Can you sell 3d printed items

An In-Depth Look Into 3D Printing Laws – Selling Prints and More – 3D Printerly

3D printing laws can definitely get confusing when looking at selling prints or printing objects that have certain protections in law. When I thought about these laws myself, it was a task trying to find relevant 3D printing laws that were clear and about specific topics.

Because of this, I decided to write an article giving people an in-depth look into the laws and regulations that surround 3D printing, from copyright and trademarks, down to actually selling 3D prints to willing customers.

We’re going to take a close, hard look at the laws and regulations associated with 3D printing, and how they can potentially affect our approach towards printing and maneuvering the 3D printing space safely.

To begin with, it’s totally safe and legal to sell your 3D printed parts on e-commerce websites like eBay, Amazon, and Etsy. People are making a fair living offering their printing capabilities on different platforms.

Shapeways, for one, is a 3D printing marketplace where you could either upload your model for their professional service or design and sell one of your own.

The Financial Side of 3D Printing & Laws

Everyone’s trying to make a few extra bucks here and there. If you have a 3D printer at your disposal, why not cash in your work, and capitalize? The information about to follow will teach you how to sell your prints and services abiding all laws, and make a bit of a living.

Get Selling

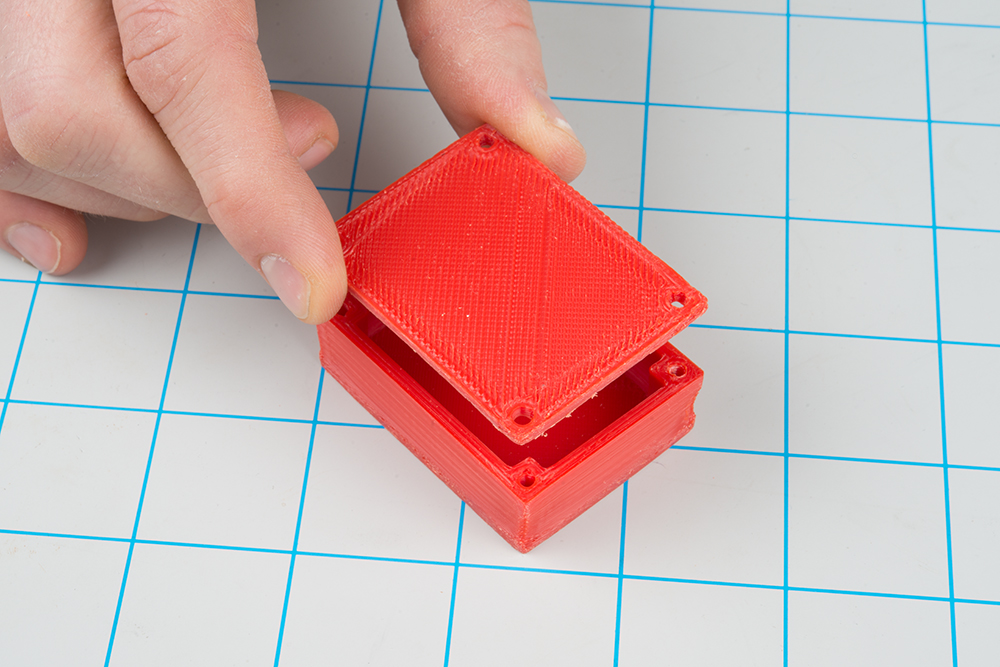

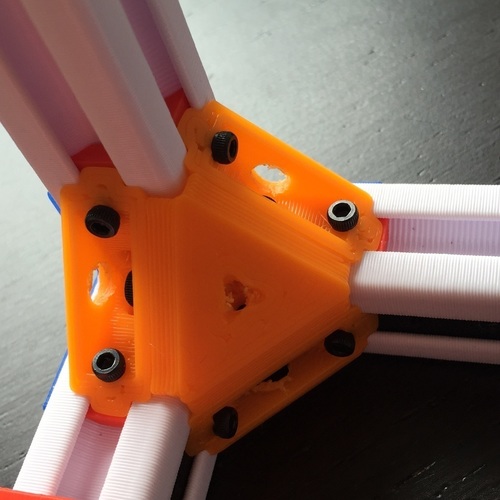

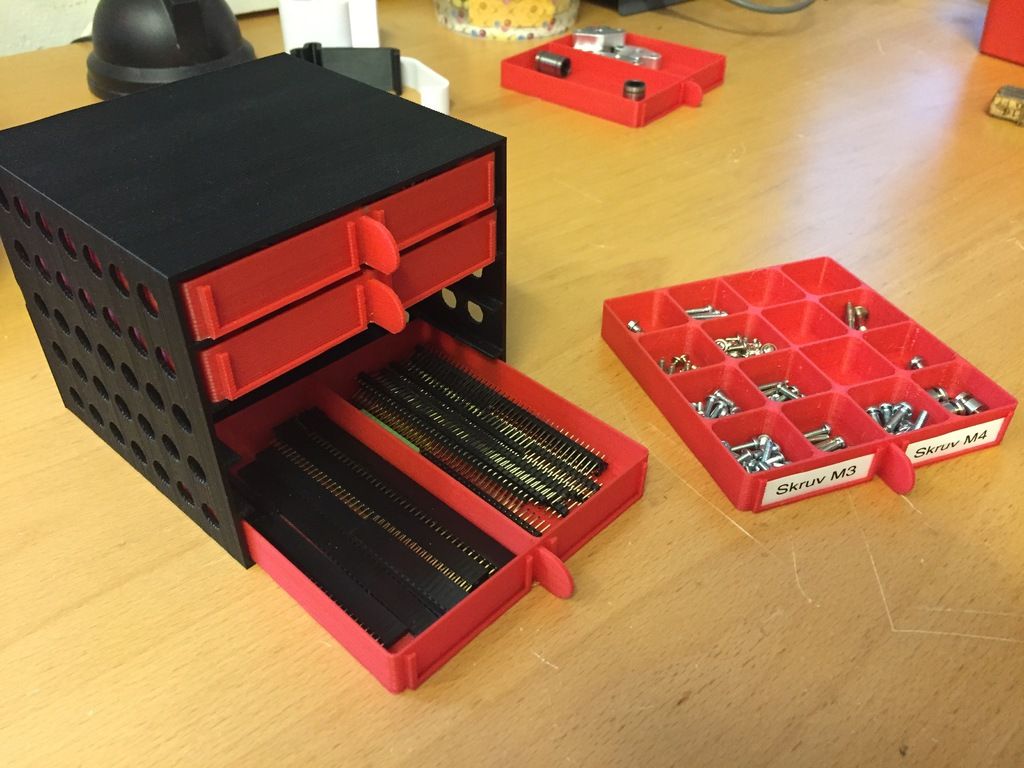

An easy way to gain monetary benefits from your 3D printer is by selling your own prints or by offering to make prints with your 3D printer.

This is quite advantageous as many commercial businesses need the diverse uses of 3D printing, but aren’t able to do due to insufficient equipment.

There are several marketplaces out there dedicated to being a platform for 3D printing services. One such site is Hubs.

One such site is Hubs.

The registration process is fairly easy, and it’s a place where you can enlist your 3D printer as a service and start to receive orders from people around the world. Accordingly, you receive payments as well from there.

Moving on, there is i.materialise, a community that gives you the opportunity to present your prints and sell them. A bigger community and marketplace, on the other hand, is Shapeways, where resides a lot of talent eager to help developers get the design they want.

The Art of The Craft

Etsy is a great online website that’s concerned with the sale of handcrafted items where 3D printed items are treated with equal respect.

There’s a certain degree of excellence associated with well-crafted, articulate 3D prints, and Etsy entertains all this very nicely. Imagination and creativity tend to sell a lot these days, and with 3D printing running the show, the possibilities are endless.

Amazon and eBay

Amazon, one of the world’s leading online stores, has its very own specified category for 3D printing. There are top-grade designers like Mixee Labs and UCODO that offer unique customization, printing, and delivering services.

However, the competition on Amazon isn’t that high as compared to Etsy or eBay. It’s more concentrated on truly distinct standalone objects worthy of being listed on the store.

If you think you’ve created a piece of absolute awesomeness, try listing it on Amazon and see how it goes from there. The benefit here is if it sells superbly, it’s going to pop up in the “Users also viewed” and “Users also purchased” sections, generating more and more sales.

eBay is purely a general platform, and selling 3D printed parts and equipment on it is no exception in the flexibility of the e-commerce giant.

