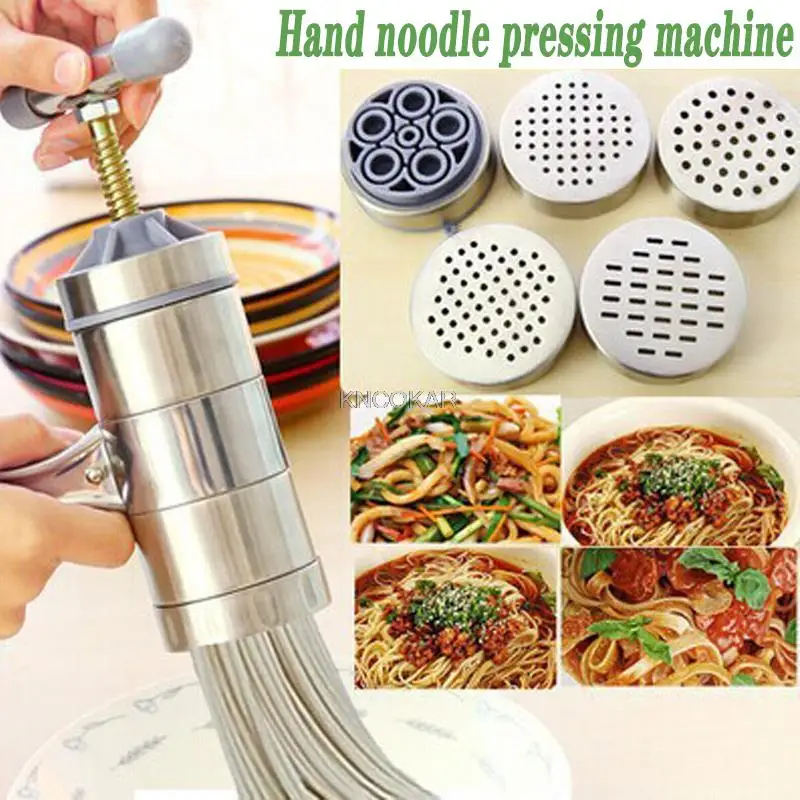

3D printed pasta maker

3D Printers Make Incredible Pastas Your Nonna Could Only Dream About

3D printed pastaIf you could make anything out of pasta, what would it be? A miniature of your cat? Edible post-it notes? A chess set?

Well start sketching, because you can. 3D printing is here to make your pasta dreams a reality.

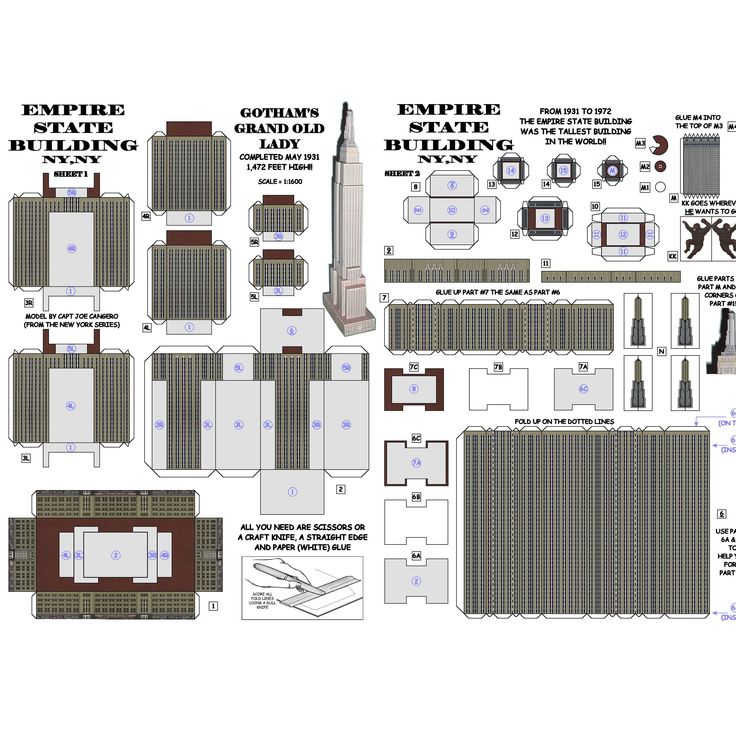

Every year, Barilla, the world's biggest pasta company, hosts a competition to create innovative new pastas for their 3D pasta printer. This year they received 1,300 design proposals, and are still in the midst of testing them out. But consider this past winner, Lune, a hollow moon-like sphere with crater-shaped holes for sauce to peek through. Or a pineapple-shaped pasta in development at the Barilla lab, with small holes to soak in sauce.

“It’s something you can’t really imagine,” says Jacqueline Delgado, the business manager of Blu 1887, Barilla’s food innovation company. “There are so many flavors and shapes that you don't realize you are eating pasta. It's hard to explain in words. ” Blu started to experiment with 3D printing seven years ago, and were able to build their own printer in 2015.

ADVERTISEMENTAD

AD

Pretty shapes are part of the fun, but the 3D-printed pasta is ultimately about innovation: using software to sculpt forms that could never be made by hand or mechanical extruder. The technology gives you the freedom to think about how geometry affects flavor and texture, and how a pasta shape interacts with a sauce.

