3D scanner next engine

NextEngine 3D Laser Scanner

Hardware

Software

Accessories

Service

3D Scanner Ultra HD

Learn More

To capture all the stuff you work with, you want 3D input at your fingertips. NextEngine's exclusive Multi-Laser Technology delivers superior precision and fidelity. Find out what has made NextEngine's Desktop 3D Scanner the World's best-seller. New Ultra HD sensors deliver stunning resolution.

$2,995

Buy Now

30-Day Money-Back Guarantee

MultiDrive

Learn More

Fully automate alignment of multiple scans with tilt/rotary object positioning. Define multiple scan families and with one click execute creation of your 3D mesh model. Just trim unwanted overlapping scan

data, fuse, and polish. A new level of simplicity for NextEngine 3D

Scanner users.

$995

Buy Now

30-Day Money-Back Guarantee

ScanStudio

Learn More

Every NextEngine 3D Scanner comes equipped with high performance Scanning and Modeling Software at no extra charge. ScanStudio manages your scanner hardware, refines your data, and assembles it into a fully healed precise mesh model.

STANDARD

ScanStudio ProScan

Learn More

Increase your scanner performance with the ScanStudio ProScan upgrade. Double scan speed for faster cycle times and capture more surface area with Large Format mode.>

$995

Buy Now

30-Day Money-Back Guarantee

CAD TOOLS

Learn More

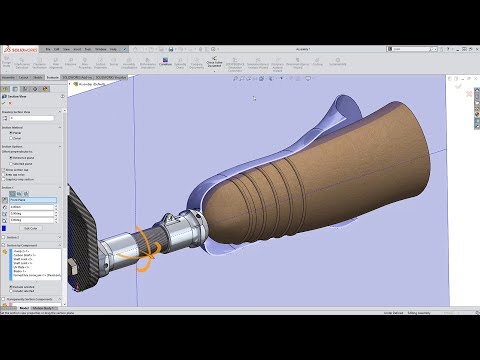

Want to convert your mesh model into a CAD model? Need spline outputs or NURBS surfaces? Want to quickly determine volume or surface area? ScanStudio CAD TOOLS gets the job done in one integrated and quick to learn package.

$995

Buy Now

30-Day Money-Back Guarantee

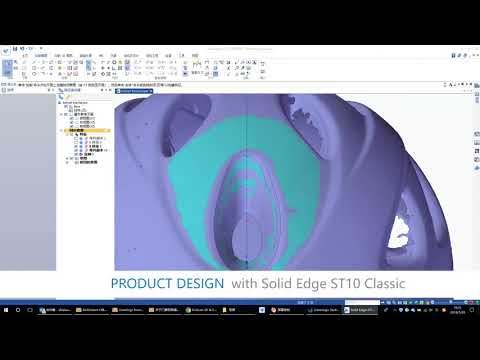

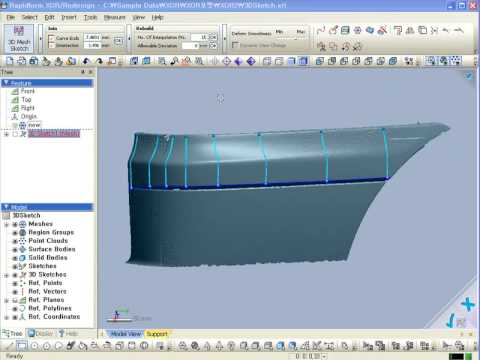

RapidWorks 4.0

Learn More

Are you a Solid Modeling CAD expert? If you need industrial-strength tools to convert Scans to CAD parts, RapidWorks is the World's state-of-the-art in Engineering Software for 3D scan data. Get robust full feature set design tools for under 3K!

Get robust full feature set design tools for under 3K!

