Arduino 3d printer software

How to Make a 3D Printer with Arduino – ELEGOO Official

Source: https://unsplash.com/

3D printing technology is wide, despite having been around for a little over 30 years. The improvements the technology has been undergoing are all slowly pushing it slowly towards a realm where everyone will be able to access simple 3D printers at low prices, getting the ability to make whatever they want from the comfort of their own homes. One of the most utilized 3D printing concepts is the Arduino.

Arduino is an open-source electronics platform that is based on easy-to-use software and hardware. They are boards that have the ability to read inputs, activating other machines, among many other automated functions. We are going to explore how to make a 3D printer using the Arduino platform, the benefits of having a DIY Arduino printer as well as some comparisons with other official models that are in the market.

Why Arduino?

Source: ELEGOO

There are perfectly good reasons why Arduino is used extensively in most DIY projects of making 3D Printers. The first Arduino kit was created in 2005, and in the last 15 years, it has become a very reliable software for people who are looking to create their own 3D printer. The following are reasons why they are the best choice for DIY 3D Printers.

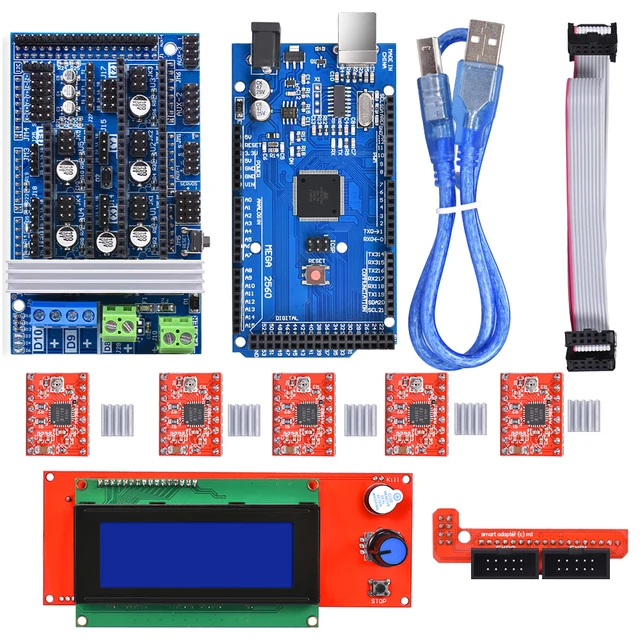

- It is cheap: Arduino is easily accessible and affordable, and the price keeps going down as more improvements are being made in the 3D printer sector. A simple Arduino kit will set you back just about $24, which is well within the affordable range of most people.

- Easy to use: An Arduino kit is usually ready to use straight from the box. The kit comes in a complete package that includes a 5V regulator, a burner, a microcontroller, a serial communication interface, LED, and headers. All you have to do is plug it into the USB port of a computer, and you are ready to roll.

- Wide range of codes: Arduino comes with a huge library of codes that are already present in the Arduino itself. The kit literally sets itself up in a number of ways, and in the event, you run into obstacles, troubleshooting is not that complicated to pull off on your own.

- Large community: There is a huge number of online forums that are full of people who use Arduino, and this provides new users with a platform where they can get help immediately from other users who have had the experience already. Every trouble you may run to will have a solution, and this makes Arduino a very resourceful tech.

- Cross-platform: Arduino is a cross-platform software that can be used on Windows, Linux, and Mac. This makes it resourceful and unlimited in many ways. You don't have to buy a particular computer to run it; all you need is to get a computer with the right specs. You will be making your 3D models in no time.

Making a 3D Printer with Arduino

The process of making a 3D printer may look daunting for those that have never used it before, but if you are a newbie to the game, the process is a little easy. The following are some of the stages that are used in making a 3D printer using the Arduino platform.

The following are some of the stages that are used in making a 3D printer using the Arduino platform.

To start off, you have to start collecting the components and supplies to start yourself off. The following are the boxes you have to tick off.

- A ramps 1.4 controller board: This is used for interfacing purposes like connecting the end-stop switch, the heatbed, the stepper motor driver, the hotend, and a host of other components with the Arduino.

- Optical end-stop switch: This is a sensor switch that comes with two markings. NO or NC (Normally Open/Normally Closed). They function as triggers when the XYZ axis of a printer reaches its endpoint. They can be used at any time to stop and start movements.

- NEMA 17 stepper motor: This is a motor that allows the user to set the speed of revolutions for the movable parts of the printer. The average motor has about 200 steps, but you can get a bigger one.

- PCB heatbed: This keeps the extruded plastic parts warm at all times to prevent them from warping.

- Power supply: A 12V/20A power supply is needed to run a simple kit. These power metrics are the minimum you should go for success.

The Process

With all the important components in place, the next step is to start making your DIY 3D printer. The stages involved include the following.

