Cead 3d printer

CEAD B.V. | Large Scale 3D Printing

Skip to contentHomeadmin2022-11-11T15:21:33+00:00

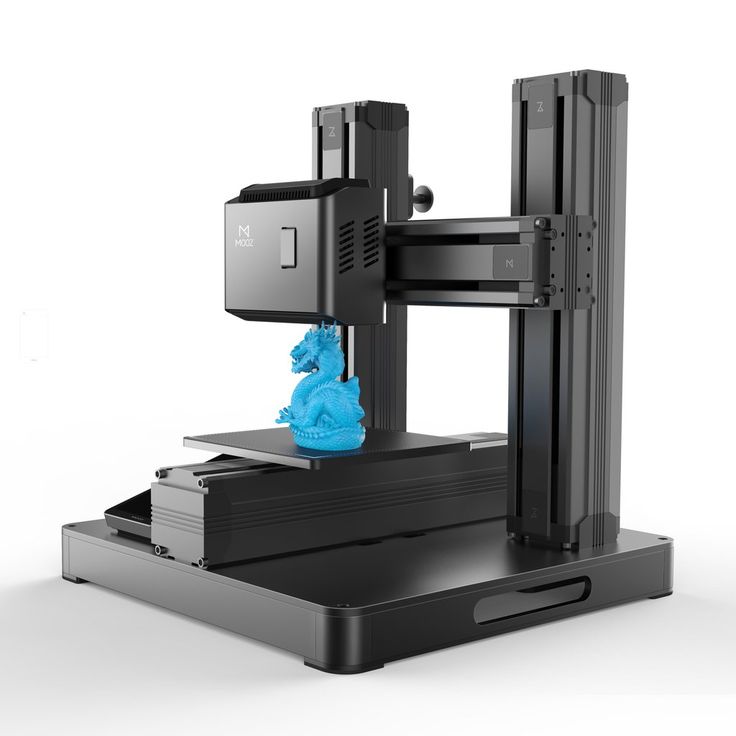

We build large scale 3D printers

CEAD delivers technology and helps with the implementation of large scale thermoplastic composite 3D printing solutions

large scale

3D printers

CEAD delivers technology and helps with the implementation of large scale thermoplastic composite 3D printing solutionsPilot Project and training

To assess the technical and commercial feasibility of a application using large scale 3D printing, a pilot project can be conducted. CEAD also provides new owners of our solutions for large scale 3D printing with training.

Services

Robot based solutions

Versatile system, completely modular. Ideal for custom solutions to fit a specific application, for example the integration of production technologies into one process such as combining additive and subtractive manufacturing.

Robot based 3D printing

Technology components

Technology components are stand alone components used for integrators and companies alike. CEAD offers its print heads as technology components that can be used to build modular large scale 3D printers.

Technology components

Discover your possibilities

The overall package provided by CEAD gives us full flexibility as a research institution. Besides size, flexibility and reliability were the main reasons for choosing CEAD’s AM Flexbot system.

The CEAD printer extends our capabilities towards larger parts, higher fiber contents and a wider range of polymers. The CEAD system was delivered very quickly — from order to installation was only 6 months.

“We were really happy with the service and product CEAD offered to us. They were willing to help us with concretizing our idea right from the start and steered us into the right direction.

Also the final product was delivered just as we expected and saved us precious hours during the production of our car!”

We are enthusiastic about the CEAD Robot Extruder and make new applications / shapes with it, such as a lampshade, rain barrels, flower pots, and doors of a classic Jeep. Because SPARK Makers Zone is an open lab, (potential) customers of CEAD can come here to print and experiment.

We have found the CEAD Robot Extruder to be the perfect tool for our needs. High throughput, high temperature, a wide variety of materials, 24/7 production possibilities, and relatively low weight, make it an ideal extruder for us.

With this 3D printer we can work faster, at lower costs and we have less manual labour.

We are delighted to show an industrial solution from CEAD for multi-axis composite printing combining Comau’s robotics, CEAD’s Additive Manufacturing and our best in class CNC technology.

We are now 3D printing molds using 30% short glass fiber-reinforced polypropylene and cutting our labor time by 50%.

Due to CEADs constructive approach and innovative ideas we always collaboratively come up with the best solutions.

Robert-Jan van Dijk, Innovation Manager at Vink Systemen B.V.

Fiber-reinforced polymer bridges are already well known for having a longer lifetime expectancy with lower life cycle costs compared to steel bridges. What’s new here is the use of a new 3D printing technology, enabling us to print large-scale fiber reinforced thermoplastic parts.

Discover your possibilities

The overall package provided by CEAD gives us full flexibility as a research institution. Besides size, flexibility and reliability were the main reasons for choosing CEAD’s AM Flexbot system.

