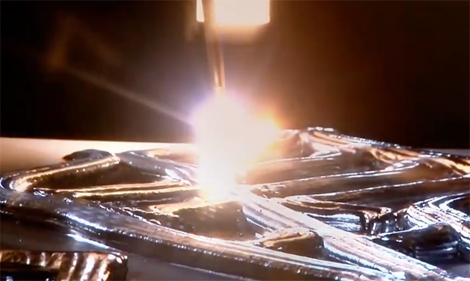

Sciaky 3d printer

Largest Metal 3D Printer Available | Industrial 3D Printing

With a maximum work envelope of 19' x 4' x 4' x 8’ (L x W x H x D, or round parts up to 96” diameter), the EBAM® 300 Series by Sciaky offers the largest build platform of any metal 3d printer commercially available.

Designed to additively manufacture large-scale parts and prototypes from high-value metals like titanium, tantalum, Inconel, niobium, and other alloys, the EBAM300 is the only 3D printer on the market that has produced a metal structure exceeding 10 feet in length.

Beyond size, the EBAM 300 is also one of the fastest industrial 3D printers commercially available with a deposition rate ranging from 7 to 20 lbs. per hour. It produced a 10-foot-long titanium aircraft structure in 48 hours at a rate of approximately 15 lbs. of metal per hour. In general, forgings that used to take 6-12 months to complete can be completed in 2 days with the EBAM 300.

This Electron Beam Additive Manufacturing (EBAM) system also provides an extremely high degree of control over part geometry and material composition because of its patented IRISS Closed-Loop Control Technology. Savings on raw materials—often precious metals—can be huge with EBAM (up to 80% for large-scale parts) because of the substantial reduction of material waste.

The EBAM 300 is used to create, improve, and repair next-generation end-use technology in the aerospace and defense industry, energy industry, metals industry, and many other verticals. It is a full-scale means of production for corporations and institutions in need of a system that can do more than build flimsy prototypes and/or headline-grabbing objects without real function.

This marks a sharp contrast between Sciaky and other 3D printing companies that say they sell “the largest 3D printer in the world” because it’s a marketable proposition.

The truth is: while there are indeed 3D printing systems that can print entire buildings, houses, car replicas, bikes, statues, etc., generally, the bigger the printer, the weaker the business case.

For example, if you run a Google search for “who makes the largest 3d printer?” you will find that most mega-scale 3D printers are a) not commercially available and b) are only useful to a small consortium of individuals and even fewer real-life applications. Why? In a nutshell, huge parts made out of sand, plastics, and other particle materials aren’t practical for most companies.

Why? In a nutshell, huge parts made out of sand, plastics, and other particle materials aren’t practical for most companies.

That’s not the case with Sciaky. We may not be able to say that we make the biggest 3d printer on the planet, but we do make the world’s largest 3d printer that is fit for the industrial/commercial production of functional metal parts.

Here’s how the EBAM 300 Series compares to some of the other largest 3D printers on the market:

|

Machine Name |

Type of Process |

Type of Materials

|

Build Envelope Size (L x W x H)

|

Chamber Dimensions

|

|

EBAM 300 Series by Sciaky |

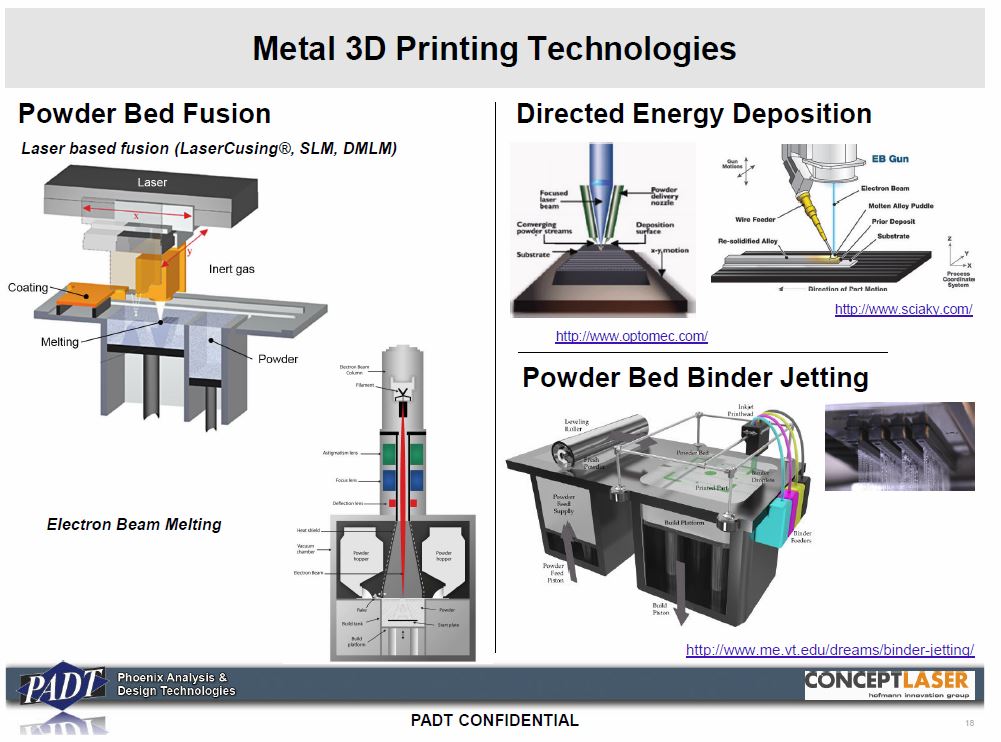

Electron Beam Additive Manufacturing

|

Metals |

240” x 55” x 54” |

300” x 108” x 132” |

|

VX4000 by Voxeljet |

Sand Casting |

Particle Materials |

157. |

767.7” x 275.6” x 149.6” |

|

Objet 1000 by Stratasys |

Polyjet |

Plastics |

39.3” x 31.4” x 19.6” |

110.3” × 70.9” × 70.9”

