Corridor crew 3d printer

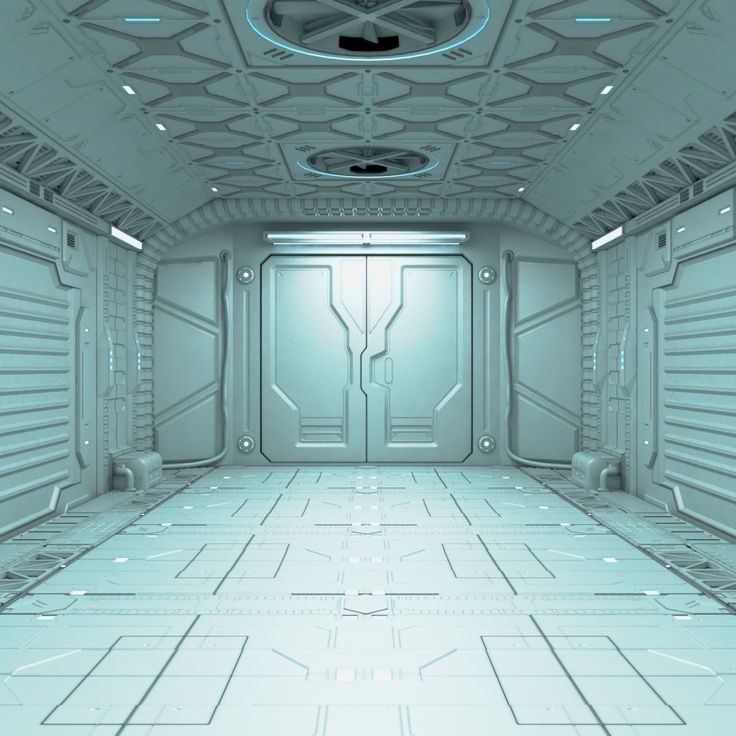

Small Rooms – Lv427Designs

-

Admin Room #1

Admin Room #1

- Regular price

- $3.00

- Sale price

- $3.00 Sale

- Unit price

- /per

-

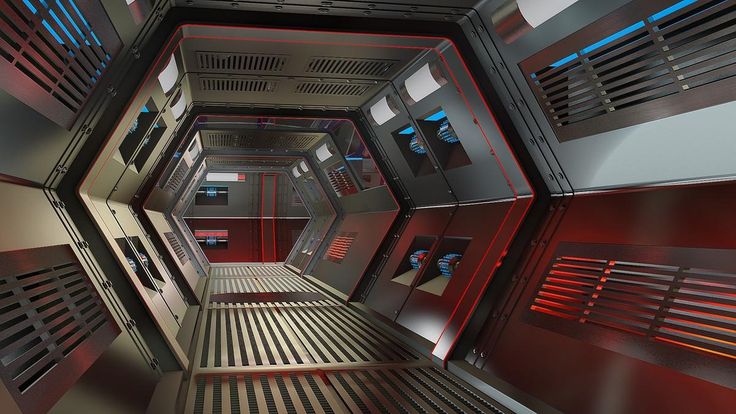

Admin Room #2

Admin Room #2

- Regular price

- $3.00

- Sale price

- $3.00 Sale

- Unit price

- /per

-

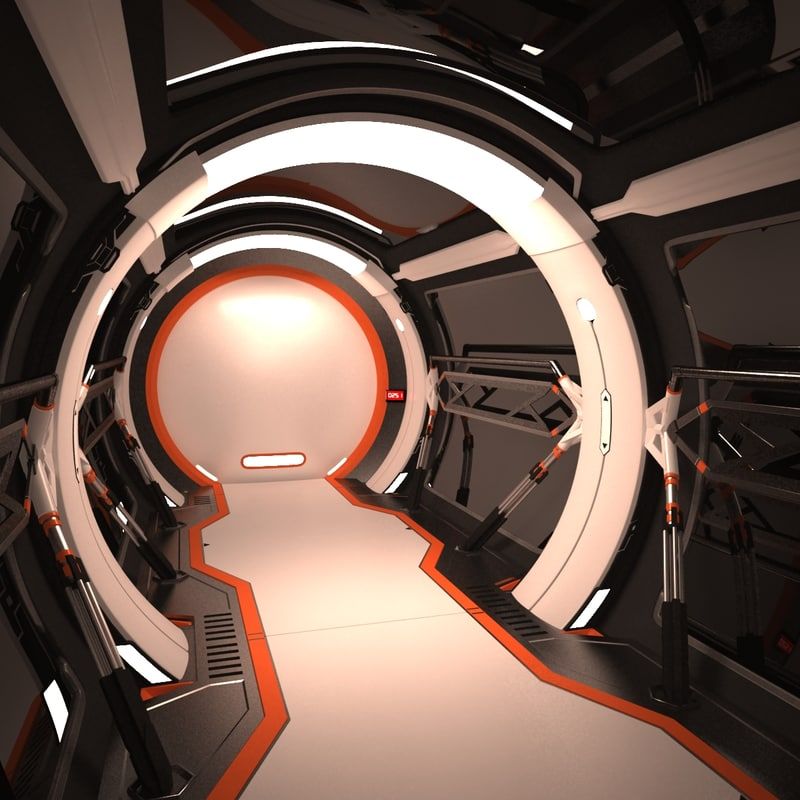

Small Medical Bay #1

Small Medical Bay #1

- Regular price

- $3.

00

- Sale price

- $3.00 Sale

- Unit price

- /per

-

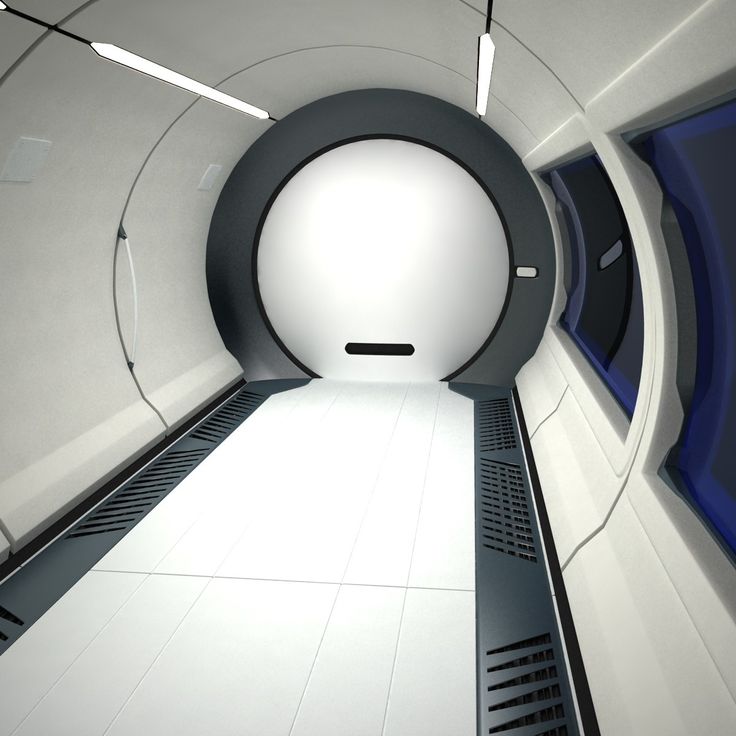

Small Medical Bay #2

Small Medical Bay #2

- Regular price

- $3.00

- Sale price

- $3.00 Sale

- Unit price

- /per

-

Crew Quarters Design #1

Crew Quarters Design #1

- Regular price

- $3.00

- Sale price

- $3.

00 Sale

00 Sale - Unit price

- /per

-

Crew Quarters Design #2

Crew Quarters Design #2

- Regular price

- $3.00

- Sale price

- $3.00 Sale

- Unit price

- /per

-

Meeting Room #1

Meeting Room #1

- Regular price

- $3.00

- Sale price

- $3.00 Sale

- Unit price

- /per

-

Meeting Room #2

Meeting Room #2

- Regular price

- $3.

00

00 - Sale price

- $3.00 Sale

- Unit price

- /per

Use left/right arrows to navigate the slideshow or swipe left/right if using a mobile device

LiDAR & 3D Scanner for iPhone & Android

Polycam - LiDAR & 3D Scanner for iPhone & Android📣 Announcing Polycam Sharing: Share captures, edit as a group, and create collaborative albums. ✨

→

Share

Share your captures with friends, co-workers, professionals, and clients across the globe. Our sharing feature is free and available on all of our platforms – iOS, Android, and web.

