3D printer for space station

Airbus sending 3D printer to space station next year to pave way for off-Earth factories

European aerospace manufacturer Airbus wants to make satellites in orbit from space junk in four years. (Image credit: Airbus)European aerospace company Airbus will send a metal-crafting 3D printer to the International Space Station next year as a first step in its plans to set up an orbital satellite factory.

The printer, called Metal3D, can work with metals that melt at temperatures of up to 2,100 degrees Fahrenheit (1,200 degrees Celsius). It will be the first metal 3D printer on the space station, Airbus said in a statement , and will enable astronauts to print parts such as radiation shields and various tools. (American company Made In Space, now a subsidiary of Redwire, has sent several 3D printers to the space station, but none of them can print metal.)

Future versions of the 3D printer, the company added, will be able to make objects using lunar soil and also recycle parts from old satellites.

Related: 3D printed satellite antennas can be made in space with help of sunlight

The Metal3D printer is only one component in a range of technologies developed by Airbus with the goal of setting up a space factory. In a series of videos, Airbus showed off a robotic manipulator designed to assemble spacecraft.

"Airbus' solution is to launch kit parts that will be assembled in space by the robotic arms from our space factory," the company said in the statement.

The robotic arms will be able to build each other in orbit, Airbus said, but could also be used to repair and refuel spacecraft.

The company said it would like to be able to manufacture entire satellites in space in the "next three to four years."

Related stories:

"Since there is enough space in space, it will be possible to build bigger structures such as huge reflectors, allowing telecom satellites to cover the entire planet," Airbus said in the statement.

Moreover, producing satellites in space will also be kinder to the environment, the company said, as fewer polluting rocket launches will be needed.

"The material for production can be sourced from the space debris floating around," Airbus said. "So with the space factory, Airbus is also helping to clean up space and ensure a sustainable future for the industry."

When it comes to the Metal3D printer, the space station is only its first destination. By the end of this decade, Airbus said, a similar device might be churning out parts of lunar rovers and habitats directly on the surface of the moon.

Follow Tereza Pultarova on Twitter @TerezaPultarova. Follow us on Twitter @Spacedotcom and on Facebook.

Join our Space Forums to keep talking space on the latest missions, night sky and more! And if you have a news tip, correction or comment, let us know at: [email protected].

Tereza is a London-based science and technology journalist, aspiring fiction writer and amateur gymnast. Originally from Prague, the Czech Republic, she spent the first seven years of her career working as a reporter, script-writer and presenter for various TV programmes of the Czech Public Service Television. She later took a career break to pursue further education and added a Master's in Science from the International Space University, France, to her Bachelor's in Journalism and Master's in Cultural Anthropology from Prague's Charles University. She worked as a reporter at the Engineering and Technology magazine, freelanced for a range of publications including Live Science, Space.com, Professional Engineering, Via Satellite and Space News and served as a maternity cover science editor at the European Space Agency.

She later took a career break to pursue further education and added a Master's in Science from the International Space University, France, to her Bachelor's in Journalism and Master's in Cultural Anthropology from Prague's Charles University. She worked as a reporter at the Engineering and Technology magazine, freelanced for a range of publications including Live Science, Space.com, Professional Engineering, Via Satellite and Space News and served as a maternity cover science editor at the European Space Agency.

3D printing in space - 3D printers for the space industry

Why is 3D printing important for the space industry?

3D printing could revolutionize space exploration by helping astronauts create objects in space and on-demand: replacement parts for repairs, custom equipment for scientific experiments, and even things like food or buildings!

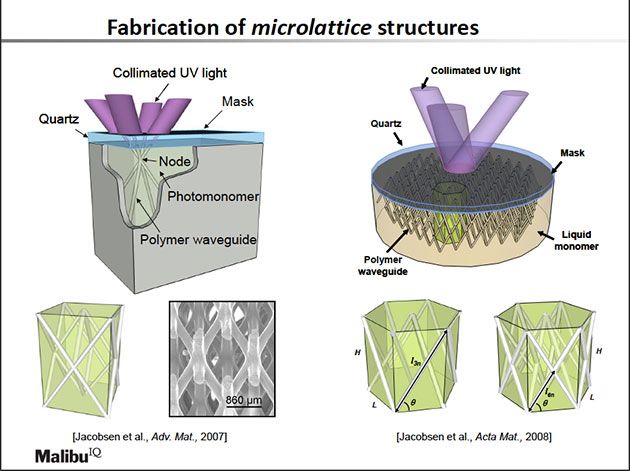

Indeed, while space is an extreme environment with very few exploitable raw materials, there is plenty of dust floating around. 3D printing technology can allow you to build solid structures from aggregated dust and microscopic particles. The European Space Agency (ESA) is considering 3D printing their base on the moon.