|

|

Lens 850-R by Optomec

|

Laser |

Metals |

35.4” x 59” x 35.4” |

118” x 118” x 118” |

|

Projet 5000 by3D Systems |

Multijet Printing Process |

Plastics |

21” x 15” x 11. |

60.3” x 35.7” x 57.1” |

|

M400 by EOS

|

Laser |

Metals |

15.8” x 15.8” x 15.8” |

N/A |

|

Arcam Q20 by Arcam |

Electron Beam Melting |

Metals |

Apx. 13.7”×15” (LxW) |

90.5” x 51.2” x 102.4” |

To learn more about 3D printing large metal parts with Sciaky’s EBAM process, call us at 877-450-2518.

TAI to 3D print 6 meter-long aerostructures with the "world's largest" electron beam machine from Sciaky

0Shares

Insiders and analysts predict the 3D printing trends to watch out for in our latest series of articles focused on the future of 3D printing.

Metal 3D printing specialist Sciaky has revealed that it plans to ship the “world’s largest” electron beam (EB) directed energy deposition (DED) system to aircraft manufacturer Turkish Aerospace Industries (TAI).

As part of a new partnership between the firms, TAI is set to install a custom Sciaky 300″ x 108″ x 132″ build volume 300 Series Electron Beam Additive Manufacturing (EBAM) 3D printer. Once fitted, the large-format system will be used to create titanium aerostructures up to 6 meters in length, in the course of several pilot projects that are expected to help TAI master its deployment of the technology.

“Sciaky’s EBAM systems are the most widely sold, large-scale DED metal 3D printers in the world, having approved parts on land, sea, air, and space applications,” said Scott Phillips, President of Sciaky. “We applaud TAI’s vision for innovation and their ambitious plans to 3D print some of the largest titanium aerostructures in the world.”

“We applaud TAI’s vision for innovation and their ambitious plans to 3D print some of the largest titanium aerostructures in the world.”

High-throughput metal 3D printing

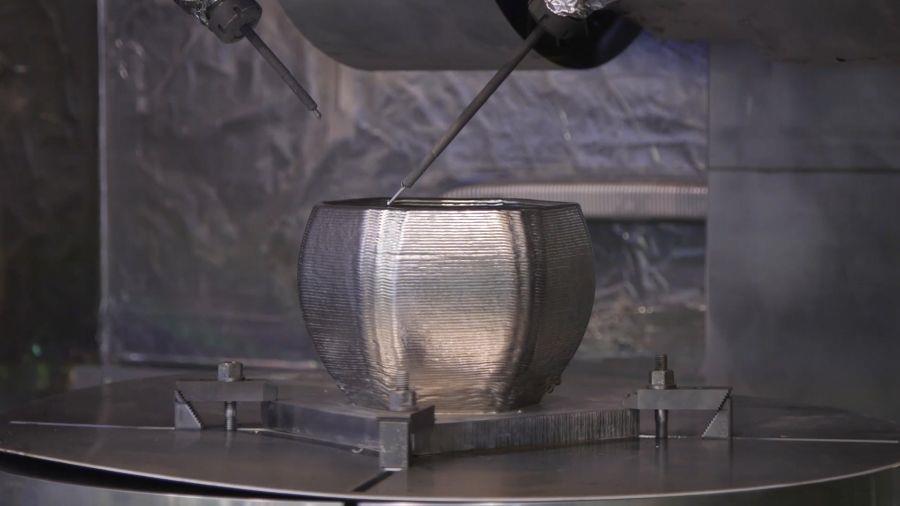

Offered initially as a service, before being incorporated into a turnkey system after a surge in client demand, Sciaky EBAM is essentially a process in which an EB gun is used to deposit wire feedstock layer-by-layer. With a deposition rate of up to 25 lbs per hour, and a dual wire feed system that allows two metals to be combined into a single melt pool, the approach enables the rapid fabrication of custom alloy parts.

At present, the company markets its EBAM technology both as a service at its 3D Printing Facility, and in the shape of its five large-format machines. The largest system in Sciaky’s offering is its 300 Series, which, thanks to its High Efficiency Pumping–Chamber and 280” x 48” x 48” part envelope, is capable of churning out colossal components at pace.

The 3D printer also comes fitted with the firm’s proprietary Interlayer Real-time Imaging and Sensing System or ‘IRSS.’ Designed to reduce variability during part production, IRSS is effectively a suite of closed-loop sensors, software logic and CNC controls which monitor key deposition parameters, and makes adjustments in real-time to ensure that throughput doesn’t come at the cost of product quality.