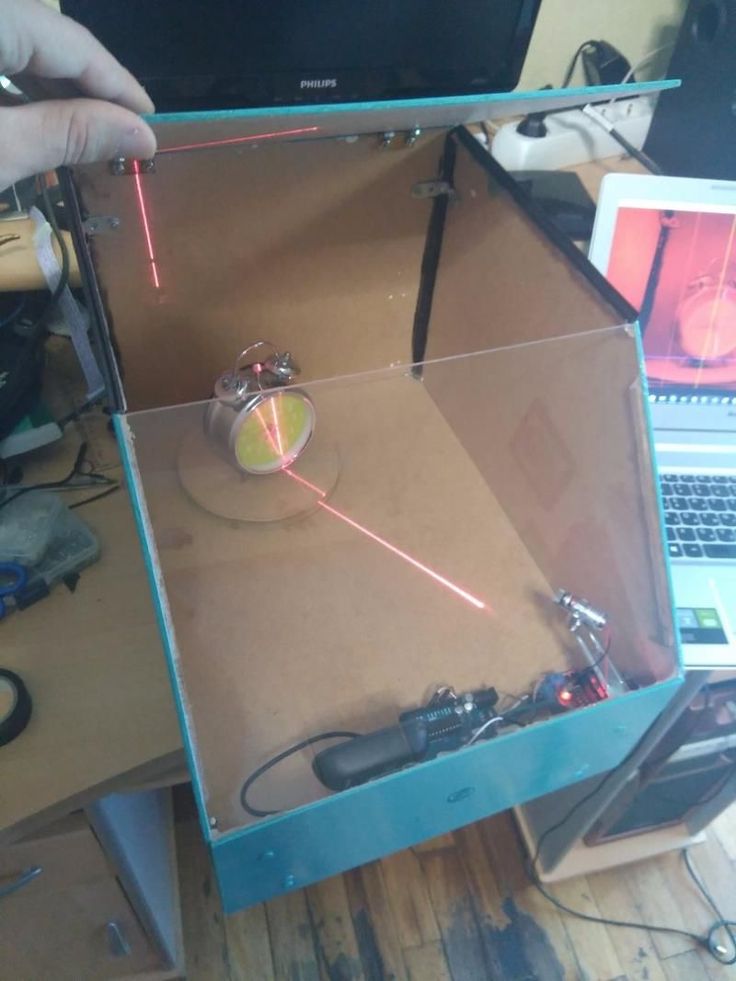

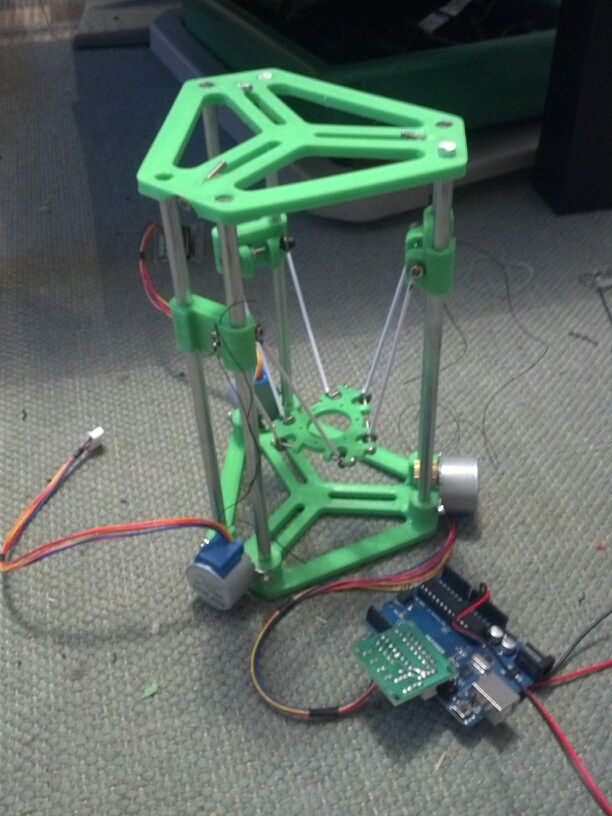

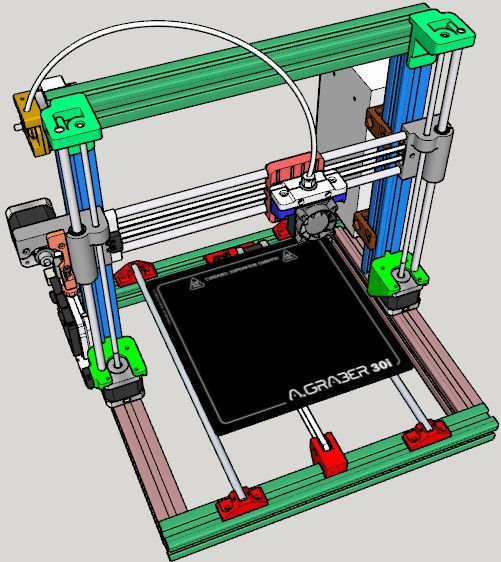

Step 1: Build the Frame

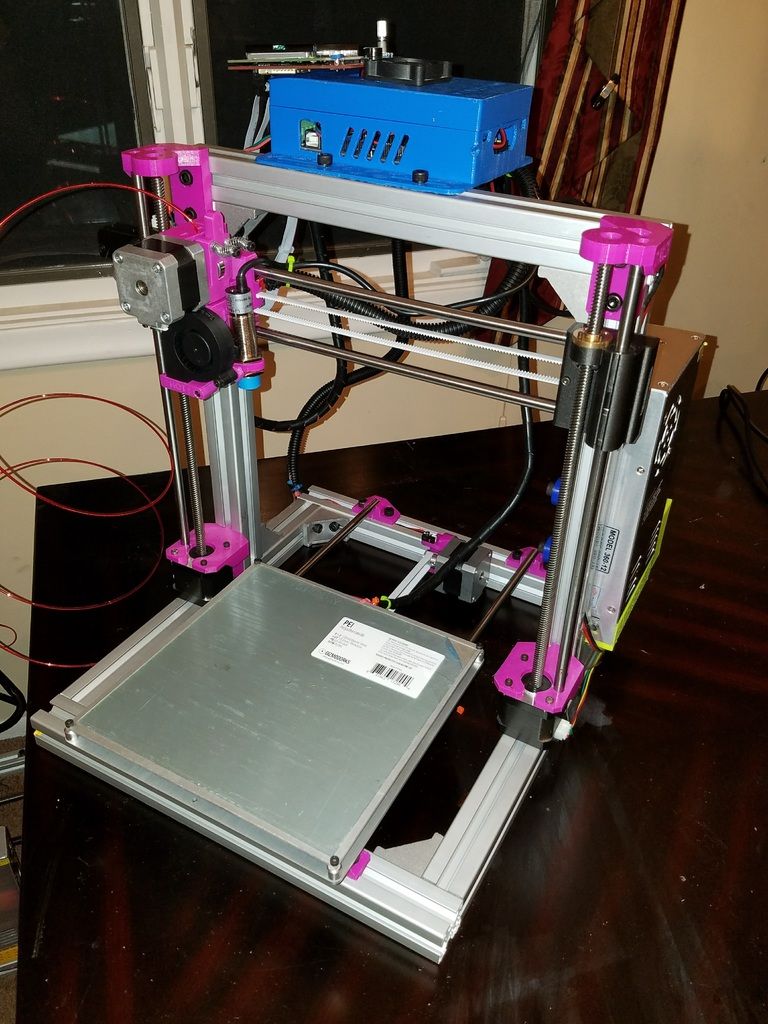

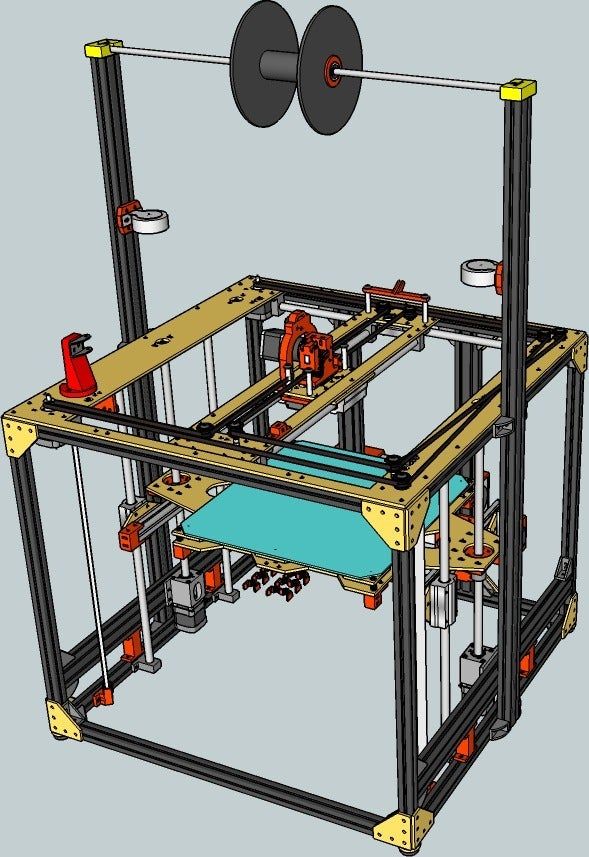

Source: https://www.pinterest.com/

The frame is the outer casing that houses the entire contraption, and it can be made to any size depending on what you need. The materials used to make the frame also vary, and the decision comes down to personal preference. The most compliant used materials are aluminum, acrylic, or hardened plastic. You have to make sure that all the parts fit well and there are no loose parts. It is important that the frame is solid because it will be providing support to the other parts that are added.

