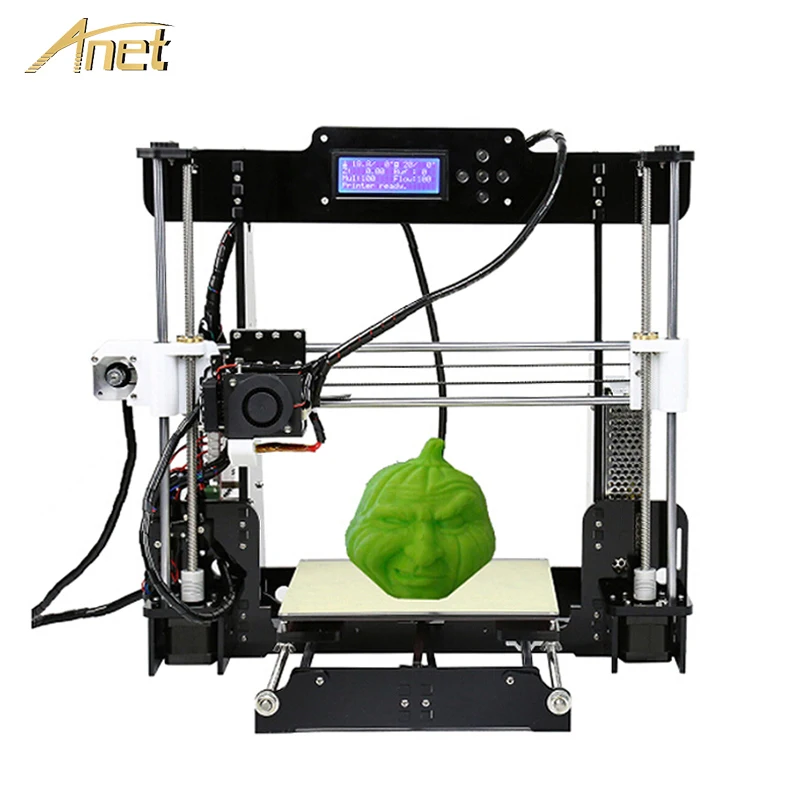

Cheap 3d printing china

PolyJet 3D Printing Services | Fast Quote High Quality

Print your PolyJet/MJP parts with extremely versatille combination of multi-material and multicolor in as fast as 1 day!

PJ printing service starting at only $25!

The Basics Of PolyJet/MJP

Click to Enlarge

PolyJet(Stratasys‘ Technology), or MultiJet Printing(3D Systems‘ Technology), works similarly to inkjet printing, but instead of jetting drops of ink onto paper, PolyJet 3D Printers jet layers of curable liquid photopolymer onto a build tray.

Inkjet print heads are used to jet liquid photopolymers onto a build platform. The material is immediately cured by UV lamps and solidified which allows to build layers on top of each other.

Where overhangs or complex shapes require support, the PolyJet 3D printer jets a removable support material, named FullCure 750/SUP706. The process of fine layer polymerization is repeated until the object is finished.

After the photopolymerization is completed, the batch is placed under a pressurized water jet. This allows any excess liquid or supports to be removed with a few human interactions.

The final product has a naturally smooth surface which can be polished further to create near full transparency for the clear resin. 3D printed models and parts are ready to handle and use right out after the cleaning process, there is no need for post-curing.

Benefits Of PolyJet/MJP

PolyJet offers the unique ability to print parts and assemblies made of multiple materials, colors/transparency, hardness with different mechanical or physical properties, all in a single build.

PolyJet technology enables horizontal layers of lowest 17 µm, fine details, and ultra-thin walls down to 0.6 mm depending on the geometry of the part. That means PolyJet is capable of building very precise mechanical components, offering you high-quality prototypes for a shorter time to market.

Benefits Of Polyjet/MJP With FacFox

Our Polyjet/MJP services allow you to make 3D printed parts and prototypes in a wide range of materials. Prototypes made using this service can be used for engineering testing or as master patterns for urethane casting molds, even molds for rapid injection molding. You can also have metal 3D printed parts made using our DMLS 3D printing service.

