Can you 3d print vinyl records

Can You 3D Print A Vinyl Record? Costs, Benefits And Drawbacks

Sign in

Welcome!Log into your account

your username

your password

Forgot your password?

Create an account

Privacy Policy

Sign up

Welcome!Register for an account

your email

your username

A password will be e-mailed to you.

Privacy Policy

Password recovery

Recover your password

your email

Search

Date:

There have been a lot of talks lately about 3D printing and its potential to revolutionize the way we manufacture products. But did you know that you can also use this technology to print vinyl records?

It may seem like an odd concept, but it actually works quite well. In this blog post, we will take a closer look at how 3D printing is being used to create vinyl records, and we will discuss some of the benefits and drawbacks of this process.

Read More About:

- Can You Build Your Own 3D Printer from Scratch? (5 min read)

- Printing a 3D Printer with a 3D Printer: Is it Possible? (5 min read)

- Is it possible to 3D print a vinyl record?

- How do you 3D print a record player?

- How much does it cost to print a vinyl record?

- What are the benefits of printing vinyl records?

- What are the drawbacks of printing vinyl records?

- Can you 3D print a music box?

- What You Can Do With a 3D printed Vinyl Record?

- Final Thoughts

Is it possible to 3D print a vinyl record?

In recent years, 3D printing technology has advanced to the point where it can be used to create a wide variety of products, from eyeglasses to prosthetic limbs.

One potential application of 3D printing is the creation of vinyl records. While the idea of being able to print your own records at home may sound far-fetched, it is actually technically possible.

But this technology has not been perfected yet, it is certainly an interesting possibility for the future of music production.

How do you 3D print a record player?

Many people are wondering how you would actually go about printing a vinyl record. The process is actually not as complicated as it may seem.

Joel from 3D printing Nerd has created a great video tutorial that explains the process in detail. Here is a link to the video tutorial:

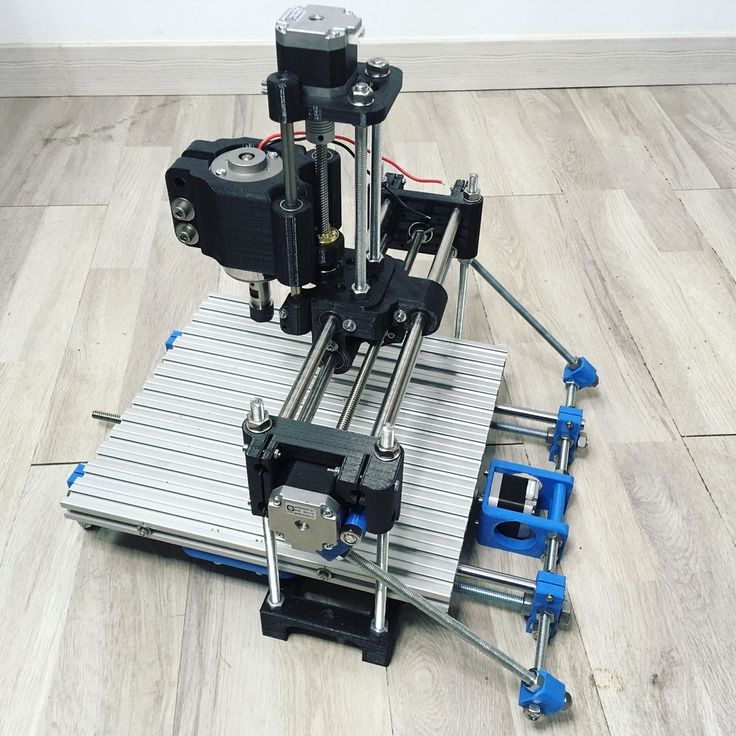

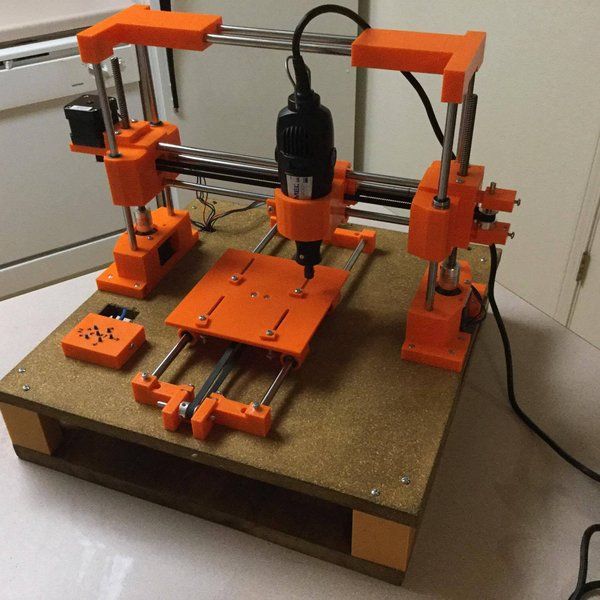

As you can see, the process is actually quite simple and fun. They used different types of 3D printer to print the different parts of the record player.