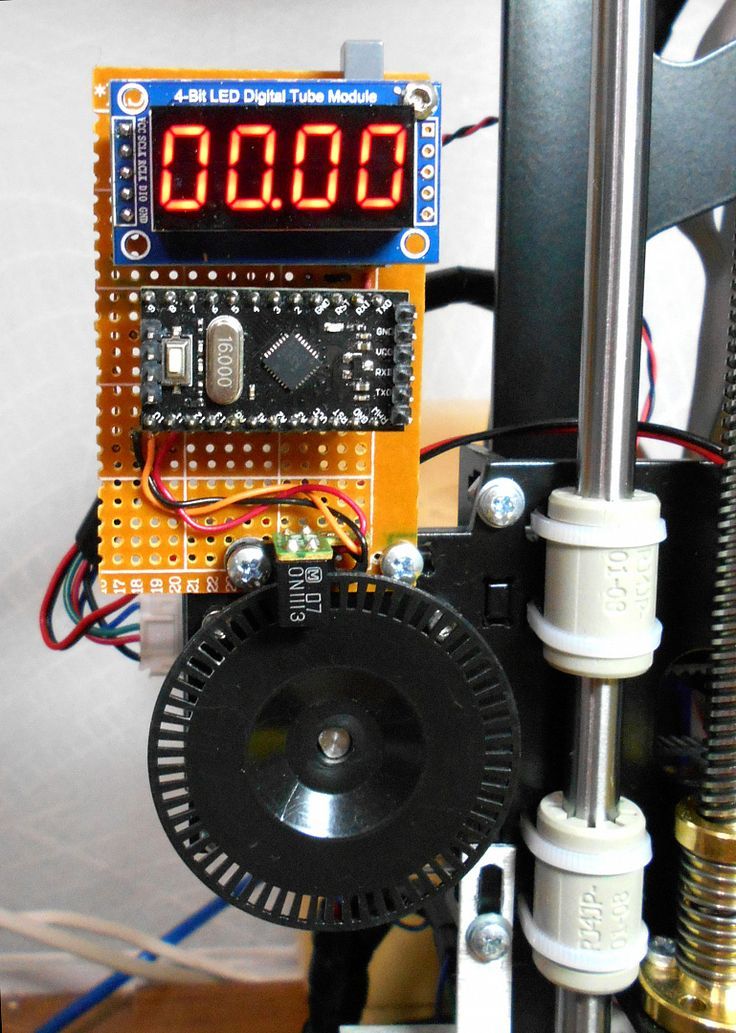

Step 2: The Display

Source: https://www.pinterest.com/

An LCD display is important as it relays the information you need to know about the printing process in the absence of a computer connection. You need an aluminum sheet for this process with some holes and screws, and nuts. You have to cut out space into the aluminum sheet through which the display screen will pop out of. Once you have all that art covered, connect the necessary display cables from the inside leading out, waiting for the main part of the printer to be installed.

You need an aluminum sheet for this process with some holes and screws, and nuts. You have to cut out space into the aluminum sheet through which the display screen will pop out of. Once you have all that art covered, connect the necessary display cables from the inside leading out, waiting for the main part of the printer to be installed.

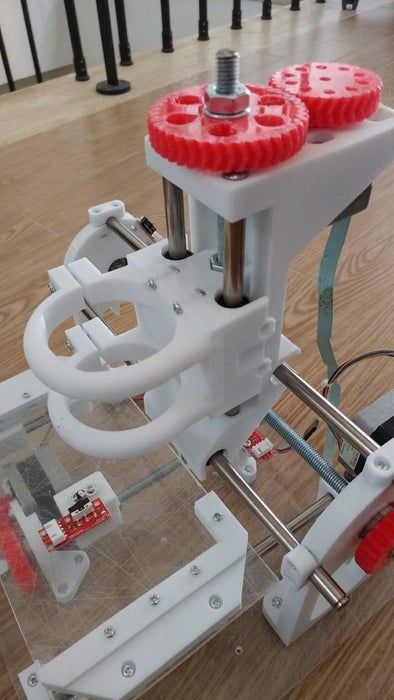

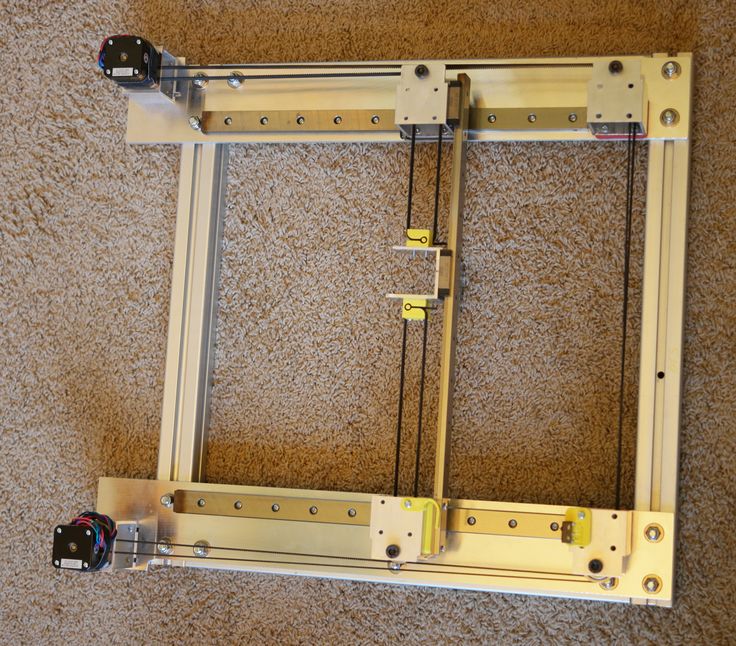

Step 3: Preparing the Y-axis and Z-axis

Source: https://www.pinterest.com/

You need an MDF base that houses a cooling fan to reduce the heat produced by the stepper motor. These are done by adding two wooden cuttings for the X-axis placement. This is followed by making the Y-axis placement that’s supposed to be at 90 degrees from the X-axis. Hold them in place using glue, or you can simply use some screws.

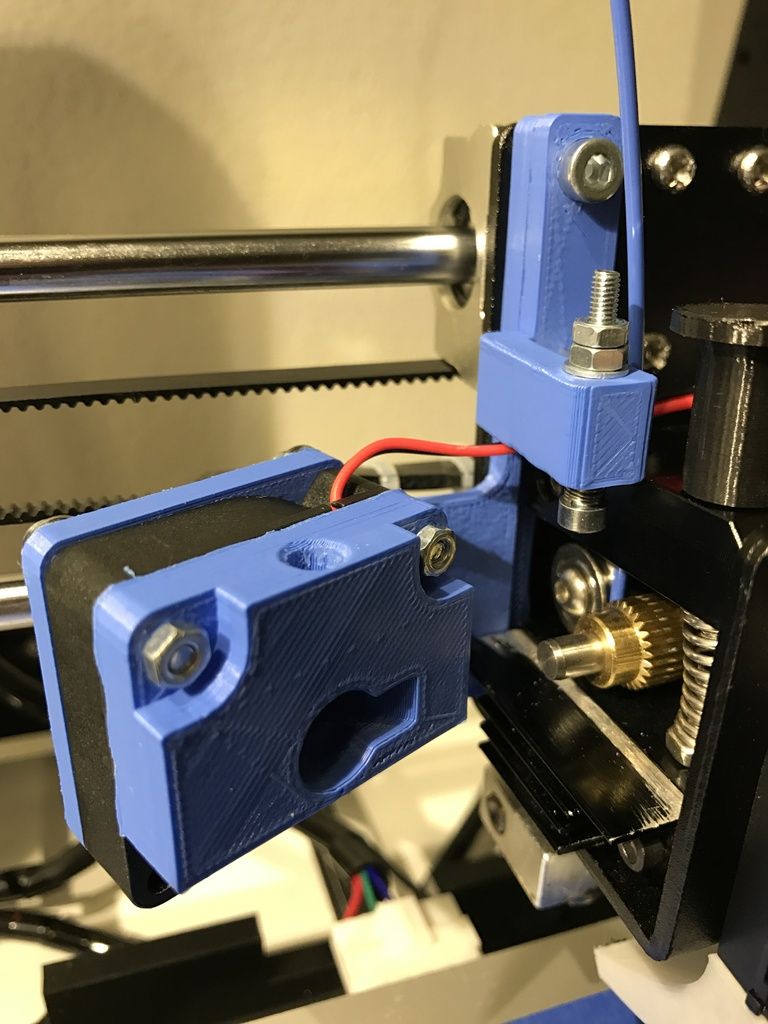

You have to add a stepper motor to the X-axis using two pieces of sliders of any length that can fit within the structure. Once the slide is screwed in place, fit your wooden mount for the hot-end, the cooling fan, and the PTFE tube. With these two in place, your 3D printer is starting to take shape.