Given that you’ve made a part on your own, and you’re the sole owner having legitimate copyrights, eBay is the place to consider when selling your part.

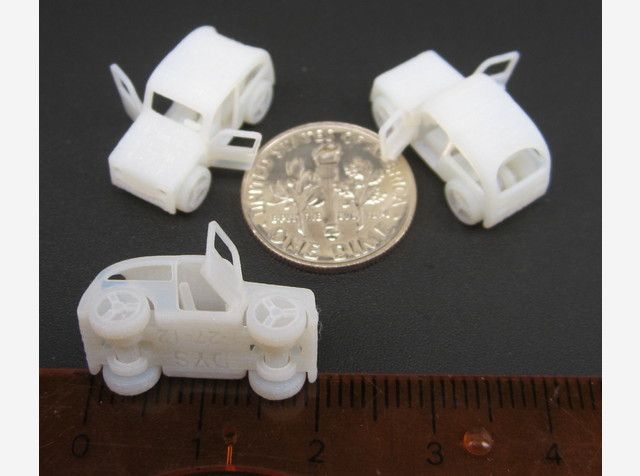

A noteworthy point here is that a person may prefer buying a cheap 3D printed part for their child’s RC car instead of getting a new one. eBay is filled with options like these, making it a fantastic place to haul in some cash with your 3D printer.

Next, we’re diving deep in detail regarding laws concerning 3D printing so keep on reading for a more knowledgeable experience. The information about to follow will ensure that you don’t end up violating someone’s copyrights, and practice a safe code of conduct.

Laws Associated With 3D Printing

We’re going to break down the legal aspects of 3D printing and what poses a risk of inviting civil action, but before we get into that, let’s take a moment to first understand some basic concepts.

Patent

A patent protects a person’s invention by providing it with legal rights. This prevents anyone else to manufacture, sell, reproduce, duplicate, and even use the invented product that has been patented.

In light of 3D printing, if anyone were to use an object made by someone else, then this happening would fall under patent infringement.

Copyright

Copyright at its core, is basically an owner’s right when he/she has made an object or produced a print. This provides the owner with full permission to customize, reproduce, showcase, and offer for sale of the copyrighted product.

Trademark

A trademark is a symbolic representation that creates a difference between one individual from another. A trademark delivers exclusive rights to the trademark owner to represent their product or service in a distinguished manner.

To talk about the trademark itself, it can be anything from a couple of words, a logo, a unique shape to something truly unique.

Now that we know what can cause an issue, let’s move further into 3D printing laws.

Intellectual Property (IP)

Intellectual Property rights are to be strongly considered when one thinks about the legality and illegality of 3D printing.

Several marketplaces like Thingiverse and Shapeways as mentioned earlier are places where you could download 3D models and print them seamlessly. In addition, there are websites available that do all the work for you, such as create your or someone else’s prints.

However, all this gives rise to multiple complications that need be to dealt with in a precise manner.

A danger revolves around the possibility that your creations could be downloaded by anyone, and you wouldn’t even know about it. Furthermore, your design could be minimally altered and people could then claim it as their own.

This is where Creative Commons comes in. This is a collection of licenses that safeguard the inventions of designers and authors alike.

The licenses, although six in total, dictate whether someone could use your product for commercial use. An NC (non-commercial) license thereby, prohibits copying the original owner’s design and put it up for sale and distribution.

In 3D printing, what you need is a 3D printer and a design for your object. This essentially means that anyone with these two components at their disposal can duplicate any design, no matter if it’s the rightful property of someone else.

This would lead to the formation of a number of fake copies, endangering intellectual rights and copyrights.

The whole summary of it is, numerous 3D printed objects may be specified by the Intellectual Property (IP) rights being the sole ownership of another individual.

Thus, printing a 3D object covered by someone else’s rights may be liable to violation, leading to infringement of rights.

The catch here is to be careful, and being wary of the license associated with designs you find online, since attending to IP laws here and there can save you from unnecessary trouble.

The following is a descriptive overview of IP laws and 3D printing.

| Intellectual property right | Registration and Protection Period | Conditions for Protection | What is Protected? | What is Not Protected? |

|---|---|---|---|---|

| Copyright | No registration, protection until 70 years after the author’s death. | Originality (required level for this condition is rather low) Applies automatically if the object meets the originality criteria under applicable law. | Original, creative objects. A 3D CAD file written from scratch (not a 3D scan from an existing object) could potentially fall hereunder because of its technical drawings, diagrams and models. Derivative works (3D CAD can be a derivative work). | Specific materials used for the production. Shapes with a purely technical function, such as moulds for another object. In some countries useful objects may be excluded. |

| Software | Same as for copyright | A form of expression. | The expression of computer code (courts may limit the scope of such protection). Some might argue that a 3D CAD is a software but courts may not follow this view. The CAD file is not meant to be executed by the computer, but, instead, read by the computer. | The functionality of software. |

| Design Right (Registered) | Registration required for long-term protection, renewable every 5 years (maximum 25 years). | New appearance and individual character of the whole or part of an object towards the informed user (overall impression of dissimilarity to previously existing designs). | The external shape and features of the whole or part of the product (3D). Appearance of the materials. | Raw materials. Internal parts not visible during normal use. An object that is commonplace in the relevant technical field. Design features configured for mechanical connection to another product (most spare parts). Features dictated by technical function only. Computer programs. |

| Design Right (Unregistered) | No registration required, protection during 3 years from the date of disclosure, not renewable. | "" | "" | "" |

| Patent Right | Registration stops after the legal protection period expires. | New. Inventive. Industrially applicable. Licit. | The innovation and technology contained in the object. A CAD file that contains a plan for a patented item, certainly if cited in the patent claims. A CAD file that contains a plan for a patented item, certainly if cited in the patent claims. | Aesthetic layout. |

| Trademark | Registration required, renewable. In rare cases registration is accepted for the shape of products. | Graphic representation. Distinctive. Licit. Available | The use in trade of the trademark as registered, including sharing on the Internet. | The private use of the trademark, because the user will not be confused about the origin when he adds the trademark himself. |

Source: https://ec.europa.eu/docsroom/documents/18921/attachments/3/translations/en/renditions/native

Important Questions That Further Clarify 3D Printing Laws

Now that we have acquired more details regarding the legal aspects of 3D printing, let’s shed some light on some important questions that, as implied, further clarify the topic in question.

Can I get in trouble for printing, but not selling, a 3D printed object covered by Intellectual Property rights?

The answer to this purely varies. First off, the patent laws restrict anyone to sell or offer to sell any print falling under someone’s intellectual property. This also includes the case when you are not trying to sell the object as well.

The law also applies even if it wasn’t in your knowledge that the object was covered by a patent. On the other hand, however, if the patented item was not sold, damage recovery without any sales might be tremendously hard.

Additionally, any recoveries made will be quite negligible due to zero profit when sales aren’t happening.

When one comes to think of copyright issues here, the proceedings are identical.

The same case of infringement applies if you happen to copy someone’s copyrighted print no matter if you had known it or not. Again, however, trying to claim any damages in monetary terms will be pointless if there’s nothing that’s been sold.

Again, however, trying to claim any damages in monetary terms will be pointless if there’s nothing that’s been sold.

It has to be strictly noted anyway that copyright infringement is a serious criminal offense if your intention is to purely replicate someone’s work, and put it up for commercial sale.

If I make a print based on a design I created purely by my own, am I violating anyone’s rights?

No, you are not. When you create a design on your own, you’re not infringing anyone’s patent or copyright. This is because for copyright violation to take effect, someone has to produce a total imitation that’s an exact copy of another person’s work.

However, it might be copyright infringement as well if you make a design that purposely imitates a design file or the final result of another person’s object.

The same situation follows for patent infringement. If you acknowledge that you’re printing an object that’s already covered by a patent, or you’re persuading others to do it, you might be indirectly held responsible for patent infringement.

The laws associated here give full authority to the patent owner to hold anyone accountable infringing their patent or encouraging people to infringe. For copyrights, the story is similar.

What if I lend someone my printer, and they use it for copyright infringement?

