Cult 3d printing

Cults・Download free 3D printer models・STL, OBJ, 3MF, CAD

Top design

By TwistyPrints

This snowman is an articulated model that needs NO supports, NO assembly, and prints very well with PLA. This bad boy also has a hole in the back , so you can hang it on your xmas tree if you want! A really nice decoration idea and a fun toy to use as a gift!

Download 3D model

01

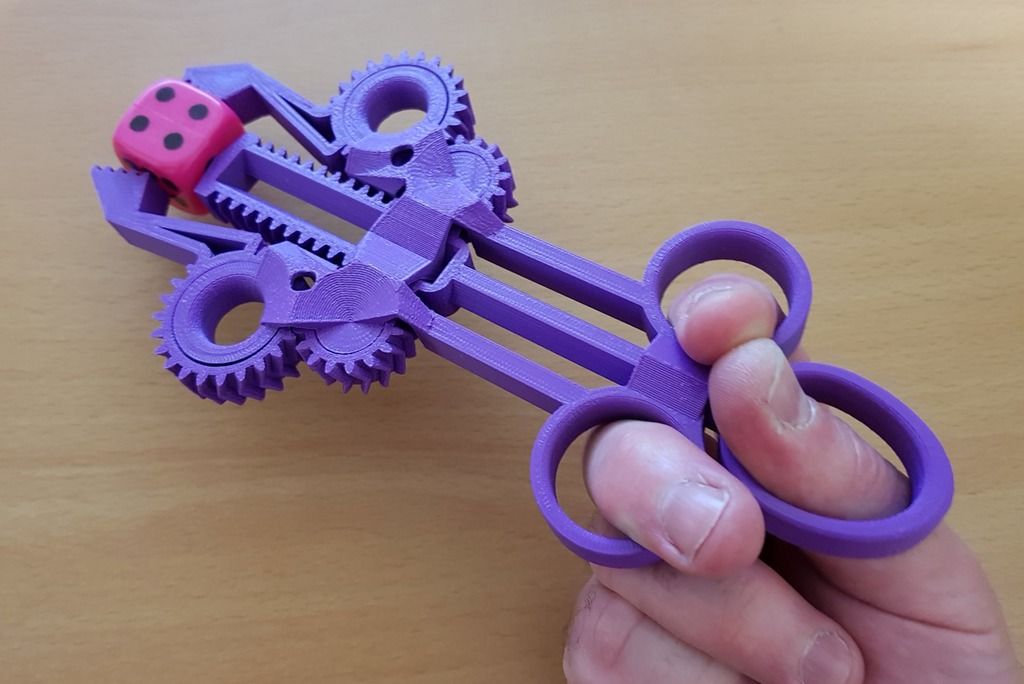

Batman Crossbow Gun / Print in Place

€2.50 -21% €1.98

Xmas Tree

Free

03Flexi Santa

€1.88

04Standing Penguin Pencil Holder

€3. -25% €2.81 75

Cat head

€20

0616 IN 1 NINTENDO DS /3DS GAME CARTRIDGE STORAGE CUBE

€2.50

07Ruben 🎅 from Rick and Morty

Free

08Cat Food Dispenser - Print in Place

€1.55

09Espresso leveler 51mm

Free

10SNOWMAN WITH LEGS

€2.89

11Penguin with a kawaii style secret heart without brackets

€2.35

12Christmas Gift Box - Centrifugal Puzzle

€2. -50% €1.37 75

75

Foldable Deer

€4.23

14Ramen Noodles Bowl Secret Tray

€2.62

15TROY'S 3D PRINTED RC DC-6/DC-7 AIRLINER

€61.16

16Hanging Cat - Print-in-place

€1.45

17Motorcycle Rallye Dakar (print in place)

€1.41

18Ghostbusters Winston Zeddemore Articulated Assembly

Free

19Slim and Smart Wallet with NFC

€2

20The little chilly dog.

..

.. €5 -40% €3

01

Earring cat

€1.03

02Christmas Park

€4.57

03Anastasia music box and jeweler for 3D printing

€3

04CRAMER Truggy RC 4x4 Full 3D Printed

€7.50

05RC 1/10 Dodge Challenger

€7.50

06ELEPHANT PIGGY BANK - NO PAINTING REQUIRED

€5

07Cosplay Paws

€4. -40% €2.82 70

70

The Space Launch System (SLS): NASA’s Artemis I Moon Rocket with platform. File STL-OBJ for 3D Printer

€2.95

01

Cactus Ornament Gift Card Holder

€2.35

02Figure of Milkman Dragon ball

€1.90

03Drogon

€20

04Gingerbread Man Candy Dish

€0.94

05Ebro B45 Complete in 1/18 scale

€20 -50% €10

Foldable 3 Stacked Snowman

€3. 75

75

HAPPY CRAB

€1.88

08Big and small Jar I BM003

Free

09Flexi Cute Gingerbread Couples

Free

10Pavlova

€25

11grinder graffiti fat cap skinny

€2.73

12Patrick Christmas Star

€3 -50% €1.50

Big head nutcracker fidget

€1.45

14AUTOMATON CAT - CHRISTMAS

Free

15Articulated Santa Claus

€2. 07

07

Furry toy: print on place flexi skeleton dog

€3

17Bic JMR design Bic darts

Free

18Monster Planters

€2.35

19Program to Create Christmas balls and other lithophany

€3.50

20Owl on tree - No supports

€1.87 -50% €0.93

01

Steve Irwin's Worst Nightmares

Free

02#3DBenchy - The jolly 3D printing torture-test

Free

03flexi turtle

Free

04Cute Mini Octopus

Free

05Condors of Conjuration

Free

06PRINT-IN-PLACE SPRING LOADED BOX

Free

07Cnidarian Fire Dispensers

Free

08King Cnidarian Fire Dispensers

Free

🔁 Updated

MORTICIA TOON EDITION (2 DESIGNS)-Discount for the weekend !