In the past, Sciaky has deployed its technology alongside the likes of Airbus to 3D print structural wing parts for its airplanes, and continually hailed the process’ aircraft frame, jet engine and missile production potential, thus its partnership with TAI is very much in keeping with its wider strategy of targeting heavy duty aerospace applications.

Sciaky’s EBAM systems feature a dual wire feed configuration. Photo via Sciaky.Sciaky’s Turkish Aerospace deal

While Turkish Aerospace was launched under Turkey’s Ministry of Industry and Technology to reduce the country’s reliance on defense imports in 1973, TAI itself wasn’t founded until 1984, when it was established as a joint Turkish-US firm, tasked with not only building F-16 aircraft, but handling their onboard system integration and flight testing.

Since then, Turkish Aerospace has undergone a wider restructuring that has seen it broaden its activities, with the aim of becoming a hub for the development of innovative aviation and aerospace technologies. This 2005 revamp effectively saw the firm reorganize into six groups focused on the production of structural, aircraft, helicopter, UAV, space system and national combat aircraft components.

Having previously dipped its toe into 3D printing, by working with the FIT Additive Manufacturing Group to produce satellite-steering device holders called ‘star tracker brackets,’ TAI has now penned a contract with Sciaky, in a deal that is set to take its adoption of advanced technologies a step further, by seeing it install a custom 300 Series EBAM 3D printer at its plant in Turkey’s capital, Ankara.

According to Sciaky, following fitting and configuration, the machine will be used to “3D print some of the largest titanium aerostructures in the industry.” Although TAI has yet to confirm the exact parts it intends to produce, the term ‘aerostructure’ can describe anything from an aircraft’s fuselage to its wing surfaces, thus it has left plenty of scope for the technology to be deployed across its business.

What has been confirmed, is that the 3D printer will be utilized to manufacture titanium parts up to six meters-long, with TAI also set to benefit from its combined EB welding and 3D printing functionalities for applications that require both. Moving forwards, Sciaky says it has committed to conducting a “series of projects” with its new partner, but the delivery schedule for its machine is “still being finalized.”

FIT AG’s 3D printed star tracker bracket on display at Formnext in 2019. Photo via FIT AG.Deploying wire-fed DED

While Sciaky’s machines continue to deposit alloys at a record-breaking pace, it’s far from the only developer of wire-fed DED technology. Reliance Precision and the University of Huddersfield, for example, are working on a fresh approach to EBAM as part of an Innovate UK-backed project that’s designed to broaden the process’ industry adoption.

Elsewhere, in another Innovate-UK program, Hybrid Manufacturing Technologies (HMT) is leading the development of a new compact wire-feed system called ‘FastWireAM. ’ As part of the project, which has been set up to fast-track the technology’s R&D, consultancy firm TWI and wire feedstock producer Epoch Wires have committed to optimizing its performance and accelerating its uptake as well.

’ As part of the project, which has been set up to fast-track the technology’s R&D, consultancy firm TWI and wire feedstock producer Epoch Wires have committed to optimizing its performance and accelerating its uptake as well.

In defense-related applications, researchers at Penn State’s College of Engineering have also been awarded $434,000 by the US Army to develop an improved means of 3D printing high-strength alloys. Using a computer modeling-based approach, the team aims to identify a Laser Directed Energy Deposition (L-DED) setup that’s capable of producing more robust metals with enhanced material efficiency.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action

. Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an engineer using Sciaky’s 300 Series EBAM 3D printer. Photo via Sciaky.

Tags 300 Series EBAM airbus Epoch Wires FIT Additive Manufacturing Group Hybrid Manufacturing Technologies Innovate UK Penn State University Reliance Precision Sciaky Scott Phillips Turkish Aerospace Industries TWI University of Huddersfield US Army

Paul Hanaphy

Paul is a history and journalism graduate with a passion for finding the latest scoop in technology news.

4 reasons why it's a waste of money / 3D printers, machines and accessories / iXBT Live

iXBT.com projects require cookies and analytics services. By continuing to visit project sites, you agree to our Cookie Policy

Are you interested in 3D printing? Do you have a 3D printer? If you answered yes to both questions, then it can be assumed that you understand the advantages and possibilities of using a 3D printer.

Knowing how to use a 3D printer helps you create your own prototypes, designs, or samples of accessories and other products. Given all its benefits, does that mean everyone should get one? Not necessary.

