Carabiner 3d print

Carabiner best 3D printer files・Cults

Carabiner

€0.72

Flexible Carabiner

€1.93 -67% €0.64

Carabiner Lock

Free

Carabiner REX & Carabiner PIRANHA

Free

Ultimate Carabiner

Free

Simple Molle Carabiner Loop

Free

carabiner

Free

Carabiner Hook for backpack

Free

Simple Carabiner

€1.20

VQR Durable Carabiner.

€1. 06

Carabiner

€0.50

PRINT IN PLACE CARABINER Carabiner O Ring Gate Clasp for any pourposes (Mosquetão Argola para Bolsa)

€1.78

Carabiner

Free

Thumby Keychain Case

€1.93

Carabiner

€0.53

S carabiner

Free

Bag cart hook

€2.89

73.5 mm carabiner

€0.50

Keychain brass knuckle carabiner

€0.50

Garmin Tempe sensor extrem carabiner

€0.62

Carabiner \ Reupload

Free

STRONG CAMPING CARABINER WITH BOTTLE OPENER

Free

SD Card & Micro SD Card Organiser with Screw-Top

€1. 14

14

Carabiner / Carabiner

€0.80

Thicker Caribiner

Free

Multipurpose Clip

Free

Carabiner for backpack

Free

Clipable hand sanitizer holder

Free

Clip Design - EDC tool clip

€4.50

FFXIV meteor logo Flexi Carabiner (print in place, no support)

Free

Screw Lock Carabiner

Free

Screw Carabiner

Free

Strong carabiner

€0.67

Carabiner with compliant mechanism

Free

carabiners

Free

caution holder

€1. 70

70

Bag hook with clasp - Practical handle for bags

€0.50

Garmin Tempe sensor carabiner

€0.62

Stencil of the climbing carbine.

€0.50

Ratcheting Carabiner

Free

Medium Carabiner

Free

Chunky RV Keychain

Free

Petzl Ultralegere Pulley

Free

Carabiner

Free

Bottle Holder

€0.50

TPU Bottle Holder

€0.50

Sports water bottle cap (R3/4" × 14TPI thread)

Free

Stick clip for climbing

€10

▷ strong carabiner 3d models 【 STLFinder 】

Strong Carabiner

thingiverse

This carabiner is fashionable, simple and strong carabiner. And carabiner was carried me few minutes. I used this parts "dd001" from http://www.thingiverse.com/thing:1008943 CAUTION don't use this carabiner to climb the mountain or Which it is...

And carabiner was carried me few minutes. I used this parts "dd001" from http://www.thingiverse.com/thing:1008943 CAUTION don't use this carabiner to climb the mountain or Which it is...

Strong Carabiner

thingiverse

Here is ergonomically curved carabiner. Stronger version is b8. b7 version scaled down to 80% makes a good key ring. This FDM gate concept was first released on thingiverse by ddf3d.com. The basic idea is the same as a standard wire gate,...

Strong carabiner

cults3d

IF YOUR NEW TO PRINTING THIS IS NOT FOR YOU! ... Thought id make one that was a little different from the rest

Strong carabiner (FreeCAD)

thingiverse

There are many good carabiners on Thingiverse, this is a very sturdy version with a locking hatch, developed in FreeCAD.

Strong Flex door Carabiner

cults3d

Here's the info of the film and the test result Measuring of the maximum force the carabiner "Strong Flex door Carabiner" from thingiverse can handle. Measured maximum force: 236 N The carabiner is printed in ABS. Infill: 100% layer height: 0.15...

Strong Flex door Carabiner

thingiverse

Check the film on youtubehttps://www.youtube.com/watch?v=WayVij-MZDE Here's the info of the film and the test result Measuring of the maximum force the carabiner "Strong Flex door Carabiner" from thingiverse can handle. Measured maximum force: 236 N...