We understand how 3D printing has become a vast business, and renting or lending a printer nowadays is commonplace. However, there’s an alarming worry regarding the actions of the person who has taken the printer from the owner. Will the owner be held responsible if anything goes wrong? Yes, and no.

As the person who violates intellectual property rights, copyrights, or patent rights is not the one who owns the printer, but someone who had taken it for use, the law says that the person who performs infringement will be the one directly answering to the law.

The owner of the 3D printer will only be partially or indirectly accountable.

In history, providers of 3D printers to various people have not been held responsible by intellectual property laws, only in the case if they have not played a direct part in the act and encouraged IP infringement.

This boils down to the fact that 3D printers have a great many uses other than this improper operation.

3D Printing Concerns in Laws

Let’s have a look at some other 3D printing concerns that need to be known about.

3D Printing and Ethical Issues

The first ethical issue relating to 3D printing arises obviously in terms of piracy. This is what The Pirate Bay says about the matter:

We believe that the next step in copying will be made from digital form into physical form. It will be physical objects. Or as we decided to call them: Physibles. Data objects that are able (and feasible) to become physical. We believe that things like three dimensional printers, scanners and such are just the first step.

We believe that in the nearby future you will print your spare parts for your vehicles. You will download your sneakers within 20 years.

The discouraging scenario that would play out following this, can possibly disrupt technology providers and how they think about the matter.

Another major ethical concern relates to health. This happens when the technology of 3D printing is used to build and repair vital human organs. By assimilating cells in 3D printing, we’ll be able to replicate organs instantly.

Although insanely helpful and a breakthrough in medicine, the thought has its fair share of controversy.

It’s widely associated with the cloning of animals and humans, and the process itself is considered condemned and a taboo, thinking that only God should be able to produce parts of living human beings.

The Political Aspect

It’s duly written on the internet that the world of 3D printing and its political, economic, and social effects have not yet been studied nor explored in full.

The revolution 3D printing is going to bring along in the future is going to be huge.

If millions of people are able to use a 3D printer for themselves, and are actively capable of making, copying, and trading with everyday life materials, Greg Beato, an editor at Reason, writes that the outcome would be a heavy strike on the government.

This could lead to the semi-permanent closure of renowned physical stores, and what follows is explained in the following words:

Once the retail and manufacturing carnage starts to scale, the government carnage will soon follow. How can it not, when only old people pay sales tax, fewer citizens obtain their incomes from traditional easy-to-tax jobs, and large corporate taxpayers start folding like daily newspapers? Without big business, big government can’t function.

Illegal 3D Printing – What’s Not Allowed

So, as we have covered most of the legal and illegal sides of 3D printing, all the protective rights, and how to avoid infringement, let us now take a look at objects that are absolutely illegal to the core.

Printing Patented Objects

The first one is pretty obvious, considering we have already discussed the laws surrounding patents and what patent rights offer to the owner.

Without the proper permission, the original holder of the patent has the right to sue anyone using, duplicating, selling or trading their patent covered object. A case for patent infringement can be filed here, highlighting the illegality of the act.

Firearms and Weapons

Although it’s not usually a problem if you’re printing firearms personally for use and that too without a license of some sort, there are limitations that make weapons illegal to print.

The restrictions are exercised only in those jurisdictions where printing assault weapons aren’t considered legal. You cannot print items of such categories at home unless you were looking for a criminal offense lately.

Cody Wilson, made his way on the news when he created blueprints of a plastic firearm somehow, and published the methodology online. The file received more than 100,000 downloads before the law had to get rid of it.

The file received more than 100,000 downloads before the law had to get rid of it.

One of the main worries was the fact that in its final form, would be undetectable.

It’s permissible to print them as long as they can be detected by airport scanners and other scanning equipment.

Bombs

If you’re thinking of 3D printing a nuclear bomb, you might as well take a moment, assess your values, and set your mind straight. You cannot print a bomb at home, our deepest apologies.

Counterfeit Printing

The brilliance of 3D printing only demands a 3D printer and a design of what you need to print. However, not everything goes in the right direction from here.

A plethora of intellectual property rights of people have been endangered by the printing of counterfeit items. This includes handheld devices, bags, laptops, and even cash. There’s no limit to what can be counterfeited with the marvel of 3D printing.

Other

Basically, what you need to keep in mind when worried about the legality or illegality of 3D prints, is whatever’s illegal to own, is also illegal to print as well. The consequences that follow may vary accordingly.

For instance, if you happen to break someone’s copyright, patent, or trademark rights, you’re enabling legal action to be taken against you. However, if you’re printing an illegal, undetectable for example, 3D firearm, you’re signing up yourself for a much serious offense.

Other items that may not bind themselves to the category of legal printing exactly, are access cards and keys that any robber, criminal or thief could take advantage of and get the better of the law. This includes handcuff keys as well.

Adding to the less bright side of 3D printing, is the deliberate use of it in printing illegal drugs. Furthermore, there’s an additional prospect of not selling drugs directly, but again, like weaponry, offering to trade the electronic design or a blueprint.

All this can be explained by an excerpt taken from an article written by Chris Gayomali, a GQ journalist. He writes,

“But with all the useful and practical applications of 3D printed drugs comes an obvious dark side. Take, for instance, the potential for amateur organic chemists to engineer their own designer drugs.

In Drugs 2.0: The Web Revolution That’s Changing How the World Gets High, author Mike Power envisions a near future where DIYers (mostly college grads with chemistry degrees) are using highly sophisticated techniques—including 3D printers—to render “controlled substances” an obsolete relic of the past”.

Next to discuss is in biological terms- virus and bacterium to be exact. While the technology bears the fruit of legitimate and helpful creations, unwarranted use can lead to disastrous results.

The book “Fabricated” written by Hod Lipson and Melba Kurman, hints towards a black-market of human organs in the near future.

Selling 3D Printed Items – How to Make Money with Your 3D Printer

3D Insider is ad supported and earns money from clicks, commissions from sales, and other ways.

3D printers have often been described as manufacturing facilities that can fit inside a garage workshop. It also follows that 3D printers can be used for commercial applications, even for small-time hobbyists. Selling 3D printed items has been common in the last few years, but is it still a game that you can enter now?

Making a profit from selling 3D printed items involves identifying a market, developing your 3D modeling skills, and establishing a price range that considers the time, effort, and material that goes into your products. You also need to be familiar with the legal issues concerning the act of selling 3D printed objects.

There are certainly still opportunities to earn with 3D printing, but there are also lots of 3D printed products out there that hardly get noticed. What can you do to help make your 3D printing venture a success?

What can you do to help make your 3D printing venture a success?

Identify a market

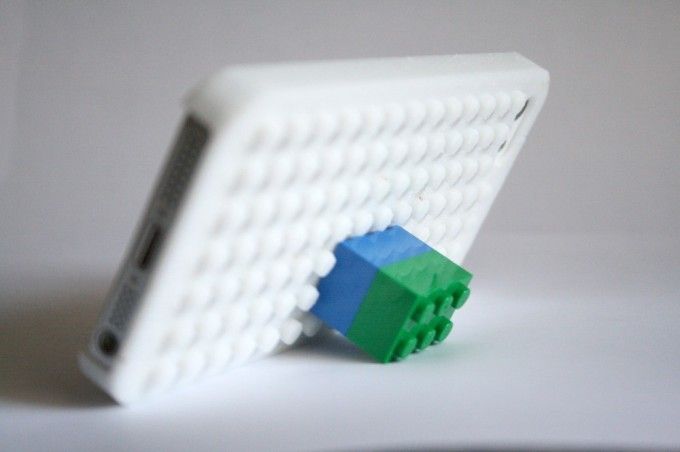

The first thing you need, before you even buy any 3D printing equipment, is an idea. Can you come up with a 3D printed object that lots of people will need or can benefit from? Does it address a fundamental issue that people commonly encounter? Perhaps you have a hobby that can be massively improved by having a unique accessory, particularly one that you cannot buy off the shelf.

Another large market for 3D printer products are pop culture fans. Is there a particular film or TV series that is hugely popular right now? Do you know of any nice cultural reference that has a dedicated and passionate fanbase?

Most people who have been successful in selling 3D printed items can come up with new ideas frequently. Fads, by their very nature, are temporary. Even an innovative idea will lose its novelty once more people can replicate it.