€6. -43% €3.93 90

90

dog fighter

€7.53

NIKE SANTA SLEIGH

€3.90

MAN TGX 2020 PRINTABLE TRUCK IN SEPARATE PARTS

€11.35

goku bust

Snow tracks for Traxxas TRX4

WWE AEW ECW WCW WWF HASBRO A TEAM JOHN HANNIBAL SMITH POSEABLE ARTICULATED FIGURE .STL .OBJ

WWE AEW ECW WCW WWF HASBRO A TEAM TEMPLETON PECK ( FELIX ) ARTICULATED POSEABLE FIGURE .STL .OBJ

margarita with cake skewer

€1.36

flying destroyer

€3 -40% €1. 80

80

lion

€1.25

COOKIE CUTTER COOKIE CUTTER CHRISTMAS CHRISTMAS RENO REINDEER

€3.76 -25% €2.82

Support Building Caravanserai

Free

COOKIE CUTTER COOKIE CUTTER CHRISTMAS CHRISTMAS GIFT GIFT GIFT

€2.82 -25% €2.12

SUPER MARIO BROS Letters and Numbers SUPER MARIO BROS Letters and Numbers

€1.07

COOKIE CUTTER COOKIE CUTTER CHRISTMAS CHRISTMAS SANTA CLAUS 2

€3.76 -25% €2. 82

82

See all 3D models

Cults, the 3D printing platform

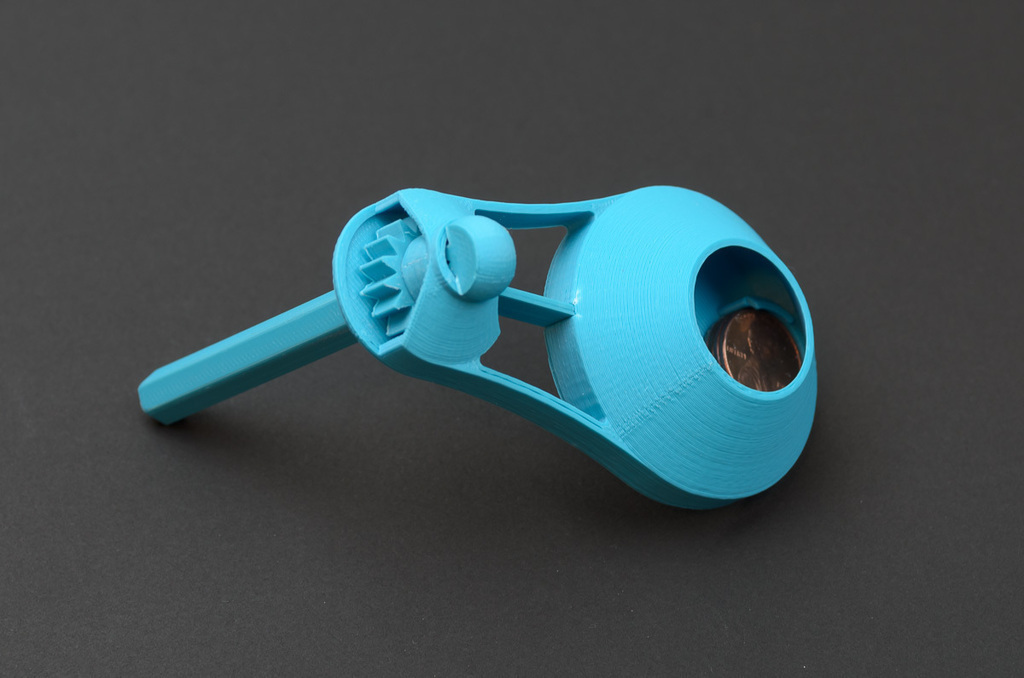

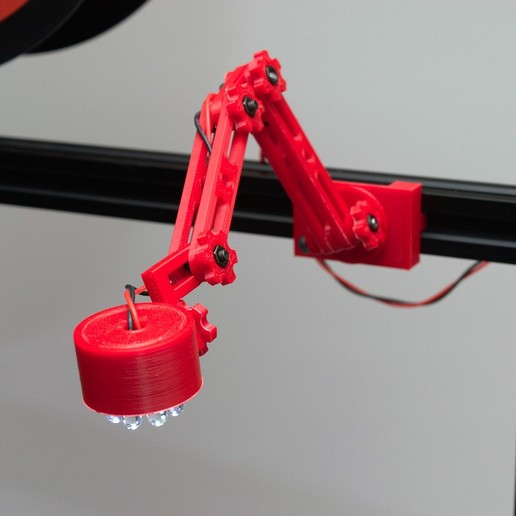

Welcome to Cults, the world’s leading independent website for 3D printer files. Discover and download the best 3D models for all your 3D printing & DIY projects.

Cults is a digital marketplace for 3D printing and design. Use our 3D model library to discover everything you can do with a 3D printer (FDM, SLA, DLP, SLS) event with CNC machining and laser cutting. You don’t know how to make a 3D file but you want to 3D print objects? Cults is for you! Browse our different categories and download the best 3D printer models for free, open-source or paid mode. The formats you can download are in STL, OBJ, 3MF, CAD, STEP, SCAD or DXF, DWG, SVG format, they are all 3D printable guaranteed or CNC compatible.

We are connecting 3D print files makers with people who want to use their 3D printer. Our 3D model repository acts as a real source of inspiration since the best designers share their best STL files daily to offer you their latest inventions!

On Cults you can also find a 3D printer nearby, get voucher codes to buy cheap 3D printers or filaments at best prices and also a whole series of 3D printing contests. Cults is a joyful community that brings together all 3D printing fans to dialogue and create together.

Commission system

You are a designer and you want to sell your 3D models optimized for 3D printing? Thanks to Cults you can earn money with your files STL, OBJ, CAD, 3MF, etc.! For each download, you will receive 80% of the net selling price (excluding VAT) via PayPal. Cults keeps 20% of commission which is used to finance bank fees (about 5%) and then all the costs related to the technical maintenance of the platform: hosting, bandwidth, accounting, email communications, translations, etc. There is no subscription system or fixed fee to pay. You sell, you win!

Cults keeps 20% of commission which is used to finance bank fees (about 5%) and then all the costs related to the technical maintenance of the platform: hosting, bandwidth, accounting, email communications, translations, etc. There is no subscription system or fixed fee to pay. You sell, you win!

If you are still hesitating to share your models on Cults, feel free to read this article Why publish my designs on Cults? List of advantages and benefits to get an idea.

