Canon ceramic 3d printing

Canon announces development of proprietary ceramic material for 3D printers, manufacturing technology for the highly accurate 3D printing of parts with complex geometries

November 27, 2018

Canon Inc.

Canon announces development of proprietary ceramic material for 3D printers, manufacturing technology for the highly accurate 3D printing of parts with complex geometries

TOKYO, November 27, 2018—Canon Inc. announced today that the company has developed a manufacturing technology for the highly accurate 3D printing of ceramic parts with complex geometries using a proprietary ceramic material for 3D printers. The 3D printed ceramic parts feature such properties of conventional ceramics as heat and corrosion resistance as well as insulating properties, and are expected to be utilized in a variety of different fields, including industrial equipment.

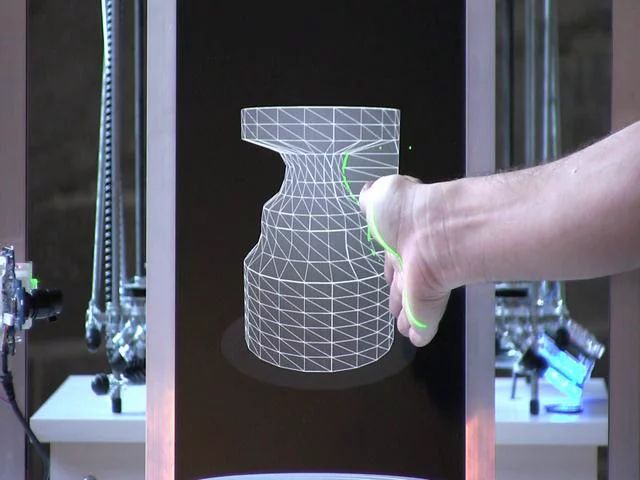

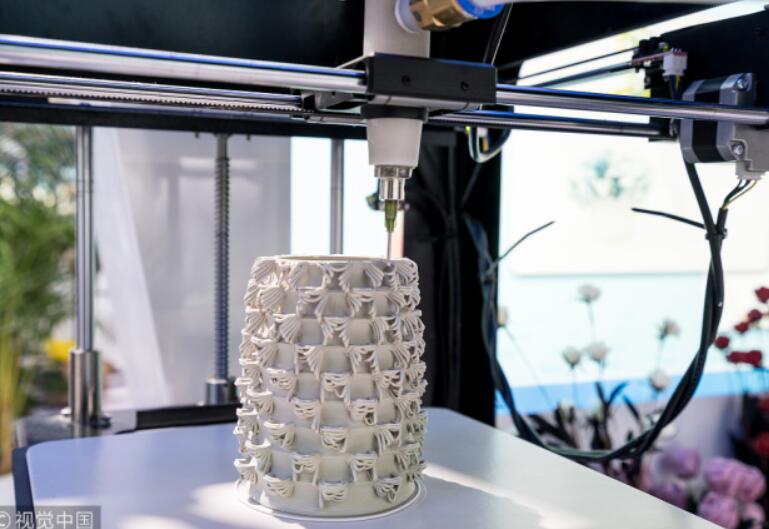

Ceramic parts created using the new technology

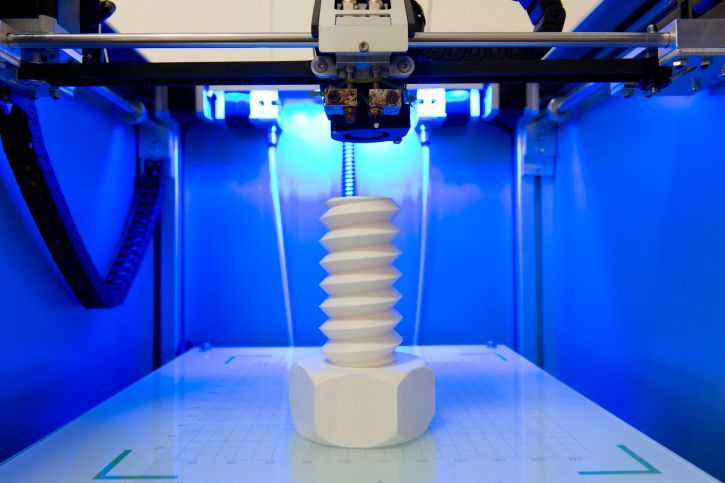

3D printers that utilize such materials as metal and resin, which enable easy prototyping and the production of a variety of parts in small lots, have started to become more common. However, many existing ceramic materials for 3D printers contain resin and the parts produced using these materials can shrink approximately 20 percent1 during the post-annealing process, making it difficult to produce ceramic parts with high accuracy.

Canon has developed a new alumina-based ceramic material suited to selective laser melting2 as well as a new parts production technology. Through this technology, a 3D printer can be used to stably produce ceramic parts with such complex geometries as hollow and porous structures, which are difficult to achieve through ordinary metal molding or cutting processes. For example, when creating honeycomb shapes3 with hexagonal hollows and a diameter of approximately 19 mm, parts can be produced with high accuracy with differences in external dimensions before and after the annealing stage of less than 0.8 percent.