3D printing technology can allow you to build solid structures from aggregated dust and microscopic particles. The European Space Agency (ESA) is considering 3D printing their base on the moon.

As for 3D printed meals for astronauts in space, NASA is funding a Systems and Materials Research Corporation project to develop a 3D food printer that can be used in a zero-gravity environment.

3D printing replacement parts in space

One of the main challenges that astronauts face is the lack of specific replacement parts on-board the space station.

A zero-gravity 3D printer

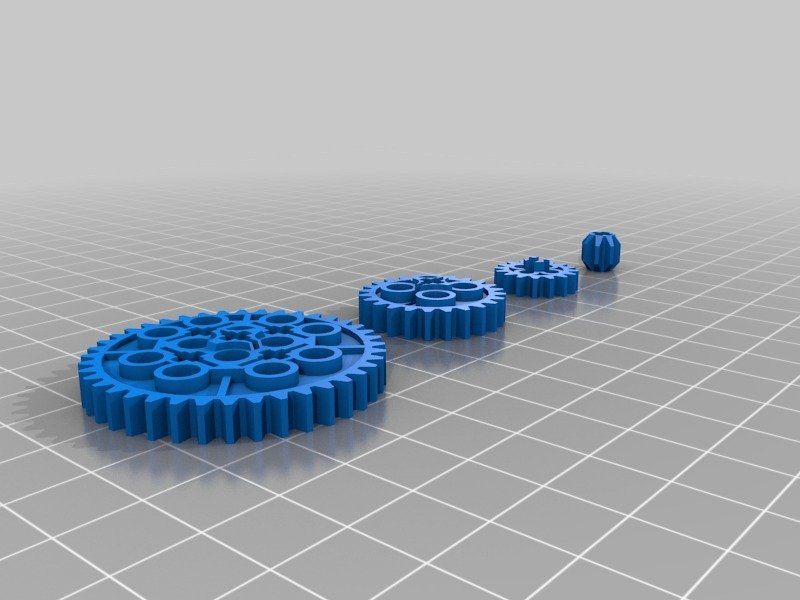

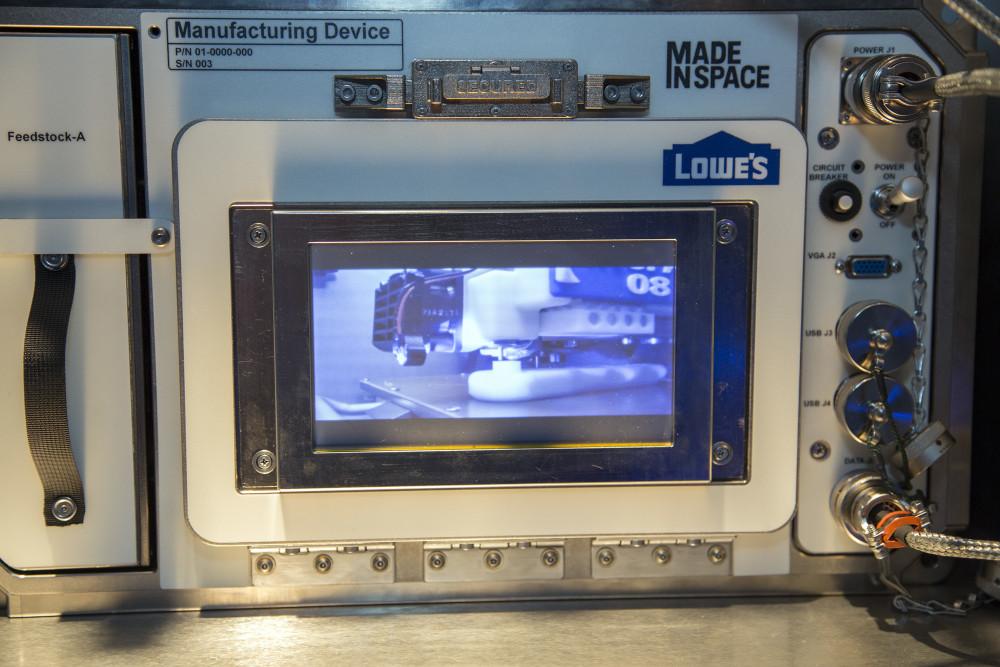

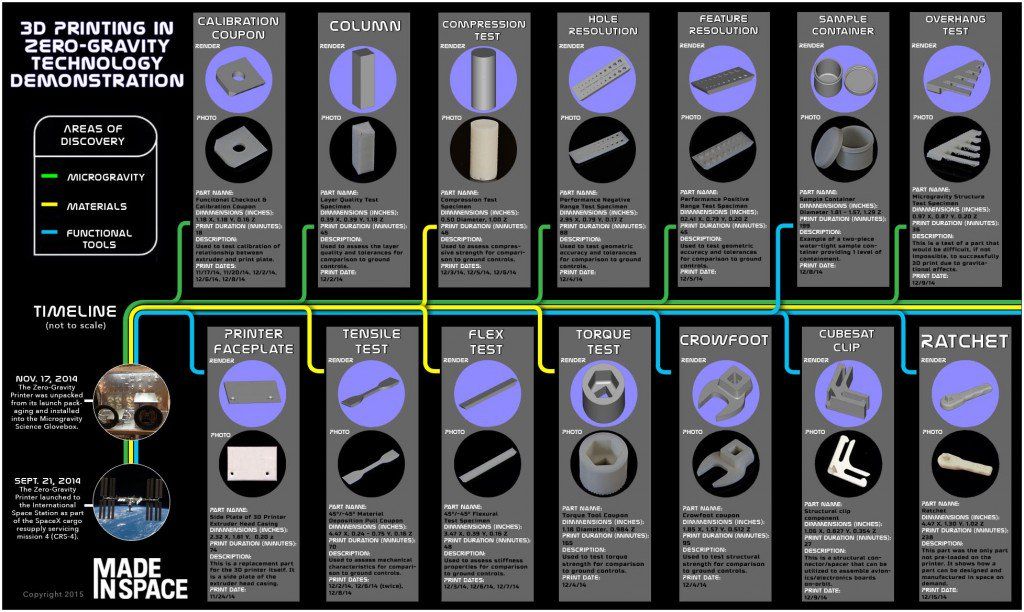

Thanks to 3D printing technology, it is now possible to manufacture spare parts in space. NASA and Made in Space are collaborating to solve that problem. The result of their experiments is the zero-G 3D printer, a 3D printer that can operate in zero-gravity environments.

NASA and Made in Space are collaborating to solve that problem. The result of their experiments is the zero-G 3D printer, a 3D printer that can operate in zero-gravity environments.

They managed to produce a ratchet wrench from a 3D file that was emailed from Earth to the space station. This 3D printer uses the Fused Filament Fabrication technology (filament extrusion) and can print objects in plastic.

Ratchet 3D printed in space by the Zero G 3D printer.“Right now if something breaks, we’re completely dependent on launching a replacement from the ground. Imagine launching everything you might ever need for a mission to Mars or an asteroid, it would be challenging or impossible.”