Edit scans as a group, and control permissions and access from within the app. Use sharing to create collaborative albums and build collections with other users. Start sharing and working together with Polycam.

Share a capture now →

3D Capture, for Everyone

LiDAR scanning and photogrammetry made easy.

Welcome

Polycam is the world’s most popular 3D scanning app for iOS, web and Android. We believe that 3D capture is for everyone, so we made it easy. Now you can scan the world around you with your mobile device, DSLR camera, or drone to get beautiful, accurate 3D models.

Captures are helpful in every single professional 3D workflow. You can use them in floor plans, architectural renderings, VFX and filmmaking, 3D art, scene building and more. Join the growing worldwide community today and try Polycam for free.

Download on theApp Store

Get it onGoogle Play

Try for freeon the web

t-rex skull@e

Provo, UTAug 4, 11AM

LiDAR Scanning

With the LiDAR sensor on Pro iOS devices you can scan the world around you in stunning 3D.

LiDAR Scanning

LiDAR scanning is the most fun and helpful feature of newer, pro-model iOS devices. Never before has 3D scanning been possible on a mobile device.

Never before has 3D scanning been possible on a mobile device.

Polycam’s free LiDAR scanning pipeline lets you capture an entire home in 3D in minutes. It’s the best LiDAR scanning app for contractors, interior designers, and architects.

Download on theApp Store

SM Tides Residence@ZARHA_DESIGN

LiScanned

w/ LiDAR

Photogrammetry

Use Photo Mode on your device or on the web to get instant, accurate 3D models of absolutely anything.

Photogrammetry

Photo Mode turns every iPhone and Android device into the start of a powerful photogrammetry pipeline. You can use it to capture your world in incredible detail.

Choose Photo Mode if you want to get high quality 3D models in minutes, and publish them to our Explore feed to share with our community across the globe. Use models for scene building, game development, VFX and more.

From the Polycam web app, you can upload images captured on any device, including your professional camera or drone.

Download on theApp Store

Get it onGoogle Play

Try for freeon the web

Yoda One For Me@MakeItMoveMedia

PhScanned

w/ photo

Free 3D Models

Discover free 3D models in the explore feed. Join the largest community of 3D capture enthusiasts and share your 3D content directly on Polycam.

Free 3D Models

You’ve never seen a 3D model collection like this before. Browse millions of 3D models and download them for free in Polycam Explore.

All captures are stylistically consistent, and can instantly be used in 3D art and VFX projects. If you can’t scan an object yourself, it probably exists in Polyworld. Create albums and collect 3D models for fun or curate models for specific projects. Whatever your use case, the Polycam Explore feed is full of the largest variety of high quality captures generated by our very own users.

get free 3D models

Explore in Augmented Reality

View your 3D models in AR. Create and save videos to wow and share.

Create and save videos to wow and share.

Augmented Reality

We believe some very cool things are around the corner in AR/VR. With Polycam, you can create AR videos by blending captures into the environment around you.

It’s the easiest way to wow friends, clients, and potential buyers. AR is great as a tool for e-commerce. You can scan your products and visualize them in 3D, with real-world dimensions.

discover AR

Drone Mapping

Upload drone imagery to Polycam Web to generate 3D scans of entire buildings, structures or city blocks.

Drone Mapping

Polycam makes it easy to turn drone footage into expansive 3D models. Upload your keyframed drone images on Polycam Web and get a capture back in minutes.

Other drone-mapping services can cost $100/month. Polycam is over ten times cheaper, and much easier to use. It’s perfect for drone pilots who want to create 3D captures from in-flight footage, but don’t want to break the bank or spend hours learning new software.

create 3D models with drones

Join the Community

Follow us everywhere and become a part of the growing Polycam world, and reach out for collaboration opportunities!

Community

Love Polycam? Want to learn more or collaborate? We love talking with our users and have a very active presence on Discord, Twitter, Instagram and TikTok. Feel free to reach out with any questions, feedback or ideas. We look forward to hearing from you.

Construction 3D printing is waiting for a breakthrough The first construction projects using this technology appeared only in 2014. We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared.

