Cube 3d printer cost

Cube 3D Printer Review 2022

3.5

See Price

Since the popularization of 3D printers, and give the inherent difficulty of 3D printing, there’s been demand for affordable, easy to use models that work out of the box.

3D Systems and the widely popularized Cube 3D printer strive to plug that gap. Does it live up the hype? Let’s investigate as we pull apart the secret inner workings of the most stylish printer on the market.

| Printing Area | 152x152x152mm |

| Print Tech | Plastic Jet Printing |

| Supported Filament | ABS and PLA |

| Extruders | 2 |

| Layer Thickness | 70 microns and 200 microns |

Table of ContentsShow

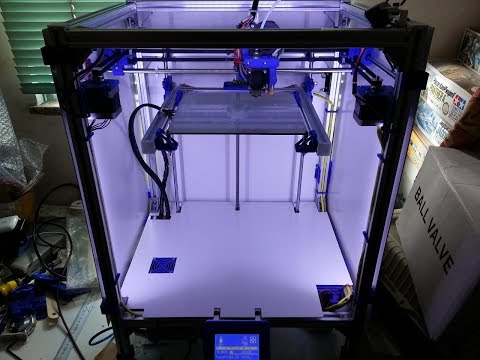

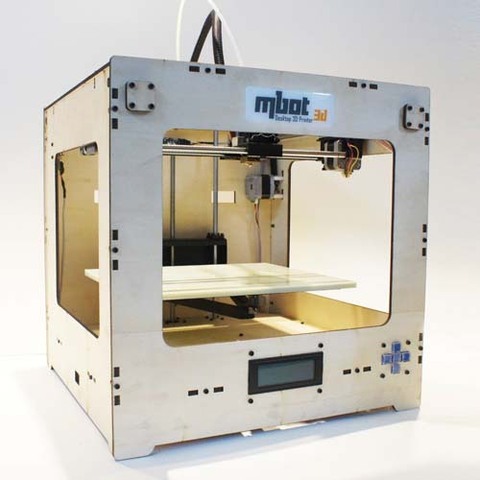

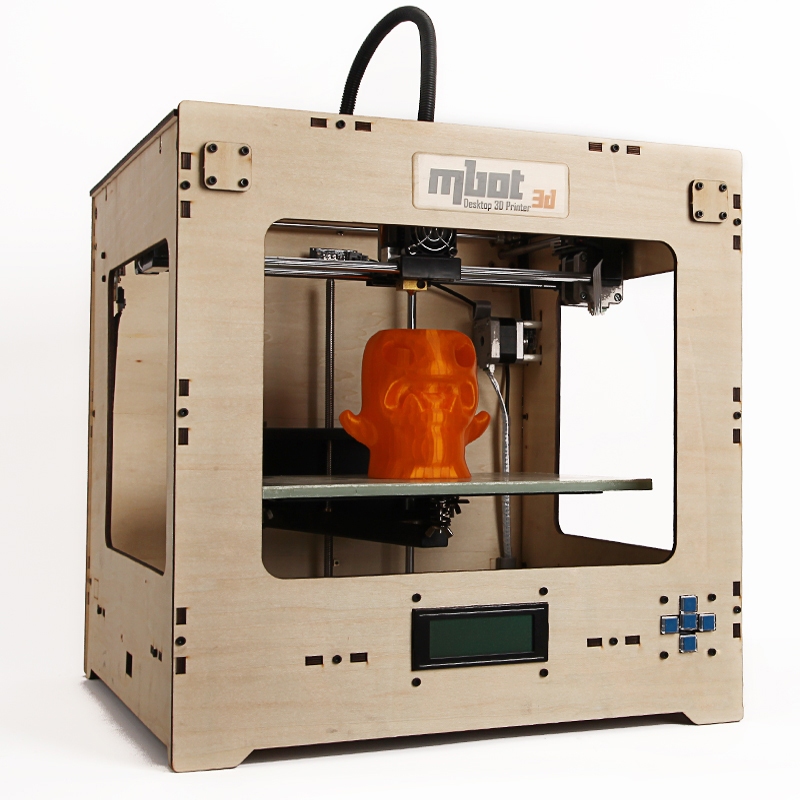

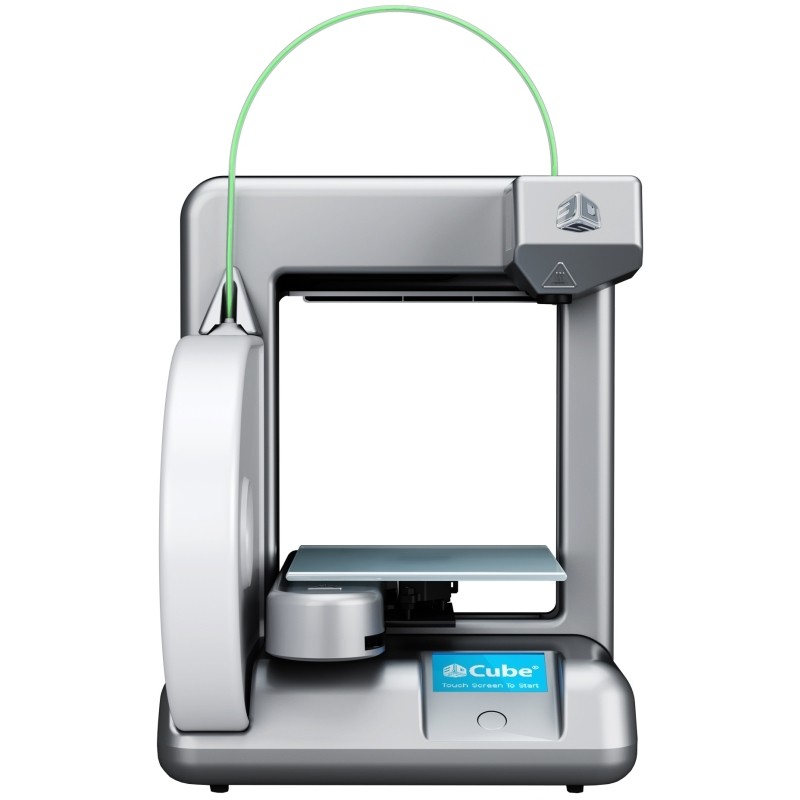

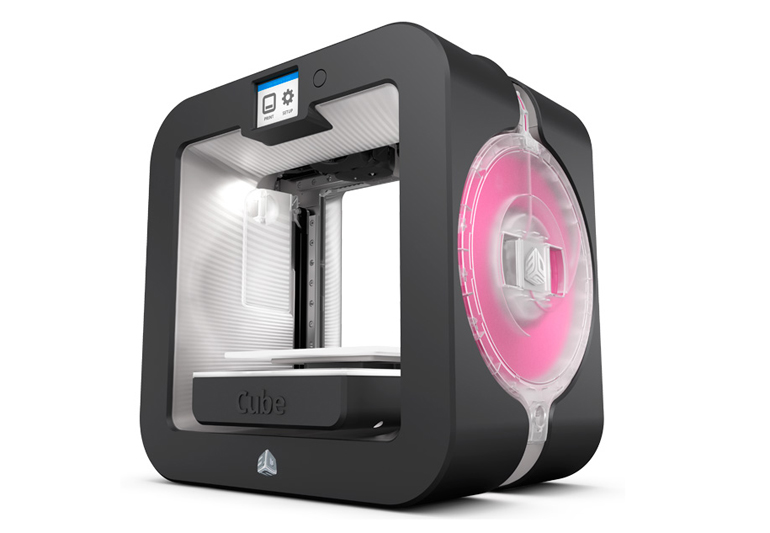

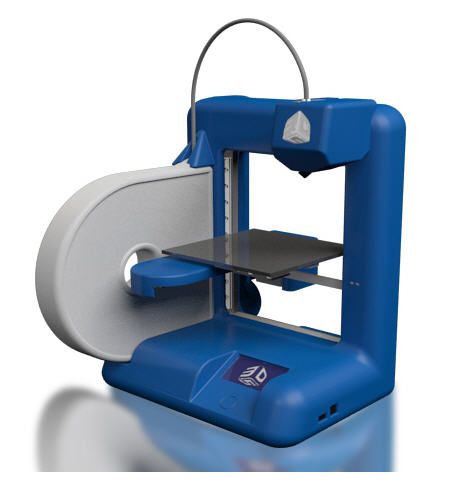

Design

3D Systems is onto its third generation of the Cube with all the enhancements this encompasses. An all-in-one cube casing houses the printer, hence the name, and is advertised primarily as a user-friendly personal desktop model. With simplicity in mind, it aims to introduce first-timers to the world of 3D printing without the oft-complicated installation of entry-level DIY models.

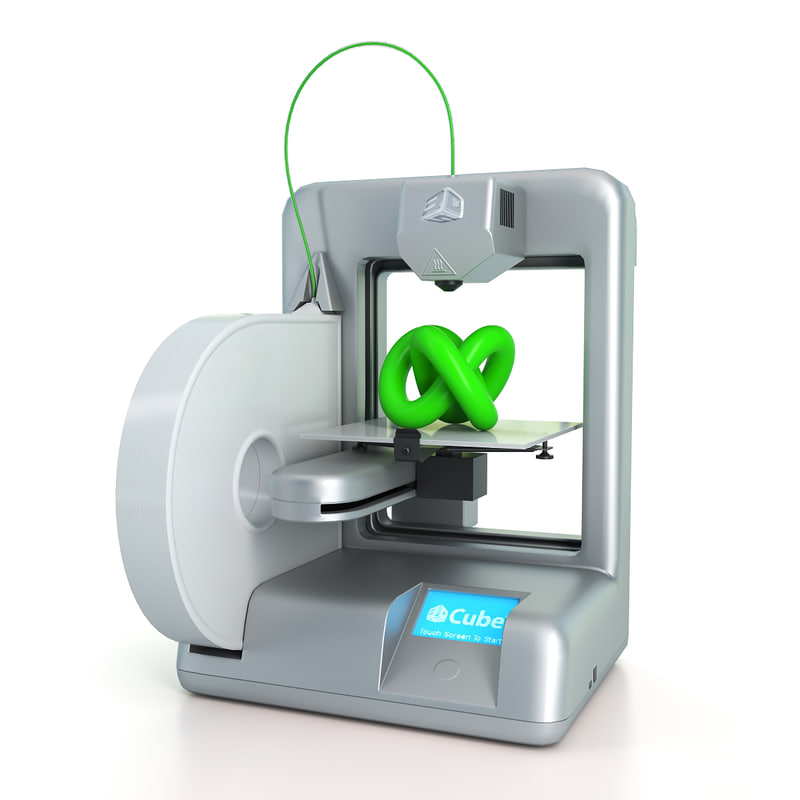

Straight out of the box, the Cube is a piece of engineering bliss. Aesthetically pleasing, compact, classy, and dare we say, beautiful, it resembles a product distributed by Apple, where functionality and ease of use are as much a consideration as design.

The sleek white exterior panels are miles away from the functional, bare-bones design of plenty rival models. So much so that the Cube is very much at home sitting alongside other home office devices rather than confined to a workshop. The self-contained shell means keeping track of diverse components isn’t a factor.

The print area is a modest 152x152x152mm, providing enough working space for most small scale projects, especially for beginners trying their hand at 3D printing for the first time. With both 0.2mm and 0.07mm (200 and 70 microns) print resolution layers, the Cube offers a degree of versatility, but not enough to cater for a large variety of print projects.

The print head ensures the X-axis, while the PrintPad (read build plate) manages the Y and Z axis. The PrintPad is removable for easy cleaning in hot soapy water. Every print job requires the application of Cube Glue, a weak adhesive produced by 3D Systems that assists the printed filament to solidly in place on the build plate. It takes some practice to apply the appropriate amount, and you need to wait for it to dry enough or suffer the consequences as we did.