With these two in place, your 3D printer is starting to take shape.

Step 4: Preparing the Bed

Source: https://www.pinterest.com/

The bed is one of the most important parts of the entire machine. It is the part that provides the platform upon which the model being printed is made. It can be made out of glass or an acrylic sheet held down by screws. You can have the base supported by another solid material. Once all that is done, place the bed on the Y-axis, and it is ready to start rolling.

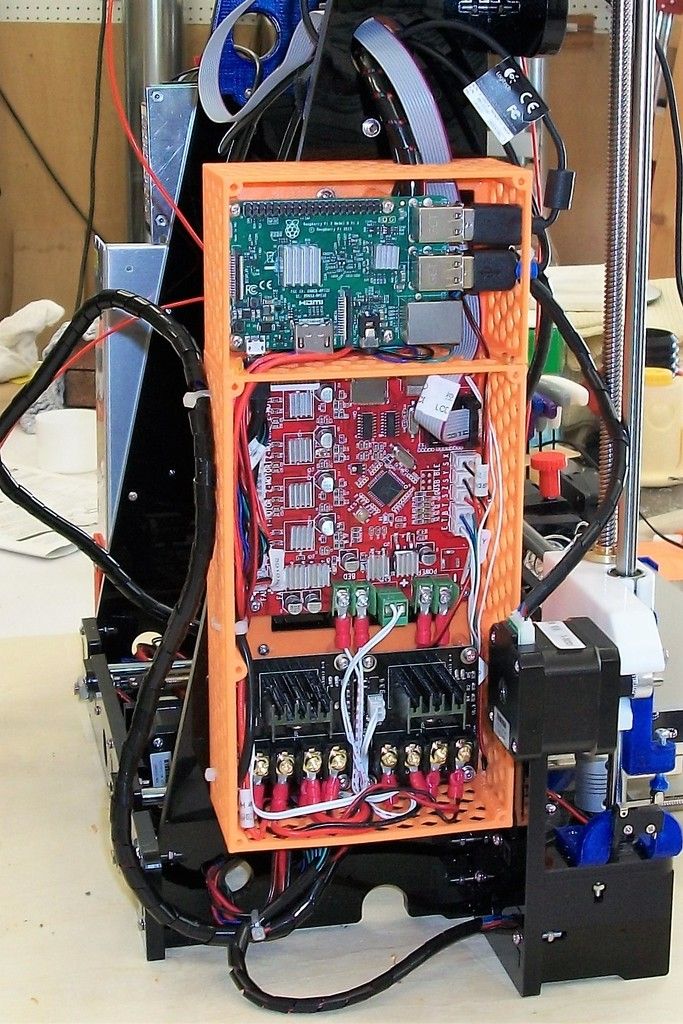

Step 5: Make the Connections

Source: https://www.pinterest.com/

The next part involves making the wiring connections of all the components that you have already laid down. All the electrical components like the ramps. The drivers and the power supply have to be linked properly for them to run as designed. To avoid entangling the wires, make sure you deal with one connection at a time, ensuring that they don’t cross each other unless there’s no other way around it.

Step 6: Make Alignments

The bed you created earlier has to align with everything else, or you may experience a lot of trouble getting the models right. Start by aligning your bed, rotating it clockwise and counterclockwise until you create some space between the hot-end tip and the bed. The margin of error should be between 0.5mm to 1mm. Anything larger than that will have the printing guy misfiring.

Step 7: Programming

Source: https://www.simplify3d.com/

With all the hardware installed and the electrical wiring and cabling in place. It is time to install the brain of the whole operation. Programming the 3D printer doesn’t require you to code from scratch. The software simply needs to be installed on the computer connected to the machine. This should not take too much of your time.

This should not take too much of your time.

Step 8: Run the Machine

Once the 3D Printer program is installed and the components are set, it is time to run the machine for the first time to finger out if it is working as designed or whether it needs some more tinkling. The number of software that you can use to model your objects is many; you are free to choose the one that works best for you and switch the machine on for the first test run. Make sure the fan is working to deal with the heat.

Building Your Own 3D Printer. Is It Worth It or Not?

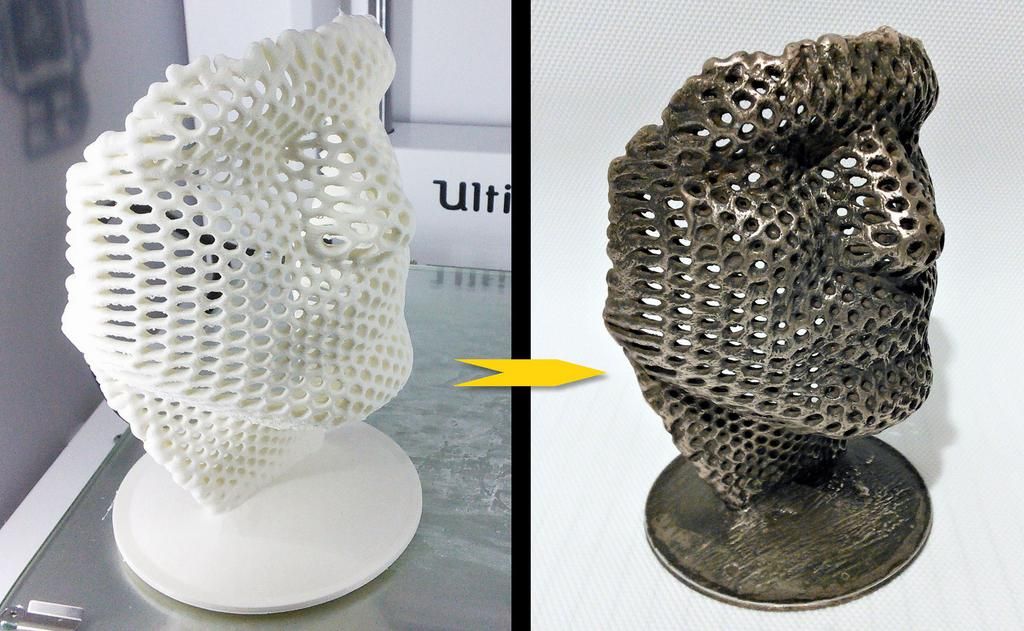

Source: https://www.pinterest.com/

Having established that making your own printer is possible, and having seen the process and what it takes to attain success, the question now is, is it worth the trouble? High-quality 3D printers cost less than $400 these days, and as much as making your own brings pride and cuts costs significantly, how do DIY 3D printers hold against professionally manufactured ones? To better get to the answer, the following are the pros and cons of DIY 3D Printers.

Pros

- DIY Kits are cheap and easy to access. For as little as $25, you can have a full package that can help you set up your own printer.

- DIY projects will make you understand 3D printing more, adding to your experience on the subject, which increases your level of knowledge and chances of success if you ever think of getting fully immersed into the industry.

- It is fast if you know what you are doing and you have all the materials you need in one place.

- There’s a huge online community of DIY 3D printer enthusiasts, and these platforms provide resources that help people learn more about 3D printing.

- The kits come with instruction manuals that anyone can follow and hack the construction. They are very easy to use.

Cons

- You still need some basic knowledge of assembling electronic parts in the right way to be able to put 3D printers together. You can’t wake up one morning and decide to make it because you feel like it.

