3D printer india online

Online Jewellery 3D Printing Service

LEARN MORE

1. What is Jewellery 3D Printing Service?

Jewellery 3D Printing Service allows you to fabricate various kinds of jewellery models within a matter of a few hours. The outputs are non-toxic, ready for hand-modeling, and extremely accurate.

2. Why should you opt for Jewellery 3D Printing Service?

Jewellery 3D Printing Service allows jewellery desginers, and jewellery shop owners to make realistic prototypes that can be cast or produced for end-usage. This method is faster, cheaper, and more accurate.

3. What is Digital Jeweller?

When you 3D print jewellery models using online services such as Makenica then you become a digital jeweller instead of a traditional jeweller who use traditional casting methods for jewellery making.

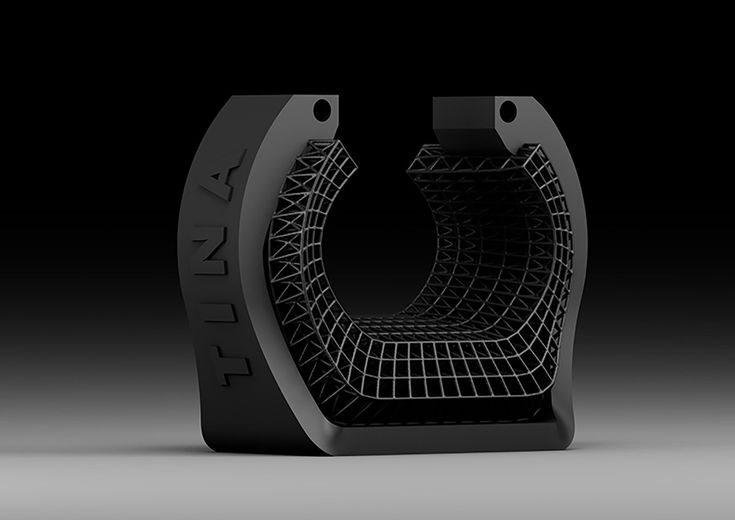

4. What is Digital Jewellery?

Digital Jewellery is the scientific name when using additive manufacturing services for jewellery and fashion applications. These services include SLA, DLP, among many others.

5. How does Digital Jewellery or Online Jewellery 3D Printing works?

Once the CAD/CAM design is completed, you can share the designs with us or upload it here. Once we receive the design, we start production as per your requirements. Apart from that, in order to produce end parts, here are a few steps that will help:

Step 1: Prototyping (using jewellery 3d printing services like Makenica.com)

Multiple iterations of a design are 3D printed with standard resin.

Step 2: Fitting & Customer Feedback

3D printed models are used for fitting and gathering customer's feedback.

Step 3: Investment pattern

Castable resin is used to 3D print an investment pattern of the final design.

Step 4: Casting (can be done using traditional method or jewellery 3d printing services)

The pattern is used to make a mold for the target material.

6. What are the Jewellery 3D Printing Service tolerances?

Here are some of the Jewellery 3D Printing Services tolerances:

| Distance Dimensions | +/- 25 microns accuracy on either side is typical. |

| Shrink Mitigation | A shrinkage rate of +/-0.15% can be expected due to the thermal expansion of the liquid, and the response of the flexible mold. |

| Surface Quality | The surface finish is externally smoothed to a glossy, satin, or matte surface. |

| Feature Definition | Extreme sharp corners and small text may appear slightly rounded. |

| Size Recommendation | Parts can be as large as 500mm on any one side. |

7. What is the minimum order quantity for Jewellery 3D Printing Services?

There is no minimum order quantity for ordering online. Although you can get cost benefits when you order in larger quantities.

8. What are the size limitations for Jewellery Casting Service?

| Maximal part size | 500 mm (40in) |

| Minimal part size | 0.1 mm (100 microns) |

| Minimal diameter | 0.1 mm (100 microns) |

9. What is the assurance on the output quality of the 3D Printed Jewellery Parts?

What is the assurance on the output quality of the 3D Printed Jewellery Parts?

