Exone 3d printer

X-Series | Desktop Metal

Team DM

Platforms

Metal and composites 3D printing 3D printing solutions for health care Industrial-grade polymer 3D printing™

Sand and tooling 3D printing solutions 3D printers for sheet metalMaterials

Breakthrough photopolymer development Advancing 3D printed upcycled woodApps & More

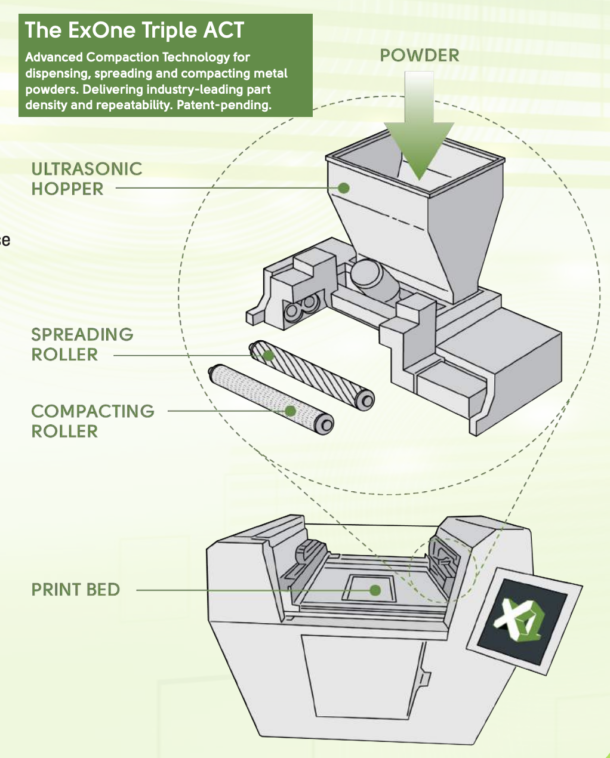

The hydraulic additive manufacturing experts Multi-material powder recoating technology Driving digital transformation in dentistryBinder jet 3D printing featuring patented Triple ACT for excellent surface quality and specialty materials, including both metals and ceramics.

Order Now Your browser does not support the video tag.Systems Overview

-

— 01

InnoventX

The most compact binder jet 3D printer for the production of metal, ceramic or composite parts.

Launched in 2018, this easy-to-use system features Triple ACT and a piezoelectric printhead. It’s suitable for education, research, prototyping, rapid product development, and short-run production of small components.

InnoventX

InnoventX

The most compact binder jet 3D printer for the production of metal, ceramic or composite parts. Launched in 2018, this easy-to-use system features Triple ACT and a piezoelectric printhead. It’s suitable for education, research, prototyping, rapid product development, and short-run production of small components.

[SPECS]

Download Spec SheetInnoventX

Print Technology

Triple Advanced Compaction Technology™

Print direction

Uni-directional

Build box size

160 x 65 x 65 mm (6.

3 x 2.5 x 2.5 in)

3 x 2.5 x 2.5 in)Max build rate (65μm layer thickness)

54 cc/hr

Binder Systems

AquaFuse™, CleanFuse™, FluidFuse™, PhenolFuse™

External dimensions

1203 x 1016 x 1434 mm (47.4 x 40.0 x 56.5 in)