Niki Werkheiser, Nasa project Manager

Future evolutions

In less than a week, the 3D file of the custom ratchet was designed, sent in space, and then manufactured by the 3D printer.

The next goal is to have a database of 3D files (STL files) of all the parts needed in the space station, in order to save time in case one of them breaks.

Being able to recycle 3D printed objects that are no longer needed and then reuse the material is also a big focus.

Solving the food problem with 3D printing

3D printing food in space

3D printers have the capacity to create a variety of products with a small amount of raw materials.

Thus, engineers found here the perfect technology for feeding astronauts on long-term space missions. NASA has invested $125,000 in SMRC, an ambitious project led by Anjan Contractor.

He succeeded in creating a food 3D printer able to 3D print pizza in space.

The different steps involved in 3D printing a pizza.Pizzas are ideal for 3D printer because they’re made of different layers on top of each other (great for additive technology process like 3D printing):

- A layer of dough is first deposited on the 3D printer’s heating bed to be directly cooked

- Second, a layer of water, oil, and tomato powder is applied (tomato sauce)

- Then, a layer of cheese is deposited

- Finally, animal and vegetal proteins are added to provide essential nutrients

This process allows to cook a pizza in a few minutes and, according to Anjan Contractor, to print carbs, proteins, macronutrients, and micronutrients that are stored in powder form within a special cartridge. These powders remain edible for around 30 years, long enough for a mission to Mars.