If there is a single factor that can drive your success in the 3D printed market, it will be your creativity. You need to be able to come up with new ideas every now and then, lest you slowly lose your market. Keep in mind that not all of your ideas will be huge sellers. Among a handful of ideas for 3D printed items, you will be lucky to profit from two or three.

You need to be able to come up with new ideas every now and then, lest you slowly lose your market. Keep in mind that not all of your ideas will be huge sellers. Among a handful of ideas for 3D printed items, you will be lucky to profit from two or three.

Make a model yourself or download it?

One hurdle that makes 3D printing intimidating is that it’s significantly harder to develop the skills for 3D modeling. If you already have 3D modeling background, then you’re fortunate – coming up with something new would be a lot easier.

If you have no experience, however, the good news is that it’s a lot easier to learn 3D modeling nowadays. Platforms like Sketchup and TinkerCAD are free to use, very friendly to beginners, and have enough tools to make simple but functional 3D models. Both of these are browser-based, so you don’t even need to download anything.

For the more advanced users, software like Blender and ZBrush provide a more sophisticated suite of tools and offer a greater degree of design freedom.

Another option is to simply download a model for 3D printing. Sites like Thingiverse, Cults 3D, or CGTrader are great for this strategy.

Just keep in mind that not all free-to-download models can be used for 3D prints that will be sold commercially. Take a look at the licenses associated with each model before deciding to sell them. A huge majority of these free models are not meant for commercial use.

If you are unsure whether a model can be sold, then it’s best to get in touch with the person who made the model. In most scenarios, an agreement can be made that allows the selling of the model while the maker gets a cut of each sale. The maker of the model can also help drive up your sales by linking to your product on the model’s download page.

Legal issues in selling 3D printed items

We briefly mentioned how a lot of commercially sold 3D printed items are marketed towards fans of popular culture. You have probably already seen replicas of movie props or action figures modeled after popular comic book characters being sold online. At this point, you may be wondering if it’s legal to sell 3D printed items modeled after the likeness of copyrighted works of art.

At this point, you may be wondering if it’s legal to sell 3D printed items modeled after the likeness of copyrighted works of art.

The short answer is no, it is not legal. Selling any 3D printed design covered by Intellectual Property Rights without the permission of the rights holder is illegal. So is selling a design that purposely imitates a copyrighted design, even if you made the model yourself.

If these laws were in place, then why are there so many 3D printed accessories being sold online that were clearly modeled from very popular intellectual properties? By the same logic, why do we see fanart of popular characters being sold online or in conventions?

The thing about selling items that violate copyright is a problem only when the copyright holder goes after you. For instance, Disney probably does not bother sending cease and desist letters to all the online sellers who peddle masks, busts, shirts, and other accessories modeled after Iron Man.

Should you decide to sell 3D printed items modeled after the likeness of a popular character, then you do so with the accepted risk that you may receive an order to delist the product eventually. This problem will likely be magnified if you start gaining huge profits from the product.

This problem will likely be magnified if you start gaining huge profits from the product.

How can you avoid this problem? Simply by creating your own work that does not imitate an item or character from popular culture. You can also create designs that are inspired by designs in the popular domain. Nobody holds the copyright for characters like Santa Claus, Count Dracula, or any of a host of mythological creatures. There are still lots of places to get your inspiration from without violating copyright laws.

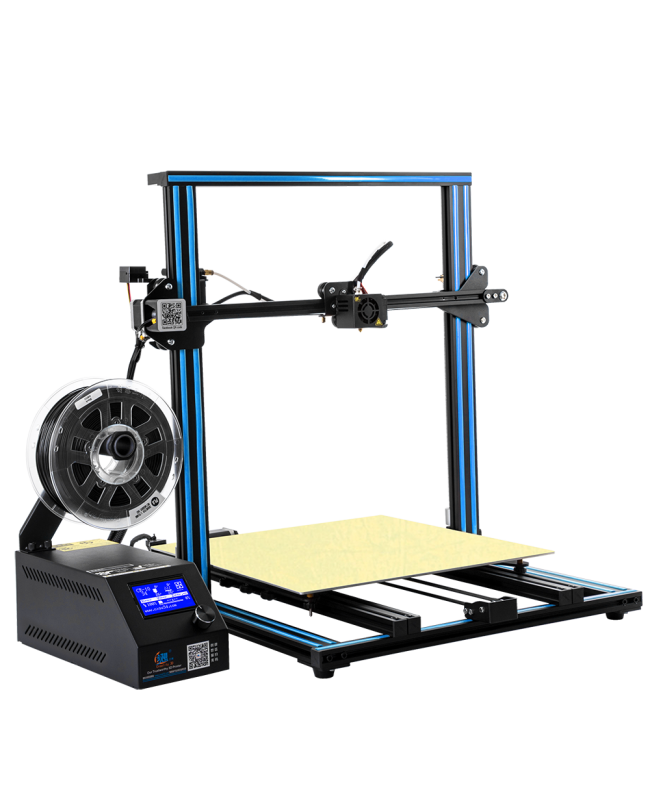

Which type of 3D printer should you get?

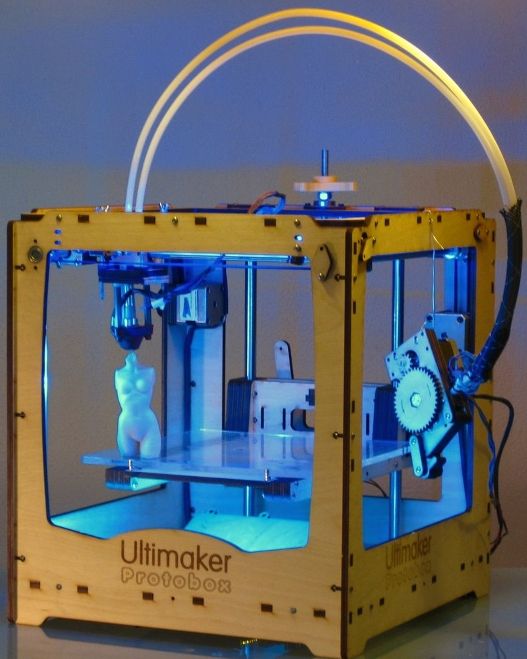

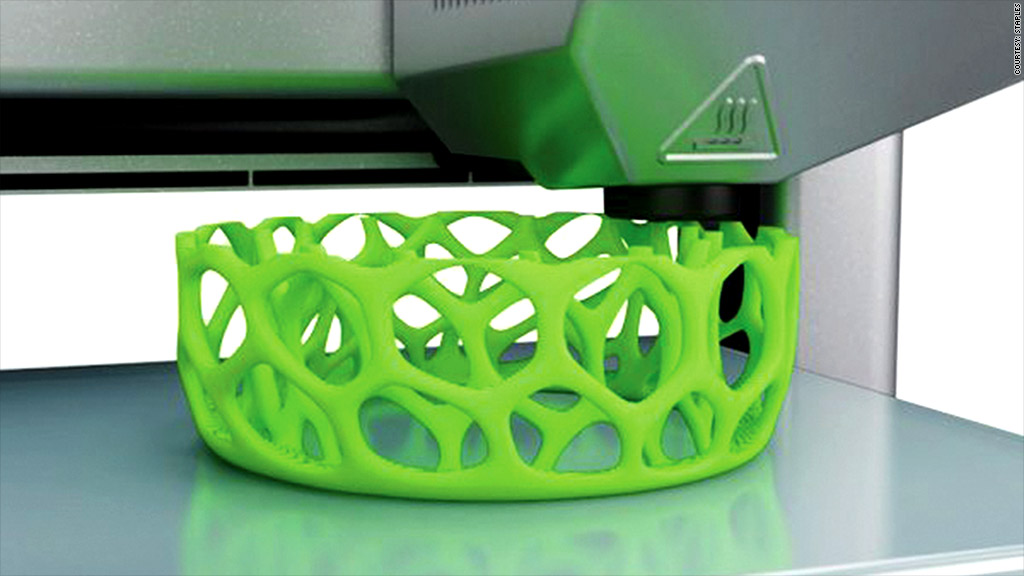

If you’re just starting out in 3D printing, then you really only have two options – Fused Deposition Modeling (FDM) or Stereolithography (SLA) printers. Both of these types of printers have become popular for beginners because of how inexpensive they have become through the years. There are desktop models for both FDM and SLA printers, so you also won’t need a lot of space.

