3D printer scanner milling machine

Proto3000 Dental | 3D Printers, Dental Mills, Dental 3D Scanners, CAD/CAM

Our solutions portfolio of 3D printers, dental mills, 3D scanners, software, advanced materials, and expert advice can transform your dental lab or clinic with a seamless, open, and integrated workflow.

Speak to an Expert

Introducing Flexcera™A new DLP 3D printing resin for the fabrication of beautiful, functional dentures with ceramic-like strength. Available as Flexcera™ Smile and Flexcera™ Base and formulated exclusively for use with

ETEC® 3D printers.

Flexcera™ Base Flexcera™ Smile

Explore our range of high-performance dental 3D printers

designed for applications from the clinic to the lab.

Explore

Dry-electropolishing technology enables quick and cost-effective post-processing of fixed, removable, and implant prosthetics

Learn More

The latest and most precise machines for your compact or heavy duty dental labs.

Learn More

We Help Your Business Grow

Explore our end-to-end solutions for digital dentistry.

- GroupCreated with Sketch. 3D Printers

- Dental Mills

- Group 2Created with Sketch. Scanners and Software

- Group 2Created with Sketch.

Advanced Materials

Advanced Materials - qa-icon Services

- Support

- GroupCreated with Sketch. 3D Printers

- Dental Mills

- Group 2Created with Sketch.

Scanners and Software

Scanners and Software - Group 2Created with Sketch. Advanced Materials

Keystone KeyPrint® Biocompatible Resins

End-use biocompatible 3D printing materials for a modeless wokflow

Learn More

Keystone KeyPrint® Laboratory Resins

Laboratory 3D printing resins for high throughput and quality

Learn More

Flexcera™ Base by Desktop Health

FDA-cleared 3D printing resin with ceramic-like strength for 3X stronger digital dentures

Learn More

- qa-icon Services Dental 3D Printing Services

Don’t have a 3D printer in-house? Don’t let that stop you from taking on digital volumes.

Our service bureau is here to assist those exploring 3D printing, or for those who require overflow services. Our in-house capabilities allow us to help you with the following applications: dental and orthodontic models, surgical guides, implant models, crown and bridge, and surgical simulation & training models.

Our service bureau is here to assist those exploring 3D printing, or for those who require overflow services. Our in-house capabilities allow us to help you with the following applications: dental and orthodontic models, surgical guides, implant models, crown and bridge, and surgical simulation & training models.upload files

- Support

Proto3000 Support

We are here to make sure your printers and mills are running like new. Our support team will make sure you don’t miss out on any valuable production time. Your productivity is our priority, and you can rest assured that our team of certified Stratasys and imes-icore technicians are standing by should any issues arise. If you have any questions or concerns, feel free to contact us.

CONTACT US

With professional 3D printers and mills designed for orthodontics and dentistry, your lab can benefit from a streamlined digital workflow. Explore everything this technology has to offer including materials, applications, educational whitepapers, and real-life stories.

Explore everything this technology has to offer including materials, applications, educational whitepapers, and real-life stories.

With professional 3D printers and mills designed for orthodontics and dentistry, your lab can benefit from a streamlined digital workflow. Explore everything this technology has to offer including materials, applications, educational whitepapers, and real-life stories.

Dental and Orthodontic Applications With 3D printing technology you can go directly from intraoral or

digital scan data to a variety of different applications. Take a look

at how we can transform the way you produce restorative,

orthodontic, crown and bridge, implant, removables,

and visual aid models.

Explore Now

Materials Our 3D printing materials and resins are designed specifically for dental

and orthodontic applications. These rigid, opaque, and bio-compatible

These rigid, opaque, and bio-compatible

materials are made with the latest chemistry allowing for in-mouth long-term applications

like dentures, aligners, and more.

Explore Now

The Final Touch Our post-processing and finishing solutions complete the

workflow with polishing systems from DLyte and sintering

systems from Dekema. Simplify your post-processing and

discover the business impact of automation.

Discover

Case Studies

Dental labs of all sizes all over the world have discovered

the transformative power of 3D printing and dental milling

technologies. Hear their stories about unearthing new

opportunities for cost reduction and streamlined workflows.

Discover

Discover Industry-Leading Dental 3D Printers, Mills, Materials and Finishing Systems

Our 3D Printers and Dental Mills from Desktop Health, imes-icore, RapidShape, and VHF are defining a new age of digital dentistry.

Einstein™

Fit for a Genius

The Einstein is set to deliver the critical features in DLP 3D printing: accuracy, speed and versatility. The proprietory NanoFit385 nm technology ensures stunning clarity, perfect fit and an impressively natural-looking finish. Fabricate faster and more thanks to Einstein's HyperPrint™ software and materials versatility, from dentures to models and everything in between.

View Product View Video

VHF R5

High-end dental restorations with the speed and efficiency of automation

The VHF R5 5-axis dental mill is an automated solution for wet and dry milling designed to tackle a range of dental applications with reliability and precision. With an impressive 150 kg of weight on a minimal footprint and a repetition accuracy of the linear axes of ±0.003 mm the VHF R5 delivers ultra HD accuracy in a space that works for your lab.

With an impressive 150 kg of weight on a minimal footprint and a repetition accuracy of the linear axes of ±0.003 mm the VHF R5 delivers ultra HD accuracy in a space that works for your lab.