-

— 02

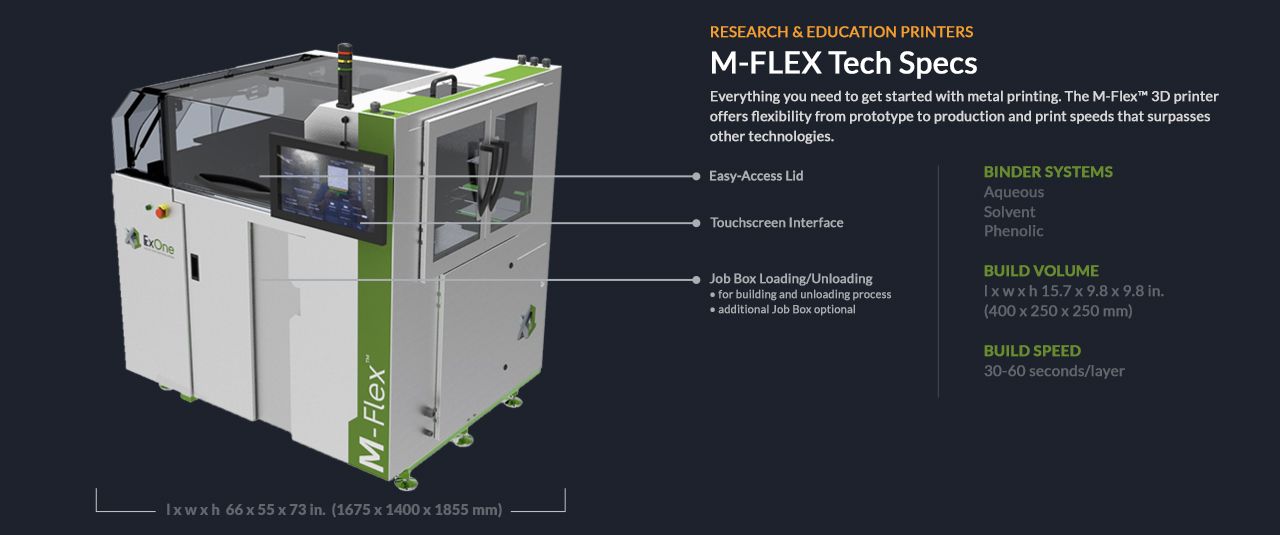

X25Pro

This mid-volume advanced binder jet 3D print system is already being used globally for the production of metal, ceramic and composite parts.

Launched in 2020, this system features Triple ACT and a piezoelectric printhead. It’s suitable for research, prototyping, rapid product development, short-run production or continuous 24/7 production.

Launched in 2020, this system features Triple ACT and a piezoelectric printhead. It’s suitable for research, prototyping, rapid product development, short-run production or continuous 24/7 production.X25Pro

X25Pro

This mid-volume advanced binder jet 3D print system is already being used globally for the production of metal, ceramic and composite parts. Launched in 2020, this system features Triple ACT and a piezoelectric printhead. It’s suitable for research, prototyping, rapid product development, short-run production or continuous 24/7 production.

[SPECS]

Download Spec SheetX25Pro

Print Technology

Triple Advanced Compaction Technology™

Print direction

Uni-directional

Build box size

400 x 250 x 250 mm (15.

75 x 9.84 x 9.84 in)

75 x 9.84 x 9.84 in)Max build rate (65μm layer thickness)

1,200 cc/hr

Binder Systems

AquaFuse™, CleanFuse™, FluidFuse™, PhenolFuse™,

External dimensions

2300 x 1800 x 2300 mm (90.5 x 70.9 x 90.5 in)

-

— 03

X160Pro

The world’s largest binder jet 3D printer for the production of metal, ceramic or composite parts.

This system features Triple ACT and a piezoelectric printhead. It's designed for continuous 24/7 production, yet supports short-run production, rapid product development, and even research and prototyping

This system features Triple ACT and a piezoelectric printhead. It's designed for continuous 24/7 production, yet supports short-run production, rapid product development, and even research and prototypingX160Pro

X160Pro

The world’s largest binder jet 3D printer for the production of metal, ceramic or composite parts. This system features Triple ACT and a piezoelectric printhead. It's designed for continuous 24/7 production, yet supports short-run production, rapid product development, and even research and prototyping

[SPECS]

Download Spec SheetX160Pro

Print Technology

Triple Advanced Compaction Technology™

Print direction

Uni-directional

Build box size

800 x 500 x 400 mm (31.

5 x 19.7 x 15.8 in)

5 x 19.7 x 15.8 in)Max build rate (65μm layer thickness)

Up to 3,120 cc/hr

Binder Systems

AquaFuse™, CleanFuse™, FluidFuse™, PhenolFuse™,

External dimensions

3300 x 3300 x 2700 mm (130 x 130 x 107 in)

Applications by Industry

_Industries

Explore applications for 3D printing across a range of industries.

Keep Up with the Latest News

ExOne announces first InnoventPro 3D printer orders, new X1 Powder Grip device, and Desktop Metal acquisition approval

0Shares

ExOne, a manufacturer of binder jet 3D printers, has announced a whole slew of developments regarding its 3D printing business.

Firstly, ExOne has announced the first set of orders for the firm’s new InnoventPro 3L metal 3D printer. Among the inaugural orders, Neoshapes, a Geneva-based jewelry startup, will use the InnoventPro 3L to 3D print luxury goods using precious metals such as gold, platinum, and silver. Global tech firm Siemens was also one of the first customers to purchase the printer.