The CEAD printer extends our capabilities towards larger parts, higher fiber contents and a wider range of polymers. The CEAD system was delivered very quickly — from order to installation was only 6 months.

“We were really happy with the service and product CEAD offered to us. They were willing to help us with concretizing our idea right from the start and steered us into the right direction. Also the final product was delivered just as we expected and saved us precious hours during the production of our car!”

We are enthusiastic about the CEAD Robot Extruder and make new applications / shapes with it, such as a lampshade, rain barrels, flower pots, and doors of a classic Jeep. Because SPARK Makers Zone is an open lab, (potential) customers of CEAD can come here to print and experiment.

We have found the CEAD Robot Extruder to be the perfect tool for our needs.

High throughput, high temperature, a wide variety of materials, 24/7 production possibilities, and relatively low weight, make it an ideal extruder for us.

With this 3D printer we can work faster, at lower costs and we have less manual labour.

We are delighted to show an industrial solution from CEAD for multi-axis composite printing combining Comau’s robotics, CEAD’s Additive Manufacturing and our best in class CNC technology.

We are now 3D printing molds using 30% short glass fiber-reinforced polypropylene and cutting our labor time by 50%.

Due to CEADs constructive approach and innovative ideas we always collaboratively come up with the best solutions.

Robert-Jan van Dijk, Innovation Manager at Vink Systemen B.V.

Fiber-reinforced polymer bridges are already well known for having a longer lifetime expectancy with lower life cycle costs compared to steel bridges.

What’s new here is the use of a new 3D printing technology, enabling us to print large-scale fiber reinforced thermoplastic parts.

Vincent2022-10-12T11:37:59+00:00

Automotive

Mold for a hydrogen fueled powered city car About Eco-Runner A multidisciplinary team of 23 TU Delft students dedicates itself for a full year to design, build, test and race the world's most efficient hydrogen powered city car. Their goal is to promote a sustainable future and to inspire and activate the public to play a part in the energy transition and to emphasize the importance of efficiency and potential of hydrogen along the way. [...]

Learn More

Scaling back production time of automotive autoclave tool from weeks to daysVincent2022-10-19T09:25:26+00:00

Combining 3D printing and CNC milling for complex building structuresVincent2022-10-25T11:55:33+00:00

3D printing with CEAD Robot Extruder in largest innovation centre in the NetherlandsCharléne van Wingerden2022-10-19T09:17:06+00:00

Using 3D printing for architectureCharléne van Wingerden2022-07-27T14:18:41+00:00

3D printed molds with Polypropylene 30% short glass fibersCharléne van Wingerden2022-07-27T14:16:08+00:00

Large-scale 3D printed bridgeCharléne van Wingerden2022-07-27T14:18:18+00:00

CEAD supplies a total package when it comes to 3D printing solutions. We not only supply the technology and the machine, but also offer assistance with installation, offer assistance with product design, training, maintenance and support. We will help you build your production process from start to finish.

We not only supply the technology and the machine, but also offer assistance with installation, offer assistance with product design, training, maintenance and support. We will help you build your production process from start to finish.

1. Proof of Concept

We start working together on the application and make a draft of the business case. Often, the case needs further assessment. This is exactly what the Proof of Concept phase is for: we focus on both the technical and commercial feasibility.

2. Hardware solution

The Proof of Concept gives insights in technical feasibility and the business case. This has allowed us to gain insights in the exact needs, and with the broad range of machines as well as the possibility a for custom machine, the best solution is delivered.

3. Implementation

The hardware solution itself is half of the work. We are eager to help you with the complete implementation from operator training to the design guidelines and integration with other hardware such as CNC milling equipment. We can even supply operators or supply engineering support.

We can even supply operators or supply engineering support.

4. Maintenance and service

Our hardware solution in combination with our maintenance service are designed for 10+ years of non-stop operation. We have an elaborate service and maintenance program with solutions to minimize the downtime of your equipment.

More about us

CEAD supplies a total package when it comes to 3D printing solutions. We not only supply the technology and the machine, but also offer assistance with installation, offer assistance with product design, training, maintenance and support. We will help you build your production process from start to finish.

1. Proof of Concept

We start working together on the application and make a draft of the business case. Often, the case needs further assessment. This is exactly what the Proof of Concept phase is for: we focus on both the technical and commercial feasibility.

2. Hardware solution

The Proof of Concept gives insights in technical feasibility and the business case. This has allowed us to gain insights in the exact needs, and with the broad range of machines as well as the possibility a for custom machine, the best solution is delivered.

This has allowed us to gain insights in the exact needs, and with the broad range of machines as well as the possibility a for custom machine, the best solution is delivered.