- They are not as high quality as those that have been manufactured by proper 3D makers. The parts found in DIY printers are too rough and rudimentary for the machine to produce superior products.

- There are very many things you may miss along the way, and this can end up frustrating you later on as that will force you to retrace your steps backward until you find the source of the malfunction. That will waste a lot of your time.

- You will always need to buy more parts the furthest along you go. There’s also the disadvantage of the parts falling apart since they're not well optimized for such an intense process. You will need replacements much faster.

- There are limitations when it comes to software configurations and upgrades since the hardware is not optimized for the software you may choose to go with. You may end up using the same software for years, and that will limit the things the printer can pull off.

Roughly, you may end spending between $100-$200 making your own DIY 3D printer. That cost may be cheaper than the standard prices for a professionally made printer, but when you weigh the strengths and weaknesses of each, the DIY is at a disadvantage. Therefore, on the question of whether to go for a DIY 3D printer or simply buy a good one, the answer comes down to what you plan to do. If the thrill of making your own is what is important, then take the DIY route. But if you want to get some professional work done, then you are better off adding that extra $200 and getting a proper 3D primer with accessories and software updates.

That cost may be cheaper than the standard prices for a professionally made printer, but when you weigh the strengths and weaknesses of each, the DIY is at a disadvantage. Therefore, on the question of whether to go for a DIY 3D printer or simply buy a good one, the answer comes down to what you plan to do. If the thrill of making your own is what is important, then take the DIY route. But if you want to get some professional work done, then you are better off adding that extra $200 and getting a proper 3D primer with accessories and software updates.

There are some things you have to pay attention to when going the DIY route, factors that will determine the success or the failure of your project. Some of them include the following.

- The size of the printer you intend to make

- The printer type (Cartesian vs. Delta)

- Extrusion type

- The cost

- Availability of liquid polymers

- Software compatibility.

Before you embark on setting anything up, you have to first determine whether all the conditions mentioned above are met; only then will you get anything done by coming up with a good plan.

Conclusion

DIY 3D Printers are effective if they are made in the right way, and there are many methods of creating them. Finding a good Arduino kit could be the difference between having a 3D printer that world and one that keeps breaking midway. Ensure you do some background research before having to gain more knowledge before committing yourself to an ambitious project like this one.

For more information on how 3D printers work, the accessories they need to function properly, and the current trends in the industry, check out our website, and you will have access to a huge pool of resources and expert advice.

How can I program a 3D printer to move using Arduino?

Ask Question

Asked

Modified 4 years, 8 months ago

Viewed 8k times

$\begingroup$

I search about that topic, but all what I found, was the mechanical part of the 3d printer. But I didn't find, how to program it using arduino.

But I didn't find, how to program it using arduino.

I want to make a cartesian 3d printer. I don't have a printer yet, but I will buy all the components that I need actually.

I know, how to control stepper motors, but I don't know, how I can program it in order to make the shape that I want.

This is my question: what I need to learn in order to let this 3d printer make this shapes?

- arduino-mega-2650

- diy-3d-printer

$\endgroup$

6

$\begingroup$

Yes. Look up Arduino Ramps 1.4

http://reprap.org/wiki/RAMPS_1.4

Following the programing is all done for you in the firmware. That said you can edit it. Just open the firmware files -- it is compiled when you upload them. Generally however one usually sticks to the preferences header alone..

http://reprap.org/wiki/List_of_Firmware

Over all you are trying to reinvent the wheel. When I started 5-6 years ago it was barely a thing. Now you buy a proven kit and get to the printing. That said if you are truly interested in designing check out.

https://www.facebook.com/groups/cncbuilddesign/

If you want help on picking a kit. Or what I really think you are looking for. A good place to start. This is one of the larger 3d printing groups. Full disclosure I run this one, but at 6k members I don't recruit.

https://www.facebook.com/groups/3DPrinterHobbyists/

I got my start in reprap IRC

http://reprap.org/wiki/IRC

Be aware there are trolls that now camp the IRC looking to sell you a printer. I would not engage with them, their printers are usually overpriced and sub par.

Best of luck.

Most of all I think you need to know it's Reprap all the way. Reprap forums, Reprap printers, Reprap kits, Reprap community. All the commercial printers started off the reprap project. Even if you buy a makerbot (don't) it's Reprap in it's roots.

Even if you buy a makerbot (don't) it's Reprap in it's roots.

https://vimeo.com/5202148

$\endgroup$

$\begingroup$

While Star Wind's answer is best as far as addressing what was not asked, but was probably the intent of the question, for educational purposes:

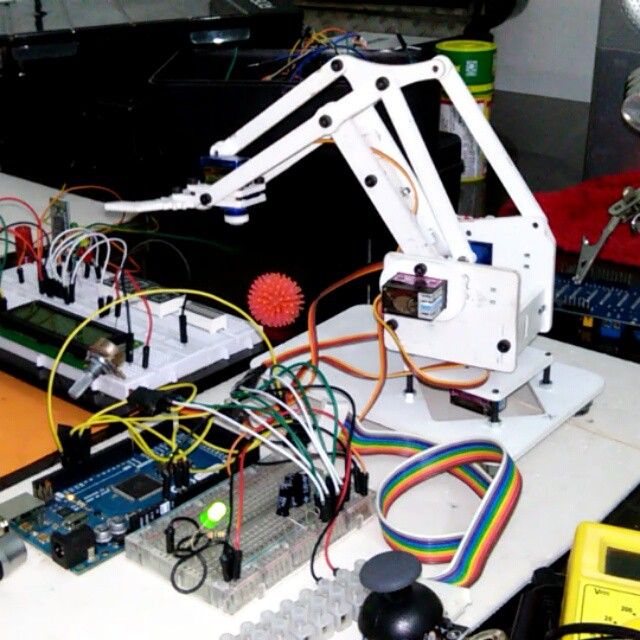

To control the printer you need an microcontroller (most popular are Arduino) which will interface with the motor drivers. Microcontrollers cannot output the current needed to control the motors, so motor drivers (such as this https://www.pololu.com/product/1182 ) are easy ways to control a stepper motor with higher current (and usually voltage). You can build your own if you are particularlly adventurous, they are essentially two H-bridge circuits.

The Arduino programming environment has a library for controlling stepper motors through a driver built in, you just tell it which pin to send the pulses to, and how fast, and a separate pin tells it to spin clockwise or counterclockwise.

For a 3D printer you need at least four motors working in unison, one for the X, Y, Z axis, and one for the extruder (E axis).

The existing programs that 3D printers use (Marlin, Sprinter, Teacup, etc) are all doing these simple steps at their core, but have implemented libraries of G-code that the printer uses to make control the stepper motors in unison to make the correct shape. Slicing programs such as Cura or Slic3r take in the 3D model and output the Gcode that the microcontroller is programmed to understand.