The company has also announced the launch of its new X1 Powder Grip, a two-liter powder container designed to enable ultra-fine MIM powder management on the InnoventPro system.

Finally, the firm’s stockholders have voted to approve ExOne’s acquisition by Desktop Metal, a rival OEM of binder jet 3D printing systems. The deal is expected to close by the end of the week, subject to customary closing conditions, and the final voting results will be filed with the U.S. Securities and Exchange Commission (SEC). Once complete, ExOne’s common stock will be removed from public markets and it will become a wholly-owned subsidiary of Desktop Metal.

The deal is expected to close by the end of the week, subject to customary closing conditions, and the final voting results will be filed with the U.S. Securities and Exchange Commission (SEC). Once complete, ExOne’s common stock will be removed from public markets and it will become a wholly-owned subsidiary of Desktop Metal.

Neoshapes, Siemens, and the InnoventPro 3L

The InnoventPro 3L is ExOne’s latest entry-level metal binder jet 3D printer. Intended as an upgrade to the Innovent+ 3D printer, the InnoventPro offers three times the build area (125 x 220 x 100 mm) of its predecessor with the same printhead as the firm’s X1 25Pro system. Equipped with ExOne’s Triple ACT advanced compaction technology and print speeds of up to 700 cc/hour, the InnoventPro is suitable for academics, researchers, and a variety of manufacturers seeking R&D, prototyping, and end-use production.

Neoshapes has already worked closely with ExOne on a proof-of-concept project for printing with precious metal on the Innovent+ 3D printer. Starting next year, the startup will scale the technology for the upcoming InnoventPro 3L in a bid to enable a new level of productivity and quality in the 3D printed luxury goods market.

Stéphane Vigié, board member of Neoshapes, said, “Our team at Neoshapes plans to run an ambitious R&D project covering all aspects of manufacturing in order to finally allow luxury brands to benefit from repetitive batch scale manufacturing of revolutionary designs, with unrivaled quick time to market.”

On the other hand, Siemens will house its newly-purchased InnoventPro at its Charlotte Advanced Technology Collaboration Hub (CATCH) located in Charlotte, North Carolina. The binder jet system will be used to develop new materials and processes that Siemens will scale up for the production-ready X1 160Pro. The InnoventPro already features a Siemens control system, which consolidates the printer’s drives, motors, sensors, and the Siemens MindSphere IoT operating system.

Tim Bell, Head of Additive Manufacturing at Siemens, adds, “We’re very excited to feature the InnoventPro in our Technology Collaboration Hub, and we look forward to demonstrating how to integrate advanced additive manufacturing systems such as the InnoventPro into our end-to-end Digital Thread.”

Aside from a supersized build area and print speeds, the InnoventPro will offer the ability to print NanoFuse particulate binders that will improve sinterability of metal parts. Photo via ExOne.The X1 Powder Grip

Developed as part of the InnoventPro’s comprehensive new powder management system, the X1 Powder Grip is designed to help users eliminate scooping, dumping, powder clouds, and cleanup in the metal binder jetting workflow. The container weighs around 9kg when fully loaded with 316L stainless steel.

To load new powder into the InnoventPro, users will only need to slot two X1 Powder Grip containers into a powder hopper which can be found at the back of the 3D printer. Once the powder release valve is unlocked, a separate conveyance system takes the hopper from the loading position to the build area where it can be accessed for printing and recoating. ExOne has also designed the X1 Powder Grip to enable easy powder reclamation and reuse when used in conjunction with the firm’s new depowdering station.

Once the powder release valve is unlocked, a separate conveyance system takes the hopper from the loading position to the build area where it can be accessed for printing and recoating. ExOne has also designed the X1 Powder Grip to enable easy powder reclamation and reuse when used in conjunction with the firm’s new depowdering station.

Following the acquisition of Freshmade 3D’s patented 3D printed tooling technology earlier this year, ExOne also recently launched its own portfolio of 3D printed tooling products. Aimed at manufacturers, the new X1 Tooling range is reportedly the world’s largest offering of industrial-grade 3D printed tooling. The product line includes tooling for plastic injection molding, forming, composite layups, metal castings, and more.