3. Implementation

The hardware solution itself is half of the work. We are eager to help you with the complete implementation from operator training to the design guidelines and integration with other hardware such as CNC milling equipment. We can even supply operators or supply engineering support.

4. Maintenance and service

Our hardware solution in combination with our maintenance service are designed for 10+ years of non-stop operation. We have an elaborate service and maintenance program with solutions to minimize the downtime of your equipment.

The possibility to attend conferences and events in person is here again, and we are excited to meet you at one of the following events. CEAD is attending events additive manufacturing and more.

View our agenda to meet CEAD and our large scale additive manufacturing solutions in person.

View events

Page load link Go to TopGantry-, Robot- and Extruder 3D Printing Solutions

Skip to contentSolutions large scale 3d printingadmin2022-11-02T09:33:57+00:00

CEAD’s years of research and development of industrial 3D printing technology is translated into our diverse range of large scale 3D printing solutions. This range of solutions includes stand alone printheads, complete robot based solutions and gantry based solutions and services such as pilot programs.

On this page an overview of these 3D printing solutions is listed. Feel free to contact us directly to find out how CEAD can help your company transform its business activities with our technology.

To assess the technical and commercial feasibility of the application using large scale 3D printing, a pilot project can be conducted together with CEAD. During this project we will investigate important aspects of the application such as the design, required material, and printing strategy.

Do you already know the feasibility of your project and which product you would like? Then select one of the other solutions below.

Read more about pilot projects

Pilot project

To assess the technical and commercial feasibility of the application using large scale 3D printing, a pilot project can be conducted together with CEAD. During this project we will investigate important aspects of the application such as the design, required material, and printing strategy.

Do you already know the feasibility of your project and which product you would like? Then select one of the other solutions below.

Read more

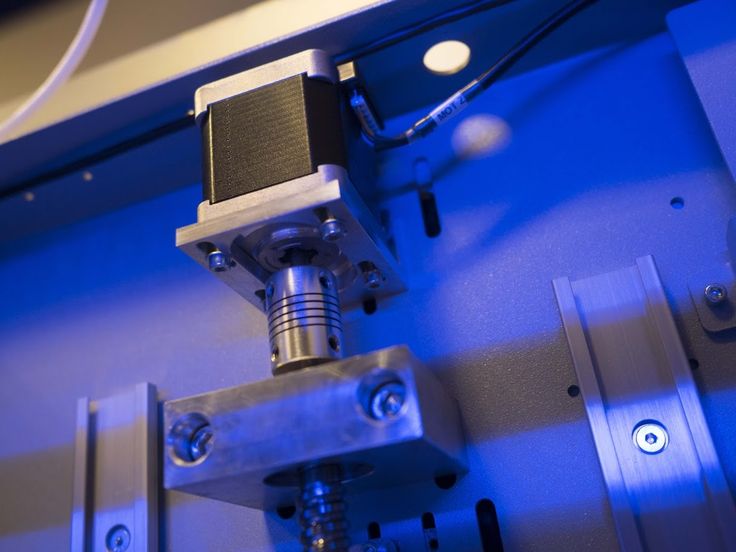

Robot extruder

CEAD offers its printheads as technology components that can be used to build large scale 3D printers. These printheads are often referred to as the robot extruder since they are regularly integrated with robotics but can also be integrated with gantry based solutions.

They are available in two sizes, the lightweight RE E25 and high output RE E50 and are able to use a wide variety of thermoplastic materials.

Read more about robot extruders

Print bed

The print bed provides a rigid, stable and easy to use building platform for large scale 3D printing. The working area of the print bed exists out of multiple aluminium bed profiles, specially designed for additive manufacturing, which guarantees a good mechanical bonding between the printed object and the bed. The print bed can be used for any thermoplastic printing material.

A tubular steel frame in combination with an independent height adjustable top layer ensures a rigid building platform for prints up to 2m x 1,2m.

Read more about the print bed

Robot extruder

CEAD offers its print heads as technology components that can be used to build large scale 3D printers. These print heads are often referred to as the robot extruder since they are regularly integrated with robotics but can also be integrated with gantry based solutions.

They are available in two sizes, the lightweight RE E25 and high output RE E50 and are able to use a wide variety of thermoplastic materials.

Read more

Print bed

The print bed provides a rigid, stable and easy to use building platform for large scale 3D printing. The working area of the print bed exists out of multiple aluminium bed profiles, specially designed for additive manufacturing, which guarantees a good mechanical bonding between the printed object and the bed. The print bed can be used for any thermoplastic printing material.

A tubular steel frame in combination with an independent height adjustable top layer ensures a rigid building platform for prints up to 2m x 1,2m.