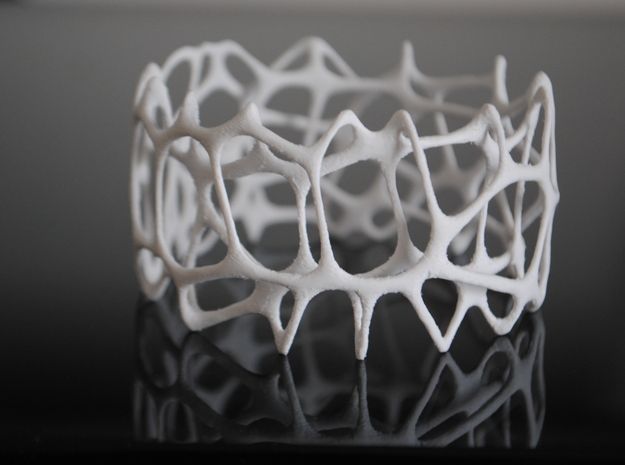

Honeycomb-shaped part

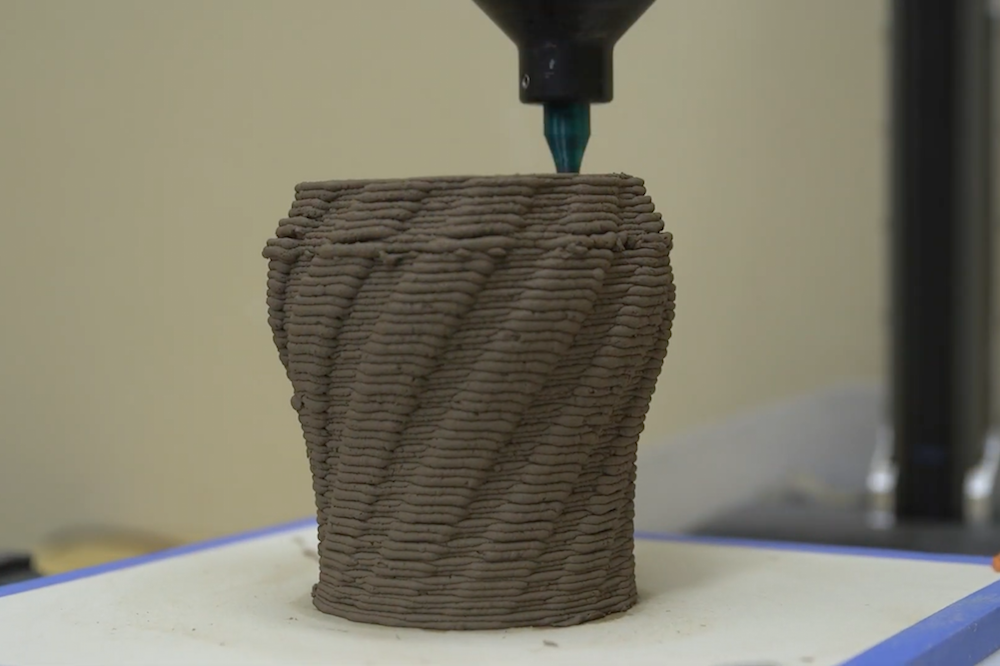

Compatible with parts of varying geometrical elements

Ceramic parts manufactured using this technology are expected to be used in all kinds of industrial fields, from parts for equipment that demands heat resistance and insulating properties, such as electric furnaces, to parts facing exposure to chemicals that require corrosion resistance. Canon Group companies, including Canon Inc. and Canon Machinery, are investigating applications for this technology in the prototyping of parts for industrial equipment.

Canon Group companies, including Canon Inc. and Canon Machinery, are investigating applications for this technology in the prototyping of parts for industrial equipment.

Going forward, Canon plans to expand the use of this technology to such areas as the medical field through the development of more compatible materials to meet an even wider range of prototyping and wide-variety, small-lot needs.