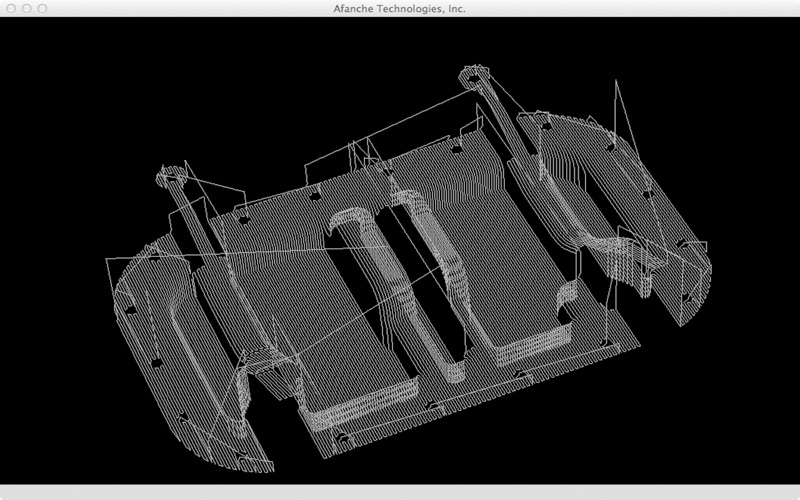

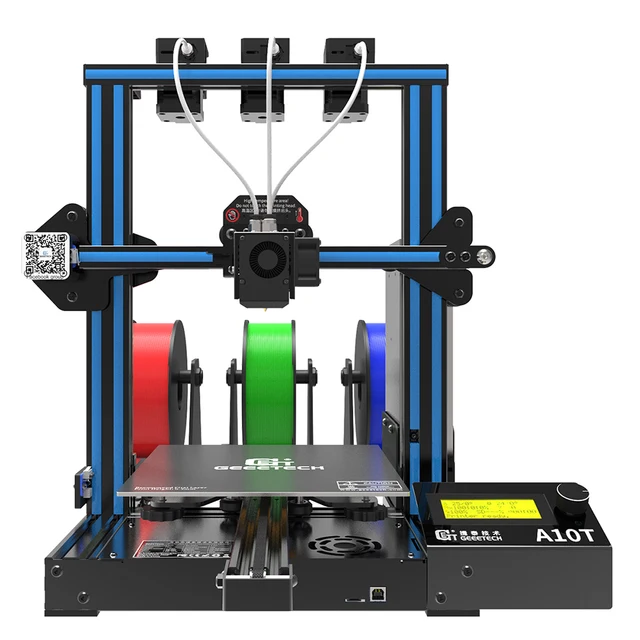

Here’s how it works: First you download your 3D model into the printer (it's the size of a small fridge), then load printer cartridges with semolina dough. And then you press print. The printer builds the pasta layer by layer, with a nozzle that moves along the X, Y and Z axes, spitting out the dough in a steady stream. It takes two to three minutes for the printer to make nine pieces of pasta.

Pasta galaxy, made by a 3D pasta printer.ADVERTISEMENTAD

AD

“We want to astonish people,” Delgado continues. “To give them pasta that can’t be done with hands. For example, for one customer we made a pasta in shape of the Eiffel Tower. We want to create totally new experiences with pasta: it can be finger food, even sweet.” She sees opportunity for custom pastas at special events like weddings, and in fine-dining restaurants.

“To give them pasta that can’t be done with hands. For example, for one customer we made a pasta in shape of the Eiffel Tower. We want to create totally new experiences with pasta: it can be finger food, even sweet.” She sees opportunity for custom pastas at special events like weddings, and in fine-dining restaurants.

The most interesting design proposal Delgado has seen? “Octopus!” she bursts in laughter. “Think about it, how it would look, if you would put it in a soup, and its arms would be all around! When you start dreaming—there are so many things you could do with pasta.”

Pasta is just one application for 3D printers and food. The first 3D restaurant in the world, Food Ink, is serving printed fine dining dishes like lobster-shaped pastries filled with lobster. And as printing technology becomes more affordable, anyone can indulge their fantasies of sculpting a hummus castle, then laying siege with with pita chips.

A 3D-printed pasta basket for your veggies.There's also a wealth of practical applications for the technology. In Germany and in Utah, scientists are printing food for elderly people who have difficulty swallowing solid foods. The machine can create elaborate-looking dishes with easy-to-chew textures, in a far more appealing and dignified presentation than a mashed-up paste. For the elderly and disabled, 3D printers offer new ways to gain access to nutritious meals without traditional cooking. The technology may not be there yet, but some day soon, it will be.

In Germany and in Utah, scientists are printing food for elderly people who have difficulty swallowing solid foods. The machine can create elaborate-looking dishes with easy-to-chew textures, in a far more appealing and dignified presentation than a mashed-up paste. For the elderly and disabled, 3D printers offer new ways to gain access to nutritious meals without traditional cooking. The technology may not be there yet, but some day soon, it will be.