The main difference between the two is that FDM printers use filament as raw material and that SLA printers use liquid resin. Either option has benefits and drawbacks. They are equally valid for those who want to start selling 3D printed items.

Either option has benefits and drawbacks. They are equally valid for those who want to start selling 3D printed items.

The debate between FDM and SLA is complex enough to take up an entirely separate article. Choosing between the two is even more difficult now that SLA printers have become a lot more affordable.

FDM printers are typically cheaper to operate, require minimal post-processing, and have larger build volumes. On the flip side, they are also slower and will require more troubleshooting and maintenance on account of having more moving parts.

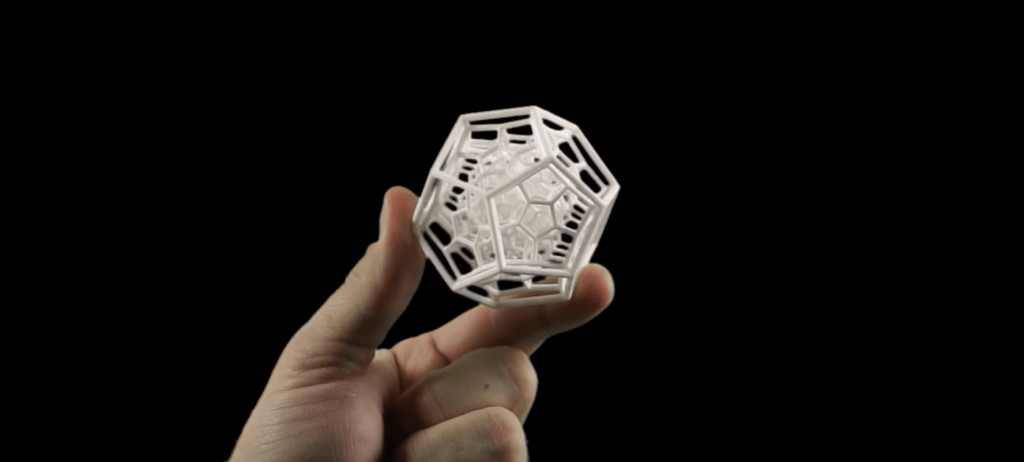

SLA printers have two huge advantages – they are faster and are a lot better for creating highly accurate details. However, the 3D printing process using SLA is notoriously messy because of having to handle toxic liquid resin. SLA printing requires considerable work in post-processing and even in the disposal of resin-contaminated items.

FDM printers are ideal if you’re printing functional items that do not need a great level of detail. When aesthetics is the focus of your products, then SLA printing is clearly superior. Most 3D printing professionals end up having both since it helps them offer services to a wider customer base.

When aesthetics is the focus of your products, then SLA printing is clearly superior. Most 3D printing professionals end up having both since it helps them offer services to a wider customer base.

Where should you sell?

Most 3D printing sellers list their products in any of the following – Amazon, eBay, or Etsy. Do your research for each platform before signing up as a seller, as there are key differences between them.

For instance, Amazon is an excellent choice if you anticipate selling a huge number of your products as you can simply forward them to Amazon Fulfillment Center so you don’t need to deal with shipping the products yourself. However, Amazon does take a hefty commission from sales, so you might need to factor that into your pricing scheme.

On the other hand, people go to Etsy for more creative or bespoke items. This is a great platform if you have no plans of mass-producing your designs.

If you have created your own original designs, then you can also sell them via Thingiverse. Take note that only the digital designs can be sold via this platform and not the actual 3D printed items. This makes the profit margin a lot lower, but you won’t be doing much work once the designs are online.

Take note that only the digital designs can be sold via this platform and not the actual 3D printed items. This makes the profit margin a lot lower, but you won’t be doing much work once the designs are online.

Conversely, you can just offer your services via social media. This is actually a very good strategy if you plan on offering print-as-you-order services for customized designs. The great thing about using social media is that the platform does not take a cut from your sales and that you can offer a more personal service to potential customers.

How much should you charge?

The price of your products should take into account all the costs that went into producing them. Just to make sure you don’t miss anything, these are the costs to consider:

- Equipment cost

- Maintenance cost

- Cost of supplies

- Marketing and promotion

- Cost of electricity and other utilities

- The cost of your time

Most of these are fairly obvious to any entrepreneurs, but the 3D printing market is notorious for undercutting the competition. For this reason, the best strategy is always to come up with a product that nobody else offers. That way, you can dictate a profitable price without having to worry about the price offered by other sellers.

For this reason, the best strategy is always to come up with a product that nobody else offers. That way, you can dictate a profitable price without having to worry about the price offered by other sellers.

Most people only sell 3D printed items as a side gig. Even if this were the case, you need to assign value to the time it takes to make your products. This includes the time spent on 3D printing, post-processing, and packaging. Post-processing is typically the most time-consuming step, especially if your products need to be sanded, polished, and painted.

Final thoughts

If you want to earn money using your 3D printer, then it’s no longer enough to just own a 3D printer. Now that so many people can afford to buy 3D printers, the market for 3D printed items is close to saturation. This means that you need to stand out with more creative or innovative products.

One thing that most people who offer 3D printing services tend to ignore is the potential consequence of selling products based on copyrighted properties. Just because a lot of people get away with it does not mean that you will be as lucky. Just to be safe, we suggest steering clear of selling any products that possibly violate copyright and intellectual property laws.

Just because a lot of people get away with it does not mean that you will be as lucky. Just to be safe, we suggest steering clear of selling any products that possibly violate copyright and intellectual property laws.

Warning; 3D printers should never be left unattended. They can pose a firesafety hazard.

Which 3D printing business will be successful? / Habr

What kind of successful business can be opened using 3D printers? I will make a reservation right away that so far there are few such examples. I'll tell you about some of them.

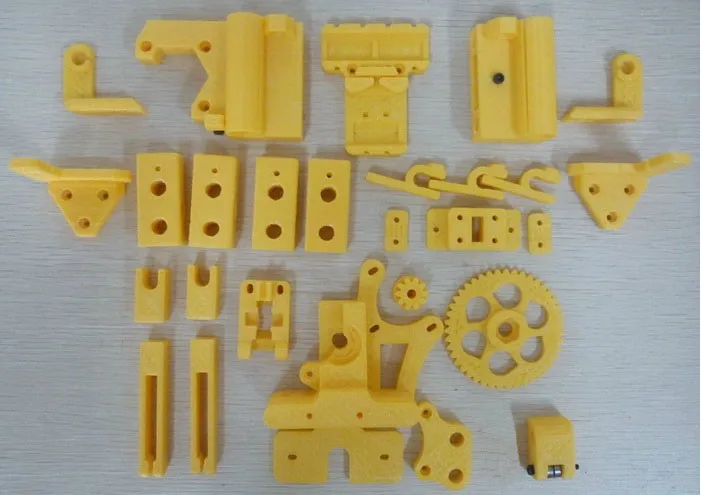

3D Printing Studio

The first thing that comes to mind is setting up a 3D printing studio. Its business model is based on modeling and printing models for the client. The main success factor is to ensure a consistently high level of equipment utilization. For such a project, it is more important to focus on mass replication than on printing single copies, even in large volumes. The cost of printing a small model should be low, and the labor costs should be high. The main production processes are the high-quality development of printing technology for each specific detail or project, the selection of the right material. The client model is checked for errors, and both the material and the printer are selected. It remains to agree on the price and, in fact, print the model. It is necessary to approve it with the customer, and, if necessary, modify it.

The main production processes are the high-quality development of printing technology for each specific detail or project, the selection of the right material. The client model is checked for errors, and both the material and the printer are selected. It remains to agree on the price and, in fact, print the model. It is necessary to approve it with the customer, and, if necessary, modify it.

You can build such a studio with almost any level of investment: start with one or two printers, gradually increase the equipment fleet or immediately invest in a 3D printer fleet. You can also purchase industrial equipment for functional prototyping and small-scale production. But in any case, the most important thing is to correctly build the business model of the enterprise.