$\endgroup$

1

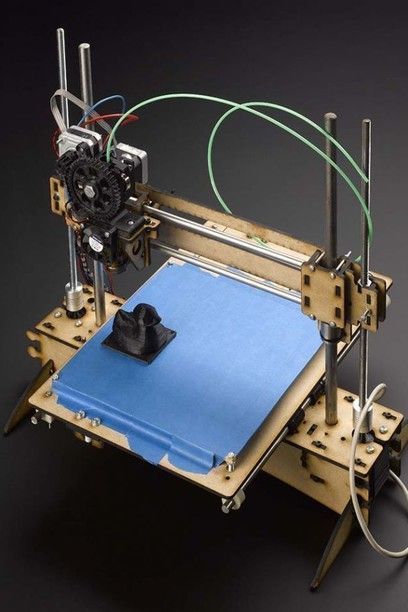

Cheap Arduino 3D Printer||Arduino-diy.com

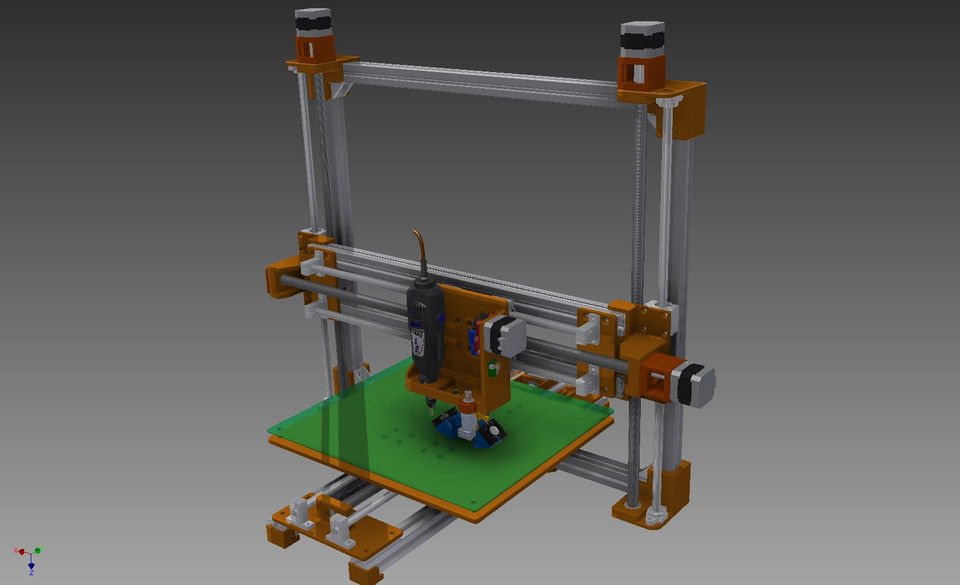

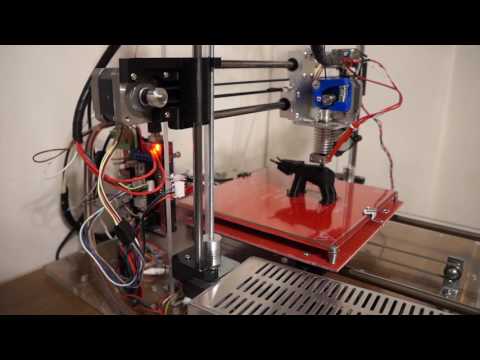

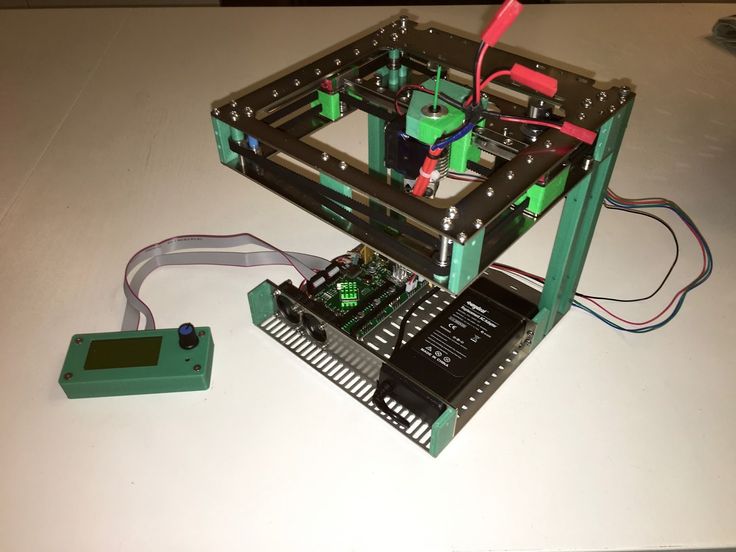

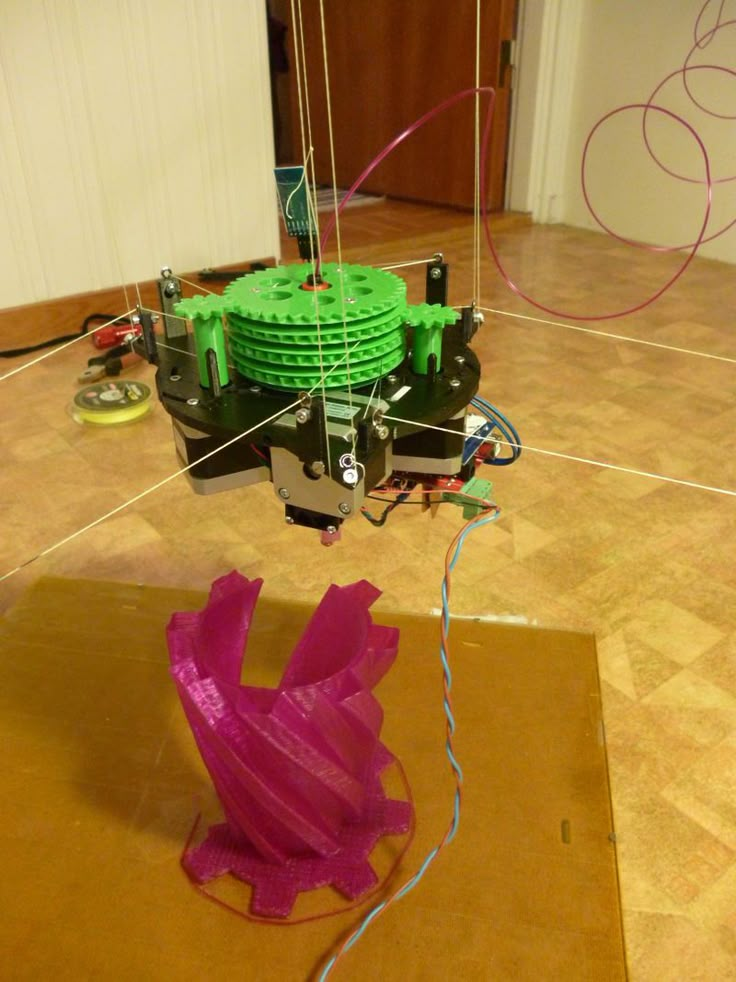

This article describes the construction of a 3D printer that costs around $60-70 (probably the cheapest concept in the world).

This 3D printer works with the cheapest motors on the market - 28Byj-48, Electronics - Ramps 1.4 controlled by Arduino.

The author of the project is a 16-year-old guy from Germany.

3D printer specifications:

Working space: 10x10x10 cm;

Speed: 20 mm/s;

Resolution (accuracy): 0.2 mm.

P.S. Under each section, in accordance with the table of contents of the article, photos are posted as a visual instruction

Mechanical part

MDF boards:

-1x 30x34 cm (Base).

-2x 6x4 cm.

-1x 34x6 cm.

-1x 15x4 cm.

- 2 GT2 pulleys + 1 m GT2 timing belt.

-10 bearings 624.

-1 pulley Mk8 for drive.

-1 PTFE tube.

Smooth rods for guides with a diameter of 8 mm:

- 2, 22 cm long.

- 4 x 17.5 cm long.

Local hardware store:

- 1 shaft with M5 thread, which you will cut into 2 pieces.

-2 M5 hex nuts.

- 8 screws M3x16 mm.

-6 screws M3x 25 mm.

-4 screws x M4x45 mm.

-2 screws M4x60 mm.

-4 screws M4x20 mm.

-20 M4 hex nuts.

-10 M3 hex nuts.

-12 small screws.

Electronics

-1 Arduino Mega 2560 board + Ramps 1.4 + 4 A4988 stepper motor drivers.