These powders remain edible for around 30 years, long enough for a mission to Mars.

3D printing a lunar base

Building a lunar habitation to ease exploration and research

Thanks to the 3D printing technology, the European Space Agency hopes it will be one day able to 3D print a base on the moon. International architecture studio Foster + Partner designed such a structure in partnership with Monolite UK, which provides the 3D printer.

According to Foster + Partner, the base must be assembled around a dome built on Earth. This dome will filter gamma rays, solar radiation and meteorites impacts. On the moon, two 3D printers would finish the build and strengthen the structure by using raw materials found on the spot.

Monolite UK says that their construction 3D printer is able to achieve a complete base in less than two weeks. The next generation is claimed to be twice as fast as this one.

Case studies: 3D technology for spacecraft

The 3D printed thruster chamber from the European Space Agency

In June 2015, the ESA unveiled the world’s first 3D printed spacecraft thruster, including a platinum combustion chamber. The use of 3D printing offered several advantages:

The use of 3D printing offered several advantages:

- Similar performances to a traditional thruster

- Possibility to use new build materials

- Lower production cost and turnover

The 3D printed oxidizer valve from the Falcon 9 rocket by SpaceX

SpaceX announced in July 2014 that they had successfully 3D printed an oxidizer valve for the 1D engine used in the Falcon 9 rocket. The oxidizer valve is a crucial part of a rocket engine– it controls the flow of liquid oxygen as it enters the engine’s combustion chamber. It took only two days to 3D print this valve, while traditional manufacturing processes take up to months to build such parts.

The SpaceX rocket engine using the 3D printed oxidizer valve during a test phase.In addition, the 3D printed valve offers some key advantages, which have led SpaceX to decide to 3D print all of their oxidizer valves:

- Higher overall performances versus traditional manufacturing processes

- Higher resistance to fracture

- Superior ductility

The SuperDraco engine by SpaceX

SpaceX announced in May 2014 that their new rocket engine, the SuperDraco, had passed all the qualification tests (certifying metal 3D printed parts is a challenge).

The SuperDraco boasts 3D printed combustion chamber, which was 3D printed using the Direct Metal Laser Sintering process (DMLS). Elon Musk is enthusiastic about the future of additive manufacturing for the space industry:

“Through 3D printing, robust and high-performing engine parts can be created at a fraction of the cost and time of traditional manufacturing methods. SpaceX is pushing the boundaries of what additive manufacturing can do in the 21st century, ultimately making our vehicles more efficient, reliable, and robust than ever before.”