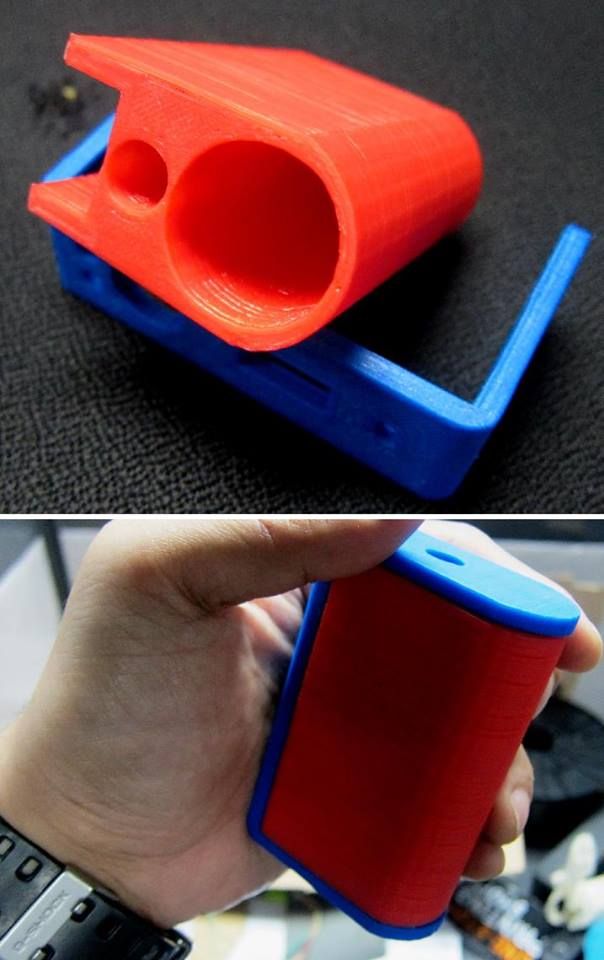

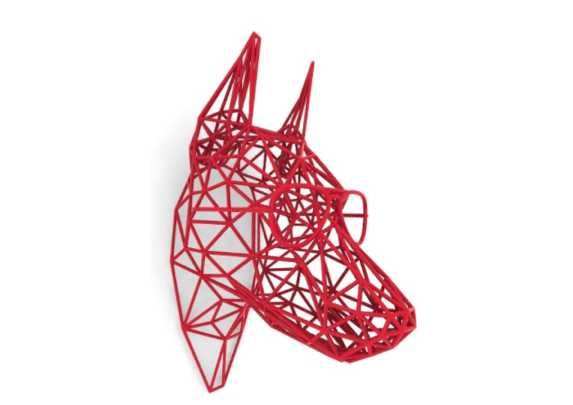

Small-scale production

The second most popular business idea is a small-scale production studio. In this case, the main task is not to find a client, but to understand what product will be in demand. There are many examples of such studios, and their success primarily depends on the quality and originality of the products offered. For clarity, consider the production of molds for the manufacture of confectionery. They are easy to model, customize, print and sell. The target audience of this product is clear and stable, the product is easily promoted in social networks, the cost is low, and the most budget 3D printers are suitable for production. The main thing here is the optimal ratio of the number of devices with production volumes. Another popular example: accessories for gamers. Game weapons, masks, costume elements from computer games for cosplayers. The product is not so massive, but consistently in demand, and its price niche is significantly higher. More time will be spent on modeling and printing, but in return you get markets around the world, since the studio is not limited to the location of your region.

There are many examples of such studios, and their success primarily depends on the quality and originality of the products offered. For clarity, consider the production of molds for the manufacture of confectionery. They are easy to model, customize, print and sell. The target audience of this product is clear and stable, the product is easily promoted in social networks, the cost is low, and the most budget 3D printers are suitable for production. The main thing here is the optimal ratio of the number of devices with production volumes. Another popular example: accessories for gamers. Game weapons, masks, costume elements from computer games for cosplayers. The product is not so massive, but consistently in demand, and its price niche is significantly higher. More time will be spent on modeling and printing, but in return you get markets around the world, since the studio is not limited to the location of your region.

3D printing of medical products

The third version of the 3D printing studio is medical. Today it is very much in demand. Prostheses, orthoses, orthopedic insoles, hearing aids, temporary crowns, aligners, spectacle frames are complex in conventional production, but our technologies greatly simplify this process. The equipment here is selected based on the specific task. Usually one company is focused on printing a particular line of models. The accumulated experience allows you to create a product with unique properties as efficiently as possible. In this direction, business goes in tandem with science. The success of the enterprise directly depends on innovative approaches in orthopedics and medicine in general.

Today it is very much in demand. Prostheses, orthoses, orthopedic insoles, hearing aids, temporary crowns, aligners, spectacle frames are complex in conventional production, but our technologies greatly simplify this process. The equipment here is selected based on the specific task. Usually one company is focused on printing a particular line of models. The accumulated experience allows you to create a product with unique properties as efficiently as possible. In this direction, business goes in tandem with science. The success of the enterprise directly depends on innovative approaches in orthopedics and medicine in general.