Mini S-Carabiner, Strong Clip

cults3d

The clearance on the clip is perfect and doesnt require any cutting or snapping, and the Carabiner is very strong, haven't broken one yet. Prints in about 6 minutes (on low resolution) on a Makerbot Rep2x. ...There is a step on the bottom side,...

Prints in about 6 minutes (on low resolution) on a Makerbot Rep2x. ...There is a step on the bottom side,...

Mini S-Carabiner, Strong Clip

thingiverse

The clearance on the clip is perfect and doesnt require any cutting or snapping, and the Carabiner is very strong, haven't broken one yet. Prints in about 6 minutes (on low resolution) on a Makerbot Rep2x. ...There is a step on the bottom side,...

*NEW* Strong Flex door Carabiner ddf3d Customized

cults3d

So glad to share the design to youNEW Strong Flex door Carabiner Check out new ORIGAMI Carabiner ! It's a long process to make the previous design as perfect as it should be, and now the core design feature was mature enough to face on the new. ..

..

*NEW* Strong Flex door Carabiner ddf3d Customized

thingiverse

So glad to share the design to youNEW Strong Flex door Carabiner Check out new ORIGAMI Carabiner ! (thing:1819242) It's a long process to make the previous design as perfect as it should be, and now the core design feature was mature enough to face...

Carabiner with strong clip

cults3d

This thing is based on thing 489709, by Charlie1982. I created the carabiner from scratch to suit my needs better, but only modified the clip slightly. The modified clip should be somewhat easier to print since I gave it more contact area with the. ..

..

Carabiner with strong clip

thingiverse

This thing is based on thing 489709, by Charlie1982. I created the carabiner from scratch to suit my needs better, but only modified the clip slightly. The modified clip should be somewhat easier to print since I gave it more contact area with the...

Carabiner with a strong clip Free 3D print model

cgtrader

This is a carabiner with a strong clip, which is also 3d printable. It's meant for printing in ABS, and perhaps PLA would work. ...The clip has to be flexible to do its function, therefore printing in ceramic is a no no

Strong Flex door Carabiner (debranded)

thingiverse

For those who believe in decommodification, I give you the debranded (and likely even stronger) awesome flex door carabiner.

strong

thingiverse

Customized version of http://www.thingiverse.com/thing:753477 Created with Customizer! ...http://www.thingiverse.com/apps/customizer/run?thing_id=753477

Strong

sketchfab

No description provided.

SUPPA STRONG

cults3d

SUPPA STRONG

strong manacle

cults3d

strong manacle

strong necklace

cults3d

strong necklace

strong manacle

cults3d

strong manacle

strong hook

thingiverse

strong hook

SUPPA STRONG

thingiverse

SUPPA__STRONG text

Spring strong

thingiverse

Strong spring to 3D print

Strong tea

sketchfab

Strong tea in the plastic jug

Strong hinge

prusaprinters

This is my attempt at a hinge will make better one in the future Print instructionsCategory: Parts Print Settings Printer Brand: Creality Printer: CR-10 Rafts: No Supports: No Resolution: 0. 15 Infill: 75 Notes: lower resolution is better ...

15 Infill: 75 Notes: lower resolution is better ...

Strong Hook

prusaprinters

... 2l Coke & 0,5l wódki wisi od godziny.... nic się nie dziej. :) Print Settings Printer: Ender 3Pro Rafts: NoSupports: No Resolution: 0.16Infill: 50% Filament: Devil Design ABS+ black Category: Outdoor & Garden

Strong Philly

thingiverse

They had a strong Marvin so why not his cousin. ...

pikachu strong

pinshape

new pikachu strong, we make a new pikachu, using a funko head pikachu style and strong man body.

BoXX Strong

grabcad

elegant design combined with the strong aluminum body that's all we need

Strong bracket

thingiverse

Strong bracket for multiple purposes. ... Hole diameter: 16mm Center height: 60mm 100x110x75mm

Services of 3D printing of parts to order in Moscow!