In this video tutorial Joel and Mark used Prusa i3 MK3, Raise3D N2, gMax 2, Artillery3D Sidewinder X2 and Creality Ender 3 printer to print a full functional record player. The printed record player is not perfect but it works great.

The printed record player is not perfect but it works great.

How much does it cost to print a vinyl record?

The cost of 3d printing a vinyl record depends on a number of factors, including the size of the record, the quality of the print, and the complexity of the design.

Generally speaking, larger records will be more expensive to print than smaller ones, and records with intricate designs will cost more than those with simple designs.

Additionally, the quality of the print can vary depending on the printer and the type of material used. However, as a general ballpark estimate, it is typically possible to 3d print a vinyl record for around $30.

But you need a high-resolution printer and the right type of material. So, the entire project could cost you a few hundred dollars.

What are the benefits of printing vinyl records?

In the past, records were made by injection molding, a process that was expensive and time-consuming. With 3d printing, records can be produced much faster and at a fraction of the cost.

In addition, 3d printing allows for more intricate designs and patterns to be incorporated into the vinyl records. As a result, 3d printed vinyl records are not only more affordable, but also more unique and stylish.

In addition to being more cost-effective and stylish, 3d printed vinyl records are also more durable than their traditional counterparts.

Because they are not made with fragile injection molding tools, 3d printed records are less likely to crack or break. Additionally, the surface of a vinyl record is less likely to be scratched when it is printed with a smooth finish.

What are the drawbacks of printing vinyl records?

Despite the benefits of 3D printing technology, there are some significant drawbacks to consider before investing in a 3D vinyl printer.

- One of the biggest issues is the quality of the sound. Because the records are made from plastic, they tend to produce a poorer sound quality than traditional vinyl records.

- In addition, 3D printed records are also more susceptible to warping and damage.

Because they are not as sturdy as traditional records, they can easily be damaged if they are not stored properly.

Because they are not as sturdy as traditional records, they can easily be damaged if they are not stored properly.

- Finally, 3D printed records are also much more expensive than traditional vinyl records. While the initial investment may be worth it for some audiophiles, others may find that the increased cost is simply not worth the hassle.

Can you 3D print a music box?

3D printing technology has come a long way in recent years, and it’s now possible to print all sorts of objects, from toys to tools. One popular use for 3D printers is making music boxes.