Read more

AM Flexbot

A modular solution capable of combining multiple processes such as 3D printing and milling.

The AM Flexbot is ideal for custom solutions to fit a specific application. Siemens Sinumerik is used to directly control the Comau robot arm, meaning no robot controller is needed. This enables very accurate operation of the robot, especially in terms of position accuracy while travelling along a path.

Read more about the AM Flexbot

AM flexbot

A modular solution capable of combing multiple processes such as 3D printing and milling.

The AM Flexbot is ideal for custom solutions to fit a specific application. Siemens Sinumerik is used to direclty control the Comau robot arm, meaning no robot controller is needed. This enables very accurate operation of the robot, especially in terms of position accuracy while travelling along a path.

The standard AM Flexbot includes;

- Robot Extruder

- Comau NJ60-2.2

- Siemens Sinumerik 840D

- Dryer

- Working table (2m x 1,2m)

- Safety caging

- Pedestal for robotic arm

Read more

BEAD

The BEAD is a hybrid solution, combining the finish and tolerances that subtractive manufacturing offers with the sustainability of additive manufacturing into one system. This system is the result of a strategic worldwide partnership between Belotti S. P.A. and CEAD, in which the expertises of both branches are combined.

P.A. and CEAD, in which the expertises of both branches are combined.

Read more about BEAD

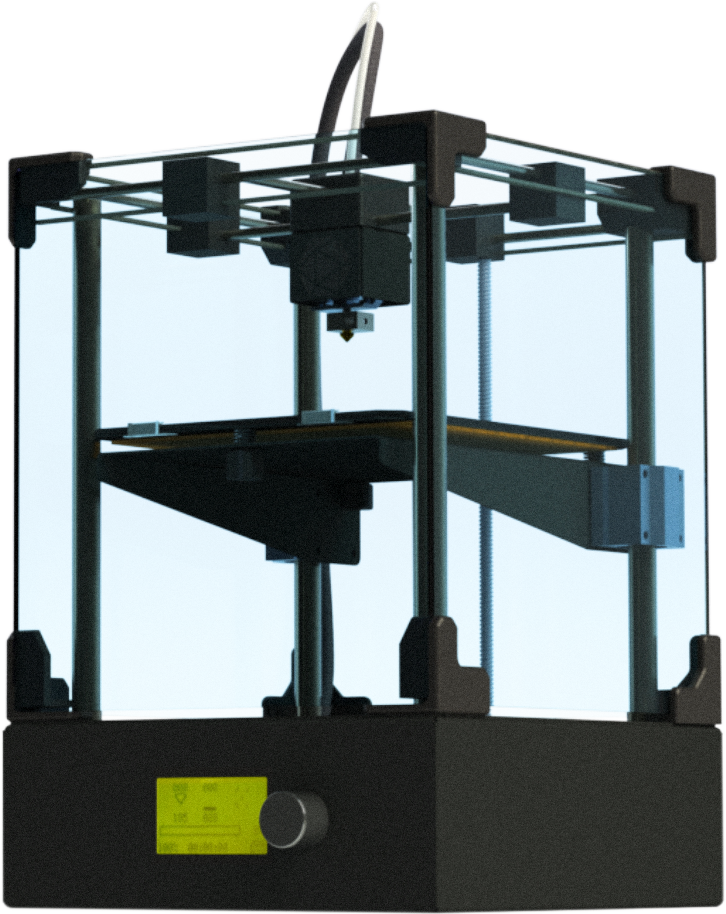

CFAM Prime

The CFAM Prime is especially engineered to run production. The machine focuses on printing speed and reliability. Ideal for efficient production of large parts or multiple parts in one production run. Complete turn key machines, ready to start printing your parts immediately.

Read more

BEAD

The BEAD is a hybrid solution, combining the finish and tolerances subtractive manufacturing offers with the sustainability of additive manufacturing into one system. This system is the result of a strategic worldwide partnership between Belotti S.P.A. and CEAD, in which the expertises of both branches are combined.

Read more

CFAM Prime

The CFAM Prime is especially engineered to run production. The machine focuses on printing speed and reliability. Ideal for efficient production of large parts or multiple parts in one production run. Complete turn key machines, ready to start printing your parts immediately.