- 1For example, when producing parts using stereolithography with ceramic materials that contain ultraviolet-curable resin.

- 2A 3D printing method typically used for metal fabrication where the material is melted using a laser.

- 3In the case of parts with a linewidth of approximately 0.4 mm, a diameter of approximately 19 mm and thickness of approximately 2 mm, as shown in the "Honeycomb-shaped part" image above.

Canon introduces new ceramic 3D printing technology

Published on December 19, 2018 by Michelle J.

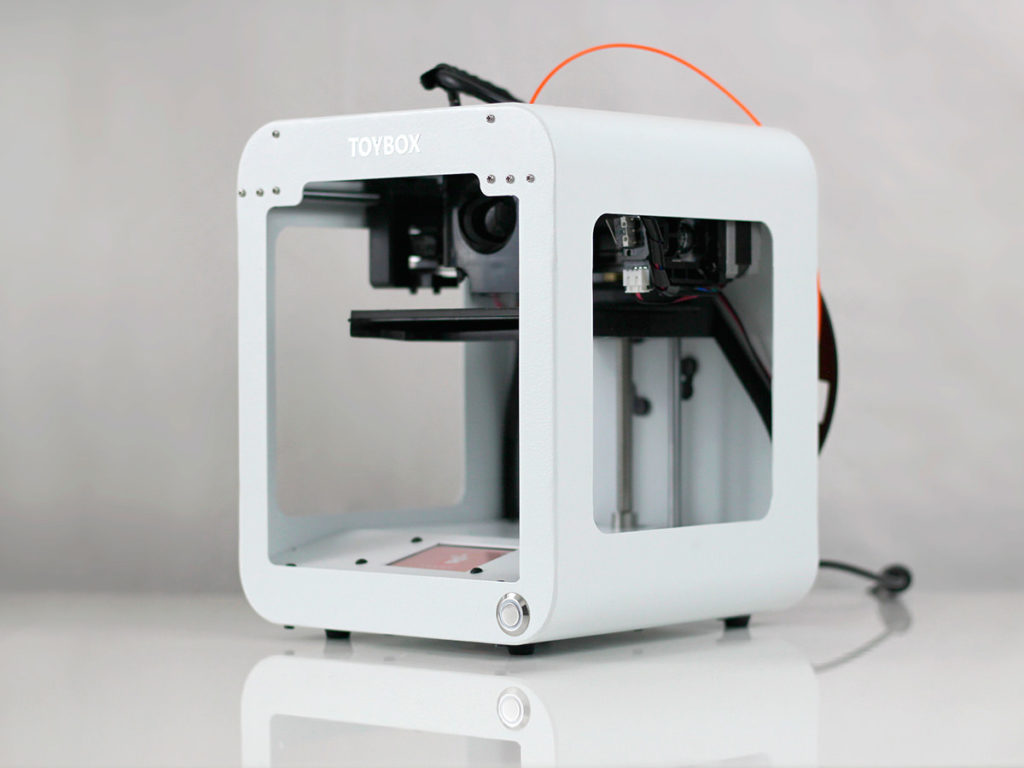

The Japanese group Canon, a specialist in cameras, copiers and printers, entered the additive manufacturing market last year. When they manufactured its FDM MARV 3D printer. This small office machine didn’t met a huge success. As it was confined to the Chinese, Korean, German and Polish markets. The 2D specialist, however, has announced that they are developing a new 3D ceramic printing technology and its proprietary material. The manufacturer states that the new Canon ceramic 3D printing technology could allow the creation of complex geometries such as honeycomb structures.