The Cube sports dual extruders for simultaneous double color or material prints housed in out of sight purpose-built plastic casings that sit inside the vertical outer side panels. ABS and PLA are the only supported materials, and the Cube only works with 3D Systems proprietary filament Smart Cartridges that come in a selection of twenty-three colors.

These are significantly more expensive than generic filament bought from a hobbyist retailer, which was a big con for us when assessing the Cube 3D printer. These materials are of a higher quality, ostensibly, to justify the higher cost. To give 3D Systems its due, the ABS provided is recyclable, while the PLA is compostable, which softens the blow for the environmentally conscious maker. The company also asks users to ship back empty cartridges for recycling.

To give 3D Systems its due, the ABS provided is recyclable, while the PLA is compostable, which softens the blow for the environmentally conscious maker. The company also asks users to ship back empty cartridges for recycling.

Each cartridge includes its own integrated, snap-in nozzle, which it must be said, is incredibly simple to install and, in theory, foregoes the need to battle with removing debris and build up from the extruders every time. Two cartridges come as standard with each new device.

Connectivity through a USB port mounted on the bottom of the side casing (the package includes a USB flash drive) and a WiFi connection allowing the user to trigger prints from their computer or via a flash drive, gives options.

3D Systems have even designed a dedicated Cubify mobile app for both Android and iOS (plus MacOS and Windows through the Cubify software) packed with printing ideas, blueprints, and guides. The software converts into the required file type and forwards the instructions to the printer. It cannot be used to design prints though.

It cannot be used to design prints though.

The user interface, we love. Inviting and perfectly intuitive, it’s hard to go wrong using the in-built 2.5” color touch screen LCD. Beginners should find getting around the settings and options a breeze. Indicators such as how much material is left are welcome additions for users who might not have yet developed the skills to gauge how much filament a project requires.

