Ctc 3d printers

CTC Thermocouples - 3D Printers - Talk Manufacturing

Maynard57

#1

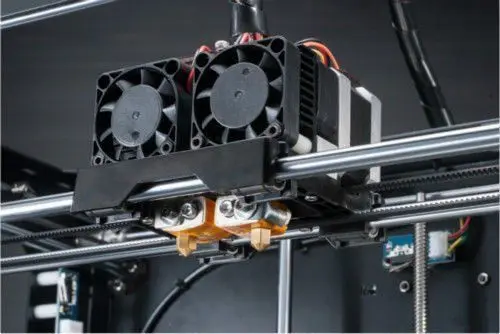

Both TC’s broke. The info I had that they were type K. Installed new type K TC’s and now machine will not get to heat. TC’s removed were s silver and a copper color wires. I think that the TC’s should be type T (copper-constantan) not type K. Did CTC produce dual extruders with type T thermocouples?

CatalystService

#2

We recently replaced the thermocouples on ours, here are the exact ones we used: Mini Solar Toy DIY Car Children Educational Puzzle IQ Gadget Hobby Robot M2 2pcs for sale online | eBay

SEngineering

#3

Double check your polarity, TCs will not read in reverse.

Maynard57

#4

Thanks for the suggestion, but polarity is correct . Wire covering color is red and blue, this would indicate an copper-constantan thermocouple.

Maynard57

#5

Well it is confirmed, the TC’s that are on my CTC dual 3D printer are type T (copper-constantan) not type K. I took the 2 old TC’s and made one that was long enough to reach from the extrude to the control board by splicing in a piece for the broken section. Printer now back up and running on the right extruder. Now to buy some type T TC’s.

MakeCoolThings

#6

These are the ones used on the CTC and other Replicator clones: Mini Solar Toy DIY Car Children Educational Puzzle IQ Gadget Hobby Robot M2 2pcs for sale online | eBay

If your printer is still under the 1-year warranty you should contact the seller and try to get parts through them, first. I had a TC go bad and got a replacement through my seller for the cost of postage.

I had a TC go bad and got a replacement through my seller for the cost of postage.

trigger99

#7

what error on the lcd is it 4# or 1#

Maynard57

#8

Not sure what the error # was. I know that it is type T (copper-constantan, red-blue tracers in insulation) as I made up a TC with a copper wire and a constantan wire from a type J (iron-constantan TC). Temperature reading on the LCD and a Omega pyrometer agree within a few degrees. Someone made the data tabel or calibration on my CTC as Type T instead of K.

trigger99

#9

i no its a k type when it stops working or stops reading it makes a sound and tell you on the lcd error 4# this is what happend to me

Maynard57

#10

Your CTC may be type K but my CTC is type T. I have been working with thermocouples for the last 50 years, and have made thousands of them for manufacturing facilities temperature processes.

I have been working with thermocouples for the last 50 years, and have made thousands of them for manufacturing facilities temperature processes.

DonJuanito

#11

If your thermocouple problem has not yet been resolved, keep in mind that in most fitted thermocouples you’ll find on the webstores, the thermocouple itself is NOT insulated from the press-fitted ring. That’s a no-go for most CTC builds as you could fry the thermocouple converter ICs on the motherboard. I replaced mine and (luckily) discovered this before installing them. I insulated the coupling with Kapton tape before refitting the ring over it…

James_Evans

#12

Hi,

Can you give me more detail on what you mean? As my old thermocouples look the same as my new yet i have indeed fried the boards chip. New board on the way.

New board on the way.

Maynard57

#13

Well, the CTC & Makerbot web sites say that the TC’c are type K (color code on wires Red & Yellow) I found that my CTC printer the wires are type T (Color code on wires Red & Blue). On type T TC’s one of the wires is copper and the other is silver color. Remember that TC’s are DC millivolts so polarity is important.