Prototypes made using this service can be used for engineering testing or as master patterns for urethane casting molds, even molds for rapid injection molding. You can also have metal 3D printed parts made using our DMLS 3D printing service.

PolyJet vs MJP

PolyJet

MultiJet Printing

Advantages

Surface & Detail

PolyJet has tolerances of +/-.004” per inch, and resin surface is ideal for post-processing like polishing and painting.

Geometry

PolyJet allows to integrate multiple components as well as thin-walled objects and intricate geometries that traditional method won’t be capable of.

Material Selection

There’re various material with special properties like toughness, heat resistance, flexibility, which simulates the end products.

Cost Saving

PolyJet is one of the cheapest method for rapid prototyping while preserving a good surface quality and accuracy.

Efficiency

PolyJet parts don’t require tooling which reduces the manufacturing lead time from weeks to days, allowing for faster innovation and speed to market.

Multi-color & Material

Prints full-colored(even transparent) material with different hardness(rigid and soft) in one object, ideal for visual display model.

Drawbacks

Durability

Photopolymers are not stable over time and most resins don’t have balanced impact/heat resistance.

Scale Effect

The unit cost and lead time will not be reduced as much as casted or molded parts.

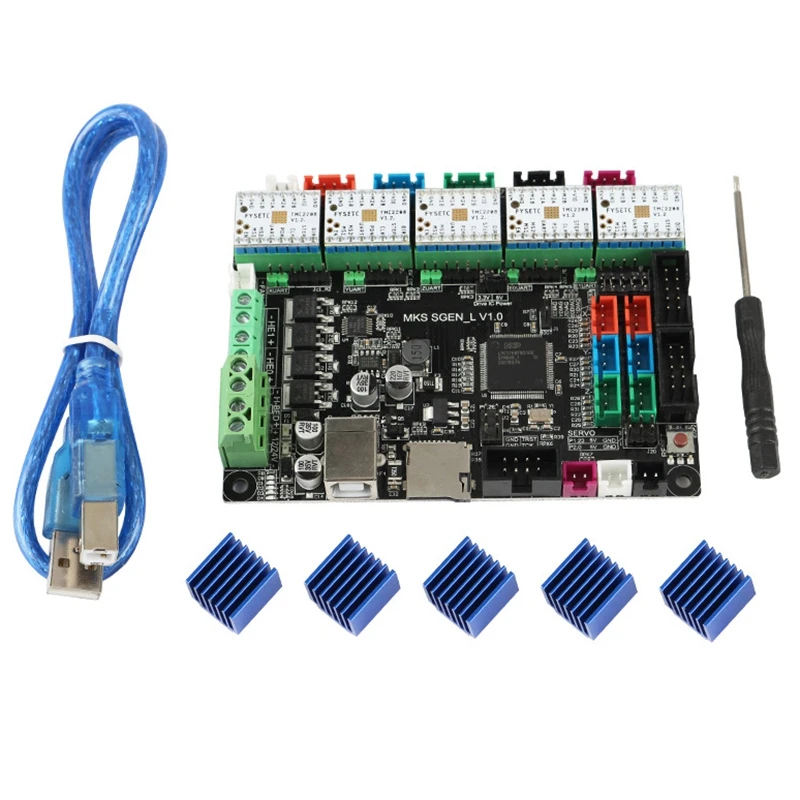

Printers & Parameters

– Printers: Stratasys J750/Objet Series, 3D Systems Objet Series, Solidscape Series

– Maximal build volume: 1000 x 800 x 500 mm(Objet 1000 Plus)

– Minimum feature size: 0.05 mm

Restrictions

– Minimum layer thickness: 0.008 mm

– Typical surface finish: 0.08 – 10 microns RA

– Accuracy: (+/- 0.1-0.2%)

Pre-build planning

Important decision on design is the orientation and support structures. This depends on:

– Geometry: Optimize it to reduce supports and layer lines.