Printing

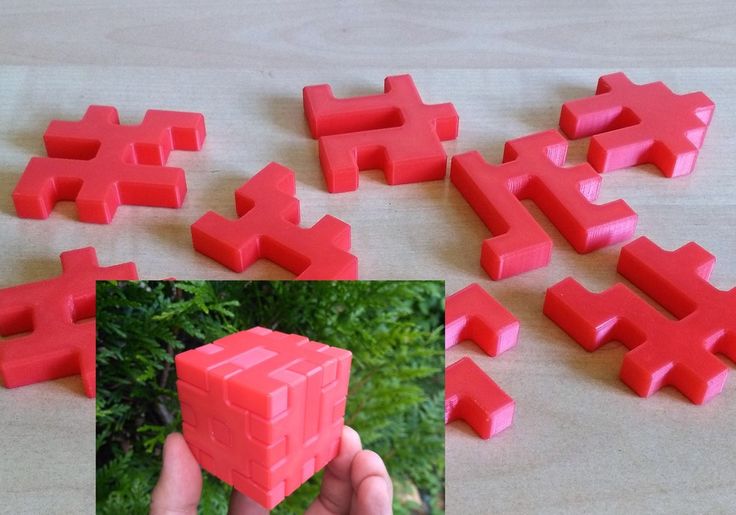

For a 3D printer touted as an out of the box solution, the printing process was hit or miss. The first few prints went well, especially for smaller prints. The results were generally error-free and full of detail with smooth contours and layers with few flaws. Ghosting was all but absent.

However, the Cube starts to struggle with larger projects that more often than not end in a bundle of filament only good for the landfill. The waste is especially hard to stomach given the exorbitant cost of the cartridges. The Cube Glue did little to fix the issue but works well for smaller prints.

Overall, the Cube is ideally suited to small jobs and is relatively economical with the material when it works correctly. From what we can gather, the lack of a heated plate, and the fact the software didn’t factor in the need for supports worked to the detriment of larger prints that require stability and uniform heat distribution as vertical layers build up.

The Cube is loud, to the point that it can become an annoyance by reverberating into adjacent rooms. For such a little machine, the noise is disproportionate possibly due to clanks bouncing off the casing.

Where our opinion of the Cube shifted drastically was when we encountered systematic jamming in the jet on the print head. The problem appeared to happen after only a handful of jobs using a brand new cartridge. Either the filament reacts badly to being exposed and goes brittle, or warehouse storage is conducive to the chemical properties of the plastic to harden more than necessary while sitting in the cartridge. It was hard to tell.

It was hard to tell.

Regardless, we have here a serious design flaw; feeding the filament through a tube doesn’t work well. Once a jam occurs, the nozzle does nothing but churn the plastic into a clumpy mess. If it isn’t a jam, the filament breaks inside the cartridge. There’s not much that can be done other than load in a replacement.

Speed wise, the Cube isn’t remarkable and gets the job done within acceptable limits.

Small prints can take anywhere from four to ten hours depending on the size, while bigger jobs were a bust most of the time, so we were never able to finish them to know how long the process takes.

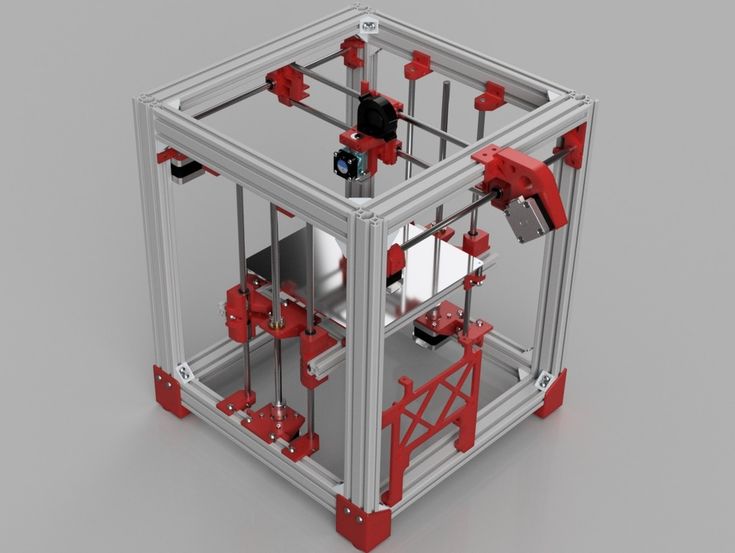

Assembly

The Cube comes pre-assembled and only requires the user to install the cartridges, a straightforward procedure. The Cube is packaged well and comes with a quick start manual, USB key, cabling, glue, spatula, plyers, power supply, and the printer itself.

The Cube self-calibrates by make sure the build plate is perfectly level and at the right distance from the print head via a set of magnets under the plate, although the device asks the user to tweak the plastic circular knobs below the plate as required. The instructions are straightforward and won’t daunt even the most unversed user.

The instructions are straightforward and won’t daunt even the most unversed user.

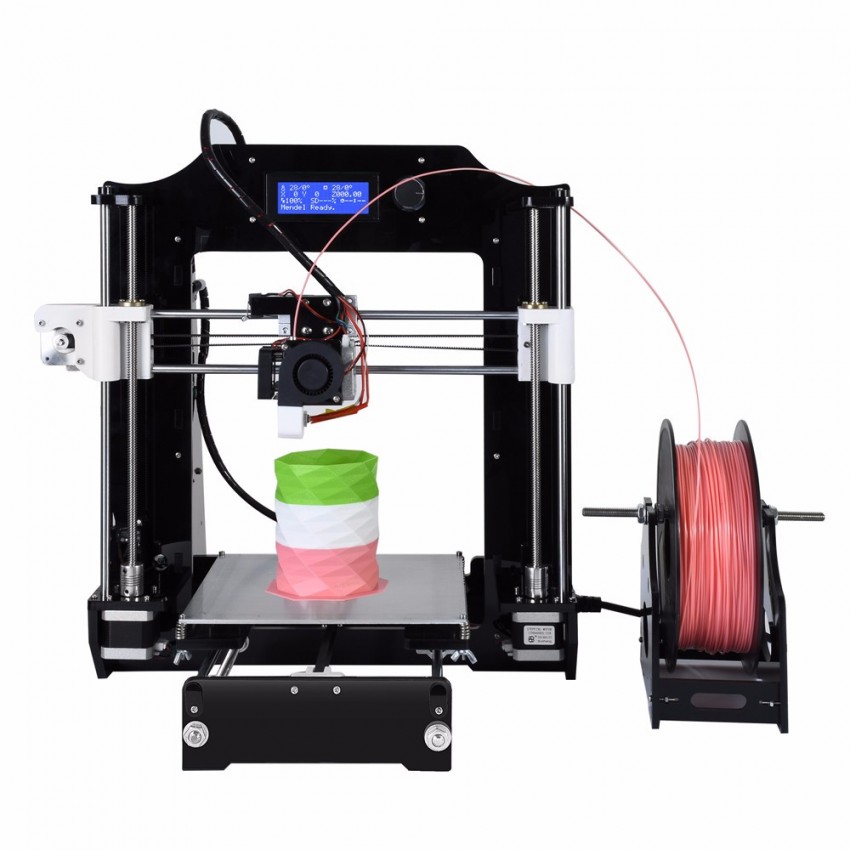

That aside, the Cube allows you to be up and printing within 45 minutes after unboxing the device, unheard of for printers in this price range where hours of assembly are the name of the game.