DonJuanito

#14

Hi. Sorry for the late response, I’ve been ill…

The main cause for burnt out MAX6675 is that the fixed “+24V” wire entering one of the heater cartridges is sometimes exposed and can be in contact with the heater block. If this happens and your thermocouple is not electrically insulated from the chassis, you’ll be sending 24V down the throat of the 5V MAX6675 input lines, frying it instantly (nearly any silicon junction dies by shorting itself, but if the current is sufficiently high, it can evaporate). So, if the short between the +24V and the heater chassis is maintained, the MAX6675 silicon die could be evaporated. In this case, the +24V could potentially propagate to any other IC on the board, including the CPUs.

If this happens and your thermocouple is not electrically insulated from the chassis, you’ll be sending 24V down the throat of the 5V MAX6675 input lines, frying it instantly (nearly any silicon junction dies by shorting itself, but if the current is sufficiently high, it can evaporate). So, if the short between the +24V and the heater chassis is maintained, the MAX6675 silicon die could be evaporated. In this case, the +24V could potentially propagate to any other IC on the board, including the CPUs.

That’s the reason why on my boards, I do two modifications :

- Connect a chassis drain wire between the heater block assembly and the power supply ground line (earth).

- Insulate both thermocouples with Kapton tape. To do this, I carefully open the FastOn eyelets, insulate the thermocouple with two to four loops of Kapton tape, then reseal the eyelet. This introduces a small offset in the head temperatures reading, but it never has had any adverse effects on my prints.

I hope these explanations are meaningful for you. In any case, contact me if you need more information or a clarification.

In any case, contact me if you need more information or a clarification.

Metal Additive Manufacturing | Concurrent Technologies Corporation

Concurrent Technologies Corporation (CTC) offers a variety of Additive Manufacturing (or 3D Printing) processes to provide our clients both complex part manufacturing and the ability to repair worn or damaged high-cost components.

Whether you need specific part geometry for performance enhancements or a cost-effective repair process for high-dollar components, CTC’s experts offer the Metal Additive Manufacturing process that can get you results in days. Our engineers can move you quickly from concept and design to manufactured product. These processes can also be merged together to provide customized solutions. Contact us today for a free quote.

Concurrent Technologies Corporation’s In-House Processes:

Concurrent Technologies Corporation applies its 30-year history in metals and metal processing solutions to be an all-encompassing service provider for Metal Additive Manufacturing/3D Printing solutions. We provide a comprehensive suite of services including reverse engineering, process development, characterization of powder and substrate, surface profile preparation, material application, post processing, final machining, and inspection. CTC also provides services to evaluate, validate, and qualify the part through mechanical and physical property characterization. All processes are controlled in-house to ensure quality results.

What We Can Do for You:

- Applicable Part Identification

- Reverse Engineering/Solid Modeling

- Prototype and Part Mfg

- Physical/Mechanical Testing

- Design Allowables and Qualification

- Equipment Selection and Transition

- Modeling and Simulation

- Fused Deposition Modeling for Plastics

Materials:

- Titanium

- Aluminum

- Tool Steel

- Copper

- Nickel

- Inconel

- Stainless Steel

- Cobalt-Chromium

- Plastics

- Tantalum, and more

Read our

brochure or watch our video

to learn about some of the innovative projects our AM experts have completed for

our clients.

In Petropavlovsk, a presentation of a prototype of a domestic 3D printer was held