– Areas that need great smoothness or post-processing

- Plastics

- Rubber

PolyJet Multi-Color

Polyjet Clear resin(Fullcure)

PolyJet Bio-Clear Resin

Polyjet PP-like(Rigur)

Polyjet Digital ABS

PolyJet Rubber

Castable Wax Ultra HD

MJP Frosted Detail Resin

Castable Wax

MJP Bio-Clear Resin(M3-Crystal)

Polyjet Rubber (Agilus/Tango)

- Default

- Other

The finish option with the quickest turnaround. Which normally includes:

- Removal of support: Supports are dissolved after printing. This is usually straight forward, however might require some extra effort for parts with complex geometric features.

- Painting

- Nano-painting

- UV Coating

- Don’t see the finish you need? Submit an RFQ with ‘Suggest’ option, we’ll look into a finishing process for you.

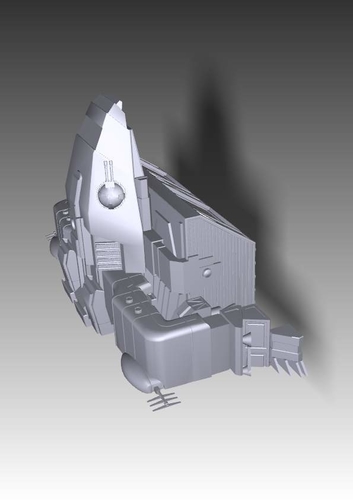

Prototypes

With PolyJet/MJP, the prototype can be made using various materials/colors/transparency/hardness. Its extremely detail and smoothness makes it outform almost all other 3D Printing technology in terms of visual prototypes.

Its extremely detail and smoothness makes it outform almost all other 3D Printing technology in terms of visual prototypes.

Rapid Molds

The heat tolerance and great mechanical properties of PolyJet/MJP digital materials let rapid molds possible to be printed directly, shortening the turnaround tremendously.

Customized Products

PolyJet/MJP can be applied to make high-quality small batched products with varied requirements, ideal for small businesses that wishes to test the market’s reaction to thier newly developed products.

Get Quotes Now!

Aerospace

Automotive

Consumer Goods

Bio & Health

Art & Creative

Architecture

Entertainments

Electronics

Education

Need more information? See our resource center!

FAQ - FacFox Docs

Dealing with rejections is one of the most difficult processes at FacFox, and it can be confusing at times. We are always trying to provide as much information and guidance as possible when processing rejections in order to help your model print successfully.

We are always trying to provide as much information and guidance as possible when processing rejections in order to help your model print successfully.

Automatic vs. manual checks

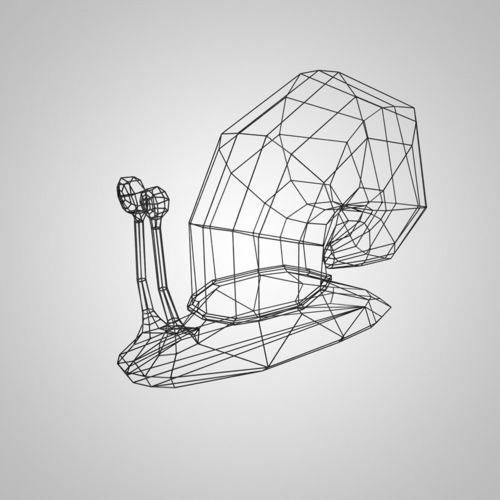

When you upload a model to FacFox Insta3DP, you can check it in 3D preview to see if our system caught any major issues. This system is perfect for last minute check of the size and structure of your model before you order it.

If your model passes the initial printability checks and wall thickness check online, this does not mean your item is printable. The initial check only verifies that your item fits in the required bounding box for the material, the wall thickness check only checks to see if any parts are below the minimum wall thickness. So it does not check to see if the geometry allows your model to be printed. Details, sprues, and wire thickness also need to be reviewed manually after an order is placed.