Support

3D Systems has discontinued the Cube, and the model is no longer in production, arguably due to lackluster reviews caused by the filament jamming issue.

As a consequence, the Cube is now available at a fraction of the cost of its initial retail price, around the $1000 mark. You can pick one up for around $200-$300 on Amazon, if not less. 3D Systems continues to sell cartridges for the time being, although third-party manufacturers have popped up selling them at a fraction of the cost.

Support wise, 3D Systems offers a 90-day warranty for parts and labor, but no refunds whatsoever due to discontinuing the product. Specific resellers may offer different refund policies.

3D Systems has a robust after-sales support service with a dedicated phone team that can help with the jamming issue by walking through a variety of detailed fixes. They’ll also walk through updating the Cubify software to the latest firmware which helps with printing problems to a certain degree. Alongside are forums, guides, and articles about getting the most out of the Cube.

They’ll also walk through updating the Cubify software to the latest firmware which helps with printing problems to a certain degree. Alongside are forums, guides, and articles about getting the most out of the Cube.

Verdict

The Cube isn’t a bad printer overall and produces some quality results for smaller projects. The design is the model’s strongest asset, and it’s hard to find fault with the look, feel, and ease of use (bar the jamming issue).

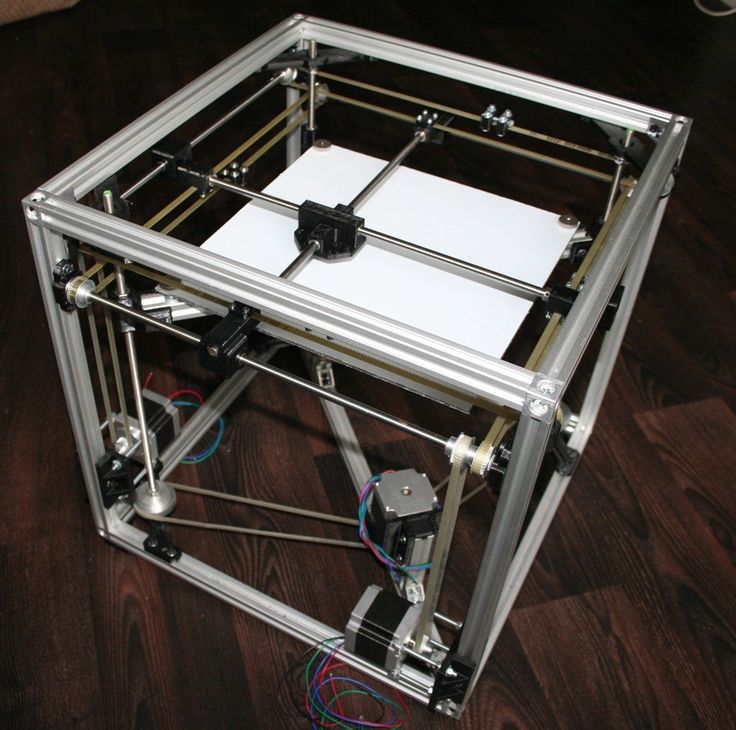

At a much-reduced price, the Cube is an ideal no-nonsense first time 3D printer for those who want to experience the joys of printing without the hassle and tinkering of similarly priced DIY equivalents. The dual extruder setup is also a bargain.

The cartridges are a downside, but if you buy them from a third-party, the costs are more palatable. There’s also a DIY fix for the jamming problem, which isn’t particularly difficult to perform and is an excellent way to introduce a beginner to the modification aspect of the hobby.

The Cube isn’t ideal, but its hard to argue with for the bargain price.

3D Systems Announces Cube®3 and CubeProTM 3D Printers Availability

Get There Easy and Print Pro with 3DS’ 2014 desktop Cube printers

Beautiful, high-definition 70-micron layer thinness for finer-res prints

Instant material loading that is easier than changing an ink cartridge

Faster speed with simultaneous multi-material and multi-color printing

Cube 3 is priced at easy-to-own $999

ROCK HILL, South Carolina – May 20, 2014 – 3D Systems (NYSE:DDD) announced today that its recently unveiled Cube® 3 and CubeProTM 3D printers will commence commercial shipments in the second half of June 2014 and are now available for pre-order on Cubify.com and through affiliated retailers, resellers and distributors. Previewed at the 2014 Consumer Electronics Show, the Cube 3 and CubePro take consumer 3D printing and desktop engineering experience to a new level, with multi-color and multi-materials, the highest resolution available at 70 micron layers, faster print speeds and printing on the go, directly from a smartphone with the new Cubify mobile app, to be released when the printers ship.

Both the Cube 3 and CubePro are designed to fit any lifestyle or workplace with 3D printing made easy and pro. Whether you are an engineer or a fashionista, a kid or a hobbyist, the Cube series can fulfill your complete range of 3D printing needs with expanding materials and design tools that are complemented by 3DS’ Cubify.com, the ultimate destination for users to co-create with brands, stylize printable content added daily and share what they’re making in the Design Feed.

Cube 3 is the only dual material, plug-and-play, kid-safe certified 3D printer that is also the easiest and most affordable to own at $999. Cube comes with two starter cartridges in neon green and white, and 25 designs to get printing quickly.

Cube 3 Features:

Print Fast, Print More – Cube 3 delivers up to 2X faster print speed and accuracy than competitors for printed parts up to 6” cubed. 70 micron-layer thinness gives prints smoothness and fine detail for textures at the highest resolution available in consumer 3D printing today. Full tech specs are available here.

Full tech specs are available here.

Simultaneous Dual Color + Multi-Material = More Choice – Cube now prints in two materials and up to two colors, simultaneously using compostable PLA and recyclable ABS plastics. Both materials are available in 23 different color cartridges. Cube offers a choice of print mode fill density: hollow, strong and almost solid in both PLA and ABS plastics with optional, easy breakaway supports for the most complex prints.

Instant Load Cartridge - Instant material loading is now easier than changing an ink cartridge. The new non-clog technology and moisture-lock cartridges ensure extended shelf life and total material usage, improving print quality and sustainability. The printer detects material type automatically based on the cartridge, eliminating the need to change print settings. The cartridges are easy to load and store while preserving the life and quality of the materials.

Kid-Safe for Everyone – Cube meets all IEC 60950 Printer Safety Requirements, making it the only consumer 3D printer that is kid-safe for the home and classroom.

Convenience in the Palm of Your Hand - Enjoy the freedom of mobile printing directly from the Cubify app for iOS and Android. Find new things to print in the curated brand collections or browse the Design Feed for inspiration to add to your Shelf. Prep and print from your smartphone direct to Cube.

Easier to Use, Sleeker Design – Building on its iconic design, the new Cube features a color touchscreen with an intuitive user interface and sleek LEDs highlighting prints in action, and is equipped with faster Wi-Fi and Bluetooth connectivity, an auto-leveling printpad and easy support removal on complex prints.