ADVERTISEMENTAD

AD

A printed-out meal also offers new ways to personalize dishes to the nutritional needs of individual eaters. American company BeeHex is developing a food printer for the U.S. Army to customize meals for individual soldiers' nutritional deficits: if the soldier hasn't eaten enough protein or needs some caffeine, the printer can make a protein bar that contains everything they need, based on their ready-made profile. And in Iceland, a food and biotech research center is using printer to reduce seafood waste by using leftover fish to create new dishes.

Could 3D printers become the microwaves of the future? “Eventually, I see it happening,” says Benjamin Feltner, the COO of BeeHex. “But it's not going to compete with throwing a Hot Pocket in a microwave. Printers are to upscale your kitchen. It's like having a chef robot sitting there.”

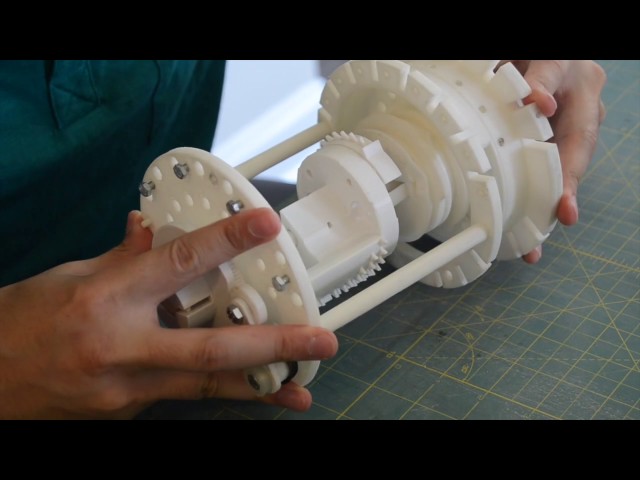

▷ philips pasta maker 3d models 【 STLFinder 】

Philips Pasta Maker Extruder.

thingiverse

This is a penne insert for the Philips pasta maker. ... 8 x 10x3 mm

Deckelöffner Philips Pasta Maker

thingiverse

Verschlussclip / Öffnergriff für den Deckel des Philips Pasta Maker Locking clip / opening handle for the lid of the Philips pasta maker You have to drill two 3mm holes. ... To fix the new part use two M3 Bolts with washers and nuts (self-locking)

... To fix the new part use two M3 Bolts with washers and nuts (self-locking)

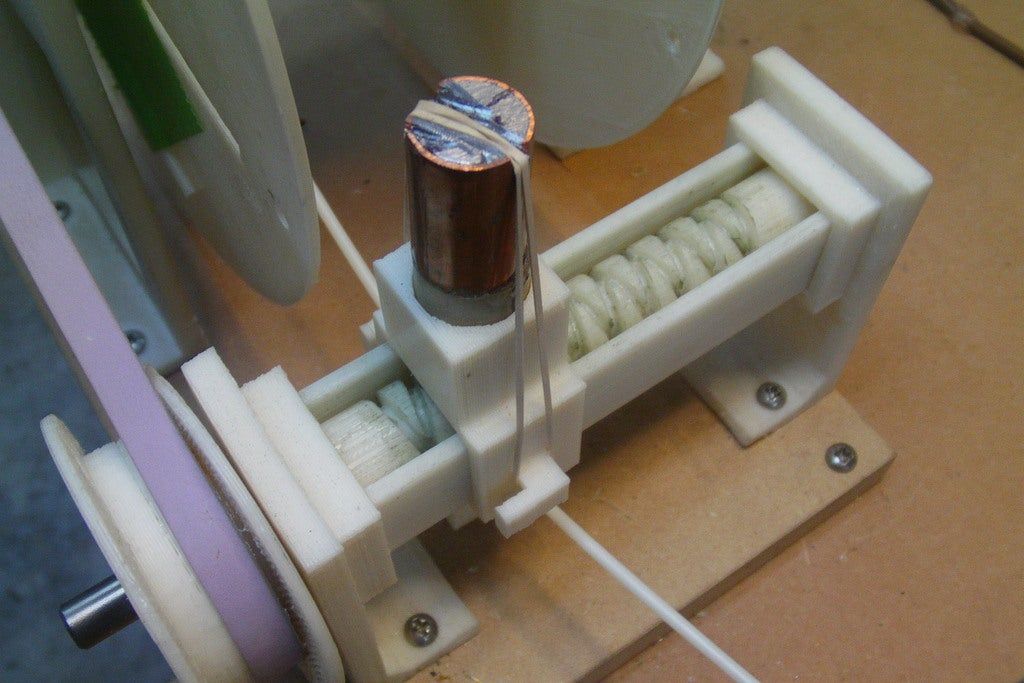

Philips pasta maker extruder

thingiverse

Extruder for Philips pasta maker. One STL makes a wide flat noodle, the other STL is blank and you can punch whatever shape you want in it. ... I updated the flat noodle extruder after failure of the first one ruined ravioli night.

Philips Pasta Maker Feet

thingiverse

Just a replacement feet for the Philips pasta maker. Originally this part is made from rubber, but I 3D printed it in PET and it works fine.

...

I have added the FreeCAD file in case you need to adjust it to your machine (https://www. freecadweb.org/) ...

freecadweb.org/) ...