Elon Musk

3D printer for ISS | Technologies in the IT Market

- home

- Market

- Technologies

05/07/2022Author Petr Chachin

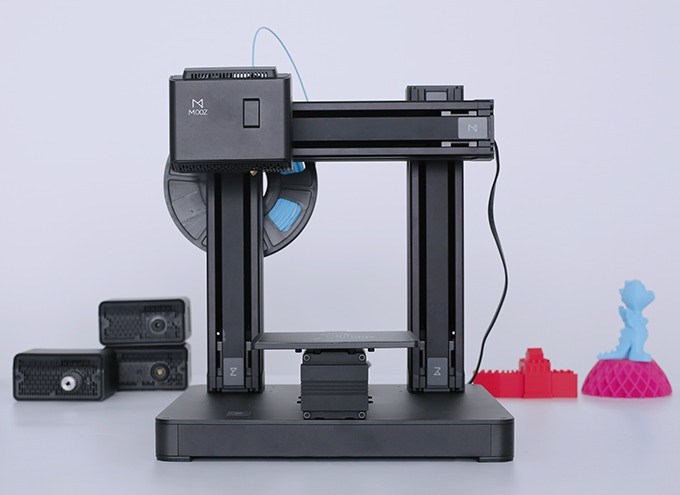

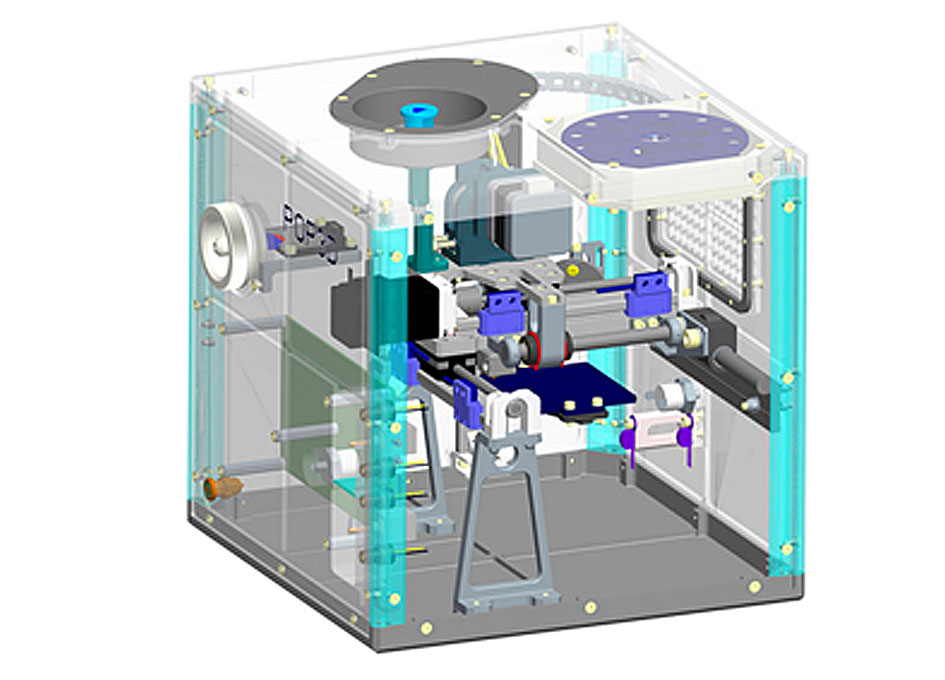

RSC Energia named after S.P. Korolev, together with Tomsk Polytechnic University and Tomsk State University, have developed a 3D printer for use on the International Space Station (ISS).

Using a thermoplastic polymer printer, samples and parts that are used in large quantities on board the station will be printed by layer-by-layer application of a molten polymer thread (filament). nine0011

Then the resulting 3D printing samples will be returned to Earth to study the mechanical characteristics of products made using additive technologies (layer-by-layer growth and synthesis of objects). This will allow a comprehensive study of the impact of microgravity on 3D printing.

The first to work with a 3D printer will be the crew of the ISS-67 expedition - Roscosmos cosmonauts Oleg Artemiev, Denis Matveev and Sergey Korsakov. The 3D printer is scheduled to be delivered to the Russian segment of the ISS on the Progress MS-20 spacecraft in June this year. Over time, the device can become part of the station's standard equipment. nine0011

Over time, the device can become part of the station's standard equipment. nine0011

It is expected that the development of additive technologies at the station will open up new opportunities for the domestic astronautics to use 3D printing in the future. For example, in lunar expeditions, astronauts will no longer depend on the delivery of the necessary components and structures on transport ships from Earth, but will be able to print them directly in space.

IT News magazine

3D printing

Previous

Apple, Google and Microsoft plan to eliminate passwords

Next

French farmers struggle with Russian gas

Want to be the first to know about new content?

Subscribe to the newsletter

news feed

Highlights of the week

By clicking on the button, I accept the terms of the agreement.

Created a device that turns empty plastic bottles into filament for a 3D printer

A user puts an empty bottle into a Polyformer, the device shreds plastic, heats it up and draws it into a filament. Approximately 33 bottles are required for 1 kg of thread...

Approximately 33 bottles are required for 1 kg of thread...

Olga BlinkovaTechnology, 06/20/22

AnkerMake M5 smart 3D printer prints 5 times faster than its competitors

The standard print speed of the device is 250 mm/s.

Anker InnovationsNews, 04/06/22

3D printing market against the backdrop of a pandemic (part III)

3D pens as a separate product segment appeared quite a long time ago, but it seems that this direction lives its own, separate from...

Evgeny KuryshevTrends, 07/20/21

The 3D printing market amid the pandemic (Part II)

According to the analytical report of Aliexpress Russia, in the fourth quarter of 2020, the demand for household 3D printers at this site increased by 74% ...