Notifications

We always contact you using the email address that is linked to your account.

The email will contain the rejection reason, suggestions to fix an issue, and a screenshot showing the affected area.

If you’ve missed a notice that your model was cancelled/rejected, please check you email (and your SPAM folder) for more information.

What do I do after my model has been rejected?

It’s important to make sure that your model meets the design guidelines of the material you have selected. In order to create a successful model that’s printable, please make sure you follow our 3D Printing Checklist before uploading your model.

You can always see the design guidelines by going to the Materials Hub, clicking on the material you’re interested in, and selecting the Design Guidelines tab on the top.

The rejection email will contain a link to the “Repair and Update” page where you can take action, either by updating the model with a revised version, print it anyway (if ordered material is eligible for this feature), or remove the model from your order.

Alternatively, on your Orders page, you will be able to take action as well.

Modify Step

If the model has any issue, we will show you the reason and give you multiple options to proceed via email notification and support message.

Print It Anyway (PITA): If you deem the areas mentioned in the pictures and explanation are acceptable and you want to take the risk to print it anyway, use this feature.

Note that by selecting this feature, you’re not eligible for a refund or reprint.

Cancel Request/Order: If you are unable to fix the problematic areas or do not want to continue with this model, this feature allows you to remove it from your order. A refund will automatically be processed in case you have been charged, if your order has not been charged yet, the payment will simply be voided for this model.

Repair and Update FAQ

Q: My revised version uses more volume than the threshold accepts.

A: We recommend to use the Cancel Order Item function and place a separate order for the revised model instead.

If your order contains multiple models, but only one needs to be reordered, you can easily create a separate order and select Combined Shipment in service.This way the new order with the revised model will be shipped together with the original order, free of additional Shipping Charges.

Q: Can I change the material instead of updating my model?

A: While this feature doesn’t allow you to change the material upon a rejection, you can use the procedure in the FAQ question above to cancel the model and place a new order with the revised material instead.

Success rate

Each printing attempt counts towards total success rate of your model.

It is possible for models to print successfully sometimes and fail at other times. This happens with models that have parts that are either under our design guidelines or just at the cusp. Sometimes they will still survive the entire production process, but this does not mean that trend will persist. To keep track of this we have created a success rate system which you can learn more about here.

Sometimes they will still survive the entire production process, but this does not mean that trend will persist. To keep track of this we have created a success rate system which you can learn more about here.

If your model is accepted and is on the edge of our guidelines, we will try to print it for you. That said, depending on the geometry of the model, sometimes we see that these attempts may fail.

With every reprint a success rate is recalculated. If this rate drops below 80%, the model is rechecked. If the rate is below 50%, we will reject this model.

Cheap 3d printing service sls 3d printer prototype supply from China factory

- 597 Reviews

- 11 Questions

- Categories: Machining >>>

- Supplier: Shenzhen,A-R,Technology,Co.

,Ltd.

,Ltd.

Description and reviews

Specifications

Cheap 3d plastic printing service, sls 3d printer prototyping, China factory supply 3d printing

NOSSISTIFICES: toys security certificates

About us:

Our factory:

FAQ:

How can I get an offer?

A. Please provide us with a solid 3D CAD model in step, IGS,X_T format, usually two dimensional (2D) drawings are not adequate for accurate quoting or fabrication of parts.

B. Please tell us your requirement for quantity, surface treatment, color, material, application environment for accurate pricing.

How can I pay?

A. Bank transfer, Alibaba order, Paypal ,Western Union, etc.

Can we sign Non Disclosure Agreements (NDA)?

Yes. If that gives you the peace of mind to sign an NDA, we are more than willing to do so. But we have the right to keep your design confidential, whether it's signed by an NDA or not. All factories are controlled by camera.

What is the advantage of our company?

1. 16 years of experience.