Read more about CFAM Prime

Page load link Go to TopTechno Print 3D Company

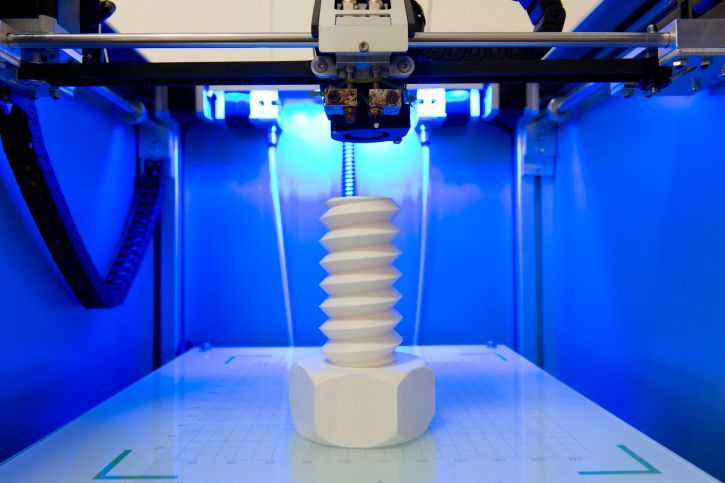

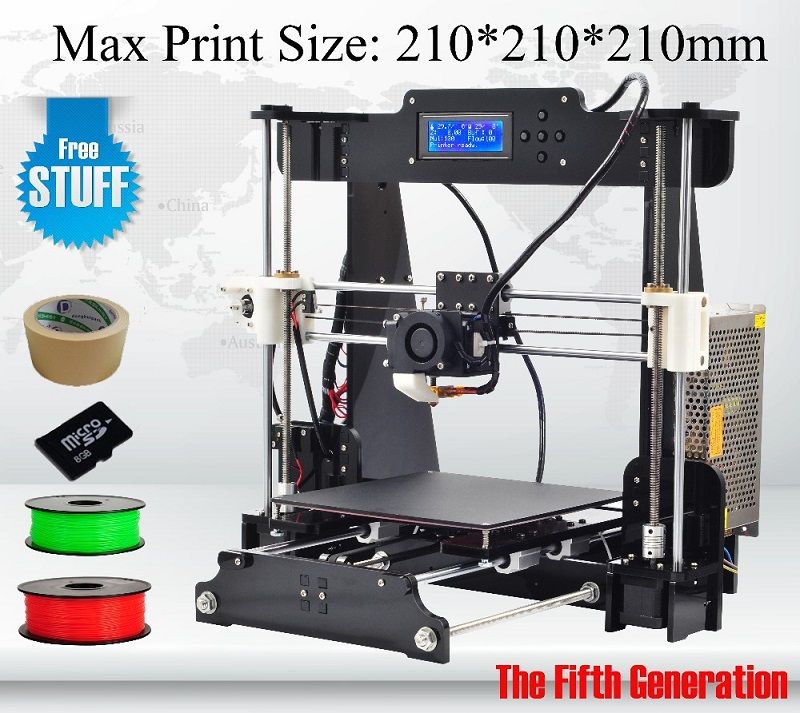

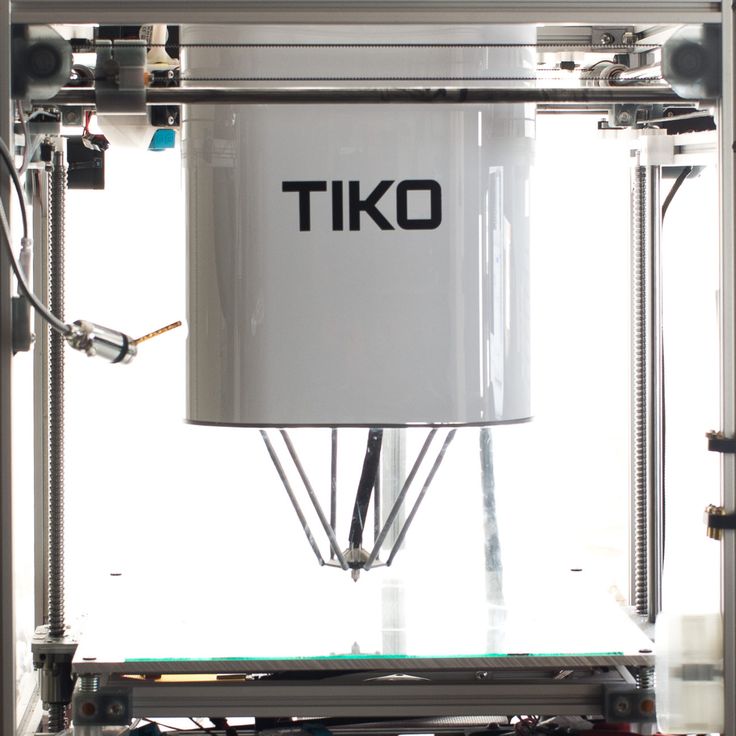

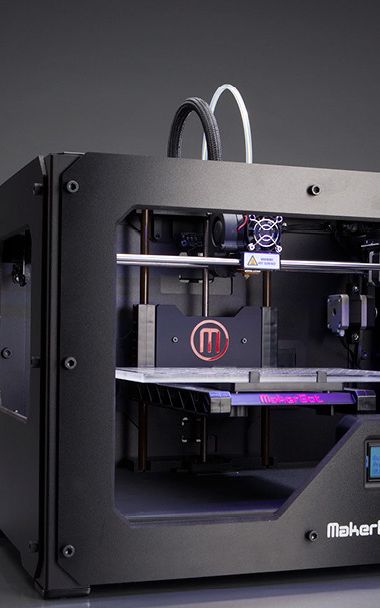

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

3D printer comparison in 2020

A variety of 3D printing technologies are available on the market today. Getting to know the nuances of each helps you understand what you can expect from the final models and decide which technology is right for you.

Stereolithography (SLA) and digital light processing (DLP) are the two most common 3D printing technologies using resins. 3D printers that use resin as consumables have become very popular due to their ability to produce highly accurate, isotropic and waterproof prototypes and models with high detail and smooth surfaces.

While these technologies used to be complex and prohibitively expensive, today's compact desktop SLA and DLP printers produce industrial quality parts at an affordable price and offer tremendous application flexibility through a wide range of materials.

Both of these processes selectively expose liquid polymer to a light source: an SLA laser, a DLP projector, forming very thin, hard layers of plastic that fold into a solid object. Although the principle of operation of these technologies is very similar, they can give significantly different results.

In this detailed guide, we will explain the features of these two 3D printing processes and see how they differ in terms of resolution, accuracy, print volume, speed, workflows, etc.

sample print

printing from my own experience. We will send a free sample of the Formlabs stereolithographic 3D printed model directly to your office.

Request a free print sample

Desktop stereolithography 3D printers contain a resin tank with a transparent bottom and a non-adhesive surface that serves as a base for the liquid resin to cure, allowing the newly formed layers to be carefully separated.

The printing process begins with the platform lowered into the resin tank, leaving a free space corresponding to the height of the layer between the platform or the last finished layer and the bottom of the tank. The laser beam is fed to two mirror galvanometers, with the help of which it enters the desired coordinates on a series of mirrors. This allows a focused beam of light to be fed upwards through the bottom of the tank, under the influence of which the polymer layer hardens.

Then the hardened layer is separated from the bottom of the tank, and the platform rises higher, and liquid polymer enters the freed space. This process is repeated until printing is complete.

This process is repeated until printing is complete.