- Designers 80%

- Cults 15%

- Banking fees 5%

Upload a 3D model

Free best 3D printer models・Cults

slingshot

€8.21

Reindeer Puzzle

€3.72 -50% €1. 85

85

POKEMON - ARMOURED MEWTWO

€2.22

Elegant Soap dish / Soap holder, ECOLOGIC! Easy to print, hygienically safe #02

Free

Cyclop

€4.70

Cat Sphynx

€3.76

Cat Archer Pose C

€3.76

Cat Archer Pose A

€3.76

Reinforced version of the bearing retainer for bearing 606

Free

Reinforced version of the bearing retainer for bearing 609

Free

Reinforced version of the bearing retainer for bearing 607

Free

Reinforced version of the bearing retainer for bearing 605

Free

Reinforced version of the bearing retainer for bearing 604

Free

Reinforced version of the bearing retainer for bearing 603

Free

Reinforced version of the bearing retainer for bearing 602

Free

Reinforced version of the bearing retainer for bearing 608

Free

complete pack of reinforced bearing retainers for standard bearings

€1

complete pack of light bearing attachment

€1

Lightweight bearing retainer for bearing 609

Free

Lightweight bearing retainer for bearing 607

Free

Lightweight bearing retainer for bearing 606

Free

Lightweight bearing retainer for bearing 605

Free

Lightweight bearing retainer for bearing 604

Free

Lightweight bearing retainer for bearing 603

Free

Lightweight bearing retainer for bearing 602

Free

Lightweight bearing retainer for bearing 608

Free

Goku Baby / Goku Bebe

€9. 40

40

FREE Christmas Gift! Rudolph the Red-Nosed Reindeer Christmas Ornmament

Free

POKEMON - SURFING PIKACHU

€1.29

POKEMON - MAGIKARP (EASY PRINT NO SUPPORT)

€1.39

Star Wars: Darth Vader - The Emperor's Apprentice

Free

BEARING TURNTABLE TO SHOW PRODUCTS

Free

CUTE AND EASY TO PRINT SANTA FRIDGE MAGNET

Free

lil Christmas guy

Free

SNOWMAN WITH LEGS

€2.89

Soap Dish - Honeycomb

€0.92

6 cylinder Engine

Free

SET OF FOUR ORNAMENTS

€2. -15% €1.99 34

34

Lego Style Brick Seattle Space Needle

Free

Folding Chair 3D Print 3D print model

€10

Surfboard Wax Case

Free

Christmas Ornaments

Free

Hellboy with a hat

Free

Beer/Pop Can Opener/Protector/BUG FREE TOP

Free

FREE Santa Ogre

Free

Hawkman head from Black Adam Movie fit for Mafex,mcfarlane dc,mezco

€12

Cable holder for soldering with tin.

€2.50

Young Qui Gon Jin

Free

FDM 3D printing guide for beginners.

Understanding Basic Terms

Understanding Basic Terms Getting started with 3D printers doesn't have to be intimidating. We have created this simple 3D printing guide for beginners to help all beginners understand the basic terms.

3D printing is a very general term. The media, especially mainstream marketing, portray 3D printing as the magical technology of the future, capable of reproducing complex objects.

But this approach makes it difficult to understand what 3D printing is from a technical point of view. nine0003

In reality, there are many different 3D printing technologies, but the most common for beginners is layer-by-layer modeling (FDM or FFF), which is the focus of this article.