When they manufactured its FDM MARV 3D printer. This small office machine didn’t met a huge success. As it was confined to the Chinese, Korean, German and Polish markets. The 2D specialist, however, has announced that they are developing a new 3D ceramic printing technology and its proprietary material. The manufacturer states that the new Canon ceramic 3D printing technology could allow the creation of complex geometries such as honeycomb structures.

Ceramic additive manufacturing is a growing niche market, although it has yet to gain as much hight as plastics or metal processes. Ceramic-based materials require an annealing process that can cause shrinkage of the workpiece and a lack of precision. Technology seems to be slowed down by these few challenges, even though some players have managed to succeed like the New York based Kwambio or the Israeli XJet. Note, however, that 3D ceramic printed parts have interesting properties. Such properties consist of good resistance to heat and corrosion, as well as insulating properties. Attributes that makes it good for sectors such as the dental industry.

Attributes that makes it good for sectors such as the dental industry.

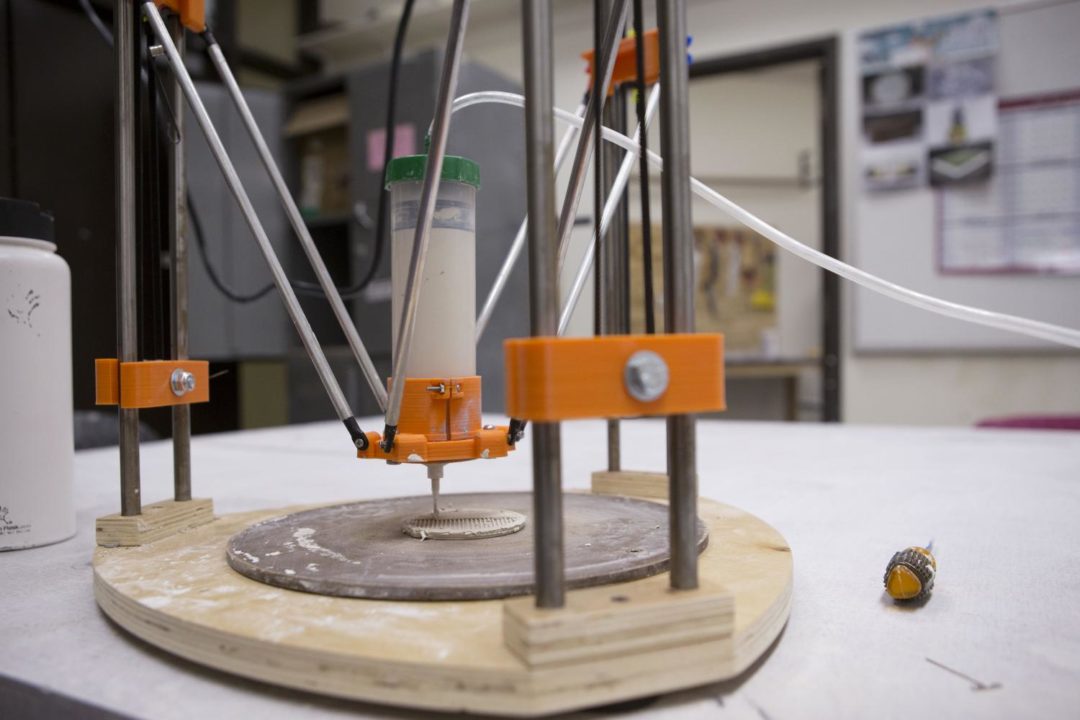

FDM MARV 3D Printer

The Canon ceramic 3D printing Technology

Canon claims to have developed a ceramic material based on alumina, adapted to its new technology but also to selective laser melting. The manufacturer, however, remains quite discreet about the technology itself. The material would stably produce complex parts such as hollow and porous structures. That would otherwise be more difficult to obtain by a process of molding or cutting metal. For example, when creating honeycomb shapes with hexagonal recesses and a diameter of about 19 mm. High accuracy can be obtained with differences in external dimensions of less than 0.8% before and after the annealing phase.