However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. nine0003

However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. nine0003 Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more. nine0003

This Internet meme shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development. nine0003

And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development. nine0003

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov y. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now? nine0010

Why do you think this happened, and why is there a surge of new projects right now? nine0010

- It seems to me that the reason is the snowball effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself. The issue of regulation and certification also plays an important role - this process is long and creates an additional lag. nine0021

In 2014-2016 the first samples of building 3D printers and prototypes of printed buildings appeared. The concepts of various form factors of construction 3D printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared. nine0021

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations. In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry.

nine0021

Thus, I believe that the specified time period is a fairly natural cycle of technology development, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at USD 354.3 million in 2022 and is projected to reach USD 11068.1 million by 2027, growing by 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals. nine0003

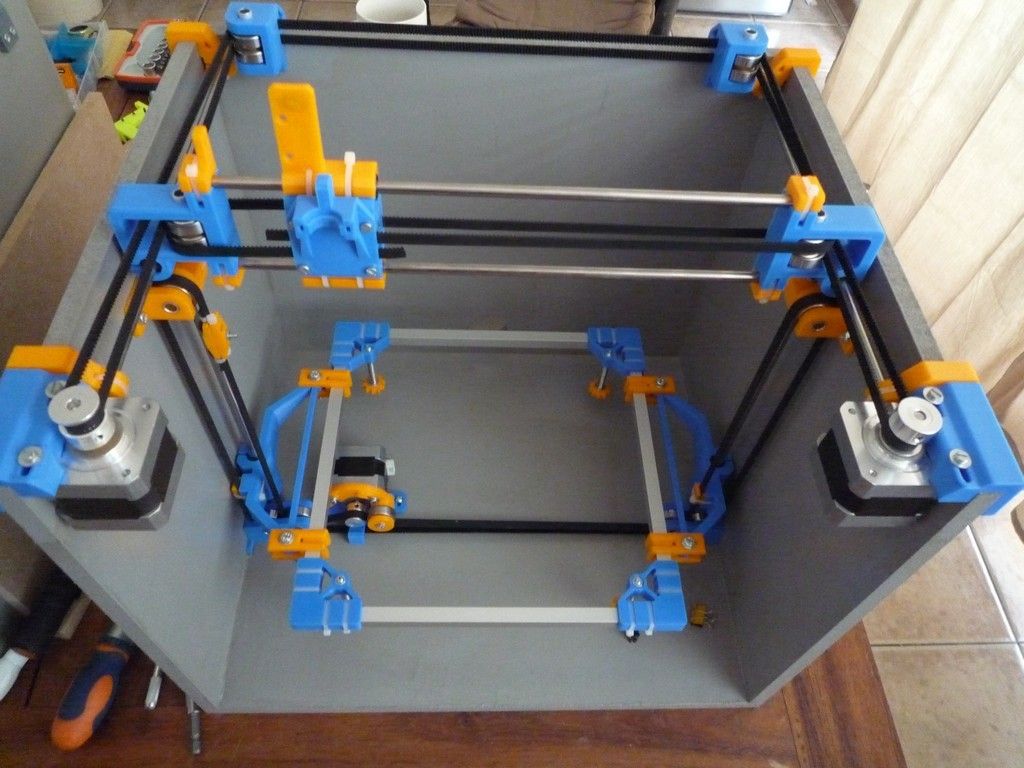

Now let's take a quick look at what the construction 3D printer is. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Printers are also portal, on the basis of a flying boom, with a robotic arm.

Pictured left is a construction printer based on a boom. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robot arm installed on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village of 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds. nine0003 Pictured is a 3D printed house in Austin, Texas. A 3D printed house in Austin, Texas.

At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers and participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

Few things unite developed, developing and poor countries, everywhere their problems and tasks, but Affordable housing shortage is a global agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse. nine0003

At the same time, the trend towards "green agenda " is developing, reducing CO2 emissions, building with more environmentally friendly materials, etc. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples. nine0003 3D printed walls.

But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples. nine0003 3D printed walls.

Today, when we talk about 3D printing houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are built as fixed formwork, which significantly saves the amount of cement used , and this, in turn, reduces the cost of construction and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly. nine0003

At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly. nine0003

Eco-concrete with the addition of polymers is being actively developed, the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects.