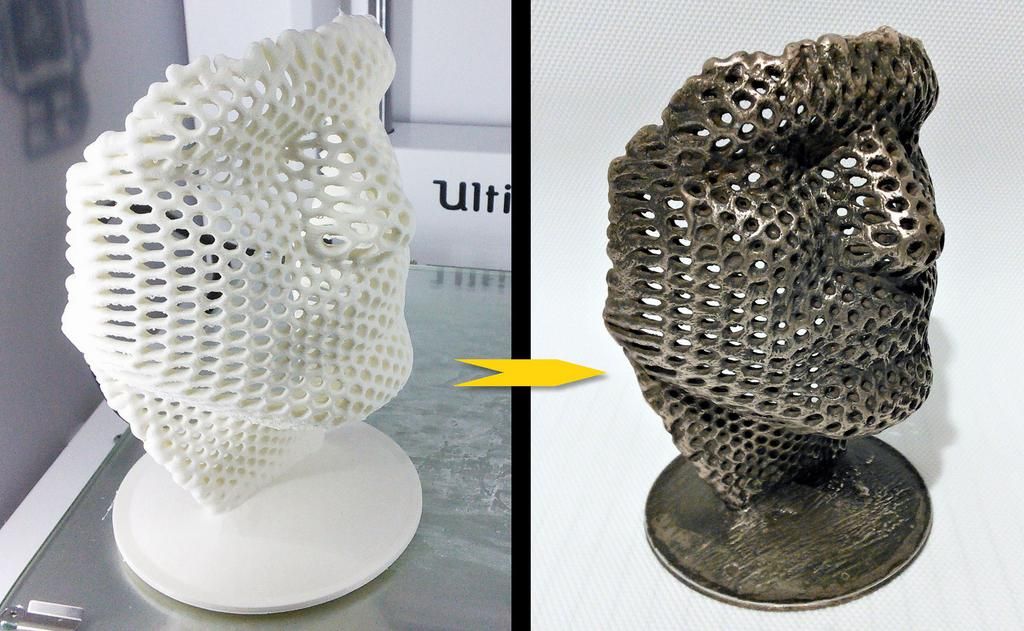

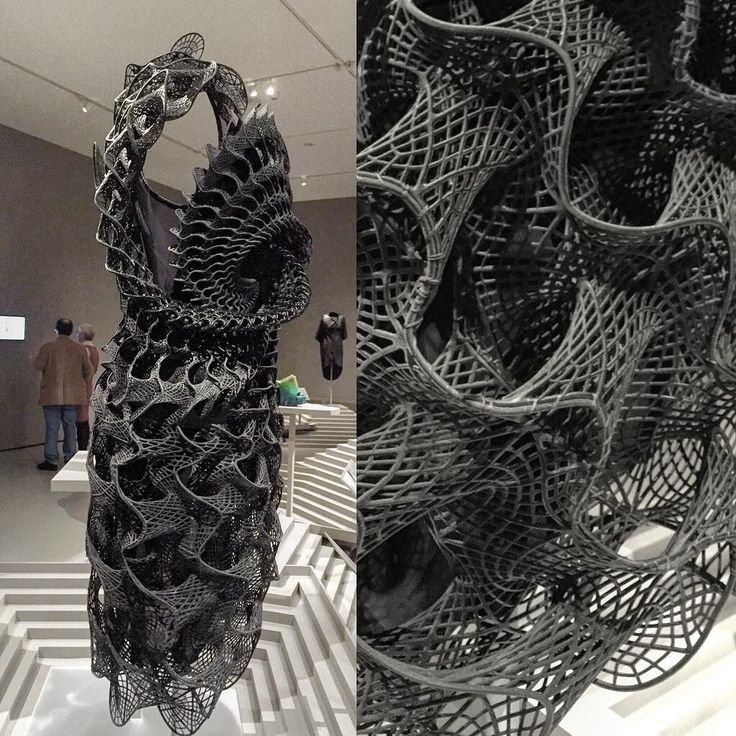

3D printing of art objects

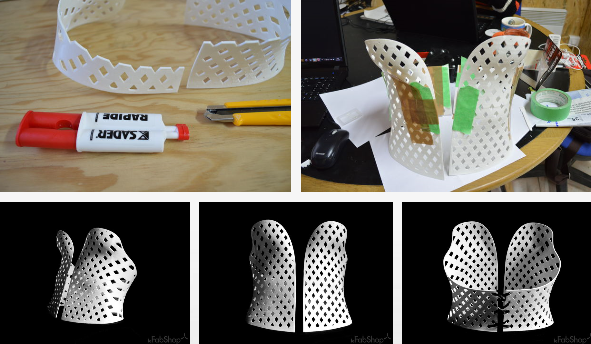

Fourth place will be given to art. 3D printing of sculptures is another way to capitalize on this technology. Creating a large art object is not an easy task, and certainly not a cheap one. However, many interiors or public spaces are in need of an aesthetic upgrade. Modern sculptors began to use the new technology in their work precisely to create final products, and not prototypes or layouts, as one might think. To achieve this goal, large-format printers using FDM technology (the model is formed from molten plastic) are needed. Typically, a computer model is divided into parts and printed on several 3D printers, after which it is glued, sanded, primed and painted in the desired colors, sometimes with the addition of texture. This makes the sculpture almost indistinguishable from those made from natural materials.

To achieve this goal, large-format printers using FDM technology (the model is formed from molten plastic) are needed. Typically, a computer model is divided into parts and printed on several 3D printers, after which it is glued, sanded, primed and painted in the desired colors, sometimes with the addition of texture. This makes the sculpture almost indistinguishable from those made from natural materials.

Another option is to show the model in full size, without post-processing, which allows viewers to see the 3D printed model at different stages of its creation.

It is difficult to fit into a short article all the variety of opportunities that 3D printing offers to enthusiasts of this technology, but we see that every day there are more and more new interesting stories of its application. It gives impetus to the development of new technologies and brings innovation to seemingly established areas such as the creation of sculptures or gingerbread. As the American inventor Chuck Hull, who patented the first 3D printer, said: “I don’t have a crystal ball that will tell me what should happen in the future, but one thing I know for sure: when smart people work on a specific task, they gradually move forward. forward".

forward".

Alexander Kornveits

Founder and CEO of Tsvetnoy Mir

successful business based on innovative technologies

“The most difficult moment is when you had to stop designing and start selling” 9002 A good engineer is not always a good entrepreneur: it often happens that many developments never reach the stage where you can build a business on them. But Fyodor Antonov and his Anisoprint team succeeded: they not only developed a technology that makes it possible to obtain durable composites - materials based on carbon fiber, but also successfully entered Western markets with their product. Fyodor Antonov, the founder of Anisoprint, told Biz360.ru about how to make money on an innovative project.

Dossier

Fedor Antonov , 34 years old, founder and director of the company Anisoprint . In 2007 he graduated from the Mekhmat of Moscow State University. After that, he worked as an engineer at the Salyut engine building plant for 3.5 years. At the same time he wrote and defended his PhD thesis. From 2010 to 2013, he worked at the Rostec Composite Materials Center. Then he worked for two years at the Skolkovo Institute of Science and Technology (Skoltech). In 2015, together with fellow scientists, he founded the Anisoprint company, which manufactures and sells composite 3D printers and materials for them.

After that, he worked as an engineer at the Salyut engine building plant for 3.5 years. At the same time he wrote and defended his PhD thesis. From 2010 to 2013, he worked at the Rostec Composite Materials Center. Then he worked for two years at the Skolkovo Institute of Science and Technology (Skoltech). In 2015, together with fellow scientists, he founded the Anisoprint company, which manufactures and sells composite 3D printers and materials for them.

A problem has become a business opportunity

Fedor Antonov has been designing and optimizing products made of composite materials for almost 10 years. In his experience, when working with composites, an approach is usually taken that does not allow them to reveal their maximum potential. They are handled in the same way as traditional materials (such as metals), although their properties are different.

- Composite is a material consisting of two or more components with a clear interface between them .

As a rule, one component is called reinforcing filler or reinforcement - the strength and rigidity of the composite depends on it. The second component is the matrix or binder. The result is a material with unique characteristics that neither the reinforcement nor the binder individually possess.

As a rule, one component is called reinforcing filler or reinforcement - the strength and rigidity of the composite depends on it. The second component is the matrix or binder. The result is a material with unique characteristics that neither the reinforcement nor the binder individually possess.

The simplest and most famous example of a composite is reinforced concrete. Polymer composites in the form of carbon fiber (or carbon fiber) are also not new - they have existed for more than 50 years. Airplanes, racing cars, etc. are made from this material. This is a composite, where the filler is carbon fibers, and the binder is polymers.

The problem with composite materials lies in their structure. All the unique properties of composites (for example, increased strength and stiffness) appear only along the direction of the fibers. And when loaded across the fibers, the strength is very low and corresponds to the strength of the binder material. This property is called anisotropy: different material properties appear in different directions. It is considered the main disadvantage of composites.

This property is called anisotropy: different material properties appear in different directions. It is considered the main disadvantage of composites.

They are trying to fight anisotropy. For example, in "classic" carbon fiber sheets of unidirectional fibers are laid layer by layer at different angles. But here another problem arises. If such material is drilled or cut, its fibers are damaged. There is a stratification of the material - its properties are lost.

“We decided to make the technology of manufacturing products from composites as flexible as possible. It would allow at any point in the structure to change the direction of the fibers and their concentration. Thus, we would receive the optimal material for a specific design. And then you do not need to drill holes in the material - it will be printed with the "correct" direction of the fibers around the hole. There are many such examples in nature. One of them is wood fibers that go around the place where the branch is attached,” says Fedor Antonov.

Prototyping

While working at Skoltech, Fedor and his colleagues developed a new technology for manufacturing composites with increased strength. By 2015, they managed to create this technology - anisoprinting. During the 3D printing process, the developers added specially processed carbon fibers to the plastic. Due to this, the strength of the plastic increased by 30 times! The resulting material was twice as strong and lighter than aircraft aluminum.

The inventors faced another question: how to produce such composites in the best way and at no extra cost. For this, Fedor and his colleagues developed a special 3D printer. Its presence made it possible not only to “theoretically” design structures, but also to manufacture them. In early 2015, a team of engineers led by Fedor Antonov patented their solution.

In the summer of 2015, they registered a legal entity - Anisoprint, for which they issued the status of a Skolkovo resident. At the same time, the new company sold its product for the first time. The print head of the 3D printer was bought by an American, the former head of the laboratory at Skoltech. He purchased the device for the University of South Carolina, where it is still in use today.

At the same time, the new company sold its product for the first time. The print head of the 3D printer was bought by an American, the former head of the laboratory at Skoltech. He purchased the device for the University of South Carolina, where it is still in use today.

After that, several more 3D printer prototypes were sold. The buyers were universities and research institutes. Among them was the Central Research Institute of Special Machine Building - one of the largest experimental and scientific centers for composite materials.

Search for investors

For two years, Fedor Antonov tried to find funding for his developments. According to him, it was almost impossible to do this: investors and funds rarely allocate money to "manufacturers", preferring IT projects.

But here the company was lucky. In the spring of 2017, Fedor took part in a competition for industrial startups, which was held at the initiative of one of the business angels. Anisoprint took one of the prizes in the competition.

Anisoprint took one of the prizes in the competition.

For six months, Fedor discussed the terms of the deal with the business angel. And when they had already reached a preliminary agreement, the founder of Anisoprint began to doubt his future partner. Just at that moment, the novice entrepreneur was introduced to another potential investor who was also interested in the project. The founder of Anisoprint does not disclose the name of the investor, the size of his investments and the terms of cooperation.