The Form 3 and Form 3L Low Force Lithography (LFS) stereolithography technology is a new step in the development of stereolithographic 3D printing.

In LFS-based 3D printers, the optical components are located in the Light Processing Unit (LPU). Inside the LPU, a galvanometer positions the high-density laser beam in the y-direction, passes it through a spatial filter, and directs it into a deflecting and parabolic mirror to ensure that the beam always remains perpendicular to the plane of the platform, ensuring print accuracy and reproducibility.

As the LPU moves in the X direction, the printed model is gently separated from the flexible bottom of the tank, which greatly reduces the forces on the models during the printing process.

LFS 3D printing greatly reduces the stress placed on parts during the printing process by using a flexible reservoir and linear illumination to deliver incredible surface quality and print accuracy.

This advanced stereo lithography technology features higher surface quality and print accuracy. The lower print tear force also allows the creation of lightweight support structures that can be detached without force, and the method itself opens up great opportunities for the further development of advanced production-ready materials. Learn more about stereolithographic 3D printing

White Paper

Download our in-depth white paper to learn how SLA printing works, why thousands of professionals use it today, and how this 3D printing technology can help your work.

Download white paper

Desktop DLP printers use a transparent bottom resin tank and a platform that descends into the tank to layer upside down models. In this they are no different from stereolithographic 3D printers.

The difference between them is the light source. DLP-based 3D printers use a digital screen to project the image of the layer onto the entire platform, causing all the desired dots to solidify at the same time.

Light is reflected on a digital micromirror screen (DMD), a dynamic mask consisting of microscopic mirrors that are located in a matrix on a semiconductor chip. The rapid switching of these tiny mirrors between lenses that direct light to the bottom of a tank or radiator determines the coordinates at which the liquid polymer must solidify in order to form the current layer.

Because the projector is a digital screen, each layer's image is made up of square pixels, resulting in a three-dimensional layer of rectangular cubes called voxels.

When it comes to 3D printer specifications, resolution is the focus, but it often leads to confusion. The basic units of the SLA and DLP processes are different forms, making it difficult to compare printers based on numbers alone.

In 3D printing, there are three dimensions to consider: two planar 2D dimensions (X and Y) and a third vertical dimension, Z, which is used for 3D printing.