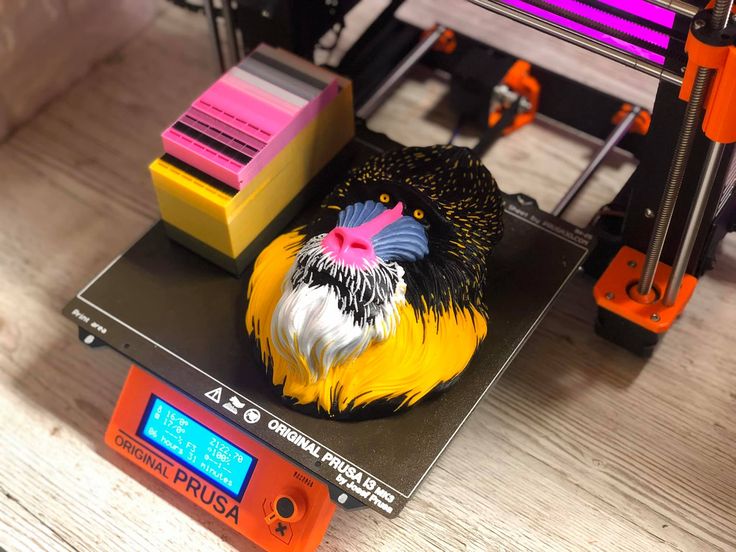

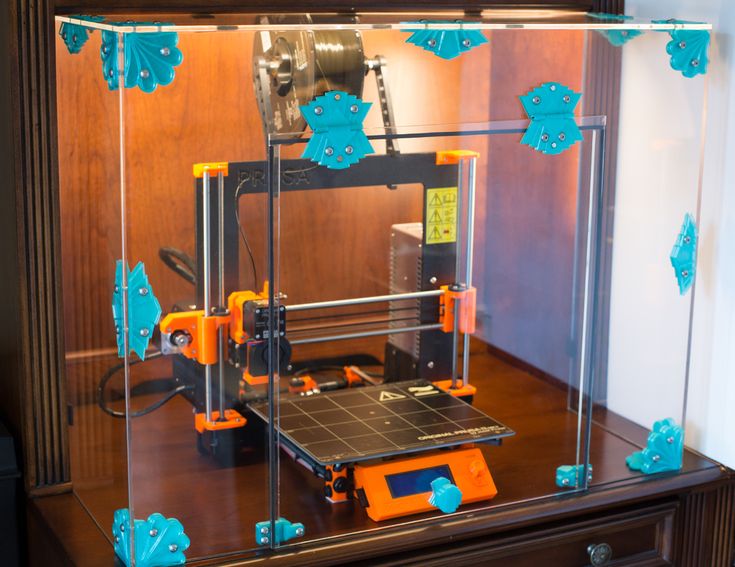

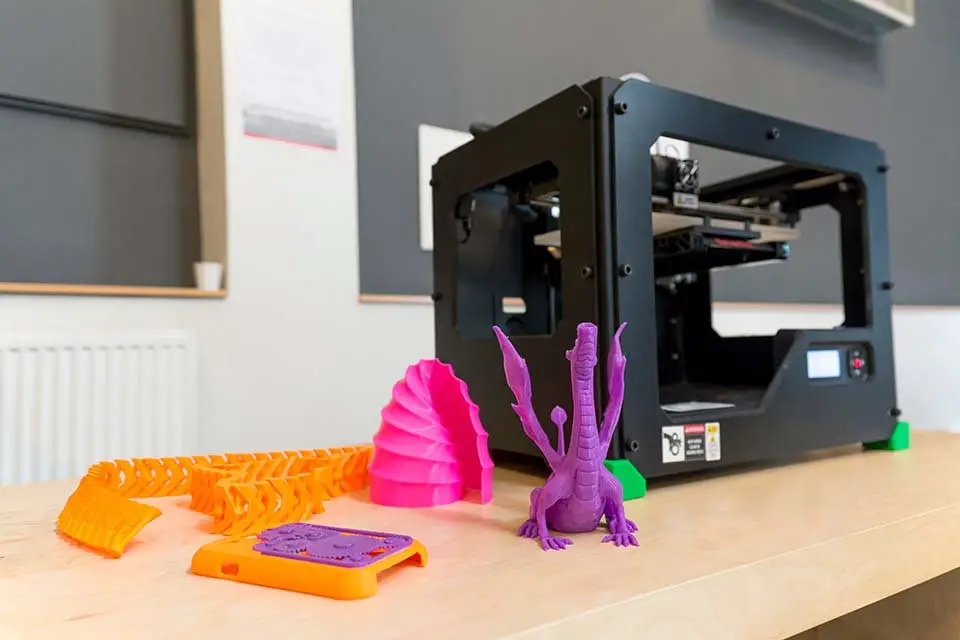

Ender 3 V2 is one of the most popular hobbyist 3D printers.

FDM prints parts using thermoplastic, which is basically a filament of material that can melt, cool, and solidify. Details are built by stacking layers on top of each other. nine0003

This technology was created because people needed a way to quickly prototype parts. Even today, rapid prototyping is one of the biggest advantages of FDM and 3D printing in general. Not surprisingly, 3D printing is also gradually becoming a powerful manufacturing solution.

Even today, rapid prototyping is one of the biggest advantages of FDM and 3D printing in general. Not surprisingly, 3D printing is also gradually becoming a powerful manufacturing solution.

Before we get into the details of how FDM works, there is one more thing worth mentioning. If you have done some research on FDM, you may have noticed that some sources use the term "FFF" instead of FDM when referring to the technology. This is because FDM is a term originally patented by Stratasys and FFF is a non-proprietary generic abbreviation. Remember, this is the same technology, only the names are different. Today, most people use the term FDM. nine0003

FDM 3D printing. How it works?

- 3D printer control interface

- 3D printing plastic (filament)

- Extruder

- Hotend (hot end)

- Fan (cooler)

- Print platform (table)

- 3D printing

The easiest way to understand how FDM works is to study the details of an FDM 3D printer. However, before we get into the specifics, it's worth mentioning that most 3D printers can move in three axes: X, Y, and Z. The X and Y axes are responsible for moving left, right, forward, and backward, while the Z is responsible for vertical movement. nine0003

However, before we get into the specifics, it's worth mentioning that most 3D printers can move in three axes: X, Y, and Z. The X and Y axes are responsible for moving left, right, forward, and backward, while the Z is responsible for vertical movement. nine0003

Now let's look at the main components of a 3D printer:

Control interface : Some modern 3D printers have a touch screen that is used to control the 3D printer. On older printers, a simple LCD with physical scrolling and a click wheel may be present instead of a touch interface. Depending on the model, an SD card slot and a USB port may also be present.

Print Bed : The bed or table of a 3D printer is essentially the surface on which parts are made. Platforms are most often made with heating to improve the adhesion of the part, but more on that later. nine0003

Extruder(s) : The extruder is the component responsible for melting and progressively depositing the plastic filament to build the model.

The extruder actually consists of two subcomponents: hot and cold. The hot end or hot end contains a heater and nozzle that actually melts the filament, while the cold end consists of a motor, drive gears and other small components that push the filament into the hot end to melt. nine0003

There is a heatsink and a fan between the hot and cold ends because it is necessary that the cold end stays cold to avoid jamming.

In addition to the heatsink fan, there is usually at least one other fan designed to cool the molten filament after it exits the extruder - this is commonly referred to as the parts cooling fan.

Print head : one or more extruders are installed on the print head (standard 3D printers have one extruder). At the top of the print head is a tube that feeds filament into the print head. nine0003

How a 3D printer prints.

The process starts when you send the 3D model file to the printer. After starting a print job, the nozzle starts to heat up. When the nozzle reaches the temperature required to melt the filament, the extruder draws the filament into the hot end in preparation for deposition modeling.

When the nozzle reaches the temperature required to melt the filament, the extruder draws the filament into the hot end in preparation for deposition modeling.

The printer is now ready to 3D print the part. The print head descends onto the build surface (platform) and begins to fuse the filament, which cools and solidifies shortly after exiting the nozzle thanks to the part cooling fans. nine0003

Plastic is applied one layer at a time, and after one layer is completed, the printhead moves up the Z-axis a short distance and the process is repeated until the part is completed.

Create, download and purchase 3D models.

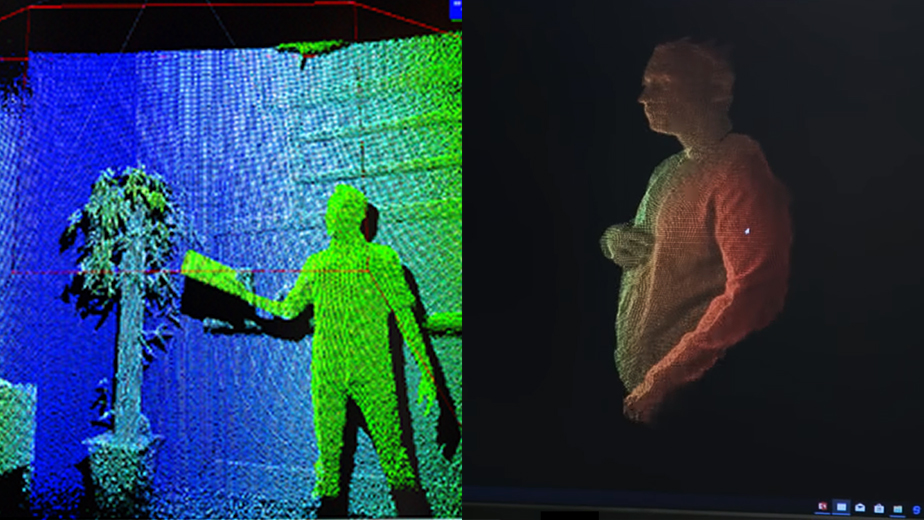

Naturally, if you want to 3D print a part, you must have a 3D model of that part. 3D models are created using 3D modeling software commonly referred to as CAD (computer-aided design) software. Here are some examples of popular 3D modeling software:

- Autodesk's Fusion 360 (Free for non-commercial use)

- Blender (free of charge)

- ZBrush (paid, but free trial available)

However, most newcomers to 3D printing do not have the skills required to use such software. If so, don't worry because there are other solutions.