Philips Pasta Maker replacement part

thingiverse

In our Philips pasta maker the core piece connecting the motor to the rotary parts broke. The pice is not available as replacement part, so i reverse engineered this part as replacement. It's not as strong, but it does its job and can be reprinted...

Philips Pasta maker Cookie blank

thingiverse

I didnt want to buy some blanks to make different pasta as they are stupid expensive when it probably cost them MAYBE a dollar to make each one MAYBE.

So i found a guy that made a blank and I modified it ti have the cookie blank. Printed it in PLA...

Printed it in PLA...

Tagliatelle pasta disc for Philips Pasta Maker

thingiverse

I design this disc for Philips pasta maker (viva model). After some test and some fails (disc broke under the high pressure of the machine) : - 0.2mm is the best for higher resistance. - 4 solid layers for top and bottom - 4 perimeters for...

Stand for Philips Pasta maker extruders

thingiverse

A stand for Philips Pasta Maker extruder. ... Compatible with official and unofficial extruders (https://www.amazon.fr/stores/page/EDA3D85E-CFE8-41A8-856D-B7783115FFF3?ingress=2)

Philips Pasta Maker Penne Plate Insert

thingiverse

This is the penne insert for the Philips pasta maker. Mine went down the disposal and got mangled. So I drew this up in Fusion 360. I printed it with the single center peg downward. The supports on that side come away pretty cleanly. I also used...

Mine went down the disposal and got mangled. So I drew this up in Fusion 360. I printed it with the single center peg downward. The supports on that side come away pretty cleanly. I also used...

Square macaroni pasta disc for Philips Pasta Maker

thingiverse

I design this disc for Philips pasta maker (viva model). After some test and some fails (disc broke under the high pressure of the machine) : - 0.2mm is the best for higher resistance. - 4 solid layers for top and bottom - 4 perimeters for...

Philips Pasta Maker HR2357 Adaptor - DIY during COVID-19

thingiverse

Philips Pasta Maker (Model Number: HR2357) parts name: adaptor, (parts number: unknown) This adaptor is connecting the motor output shaft and the kneading arm. It is somehow easily broken and difficult to find the replacement part.

...

It is somehow easily broken and difficult to find the replacement part.

...

Udon - Bigoli shaping disk for Philips Pasta Maker

prusaprinters

Shaping disk modeled to fit perfectly any Philips Pasta Maker Viva Collection. Mine follows the default 4-hole pattern which is rare for other similar models I've seen.</p><p>Be sure the printer has the wall flow calibrated, try to reduce stringing...

Philips avance pasta maker extruder support

thingiverse

A support for extruder of Philips avance pasta maker. ...You can also put the cleaning tools in it.

Tagliatelle 7mm pasta disc for Philips Pasta Maker

thingiverse

https://www.thingiverse.com/thing:4441076 presented a thumb screw to replace the wing nut on the front-left corner of the BIBO bed. It is too wide for the other two positions. I have created a smaller version to fit the right-front corner and the...

Pasta Maker Extruder Philips

thingiverse

Pasta extruder for Philips Pasta Maker Please do not hesitate to publish your 3D Print ;-)...

Pasta MAker

grabcad

Traditional Italian Pasta Maker

Strozzapreti die for Philips Pasta and Noodle Maker HR2375/06

thingiverse

This is a remix of Andreaweb80's fusilli die for the Philips Pasta and Noodle Maker HR2375/06. It is sized to be annealed after printing (if you don't know what this is please look it up) and therefore shrinking down to spec. If you try to use it...

It is sized to be annealed after printing (if you don't know what this is please look it up) and therefore shrinking down to spec. If you try to use it...

Pasta Maker - Kitchen Aid

thingiverse

#Pasta Maker # ##for Kitchen Aid and Carrera No.657 __First Version of a DIY Pasta Maker for the Kitchen Aid or Carrera maschine.__ This Design was developed to rebuild cheap hand pasta maker into a electric driven one. I use it with a Carrera...

Pasta Maker Drill Bit

thingiverse

I use it to turn my Emperia pasta maker with a drill instead of cranking it by hand. This bit might work with other brands of pasta machines you just have to print some and try it out. The STL file has one bits in it, but you should consider printing...

The STL file has one bits in it, but you should consider printing...

Pasta Maker Free 3D model

cgtrader

Pasta Maker

Philips VIVA pasta disc

thingiverse

My first attempt at making a custom pasta shape for the Philips VIVA pasta maker. ... I had to do a little bit of surgery with a utility knife after the print to get the excess material out of the way (I'm not sure why it printed this way.) Also, I had...

Philips Pasta Extruder - Udon

thingiverse

Philips Pasta Extruder for Udon Tested with model HR2375/00. ...

...

Hand crank for pasta maker.

thingiverse

If you need a new hand crank for your pasta maker, this will work. ...I've tested it.

Pasta Maker dies/extruder holder

thingiverse

I made this Pasta maker extruder holder in order to keep everything in order. ... There is space for 5 Extruders Infill 40% material PLA

Silvercrest Lidl Pasta maker dies

thingiverse

Pasta die to use with Lidl Silvercrest pasta maker machine. Die for 1.5 mm spaghetti/noodle

Die for pappardelle 1 mm

included STL and Fusion360 files to design your own.