The resolution of the Z measurement is determined by the thickness of the layer that the 3D printer can print. Printers based on SLA and DLP technologies have one of the best Z resolutions of any other process, allowing you to print layers with minimal thickness. Typically, users can set the layer height to between 25-300µm, allowing developers to trade-off between level of detail and speed.

Printers based on SLA and DLP technologies have one of the best Z resolutions of any other process, allowing you to print layers with minimal thickness. Typically, users can set the layer height to between 25-300µm, allowing developers to trade-off between level of detail and speed.

In DLP printers, XY resolution is determined by the pixel size, the smallest detail that the projector can reproduce in one layer. It depends on the resolution of the projector (the most common is Full HD (1080p)) and its distance from the optical glass. Therefore, most desktop DLP printers have a constant XY resolution of 35 to 100 microns.

In stereolithographic 3D printers, the XY resolution is determined based on the size of the laser spot and the number of steps that can be used to control the beam. For example, a Form 3 3D printer based on LFS technology has a laser with a spot size of 85 μm, but due to the constant line scanning process, the laser can move at a smaller step, and the printer can consistently print models with an XY resolution of 25 μm.

Resolution itself is often only an indicator of vanity. It gives some idea of the performance, but does not necessarily directly correspond to the accuracy and quality of the print.

Learn more about resolution in 3D printing in our detailed guide.

Since 3D printing is an additive process, violations can potentially occur in every layer. The process of forming layers affects the level of accuracy and correctness of each layer. Accuracy and accuracy depend on many factors: 3D printing process, materials, software settings, post-processing, etc.

In general, SLA and DLP printers are among the most accurate. Differences in print accuracy are often more noticeable between printers from different manufacturers than between the technologies themselves.

For example, entry-level SLA or DLP printers may use off-the-shelf projectors, lasers, or galvanometers, and their manufacturers strive to achieve optimum performance from these parts. Professional SLA and DLP printers (such as Formlabs Form 3) have a special optical system that is adjusted according to the needs of users.

Precision is critical for parts such as mouth guards (left) and surgical templates (right).

Precision is critical for parts such as mouthguards (left) and surgical guides (right).

Equally important is calibration. When using DLP projectors, manufacturers face uneven distribution of light on the platform and optical lens distortion, which means that the size and shape of the pixels in the middle and at the edges are different. Stereolithographic 3D printers use the same light source for all parts of the model, ensuring uniformity, but they still need to be carefully calibrated to avoid distortion.

Even a 3D printer with the best components and the best degree of calibration can produce different results depending on the consumables used. Resin parameters have to be changed to ensure the best quality, but they may not be available for new materials that have not been properly tested with the appropriate 3D printer model.

What conclusion can be drawn from this? Knowing only the technical characteristics, it is impossible to get a complete picture of the quality. The best way to evaluate a 3D printer is to study the models printed on it or ask the manufacturer to make a test model for your project.

The best way to evaluate a 3D printer is to study the models printed on it or ask the manufacturer to make a test model for your project.

DLP printers have an inverse relationship between resolution and working volume. The resolution depends on the projector, which determines the number of pixels/voxels available. If you move the projector closer to the optical glass, the pixels will become smaller and the resolution will increase, but the working area will be limited.

Some manufacturers install multiple projectors side by side or use a 4K high-definition projector to increase the working area, but this increases the cost significantly. The price of such models is much higher than other desktop 3D printers.

Therefore, DLP printers are usually optimized for specific purposes. Some of them have a smaller workspace and allow you to produce in high resolution such small and detailed models as jewelry, while others can print larger parts, but with a lower resolution.

The stereolithography process is inherently more scalable because the print volume of an SLA printer is independent of model resolution. A single model can be of any size and resolution, and can be placed anywhere on the workspace. This allows you to print large high-resolution 3D models or large batches of finely detailed models to increase printer performance.

Another hurdle to increase print volume in both SL and DLP printers is the release force. When printing large models, the forces applied to them increase exponentially as the cured layer separates from the reservoir.

With LFS printing, the flexible film at the base of the resin reservoir gently peels off when the platform pulls the model up, greatly reducing stress on the model. This unique feature has dramatically increased print volume in the first affordable large-format stereolithography printer, the Form 3L.

Form 3L is the first affordable 30 x 33.5 x 20cm large format 3D lithography 3D printer. compared to solutions based on other technologies. When we talk about differences, in most cases they are only visible on very small parts and models with a high degree of detail.

compared to solutions based on other technologies. When we talk about differences, in most cases they are only visible on very small parts and models with a high degree of detail.

Because 3D printers print in layers, finished models often have noticeable horizontal lines. And due to the fact that digital light processing technology uses rectangular voxels, the effect of vertical lines can also be observed.