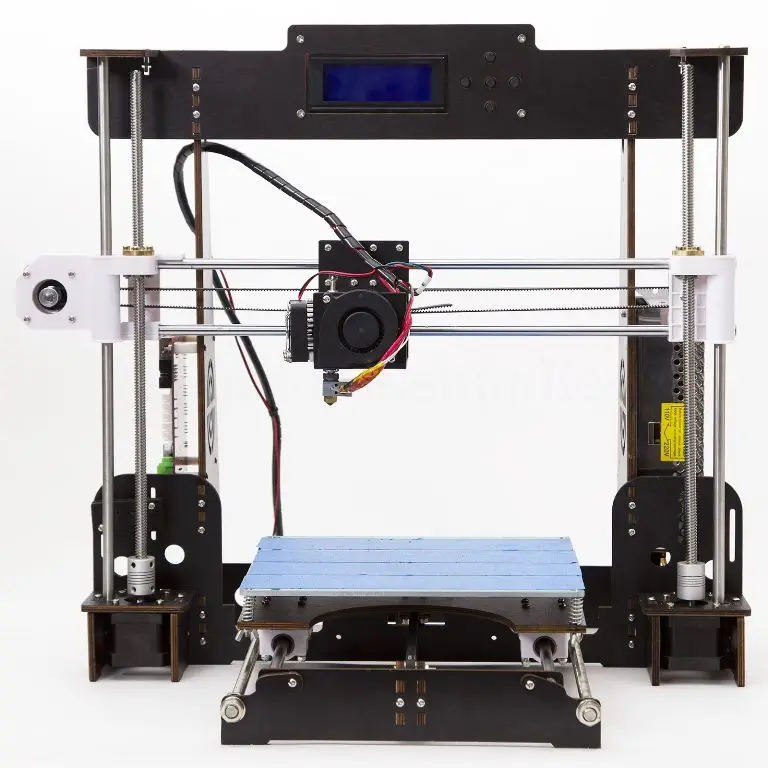

In Petropavlovsk, at the plant named after S.M. Kirov hosted a presentation of a prototype of a domestic 3D printer, BNews.kz correspondent reports.

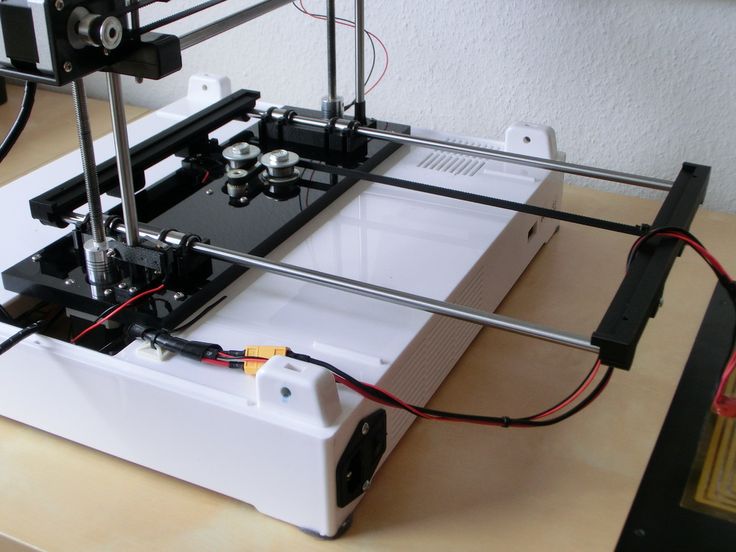

According to Dauren Abilmazhinov, Deputy Director of the Marketing Department, it took 4 months to develop a domestic 3D printer.

“A group of engineers headed by chief engineer Evgeny Belousov worked on its creation. European, American, Chinese analogues were taken as a basis. We took their idea, but practically the printer is 100% ours from Kazakhstan. We also saw a pilot project in Moscow on the use of 3D printers on school subjects such as "Technology", "Physics", "Robotics" and others. Our printer is very reliable, it has a table size of 300 by 300 and importantly it uses such a cheap material as plastic and is very affordable for schools. We believe that schools should use this printer. No wonder our President said that the technology associated with 3D printers should be promoted.

In fact, today we are advanced in Kazakhstan, in terms of its promotion,” D. Abilmazhinov explained.

According to him, the estimated cost of a 3D printer will be no more than 500 thousand tenge, which is quite affordable for every school.

