the user and limiting his actions to placing the examined object in the 3D scanner’s field of view.

• Innovative white LED light 3D scanning technology. Resistant to sudden voltage drops and blackouts - assures over 20 000 working hours. Lack of any mechanical parts inside the 3D scanner guarantees long and easy usage.

The SMARTTECh4D DUAL VOLUME is used and recommended by the Automotive Industry Institute (PIMOT), KGHM Letia, Regional Center of Engineering “New Star” in Perm, as well as the National Defense University in Astana.

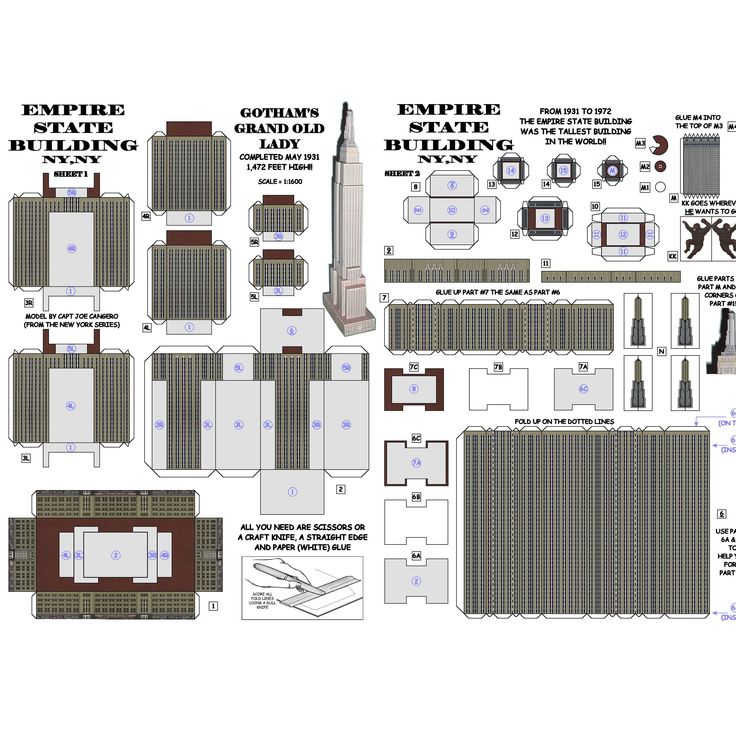

3D scanner is available with a new SMARTTECh4Dmeasure 64 Bit software. In this new software - one of the most important is the ability to display huge amount of data - point clouds where it’s size exceeds amount of 300 million pts with a speed of 5 frames per second, which allows you to work without simplifying. For less demanding projects we implemented the possibility of obtaining a triangle meshes in the STL format directly from the 3D scanner, which can be immediately sent for example to 3D printer

Check out our video:

Installation for measuring the volume of bulk materials from the manufacturer NPP Prizma

| Home / Volume measurement system for bulk materials Installation for measuring the volume of bulk materials Bulk material volume measurement unit is designed for non-contact volume measurement of bulk materials transported by a belt conveyor. The unit performs the following functions:

|

An LS2D laser scanner is placed above the conveyor belt to measure the volume of traffic. The direction of scanning is perpendicular to the direction of movement of the conveyor belt.

At the beginning of work, the zero profile of the conveyor belt is formed and set by scanning it without material. nine0008

The LS2D laser sensor scans the profile of a conveyor belt and transfers the measurement results to a computer. Based on the measurement results of an empty conveyor belt and a conveyor belt filled with material, the volume of cargo traffic for a given time interval is calculated. The use of filtering algorithms makes it possible to exclude erroneous data and improve the accuracy of measurements. The software generates a report on the measurement results.

An example of the operation of the software of the installation for measuring the volume of bulk materials:

This bulk volume measurement system can be flexibly adapted to customer requirements.

|

© 2021, NPP "Prisma" | Head office: Yekaterinburg, st. | Website development: web-studio "Fore-Site"

|

Automatic 3D package size scanner / Sudo Null IT News

We were recently given a very specific task, from the warehouse of one of the Russian distributors of electronic components, from which we send our products to our customers, among many other parcels. OK then! Let's try…. Moreover, some time ago we had such an ultrasonic sensor for measuring distances in our samples. At a price, it differed markedly from the widely used ones, but the manufacturer promised better measurement accuracy. Yes, and just at that time we made our own version of the microcontroller, compatible in functions with Arduino Leonardo, supplying the board with screw connectors, LCD sockets and a number of other gadgets designed to expand the capabilities of the module in the future. nine0008

nine0008

This is how the packer's workplace looks like, where he weighs and measures the package:

Let's try to improve and automate it.