Tested on Anycubic mono (standard resin) and Prusa MK3s. Perfect fit.

Die for 1.5 mm spaghetti/noodle

Die for pappardelle 1 mm

included STL and Fusion360 files to design your own.

Tested on Anycubic mono (standard resin) and Prusa MK3s. Perfect fit.

Sprocket gears for pasta noodles maker

myminifactory

Sprocket gears for pasta noodles maker. ...Product of Mechanika Praha.

Noodle Maker Collection for DIY Pasta

prusaprinters

Panic buyer bought all the noodles in your supermarket?Then just make your own pasta - with our DIY Pasta Collection!The first part of our collection is a noodle dough cutter to easily cut out different noodle shapes. It works like a pizza cutter,...

It works like a pizza cutter,...

Philips Pasta Extruder - Vietnamese "banh canh" version

thingiverse

My wife bought a Philips Pasta Maker ([amazon](https://amzn.to/2oI2GJ0)) and the machine is super! However, it does not have the extruder that can produce the Vietnamese pasta called "banh canh" ([wiki](https://en.wikipedia.org/wiki/B%C3%A1nh_canh))....

Pasta

sketchfab

tubo de pasta dos dentes

Pasta

sketchfab

Uploaded with 3dScannerApp. com - pasta test

com - pasta test

07.04.2021

Content

-

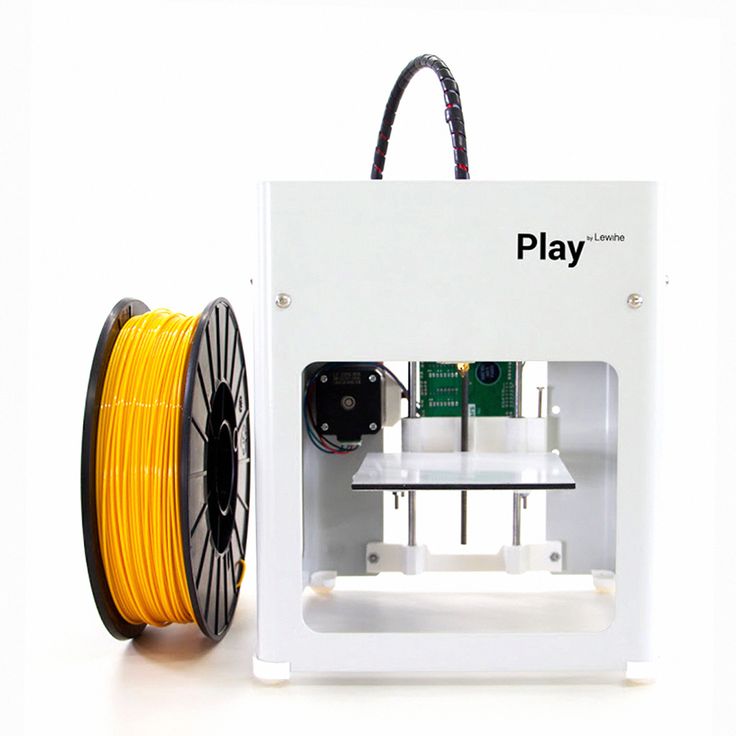

- What is a food 3D printer

- Field of use

- used raw materials

- 9000 9000 9000 9000

- Top 10 Best Food Printers: A List of the Most Current Models

- 1. PancakeBot 2.0

- 2. Wiiboox Sweetin

- 3. Choc Creator V2.0 Plus

- 4. Choc Creator V2.0 Plus Food 3D Printer with Cooling Chamber

- 5. byFlow Focus

- 6. Chefjet Pro

- 7. Foodini

- 8. Mmuse – Chocolate 3D Printer Commercial ArtcakesOT7 .90BOT Printer F5

- 10. ZMorph VX

- What is a food 3D printer

- Selection guide

- Output

A food printer is a high-tech device that is used to create culinary masterpieces. The decorative design of food products has reached a new level thanks to the use of modern technologies: high-quality and large-format printing is carried out on cakes, waffles, pancakes and even coffee. Here are the top best 3D food printers in different price categories for people who are fond of cooking. nine0003

Here are the top best 3D food printers in different price categories for people who are fond of cooking. nine0003

What is a 3D food printer

The main feature of a food 3D printer is the raw materials used: instead of printing ink, the device is filled with edible ingredients. The database stores a large number of different recipes, and in order to print a dish, you just need to select one of them and activate the printing process. The final product is layered on a work surface or on a plate: it can be baked in the oven or sent to the freezer. nine0003

Application

Futuristic 3D Printed Sugar Candy

Cookies printed with icing

Chocolate logos of famous companies

Cream Photo Print

Buying a food 3D printer is worth the owners of coffee houses, author's bakeries and private workshops. The finished product has a unique shape and bright appearance. Food printers are often used to create custom wedding cakes, cartoon character cookies, Christmas gingerbread cookies, and so on. The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products. nine0003

Food printers are often used to create custom wedding cakes, cartoon character cookies, Christmas gingerbread cookies, and so on. The possibilities of a baker who owns such a device are endless: the main thing is to buy quality products. nine0003

Raw materials used

The following ingredients are used as raw materials:

-

Chocolate without additives and impurities;

-

Mastic;

-

Sugar;

-

Whipped cottage cheese;

-

Vegetable and fruit pastes; nine0003

-

Fish and meat pates;

-

Flour;

-

Cheese, etc.