-4 stepper motors 28byj-48.

-3 optical limit switches.

-1 Nema 17 stepper motor (we also order from Ali or Ebay. Such drives cost about 10 dollars).

Extruder tip:

-1 E3D-V5 Aliexpress extruder

or more expensive but with cooling

-1 E3D-V6 Aliexpress extruder.

Knots to be printed on a 3D printer

Download the latest versions of 3D models of units to be printed from the link: Thingiverse

.

2 "Z-Motor" parts

2 "Y-End" parts

2 "X-End" parts

1 "X-Carriage" part

1 "Motor" part

1 "Hotend" part

1 piece "Hotend Clamp"

Download mechanism for extruder here: Thingiverse.

28BYJ-48 Stepper Motor Modification

In order to convert the 28BYJ-48 stepper motor from unipolar to bipolar, you need to open the plastic cover.

Then remove the red cable and open the contact track from it as shown in the figure.

Now at the other end is the output that you will connect to the Ramps, arrange the pins as follows:

blue--yellow--orange--pink

With this little modification, you can connect these motors directly to the pins provided on the Arduino Ramps 1.4 shield

Y Axis

First you need to glue two wooden boards together.

Then place the printed parts "Motor", "Z-Motor" on the wooden boards.

Then fix the printed parts with the screws.

Next step: fit the motors into the slots and then the LM8UU bearings.

Install the pulley on the motor and the 624zz bearings next to it.

Use plastic ties to secure LM8UU bearings.

Next - install two guide rails 17.5 cm long with a diameter of 8 mm.

Finally, pull the belt through the "Y-ends" and install the limit switch.

X-Axis

For X-Axis you need:

Install two M4x45mm bolts in the "X-End".

Connect the motor as shown in the illustrations.

Tension the belt and install the limit switch.

Mount the extruder with two screws M3x25 and tighten with nuts.

Z Axis

In order to assemble the Z axis, you need:

Install LM8UU bearings in "X-Carriage" + "X-Ends".

Post install "X-Ends" + "X-carriage" on rails 17.5 cm (X-Axis) and 21cm (Z-Axis).

After that it is necessary to connect the threaded shaft with the motor

Printing table

We drill four holes with a diameter of 3 mm in a wooden plate 20x13 cm.

After that we tighten 4 bolts M3x25.

We assemble the entire 3D printer

We assemble it in accordance with the figures below. There is no point in giving additional explanations. The main thing is that the previous steps are correctly implemented. In this case, there should be no problems.

We connect electronics to the 3D printer

We connect electronics (including Arduino) in accordance with the figure below.

Software for Arduino

You can download the Arduino IDE configuration file from www.repetier.com.

This should be enough. You can carry out direct adjustment for your received design, dimensions, etc.

Photo of the printing process and results

After some calibration, good cube samples were printed with dimensions of 1x1x1 cm. As a result, there is a significant displacement of the layers.

So I recommend setting the A4988 to 1/16 microstepping and adjusting the current to the minimum value.

You can also play around with the Arduino firmware to get better results.

Leave your comments, questions and share your personal experience below. In the discussion, new ideas and projects are often born!

Top 20 Free 3D Printing and 3D Printing Software

Looking for a 3D printing software? We've rounded up the top 20 software tools for beginners and professionals alike. Most slicers are free.

What is a slicer? This is a program for preparing a digital model for printing. Models for 3D printing are usually distributed in STL files. To turn an STL file into G-code (a language that a 3D printer understands), a slicer program is required. It is called a slicer because it cuts (to slice - English) a 3D model into many flat two-dimensional layers, from which a 3D printer will add a physical object.

Which slicer should I choose? In this article, we will tell you which slicer is best for 3D printing for each stage of your work. Which one is better for preparing a 3D model for printing? But what if you need to create a 3D model from scratch? And if you are only taking the first steps in 3D?

Don't be afraid, we've answered all of these questions, including the required skill level for each program and where you can download it. The great thing is that most of these programs are completely free and open source.

- Cura

- CraftWare

- 123D Catch

- 3D Slash

- TinkerCAD

- 3DTin

- Sculptris

- ViewSTL

- Netfabb Basic

- Repetier

- FreeCAD

- SketchUp

- 3D Tool

- Meshfix

- Simplify3D

- Slic3r

- Blender

- MeshLab

- Meshmixer

- OctoPrint

#1: Cura

For beginners who need a slicer to prepare STL files for 3D printing

Cura is the default slicer software for all Ultimaker 3D printers, but can be used with most others , including RepRap, Makerbot, Printrbot, Lulzbot and Witbox. The program is completely open source, its capabilities can be extended using plugins.

The program is completely open source, its capabilities can be extended using plugins.

This program is very easy to use and allows you to manage the most important 3D printing settings through a clear interface. Start in Basic mode to quickly get up to speed and change print quality settings. If finer control is required, switch to Expert mode.

Cura can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: Cura

Price: Free

Systems: PC, Mac, Linux

#2: CraftWare

For beginners to prepare STL files for 3D printing its crowdfunding device CraftBot. However, the program works with other printers.

Like Cura, CraftWare allows you to switch from "Easy" to "Expert" mode, depending on how confident you feel. It's a colorful app that features a visual G-code visualization with each function represented by a different color. But the most outstanding feature is the individual support service. As far as we know, only the paid program Simplify3D has this.

As far as we know, only the paid program Simplify3D has this.

Please note, however, that this program is still in beta, so bugs may occur.

Download: CraftWare

Price: Free

Systems: PC, Mac

#3: 123D Catch

-systems, smartphones and tablets, which allows you to convert images of objects into a 3D model. Pictures can be taken with a smartphone/tablet or digital camera.

You need a lot of photos of the object from different angles - the more the better - after which a 3D model will be compiled from them.

123D Catch is more of a fun app than a professional 3D printing tool, but after some tambourine dancing, you can get good results, especially when paired with an STL editor like MeshLab or Meshmixer.

Price: Free

Systems: PC, Android, iOS, Windows Phone

#4: 3D Slash

For beginners who want to create 3D printable models

This is a 3D printing program that is both amazingly simple and refreshingly new. With 3D Slash, you can design 3D models using your dice skills.

With 3D Slash, you can design 3D models using your dice skills.

You can start with a large block and, like a virtual sculptor, remove small cups from it with tools such as a hammer or drill, or start from empty space and build a model out of cubes and other shapes. You can paint with flowers or use template pictures.

Other features worth mentioning are tools for creating logos and 3D text. The Logo Wizard imports an image and creates a 3D model, while the Text Wizard allows you to enter and format text, and then turn it into 3D.

Recommended!

Download: 3dslash.net

Price: Free

Systems: PC, Mac, Linux, Browser

#5: TinkerCAD

For beginners who want to create printable 3D models

TinkerCAD is an online 3D printing computer-aided design (CAD) system that is a good starting point for beginners. Since its capabilities are limited compared to Blender, FreeCAD and SketchUp, many users switch to more powerful tools after some time.

As in 3D Slash, here you can build models from basic shapes. At the same time, unlike 3D Slash, TinkerCAD allows you to create vector shapes in 2D and convert them into three-dimensional models.

Come in: Autodesk TinkerCAD

Price: Free

Systems: Browser

#6: 3DTin

For beginners who want to create 3D printable models

is a great online intuitive tool 3DTin choice for beginners in 3D modeling. All you need is a Chrome or Firefox browser with WebGL enabled.

Choose from a huge library of 3D shapes and add them to your sketch. All sketches are stored in the cloud, access to them is free if you honor the Creative Commons license. Everything can be exported to STL or OBJ formats.