The silver surface is scales, they are connected to the computer via their own COM port and automatically transfer the weight to the accounting system. But to measure the size of the box, local innovators placed rulers next to the scales, from improvised means. This markedly increased productivity, but data had to be entered into the system manually using the keyboard. nine0008

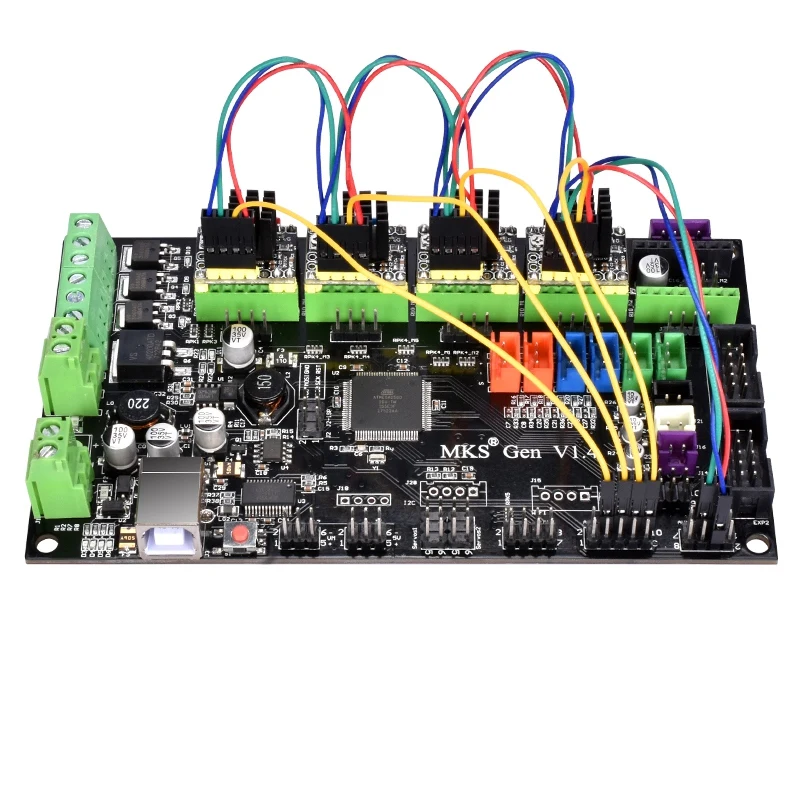

So, for the prototype, we take the workplace as a basis and add sensors to the Tree-Cartesian coordinate system, turn them inside the axes, connect them to the microcontroller, write a sketch in the ARDUINO IDE using the sensor library and built-in Leonardo capabilities. Namely, the used Atmega 32u4 microcontroller implements a connection to a computer via the built-in USB interface using HID device technology. This is how keyboards, mice, merchant barcode scanners work.![]() This is exactly what we need - to transfer data to the keyboard buffer, simulating manual data entry. nine0008

This is exactly what we need - to transfer data to the keyboard buffer, simulating manual data entry. nine0008

Watch the video, what happened in the "draft version"

We wrote a simple sketch. Having implemented only the basic functions, but nothing prevents it from being supplemented with various services such as manual calibration, changing the unit of measure, setting the transmitted characters depending on the accounting system used, etc. The controller's memory is quite large and will allow it to be done in the future if necessary.

In the meantime, the sketch works according to the following logic:

• After switching on, each of the three sensors measures the distance from itself to the opposite wall and remembers this distance as the base

• Switches to operating mode and measures the current distance cyclically

• If the current distance is noticeably different from the base one, the device considers that a box has been placed in the measurement area. The measurement takes place along three axes according to the formula:

The measurement takes place along three axes according to the formula:

Side Size = Base - Current Distance

• The three-axis dimension is written to the corresponding variables.

• Transfer to the computer is carried out by pressing a button by the operator. This is done to eliminate false positives. nine0106 • After data transfer, pressing the button is blocked until the box is removed. The system will feel this by measuring the current distance - it will again become equal to the base one.

• The cycle is repeated - the system is waiting for a new box

So, we have done, installed, set up the sensors for the experiment at fixed base distances ... and left for trial operation. What did she show? We did not obtain nanoaccuracy of measurements, but the accuracy is quite suitable for the set logistic task. nine0008

In addition:

• Performance enhancement - Yes.

• Convenience for the packer - Yes.

The second stage of our development has come - bringing it to a presentation.

It can also be used to determine the number of items moved along the conveyor. The measurement results are displayed on the PC screen or on the analog device indicator. This unit is indispensable in the production of building materials, mining, chemical, pulp and paper, food industry, processing of agricultural products. nine0008

It can also be used to determine the number of items moved along the conveyor. The measurement results are displayed on the PC screen or on the analog device indicator. This unit is indispensable in the production of building materials, mining, chemical, pulp and paper, food industry, processing of agricultural products. nine0008

March 8, p. 205, of. 319

March 8, p. 205, of. 319