Sustainable Systems – 3DS is committed to making consumer 3D printing affordable, safe and sustainable. Send back empty cartridges to designated 3DS locations for reuse in exchange for a discount on new cartridges and return used ABS and PLA prints for responsible recycling or composting by 3DS. All Cubes will be shipped from local distribution centers reducing freight. Cube comes with a proprietary print pad that conserves power compared to other 3D printers.

Cube comes with a proprietary print pad that conserves power compared to other 3D printers.

The professionally capable CubePro is the only triple material, controlled print chamber, engineer’s desktop 3D printer, that starts at $2,799 making it an affordable tool for the garage entrepreneur at home, independent designer and engineer’s desktop.

CubePro Features:

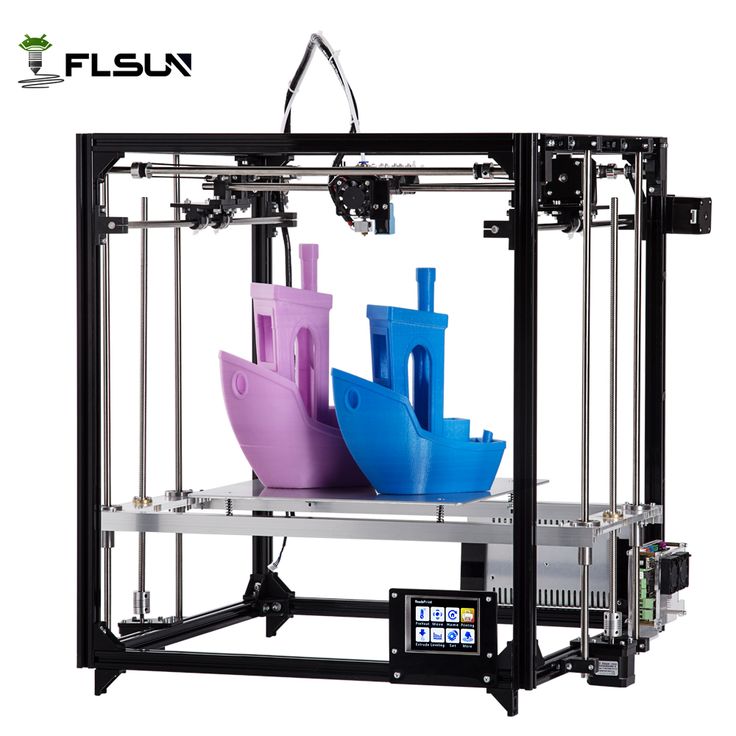

Print Big, Print Fast – Print more and faster with the largest-in-class print platform, high-resolution prints and quick set up. With prints 2.5 times larger than any other desktop prosumer and hobbyist printer (10.8” x 10.45” x 9.5” or 275 mm x 265 mm x 240 mm), and guaranteed faster, more precise prints with easy feed cartridges for prolonged material life.

Print Precise, Print Professional - Ultra high-resolution settings of 70-micron thin print layers, professional quality printing has never been so easy and fast. Choose automated slicing settings for quick draft prints or utilize Advanced Mode to set custom infill patterns, inner and outer surface layer sizing and outer wall thinness. Full technical specifications are available here.

Full technical specifications are available here.

Controlled Print Chamber – Controlled process environment ensures true to CAD prints and delivers professional quality every time. Automated settings deliver safe home printing in your mancave, on your workbench and at your desktop.

Triple Color + Materials = Thousands of Options – Available in three print head configurations, CubePro allows users to get more expressive with 3D printing in up to three simultaneous colors and more color options. In addition to ABS and PLA plastic, CubePro also supports a new engineering grade nylon material, perfect for end-use applications, making it a very versatile engineering and hobbyist printer.

Connect Better– Connect intuitively through an easy-to-use color touchscreen display and WiFi capability.

Sustainable Systems – 3DS is committed to making prosumer 3D printing affordable, safe and sustainable. Send back empty cartridges to designated 3DS locations for reuse in exchange for a discount on new cartridges and return used ABS, Nylon and PLA prints for responsible recycling or composting by 3DS. CubePros will be shipped from local distribution centers reducing freight. The new CubePro comes with a proprietary print pad that conserves power compared to other 3D printers.

Send back empty cartridges to designated 3DS locations for reuse in exchange for a discount on new cartridges and return used ABS, Nylon and PLA prints for responsible recycling or composting by 3DS. CubePros will be shipped from local distribution centers reducing freight. The new CubePro comes with a proprietary print pad that conserves power compared to other 3D printers.

Which room in your home will your Cube live in? Learn more about 3D printing made easy for your lifestyle here. Watch a video of the new Cube 3 and CubePro.

###

Forward-Looking Statements

Certain statements made in this release that are not statements of historical or current facts are forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements may involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the company to be materially different from historical results or from any future results or projections expressed or implied by such forward-looking statements. In addition to statements that explicitly describe such risks and uncertainties, readers are urged to consider statements in the conditional or future tenses or that include terms such as “believes,” “belief,” “expects,” “estimates,” “intends,” “anticipates” or “plans” to be uncertain and forward-looking. Forward-looking statements may include comments as to the company’s beliefs and expectations as to future events and trends affecting its business and are necessarily subject to uncertainties, many of which are outside the control of the company. The factors described under the headings “Forward-Looking Statements,” “Cautionary Statements and Risk Factors,” and “Risk Factors” in the company’s periodic filings with the Securities and Exchange Commission, as well as other factors, could cause actual results to differ materially from those reflected or predicted in forward-looking statements.

In addition to statements that explicitly describe such risks and uncertainties, readers are urged to consider statements in the conditional or future tenses or that include terms such as “believes,” “belief,” “expects,” “estimates,” “intends,” “anticipates” or “plans” to be uncertain and forward-looking. Forward-looking statements may include comments as to the company’s beliefs and expectations as to future events and trends affecting its business and are necessarily subject to uncertainties, many of which are outside the control of the company. The factors described under the headings “Forward-Looking Statements,” “Cautionary Statements and Risk Factors,” and “Risk Factors” in the company’s periodic filings with the Securities and Exchange Commission, as well as other factors, could cause actual results to differ materially from those reflected or predicted in forward-looking statements.

About 3D Systems

3D Systems is a leading provider of 3D printing centric design-to-manufacturing solutions including 3D printers, print materials and cloud sourced on-demand custom parts for professionals and consumers alike in materials including plastics, metals, ceramics and edibles. The company also provides integrated 3D scan-based design, freeform modeling and inspection tools and an integrated 3D planning and printing digital thread for personalized surgery and patient specific medical devices. Its products and services replace and complement traditional methods and reduce the time and cost of designing new products by printing real parts directly from digital input. These solutions are used to rapidly design, create, communicate, prototype or produce functional parts and assemblies, empowering customers to manufacture the future.

The company also provides integrated 3D scan-based design, freeform modeling and inspection tools and an integrated 3D planning and printing digital thread for personalized surgery and patient specific medical devices. Its products and services replace and complement traditional methods and reduce the time and cost of designing new products by printing real parts directly from digital input. These solutions are used to rapidly design, create, communicate, prototype or produce functional parts and assemblies, empowering customers to manufacture the future.