$2,995

Buy Now

30-Day Money-Back Guarantee

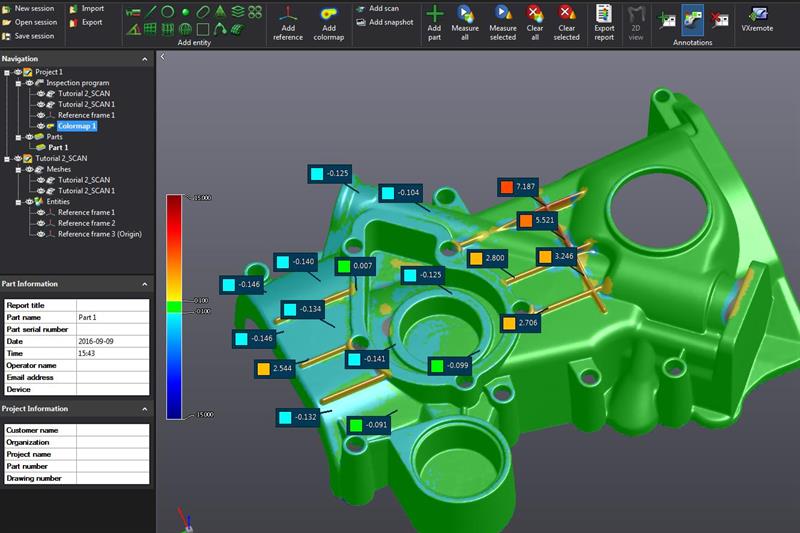

QA-Scan 4.0

Learn More

Need fast verification that a physical sample meets design requirements?

QA-Scan provides easy-to-use tools for precisely comparing 3D scans with CAD models. Made for high volume applications, QA-Scan automatically aligns your data, checks tolerances, and produces detailed GD&T reports.

$1,995

Buy Now

3D Curriculum

Learn More

Ten simple lesson plans help students become proficient with the NextEngine 3D Scanner and RapidWorks reverse engineering software. Capture the imagination of your students as they explore the future of 3D design.

$995

Buy Now

Black Bases

Reduce trimming time, replace white platforms on your AutoDrive or MultiDrive positioner with black platforms nearly invisible to the scanner.

$10

Buy Now

AutoDrive Extension

24 inch extension between Scanner and AutoDrive increases flexibility to orientate large objects.

$10

Buy Now

PaintPens

Learn More

Scan your transparent or mirror-finish objects with these convenient valve-action paint pens. Coat parts with water-based white tempra paint for excellent scanability. Wipes off with a damp sponge. Use at your desk and store in a drawer. One set of PaintPens is included with your scanner.

$15

Buy Now

Extra PowderPen

Learn More

Scan shiny objects with handy pushbutton powder brush pen. Coat parts with microfine talc granules suspended with a trace of lanolin for mild clinging to surfaces. Wipes off easily with a tissue. One PowderPen is included with your scanner.

$10

Buy Now

Extra PartGripper

Learn More

Adjustable stainless steel part-holding fixture has soft silicone pads to protect and grip your part. Use additional Grippers for difficult objects, or to modify for special purpose jigs. One PartGripper is included with your scanner.

Use additional Grippers for difficult objects, or to modify for special purpose jigs. One PartGripper is included with your scanner.

$55

Buy Now

3 Year Extended Warranty

Total warranty coverage for your 3D scanner for repair/replacement of any defect for 3 full years. No charge for any parts, labor, or services.

$295

Buy Now

RapidWorks ProCare

Learn More

Talk with our engineers via phone or real-time NextWiki chat, and get one-on-one assistance from reverse engineering experts. 3 Years of Software upgrades for RapidWorks, plus phone support, priority real-time chat, priority e-mail support, and project-specific assistance.

$995

Buy Now

QA-Scan ProCare

Talk with our engineers via phone or real-time NextWiki chat, and get one-on-one assistance from experts. 3 Years of Software upgrades for QA-Scan, plus phone support, priority real-time chat, priority e-mail support, and project-specific assistance.

$795

Buy Now

ScanStudio ProCare

Learn More

Extends support for your Scanner and ScanStudio software for 3 full years. Includes unlimited support and all major software upgrades.

$295

Buy Now

NextEngine 3D Laser Scanner

Page 123

What is "High Definition" 3D scanning, anyway? Simply put, it measures your object in more places.

Accuracy is important, but it's not enough. When you want fine detail in a 3D shape, the density of points matters even more. If 0.005 inch accuracy points are spaced 0.050 inches apart, a curve would look like stair-steps. Each step is accurate, but the sparse spacing wouldn't map the curve. But when points are packed finer than the accuracy spec, (at say, 0.002 inch), model quality goes way up.

Try our comparison widget (at right), and see why HD Scanning produces a superior model. In fact, HD captures so many points, it took a year to build the software needed to process them. There's a lot more to like in our HD technology, including scanning twice as fast, and much larger areas. Check out the features below.

In fact, HD captures so many points, it took a year to build the software needed to process them. There's a lot more to like in our HD technology, including scanning twice as fast, and much larger areas. Check out the features below.