Regarding the applications of this ceramic additive manufacturing technology, Canon says: “Ceramic parts manufactured using this technology are expected to be used in all kinds of industrial fields, from parts for equipment that demands heat resistance and insulating properties, such as electric furnaces, to parts facing exposure to chemicals that require corrosion resistance. ” Eventually, the Japanese manufacturer hopes to expand its 3D printing process of ceramics in the health sector. This by developing a material compatible with medical and surgical uses. Find more information on the Canon ceramic 3D printing process HERE.

” Eventually, the Japanese manufacturer hopes to expand its 3D printing process of ceramics in the health sector. This by developing a material compatible with medical and surgical uses. Find more information on the Canon ceramic 3D printing process HERE.

- 3D printed ceramic parts

What do you think of this new Canon ceramic 3D printing technology? Let us know what you think in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

📷 Best Camera 3D Print Files・Cults

📷 Best Camera 3D Print Files

Free Download Camera Accessories 3D Files

printer accessories for your camera. You can find handles, cases, protective cases, straps, tripods for your Canon, Nikon, Leica, Sony, Panasonic cameras, etc. 3D printing will help you get the most out of your camera.

Lens Cap Holder

Free

Lens Hood

Free

Camera Gimbal

Free

Made with Love Bokeh Kit

Free

LiftPod - Multipurpose Foldable Stand

Free

Bokeh Kit

Free

SD Card Holder

Free

Professional DSLR slider V4.

0

0 Free

Flip Lens Cap

Free

Electric_Driver_Upgrade_For_Slider_V4.0

Free

LiftPod - Easy Lock Edition

Free

Adapter thread M42 to Sony E (NEX)

Free

Shoulder rig

Free

Smartphone teleprompter - tripod adapter

Free

Foldable Mini Tripod

Free

3D printed pinhole camera

Free

SD and micro SD holder 1-10 elements

Free

60 NeoPixel Ring Camera Mount

Free

DSLR Camera FollowSlider V2.

0

0 Free

Camera hot shoe - Universal phone holder

Free

3D Printed Pinhole 35 mm

Free

Canon EF Eyecup

Free

Camera Lens Cap Holder - 62mm

Free

Canon lens hood

Free

Simple Camera Slider

Free

Tripod Ball Head

Free

Sony A6000/A7 Hot Shoe Cover

Free

Sony E-mount Rear Lens Cap

Free

Proteus LED Light Panel - DIY and Expandable

Free

Cage modular DSLR

Free

Rollei QAL-40 Camera Mounting Plate (C4i, C5i, C40i, C50i, Compact Traveler No 1, Compact Traveler No 10, CT-4A, CT-5A, CT-5C, M5 Mini, PGA-584, PGA-484, TT-1, T2S)

Free

Tripod Leveler

Free

Smooth Q Gimbal - Camera Attachment (Sony RX100 & Others)

Free

Shoulder rig for DSLR (NOT just for Canon 5D)

Free

Adapter m43 (m4/3) to canon FD lens

1,50 €

Mini Tripods

Free

Hand held Camera Rig

Free

SONY 9 55mm lens cap0009

Free

Camera speedlight umbrella flash holder

Free

1-Wege-Stativneiger, 1 Way Tilt Head

Free

Sony A-Mount Overhead Lens Mount

Free

Motorized Camera Slider MK3

Free

Sony E-Mount body to Nikon F-Mount Lens adapter

Free

Protective cage for cage modular DSLR

Free

Digital Camera Pinhole Adapter

Free

Handle for Cage modular DSLR

Free

Lens Cap

Free

Trekking Pole Monopod with Quick-Release

Free

Here is our selection of best STL files for camera , all these accessories are taken from Cults STL file library and available for 3D printing .