“We showed the printer at the collegium of the Ministry of Education, we liked it, some recommendations were given, which we are finalizing. Nazarbayev Intellectual School is ready to introduce a printer in a pilot project and we also decide to install a printer in one of the city's schools. A 3D printer develops modeling and robotics skills in schoolchildren, develops spatial and constructive thinking,” Abilmazhinov added.

He also noted that the plant plans to create such printers for industrial enterprises.

The graduates of the North-Kazakhstan State University named after A.I. M. Kozybaeva Stas Savchenko, Alexander Reshetan and Maxim Kropevyanov.

“In the beginning, I wanted to create a laser printer for myself, but then I decided that a 3D printer is better.

I shared it at work, received an order from the plant management to develop our own, purchased printers from other companies, and in 4 months we created our own - Kazakhstani one, ”says Stas.

He also showed how the printer works and the items they made, in particular the gear, which takes a lot of time to make on a machine, but it is much easier on a printer.

“I really enjoy working at the factory, I've been here for five years. I am proud that I work at a plant that was created a little less than a century ago in Moscow. During the war period, he was evacuated, like many other industrial enterprises, to Kazakhstan, finding a new home in Petropavlovsk. During its long history, the enterprise has been on the verge of collapse more than once, but the wisdom of the management, the courage of the older generation and the hard work of the youth helped to survive the "troubled" time. Today, the enterprise is increasing production volumes, mastering new areas of technology and never ceases to make bold plans for the future,” Stas Savchenko said in conclusion.

In the Astrakhan region, 16 labor rooms in 12 rural schools were equipped with the latest technology

19.04.2022 09:19

Governor of the Astrakhan region Igor Babushkin held a working meeting with the General Director of the Caspian Pipeline Consortium Nikolay Nikolaevich Gorban. The head of the region announced this in his telegram channel.

Igor Babushkin said that for 20 years CPC has been a reliable socially responsible partner of the Astrakhan region. Now the company has purchased the necessary equipment for Astrakhan schools, for example, 16 labor rooms in 12 rural schools in the Kharabalinsky, Enotaevsky, Krasnoyarsk, Limansky and Narimanov regions were equipped with the latest technology. New furniture, inventory, laptops, laboratory and technological equipment, and even 3D printers appeared in the classrooms.

The head of the region noted that the projects supported by the company are very important for the Astrakhan region, because they are aimed at preserving the environment, developing medicine and culture, and most importantly, supporting young people.

Maria Ovchinnikova

Subscribe to our Telegram, as well as Odnoklassniki and VKontakte.

News smi2.ru

Loading...

Astrakhan News

12.02 Astrakhan region became a participant of the pilot project of Rosreestr "Land for tourism"

12.02 On some streets of Astrakhan there will be a planned power outage

12.02 In Astrakhan, the week will start with a snowfall

11.02 Astrakhan citizens were told about the importance of oral cavity prevention

11.02 In Astrakhan, the Tatar-Bazar, which was damaged by a fire, is being restored

11.02 In Astrakhan, on February 11, on Zelenaya Street, the body of a man tormented by dogs was found.

11.02 Almost all of Astrakhan turned off cold water

11. 02 In Astrakhan, the minibus tried to escape from the traffic police

02 In Astrakhan, the minibus tried to escape from the traffic police

11.02 A solemn reception was held in Astrakhan in honor of the 44th anniversary of the Islamic Revolution in Iran

11.02 In Astrakhan, from February 13 to 18, traffic will be limited on Chekhov Street

11.02 Astrakhan cultural institutions will take part in a campaign dedicated to Fyodor Chaliapin

11.02 3 cases of African swine fever found in the Astrakhan region

11.02 A 43-year-old Astrakhan stole a "seven"

10.02 Astrakhan region will take part in the competition "The route is built"

10.02 In the Astrakhan "Ecopriyut" no cases of cruel treatment of animals were recorded

10.02 The Governor of the Astrakhan region awarded a diploma to the journalist of radio "Southern Wave"

10.