All new NextEngine 3D Scanners are already equipped for HD scanning. Just get our new ScanStudio HD or HD PRO software release, and start experiencing the difference. And if you bought your system in '07, NextEngine has an awesome deal to get you an HD machine. Learn More

Got an SD scanner? You're one of the early enthusiasts who got your very own 3D scanner as soon as it came out. Since our debut, we've quickly grown to have thousands of users all around the world. Our new HD Technology incorporates what we've learned from the experiences you've shared.

Technology companies constantly improve products, so you bought a first generation '07 model, and now you need to buy a new one or you'll miss out on the latest cool features, right? Nope. At NextEngine, we do things differently. In our view, it was those of you who first bought our technology that made success possible. We're now the leading supplier of 3D Scanners in the World, and we're very grateful that you trusted us. So we're doing something unheard of in the High Tech industry. We'll let you exchange your first generation system for a brand new HD unit.

At NextEngine, we do things differently. In our view, it was those of you who first bought our technology that made success possible. We're now the leading supplier of 3D Scanners in the World, and we're very grateful that you trusted us. So we're doing something unheard of in the High Tech industry. We'll let you exchange your first generation system for a brand new HD unit.

If you don't need HD, your SD scanner will continue to work fine with SD software, and you don't need to do anything. But if you buy the new HD PRO Software, it requires the new HD Hardware, so we'll exchange it for you for just $995 plus shipping. Pretty cool, huh? Learn More

Order: Order ScanStudio HD PRO on the NextEngine online store for $995, and you'll be prompted for your serial number. Then the additional $995 exchange fee plus return shipping will be adjusted to your order after it has been placed. After receiving your order confirmation email, you'll be contacted with shipping details for your SD unit. You'll get a brand new HD Scanner and ScanStudio HD PRO for about $2,000 less than the current price.

You'll get a brand new HD Scanner and ScanStudio HD PRO for about $2,000 less than the current price.

Shipping: You can keep using your existing system until your new HD is ready. Once we receive your SD, your new HD system will be on its way. Your new system also comes with a new warranty and unlimited support for a full year.

Eligibility To qualify for the exchange program, you must purchase ScanStudio HD PRO, and you must be the original purchaser of your SD scanner.

ScanControls Scanner and AutoDrive

AlignAutomated alignment of scan sets

FuseMerge scans into a single-mesh model

ProcessingSmart filters reduce edge artifacts + noise

4X SamplingHigher quality points through oversampling

7 Color7 channel color capture for high accuracy

2X SpeedSmart filters reduce edge artifacts + noise

Large AreaUltra wide-mode depth range over 30 in.

4X Density4 times more points (4 million max.)

how to assemble a 3D scanner from scrap materials and digitize reality — T&P

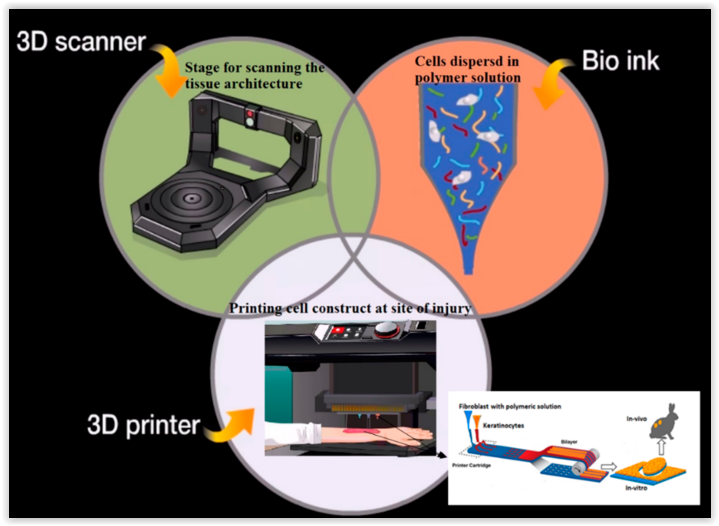

The first 3D printers that cost less than a gaming computer have become a mandatory attribute of almost any hackspace or fablab (laboratory of technical creativity and electronic art).