If so, don't worry because there are other solutions.

First, there are simpler CAD software options like Tinkercad, a program that almost anyone can use without any prior experience. This is an online application developed by Autodesk, one of the leading developers of CAD software. nine0003

Downloading files

With so many people having access to 3D printers in recent years, several websites have become repositories for 3D models.

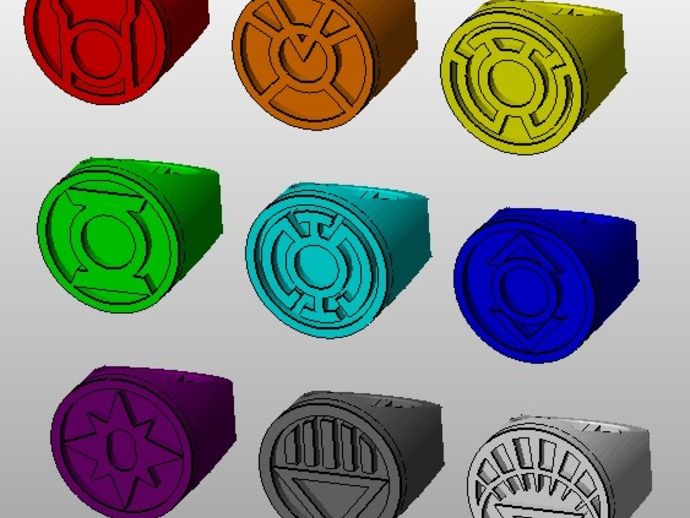

Some of the most popular are:

- Thingiverse (free)

- MyMiniFactory (many free, some paid)

- Cults3D (free and paid)

- CGTrader (some free and most paid)

- PrusaPrinters (all free) nine0091

- PLA

- ABS

- PETG

- Flexible (TPU, TPE)

- Nylon

- With additives (wood, metal, etc.)

- Polycarbonate (PC)

- HIPS

- PVA

- Filament Spool.

- Heating element.

- Nozzle.

- 3D printer table (platform).

- Printed object.

- Supports (supports). nine0026

So anyone can get their hands on a model without any modeling skills.

Model preparation.

3D models must be prepared for 3D printing using special software that translates the model into machine instructions. This is done using slicing software, also called a slicer. 3D models are imported into a slicer, which then actually "cuts" the model into layers. The resulting files consist of a G-code, which is essentially a long list of instructions that a 3D printer follows to build a model. nine0003

3D models are imported into a slicer, which then actually "cuts" the model into layers. The resulting files consist of a G-code, which is essentially a long list of instructions that a 3D printer follows to build a model. nine0003

G-code is the "language" of 3D printers and CNC machines. These files contain important parameters needed to create a model, such as print speed and temperature, wall thickness, infill percentage, layer height, and many others. In other words, 3D printing is impossible without G-code files!

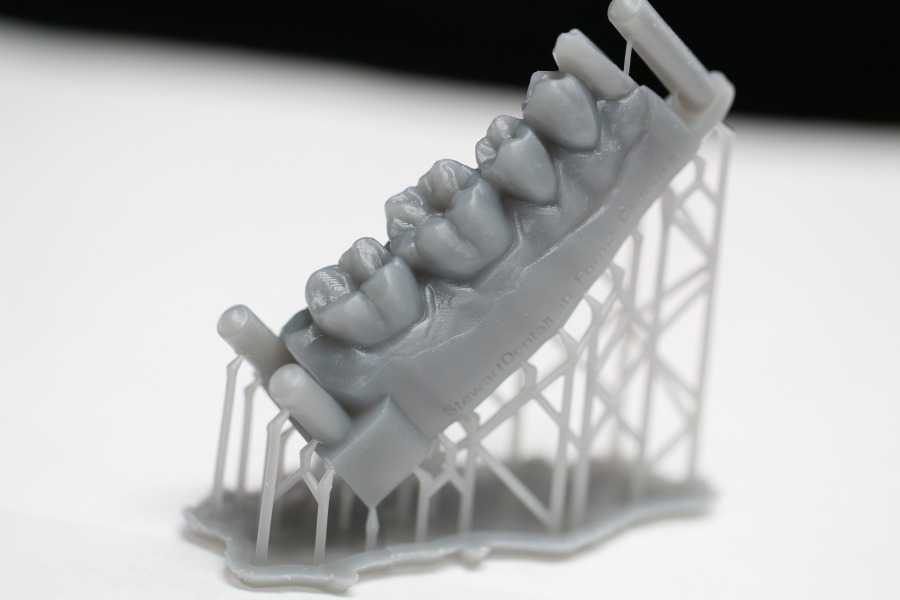

Supports (support structures)

Another of the main functions of the slicer is the generation of support structures (supports). In particular, supports are needed for parts with attachments.

9The 0002 Slicer allows you to choose where to place the supports and how tight you want them to be. Some slicers even offer users the ability to select different types of support structures for easier removal or strength.Printer preparation.

Before you start printing on a 3D printer, there are a few mandatory steps to take:

Plastic loading: The extruder must be ready to extrude the filament before printing begins. The loading process begins with heating the hot end to the melt temperature, and then the filament is directly loaded into the heated extruder. nine0003

The loading process begins with heating the hot end to the melt temperature, and then the filament is directly loaded into the heated extruder. nine0003

Platform Leveling: In order for the printer to successfully print an object, the table must be as level as possible.

Depending on the printer, platform calibration can be performed manually, semi-automatically or automatically.

Platform leveling is very important because, for example, if the nozzle is too far from the table, the first and most important layer will not adhere to the surface, resulting in you not being able to print your object.

Materials for FDM 3D printing. nine0021

As we already mentioned, FDM 3D printers use spools of plastic as part material. Filament is basically a thermoplastic specifically designed to melt and cool while maintaining its structural integrity.

3D printing filaments usually come in two diameters: 1.75mm and 3mm (or 2.85mm). Most 3D printers use 1. 75 diameter plastic, which is why the variety of types and shades of 1.75 filament significantly exceeds 2.85. nine0003

75 diameter plastic, which is why the variety of types and shades of 1.75 filament significantly exceeds 2.85. nine0003

We recommend that before you buy a 3D printer, be sure to clarify which filament it works with.