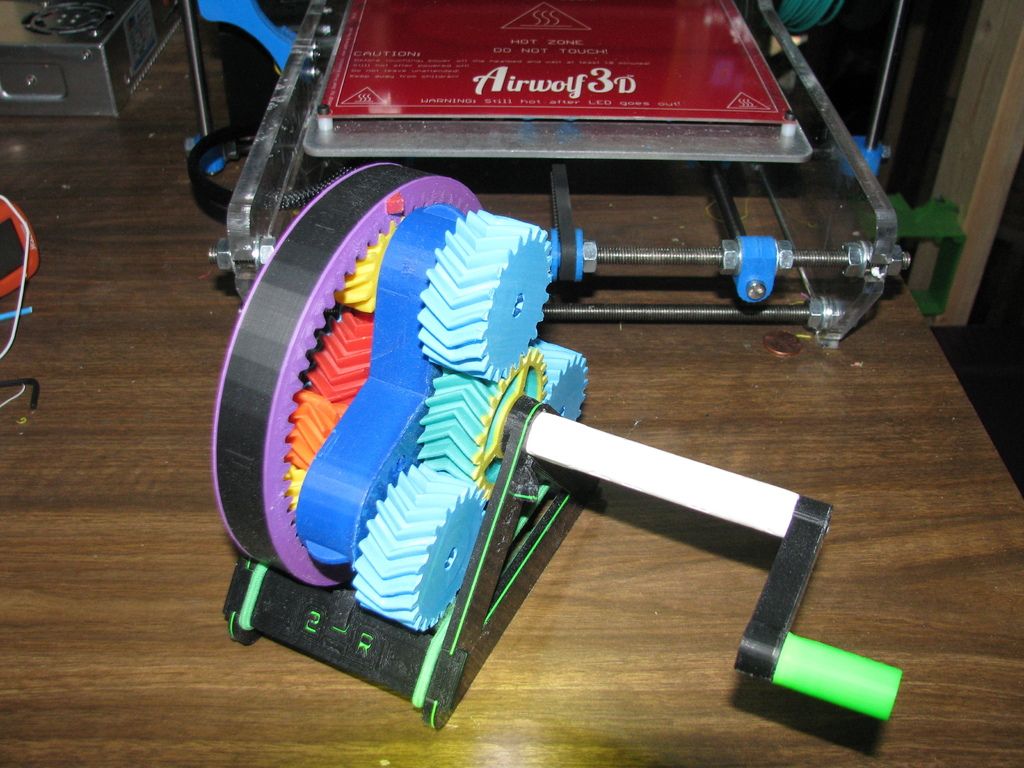

Music boxes are relatively simple devices, consisting of a cylinder with pins that strike a tuned steel comb when the cylinder is turned. This makes them ideal candidates for 3D printing, as the moving parts can be easily printed using a standard desktop 3D printer.

The only other major component of a music box is the musical movement, which can be sourced from online retailers. With a 3D printer and a few simple components, you can easily create your own music box.

What You Can Do With a 3D printed Vinyl Record?

Now that you know how to print a vinyl record, what can you do with it? You can sell it, of course!

But there are other options as well. For example, you could use it to create a one-of-a-kind gift for a music lover in your life. Or you could use it as a promotional tool for your band or business. The sky’s the limit!

Also, check out our blog to learn more about how you can make decent money by selling your 3d printed objects.

Final Thoughts

As you can see, there are a number of advantages and disadvantages to printing vinyl records. Ultimately, the decision of whether or not to print vinyl records is up to you. If you have the budget and the time, it can be a great way to create unique gifts or promotional materials. However, if you’re pressed for time or money, you may want to stick with traditional pressing methods.

Whichever route you choose, we hope this article has given you a better understanding of the pros and cons of printing vinyl records. Thanks for reading!

Thanks for reading!

Can you think of any other advantages or disadvantages to printing vinyl records? Let us know in the comments below!

If you’re interested in learning more about 3d printing, be sure to check out our other articles.

Share post:

Popular

More like this

Related

By continuing to use the site, you agree to the use of cookies. more information

Can You 3d Print Vinyl Records? 3d Printing Vinyl Record

Can You 3d Print Vinyl Records? The answer to this question is yes, but it’s not as easy as printing a picture.

The process of 3D printing vinyl records requires an understanding of the equipment and software that are needed for this task.

It also involves some basic knowledge about vinyl record production.

This blog post will break down what you need to know in order to successfully 3D print your own vinyl records at home or in the studio!

On This Page

Related:

- Top 7 Best Dual Extruder 3d Printer Under $500

- Top 7 Best Filament For Lithophanes

- 7 Best Hairspray For 3d Printing

- Top 7 Best Direct Drive Extruder

- Top 7 Best Resin For 3d Printer

Can you 3d print vinyl records? Check your printed record

Theoretically, you can. In reality, the process becomes a bit complicated, and actually making a record from it is not advised. For that reason, we do not sell 3D printable vinyl records at Shapeways, but there are some other products that have been made with 3D printed molds:

In reality, the process becomes a bit complicated, and actually making a record from it is not advised. For that reason, we do not sell 3D printable vinyl records at Shapeways, but there are some other products that have been made with 3D printed molds:

All of these were machined from large wax parts, which might be a reasonable approach if you want to produce a lot of these records or already have access to a machine shop or milling equipment.

There are several tutorials online about how to build your own wax duplicator so this might be an interesting project for someone who wants to delve into the world of recording their own music on vinyl. We would advise against trying to buy one of our larger waxes and attempting this process since the mold is optimized for the injection-molding process.

Finally, you can always apply to own a 3D printer yourself so that you can experiment with your own 3D printable records!

While it might not be cheap at first to buy a 3D printer, it would allow you the freedom of trying out all sorts of interesting techniques.

To give just one example, that may or may not have been already attempted by others: printing actual records in resin and actually playing them on a record player… if anyone attempts this we’d love to hear about it in the Shapeways community!

Can You 3d Print Vinyl Records?(cre: wired)

3D print Vinyl material – Desktop metal zone

3D print Vinyl material is getting more and more popular in the 3D printing industry. This material is durable, versatile, lightweight, impact-resistant, and perfect for rapid prototyping. With its special glossy finish, it will give your object a nice look.