2. Professional technology and high-precision prototypes

3. High quality and competitive price.

4. Focus on customer needs.

Why do a rapid prototype?

Prototypes allow the design team to test functionality and ensure proper design and fit. Prototypes can be used for sales meetings, customer presentations, and trade shows in general, time to market can be reduced as precision in design ensures a streamlined project schedule.

Package and shipping:

1. For shipping: we usually choose DHL, Fedex and Ups express, the delivery time is about 3-5 days

For shipping: we usually choose DHL, Fedex and Ups express, the delivery time is about 3-5 days

2. For packaging: we will use a good shape to pack each product, and we can guarantee all product received well

You just need:

Contact us! We will be your best cooperative partner!

Similar items

Cnc turning parts of electric motorcycle turning services aluminum cnc machining parts

US $0.10-$1.70

OEM Custom Design 3D Printing Service Custom Material Supplier Rapid Prototype Custom 3D Printing

US $1.00-$100.00

hot sale and high quality CNC machining brass material fitting

US $0. 7831-$6.6561

7831-$6.6561

CNC Machining, Professional Custom Machining, CNC Aluminum Parts Machining, Color Anodizing, Mechanical Aluminum Parts

US $0.10-$1.00

OEM CNC Prototype Custom Service CNC Corom Machined Milling Parts Aluminum Brass Service CNC Service

US $1.00-$3.00

Wood Laser Cutting Service

US $0.80-$1.80

FR4 Epoxy Board CNC Mechanical Gasket

US $1.00-$200.00

Roller for cutting can mask n95 semi-automatic roller cutter

US $650.00-$750.00

Industrial Custom 3D Printing Services in China

We use cookies to personalize content and ads, to provide social media features, and to analyze our traffic. We also share information about your use of our site with our social media, advertising and analytics partners. Privacy policy

We also share information about your use of our site with our social media, advertising and analytics partners. Privacy policy

With two decades of on-demand manufacturing and prototyping services, ProtoFab is the ideal partner to bring ideas to life. We have a wide range of processes and materials to choose from, each with their own benefits and applications.

What is CNC?

CNC (Computer Numerical Control) Machining is a subtractive process that uses precise tools to cut material to obtain the desired part or product. The software-controlled instrument head is much more accurate than any human and allows for accurate reproduction.

Who needs CNC machining?

CNC machining is better for working with metals than 3D printing, although metal 3D printing is also possible. Other materials often used in CNC machining include wood, foam, and wax, and it should be noted that each type of material requires different tools. CNC machining is slower than 3D printing, but once prepared, the subtraction method is significantly faster than the additive method used in 3D printing CNC machining is also generally more accurate than 3D printing, with tolerances up to 0. 001 mm. A disadvantage of CNC machining is that very complex designs may not be possible due to tool access issues. Therefore, CNC machining is best suited for relatively simple designs using traditional materials such as metal or wood and where a high level of precision is required.

001 mm. A disadvantage of CNC machining is that very complex designs may not be possible due to tool access issues. Therefore, CNC machining is best suited for relatively simple designs using traditional materials such as metal or wood and where a high level of precision is required.

Process

The CNC machining process is somewhat similar to 3D printing. As with 3D printing, a detailed CAD drawing is needed, which is analyzed by a technician and imported into specialized software. In the case of CNC processing, in ProtoFab we convert the files to a format and import them into Mastercam. During the programming phase, the technician must decide what type of cutting tool to use based on the materials used and any specific problems caused by the shape. Once the tools are ready and programming is complete, the cutting process can begin. Both CNC milling and turning are available at ProtoFab. Milling is the method used for normal parts, while turning is used for parts with cylindrical parts. Once the cutting is completed, each piece is sent to post-processing where the finishing process begins.

Once the cutting is completed, each piece is sent to post-processing where the finishing process begins.

What is 3D printing?