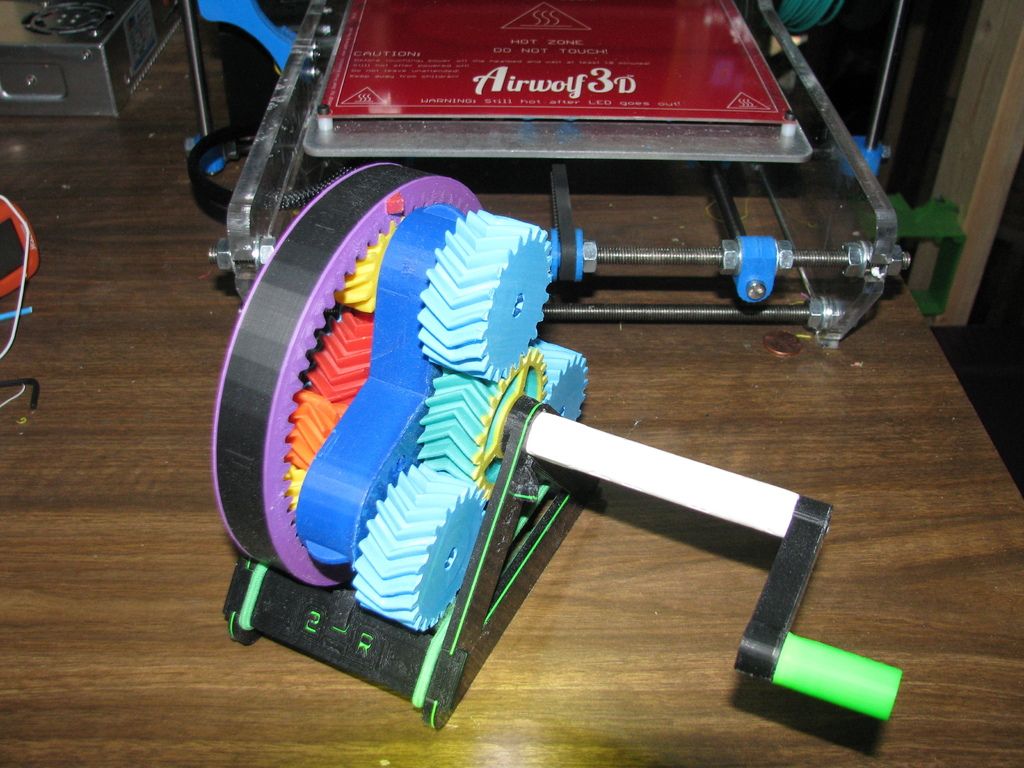

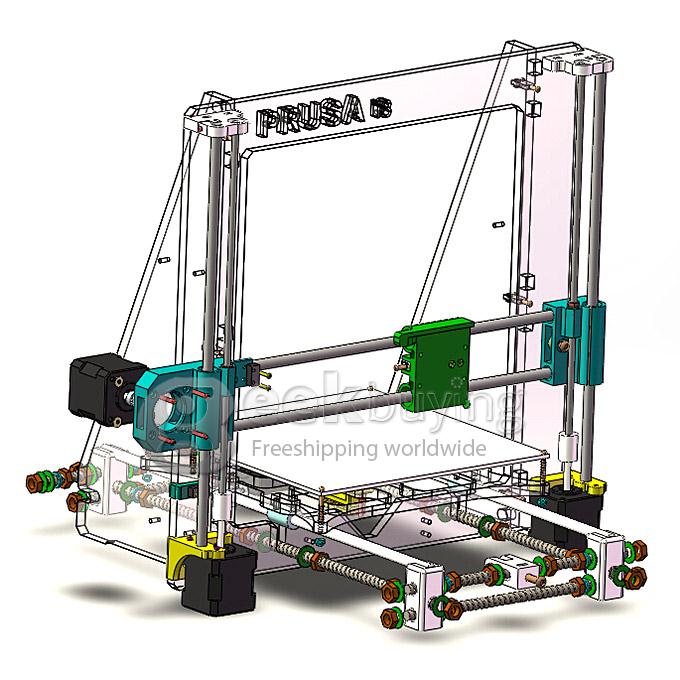

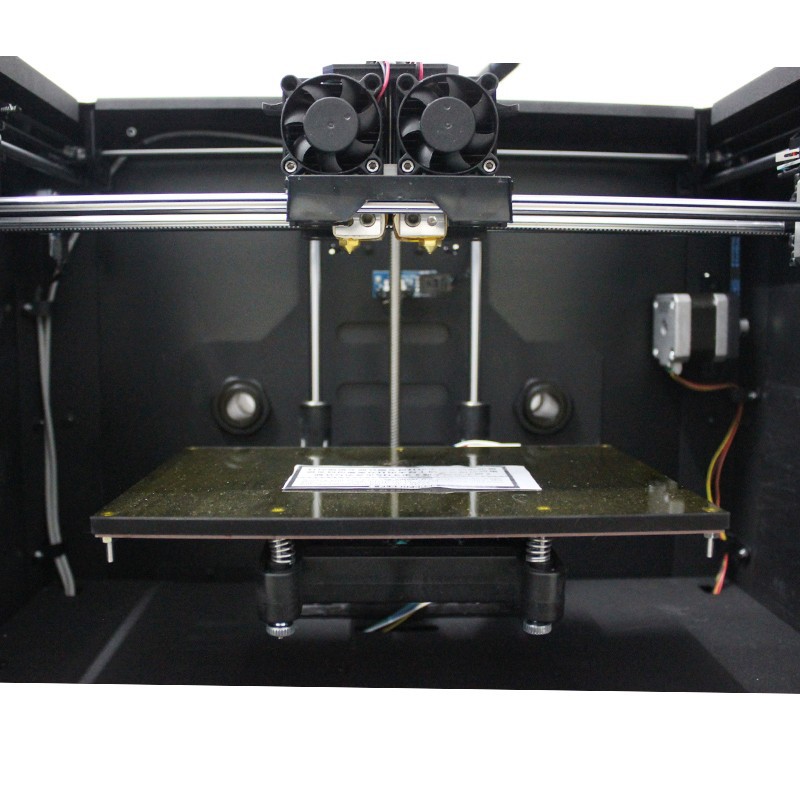

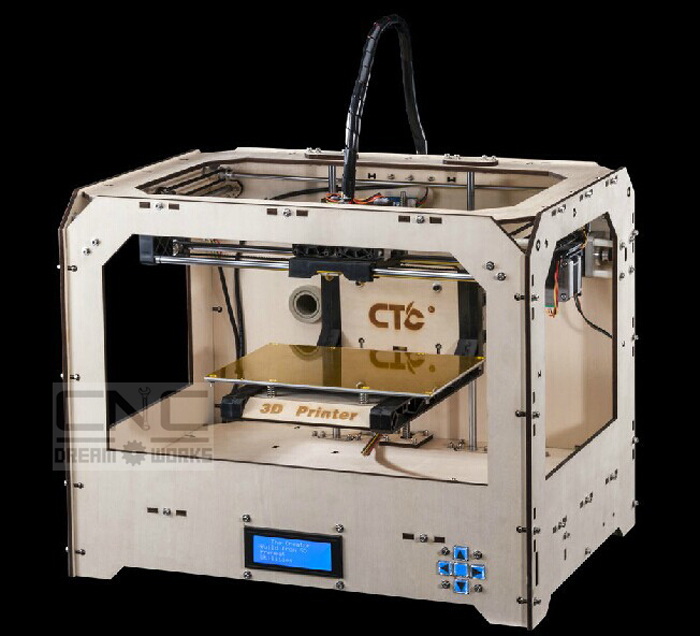

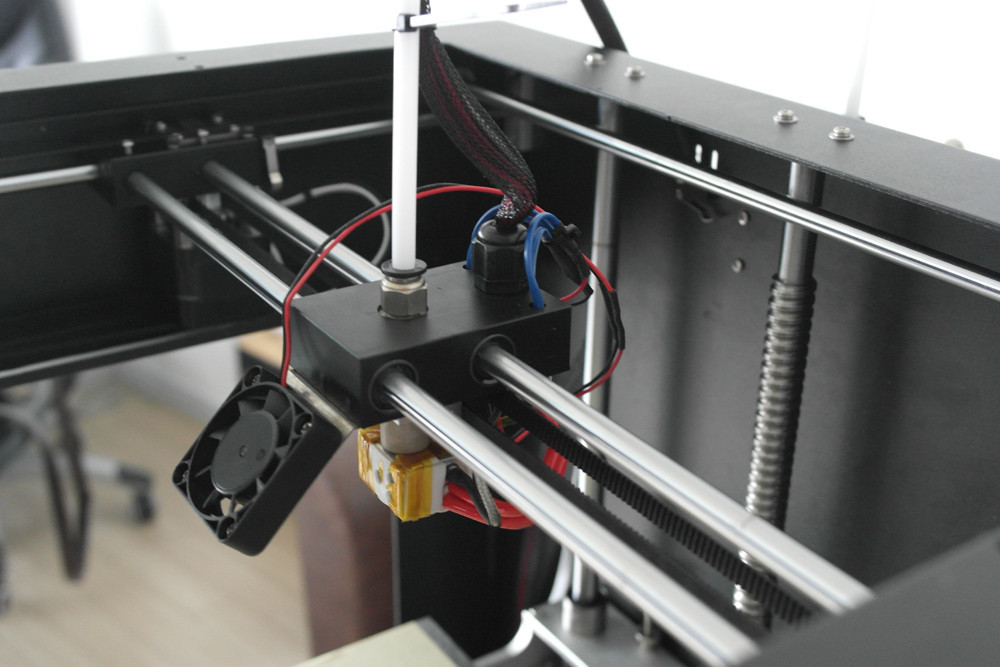

https://ru.pinterest.com/pin/297659856593251184/There are several good reasons why you should not buy a 3D