Leadership Through Innovation and Technology

- 3DS invented 3D printing with its Stereolithography (SLA) printer and was the first to commercialize it in 1989.

- 3DS invented Selective Laser Sintering (SLS) printing and was the first to commercialize it in 1992.

- 3DS invented the Color-Jet-Printing (CJP) class of 3D printers and was the first to commercialize 3D powder-based systems in 1994.

- 3DS invented Multi-Jet-Printing (MJP) printers and was the first to commercialize it in 1996.

Today its comprehensive range of 3D printers is the industry’s benchmark for production-grade manufacturing in aerospace, automotive, personalized surgery, medical devices and a variety of consumer, electronic and fashion accessories.

More information on the company is available at www.3DSystems.com.

Top 20 Free 3D Printing & 3D Printing Software

Looking for 3D printing software? We've rounded up the top 20 software tools for beginners and professionals alike. Most slicers are free.

What is a slicer? This is a program for preparing a digital model for printing. Models for 3D printing are usually distributed in STL files. To turn an STL file into G-code (a language that a 3D printer understands), a slicer program is required. It is called a slicer because it cuts (to slice - English) a 3D model into many flat two-dimensional layers, from which a 3D printer will add a physical object. nine0005

nine0005

Which slicer should I choose? In this article, we will tell you which slicer is best for 3D printing for each stage of your work. Which one is better for preparing a 3D model for printing? But what if you need to create a 3D model from scratch? And if you are only taking the first steps in 3D?

Don't be afraid: we've answered all of these questions, including the required skill level for each program and where you can download it. The great thing is that most of these programs are completely free and open source. nine0005

- Cura

- CraftWare

- 123D Catch

- 3D Slash

- TinkerCAD

- 3DTin

- Sculptris

- ViewSTL

- Netfabb Basic

- Repetier

- FreeCAD

- SketchUp

- 3D Tool

- Meshfix

- Simplify3D

- Slic3r

- Blender

- MeshLab

- Meshmixer

- OctoPrint

#1: Cura

For beginners who need a slicer to prepare STL files for 3D printing

Cura is the default slicer software for all Ultimaker 3D printers, but can be used with most others , including RepRap, Makerbot, Printrbot, Lulzbot and Witbox. The program is completely open source, its capabilities can be extended using plugins.

The program is completely open source, its capabilities can be extended using plugins.

This program is very easy to use and allows you to manage the most important 3D printing settings through a clear interface. Start in Basic mode to quickly get up to speed and change print quality settings. If finer control is required, switch to Expert mode. nine0005

Cura can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: Cura

Price: Free

Systems: PC, Mac, Linux

#2: CraftWare

3D printers by the Hungarian startup CraftUnique to support their CraftBot crowdfunding machine. However, the program works with other printers. nine0005

Like Cura, CraftWare allows you to switch from "Easy" to "Expert" mode, depending on how confident you feel. It's a colorful app that features a visual G-code visualization with each function represented by a different color. But the most outstanding feature is the individual support service. As far as we know, only the paid program Simplify3D has this.

As far as we know, only the paid program Simplify3D has this.

Please note, however, that this program is still in beta, so bugs may occur. nine0005

Download: CraftWare

Price: Free

Systems: PC, Mac

#3: 123D Catch

-systems, smartphones and tablets, which allows you to convert images of objects into a 3D model. Pictures can be taken with a smartphone/tablet or digital camera.

You need many photos of an object from different angles - the more the better - after which they will be compiled into a 3D model. nine0005

123D Catch is more of a fun app than a professional 3D printing tool, but after some tambourine dancing, you can get good results, especially when paired with an STL editor like MeshLab or Meshmixer.

Price: Free

Systems: PC, Android, iOS, Windows Phone

#4: 3D Slash

and surprisingly simple, and refreshingly new. With 3D Slash, you can design 3D models using your dice skills. nine0005

nine0005

You can start with a large block and, like a virtual sculptor, remove small cups from it with tools such as a hammer or drill, or start from empty space and build a model from cubes and other shapes. You can paint with flowers or use template pictures.

Other features worth mentioning are tools for creating logos and 3D text. The Logo Wizard imports an image and creates a 3D model, while the Text Wizard allows you to enter and format text, and then turn it into 3D. nine0005

Recommended!

Download: 3dslash.net

Price: Free

Systems: PC, Mac, Linux, Browser

#5: TinkerCAD

- A computer-aided design (CAD) system for 3D printing, which is a good starting point for beginners. Since its capabilities are limited compared to Blender, FreeCAD and SketchUp, many users switch to more powerful tools after some time. nine0005

As in 3D Slash, here you can build models from basic shapes. At the same time, unlike 3D Slash, TinkerCAD allows you to create vector shapes in 2D and convert them into three-dimensional models.

Come in: Autodesk TinkerCAD

Price: Free

Systems: Browser

#6: 3DTin

For beginners who want to create 3D printable models

another easy and intuitive online tool choice for beginners in 3D modeling. All you need is a Chrome or Firefox browser with WebGL enabled. nine0005

Choose from a huge library of 3D shapes and add them to your sketch. All sketches are stored in the cloud, access to them is free if you honor the Creative Commons license. Everything can be exported to STL or OBJ formats.

Enter: 3DTin

Price: Free

Systems: Browser

#7: Sculptris

For beginners who want to create 3D printable models

clay. This is a fantastic 3D modeling program if figurines are your main task. For example, you can make a bust of your favorite video game or comic book character. Sculptris is completely free and bills itself as a stepping stone to the more complex (and expensive) ZBrush tool. nine0005

nine0005

Download: Pixologic Sculptris

Price: Free

Systems: PC, Mac

#8: ViewSTL

For beginners who want to view STL files

ViewSTL is the easiest way to view STL files . Simply open a web page and drag the STL onto the dotted box.

The STL online viewer allows you to display the model in one of three views: flat shading (for a quick view), smooth shading (for a high-quality image), and wireframe. nine0005

Enter: ViewSTL

Price: Free

Systems: Browser

#9: Netfabb Basic

some nice features that allow you to analyze, "repair" and edit STL files before moving on to the model cutting stage.

A good choice if you need more than just a slicer and want to be able to quickly fix STL files without having to learn programs like MeshLab or Meshmixer. nine0005

Don't let the 'Basic' in the title fool you, Netfabb Basic is actually a very powerful 3D printing tool. It's "basic" only in the sense that it doesn't cost €1,500 like Netfabb Professional!

Download: netfabb. de

de

Price: Free

Systems: PC, Mac, Linux

No. 10: Repetier

For advanced to prepare STL files for 3D printing

9002 the next level of 3D printer slicer software, but if you want to stay open source, you should look into Repetier. It is the great grandfather of 3D printing software and a favorite of the RepRap community. nine0005To date, the program is moving by leaps and bounds from the level for beginners to advanced users. Packaged in an all-in-one configuration, it supports up to 16 extruders, multi-slicing via plug-ins, and virtually every fusing 3D printer on the market. Get ready to tinker!