This collection includes free 3D files of camera accessories. Many 3D models of were created by members of our 9 community0202 3D designers as well as photographers. Therefore, they are fully aware of the operating limitations of each camera. They have designed a very wide range of 3D printed camera accessories for cameras for owners of Canon, Nikon, Leica, Sony or Panasonic cameras. All brands of cameras are represented here.

Many camera parts are made of plastic, as are accessories such as tripods, sun visors or shutters. In this context, it is quite logical to think about 3D printing. Therefore 3D designers compete in ingenuity, creating truly ingenious models, such as gambling or time-lapse automatic accessories.

Pandemic 3D printing market

- home

- News AT

- Russia and CIS

- 3D printing market amid pandemic

3D printing has become one of those areas of the economy that, instead of stagnation amid the pandemic, on the contrary, shows a very noticeable positive trend. There are quite a few reasons for this.

There are quite a few reasons for this.

First, the relative freshness of the technology: in fact, 3D printing is only gaining momentum, becoming truly mass. Secondly, its demand during the pandemic due to the ability to significantly increase the output of medical devices and protective equipment with its help. Thirdly, the growing popularity of 3D printing among non-professional users, technical enthusiasts, some of whom, amid the transition to remote work, have a little more free time for hobbies.

In this review, we tried to find out how great the potential of 3D printing technologies is, what interesting things have happened in this market over the past year and a half, and what trends will determine its development in the near future.

The consequences of the pandemic

Perhaps the most important topic, without which no serious material can do today, is an attempt to answer the question of how exactly the coronavirus crisis has affected the market. In our case, the market for 3D technologies.

In our case, the market for 3D technologies.

Founder and CEO of Tsvetnoy Mir, Alexander KORNVEITZ emphasizes that when supply chains were disrupted, 3D printing technology came to the rescue of hospitals experiencing difficulties with masks, valves for ventilators, nasal swabs for taking PCR tests and many more. by other means. It turned out that all this can be printed on any 3D printers in the shortest possible time - from the simplest home models to industrial complexes. This saved the lives of many people and brought a lot of attention to 3D printing. “In this regard, the market of desktop 3D printers in 2020, both in Russia and in the world, showed impressive dynamics. In particular, in our company, unit sales increased by 35%,” concludes Mr. Kornweitz.

Vice President and General Manager Eastern Europe HP Inc. Alexey VORONKOV points out that the COVID-19 crisis has shown how vulnerable existing supply chains are. It is enough for one plant to suspend production for several weeks, as entire industries begin to experience a shortage of components for the manufacture of their products. Mr. Voronkov is confident that additive manufacturing is changing the approach in this area: now you can produce some kind of spare part or even completely finished products directly at your enterprise, reducing, if not completely eliminating dependence on suppliers. In addition to reducing production times and the cost of finished products, new 3D printing technologies can improve the environmental situation, as the carbon footprint of trade between countries and continents is reduced by simplifying logistics in trade relations between countries and continents.

Mr. Voronkov is confident that additive manufacturing is changing the approach in this area: now you can produce some kind of spare part or even completely finished products directly at your enterprise, reducing, if not completely eliminating dependence on suppliers. In addition to reducing production times and the cost of finished products, new 3D printing technologies can improve the environmental situation, as the carbon footprint of trade between countries and continents is reduced by simplifying logistics in trade relations between countries and continents.

The founder of Top 3D Group, Vasily KISELEV , explains that last year's growth was not as strong as it could have been, as a huge number of customers, for example from the public sector, still postponed transactions due to budget problems. However, due to the pipeline of the previous year, large projects planned earlier were implemented - this compensated for the drawdown of the public sector and private traders.