Every Jewellery 3D Printing service order includes our standard inspection file that includes reports and certifications such as:

- Critical dimensions

- Quantity of parts

- Removal of sharp edges and burrs

- Number of parts inspected

- Surface finish

- Threads and tolerances

- Full dimensional inspection report

- Resin material test report

- ISO9001, ISO14001, ISO27001, and IATF 16949 certifications

10. Which cities do we provide Jewellery 3D Printed Services or 3D Dental Dentistry Services in?

Makenica provides Jewellery 3d printing services in all tier-1,2 & 3 cities.

TIER-1 CITIES:

Bangalore

Chennai

Delhi

Hyderabad

Kolkata

Mumbai

Ahmedabad

Pune

TIER-2 CITIES:

Agra

Ajmer

Aligarh

Amravati

Amritsar

Asansol

Aurangabad

Bareilly

Belgaum

Bhavnagar

Bhiwandi

Bhopal

Bhubaneswar

Bikaner

Bilaspur

Bokaro Steel City

Chandigarh

Coimbatore

Cuttack

Dehradun

Dhanbad

Bhilai

Durgapur

Erode

Faridabad

Firozabad

Ghaziabad

Gorakhpur

Gulbarga

Guntur

Gwalior

Gurgaon

Guwahati

Hamirpur

Hubli–Dharwad

Indore

Jabalpur

Jaipur

Jalandhar

Jammu

Jamnagar

Jamshedpur

Jhansi

Jodhpur

Kakinada

Kannur

Kanpur

Kochi

Kolhapur

Kollam

Kozhikode

Kurnool

Ludhiana

Lucknow

Madurai

Malappuram

Mathura

Goa

Mangalore

Meerut

Moradabad

Mysore

Nagpur

Nanded

Nashik

Nellore

Noida

Patna

Pondicherry

Purulia Prayagraj

Raipur

Rajkot

Rajahmundry

Ranchi

Rourkela

Salem

Sangli

Shimla

Siliguri

Solapur

Srinagar

Surat

Thiruvananthapuram

Thrissur

Tiruchirappalli

Tiruppur

Ujjain

Bijapur

Vadodara

Varanasi

Vasai-Virar City

Vijayawada

Visakhapatnam

Vellore

Warangal

3D Printing Services in Bangalore

1. What is 3D printing and how does it work?

What is 3D printing and how does it work?

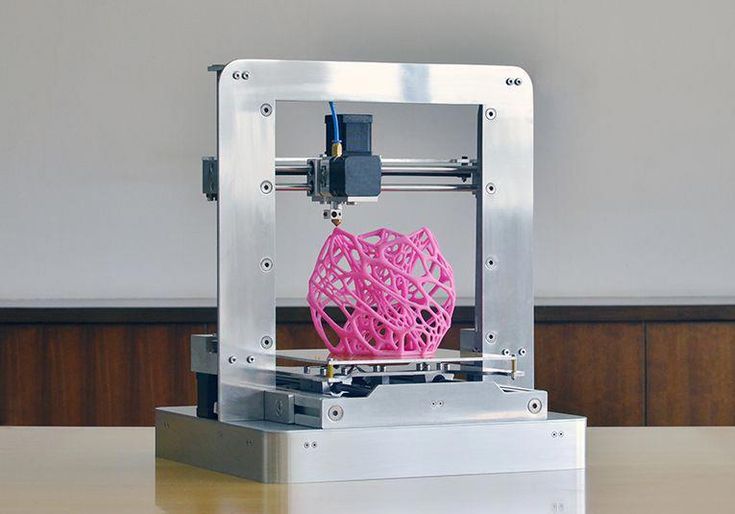

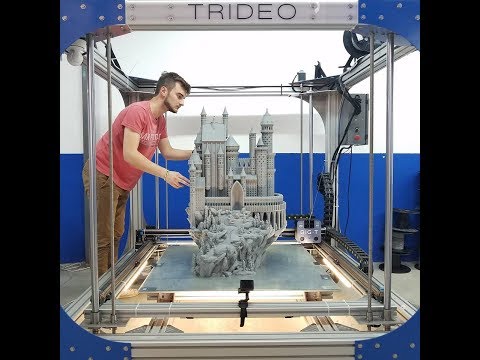

3D printing Bangalore is the process of creating a three-dimensional, physical object from a digital model. 3D printing service is sometimes referred to as “additive manufacturing,” although this term is used more frequently within the manufacturing industry to describe online 3D printing’s role in the industrial process.