What's more, Repetier Host works remotely via Repetier Server, so that the 3D printer can be controlled via a browser, tablet or smartphone. nine0005

Download: Repetier

Price: Free

Systems: PC, Mac, Linux

#11: FreeCAD

The program is a great option for developing your design skills. More technically, this parametric 3D modeling program allows you to easily change the project by rolling back through the history of the model and editing the parameters. nine0005

nine0005

Download: freecadweb.org

Price: Free

Systems: PC, Mac, Linux

#12: SketchUp

For beginners who want to create 3D printable models

SketchUp is the perfect combination of simplicity and the perfect combination functionality, with a user-friendly interface and a relatively flat learning curve (i.e., as experience grows with the time spent), the ideal program for developing three-dimensional models.

The Make SketchUp version is free and will include everything you need for 3D modeling if you also download and install the free STL exporter. There is also a professional edition for architects, interior designers and engineers. nine0005

Download: sketchup.com

Price: Free (SketchUp Make), $695 (SketchUp Pro)

Systems: PC, Mac, Linux

#13: 3D-Tool Free Viewer

view and validate STL files

3D-Tool Free Viewer is a sophisticated tool that, among other things, allows you to check the structural integrity and printability of your file. With the Cross-Section function, for example, you can look at the model from the inside and check the wall thickness. Very useful if you want to check your STL file for killer errors before printing. nine0005

With the Cross-Section function, for example, you can look at the model from the inside and check the wall thickness. Very useful if you want to check your STL file for killer errors before printing. nine0005

Download: 3D-Tool

Price: Free

Systems: PC

#14: Meshfix

your model for errors.

Price: Free

Systems: Browser

#15: Simplify3D

For professionals to prepare STL files for 3D printing print. A flexible algorithm checks the model for problems, fixes them, shows a preview of the printing process (ideal for identifying potential problems), and then slices it. nine0005

This slicer offers the best infill pattern options in the competition. For models that require supports, Simplify3D will create the appropriate structures on its own and give you full control over their placement. For printers with a dual extruder, when printing with different materials, the Dual Extrusion wizard will help, as a result of which, for example, it will be easier to remove the dissolving filament.

Simplify3D supports 90% of today's commercially available desktop 3D printers and is compatible with Marlin, Sprinter, Repetier, XYZprinting, FlashForge, Sailfish and MakerBot firmware. Simplify3D can also be used to directly control the printer, but then the printer and computer must be connected to each other. nine0005

Download: simplify3d.com

Price: $149

Systems: PC, Mac, Linux

#16: Slic3r

source code, which has a reputation as a carrier of super new functionality, which you will not find anywhere else. The current version of the program is able to show the model from multiple angles, so that the user gets a better preview experience.

There's also an incredible 3D honeycomb infill, the first of its kind that can extend over multiple layers rather than repeating itself like a stamp. This significantly increases the strength of the internal filling of the model and the final printout.

Another option is direct integration with Octoprint. Once the files on the user's desktop are sliced, they can be directly uploaded to Octoprint with one click.

Once the files on the user's desktop are sliced, they can be directly uploaded to Octoprint with one click.

Download: Slic3r

Price: Free

Systems: PC, Mac, Linux

#17: Blender

For professionals who want to create 3D printable models

Blender is a popular computer-aided design (CAD) system with a steep learning curve. Not at all the best choice for beginners, but what you need if you are quite experienced and need something more complex for modeling and printing.

In short, Blender is one of the most powerful tools out there. Its community is always ready to help, there are a lot of educational materials. It's also open source, so enthusiasts often write extensions to make it even better and more powerful. nine0005

Download: blender.org

Price: Free

Systems: PC, Mac, Linux

#18: MeshLab

For professionals to prepare STL files for 3D printing

MeshLab - advanced editor. It allows you to remove parts of a 3D model, merge two models into one, patch holes. If you need a program to modify models for 3D printing or some kind of "repair" work, MeshLab is the right choice.

It allows you to remove parts of a 3D model, merge two models into one, patch holes. If you need a program to modify models for 3D printing or some kind of "repair" work, MeshLab is the right choice.

Price: Free

Systems: PC, Mac, Linux

#19: Meshmixer

For professionals to prepare STL files for 3D printing files. It's especially good for identifying potential problems and fixing them automatically. For example, it will show paper-thin walls that can lead to problems with 3D printing. Meshmixer is part of the Autodesk family of 3D printer software, so it should work well with tools like TinkerCAD. nine0005

Price: Free

Systems: PC, Mac

#20: OctoPrint

start, pause or interrupt 3D print jobs. Combined with Wi-Fi capable devices, it makes for a great monitor for remotely monitoring the 3D printing process.

Octoprint understands the G-codes of almost all 3D printers and slicers and includes a gCodeVisualizer to visualize this code before or during printing. nine0005

nine0005

If you want to work away from your 3D printer and control it remotely, Octoprint is the best you can find.