The confectionery pattern is applied to sugar, wafer or shock transfer paper. The first type has a sweetish aftertaste and aroma of vanilla. Due to the snow-white surface, no additional coating is required: the drawings look bright and clear. The wafer paper is made from rice flour and does not have a special taste, due to the light shade, the final drawings look less clear. Shock transfer paper is completely transparent and is suitable for transferring a design to a product (for example, a cake). For the packaging of finished products, food-grade plastic for a 3D printer is used. nine0003

Shock transfer paper is completely transparent and is suitable for transferring a design to a product (for example, a cake). For the packaging of finished products, food-grade plastic for a 3D printer is used. nine0003

Interesting! Food printers are involved in waste reduction. Unattractive fruit and confectionery leftovers are used in the preparation of printing mixes. This makes it possible to use the means of production more efficiently.

Types of 3D food printers

Cooking enthusiasts can take advantage of the following food printing devices:

-

Food 3D printers are devices that print dishes whose recipes are listed in a database. The final product is layer-by-layer superimposed on the work surface, and the raw material comes from filled cartridges; nine0003

-

Confectionery printers are used to transfer images onto specialty paper or to design small confectionery products such as candies.

Such printers print an image on pre-prepared paper: rice, wafer or shock transfer;

Such printers print an image on pre-prepared paper: rice, wafer or shock transfer; -

Food plotters transfer the image not to paper, but directly to the finished product. For example, a plotter is used to transfer an image directly onto a cake. nine0003

There are several types of food 3D printers:

-

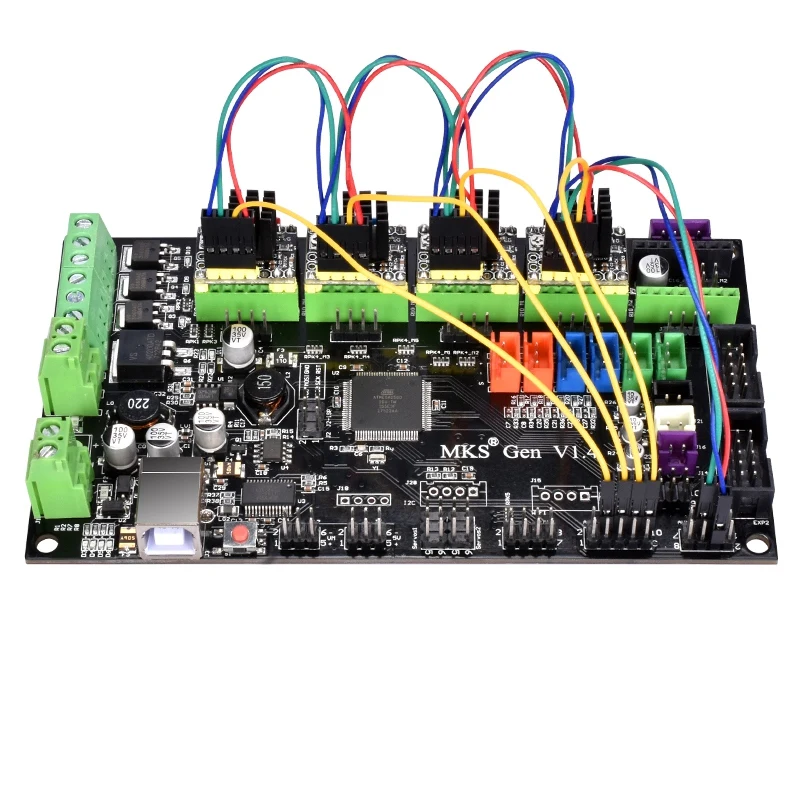

Extrusion - paint is applied to the surface before the dish is created. The process is controlled by the computer with the loaded image. The system has an extruder that heats the food mixture, and the distribution of raw materials depends on the print head. The raw material is loaded into a syringe placed in the head. This means that in order to combine different shades, you have to periodically stop printing and change the syringe; nine0003

-

A carousel-type food 3D printer also has an extruder, but its main feature is the method of feeding raw materials: the containers rotate around the working surface, the supply and dosage of the material used depends on the recipe specified in the program.

The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

The storage can contain countless recipes, and operation does not cause difficulties even for an inexperienced user.

Popular brands

Eminent manufacturers offer the best value for money food 3D printer. Quality devices provide accurate printing, high speed, durability, simplicity and ease of use.

Wiibox

This company manufactures 3D printers with high build quality and high productivity. These are universal mechanisms that fill both chocolate paste and mashed potatoes. Numerous positive reviews confirm the high quality of Wiibox products. nine0003

byFlow

The Dutch company byFlow specializes in food printing technology. The pursuit of excellence helps the company open up new horizons: the technique prints products from spinach, meat emulsion and other materials. High build quality, ease of use and durability - all these characteristics are applicable to the products of this company.