Converting the extruder from 2.85 to 1.75 is possible, but requires fiddling, time and additional accessories.

One of the best things about FDM 3D printers is that they can handle a wide range of plastics.

Here are just a few of the different types that are used in FDM 3D printing:

Standard:

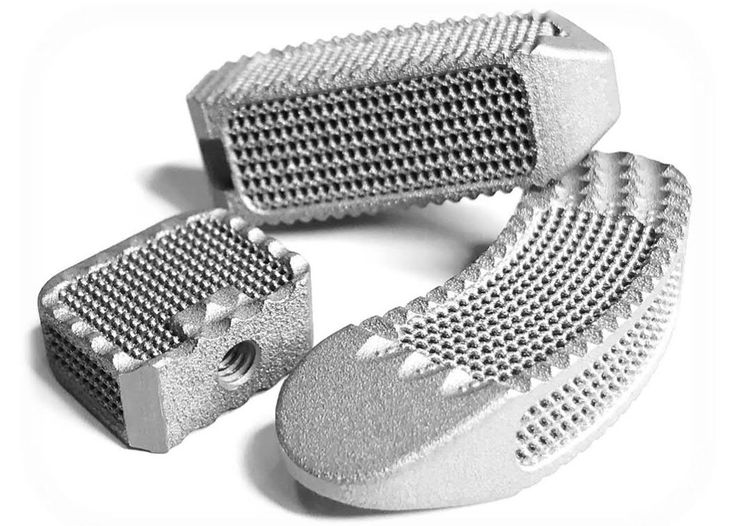

Engineering:

For supports:

Among other things, FDM filament is one of the cheapest materials used in the world of 3D printing.

Post-processing of printed products.

Post-processing is the final steps you must take to complete your object. nine0003

nine0003

Below we have listed some of the post-processing steps for a 3D printed part. You don't necessarily need to complete each of these steps.

Most often, post-processing is completed at the stage of removal of supports.

Support Removal : After printing, support structures are mechanically removed by simply breaking them off. As a result, you can see marks left on the surface of the part.

If you have bought a 3D printer with two extruders, you can use special soluble plastics to print supports. In this case, you just need to place the object in water if you printed with PLA+PVA or in limonene if you printed with ABS+HIPS. nine0003

Sanding : Your part may have imperfections (for example, after removing supports). In this case, grinding comes into play. Light sanding of 3D printed parts can make the surface smoother.

Coloring : You will often print in one color. To add more colors, details or protection, you can paint your model!

Polishing or Smoothing : Epoxy is one way to smooth the surface of a printed part. For ABS, an acetone steam bath is often used. Under the influence of acetone vapors, ABS begins to dissolve and, if this process is stopped in time, you will get a smooth and glossy part. nine0003

For ABS, an acetone steam bath is often used. Under the influence of acetone vapors, ABS begins to dissolve and, if this process is stopped in time, you will get a smooth and glossy part. nine0003

Gluing : If you want to print a large 3D model that won't fit in your printer's build chamber, you can print the part in two or more parts and then glue them together.

Common 3D printer problems.

Let's discuss some of the most common problems beginners may encounter when using a 3D printer.

Warp : This problem occurs due to temperature differences during the 3D printing process. 3D Print Delamination - 5 Tips and Tricks to Avoid Delamination. nine0003

Plastic bleed (snot) : Thin extra filaments of plastic on your model may be caused by incorrect temperature or retraction settings. Some types of plastic, such as PETG, are more prone to free flow from the nozzle.

Nozzle Clog : Nozzle clogging is one of the most annoying problems of FDM 3D printers.

If you hear a strange printhead sound and no plastic comes out of the nozzle, the nozzle may be clogged. This can be caused, for example, by poor filament quality or incorrect temperature settings. nine0003

Layer Offset : This problem can be caused by vibrations and wobbles in your printer, insufficient X and Y belt tension, or excessively high print speeds.

Underextrusion : Underextrusion occurs when not enough plastic is extruded during printing. This can result in gaps, missing layers, and even small dots or holes in the layers. With insufficient extrusion, the quality and even the strength of the parts deteriorate. nine0003

Overextrusion : As the name suggests, overextrusion occurs when your 3D printer extrudes too much material. This can lead to sagging layers, broken geometry, and poor quality of your prints. Check your filament diameter, play with the print speed and fluidity settings in your slicer.

FDM 3D printing. Explanation in simple words.

What is FDM technology? How does an FDM 3D printer work? Requirements that model designers must follow. nine0003

Print area and layer height. Deformation. layer adhesion. Use of minimalistic support structures. Filling and wall thickness.

Pros and cons. Top 3 recommendations for FDM 3D printers. Conclusion.

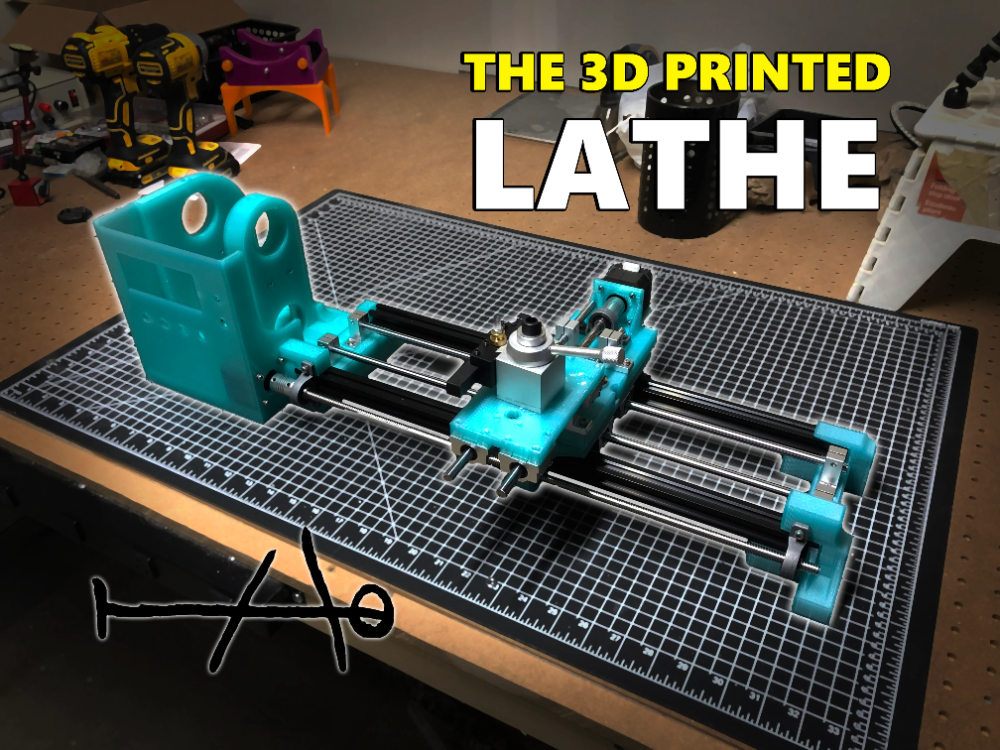

In this article, we'll look at FDM technology, which finds its most common use in the world of 3D printing. FDM stands for Fused Deposition Modeling, sometimes also known as FFF - Fused Filament Fabrication.