printer. Below, I will detail four reasons and explain why buying a 3D printer is not the best decision.

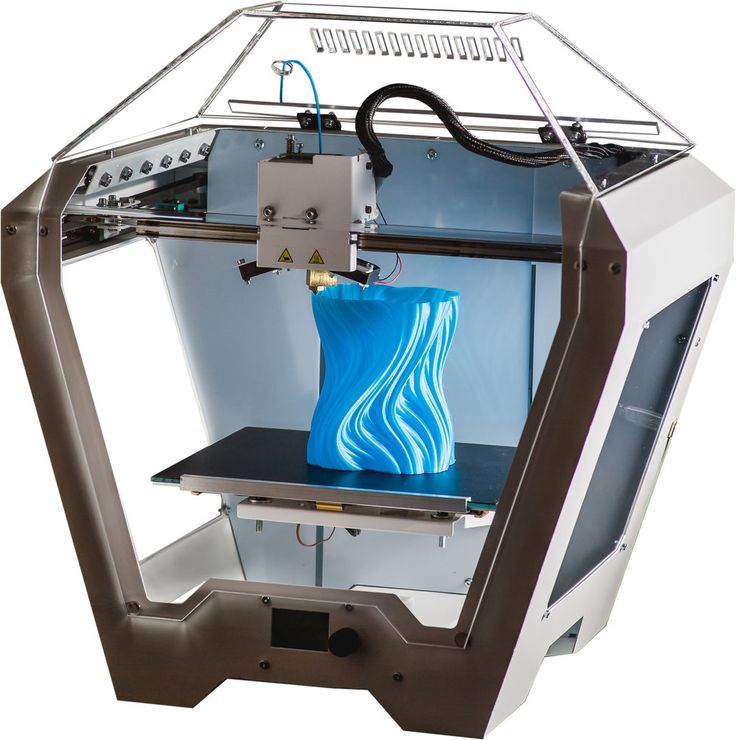

At the time of this writing, there are many different types of 3D printers on the market. While many of them have been around for almost a decade, the technology is in a state of flux.