General Director of 3D Vision Ilya VINOGRADOV says that from March to June 2020, there was a drop in demand for certain technologies by up to 50% of the volume over the same period of 2019of the year. But in the summer, the market began to gradually recover, and already in the fall, demand exceeded the figures for the same period in 2019. This year, 3D printing services also remain in demand, especially from large companies. Already in January, projects were unfrozen, new developments began. By the way, 3D Vision decided not to cut staff during the crisis, which gave certain competitive advantages in the revitalizing market. As a result, according to Mr. Vinogradov, the volumes of the first quarter of 2021 more than cover the problems of the last year.

The 3D equipment market is experiencing the biggest drop, especially in the industrial and professional equipment sector. The private sector almost completely postponed all projects until more stable times, as these installations were considered more in the scope of new directions. “If we talk about companies with full or partial government funding, they transferred only those projects that were not finally agreed upon, where negotiations were held, technology selection or stages of demonstration launches and provision of an experimental batch of parts for testing,” says Mr. Vinogradov.

“If we talk about companies with full or partial government funding, they transferred only those projects that were not finally agreed upon, where negotiations were held, technology selection or stages of demonstration launches and provision of an experimental batch of parts for testing,” says Mr. Vinogradov.

Andrey TYRSA , commercial director of PICASO 3D, notes that, according to analytical reports, a new type of client has appeared - companies whose usual work process has been disrupted due to the restrictions imposed and the temporary collapse of the usual technological chains. Not realizing how soon it would be possible to return to the usual format, many decided to try additive technologies, because their use is largely possible without the personal presence of a person, which, in turn, reduces contacts between employees while maintaining business processes.

“As for PICASO 3D, we closed 2020 quite well, showing a slight increase compared to previous periods. The forecasts for 2021 are also good, and we hope that they will come true. The growth of the entire industry continues, and this cannot but rejoice,” Mr. Tyrsa sums up.

The forecasts for 2021 are also good, and we hope that they will come true. The growth of the entire industry continues, and this cannot but rejoice,” Mr. Tyrsa sums up.

Executive Director of SIU System Maria BORISOVA I am sure that the pandemic has affected all industries, since no one was ready to stop production. The advantage of the SIU System was the service department, which significantly increased its competence over the year and learned how to independently carry out commissioning work for machines that the team had only observed before. According to Ms. Borisova, trading and manufacturing companies were in a better position, as they got the opportunity to take advantage of additive equipment in practice and demonstrate to the whole world a quick re-profiling to the needs of the country. “At the beginning of March 2020, we transferred our production to the Technopolis Moscow SEZ, and on March 18, the entire office went remote. We refocused production and began to produce ventilator valves, mask adapters, protective screens, products for contactless pressing of buttons and opening doors. They even developed reusable masks with silicone pads for ease of wearing. And most importantly, the company managed to fully retain the team and production has been working non-stop all this time. Thus, 2020 ended with excellent results,” concluded Ms. Borisova.

They even developed reusable masks with silicone pads for ease of wearing. And most importantly, the company managed to fully retain the team and production has been working non-stop all this time. Thus, 2020 ended with excellent results,” concluded Ms. Borisova.

Trends and events

The development of any high-tech market (namely, the 3D printing segment is one of them) is directly related to new technologies, devices and materials. Business events play an important role here, sometimes greatly changing the balance of power in the market: mergers and acquisitions, transition to other technological processes.

We asked our speakers to mark the most important, from their point of view, moments in the 3D technology market for 2020-2021.

A breakthrough in photopolymer 3D printing Alexander KORNVEITZ (“Colored World”) compares with 2013, when MakerBot launched the first affordable 3D printer for home and office use, the MakerBot Replicator 2, on the market. user (before that they cost hundreds of thousands of dollars and were available only to large companies). “21st-century technologists have challenged the old-school engineers, and this has completely changed the rules of the game,” says Mr. Kornweitz. Today, approximately the same can be said about photopolymer 3D printing using LCD technology, that is, creating models by illuminating resin with an LED lamp through an LCD matrix. The new 4K monochrome displays have already improved the speed, quality and accuracy of printing, increased the maximum size of manufactured models, and reduced the price of printers by several times. Not least of all, this is due to the significantly increased lifetime of the new mono displays, he explains.