TOTALPRINT3D provides custom 3D printing services in Moscow and throughout Russia.

We make functional parts, spare parts, prototypes and figurines from plastic on a 3D printer from

1 pc. with a guarantee of quality and timing.

| Order 3D printing |

3D printing of plastic parts

with a guarantee!

TOTALPRINT3D provides custom 3D printing services in Moscow and throughout Russia.

We 3D print functional parts, spare parts, prototypes and plastic figurines from 1 piece.

| Order 3D printing |

Today, 3D printing is the fastest and most economical way to make almost any plastic part!

Consider manufacturing parts for your ideas and projects using the most popular technologies (FDM, SLS, SLA, DLP) from industrial plastics and composites.

Why should 3D printing be ordered from us?

Manufacture from 1 part

We manufacture both piece parts and small series orders.

Own fleet of equipment

We do not resell the services of other manufacturers. All orders are made only by the Totalprint3D team using their own equipment!

Proven materials

We use only proven engineering plastics and composites based on them from a domestic manufacturer!

We work with Phys. and Yur. persons

We work under an agreement with individuals and legal entities. If necessary, we conclude a confidentiality agreement (NDA).

If necessary, we conclude a confidentiality agreement (NDA).

Strict reporting

You can check the progress of work at any time! We will send a detailed photo and video report!

Convenient payment system

For individuals, we use card payments through the online cash desk.

For legal entities and individual entrepreneurs, payment is made by bank transfer.

Professional team

Our team consists of young engineers with more than 5 years of experience in 3D technologies in various industries!

Precise dimensions

We provide precision parts from 0.05 mm!

We do post-processing of parts

At the request of the customer, we produce finishing products: chemical polishing, grinding and painting products.