Enter: 3DTin

Price: Free

Systems: Browser

#7: Sculptris

For beginners who want to create 3D printable models

clay. This is a fantastic 3D modeling program if figurines are your main task. For example, you can make a bust of your favorite video game or comic book character. Sculptris is completely free and bills itself as a stepping stone to the more complex (and expensive) ZBrush tool.

For example, you can make a bust of your favorite video game or comic book character. Sculptris is completely free and bills itself as a stepping stone to the more complex (and expensive) ZBrush tool.

Download: Pixologic Sculptris

Price: Free

Systems: PC, Mac

#8: ViewSTL

For beginners who want to view STL files

ViewSTL is the easiest way to view STL files . Simply open a web page and drag the STL onto the dotted box.

The STL online viewer allows you to display the model in one of three views: flat shading (for a quick view), smooth shading (for a high-quality image), and wireframe.

Enter: ViewSTL

Price: Free

Systems: Browser

#9: Netfabb Basic

some nice features that allow you to analyze, "repair" and edit STL files before moving on to the model cutting stage.

A good choice if you need more than just a slicer and want to be able to quickly fix STL files without having to learn programs like MeshLab or Meshmixer.

Don't let the 'Basic' in the name fool you, Netfabb Basic is actually a very powerful 3D printing tool. It's "basic" only in the sense that it doesn't cost €1,500 like Netfabb Professional!

Download: netfabb.de

Price: Free

Systems: PC, Mac, Linux

No. 10: Repetier

For advanced to prepare STL files for 3D printing

9002 the next level of 3D printer slicer software, but if you want to stay open source, you should look into Repetier. It is the great grandfather of 3D printing software and a favorite of the RepRap community.Today the program is moving by leaps and bounds from the level for beginners to advanced users. Packaged in an all-in-one configuration, it supports up to 16 extruders, multi-slicing via plug-ins, and virtually every fusing 3D printer on the market. Get ready to tinker!

What's more, Repetier Host works remotely via Repetier Server, so that the 3D printer can be controlled via a browser, tablet or smartphone.

Download: Repetier

Price: Free

Systems: PC, Mac, Linux

#11: FreeCAD

The program is a great option for developing your design skills. More technically, this parametric 3D modeling program allows you to easily change the project by rolling back through the history of the model and editing the parameters.

Download: freecadweb.org

Price: Free

Systems: PC, Mac, Linux

#12: SketchUp

For beginners who want to create 3D printable models

SketchUp functionality, with a user-friendly interface and a relatively flat learning curve (i.e., as experience grows with the time spent), the ideal program for developing three-dimensional models.

The Make SketchUp version is free and will have everything you need for 3D modeling if you also download and install the free STL exporter. There is also a professional edition for architects, interior designers and engineers.

Download: sketchup. com

com

Price: Free (SketchUp Make), $695 (SketchUp Pro)

Systems: PC, Mac, Linux

#13: 3D-Tool Free Viewer

view and check STL files

3D-Tool Free Viewer is a sophisticated tool that, among other things, allows you to check the structural integrity and printability of your file. With the Cross-Section function, for example, you can look at the model from the inside and check the wall thickness. Very useful if you want to check your STL file for killer errors before printing.

Download: 3D-Tool

Price: Free

Systems: PC

#14: Meshfix

your model for errors.

Price: Free

Systems: Browser

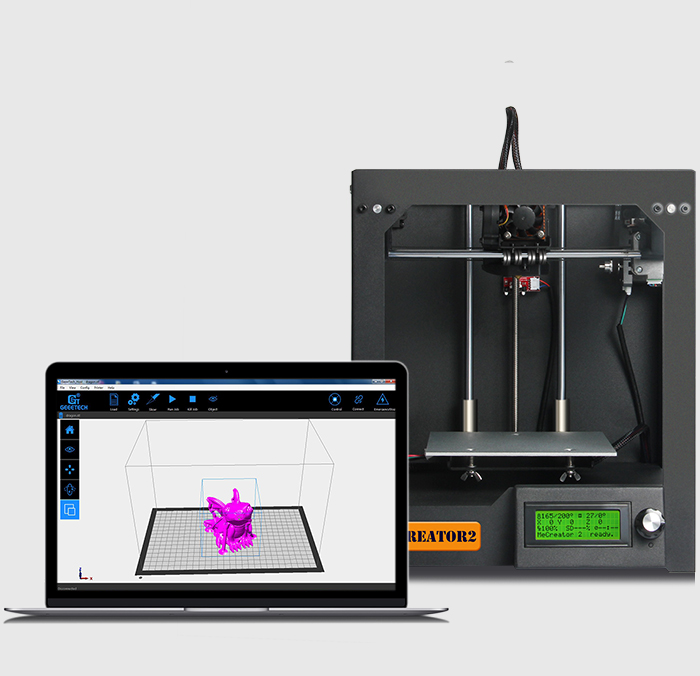

#15: Simplify3D

For professionals to prepare STL files for 3D printing print. A flexible algorithm checks the model for problems, fixes them, shows a preview of the printing process (ideal for identifying potential problems), and then slices it.

This slicer offers the best infill pattern options in the competition. For models that require supports, Simplify3D will create the appropriate structures on its own and give you full control over their placement. For printers with a dual extruder, when printing with different materials, the Dual Extrusion wizard will help, as a result of which, for example, it will be easier to remove the dissolving filament.

For models that require supports, Simplify3D will create the appropriate structures on its own and give you full control over their placement. For printers with a dual extruder, when printing with different materials, the Dual Extrusion wizard will help, as a result of which, for example, it will be easier to remove the dissolving filament.

Simplify3D supports 90% of today's commercially available desktop 3D printers and is compatible with Marlin, Sprinter, Repetier, XYZprinting, FlashForge, Sailfish and MakerBot firmware. Simplify3D can also be used to directly control the printer, but then the printer and computer must be connected to each other.

Download: simplify3d.com

Price: $149

Systems: PC, Mac, Linux

#16: Slic3r

source code, which has a reputation as a carrier of super new functionality, which you will not find anywhere else. The current version of the program is able to show the model from multiple angles, so that the user gets a better preview experience.

There's also an incredible 3D honeycomb infill, the first of its kind that can extend over multiple layers rather than repeating itself like a stamp. This significantly increases the strength of the internal filling of the model and the final printout.

Another option is direct integration with Octoprint. Once the files on the user's desktop are sliced, they can be directly uploaded to Octoprint with one click.

Download: Slic3r

Price: Free

Systems: PC, Mac, Linux

#17: Blender

For professionals who want to create 3D printable models

Blender is a popular computer-aided design (CAD) system with a steep learning curve. Not at all the best choice for beginners, but what you need if you are quite experienced and need something more complex for modeling and printing.

In short, Blender is one of the most powerful tools in existence. Its community is always ready to help, there are a lot of educational materials. It's also open source, so enthusiasts often write extensions to make it even better and more powerful.

It's also open source, so enthusiasts often write extensions to make it even better and more powerful.

Download: blender.org

Price: Free

Systems: PC, Mac, Linux

#18: MeshLab

For professionals to prepare STL files for 3D printing

MeshLab - advanced editor. It allows you to remove parts of a 3D model, merge two models into one, patch holes. If you need a program to modify models for 3D printing or some kind of "repair" work, MeshLab is the right choice.

Price: Free

Systems: PC, Mac, Linux

#19: Meshmixer

For professionals to prepare STL files for 3D printing files. It's especially good for identifying potential problems and fixing them automatically. For example, it will show paper-thin walls that can lead to problems with 3D printing. Meshmixer is part of the Autodesk family of 3D printer software, so it should work well with tools like TinkerCAD.

Price: Free

Systems: PC, Mac

#20: OctoPrint

start, pause or interrupt 3D print jobs.