Before you begin to print with this material make sure that your 3D printer can use it.

Not all machines are compatible with this new material. If your machine is not able to extrude this material make sure to upgrade it or contact us for an upgrade!

We have done several tests on DLP printers but most of our customers are using FDM printers like Ultimaker2 or Makerbot Replicator 2/2X/2S/2GO etc. For these types of printers, you will need to use special photo-curable material.

The standard PLA cartridge will not work with this new material, so the first thing to do is to get an empty PLA cartridge to be able to print with it using your existing machine!

Vinyl 3D printing materials are considered DLP resins in our industry meaning that they cure when the light passes through the liquid resin. To achieve this you need a projector that can project images on your object in order for them to harden layer by layer until your objects are done.

You can also take off the protective cap of the cartridge and then expose it in any other way but projecting an image on it. It is possible to buy UV lamps or make one yourself.

When it comes to the light, you need to use a UV light with a 365 nm wavelength.

This is completely different from regular 3D printer filaments which are using 405 nm or even worse 488nm lights.

The reason why you have to use the right one is because of so-called photoinitiators which are added to vinyl resins themselves.

If your project requires exposure time longer than 30 seconds it’s impossible to do that on 405nm lights since they cannot pass enough energy through layers in order for them to harden properly.

So you will end up having an object which looks OK at first glance but when you start sanding it down, polishing it, etc some details will be lost forever!

Vinyl materials are not completely transparent so you will have to use a projector with good lights in order for your objects to look nice.

One more thing which is important to remember, especially during the production process of vinyl material, is that you need to reduce the amount of UV light drastically since it tends to break down the molecules of the liquid even further!

The optimal exposure time for our materials is around 2-5 seconds using a 365nm wavelength.

However, depending on your 3D printing machine this might not be enough to harden your object properly, and then you will end up with an unfinished print.

We recommend our customers not to go over 8-10 seconds per layer maximum otherwise you will end up having a non-printable filament due to its quality dropping so much that it will refuse to print.

Another tip is that since the light exposure time is reduced, it’s good to increase your layers as well. Since we do not have a proper safety data sheet we cannot tell you what we recommend but usually, we make prints with 15-20% more layers than usual and slower speeds (around 40 mm/s) and this seems like a reasonable compromise between quality and speed.

Can You 3d Print Vinyl Records?(cre: instructables)

3D printed vinyl record wall mounting brackets – Laser cut records – Follow printer data

3D printed vinyl record wall mounting brackets. Straight from the spaghetti head, I present to you the latest in my 3D printing experiments: a set of (2) laser cut and engraved adjustable 3D printed vinyl record wall mounting brackets.

These are currently on sale at Shapeways for $29. 99 and ship worldwide if you can find someone with a big enough printer to print them out for you locally.

They’re easy to install and will work for “Ikea” and other flat-pack floating wall shelf systems as well as standard 5/8″ plaster or drywall anchors.

You may remember my earlier post about making these same objects using traditional digital sculpting tools such as Pixologic’s ZBrush and The Foundry’s Mari. But I’m a big believer in using the right tool for the job and 3D printing is a great way to quickly prototype an idea you have been kicking around or just let your imagination run wild with.

Conclusion

Vinyl records are making a comeback. But, did you know that they can be 3d printed? If not, read on to learn more about how vinyl is being reinvented for the digital age.

Many people have begun collecting these vintage pieces of music history and some artists even release new songs in this format exclusively! We hope you find our insights useful as you enjoy all the wonderful things that come along with playing old-school vinyl albums again! As always, we’re happy to answer any questions or concerns in the comments section if needed. Thanks for reading!

Further Reading:

- Top 7 Best 3d Printer For Board Games

- Top 7 Best Creality 3d Printers

- 7 Best Filaments For Ender 3

- Top 7 Best 3d Printer For Nylon

- Top 7 Best 3D Printer For Cosplay Armor

Tags: #Suppressor #Nylon #Chromebook #Wax #Car #Game #Records #Kevlar #Hollow #Colors #Lenses #Aquarium #Tools #Biodegradable #Abs

Tags: printed record, laser cut records, printed records azom, cut records amanda, desktop metal zone, printed records amanda, printed record laser, record laser cut, raw audio data, audio report, follow diameter model, groove site sales, news add, id video, processing, amanda

3D printed vinyl and the eternal dispute

?

|

Vinyl record filament.