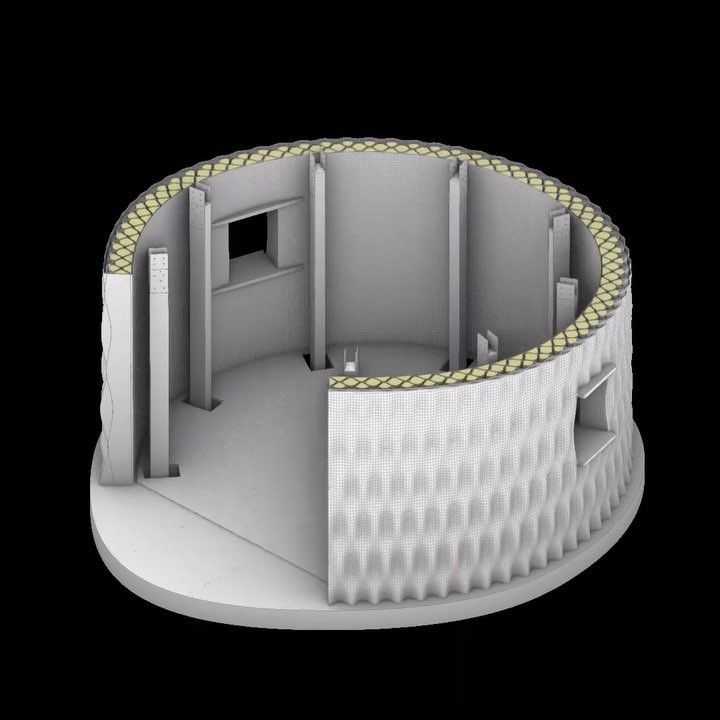

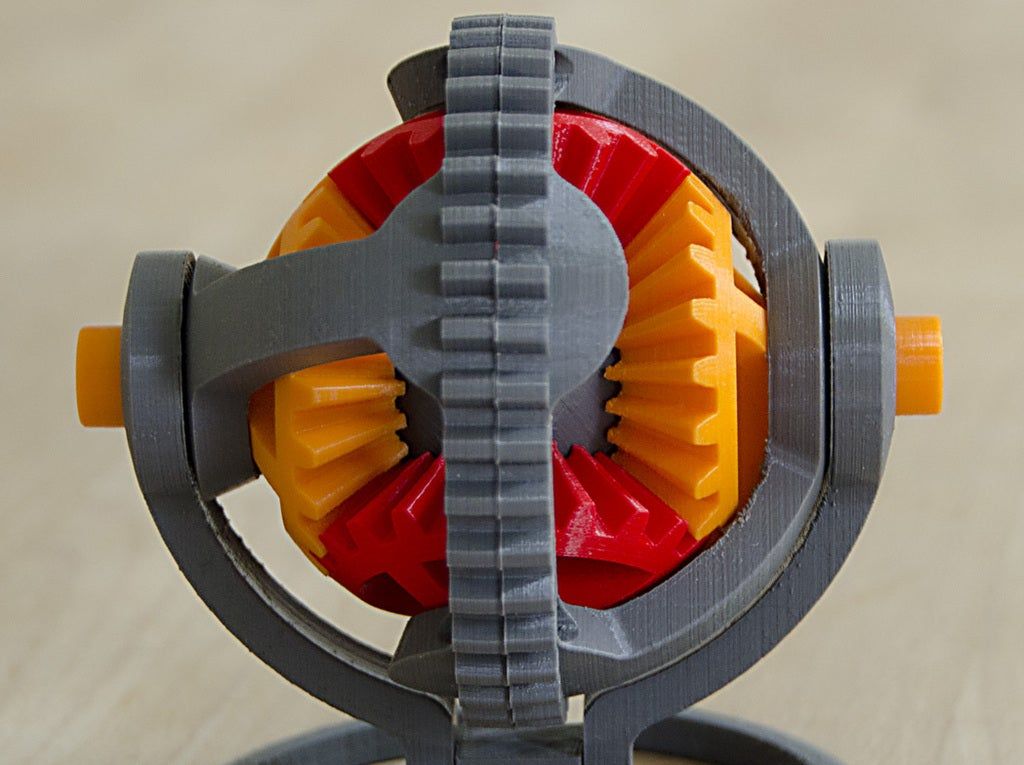

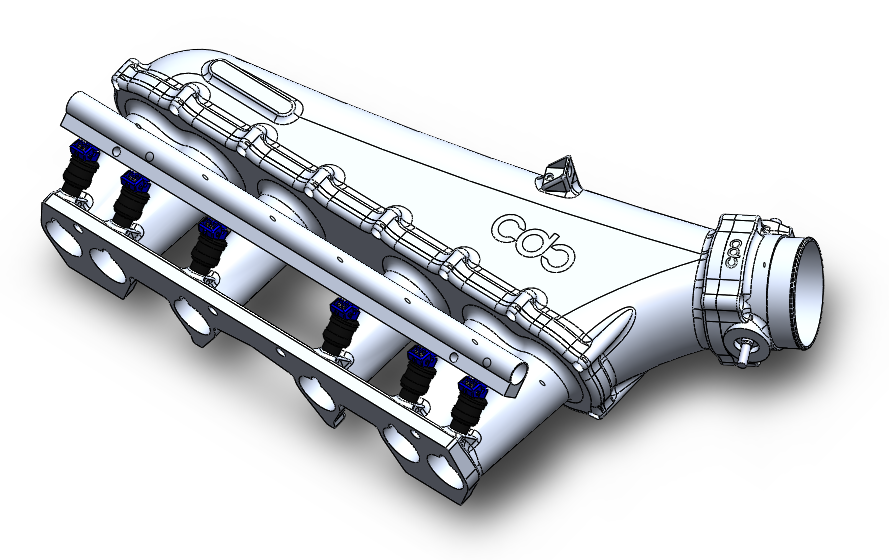

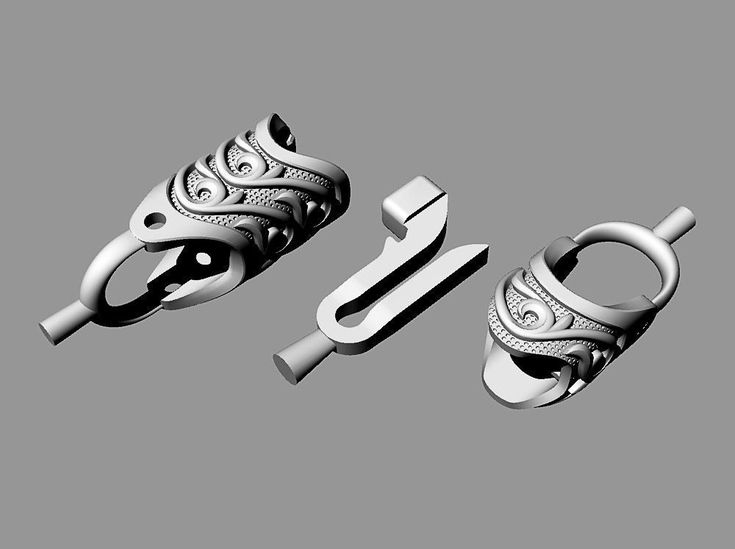

Examples of 3D printing in TOTALPRINT3D:

More projects you can see in our INSTAGRAM.

Materials for 3D printing:

We have selected the 20 most popular materials for 3D printing, which will suit most of your tasks.

Base Resins

Composite Resins

Photopolymers

Special Materials

Base Resins

Composite Resins Photopolymers Special Materials

ABS is the base material used for 3D printing. Its main advantage is high rigidity, interlayer adhesion and excellent machinability with an abrasive tool. Of the negative properties of this material, it should be noted toxicity (in no case should contact with food be allowed), rapid destruction under the influence of ultraviolet radiation and poor resistance to solvents.

Medium strength, suitable for body and functional parts operating in non-aggressive environments. It softens at about +70 degrees.

Perhaps the most common plastic for 3D printing!

Low shrinkage, high stiffness and solvent resistance. However, it has low heat resistance (it softens at +50 degrees), it is rather difficult to process with abrasive and cutting tools at high speeds and is destroyed under the influence of ultraviolet radiation.

This material is perfect for making product prototypes and unloaded functional parts.

ATTENTION! Advertising claims about environmental safety and suitability for contact with food have no evidence base! Plastic decomposes only in special bioreactors!