“Having the first offer in hand, I could already choose. And I immediately told the second investor that I needed more favorable conditions. Quite quickly, without long disputes and discussions, we agreed on everything. Until the end of 2018, we signed a preliminary agreement with a new partner. In the end, he invested in us. With this money, we started full-fledged development,” says Fedor.

In the end, he invested in us. With this money, we started full-fledged development,” says Fedor.

Lab-to-market entry

At the end of 2017, after two years of work, Anisoprint had a prototype of a new 3D printer model ready. It was first shown at the main 3D printing exhibition Formnext in Frankfurt in November 2017. After that, the company received the first pre-orders for its product.

Almost the whole of 2018 was spent on finalizing the prototype and launching mass production. At the same Frankfurt trade show at the end of 2018, Anisoprint officially started selling its device. The first batch of 30 printers was shipped to customers that same year. Investments in the development phase before the launch of mass production of the product amounted to approximately $ 700,000.

“The most difficult moment was the transition “from the laboratory to the market”: when it was necessary to stop designing and start selling. For us, it was a step into the absolute unknown. I had no business experience and no business education. And my whole team was also not commercial, but scientific and engineering. It's one thing when there is a prototype in the laboratory, and you "play" with it. And it’s quite another when you need to ship products to customers who have their own expectations and requirements,” Fedor Antonov admits.

For us, it was a step into the absolute unknown. I had no business experience and no business education. And my whole team was also not commercial, but scientific and engineering. It's one thing when there is a prototype in the laboratory, and you "play" with it. And it’s quite another when you need to ship products to customers who have their own expectations and requirements,” Fedor Antonov admits.

Not only 3 D - printers

Today Anisoprint offers three types of products: 3D printers, reinforcing fibers and software. The company does not sell plastic for the production of composites - its customers buy it themselves. The technology allows the use of different types of plastics as a binder.

When buying a printer, the package includes basic software and one reel of reinforcing fiber. During the printing process, it is applied together with plastic to form a composite. The program based on the 3D model allows you to create various types and trajectories of reinforcement (strengthening) of the material.

Anisoprint manufactures two desktop printer formats. One of them has an A4 size workspace and costs 12,000 euros. A larger printer with an A3 working area sells for 19,000 euros. Along with the printer, they often buy an additional set of fibers, spare printheads or other spare parts, as well as a training course on working with the device. In the future, customers turn to the company for new batches of reinforcing fiber.

“Now the main income comes from iron. But the bigger the customer base, the bigger the fiber sales will be. According to our plan, in a few years the sale of the material will account for half of the total revenue,” Fedor notes.

The company employs 17 people: 10 engineers, 2 marketing specialists, and an administrative team. Two employees are employed in production in Skolkovo.

Transfer of production abroad

Anisoprint produced the first batch of 15 printers in Russia. After that, it was decided to move production abroad. The main reason for this decision is the focus of the project on foreign markets. The company found a production facility in Germany, where they made several test samples, after which they signed a contract.

The main reason for this decision is the focus of the project on foreign markets. The company found a production facility in Germany, where they made several test samples, after which they signed a contract.

“To export something from Russia for export is long, expensive, difficult and unpredictable. There are many problems to be solved: customs, export permits, duties, etc. When we exported the first printers, there were so many headaches that we decided: we don’t want this anymore,” Fedor explains.

The contracting company Anisoprint is located in Bavaria, near the city of Augsburg. There they make a frame for the printer, perform final assembly, acceptance and packaging of products. Pilot production of printers, as well as the manufacture of printheads and fiber, remained in Skolkovo.

Applications

The main consumers of Anisoprint products are educational and research institutions: institutes, universities, laboratories. With the help of such printers, they conduct various studies. First of all, their work relates to the design of new composite materials.

With the help of such printers, they conduct various studies. First of all, their work relates to the design of new composite materials.

Also among the company's clients are research centers at large corporations. They are looking for opportunities and applications for anisoprinting technology in the future. For example, one of the buyers is the research center of the BMW automaker.

The founders of the Anisoprint project are confident that their technology will be in demand in aviation, space, and the automotive industry. With its help, you can make parts for aircraft or cars. But before the start of industrial use, anisoprinting technology, materials and equipment must be certified. This procedure is costly and time consuming.

“We offer one of the newest and most promising 3D printing technologies. It opens up many new possibilities. Many large companies understand this and invest in its research. And when they are convinced that there are areas of application and opportunities to benefit, they will be ready to invest in certification and bringing the technology to industrial use,” Fedor Antonov is sure.

It opens up many new possibilities. Many large companies understand this and invest in its research. And when they are convinced that there are areas of application and opportunities to benefit, they will be ready to invest in certification and bringing the technology to industrial use,” Fedor Antonov is sure.

Another market segment for Anisoprint products is the manufacture of parts for various tools. These are clamps, grips, clamps for welding, assembly, milling, as well as for automated lines. All these devices have one thing in common: they have a rather large load. 3D printing technology allows you to make them right on the spot - quickly, cheaply and with high precision. Certification is not required in this case.

End customers

Since the majority of clients represent the research and development segment, they have a good understanding of the technology for manufacturing high-strength composites and are able to work with the necessary equipment. There are not so many buyers without experience with 3D printers - they are mainly from the industrial sector. The company pays special attention to them: they train and help them get used to the equipment.

There are not so many buyers without experience with 3D printers - they are mainly from the industrial sector. The company pays special attention to them: they train and help them get used to the equipment.

“In inexperienced customers, we sometimes encounter inflated expectations regarding the capabilities of the technology. Many people think that a 3D printer is a miracle. You press the button and everything magically prints by itself. For some reason, when buying a milling machine, no one thinks so. But while we do not have so many clients, we manage to communicate with everyone. We train them, and they gradually start to succeed, ”says Fedor.

As with any new technology, Anisoprint's products sometimes had some minor technical hiccups. However, they were quickly eliminated. According to the founder of the project, there were no cases of serious complaints about the products or the return of purchases. At the same time, repeated orders have already met more than once. Some customers ordered one or more printers after purchasing one device.

Some customers ordered one or more printers after purchasing one device.

Sales through dealers

The main markets for Anisoprint are Germany and France. The company's products are also sold in England, Italy, the Scandinavian countries and Eastern Europe. In each of these countries or regions, the company has official distributors.

According to Fedor Antonov, for a project with an international market, this is the best way to organize sales. Its main advantage is the client base of each of the dealers. It is also important that distributors communicate with customers in the same language, understand their mentality and peculiarities, understand the regional specifics of their country. Sales in Russia are also conducted through distributors. This allows the company not to hire and train its own managers.

“With limited resources, expanding the staff is quite expensive. Moreover, sales in our field are quite long and complex: it usually takes from 3 to 9 to close a deal. months. Until a person learns to sell, it will take quite a long time. And distributors already know how to work with similar products,” says Fedor.

months. Until a person learns to sell, it will take quite a long time. And distributors already know how to work with similar products,” says Fedor.

However, there are also disadvantages in working through dealers. Not all of them know the product as well as the developers themselves. They are not always able to correctly explain to the client the benefits and values of Anisoprint products. Sometimes this leads to disruption of transactions and loss of customers.

“Another disadvantage is that dealers offer their customers not only our products. And they pay more attention to the most famous brands, which are the easiest to sell. As a rule, these are American brands investing millions in marketing. We are also trying to work on recognition, but it is still difficult for us to compete with the budgets of the Americans, ”adds Fedor.

Online and offline promotion

As with most innovative products, Anisoprint's main promotional channel is exhibitions. The project team travels to three or four major events in Europe. Small regional exhibitions are attended by distributors. They have demo printers that they show to potential customers.

The project team travels to three or four major events in Europe. Small regional exhibitions are attended by distributors. They have demo printers that they show to potential customers.

The company also uses all major online promotion channels, primarily content marketing and paid advertising in social networks and search engines. “In terms of customer acquisition cost, they are even more effective than exhibitions. But in our case, it is important to constantly “be in sight”. Exhibitions mean strengthening ties, searching for new partners, recognizing the brand in the market,” Fedor Antonov explains.

What's next

In 2019, about 70 Anisoprint devices were sold. The total revenue for the year is approaching $1 million. Almost all the money earned is invested in increasing production volumes. To scale the project, Fedor plans to attract investments. The investment is expected to pay off in about 3 years.

“With small business volumes, profitability indicators are much worse than with large ones.