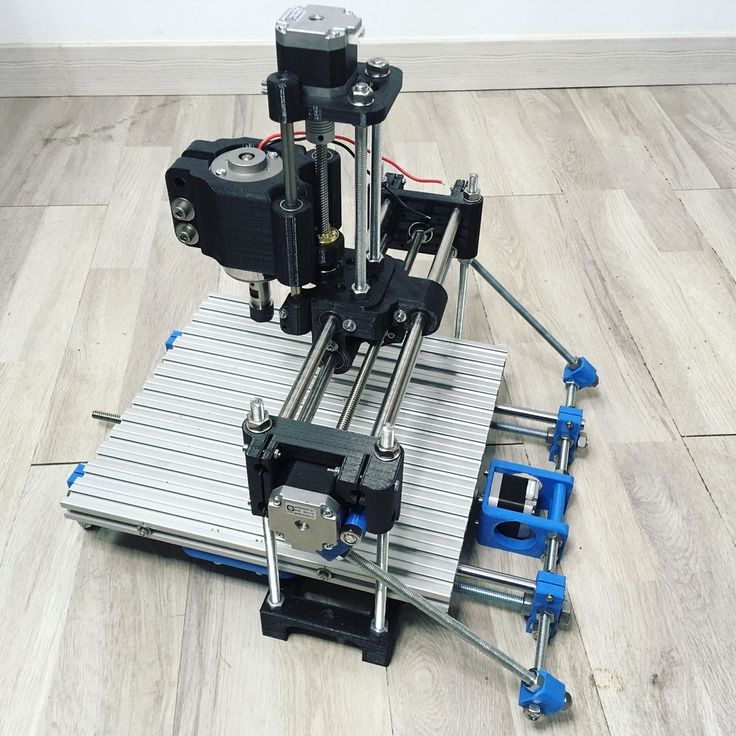

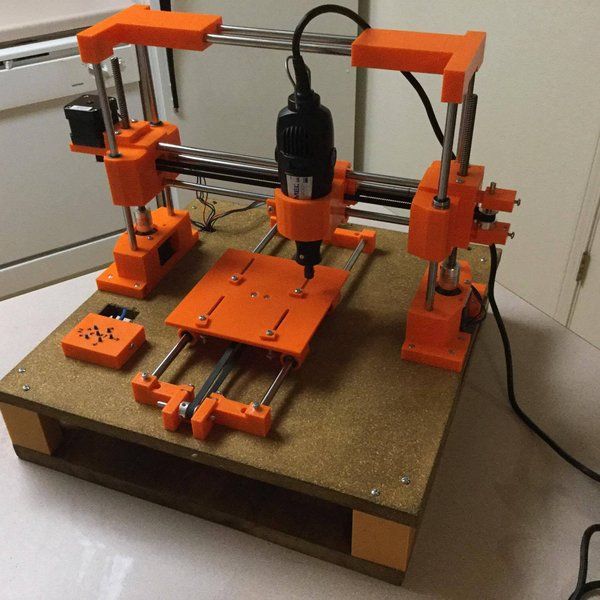

www.slav-dvor.ruThe best 3D printers today will be very different from the 3D printers of a decade ago, but they still can't produce good results without pre-configuration, while most people buy 3D printers because I heard they are easy to use.

This may be true, provided that you are already familiar with the technology firsthand, 3D printing is still at a relatively early stage, and even the most expensive models will not give you perfect results right out of the box, which is an additional expense. on the material for the duration of the training and it depends only on you how quickly you master 3D printing and stop translating the material for printing.

on the material for the duration of the training and it depends only on you how quickly you master 3D printing and stop translating the material for printing.

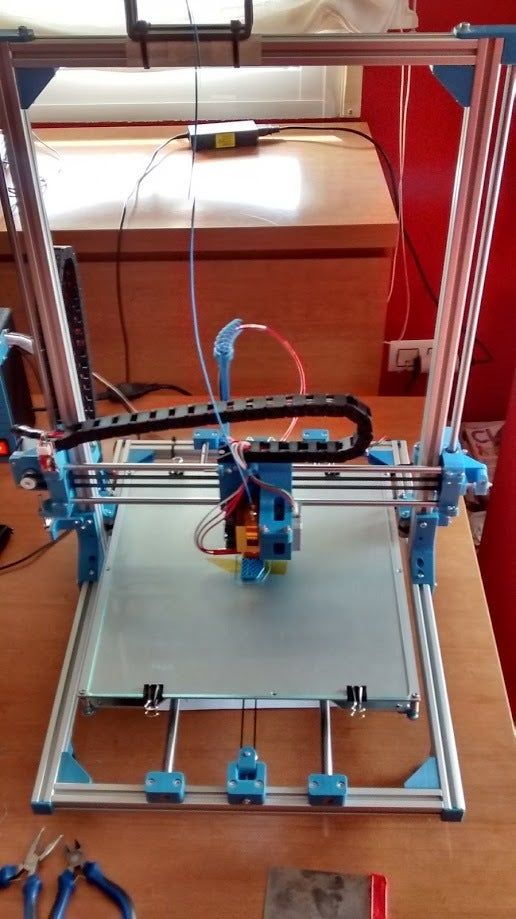

3D printing is great technology, but not for everyone. If you are an engineer or "creator" you might be a great candidate for 3D printing. But if you don't plan on making a living as a designer, or just love making things, it might not be worth investing in a 3D printer.