This material is also called "ABS killer". It has medium hardness, does not dissolve in anything, does not shrink during printing and is resistant to ultraviolet radiation, it is quite well processed by abrasives and cutting tools. It softens at about +70 degrees.

Suitable for everything! It is acceptable to use with food products (cutting for dough and mastic).

This material is almost similar in properties to ABS plastic, but it is suitable for contact with food products (you can make punches for cookies!) and in the case of special solvent treatment you can get a transparent product. Ideal for bottle mockups, neon letters and lights).

The material is similar in properties to ABS, but unlike ABS, it is UV resistant. Suitable for parts that are installed outdoors.

Suitable for parts that are installed outdoors.

Impact-resistant glass-filled (30%) polyurethane-based composite with heat resistance up to 110 degrees. "Soft" version of TPU GF-10.

Possesses high chemical resistance to solutions of acids and alkalis, fats, oils, xylene, diesel fuel. Limited to gasoline, kerosene, acetone, dichloromethane. Excellent for drilling and threading. Very difficult to sand and paint (special primer required).

WARNING! Available in off-white and black only.

Impact-resistant glass-filled (10%) composite based on polyurethane with heat resistance up to 110 degrees for printing large gears, strong housings, mechanically loaded parts, aerodynamic body kits for cars.

Possesses high chemical resistance to solutions of acids and alkalis, fats, oils, xylene, diesel fuel. Limited to gasoline, kerosene, acetone, dichloromethane. Excellent for drilling and threading. Very difficult to sand and paint (special primer required).