More recently, the company partnered with powder metallurgy specialist SSI Sintered Specialities to ramp up its production capabilities. As part of the firms’ collaboration, SSI Sintered Specialties will install ExOne’s X1 160Pro and InnoventPro 3L systems at its HQ in Wisconsin next year, where they’re set to be used within extensive binder jet material, automation, and process R&D, while also manufacturing complex parts for the company’s clientele at scale.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the X1 Powder Grip container. Photo via ExOne.

Tags Desktop Metal Exone INNOVENT+ InnoventPro Neoshapes Siemens Stéphane Vigié Tim Bell X1 160PRO X1 25PRO

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

Personal 3D Printer Market Business Opportunity & Future Growth Analysis Report 2028

<

Marketing Reports recently released a research report titled "Global Personal 3D Printer Industry Research Report, Growth Trends and Competitive Analysis for 2022- 2028”, which assesses various factors influencing its development. The Global Personal 3D Printer Market Report offers high quality, accurate and comprehensive research to provide players with valuable insights to make strategic business decisions. Research analysts have conducted an in-depth segment analysis of the global Personal 3D Printer market by type, application and geography. The supplier landscape is also highlighted to inform readers about future changes in market competition. As part of competitive analysis, the report includes detailed company profiles of major players in the global 3D Printer market.

The Global Personal 3D Printer Market Report offers high quality, accurate and comprehensive research to provide players with valuable insights to make strategic business decisions. Research analysts have conducted an in-depth segment analysis of the global Personal 3D Printer market by type, application and geography. The supplier landscape is also highlighted to inform readers about future changes in market competition. As part of competitive analysis, the report includes detailed company profiles of major players in the global 3D Printer market.

Request a sample PDF of this report:

https://www.marketinsightsreports.com/reports/102110319949/2022-2029-global-personal-3d-printers-professional-market-research-report-analysis-from- perspective-of-segmentation-competitor-landscape-type-application-and-geography/inquiry?https://edk.news&Mode=206

Key Players Mentioned in Personal 3D Printer Market Research Report: EOS Gmbh

Electro Optical systems

3D systems

Stratasys

SLM Solutions

Arkam

Exon

Voxeljet Technology GmbH

Optomec

Concept Laser

Solid Landscape

Key Market Segmentation:

country level for 2022-2028. In our report, the market is categorized by product type, packaging type, and distribution channel.

In our report, the market is categorized by product type, packaging type, and distribution channel.

Breakdown by product type:

Polyruk

Modeling Offering Fruster (FDM)

Selective laser sintering (SLS)

Stereo lithography

Other

Separation of packaging:

9000Regionally, the global 3D Personal Printer market is divided into North America, Europe, Asia Pacific, Latin America, Middle East and Africa. In addition, the classification of market data and analysis of the region by country are covered in the market research report. In addition, the regions are divided into countries and regional groups:

- North America (USA and Canada)

- Europe (Germany, UK, France, Italy, Spain, Russia and the rest of Europe)

- Asia Pacific (China, India, Japan, South Korea, Indonesia, Taiwan, Australia, New Zealand and the rest of the Asia-Pacific region)

- Latin America (Brazil, Mexico and the rest of Latin America)

- Middle East and Africa (GCC (Saudi Arabia, UAE, Bahrain, Kuwait, Qatar, Oman), North Africa, South Africa and the rest of the Middle East and Africa)

Ask an analyst to set up and view a full report with a table of contents and a list of figures :

-research-report-analysis-from-perspective-of-segmentation-competitor-landscape-type-application-and-geography?https://edk. news&Mode=206

news&Mode=206

We update our reports if you need the latest primary and secondary data (2022-2028) with cost module, business strategy, distribution channel, etc. Click "Request a free sample report", the published report will be delivered to you in PDF format by email within 24 to 48 hours .