FDM 3D printing belongs to the family of extrusion technologies. It represents the largest installed base of 3D printers worldwide. That is why this is the first technology that a newcomer to additive manufacturing is introduced to. nine0003

Now consumers can create finished products right at home. The question arises: how did it all begin? Let's find out!

What is FDM technology?

FDM technology was created by Scott and Lisa Crump in 1988. Interestingly, the technology began when Crump created a frog toy for his two-year-old daughter using a hot glue gun and a mixture of polyethylene and candle wax.

Interestingly, the technology began when Crump created a frog toy for his two-year-old daughter using a hot glue gun and a mixture of polyethylene and candle wax.

Parents managed to create a toy frog, after which they patented this technology in their name and founded a company called Stratasys. nine0003

The company, founded in 1989, then created software that converted STL files to other formats.

STL is an abbreviation for stereolithography. It is important to note that prior to this invention, 3D printers could not communicate with computers.

This software also made the so-called section of the 3D model. As you can imagine, this was a huge breakthrough in additive manufacturing.

In FDM, a product is created by selectively applying molten material along a predetermined path. This welding is done layer by layer, and the materials used here are thermoplastic polymers that come in filament form. nine0003

Now that you have a basic knowledge of FDM 3D printing, let's learn step by step (layer by layer) how it works.

How does an FDM 3D printer work?

To better understand how the FDM 3D printer works, the picture shows its schematic diagram:

Now you know that FDM welding occurs layer by layer.

The processes involved in FDM technology can be conditionally divided into 3 main stages.

Stage 1. You need to have a ready 3D model for printing. You can create it yourself in a CAD program, or you can find it ready-made from countless resources on the Internet.

Read also. Top 25 sites with free STL files for 3D printers.

Step 2. The process starts by loading the filament. These thermoplastic filaments are FDM printing material. The filament is fed into the extruder when the temperature of the printhead reaches the melting point of the particular filament. The temperature will be different depending on the choice of materials in FDM 3D printers. nine0003

The temperature will be different depending on the choice of materials in FDM 3D printers. nine0003

Step 3. Now that you have selected the file and loaded the material into the 3D printer, the fusing process begins.

One layer after another, the material is applied according to the 3D design that was entered into the FDM 3D printer. After each layer, the thermoplastic is cooled by cooling fans attached to the extrusion die.

After each layer is completed, the platform lowers to make room for the next layer. The next layer is superimposed on the previous one, and the whole process continues until the entire 3D part is printed completely. nine0003

Now that you've seen the step-by-step operation of an FDM 3D printer, it's time to take a look at some typical specifications that every 3D printer owner should keep in mind.

Requirements to be followed by model designers.

Like any technique, FDM technology has its own characteristics and limitations. A good designer should use this technique in a way that maximizes specialization and minimizes limitations.

A good designer should use this technique in a way that maximizes specialization and minimizes limitations.

Therefore, before designing with an FDM 3D printer, the designer should keep the following things in mind.

Print area and layer height.

A typical desktop 3D printer used in the home has an average size of 200 x 200 x 200 mm. A 3D printer that is used for industrial purposes has dimensions of 1000 × 1000 × 1000 mm.

When printing with a home printer, large parts should be broken into small parts and then assembled, while if you use an industrial 3D printer, you can print the whole part on it. nine0003

The height of the layer directly affects the surface quality of the product, as well as the accuracy of geometric parameters.

Here comes the first contradiction: if you choose a low layer height (20-100 µm), you can produce parts that are smooth and have curved geometry, but spend a fair amount of time printing.

Higher layer heights (>200 µm) will allow you to work faster, but you will end up with stepped detail and some geometry discrepancies. With FDM technology, you cannot achieve perfect surface quality by printing at high speed with a layer height >200 µm. nine0003

With FDM technology, you cannot achieve perfect surface quality by printing at high speed with a layer height >200 µm. nine0003

So, remember the rule: whenever you need to create a curved geometry or need precise and sharp corners of the product, set the layer height to a low value.

If you just need to look or feel a part and high precision is not required, produce faster by setting a higher layer height.

Deformation.

This effect is caused by the hardening that the thermoplastic material undergoes after layer-by-layer deposition.

Regardless of the geometry of the material, the cooling rate on different parts of its surface will be different. When deforming, the material chosen by the designer plays an important role. nine0003

Based on our experience, we can conclude that ABS, a common thermoplastic material used in FDM printing, is more sensitive to deformation than PLA or PETG. The reason for this effect is a higher glass transition temperature and a relatively high coefficient of thermal expansion.

Thin projections are also subject to more warping. Thus, before FDM 3D printing such models, always add additional material to the edges of the product. This will increase its total area that will remain in contact with the printer bed. nine0003

On the other hand, large flat areas should also be avoided for FDM applications, as they are also prone to deformation. Sharp corners are more prone to warping, so when printing with an FDM printer, it is important to keep the fillets in the design whenever possible to avoid buckling.

Layer adhesion.

When studying the general topography of any material, it is clearly seen that the higher the adhesion of the layers, the higher its strength.

This rule also applies to parts printed with FDM 3D printing. Remember, modeling happens layer by layer. nine0003

This means that the high temperature of the thermoplastic material will melt some of the surface of the previous layer and allow the new layer to bond to the previous one.

This will also deform the material. Parts produced with FDM will always have a slightly wavy or stepped surface that may need post-processing after being printed on an FDM printer.

Use of minimalist support structures.

Sometimes a 3D design cannot go through the printing process without a support structure. nine0003

The reason for using the support structure is that the thermoplastic material cannot be applied to air. Supports provide support for structures with ledges or other constraints.