Very difficult to sand and paint (special primer required).

ATTENTION! Available in off-white and black only.

Composite based on ABS and PA6 with 8% fiberglass.

Suitable for end-to-end applications where high impact and UV resistance is required.

Inert to most commercially available chemical solvents, ideal for underhood printing and auto tuning.

WARNING! Available in off-white and black only.

Impact-resistant carbon-filled (5%) material for mechanically loaded parts (gears, tool elements, housings, etc.). Resistant to all types of solvents, gasolines, acids and alkalis, oils and fats.

Works well with abrasive and cutting tools, incl. at high speeds.

Structural composite based on chopped glass fiber reinforced ABS. Fiberglass content - 12%.

It has outstanding strength characteristics (compared to most 3D printing materials), increased hardness, elasticity, tensile and compressive strength, low print shrinkage.

Unlike plastic FORMAX - not electrically conductive!

VIKA softening point: 118°C.

Available in black only.

High impact flame retardant (UL94 V-0) polymer/polymer composite based on ASA (acrylonitrile styrene acrylate) modified with polycarbonate (PC). Designed for professional use. Ideal for the manufacture of connector blocks for wires, electrical instrument cases, electrical connectors, parts with increased fire safety requirements. Possesses the highest resistance to burning, self-extinguishing.

Engineering material based on ABS with added carbon fiber (30%), capable of withstanding heavy loads and high temperatures, with virtually no shrinkage during printing.

Compared to conventional ABS, it has the following advantages:

- Increased strength and rigidity

- Very good dimensional stability

- Lightweight

- Excellent finish (hidden layers)

CAUTION! Conductive material!

The material is similar in its characteristics to TOTALPRO CF-5 carbon fiber, but due to the foaming structure it has a reduced density (up to 0. 8 g/cm3 versus 1.15 g/cm3 for CF-5). This property makes it possible to successfully use this plastic in the manufacture of elements of unmanned aerial vehicles and radio-controlled aircraft / helicopters, as well as in the creation of objects with positive buoyancy.

8 g/cm3 versus 1.15 g/cm3 for CF-5). This property makes it possible to successfully use this plastic in the manufacture of elements of unmanned aerial vehicles and radio-controlled aircraft / helicopters, as well as in the creation of objects with positive buoyancy.

If you ask us "what is the strongest plastic for 3D printing?", then the answer is unequivocal - ULTRAN 630! This is the most durable material for 3D printing currently available in Russia (in terms of tensile strength, it is comparable to aluminum alloys). In addition to outstanding strength, it is resistant to all external influences (solvents, ultraviolet, etc.) and is the most heat-resistant plastic (it softens after 135 degrees).

Excellent for:

- surgical items to be sterilized in steam autoclaves;

- power parts;

- parts exposed to aggressive chemical attack;

If you are familiar with Lost Wax Casting (LVM), then this material is for you! This modified wax is designed to create printing waxes of simple and complex parts for further casting from metal (usually steel, aluminum, bronze, brass).

Flexible materials of various stiffness are intended primarily for 3D printing of rubber-like products.

Gray photopolymer base.

Highly detailed and medium durability.

Suitable for figurines, mockup parts and accurate prototypes.

Orange high precision photopolymer.

Has very high (~130 degrees) heat resistance and amazing detail. Hard and brittle. It is intended, first of all, for high-precision details of mock-ups, figurines, master models for pouring into silicone.

Photopolymer with improved impact and bending strength. Ideal for various technical parts subject to cyclic loads (latches, clamps, carabiners, etc.).

Structural photopolymer, properties similar to ABS plastic.

Excellent for micro gears and functional parts.

Photopolymer with heat resistance up to 190 degrees! It has high rigidity and is intended for functional parts operating for a long time at high temperatures (bushings, dielectric spacers, etc. )

)

Price of 3D printing services:

Attention! The minimum order amount is 4000r.