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire homes, it only makes wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds. nine0003

nine0003

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany. nine0003

"There are spots on the sun." Despite all the advantages of construction 3D printing, has several significant disadvantages of . The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

-

Ribbed walls can be plastered, painted and played with as a design element.

That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards. nine0003

That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards. nine0003

-

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

-

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing. nine0003

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project. nine0003

In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project. nine0003

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop. Ribbed surface and temperature restrictions in this case do not play any role. Construction takes place in the shop, after which the object is transported to the installation site.

3D printed wind tower. 3D printed wind tower. nine0002 Construction 3D printing, or, as it is also called, additive construction, has just appeared, and I want to believe in its bright future. There are many prerequisites for this, but a lot still needs to be done for success. First of all, it is necessary to develop principles for designing houses for building 3D printing. Then it is necessary to attract top architects to create landmark projects, which can be followed by the mass introduction of a new and very promising technology. Construction 3D printing could help solve the global housing shortage and bring more automation to other areas of construction. nine0010

First of all, it is necessary to develop principles for designing houses for building 3D printing. Then it is necessary to attract top architects to create landmark projects, which can be followed by the mass introduction of a new and very promising technology. Construction 3D printing could help solve the global housing shortage and bring more automation to other areas of construction. nine0010 Alexander Kornveits

Expert in the field of additive technologies and 3D printing, head of the Tsvetnoy Mir company The 3D printer needs to set the parameters of the building and supply concrete. The robot does the rest. Instead of a brigade of builders, three people will cope. The two-story building was the first in Russia, previously only one-story buildings were printed. About how the unique construction took place - in the material Mir24.tv. nine0134

It is being built not by the day, but by the hour. Layer by layer, the robot builds a reinforced frame - walls and partitions. A mixture of granulated sand, cement and modified additives is fed automatically. At the same time, the future building should already have a foundation.

A mixture of granulated sand, cement and modified additives is fed automatically. At the same time, the future building should already have a foundation.

First, the 3D printer builds a kind of formwork out of concrete, the frame of the future wall. The voids are filled with reinforcement for greater rigidity. After that, the robot comes into play again. He fills the structure with mortar. It turns out a reinforced concrete wall. nine0003

“On the 28th day we did a test of the cubes, for the builders it will be clear. This mixture showed its strength around the 200 mark. For understanding: the cinder block, which is usually used to build walls, has a mark of 50-75, ”says Director of Smart Build Dmitry Prokhorenko .

Stavropol company Smart Build has developed a special device for printing houses. But the first built building is an office building. In the regional industrial park, a two-story building was erected in a short time. nine0003

The construction robot has a number of advantages. First, accuracy. The parameters for applying layers are calculated by the computer. Secondly, the printer does not get tired. And another important factor is the continuity of work.

First, accuracy. The parameters for applying layers are calculated by the computer. Secondly, the printer does not get tired. And another important factor is the continuity of work.

In terms of construction speed, the technology is much superior to traditional construction. A printer can build a one-story house in a day, a two-story building in three days. The Russian apparatus is no worse than American or Chinese.

“We are not chasing the speed of construction yet, we work 4-5 hours a day,” says Dmitry Prokhorenko. – Now our priority is not speed, but production automation. For example, while the solution is fed into the printer manually, which slows down the process. But we have already developed an automatic solution supply system. nine0003

A 3D printer is the fruit of a collaboration between engineers and builders. SKD assembly, successful anti-vandal design, software. The robot is easy to control.

“In our printer, perhaps 90% is all domestic.

A small part of materials from Belarus. But most of it is our production. The only thing that we buy at the moment in Taiwan is a microprocessor and motors,” says Dmitry Prokhorenko.

The company has already found a replacement for imported engines in the domestic market - in case of a supply failure. During the year, engineers expect to receive a domestic controller.

Printed house will cost 20 percent less than traditional construction. Savings are achieved through the wages of employees. Instead of a whole team at a 3D construction site, only three people are needed - a printer operator and two handymen.

On the experimental object, the walls harden in two hours, after another two, floor slabs can be laid on them. The printed house will have no freeze seams, which guarantees better thermal insulation. nine0003

A few days later, the builders start finishing. The plaster lays flat. Adhesion to the corrugated surface of the wall is good.