Evgeny KuryshevTrends , 06/04/21

Load more1 2 3 four five »» Next →

3D printing and space: the most important

1. The use of additive technologies in the manufacture of spacecraft parts.

3D printing is actively used in the aerospace industry for the manufacture of prototypes, engine parts and tooling. Its use allows the manufacturer to reduce the cost of products, improve their performance, and significantly reduce the time of manufacture of individual products. All major companies involved in aerospace production are turning to additive technologies in one way or another.

Mostly 3D printed engine parts. Thus, the American company Aerojet Rocketdyne has signed a contract for 1.6 billion dollars for the production of the RS-25 rocket engine, some of the parts for which will be made on a 3D printer. Production of a single part by traditional methods could take half a year - 3D printing allowed Aerojet Rocketdyne to reduce time and costs, significantly speed up the prototype production process. In addition, the company successfully uses additive technologies in other projects. nine0011

Another US company, Rocket Lab, is building New Zealand's first orbital launch station. It is from there that it is planned to launch the world's first rocket, the oxygen-hydrocarbon engine of which is completely printed on a 3D printer.

It is from there that it is planned to launch the world's first rocket, the oxygen-hydrocarbon engine of which is completely printed on a 3D printer.

The list would be incomplete without businessman and designer Elon Musk. His company SpaceX has successfully tested 3D-printed SuperDraco engines to be used in the Dragon spacecraft and is also working on the Raptor Rocket propulsion system. nine0011

Other industrial giants didn't stop at engines. Blue Origin used over 400 3D printed parts on New Sheppard's first flight in June 2015.

And Boeing has contracted Oxford Performance Materials, a leading additive manufacturing specialist, to produce 600 3D printed parts for the new Starliner space taxis.

Additive technologies are also used in promising projects of the near future. NASA is using advanced techniques in preparing for a Mars mission: 3D printing is already being used to create prototypes, manufacture parts in space, and even make engine parts for a future ship that will go to Mars. nine0011

nine0011

The Russian aerospace industry is also starting to introduce 3D printing. For these purposes, the Roscosmos Corporation has received a unique domestic 3D printer Router 3131 with a large print field. He will create elements of spacecraft.

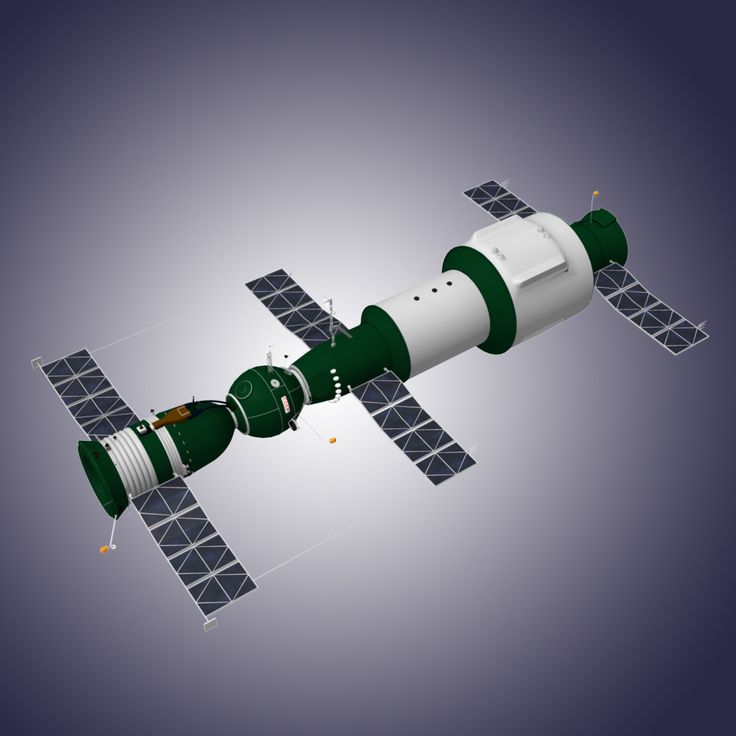

2. The use of 3D printing in the production of satellites and vehicles.

Another direction in the aerospace industry, which we decided to consider separately, is additive technologies in the production of satellites. Unlike a rocket, the cost of a satellite is significantly lower, but it can also be reduced by paying attention to innovative technologies. nine0011

Aerospace giant Boeing has done just that by using 3D printing to manufacture modular satellites. Now one device costs, on average, 150 million dollars - this price is due not only to the high-tech component, but also to the significant cost of the labor force involved in production. When using 3D printers, the cost and production time of satellites are significantly reduced.