You can see the full price list for the services provided in the PRICES section

3D printing "PRO"

From 30 r/cc

3D printing with structural composite plastics based on ABS, polyurethane and polyamide, reinforced with glass and carbon fibers.

It is used in the manufacture of functional parts subject to various loads (mechanical, thermal, chemical).

| ORDER |

3D printing "LIGHT"

From 8 r/cc.

3D printing with base plastics PLA, ABS, SBS, PETG

It is used for models, figurines, decorative details, templates, equipment and other products that are not subject to mechanical and thermal loads.

| ORDER |

Where are we?

Detailed contact information and directions to the pickup point can be found in the CONTACTS section

Where are we located?

Detailed contact information and directions for

to the point of issue of orders can be found in the section CONTACTS

E-mail: zakaz@totalprint3d. ru

ru

Phone: +7(495)109-19-72

Office and production:

Moscow, Vnukovo, st. 1st regular d.6

Receiving samples and issuing orders:

Moscow, Leningradsky pr-t d.45Gk37

ONLY ON WEEKDAYS! from 8:00 to 17:00.

Working hours:

Weekdays: 10:00-19:00 (break 13:00-14:00)

Weekends: 10:00-16:00 (break 13:00-14:00)

Download company details

Can airguns and firearms be printed

Is it possible to make a gun on a 3D printer and is it legal?

Today's 3D printers offer enormous possibilities. They can print products of almost any complexity. Until quite recently, it was difficult to even imagine that a plastic weapon could shoot. However, it is already possible to make a pistol on a 3D printer, which, although not reliable, still fires live ammunition.

Can firearms be 3D printed?

Back in 2013, a young American gun fighter proved that plastic guns could be 3D printed. He was the first in the world to make a pistol in this way, in which only the striker was made separately from metal. All other parts were printed on an FDM printer.

He was the first in the world to make a pistol in this way, in which only the striker was made separately from metal. All other parts were printed on an FDM printer.

Today's 3D printers are capable of printing any CAD model, and these models of firearms have been available for over 10 years. If in previous years their printing required professional skills, now almost any user can master them. With a 3D printer and a finished model, it became quite possible to print a gun. Another thing is that such "creativity" is punishable by the laws of most countries.

The evolution of 3D printed weapons

Despite all the prohibitions and restrictions, the evolution of 3D printed firearms is moving at a great speed. The beginning was laid by the single-shot plastic pistol Liberator by American K. Wilson, which appeared in 2013. It had a simple design and was chambered for 380 ACP. Already after 10-12 shots, this weapon became unusable. However, the very possibility of printing firearms served as an impetus for the development of the idea. The author of the first pistol himself founded the Defense Distributed company, which began to actively improve the technology.

The author of the first pistol himself founded the Defense Distributed company, which began to actively improve the technology.

One of the ways to increase the durability of weapons was to increase the number of their barrels. At the beginning of 2014, the Japanese Y. Imura makes a 38 caliber Zig Zag pistol. He was able to fire up to 6 shots non-stop. The author of the weapon was recognized as a criminal and convicted.

The next step was the production of a six-shot revolver by J. Patrick in 2015. The PM522 Washbear has been shown in action on YouTube. The weapon was noticeably safer for the shooter compared to previous versions, but still allowed to fire only a few dozen rounds.

The first semi-automatic pistol for a 9 mm bullet appeared in 2016 under the name Shuty-MP1. It was developed by a handicraft gunsmith who hid under the pseudonym Derwood. It wasn't exactly a plastic weapon. The author used some metal parts from factory pistols - a barrel, a firing pin, a bolt and several springs. This made it possible to ensure a rate of fire of more than 46 rounds / min. However, when changing the store, the plastic case had to be cooled. In 2017, the same master proposed an improved model - Shuty AP-9.