Highlights of the report:

- Market indicators (2017-2021)

- Market overview (2022-2028)

- Market trends

- Market drivers and success factors

- Impact of COVID-19 on the global market

- Value chain analysis

- World market structure

- Comprehensive mapping of the competitive environment

If you need specific information that is not currently within the scope of the report, we will provide it to you as part of the setup. Severe hereditary skin disease cured by genome editing Anna Manshina, N+1 Chinese biotechnologists test CRISPR/Cas9 genome editing technology on a mouse modelfor the treatment of severe hereditary skin disease. Dystrophic epidermolysis bullosa (DEB) is a severe genetic skin disease in humans. It is caused by a mutation in the Col7a1 gene that produces non-working type VII collagen. Such collagen poorly binds the inner layers of the skin with the outer ones, as a result of which, in patients with DHE, the epidermis lags behind at the slightest mechanical impact. Today, there is only symptomatic treatment for DBE, it is not completely curable. The development of radical treatment is carried out in three areas: protein, cell and gene therapy. Treatment at the gene level is the most promising direction, it can remove the cause of the disease, the Col7a1 mutation. In a new work, scientists used the CRISPR/Cas9 genome editing system to treat DEB. This system is based on the action of the bacterial protein Cas9, which finds a mutated DNA region and cuts it out. After that, the cell starts the natural mechanism of DNA repair. As a model of human disease, the scientists used a mouse strain containing a point mutation in exon 80 of the Col7a1 gene. Biologists suggested that for DHE therapy, it is enough to remove this mutant exon from the gene, after which a shortened, but functional version of collagen should be formed. At the first stage of the experiment, to deliver the genome editing system to tissues, scientists used plasmids (circular DNA molecules) that encode both a guide RNA that searches for a target for editing and the Cas9 nuclease protein. After entering the cells, these plasmids began to work and the synthesis of Cas9 took place already in place. However, the results of this preliminary experiment were not very good due to the fact that the plasmids did not penetrate well into the desired tissues. This delivery method worked, the complex got into the right tissues and in sufficient quantities to fix the damaged gene. After treatment, the connection between the inner and outer layers of the skin in mice doubled, from thirty to sixty percent. The scientists also noted that the use of the Cas9 ribonucleoprotein/sgRNA may be safer than plasmids. The complex does not replicate in a living cell, which means that the likelihood that other genes that are similar to mutants will be damaged during therapy is reduced. However, clinical trials are still far away, more data are needed on the long-term effects of the treatment. CRISPR/Cas9 is a simple and versatile gene therapy technology. With its help, it is possible to treat hereditary blindness and various genetic diseases, and the startup Editas Medicine promises to edit the genome this year. Portal "Eternal Youth" http://vechnayamolodost.ru skin hereditary diseases gene therapy Printable version Error in the text? Hereditary skin diseases have evolved in recent years from a minor topic to an important focus of basic and clinical research. There is no doubt that genetics has an important role to play in unraveling the pathogenesis of many common familial skin diseases, as well as in developing new treatments for these diseases. read A deep learning algorithm developed by Stanford researchers makes diagnoses as accurate as highly experienced dermatologists. read A 100 cm2 piece of leather is made in 35 minutes. The researchers believe that through automation and standardization of printing, we can expect a significant reduction in the cost of leather. read Scientists from China have created a prototype of artificial "skin with hair" - a highly sensitive sensor that allows you to feel a wide range of influences. read Hormone creams and serums are one of the main horror stories in the cosmetics market: it is believed that they can cause tumors or increase hair growth on a woman's body.

Scientists used a new delivery method and improved the accuracy of the "genomic scissors" by using the Cas9 ribonucleoprotein complex and sgRNA guide RNA. An article about the study was published in Proceedings of the National Academy of Sciences (Wu et al., Efficient in vivo gene editing using ribonucleoproteins in skin stem cells of recessive dystrophic epidermolysis bullosa mouse model).

Scientists used a new delivery method and improved the accuracy of the "genomic scissors" by using the Cas9 ribonucleoprotein complex and sgRNA guide RNA. An article about the study was published in Proceedings of the National Academy of Sciences (Wu et al., Efficient in vivo gene editing using ribonucleoproteins in skin stem cells of recessive dystrophic epidermolysis bullosa mouse model).

Therefore, instead of plasmids, it was decided to introduce mice with a ready-made complex for editing the genome - ribonucleoprotein Cas9/sgRNA. This complex consists of the Cas9 protein and a guide RNA that directs the protein to damaged DNA.

Therefore, instead of plasmids, it was decided to introduce mice with a ready-made complex for editing the genome - ribonucleoprotein Cas9/sgRNA. This complex consists of the Cas9 protein and a guide RNA that directs the protein to damaged DNA.

02/01/2017

Read related articles:

Select it and press ctrl + enter Read also:

Genetic aspects of skin diseases

Mole or cancer?

Leather from a 3D printer

Robots will have hairy arms

Hormone creams: myths and truths

Learn more