The cost of a 3D printer is significant. Although the price of consumer-grade 3D printers has dropped significantly over the past few years, they are still a luxury. If you just want to occasionally create products for your personal use or print souvenirs for your family, it's best not to invest in a 3D printer.

We all know that 3D printing is a relatively new product. This can lead to the misconception that you can just buy a 3D printer and print whatever you want. But it's not.

The only way to know if a 3D printer is right for you is to explore different models and then buy the one that suits your needs. For many people, this means buying a basic 3D printer with the features you need.

For many people, this means buying a basic 3D printer with the features you need.

This does not mean that you should buy the printer as cheaply as possible. You just have to make sure the printer has the features you need. This may mean investing in a printer with a high print volume, that is, the maximum distance at which an object can be printed.

We all know that 3D printing can be used to create amazing things. However, many do not use the full potential of their 3D printer. Many people, for example, see 3D printing as a way to print plastic guns. Although this is far from the only high-quality application of 3D printing.

stockimg.netOne of the best uses for 3D printing can be found on Kickstarter. Kickstarter is a site where creators can post projects they are trying to fund. These projects can range from new products to new ideas and new technologies.

Taken from https://www.kickstarter.com/projects/rocket1/kirin-ultimate-dsp-4k-light-engine-for-3d-printing?ref=discovery&term=3d%20printer Projects posted on Kickstarter often are inspired by someone's immediate needs: a designer who needs funds to create a product, a scientist who needs funds to create a new product, or a person who simply needs funds to help bring their idea to market.

These projects are also a great way to learn what kinds of products are made with 3D printers. By studying the types of products people create with 3D printers, you can get a better idea of what a 3D printer is capable of.

3D printing is a great technology. But she's not for everyone. If you just want to make "fun stuff" use a 3D printing service instead of buying a full 3D printer if you don't have a clear goal, you'll just be wasting your money on training materials and the 3D printer itself.

stockimg.netWhat do you think about this issue? Write in the comments.

Also recommended reading:

Cheap and Toxic: ABS Plastic Review

Hi-Tech Plast Filament Review: Cheapest PLA Plastic I've Seen

Is colorless PLA stronger than colored PLA? How the color of a PLA filament affects its physical properties will provide basic skills and knowledge. You can buy immediately CO2...

Agree, that many men like to spend their weekends in bars, sipping beer and chatting with those who turn up by the hand. And if the beer is craft, then indispensable ingredient of such...

And if the beer is craft, then indispensable ingredient of such...

An instinct is an inborn predisposition of a living organism to a certain pattern of behavior characteristic of the species. A key stimulus is needed to trigger the instinct. It will launch an innate...

More recently, it became known that a version of the new browser from Yandex for corporate clients has been presented. This assembly received more advanced features, better protection during...

Egyptian pyramids are majestic structures that were built more than 4 thousand years ago. They are a symbol of ancient civilization and attract the attention of tourists from all over the world....

Google has built a feature called Sleep Sounds into its Android software. Anyone with a smartphone running Android 10 or later can use it...

XJRP SPS350H industrial 3D printer (SLA) - 3D printing equipment supply from Foliplast company with best service

XJRP SPS350H industrial 3D printer (SLA) — supply of equipment for 3D printing from the company Foliplast with the best service- Home

- Catalog

- Industrial 3D Printers

- XJRP SPS350H Industrial 3D Printer

- Description

- Characteristics

- Documents

- Payment and delivery

- Reviews

- Product photo

Description

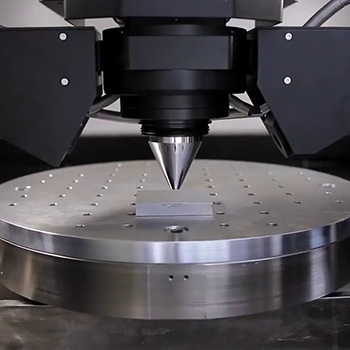

Laser stereolithography was one of the first types of rapid prototyping technologies. The abbreviation SLA refers to the actual equipment, but now it is commonly used in the meaning of technology.

The abbreviation SLA refers to the actual equipment, but now it is commonly used in the meaning of technology.

Laser stereolithography is based on the action of a laser beam on a liquid photopolymer resin. Under the action of radiation, the resin hardens-polymerizes at the point of contact. The beam runs around the contours of the future product, after which a new thin layer of photopolymer is poured and the process is repeated again. Thus, the product is literally built up layer by layer.

Stereolithography allows you to create products of any complexity. Electronic control of the laser beam is performed according to the data of the presented mathematical model. Therefore, to grow a prototype, no additional equipment is required.

Laser stereolithography (SLA) ensures high precision. The base material is easy to process and, if necessary, the created surfaces can be brought to a mirror finish. Compared to other technologies, stereolithography makes it possible to obtain a high strength of the finished sample.