3D printing is an additive manufacturing process in which a three-dimensional object can be created by precisely adding layers of material. It revolutionizes multiple industries and offers previously unimaginable levels of customizability and convenience. 3D printing is capable of producing complex parts that are literally impossible with traditional methods, all it takes is a CAD drawing. Because it is an additive process, parts can be produced with an absolute minimum of waste, and the rapid nature of the technology makes it ideal for modern industries that cannot afford to wait.

Who is 3D printing for?

3D printing is one of the most versatile manufacturing technologies and can be used in almost any industry. It is best used in cases where the part or product has a very complex shape, such as lattice structures, or when internal detailing is required. It is also particularly suitable for rapid production, and often a 3D printer can produce a finished product without the need for further assembly. It is also useful for extremely short runs, such as just one or two prototypes, as there are no tooling costs and no need to make a mold.

It is also particularly suitable for rapid production, and often a 3D printer can produce a finished product without the need for further assembly. It is also useful for extremely short runs, such as just one or two prototypes, as there are no tooling costs and no need to make a mold.

Process

First, a detailed CAD file imported into 3D printing software (Magics). This software analyzes a CAD drawing and breaks it down into ultra-thin cross-sectional layers. The engineer will analyze the object to be printed and decide if additional supports need to be printed so that the structure can remain stable. This extra material is later removed in post-production. The printer head is controlled by a laser and gradually builds up the object, working along thin cross sections identified by the software. A wide range of materials is available, and this range is constantly increasing as technology becomes more advanced.

What is small batch production?

With the continued development of modern manufacturing technologies and businesses increasingly looking for flexibility in manufacturing, low volume manufacturing has become much more popular in recent years. As a term, this is difficult to define specifically, but we can say that low-volume production implies a significantly lower quantity than full-scale production and uses more flexible methods. At ProtoFab we specialize in this type of production and can make the process as simple and efficient as possible.

As a term, this is difficult to define specifically, but we can say that low-volume production implies a significantly lower quantity than full-scale production and uses more flexible methods. At ProtoFab we specialize in this type of production and can make the process as simple and efficient as possible.

Benefits of low volume production

There are at least 3 reasons why companies choose low volume production. First of all, the use of small-scale production can reduce many of the costs associated with full-scale production. Even up to about 100,000 units, it may be more economical to use low volume production, depending on the materials used. For small volumes, such as a few thousand, the economic benefit can be enormous.

Second, low volume production is inherently more flexible. Tweaks can be made easily, and adjustments can often be made reactively based on consumer feedback. In mass production, this sort of tweaking is usually out of the question, and minor flaws are baked all over. Low volume production is also much faster and allows for very fast time to market, which is very important in some industries.

Low volume production is also much faster and allows for very fast time to market, which is very important in some industries.

Finally, small-scale production can be used as a bridge to full-scale production. The initial run can be done on a low volume to keep costs down and maintain flexibility, and once the product is successful and any problems have been ironed out, production can be switched to full scale. In general, low-volume manufacturing offers many benefits and is worth considering for a wide range of industries and product types. Feel free to contact us to find out more.

What is plastic injection molding?

Plastic injection molding is one of the fastest production technologies. The liquid plastic is injected into a mold where it cools, solidifies and is ejected. The same mold can be used countless times, and the process of making a part can take only a few seconds. There are thousands of different types of plastics available, and a variety of polishes and textures can be applied, allowing for a huge degree of customization and flexibility.

Who is plastic injection molding intended for?

Plastic injection molding is great for those who want to produce a relatively large number of parts or products quickly and economically. After the initial cost of the tool, further costs are very low, so it makes sense to use plastic injection molding for long runs. If you only require a small number of prototypes, 3D printing is likely to be more cost effective. Unlike vacuum casting, the same mold can be used over and over again over 100,000 times, so usually only one mold is needed. The ability to mix different types of plastics (through co-injection molding) is another reason why people choose plastic injection molding. For other manufacturing technologies, it may be difficult to fabricate structures from mixed materials. Common uses for plastic injection molding include pilot work, low volume production, and parts on demand.