Choc Edge

Choc Edge is committed to revolutionizing the world of chocolate making. Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Numerous experiments and focus on consumer feedback help to create more powerful devices that provide the optimal temperature for preparing and storing chocolate figures.

Attention! Printing dishes helps save time on cooking: instead of culinary worries, the user can simply activate the printing process and get on with other things.

nine0134Free shipping

Add to compare

Item added to compare Go

Manufacturer Choc Edge Available on credit. To checkout, add the product to the basket and follow the instructions Go nine0003

Manufacturer Wiiboox Free Shipping

Add to compare

Item added to compare Go

Manufacturer Choc Edge Top 10 Best Food Printers: List of the Most Current Models

Before you buy a food 3D printer, you need to familiarize yourself with the most popular devices on the world market.

The top is based on ratings and customer reviews. nine0003

1. PancakeBot 2.0

PancakeBot 2.0 is easy to use, which means it's suitable for inexperienced users too. Users can choose from suggested designs in the software, or create their own. Used to print pancakes.

Pros:

Ease of operation;

A wide range of proposed projects; nine0003

High speed.

Cons:

2. Wiiboox Sweetin

Buying a food printer from Wiiboox is worth not only for confectionery lovers, but also for ordinary chefs: the device prints cakes, cookies and even mashed potatoes. The main raw materials can be meat, cheese, chocolate, jam, mashed potatoes, dough and much more. A convenient touch panel helps to set the desired mode of operation, and a stylish appearance complements the interior of any establishment. nine0003

Pros:

Versatility: the ability to print not only sweet dishes, but also side dishes;

Attractive appearance;

High build quality;

Convenient control by touch panel.

nine0173 Cons:

High price.

3. Choc Creator V2.0 Plus

When talking about which chocolate 3D printer to buy, it is worth mentioning the numerous advantages of Choc Creator V2.0 Plus. The new model has become more perfect: the developers have worked hard to eliminate the shortcomings of the previous version. The modern model has small dimensions, thanks to which it can be used in any kitchen, and the uniform heating of the syringe ensures high-quality and uninterrupted operation. In practice, the chocolate printer has shown tremendous potential: it prints complex figures from chocolate. nine0003

Pros of :

Attractive appearance;

Uninterrupted work;

Durability;

The ability to create durable and beautiful chocolate figures.

Cons :

4.

Choc Creator V2.0 Plus 3D food printer with cold chamber

The new version of the Choc Creator V2.0 Plus printer is equipped with cooling chambers by popular demand. Users say that it is too problematic to maintain the optimal temperature in the room to preserve the integrity of the chocolate figurines: therefore, the new device cools the raw materials. The price of a food 3D printer with a cooling system is somewhat higher than a classic one, but the high performance of the final product justifies any costs. nine0003

Pros of :

Availability of a cooling system for finished products;

High printing precision;

Long service life;

Ease of use: You can turn the fans on and off with the side buttons.

Cons :

High price.

Attention! Confectionery food 3D printers are often used by artists to create edible masterpieces.

This is a unique technology that helps to unleash the creative potential of the chef.

5. byFlow Focus

Food printer from the Dutch company byFlow, which specializes in 3D printing of food. The compact high-tech device is used for the bakery industry, and the cartridges are suitable for the application of any pasty ingredients. nine0003

Pros:

Cons:

6. Chefjet Pro

Buying a ChefJet Pro food printer is a must for people who dream of making bright and stylish sweets. The device is created on the principle of inkjet printing: sugar-containing powder materials are used instead of paints. The final product is made by powder layering. The printer is suitable for combining different shades and creating gradients. nine0003

Pros:

The ability to create unique flavors;

Neat and bright printing;

Aesthetic appearance of the device.

Cons:

- nine0015

High price.

7. Foodini

The 3D food printer from Foodini works on the principle of a stationary printer, but instead of printing inks, layer-by-layer imposition of edible raw materials is used: dough, cream, chocolate, cream, etc. The device is versatile: the user himself can choose the material, or use ready-made cartridges with products.

Pros:

Practicality; nine0003

High build quality;

Attractive appearance;

Availability of an online platform with unique recipes.

Cons:

8. Mmuse – Chocolate 3D Printer

The closed MMuse 3D printer is suitable for chocolate printing. Chocolate beans are used as raw materials: they are heated in an extruder and fed to the work surface through the print head.

nine0003

Pros:

Cons:

9. ZBOT Commercial Art Pancakes Printer F5

ZBOT Commercial Art Pancakes Printer F5 3D Printer

A food printer from Chinese manufacturers is used in the process of making pancakes of various shapes. Ease of operation allows the device to be used by children under adult supervision. nine0003

Pros:

Ease of operation;

High build quality;

Affordable cost.

Cons:

10. ZMorph VX

A multifunctional 3D printer capable of printing not only food, but also rubber, ABS plastic, polylactide, PVA, nylon, elastic and metal materials. The product is able to print with chocolate, butter, cookies, icing and other ingredients. In addition, there is a function of engraving and CNC milling. nine0003

Pros:

Cons:

High price.