Now 3D scanners have joined them. MIPT student and employee of the Polytechnic Museum Daniil Velovaty himself assembled a three-dimensional scanner from a laser, a webcam, and scrap materials. As part of the special project Phystech. Reader" he told T&P about the future of reality scanning. nine0003

Now 3D scanners have joined them. MIPT student and employee of the Polytechnic Museum Daniil Velovaty himself assembled a three-dimensional scanner from a laser, a webcam, and scrap materials. As part of the special project Phystech. Reader" he told T&P about the future of reality scanning. nine0003

Daniil Velovaty

It was easy to get used to 3D printers: I drew the desired detail or figure on the computer, loaded it into the printer, and a few hours later I took its embodiment in plastic. Yes, what about plastic, they are already printing in metal, and even in organic matter: they recently printed a living liver. No wonder you want to go further. The next step is scanning. Oddly enough, but before the advent of 3D printers, there was no great need to transfer a real object to the digital world: the creators of games and films simply hired artists who drew whatever was needed. The need for scanners arose only when it was important to convey the relief and shape of an object with very high accuracy. At the same time, neither the duration of the scan nor the cost were often completely unimportant. This is how the first representatives of 3D scanners appeared: lidars. nine0007

At the same time, neither the duration of the scan nor the cost were often completely unimportant. This is how the first representatives of 3D scanners appeared: lidars. nine0007

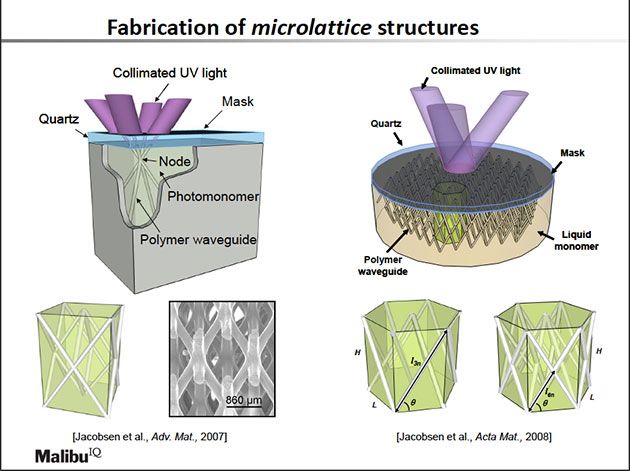

Lidar (from English Light Detection and Ranging) is an expensive but very accurate device. It allows you to build 3D models of objects with an accuracy of millimeters, the size of which can be compared with the size of a building. From the decoding of the abbreviation LIDAR, it follows that it is any rangefinder that measures distance using light. An incredible number of devices fall under this description. But most often, devices like this are called lidars:

A special system of mirrors is placed inside the device. A phase laser rangefinder is installed here, which measures the distance using a laser, and two mirrors serve to deflect the laser beam in two planes. Thus, the ray runs through a certain sector of space and builds its 3D model. As you might guess, the speed of such a scanner depends on the speed of the rangefinder and the speed of rotation of the mirrors. And since all this is quite complex equipment that requires fine tuning, it costs quite a lot of money. It is much more profitable to order a scan than to buy the device itself. Moreover, you still need to figure out how to use it. nine0007

And since all this is quite complex equipment that requires fine tuning, it costs quite a lot of money. It is much more profitable to order a scan than to buy the device itself. Moreover, you still need to figure out how to use it. nine0007