Process

First, a mold is made, usually CNC machined from aluminium. The material is produced in the form of granules, which are melted in a barrel. This liquid is then compressed and injected into the mold through a guide system where it rapidly solidifies. The ejector pins then push the solid into the feed hopper and the process can be repeated again. The time it takes to make each part depends on its size and the material used. This ranges from a few seconds for small projects to one or two minutes for larger and more complex projects. It should be noted that the production phase is fully automated, so labor costs are kept to a minimum.

This liquid is then compressed and injected into the mold through a guide system where it rapidly solidifies. The ejector pins then push the solid into the feed hopper and the process can be repeated again. The time it takes to make each part depends on its size and the material used. This ranges from a few seconds for small projects to one or two minutes for larger and more complex projects. It should be noted that the production phase is fully automated, so labor costs are kept to a minimum.

What is vacuum casting?

Vacuum casting uses a vacuum chamber to force liquid plastic into a finished mold where it then solidifies. Molds are usually made from silicone rubber and are in turn based on a master model.

Who is vacuum casting used for?

Vacuum casting is the ideal solution for rapid low cost prototyping. Molds can be produced cheaply and with a high degree of detail, so prototypes require little to no post-processing. Each form has a print run of about 50 copies and can be made quickly. For short runs, the technique is more economical than plastic injection molding due to the initial cost of the injection molding tool. However, for long batches, vacuum casting is less suitable.

For short runs, the technique is more economical than plastic injection molding due to the initial cost of the injection molding tool. However, for long batches, vacuum casting is less suitable.

Process

The first thing required is a master model. This can be provided by the customer, but is most commonly produced by ProtoFab using CNC machining. The master model is usually made of metal, but plastic is also acceptable, the main requirement is to withstand temperatures of 40 ° C for a long period. The master model is placed in a mold box, and the silicone rubber mold consists of two parts. The mold has a series of very small holes cut into it to allow air to escape and prevent pressure from building up.

The mold is the exact opposite of the master mold, so all it takes is filling the mold with material and getting a copy. However, simply pouring liquid material into a mold can sometimes produce inadequate results, so a vacuum chamber is required to push the material into even the tiniest of gaps, providing a perfect copy. Once the material has filled the mold, it is placed in a curing oven until the new object is completely cured. It is then removed from the mold and the process can start again. The molds can be used multiple times, up to a maximum of 50, without any reduction in copy quality.

Once the material has filled the mold, it is placed in a curing oven until the new object is completely cured. It is then removed from the mold and the process can start again. The molds can be used multiple times, up to a maximum of 50, without any reduction in copy quality.

What is a finish?

As the name implies, finishing is the final stage of production and comes after the actual production. At ProtoFab we offer a wide range of finishing services including painting, anodizing and steam polishing. Our finishing departments can adapt to the most specific requirements and have access to a wide range of cutting-edge technologies, allowing almost limitless customization during the finishing phase.

Services available

Painting is more than just slapping paint. The slightest defects that occur during the dyeing stage can spoil the product, and it is important to ensure complete uniformity throughout the cycle. Coloring takes place in laboratory conditions in a climatic chamber. A wide variety of paint finishes are available, including matte, glossy, semi-gloss and metallic.

A wide variety of paint finishes are available, including matte, glossy, semi-gloss and metallic.

Color matching. We are well aware of the importance of an exact match to the intended color. Staining always takes place in a controlled environment with constant light and climate conditions that can avoid some of the common problems when visually matching the sample. In addition to matching with a physical sample, we can also match Pantone colors exactly.

Sanding and polishing - we can provide custom finishes from mirror polished to rough sanded. Sanding can also be used to prepare the product for various varnishes such as matt.

Steam polishing is an advanced technique for removing small imperfections even in hard to reach areas. The surface of the plastic is exploded by the chemical vapor, which causes the surface to melt directly, but only to a tiny depth. As it hardens, any small defects disappear, and the surface becomes smooth and uniform.