This made it possible to ensure a rate of fire of more than 46 rounds / min. However, when changing the store, the plastic case had to be cooled. In 2017, the same master proposed an improved model - Shuty AP-9.

The main contribution to the development of 3D printed weapons technology was made by Defense Distributed, which brought together a group of like-minded activists. First, these enthusiasts won legal proceedings in the United States and obtained permission to 3D-print weapons, which greatly expanded their capabilities. Secondly, they were able to set up a professional business with product testing and quality control. As a result, in 2018–19 they developed numerous models of a variety of firearms - from pistols to carbines. They posted over 30 files for printing original gun parts. Most of them were plastic, and the metal parts were not made from purchased, ready-made elements, but from simple metal profiles (tubes, strips, etc.), which are sold in ordinary hardware stores. This made it possible to exclude the use of parts patented by gunsmiths.

This made it possible to exclude the use of parts patented by gunsmiths.

At the moment, the semi-automatic carbine FGC-9, developed on the basis of the Shuty AP-9, has become the pinnacle of "creativity" of Defense Distributed. At the same time, there is not a single factory part in it. The barrel for the 9 mm cartridge is made of steel pipe using electrochemical processing.

Where can I get drawings and what should I look for?

Gun manufacturing bans make it much more difficult to get blueprints and models of guns for 3D printing. The right to free placement of information was achieved only by Defense Distributed. Their website provides free access to drawings, models and technologies. Other information can be found on the Internet, but they are usually illegal.

When choosing a model, pay attention to the following information:

- material used;

- cartridge for which the model is designed;

- number of cartridges in the magazine, rate of fire;

- duration of operation before failure.

It is important to clarify which metal parts will need to be purchased separately, in addition to plastic for printing on a printer.

What does the law say in different countries?

The only country where firearms can be 3D printed is the United States. Gun Control Act 19 applies here68, giving Americans the right to make weapons, but only for personal use. Only one limitation is put forward: it must be determined by metal detectors, that is, it must have a metal element. In virtually all other countries, homemade manufacture and repair of weapons for any purpose is prohibited by law. In Russia, printing it on a 3D printer falls under the Criminal Code of the Russian Federation and is punishable by imprisonment.

Should we be afraid of plastic weapons?

The question of how dangerous a weapon printed on a printer is becoming increasingly important. Despite all the prohibitions, it is extremely difficult to control the spread of technology around the world. The availability of 3D printers and the increase in their functionality make it possible to master the production of plastic guns at home. How dangerous is such a weapon?

The availability of 3D printers and the increase in their functionality make it possible to master the production of plastic guns at home. How dangerous is such a weapon?

Most experts agree that currently printed weapons are more of an interesting toy. It is quite expensive and is designed to carry out only a few dozen shots. Moreover, such pistols are quite dangerous for the shooter himself with live ammunition, because they can explode in their hands.

However, the danger cannot be underestimated. It is easier and cheaper for a “serious” criminal to buy illegal military weapons than to make them on a printer. At the same time, there may be "enthusiasts" who, for their own interest, can make a pistol and try it out in action. Such inadequate people represent an undoubted danger. In addition, the temptation is great for terrorists. Metal detectors do not detect a plastic gun, which means that it is easier to carry it, for example, on an airplane.

Important! Plastic weapons have a very small resource.

At the same time, sometimes just one shot is enough to kill a person.

3D printed firearms have the following advantages:

- the ability to make military weapons at home;

- light weight;

- availability of materials;

- Ability to copy famous weapon models.

Always remember that there are significant disadvantages:

- illegal manufacture;

- high cost of weapons;

- very small resource and limited rate of fire;

- danger to the shooter himself.

Currently, plastic weapons have more disadvantages than advantages, and most importantly, you can get a real prison term for making them.

Prospects for printing weapons

The development potential of 3D printing of firearms is far from exhausted. The expansion of equipment capabilities and the development of innovative materials indicate that in the near future such weapons may approach military weapons in terms of characteristics.