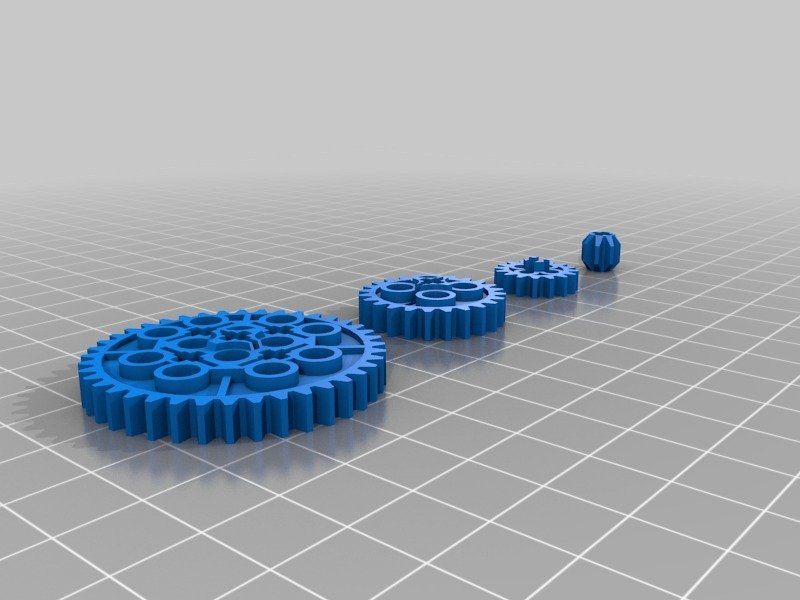

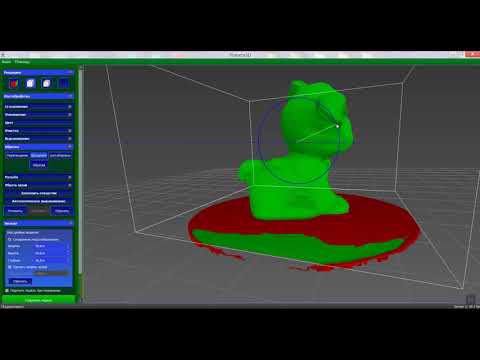

As industrial devices were, to put it mildly, beyond the reach of the average consumer, and the need to scan reality grew, cheap desktop and handheld 3D scanners appeared. The former, as a rule, have a turntable on which the object under study is placed. A few minutes after the start of the scan, we will get the finished model. Of course, the scan quality and the size of the scanned area are incomparable with lidars, but they cost several orders of magnitude cheaper. It is to this class of devices that the scanner we developed belongs. The main problem with these scanners is that the object to be scanned must fit on a turntable, which greatly limits the scope. Another significant disadvantage of these scanners is the incompleteness of scanning and blind spots. If, for example, you try to scan a vase, the scanner will only see its outer part, and not the cavity inside. nine0007

If, for example, you try to scan a vase, the scanner will only see its outer part, and not the cavity inside. nine0007

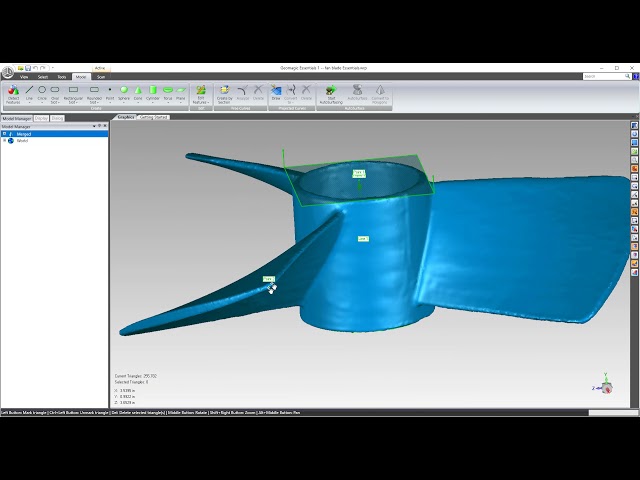

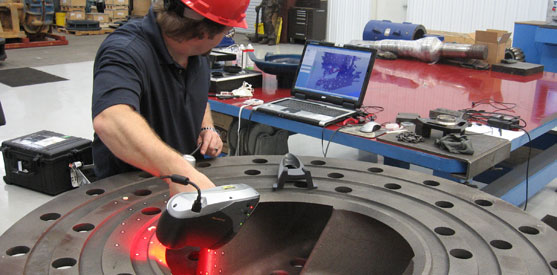

The second type of scanners are handheld 3D scanners. They need to be moved around the object by hand, but they build a model with the help of cameras. The operation algorithm of such scanners is much more complicated, they are more expensive, and the quality of the result is worse, but they allow you to scan large objects and spend less time on it. They look something like this:

One of the main advantages of such a scanner is that it is not limited by the scanning area. We can scan, for example, a person's face without having to place their head on a turntable. With a certain diligence, even an entire room can be scanned, if only the positioning accuracy allows it. To improve accuracy, you can stick special marks that the scanner finds and uses as reference points. Actually, in the photo above, this is what was done. This approach limits the scanning area, but, unfortunately, here either the sheep are safe or the wolves are full. nine0007