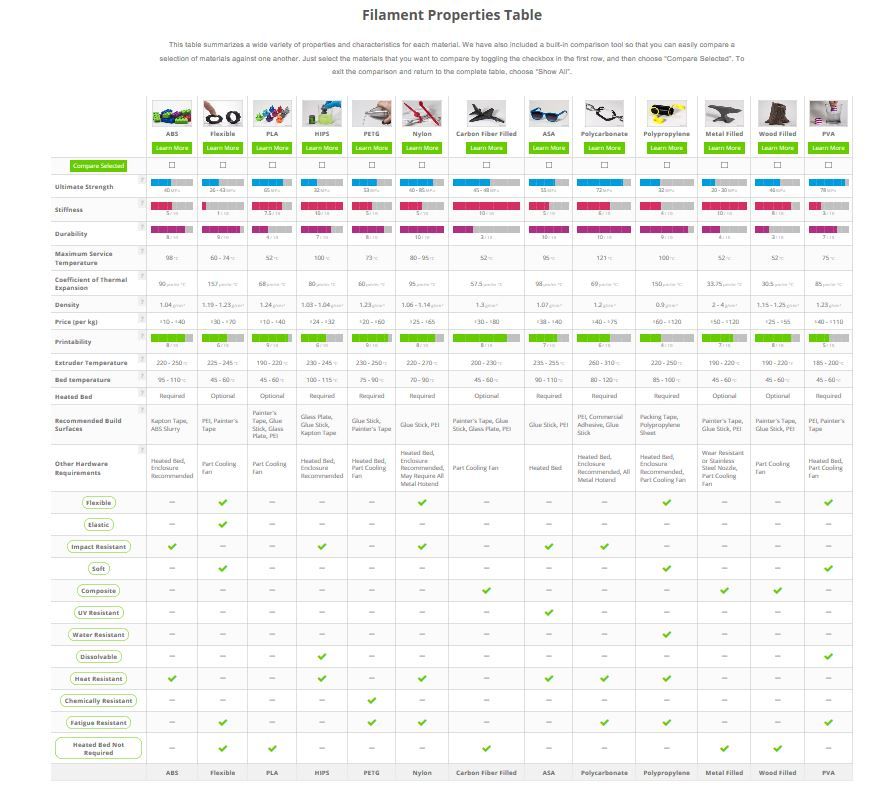

Small start-ups and research projects have more modest goals, but 3D printing helps them too. A team of researchers at Northwestern Nazarene University in Idaho awaits the launch of their 3D-printed MakerSat satellite, the first in the state, into space. The dimensions of the device are only 10x10x11.35 cm, and it is created from available polymers for 3D printing (ABS, ULTEM and nylon). nine0011

High-performance satellite developer Millennium Space Systems recently announced the completion of work on a pre-production model of the ALTAIR series, which is now being prepared for launch into space. The new technologies used in the design of the satellite will make new space missions possible. For example, 3D printing will save on the cost of sending parts into space and reduce the time it takes to prepare and conduct missions.

Russian scientists also excelled. In 2016, the Tomsk-TPU-120 small satellite was developed at the Tomsk Polytechnic University. When creating the device, scientists and students of Tomsk Polytechnic University used additive technologies - the frame and most of the components are printed on a 3D printer. On March 31, 2016, the 3D satellite left the Earth and settled in orbit. nine0011

On March 31, 2016, the 3D satellite left the Earth and settled in orbit. nine0011

Juno flew even further. The NASA space station with that name entered Jupiter's orbit in the summer of 2016. This event is also important for 3D printing, as Juno became the first spacecraft with 3D printed parts - titanium waveguide elements manufactured by Lockheed Martin.