This is the part that designers need to take care of the most. The FDM part should be printed in such a way that it requires the least number of support structures.

Because the support structures will be printed in the same way as the FDM part is printed. And this will only complicate post-processing. Moreover, surface finish also deteriorates when supports are removed from printed parts. nine0003

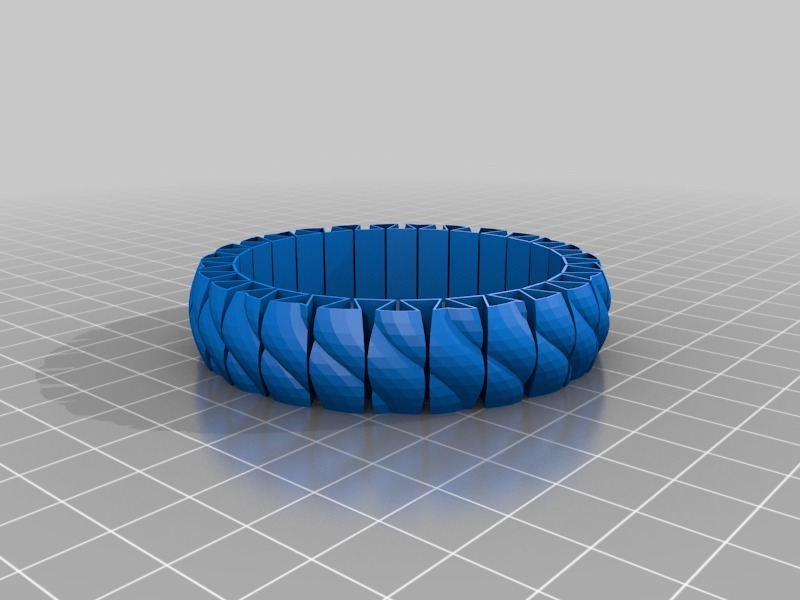

Filling and wall thickness.

A fact to know about FDM printing is that parts are not always solid. Choosing the right infill and wall thickness around the perimeter will save time as well as save material.

Choosing the right infill and wall thickness around the perimeter will save time as well as save material.

The outer material routed by the passes is called the wall and the inner material is called the infill.

Both parameters affect the overall strength of the FDM part. For different types of printers, general settings are available that the 3D printer operator should be aware of. This is necessary to ensure the accuracy of the design. nine0003

Pros and cons.

Now that you have a comprehensive understanding of FDM 3D printing, it's time to learn about the pros and cons of this method compared to other 3D printing methods.

Pros:

Unlike other 3D printing methods, a huge range of sizes can be produced. FDM 3D printing can produce parts ranging in size from a few millimeters to several meters. The reason for this huge scalability is that FDM has less restrictions on the printable area. nine0003

FDM 3D printing can be done using a huge variety of materials. Thermoplastic materials can be subject to several modifications. Despite modifications, the material gives fantastic end results.

Thermoplastic materials can be subject to several modifications. Despite modifications, the material gives fantastic end results.

Compared to some traditional technologies, FDM 3D printing is faster and therefore more can be produced in the same amount of time.

The FDM process is also the most cost-effective 3D printing technology for custom thermoplastic parts. Because thermoplastic materials are available in a wide range and are compatible when it comes to prototyping. nine0003

Cons:

The accuracy and detail of FDM printing is lower than other technologies.

The gradual cooling of the material can lead to deformation and twisting of parts. Material shrinkage can cause your object to lose its shape. Platform calibration and proper temperature settings make up for this, but it will take you some time to come up with the ideal settings for each printer and media.

Layer adhesion mechanism makes FDM technology naturally anisotropic. Because the parts produced have visible lines, which are formed by applying layer after layer. It also increases the time it takes for post-processing to get a smoother surface than other methods. nine0003

Because the parts produced have visible lines, which are formed by applying layer after layer. It also increases the time it takes for post-processing to get a smoother surface than other methods. nine0003

Top 3 recommendations for FDM 3D printers.

FDM 3D printers are available in a wide range of prices. 3D printers for the home are usually cheaper than commercial ones.

Creality's Ender 3 v2 3D Printer is recognized as the best value-for-money home printer worldwide.

Creality Ender-3 V2 is an upgraded version of the Ender-3 3D printer. Silicon carbide glass heating platform with excellent adhesive properties, all-metal body construction and a safe, powerful power supply will give you quality results at a budget price. nine0003

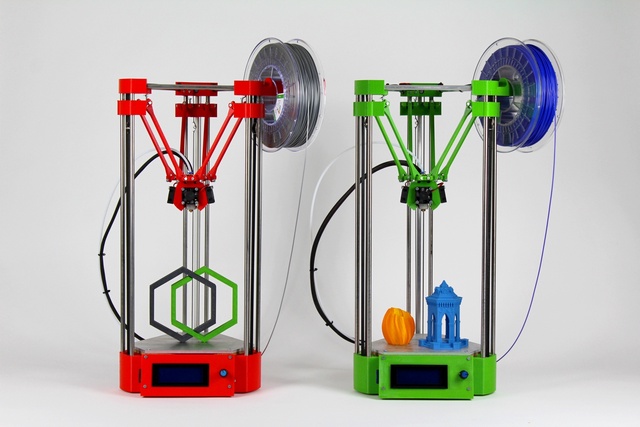

Among 3D printers with 2 extruders, Flashforge's Creator Pro 2 holds the lead for home and semi-professional use.

Flashforge Creator pro 2 is an updated version of the original Creator Pro. This is a fully enclosed 3D printer with IDEX smart dual independent extrusion system. It has an intuitive user interface, a print area of 200x148x150mm and a metal frame for stable printing.

It has an intuitive user interface, a print area of 200x148x150mm and a metal frame for stable printing.

Flashforge Creator Pro 2 provides beginners with high print quality and ease of use, thanks to its robust design, new touch display and open source code. nine0003

If you need to print large items, the CR-10S Pro Creality 3D Printer is the one to go for.

Creality CR-10S PRO is a 3D printer with a large print area (300x300x400), low filament sensor, platform auto-calibration, and a function to resume printing after a power outage. Powerful power supply, high-temperature Teflon tube, upgraded motherboard and other improvements will help you get high print quality, reduce noise, and enjoy the 3D printing process at an affordable price. nine0003

Output.

If you are or plan to become a manufacturer, there are some rules you need to remember about FDM printing.

FDM is known as a low-cost 3D printing method that allows you to create prototypes and functional parts faster than other traditional technologies.