Consumables

Follow author

Follow

Don't want to

28

Hello Friends!

Remember, vinyl is not to be trifled with! If possible, you should not experiment with melting this material at all.

Today I will try to print from vinyl records. I can imagine how dissatisfied fans of vinyl records will be. I have a lot of this stuff. I will donate 5 pieces for the sake of the experiment.

I didn't expect the heads to be so flexible. The label can not be torn off the plate, pasted on the Soviet glue. It remains only to cut out this pasted circle. It was possible to shove the entire record into the grinder.

The shredder looks like it was designed to shred vinyl records. For further grinding, I will use the Chinese saucepan that you saw in past videos. I grind the material with a respirator, being afraid that small particles of the material can fly in the air.

Vinyl cured to dust, just a little check on a Chinese extruder. To begin with, I will set the temperature on the extruder to 180 degrees so that the previous test polymer comes out, after which I will lower the temperature.

It's hot! I didn't expect vinyl to be so malleable. The filament is even. I believe that the finer the material is crushed, the more stable the filament is. There are slight deviations, but it's not terrible. I have seen factory filament with much larger deviations. I thought that the filament would turn out to be brittle, but it was not there. It turned out a very elastic and durable thread.

Now is the time to print a test disc. Instead of glue, I print the first layer of PLA plastic and then change the filament to the test one. It's a miracle that I started printing the first time. Nozzle temperature 245°, table 60° nozzle diameter 0.8mm., Z step 0.20mm. Of course with a nozzle diameter of 0.4mm. the tested part would have turned out much more attractive. I'm printing these discs to see if it's possible to print with the tested plastics.

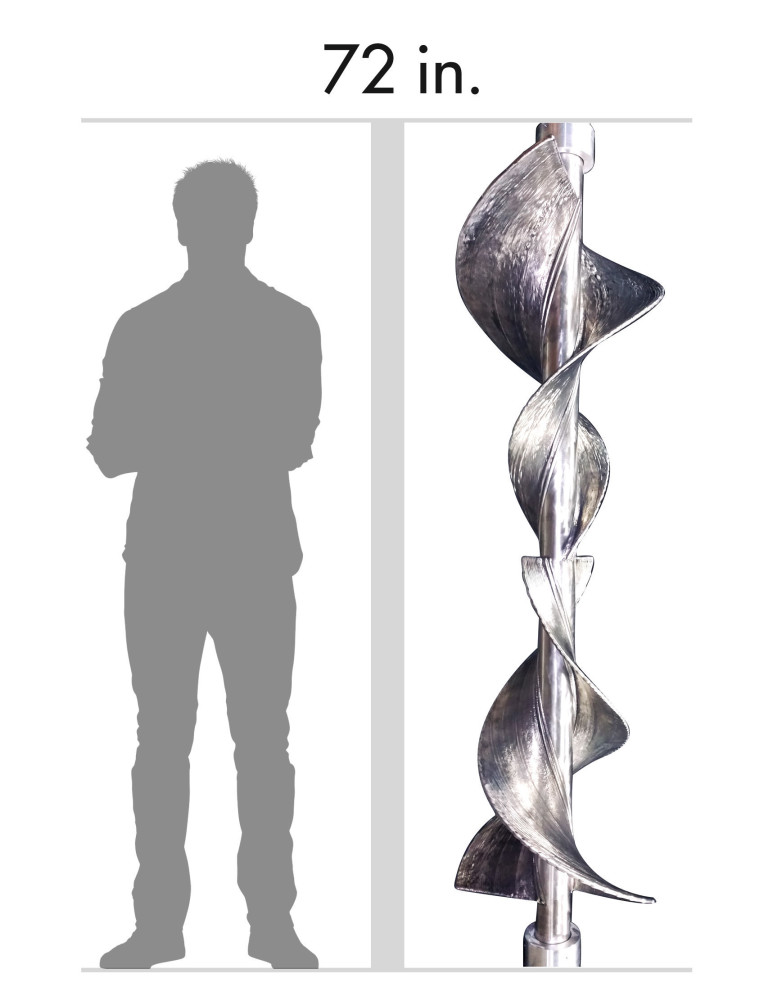

Next I want to test the spiral print. It has already become a tradition. Previous samples I printed from car headlights, PVC windows, audio tape. At first, of course, I was a little upset that such a low-quality print was obtained.

I looked closely and noticed that the previous layers do not have time to cool. Most likely for printing with this polymer you need a good airflow. Unfortunately, there was no airflow on the printer on which I am testing.