3D printing in Bangalore begins with a 3D CAD model that is sliced into fine layers. The software turns these layers into instructions for your 3D printer, which deposits material layer by layer until the model is replicated. Excess material is removed post-process, leaving the user with a complete physical object. The software and materials that are used vary depending on the user’s intended application for the product.

2. What materials can be used in 3d printing?

Below are the materials used for 3D Printing in Bangalore:

ABS

ABS is a low-cost material, great for printing tough and durable parts that can withstand high temperatures while 3D Printing online.

Flexible

Flexible filaments, commonly referred to as TPE or TPU, are known for their elasticity allowing the material to easily stretch and bend for 3D Printing in Bangalore.

PLA

PLA is the go-to material for most users due to its ease-of-use, dimensional accuracy, and low cost.

HIPS

HIPS is a lightweight material most commonly used as a dissolvable support structure for ABS models in online 3D Printing India.

PETG

PET and PETG filaments are known for their ease of printability, smooth surface finish, and water resistance.

Nylon

Nylon is a tough and semi-flexible material that offers high impact and abrasion resistance. It is an ideal choice for printing durable parts.

Carbon Fiber Filled

Carbon fiber filaments contain short fibers that are infused into a PLA or ABS base material to help increase strength and stiffness.

ASA

ASA is a common alternative to ABS and is great for outdoor applications due to its high UV, temperature, and impact resistance for 3D Printing in India.

Polycarbonate

Polycarbonate is known for its strength and durability. It has very high heat and impact resistance making it an ideal choice for tough environments.

Polypropylene

Polypropylene is great for high-cycle, low strength applications due to its fatigue resistance, semi-flexible, and lightweight characteristics.

Metal Filled

Metal filled filaments are made by mixing a fine metal powder into a base material, providing a unique metallic finish, and added weight.

Wood Filled

Wood filaments combine a PLA base material with cork, wood dust, or other derivatives, giving the models a real wooden look and feel.

PVA

PVA is commonly known for its ability to be dissolved in water and is often used as a support material for complex prints in 3D Printing Bangalore.

3. Is 3D printing the future?

In short, Yes. 3D printing in Bangalore provides the design freedom to experiment with more effective and efficient part shapes, with fewer potential points of failure improving the management of a sensitive thermal environment. As product development cycles shrink across every industry, these capabilities give manufacturers a level of design, production, and supply chain flexibility previously unobtainable.

4. Why is 3D printing not popular?

3D printing Bangalore is an upcoming technology, and it is already a part of INDUSTRY 4.0 . But on par we have to accept the fact that it is not commonly used except for the industrialists down the lane. According to us, a few reasons for its reduced popularity:

- 3D printers are costly ones but a one time investment.

- Basic CAD knowledge is necessary for working with 3D printing in Bangalore.

- Above all there are no predetermined properties for the printer materials i.

e., we do not know the performance of 3D printed materials

e., we do not know the performance of 3D printed materials - Any breakage caused by the whole component has to be replaced . It cannot be repaired unlike steel components.

5. Limited raw materials, not all material can be 3d printed with 3D Printing Bangalore.

5. Is 3D printing time consuming?

The quantity of parts being produced also has an impact on the amount of time it takes to complete a 3D printing Bangalore job. However, the reduction in print time is not as greatly reduced for more complex parts with short layers as the actual printing process is still fairly time-consuming.

6. How popular is 3D printing in Bangalore?

With the help of 3D Printing Bangalore, you can print anything from electronics to jewellery just sitting at home. Yes, that is what 3d printing service does! It has been in use in the industrial setting for almost 30 years and now it is advancing towards consumer as well as small scale-oriented businesses in Bangalore.