Selection guide

The modern market offers a wide range of food printers. Before making a purchase, you need to carefully study the characteristics of each model and build on your own preferences. Experts have created several recommendations for choosing: nine0003

In case you want to create realistic images for confectionery 3D printing, pay attention to the diameter of the nozzle: the narrower it is, the more accurate the image will be;

- nine0007

It is better for people living in regions with a warm climate to purchase chocolate 3D printers with a cooling system: such devices ensure that the figurines are kept at the optimum temperature;

The possibility of self-refilling the cartridge is the most practical and economical way to operate the printer;

Print speed is an important consideration for restaurant owners. Large batches of dishes must be produced quickly, and for home use this is not a very strict selection criterion.

Output

In the catalog of our online store, you can choose the best food printers from famous brands to create culinary masterpieces. Explore our range, learn about the characteristics of each printer and make great purchases. nine0003

#Useful

Expert in the field of additive and subtractive technologies, 3D equipment and CNC machines with over 10 years of experience.

Share

all materials

Overview of 3DCeram ceramic 3D printers

Ceramic is a unique material. Due to its low weight, strength, chemical resistance, toughness and biocompatibility, the resource is in demand in various industries, providing the ability to quickly produce useful things on a 3D printer. Additive manufacturing of ceramic products allows you to create objects of individual configuration. The technique involves the prompt introduction of design changes and helps to achieve the desired characteristics of a part or a finished item.

nine0003

Printing technologies used

Ceramic 3D printing is done in different ways: paste extrusion, powder sintering or photopolymerization.

But most often ceramic printers work on SLA technology. The method is based on the illumination of ceramic paste with a laser to form three-dimensional objects or prototypes. The construction is done in layers, and each layer is scanned and drawn with a beam according to the digital model. After building the next level, the working platform is lowered to a given layer thickness, a new portion of the paste is leveled, and the process of scanning the next section of the part is performed. nine0003

The technique helps to achieve uniform shrinkage during sintering, which guarantees maximum accuracy in the construction of the element.

The Ceramaker 3D printer series is a development of the company that implements the additive technology of layer-by-layer curing of a specialized paste - a composite of a photopolymer substance with ceramic powder.

After completion of the model building cycle, the surface is freed from particles of non-polymerized composition and washed in a special solution. Then the object goes through the stage of burning out the photopolymer, which acts as a temporary binder. Next, the final sintering of the workpiece at a high temperature is performed. nine0003

Ceramic Printing Materials

3DCeram has developed original formulations that use its ceramic 3D printers. Raw materials are fed evenly, with a given accuracy, which ensures the high quality of the manufactured object and its compliance with strict industrial criteria.

Ceramic resources are neither metallic nor organic. Usually they are molded at room temperature, and acquire special properties during the sintering process. The choice of material for printing a product depends on the conditions in which the parts are to be used. nine00033DCeram offers the following options:

Zirconia is a material with excellent mechanical properties that are stable at all temperatures.

The composition is characterized by low thermal conductivity and chemical inertness. Products from this resource are hard and wear-resistant.

Alumina is the base material required by the industry. AL203 stands out for its mechanical strength and is a good dielectric. nine0057

Silicon nitride - compound resistant to heat and corrosion. The resource is actively used in the manufacture of pumps and valves.

Silicore is a compound used to make blade cores. Porous ceramics with good leaching properties are compatible with various alloys.

Tricalcium phosphate is a biocompatible raw material used for the production of implants;

Hydroxyapatite is a resource in demand in biomedicine for “growing” bone substitutes, since it is characterized by good osseointegration; nine0003

Aluminum nitride - electrical insulator with high thermal conductivity, in demand in the electronics industry;

Cordierite is a low thermal expansion ceramic suitable for vacuum applications.

Raw materials are supplied by means of a hopper filled before starting the printer. However, the device can also be filled while the equipment is in operation.

Ceramic 3D printer software

The company supplies equipment with open source software that allows the buyer to develop and use their own formulations. The printers support Windows, Linux and OSX operating systems.

Review of 3DCeram ceramic 3D printers

The French engineering company offers interesting solutions for the manufacture of complex ceramic parts for various industries. What can be done with a 3D printer for sale? The possibility of printing finished items and individual elements of ceramics interested jewelers and watchmakers. End products and spare parts are durable, resistant to scratches and chips, hypoallergenic. 3D printing with clay is in demand for creating designer masterpieces, art objects and interior elements. Also, proprietary technology is actively involved in the aerospace and aviation industries, mechanical engineering, and biomedicine.

nine0057 The Ceramaker printer series is designed to produce detailed and functional elements with consistently high quality.

Popular ceramic printers

The Ceramaker 100 is a development and prototyping device. The printer is easy to operate and uses materials economically. The equipment is equipped with modules of various sizes, which makes it possible to optimize the consumption of paste during printing. Open settings allow you to adapt to personal requirements. nine0003

Ceramaker 900 – industrial technology. The device creates models with high surface quality, is used to manufacture functional elements that have the same characteristics as parts created by traditional methods (pressing, casting). It is the only machine on the market capable of producing objects according to the established specifications and criteria of the end user. This multi-component printer is capable of producing both simple structural elements and full-fledged functional devices.