DLP printers use rectangular voxels to render images, which can result in vertical lines. In this image, the vertical voxel lines are shown as they appear when printed (left), highlighted for better visibility (right).

Since voxels are rectangular, they affect the shape of the curved edges. Let's draw an analogy with creating a round shape from a LEGO constructor - the edges will have a stepped shape both along the Z axis and on the X-Y plane.

The rectangular shape of the voxels makes the curved edges appear jagged. Removing visible voxels and layer lines requires post-processing such as sanding.

Layer lines are virtually invisible when printed on LFS-based 3D printers. As a result, surface roughness is reduced, resulting in a smooth surface, and when using transparent materials, models with greater transparency.

When talking about the speed of 3D printing, it is important to consider not only the printing speed itself, but also the productivity.

The overall print speed of 3D printers based on SLA and DLP technologies is approximately the same. Since the projector exposes each layer as a whole, the speed of DLP 3D printing is uniform and depends only on the height of the model, while SLA 3D printers laser shape each part. As practice shows, as a result, stereolithographic 3D printers become comparable in speed or even faster when printing a single small or medium model, while DLP printers are faster at printing large solid models or several models that almost completely fill the space of the platform.

But do not forget that in printers based on DLP technology, there is an inverse relationship between resolution and working volume. A small DLP printer can quickly print small models or high-resolution (small) batches of small models, but print volume limits model size and device performance. Another high volume device can produce larger models, or batches of smaller models, faster but at lower resolution than a stereolithographic printer.

A small DLP printer can quickly print small models or high-resolution (small) batches of small models, but print volume limits model size and device performance. Another high volume device can produce larger models, or batches of smaller models, faster but at lower resolution than a stereolithographic printer.

With a stereolithographic 3D printer, all this can be done on one machine. At the same time, users can decide what they want to optimize in each case: resolution, speed or performance.

DLP printers use rectangular voxels to render images, which can result in vertical lines. In this image, the vertical voxel lines are shown as they appear when printed (left), highlighted for better visibility (right).

Stereolithographic 3D printers have higher print volumes, batch production, and overnight prints for increased productivity.

| 100 microns | 200 microns |

|---|---|

| | |

| 100 microns | 200 microns |

|---|---|

| | |

| 100 Microns | 200 Microns |

|---|---|

| | 9 3 HRS 9 Min 9 Min 9 Min 9 Min 9 Min 9 Min 9 Min 9 Min0181

Stereolithographic 3D printers have higher print volumes, batch production, and overnight printing of models, increasing productivity.

INTERACTIVE

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate savings

As with accuracy, differences in workflows and available materials are more printer dependent than technology.

Most SLA and DLP printers are plug and play and allow easy replacement of platforms and resin tanks. Some more sophisticated models come with a cartridge system to automatically refill the reservoir with liquid resin, requiring less attention and making it easier to print at night.

Some printers come with their own software for preparing 3D models for printing (for example, PreForm for Formlabs stereolithographic 3D printers), while other manufacturers offer ready-made standard solutions. Different software tools have different features, such as PreForm allows you to customize the printing process with one click, powerful tools for optimizing the density and size of supporting structures, adjustable layer thickness, and features to save materials and time. Fortunately, the software can be downloaded and tested before purchasing a 3D printer.

Fortunately, the software can be downloaded and tested before purchasing a 3D printer.

As with precision, differences in workflows and available media are more printer dependent than technology.

3D printers can work with a wide range of polymer materials for various applications.

One of the main advantages of polymer-based 3D printing is the large number of materials from which models can be made for various purposes. Polymers with different compositions have a variety of characteristics: they can be soft or hard, contain additives such as glass and ceramics, or have special mechanical properties such as high bending temperature under load or impact resistance.

But at the same time, the range of supported materials depends on the specific model of the 3D printer, so we recommend that you check this information with the manufacturer before making a purchase.

SLA and DLP prints require post-processing after printing. First, the models must be washed in solvent to remove excess resin. In some cases, such as models made from engineering and biocompatible materials, final polymerization is also required. For stereolithographic 3D printers, Formlabs offers solutions to automate these steps, saving you time and effort.

In some cases, such as models made from engineering and biocompatible materials, final polymerization is also required. For stereolithographic 3D printers, Formlabs offers solutions to automate these steps, saving you time and effort.

Finally, 3D models printed on supporting structures require the removal of such structures. This must be done manually - the process is similar for both SLA and DLP printers. LFS-based 3D printers use lightweight support structures with very small contact points, allowing for easy release with minimal marks.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

We hope that after understanding the differences in technologies and print results, it will be much easier for you to choose a 3D printer that best suits your needs and workflow.