3. Space 3D printers.

Astronauts in orbit often cannot provide themselves with everything they need and have to wait for cargo that arrives at the International Space Station (ISS) during scheduled flights. Unfortunately, during this time the crew is not insured against accidents or breakdowns of important systems. 3D printing experiments in space offer the potential to print needed parts if any parts fail in space. This is very important for future flights to Mars and other planets: for a long time, the colonists will not be able to receive help from Earth. Therefore, in the forthcoming expeditions, it is extremely important to use all available opportunities for the manufacture of products on board ships and space stations. nine0011

nine0011

Such experiments have been carried out on the ISS since 2014. It was then that the Zero G 3D printer manufactured by Made in Space was delivered to the American segment of the station. The first print took place on November 24, 2014 and marked a new era in the development of 3D technologies. The printed object was a part of the printer itself, the faceplate of the printhead, symbolizing the ability to one day print a 3D printer in space on a 3D printer. In 2016, another Made in Space printer called the Additive Manufacturing Facility (AMF) was delivered to the ISS. nine0011

Since then, print trials on the ISS have taken place regularly. One of the latest ideas was an innovative plan by the Canadian company 3D4MD, which involved printing medical devices, such as splints or surgical instruments, on the ISS. To create devices such as custom splints for broken fingers, 3D4MD's developers could use, for example, measurements taken during the preparation of spacesuits and create a model on Earth. The 3D model can then be sent to the ISS, where the tire will be 3D printed. nine0011

The 3D model can then be sent to the ISS, where the tire will be 3D printed. nine0011

Roscosmos is also developing a similar project. An experiment called "3D printing" should confirm the possibility of using a 3D printer in the absence of gravity. This device was created within the walls of the Tomsk Polytechnic Institute and agreed with the engineers of RSC Energia. The printer will go to the ISS in 2018.

Not being able to conduct experiments in space, other powers organize experiments on the ground. A development team from China recently successfully tested the first 3D printer designed for weightless conditions. Many difficult tests were carried out in the French city of Bordeaux. nine0011

4. 3D bioprinting in space.

It is known that in outer space there is electromagnetic and radiation radiation that has a detrimental effect on biological tissues. In order for the astronaut to be able to endure all the hardships of the flight, the protection of the ship alone is not enough - it is necessary to think about high-quality medical care. And if it does not help, then it’s about replacing any organs.

And if it does not help, then it’s about replacing any organs.

That is why the Russian United Rocket and Space Corporation (ORSC) agreed on an experiment to use a 3D bioprinter on the International Space Station (ISS). Its developer was the Russian laboratory 3D Bioprinting Solutionsspecializing in bioprinting technologies. Scientists hope that the magnetic bioprinter will make it possible to create tissues and organs in space. It is expected that the device will be delivered to the ISS by 2018. nine0011

There are no analogues of the Russian project abroad yet.

5. Construction of structures using construction 3D printing.

One of the most basic problems in the construction of buildings on extraterrestrial objects is the limited amount or lack of building material. The only available raw materials that do not need to be transported from our planet are local geological rocks. It is not surprising that scientists are solving the problem of using them in the construction of buildings. nine0011

nine0011

For example, engineers at Northwestern University in the US have found a way to use quality materials in situations where resources are limited. We are talking about the process of additive manufacturing from special materials that mimic the lunar and Martian regolith. These are strong and elastic materials that are produced using powdered substances that resemble rocks from the surface of the Moon and Mars.

It is likely that this technology will be used in the colonization of Mars. Due to extreme temperatures and high radiation on the surface of the "red planet", the first colonizers will need reliable shelters. NASA experts propose using 3D printing to create a "dome" of ice from the surface of Mars, covered with a transparent membrane of fluoroplast-40. One of the main advantages of a water-based dwelling is that such walls protect from cosmic radiation, but do not prevent the penetration of light - this creates some comfort. In addition, when choosing materials, other criteria were taken into account - their strength and reliability, the ability to withstand the difficult conditions of Mars. nine0011

nine0011

The European Space Agency (ESA) is working in the same direction and has already achieved some results. Scientists from the Austrian University of Applied Sciences in Wiener Neustadt managed to 3D print a small needle and a corner wall from JSC-Mars-1A material, which mimics Martian soil.

In addition to serious research, there are quite unexpected projects. So, experts from the ESA we mentioned thought about saving the souls of the first lunar colonists and planned to build a temple on the moon using 3D printing. This building, poetically named Temple of Eternal Light, will be located in the center of a residential complex for the first lunar settlers and will combine a prayer place and an observatory. The designers believe that the temples on the moon will revive the lost connection between mankind and the cosmos. nine0011

However, according to Vyacheslav Bobin, head of the Center for the Study of Natural Substances at the Institute for the Integrated Exploration of the Subsoil of the Russian Academy of Sciences, the construction of settlements on the Moon is not such a fantastic prospect as you might think.