How it works:

Layer-by-layer growth for the rapid production of prototypes (physical samples) of any complexity and shape directly from a three-dimensional mathematical model (CAD data) without the need for any tooling, machining.

Main objectives of the received products :

- Evaluation of construction, design and ergonomics;

- Functionality evaluation;

- Collection analysis;

- Master models for the manufacture of silicone equipment.

Laser stereolithography has the following advantages:

- Ability to manufacture prototypes of any complexity, including thin-walled, undercut, etc.;

- High construction accuracy and excellent surface quality;

- Ease of processing prototypes and manufacturing tooling;

- The possibility of independent use of resins with different characteristics;

- Wasteless production.

You can buy the XJRP SPS350H 3D printer at the representative offices of our company in Moscow, St. Petersburg, Nizhny Novgorod and other cities of Russia, or order on our website by calling 8 (800) 302-13-41. Placing an order for new or used XJRP 3D printers is also possible online, for this you need to leave a request in the product card or contact form. After filling out, the manager will contact you to clarify the order, provide up-to-date information about prices, discounts and payment methods. Make an order today and in the near future you will be able to see the benefits of using XJRP 3D printers.

Characteristics

| Equipment type | 3D printer |

| Print Technology | SLA (Laser Stereolithography) |

| Construction area size, WxHxD, mm | 350 X 350 X 350 |

| Max build speed | 160 |

| Max scanning speed, m/s | 14 |

| Construction accuracy, mm | ±0. 1mm(L ≤ 100mm) or ±0.1% *L(L>100mm) 1mm(L ≤ 100mm) or ±0.1% *L(L>100mm) |

| Layer thickness (adjustable), mm | 0.05 ~ 0.2 |

| Laser model | AOC:FOTIA-355-3W-50K (PULSE-355-3AH) |

| Laser spot diameter, mm | 0.07--0.5mm (adjustable) |

| Optical system | Dynamic VariSCAN20(DF20-DBP) |

| Scanning System | HurrSCAN II 10 (F10-DBP) |

| Amounts of material included in the delivery, kg | 80 |

| Software | RPmanager/RPdata/MagicsBP/Win7 |

| Dimensions | 1370 x 950 x 1950 |

| Machine weight (excluding material), kg | 840 |

| Power, kW | 3 |

Documents

2018 XJRP spec_RU

460 Kb

Payment and delivery

It is possible to pay for goods and services purchased at TPK Foliplast LLC by means of a non-cash transfer of funds by the customer to the settlement account of the organization.

About delivery

Delivery of goods can be carried out by self-delivery from the main warehouse of TPK Foliplast or with the help of transport companies. Delivery to the regions of Russia by a specific transport company is agreed with the client individually.

For the convenience of preliminary calculation of shipping costs, we provide links to calculators of popular transport companies:

Cost calculation

Cost calculation

Cost calculation

Cost calculation

Cost calculation

Cost calculation

In such regions as: Nizhny Novgorod, Moscow, St. Petersburg, Samara, Kazan, Novosibirsk, our products can be obtained at the following addresses:

| Nizhny Novgorod (production and main warehouse): | st. Pamirskaya, 11n Pamirskaya, 11n |

Moscow:

| Major Express - st. Dobrolyubova, d. 2, building 1 | CDEK - Aviamotornaya st., 67/8, building 1 | ||

| Business Lines - st. Lobnenskaya, 18, building 2 | DPD - Kirovogradskaya street, 15 | ||

| Baikal Service - st. Plekhanova, 11, building 6 | PEK - 1st Vyazovsky pr., 4, building 19 |

St. Petersburg:

| Major Express - st. Dvinskaya, 23 | CDEK - st. Rossiyskiy Ave., 8 | ||

| Business Lines - 1st Verkhniy Lane, 12 B | DPD - st. Domostroitelnaya, 1, Letter B Domostroitelnaya, 1, Letter B | ||

| Baikal Service - 1st Upper Lane, 12 E | PEK - st. Tosina, 9 |

Samara:

| Major Express - st. Stara Zagora, 25 | CDEK - st. Volskaya, 71 | ||

| Business Lines - st. Democratic, 45A | DPD - st. Vrubel, 11 | ||

| Baikal Service - st. Tovarnaya, d. 8, building 1 | PEK - st. Zemetsa, d. 32, bldg. 354 |

Kazan:

| Major Express - st. Vosstaniya, d. 100, building. 211a | CDEK - st. Dekabristov, 156 | ||

Business Lines - st. Adela Kutuya, 151 Adela Kutuya, 151 | DPD - st. Hlebozavodskaya, 7 V | ||

| Baikal Service - st. Bukharskaya, 3 | PEK - st. Tikhoretskaya, 19 |

Novosibirsk:

| Major Express - st. Family Shamshin, 30 | CDEK - st. Krivoshchekovskaya, 15, bldg. 1 | ||

| Business Lines - st. Sukharnaya, 35/1 | DPD - st. Bolshaya, d. 256 B, building. 1 | ||

| Baikal Service - st. Chukotskaya, d. 2B, bldg. 1 | PEK - st. Planetnaya, 30, bldg. 2A |

Photo of finished product

Photo of finished product

A wide range of Large selection of equipment and materials

Leasing Possibility of leasing

Profile specialists Qualified specialists in their field

Similar items

- Learn more

5” x 78.7” x 39.4”

5” x 78.7” x 39.4”  8”

8”