nine0007

In our lab, we decided to create a cheap 3D scanner with an accuracy comparable to that of 3D printing. This was our first serious project, so we made mistakes, misunderstood a lot, and learned even more along the way. We first built a simple laser rangefinder using a laser pointer and a webcam. To understand how a 2D camera can measure distance, you have to use your imagination. Imagine a thread stretched in the air, along which a spider is crawling. If we stand close to the rope, we see how the spider is crawling straight towards us (not a very pleasant sight). And if now we shine a lamp on this whole structure from the side, we will see a shadow on the floor. Since the light comes from the side, the projection of the spider will move along the projection of the thread. By measuring the distance from the beginning of the thread's shadow to the spider's shadow, we can calculate how far the spider has crawled by multiplying by some factor, because we are creating a contraction mapping. nine0007

nine0007

Our scanner works in approximately the same way. Only instead of a thread - a laser beam, and instead of a screen with a shadow - a camera. Just as a spider moves along a thread, a spot moves along the laser beam, which occurs when this beam encounters an obstacle. Having found the position of the spot in the photograph, we can determine the distance to the object on which this spot is located. In words, it is difficult. It looks simpler in the picture:

The farther the wall, the closer to the dotted line will be the pfc point on the camera matrix

But such a rangefinder measures the distance to a single point, and this takes a very long time. Therefore, we put a lens on the laser, which turns the laser spot into a laser line. Now we measure the distance to hundreds of points at once (after all, a line can be represented as a set of points), it remains to build a system that allows this line to go through the entire object, and for this we need a turntable on which the object is placed.

The scanner itself is assembled from plywood pieces that have been laser cut. To rotate the table, a stepper motor is used, which is controlled by a board developed by us. It also controls the brightness of the laser and backlight. nine0007

The image from the camera is processed on a computer; a Java program was written for this. After scanning is completed, the program generates a so-called point cloud, which, using another program, are combined into a full-fledged model. This model can already be printed on a 3D printer, that is, a copy of a real object can be obtained.

Don't miss the next lecture:

Theory and practice

Tags

#3D printers

#MIPT

#Technologies

-

9 431

3D 3D-prices, photos, characteristics

Use 3D scanners

are widely used in such industries as:

- Industry,

9005 9 - Avia, Aviation - and mechanical engineering,

- medicine,

- education,

- architecture and design,

- production of consumer goods.

Such equipment allows: to carry out engineering developments using CAD (computer-aided design systems), to check the compliance of the physical characteristics of parts with the specified parameters, to detect defects at the early stages of the production process.

3D scans

Single shots. The scanner measures the distance to an object at various points and records all measurements taken as separate images. After comparing the obtained images, a digital model of the object is displayed on the monitor. nine0059

Continuous scan. Inspection of the object is carried out using wave radiation (optical-acoustic or laser beams). A special camera registers the position of the beam at each moment of time and captures all distortions in the shape of the scanned object. The obtained data can be visualized into a three-dimensional model directly during the scanning process or after it.

OfiTrade offers 3D scanners from world famous manufacturers - Creaform, Solutionix, Basis Software, DAVID. Creaform and Solutionix brands produce the most advanced scanners, which are characterized by high accuracy and speed, excellent resolution and detail of digital models. Our range includes several types of 3D scanners. You can choose the best option for your specific task. nine0007

Creaform and Solutionix brands produce the most advanced scanners, which are characterized by high accuracy and speed, excellent resolution and detail of digital models. Our range includes several types of 3D scanners. You can choose the best option for your specific task. nine0007

| What do you need? | Our solution | Your benefit |

|---|---|---|

| Measuring the linear dimensions of complex body parts, determining deviations in their shape and surface arrangement. | Coordinate measuring machines (CMM): Advantages:

Restrictions:

| High-precision measurement of small parts, templates and subassemblies will help to avoid the release of defective products. |

| Non-contact scanning of objects from any distance. | 3D laser scanners: Advantages:

Restrictions:

| With laser scanners, you can make the most realistic 3D visualization of small parts and large objects. A wide scope of equipment will give your company a tangible competitive advantage. |

| Correction of 3D object models right in the process of scanning. nine0007 | Tracked 3D scanners: Benefits:

Limitations:

| You will be able to measure objects in real time, carry out timely quality control of parts and products. |

| High-speed detailed scanning. | 3D structured light scanners: Advantages:

Restrictions:

| Thanks to its high speed, even large objects can be scanned in minutes. This saves time for employees and improves overall productivity. nine0007 |

| Fast scanning of small objects. | 3D handheld scanners: Advantages:

Limits:

| Mobile 3D scanners are extremely easy to use - no expensive training is required for your staff. |

This will reduce waste and increase profits. nine0007

This will reduce waste and increase profits. nine0007