Download: octoprint.org

Price: Free

Systems: PC, Mac, Linux

Source

Custom 3D Printing | 3D Printing of Large Plastic Products from Tsar3D

How printing works on an FDM 3D printer

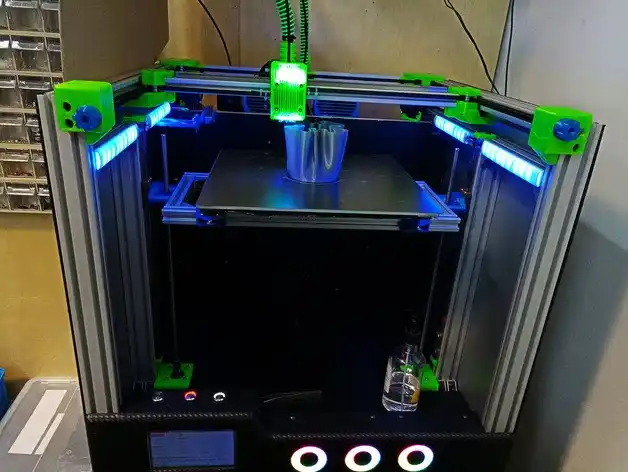

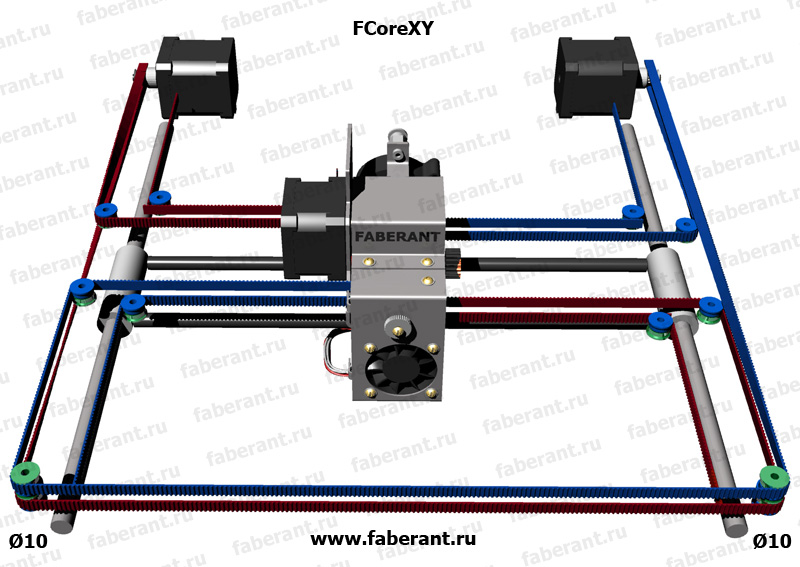

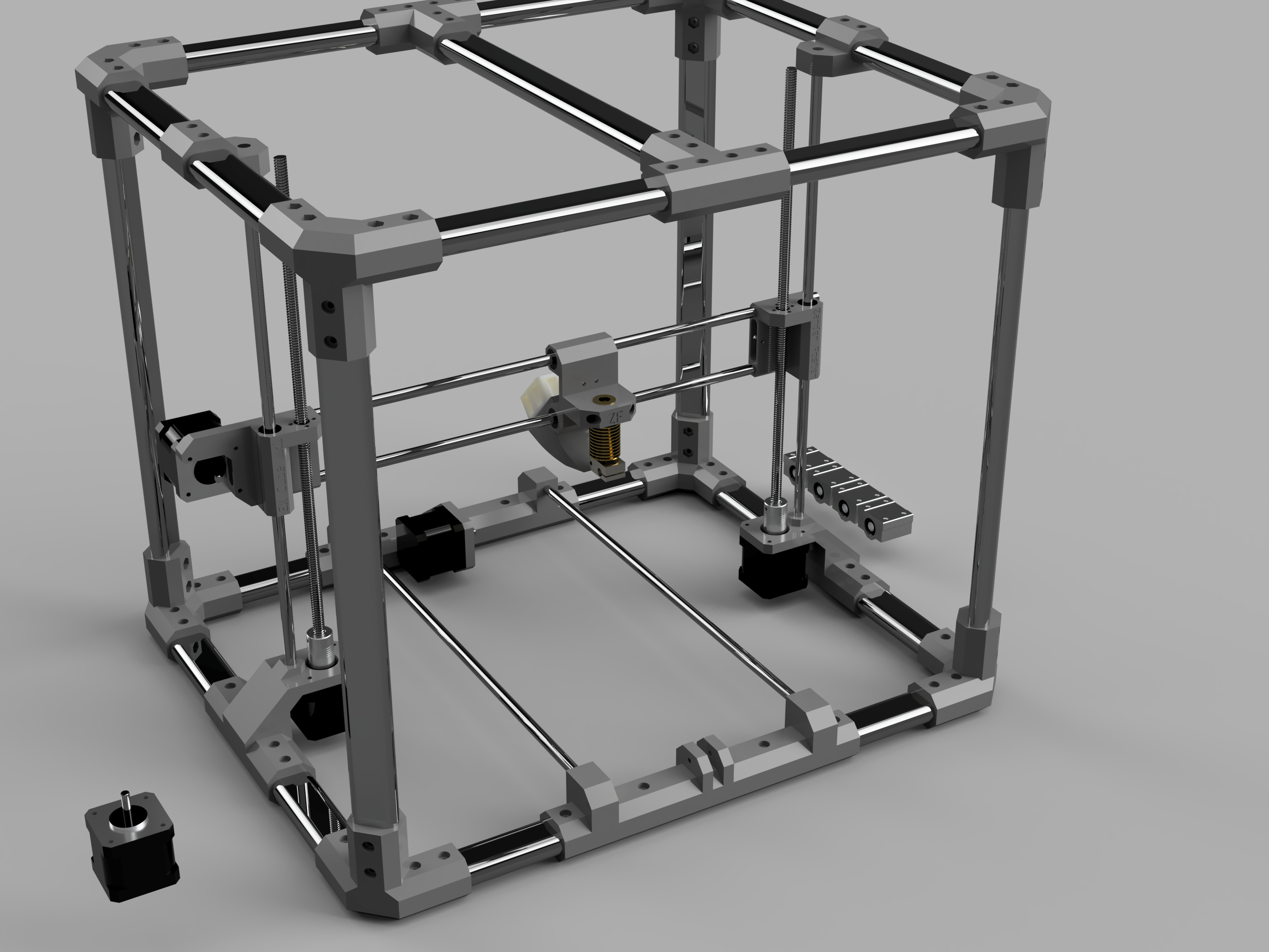

A simplified scheme for 3D printing using FDM technology (FFF)

The essence of technology 3D printing FDM consists of the following: A plastic filament is pushed into the nozzle of an extruder moving along a program in a horizontal plane. After the start of the 3D printing process, the plastic is melted in the nozzle and applied in layers, forming the product according to the 3D model loaded into the printer. If it is necessary to form overhanging geometry elements, then the printer uses a second extruder to extrude supporting structures from the second type of plastic for 3D printers. This support plastic breaks off or dissolves after printing is complete. nine0005

nine0005

Why order 3D printing from us

Extensive experience in the industry

We are experts in the application of FDM 3D printing for commercial enterprises

Own fleet of 3D printers

We fulfill orders in our own production, so the cost of the service is minimal 9005 9005 Economic efficiency

We provide the best price / quality ratio depending on the requirements for the product

Material and maximum dimensions of parts

Our main work is 3D printing of large items made of PLA plastic. It is a durable plastic that can be sanded and painted. The softening temperature is about 50 degrees Celsius, melting - 175 degrees Celsius. Density - 1.25 g/cm3 cu. .3 MPa

Printing from ABS, PETG, SBS, carbon-filled, metal-filled and other plastics and composites is also possible.

The maximum dimensions of the printed part are 1.2 meters x 0.6 meters in the horizontal plane and 0.9meters in height.

Also available with PETG. SBS is used as plastic for supports.

Benefits of printing with our 3D printers

Our industrial 3D printers are equipped with professional high performance extruders. As a result of their application, the best interlayer adhesion is obtained, the product is obtained with monolithic walls. In addition, the speed of 3D printing is generally faster - up to 10 times compared to printing on desktop 3D printers. nine0005

When printing large parts, the choice often arises: to print the product as a whole or from parts with subsequent gluing.

The correct solution in this case is to 3D print entirely on a large printer, because there is no need for gluing and grinding of joints - this leads to a reduction in manufacturing costs up to 70%, because gluing and grinding is done by hand and is a laborious process that requires time, equipment and consumables.

Also, in 3D printing, the main reason for the inapplicability of gluing a product from parts is too large deviations in the dimensions of the product. nine0005

Delivery

Tsar3D operates throughout Russia and the CIS. We carry out high-quality packaging of 3D printed parts, models and send orders by transport companies, so we can bring the finished product to your city.

Custom 3D printing

3D printing throughout Russia

We accept orders from customers throughout Russia and the CIS. You can always remotely order 3D printing of large and small products by contacting us via the feedback form or by phone. Let's carry out delivery to any region of the Russian Federation. nine0005

3D printing in Moscow

We carry out high-quality 3D printing in Moscow and Moscow region on favorable terms for our regular customers. Delivery to the city within 1-3 working days.

3D printing in St. Petersburg

Cheap and fast 3D printing in St.