7. What can 3D printers make?

There’s much more on the list of applications for 3D printing in Bangalore, all happening now in myriad industries using a variety of innovative technologies and materials. Think dentistry, eyewear, prosthetics, furniture design, archaeology, palaeontology, and forensic sciences, to name just a few. And you can be sure that the creative and diverse uses for 3D printing Bangalore will continue to grow — and continue to improve the way we live and work.

8. Is nylon good for 3D printing?

Yes. When it comes to 3D printing materials, Nylon has to be mentioned as one of the most popular materials for professional users. This can be attributed in large part to its popularity outside of 3D printing Bangalore. Nylon has a wide range of applications thanks to its unique properties and the benefits of 3D printing in Bangalore mean that parts can be made on the fly easily and inexpensively.

9. Is there a Limitation to what shapes you can 3D print?

No limits in terms of shapes, but no information on manufacturability. One of the principal advantages of 3D Printing Bangalore is that it is possible to imagine all shapes without the limits of the constraints of the plastics industry, such as undercuts, hollowness, respect for thicknesses, etc.

One of the principal advantages of 3D Printing Bangalore is that it is possible to imagine all shapes without the limits of the constraints of the plastics industry, such as undercuts, hollowness, respect for thicknesses, etc.

10. How can Makenica help me?

Makenica offers 3D Printing services in India with which it is possible to print complex geometric shapes and interlocking parts that require no assembly. It is also possible to produce single objects, in small quantities, at low cost and fast delivery. This technology of 3D Printing Bangalore at Makenica also helps in the reduction of production-related material loss.

11. Why to Choose Our 3D Printing Service in Bangalore?

Here are the reasons why 3D Printing Bangalore with Makenica is popular:

- Flexible Design

- Rapid Prototyping

- Print on Demand

- Strong and Lightweight Parts

- Fast Design and Production

- Minimising Waste

- Cost Effective

- Ease of Access

- Environmentally Friendly

- Advanced Equipment

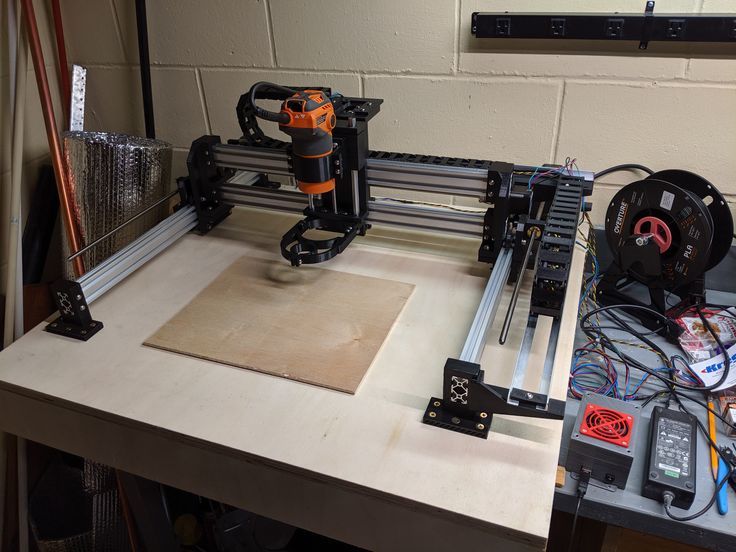

12. What types of 3D printers are there?

What types of 3D printers are there?

The seven different types of 3D printers used for 3D Printing in Bangalore are:

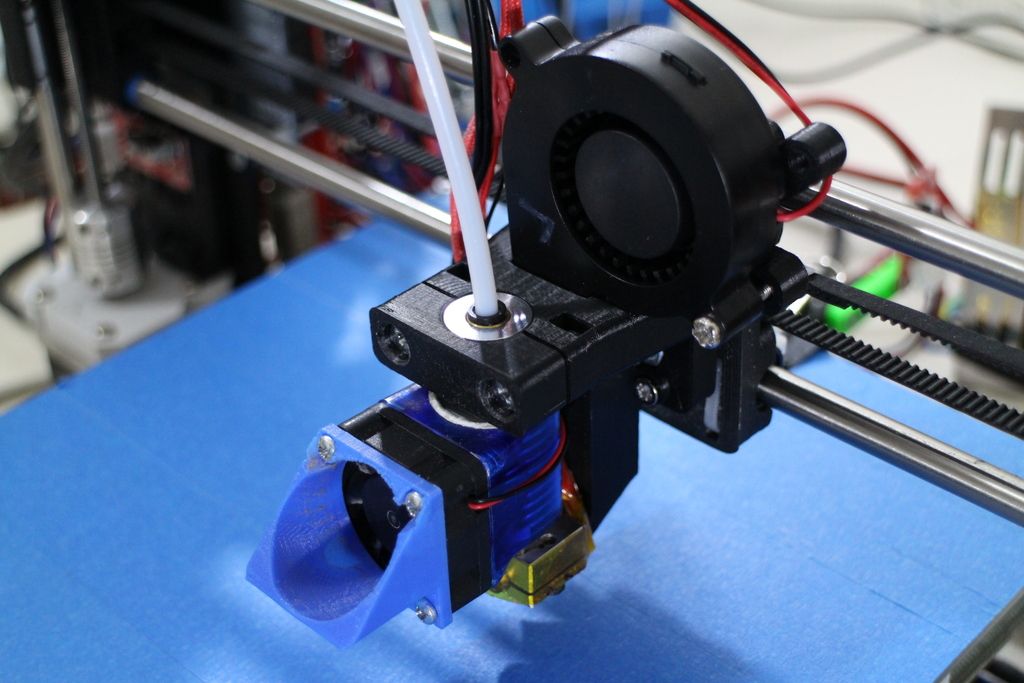

Fused deposition modelling (FDM)

Stereolithography(SLA)

Digital Light Processing(DLP)

Selective Laser Sintering (SLS)

Selective laser melting (SLM)

Laminated object manufacturing (LOM)

Digital Beam Melting (EBM)

13. Which Cities Makenica Service in India ?

Makenica, with a significant presence, is the country's greatest pool of 3D Printing expertise, with competent professionals. Makenica has five facilities in Bangalore, with headquarters in the United States. This broad reach has enabled us to provide excellent service to a large customer base. The online 3D Printing services available at Makenica range from personalised to one-of-a-kind bespoke solutions. Each customer is guided on their route to quality production by our team of specialists.