user (before that they cost hundreds of thousands of dollars and were available only to large companies). “21st-century technologists have challenged the old-school engineers, and this has completely changed the rules of the game,” says Mr. Kornweitz. Today, approximately the same can be said about photopolymer 3D printing using LCD technology, that is, creating models by illuminating resin with an LED lamp through an LCD matrix. The new 4K monochrome displays have already improved the speed, quality and accuracy of printing, increased the maximum size of manufactured models, and reduced the price of printers by several times. Not least of all, this is due to the significantly increased lifetime of the new mono displays, he explains.

Vasily KISELEV (Top 3D Group) considers medicine one of the most vulnerable sectors last year and at the beginning of this year, where there was a shortage of equipment to combat the consequences of the virus. This is where additive manufacturing technologies come in handy. Even at the very beginning of the pandemic, enthusiasts using 3D equipment managed to produce a large number of parts for personal protective equipment and ventilators, and later, consumables for testing for COVID-19.

Even at the very beginning of the pandemic, enthusiasts using 3D equipment managed to produce a large number of parts for personal protective equipment and ventilators, and later, consumables for testing for COVID-19.

As the main trend of recent years, Mr. Kiselev calls the move away from positioning 3D printing as a means mainly for creating prototypes - now it is more and more important to use this technology to produce full-fledged final products. Moreover, there are active investments in the field of post-processing and scalability. Among other trends, he points to selective laser sintering (SLS) technology, which, according to forecasts, will occupy an increasing part of the 3D printing market until 2025 due to a high average annual growth rate.

Among the significant events of , Ilya VINOGRADOV (3D Vision) highlights the purchase in December 2020 by giant Stratasys of a relatively small start-up Origin, which specializes in the development of photopolymer printers. In addition, in February 2021, the same Stratasys announced the purchase of RPS, a manufacturer of industrial SLA printers, and Desktop Metal acquired the well-known manufacturer EnvisionTEC. Bosch plans to buy Ultimaker and there are rumors that Canon is looking to enter the 3D technology market. Mr. Vinogradov notes that the 3D market in Russia is developing as rapidly as in the rest of the world: new interesting manufacturers have appeared, more cost-effective solutions based on SLS and SLM technologies are being presented, which is relevant for the education sector and private enterprises.

In addition, in February 2021, the same Stratasys announced the purchase of RPS, a manufacturer of industrial SLA printers, and Desktop Metal acquired the well-known manufacturer EnvisionTEC. Bosch plans to buy Ultimaker and there are rumors that Canon is looking to enter the 3D technology market. Mr. Vinogradov notes that the 3D market in Russia is developing as rapidly as in the rest of the world: new interesting manufacturers have appeared, more cost-effective solutions based on SLS and SLM technologies are being presented, which is relevant for the education sector and private enterprises.

General Director of IMPRINTA Artem SOLOMNIKOV calls the release of a new model of a 3D printer of his own production one of the main events of the Russian market. And it can be understood - this interesting decision caused an ambiguous reaction from the audience. In particular, in the original version, the printer does not have an output for connecting Flash cards, which was the subject of controversy and criticism.

According to Andrey TYRSA (PICASO 3D), , in 2020 his company managed to obtain two patents for inventions - in the USA and China, and this is an important step in preparing for export deliveries. In addition, new positions have been added to the line of professional X-Line 3D printing materials. Now the X-Line collaboration includes eight materials from three manufacturers: PICASO 3D, REC 3D and Filamentarno. Together, these companies are developing and promoting Russian engineering materials on the international market, Mr. Tyrsa explains.

Alexey VORONKOV (HP Inc.) said that last year HP introduced a new unique material for 3D printing of finished parts - versatile and durable reusable polypropylene, which is suitable for solving a wide range of tasks in consumer, automotive, manufacturing and medical fields, and also helps to optimize costs and increase productivity. He notes that industrial 3D printing has played a major role in the midst of the COVID-19 pandemic.