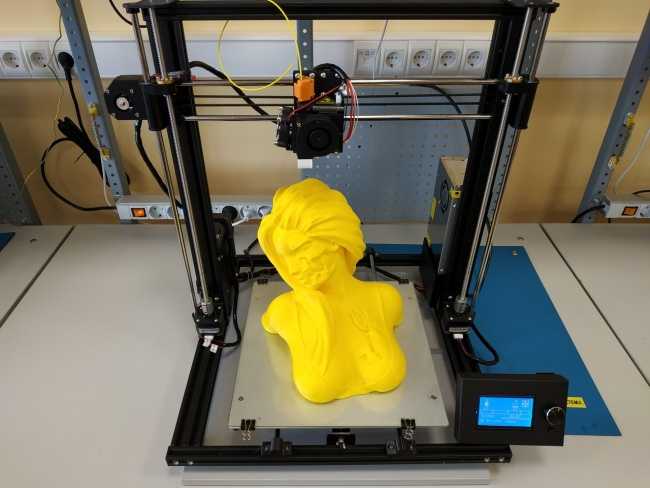

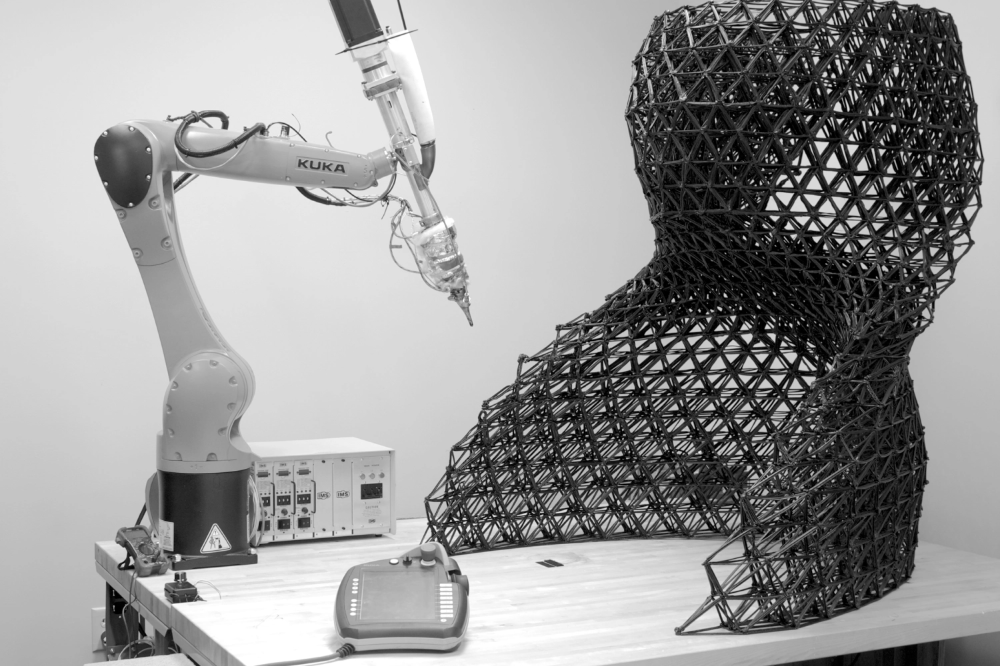

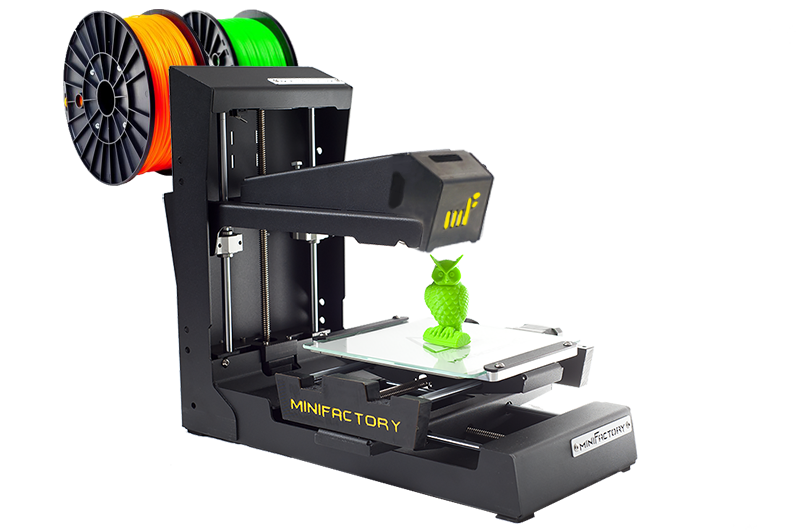

Vector PLA 3D - India's first 3D printer

Archive

China is rapidly catching up with the West, breaking down barriers and expanding its reach in the 3D printing and additive manufacturing industry.

South Korea is also striving to take its rightful place in this industry. Through government funding programs and the creation of new initiatives, they plan to significantly increase their presence in the 3D printing market. However, the second most populous nation on the Asian continent, India, has barely made it to the front of the 3D printing industry. But that could change quickly in the near future.

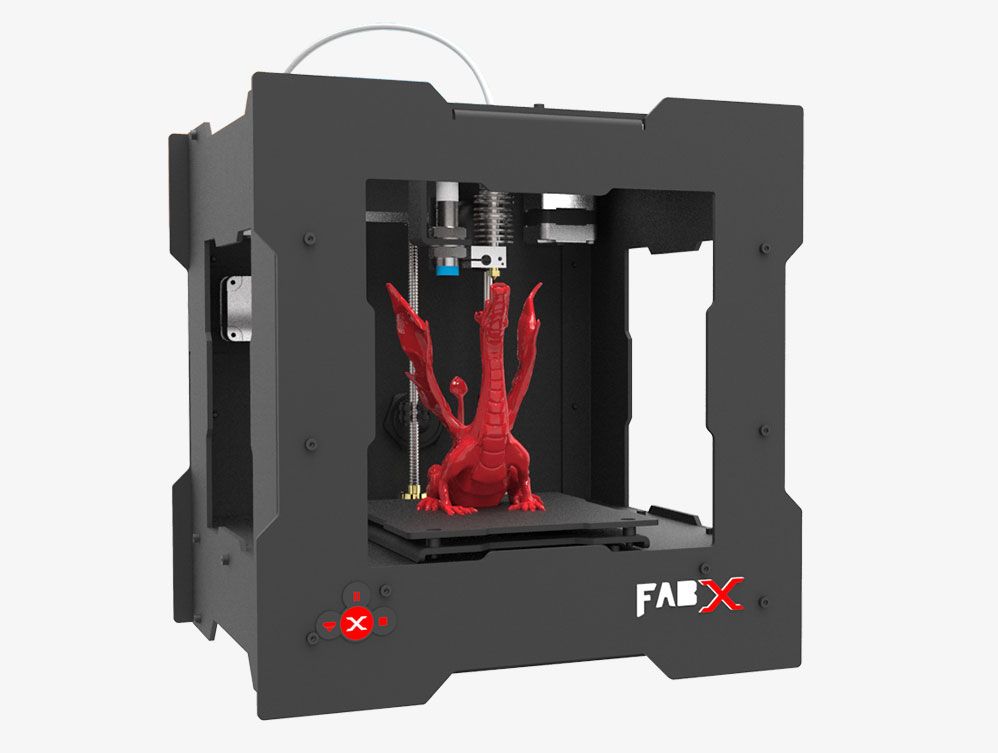

South Korea is also striving to take its rightful place in this industry. Through government funding programs and the creation of new initiatives, they plan to significantly increase their presence in the 3D printing market. However, the second most populous nation on the Asian continent, India, has barely made it to the front of the 3D printing industry. But that could change quickly in the near future. Mumbai-based J Group Robotics™ today announced the launch of India's first Vector PLA 3D 3D printer. Vector PLA 3D will be available in seven different colors and will be priced at Rs 149,000 ($2276).

The main specifications of this new 3D printer are listed below:

- Working volume: 190 x 190 x 210 mm

- Designed for materials: PLA, ABS+, wood, stone, glow in the dark filaments

- Compatible with operating systems: Windows, Macintosh and Linux

- Print resolution: 100 microns

- Layer thickness: 20 µm (minimum error is 0.

020000 mm)

020000 mm) - Software: Printware

- Supported file types: STL / .OBJ / .DAE / .AMF

- Other: SD card slot

The company says Vector PLA 3D is designed for the manufacturing industry at all levels, but is also reasonably affordable for printing enthusiasts and those who would like to have a 3D printer at home. With India's rising middle class, perhaps now is the time to introduce this printer to the country.

“3D printing is a revolutionary technology and by offering Vector PLA 3D we aim to help reduce the cost of prototyping in the manufacturing industry,” said Vishal Jariwala, Founder and Chairman of J Group Robotics. “We want to go beyond Mumbai. We organize seminars and workshops in schools and colleges where we help students with projects related to the creation of 3D printed robots.”

It is certainly good to see that India has also joined a number of countries developing this new and promising industry. After all, the more competition appears in this area around the globe, the faster innovations will appear, which means that this technology will be able to take its rightful place in the life of each of us.

After all, the more competition appears in this area around the globe, the faster innovations will appear, which means that this technology will be able to take its rightful place in the life of each of us.

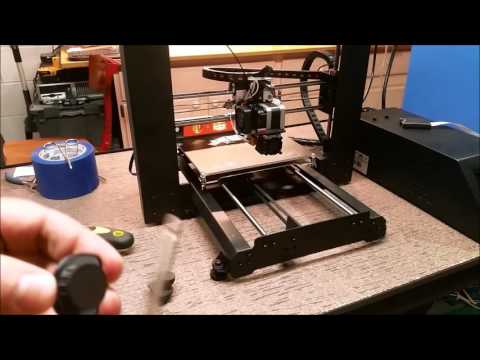

In the video below you can see the new Vector PLA 3D printer from India in action:

Share your thoughts on this new printer and the development of printing technology in Asia in the comments to this article.

Article prepared for 3DToday.ru

Article comments

More interesting articles

6

Subscribe to the author

Subscribe

Don't want

One of the newest developments in 3D printing devices has been the advent of extruders. No, it's not...

Read more

four

Subscribe to the author

Subscribe

Don't want

If yesterday 3D printing was the lot of boys of different age groups trying to adapt new. ..

..

Read more

four

Subscribe to the author

Subscribe to the author

Don't want to

3D printing progress has gained such rapid speed in recent years that we will soon stop...

Read more

countries with equipment replacement

India is confidently moving towards the introduction of high technologies in the military industry. Now it's the turn to use 3D printing for the needs of the Indian Navy.0102 Armiya.az with reference to Military Review.

The Indian Navy has entered into an agreement with the Think3D service bureau to use 3D printing technology in the production of spare parts for equipment used on ships. At one time, the naval command experienced very big problems with the organization of the supply of spare parts, since the Indian fleet used old imported equipment and it was always quite difficult to find parts for it.

Since most of the machinery used on Indian ships was supplied from other countries, and its production could already be stopped there, if a component had to be replaced, the Indian Navy incurred very high financial costs. Many ships were idle at the bases and could not be operated due to the fact that the Indian Navy could not find components to replace certain equipment.

Thanks to 3D printing technology, spare parts for Indian ship equipment can now be produced independently. As an example, Think3D cites the situation with the replacement of centrifugal pump impellers, which were able to replace using 3D printing. At one time, the failure of the impellers became a real problem for the Indian fleet, which was aggravated by the fact that the impellers fail quite often.

Each ship has several pumps and impellers, respectively, and constant breakdowns made it difficult for the Indian Navy ships to operate and fulfill their tasks. The production of a new impeller often required at least three months, and if you add to this the waiting time, the conclusion of a supply contract, even more. 3D printing, in turn, has made it possible to reduce organizational, time and financial costs and significantly speed up the process of production and replacement of impellers.

3D printing, in turn, has made it possible to reduce organizational, time and financial costs and significantly speed up the process of production and replacement of impellers.

The flagship 3D printer for the Indian Navy is Think3D, founded in 2014. It offers 3D printing, design, scanning and mass production services, and has a $6 million 3D printer that produces medical equipment. The printer is located in AP MedTech Zone, a medical equipment manufacturing park in Andhra Pradesh.

After receiving an order from the Indian Navy, Think3D visited warships to familiarize themselves with the problem and collected information about the impellers used on them, including material properties. The first step was a 3D scan of the impeller using an EinScan Pro + 3D scanner. Then, using the ANSYS software, the specialists of the bureau determined the specifics of the further 3D printing process and found out which materials should be used.

The next step was to test the suitability of materials such as nylon composites, glass-filled nylon, PA12, plastics. Materials were required to have damping properties. In addition, the part had to acquire elasticity sufficient to withstand constant vibrations. Therefore, the possibility of using different materials with high brittleness was excluded. Which material the organization ended up choosing is still unknown, as Think3D made the decision to keep this information secret.

Materials were required to have damping properties. In addition, the part had to acquire elasticity sufficient to withstand constant vibrations. Therefore, the possibility of using different materials with high brittleness was excluded. Which material the organization ended up choosing is still unknown, as Think3D made the decision to keep this information secret.

HP's Multi Jet Fusion technology printed an impeller with the desired properties. The part was then post-machined and tested on a ship, demonstrating high performance. As a result, the entire process of creating a part, which previously took at least 3 months, was completed in just 2 days.

The cost of manufacturing the component was 40% lower than what would have been spent if the impeller had been made in the traditional way. Last but not least, the 3D-printed impeller turned out to be 8 times lighter than the traditional one - if the latter weighs 8-9kg, the Think3D product weighs only 1 kg.

The Indian Navy and the Think3D bureau are now considering installing a 3D printer on board the ship.

.jpg)