View Product

Rapidshape D50+

The more, the better.

The Rapidshape D50+ has a print range three times (3x) larger than the D30+.

For an even greater dental lab productivity, with the optional patented separation unit, you can skyrocket the number of pieces 3D printed in a day.

View Product

CORiTEC 350i series

The Automated All-In-One Solution

The CORiTEC 350i series from imes-icore are the ultimate milling machines for dental production. Their unique capabilities and automation systems make them ideal for demanding production environments where accuracy, efficiency, reliability, and throughput are essential. Their robust design allows for the processing of a range of materials including glass ceramics, composites, polymers, pre-milled abutments, and metals.

Their robust design allows for the processing of a range of materials including glass ceramics, composites, polymers, pre-milled abutments, and metals.

View Product View Video

DLyte Dental Compact Series

Automate the polishing of casted, sintered, milled, and 3D printed metal parts

The innovative DLyte machines are engineered for surface finishing of metal alloys including titanium, based on the patented DryLyte technology. This technology allows the grinding, rounding, and deburring as well as surface smoothing and high gloss polishing of any casting, sintered or milling metal parts such as dental skeletals, spacers, implants, and orthodontic brackets.

View Product View Video

Einstein™

CORiTEC 350i series

DLyte Dental Compact Series

Shaw Labs Uses Stratasys 3D Printers to Complete Digital Workflow

Shaw Group has been on the forefront of changes in the dental industry. Now with the transition of dental applications to a digital workflow, their team has invested in CAD/CAM, 3D scanning, and now Stratasys dental 3D printers.

Now with the transition of dental applications to a digital workflow, their team has invested in CAD/CAM, 3D scanning, and now Stratasys dental 3D printers.

View Case Study View Video

Shaw Labs Uses Stratasys 3D Printers to Complete Digital Workflow

Digitize Your Workflow

Work with our team of digital dentistry experts to develop a digital workflow for a wide range of dental applications

Fixed Restorations

Including 3D printed or milled crowns, bridges, onlay, inlay, veneers, and implant bars

Implant Restorations

Including bars, abutments, and abutment crowns

Removables

Including 3D printed or milled dentures, removable partial dentures (RPDs), night guards, and bite splints

Guided Surgery

Including implant planning and 3D printed biocompatible surgical guides

Orthodontics

Including clear aligners, indirect bonding trays, and ortho appliances

Education and Training

Typodonts, realistic teeth, gum simulation, study models, and training models

Treatment Planning and Visualization

Including software tools for visualization, simulation, digital archiving, surgical planning, diagnostics, and maxillofacial

3D Printing and Dental Implants

A New Method to Create Surgical Guides Elevates the Standards of Care

View White Paper

Speak to an Expert

Sign Up to Receive Our Latest News & Hottest Promotions

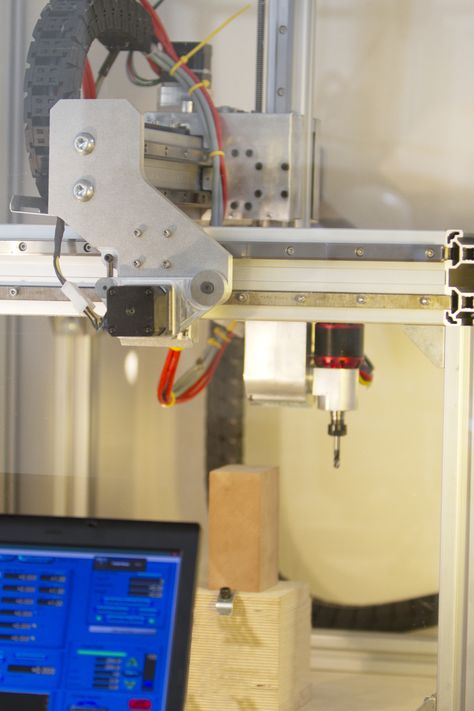

3D print, mill and scan with the FABtotum hybrid fabrication machine

Electronics

August 28, 2013

View 10 Images

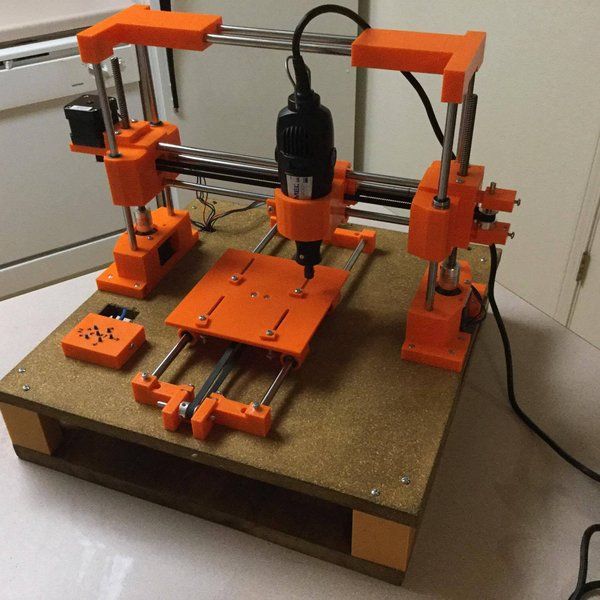

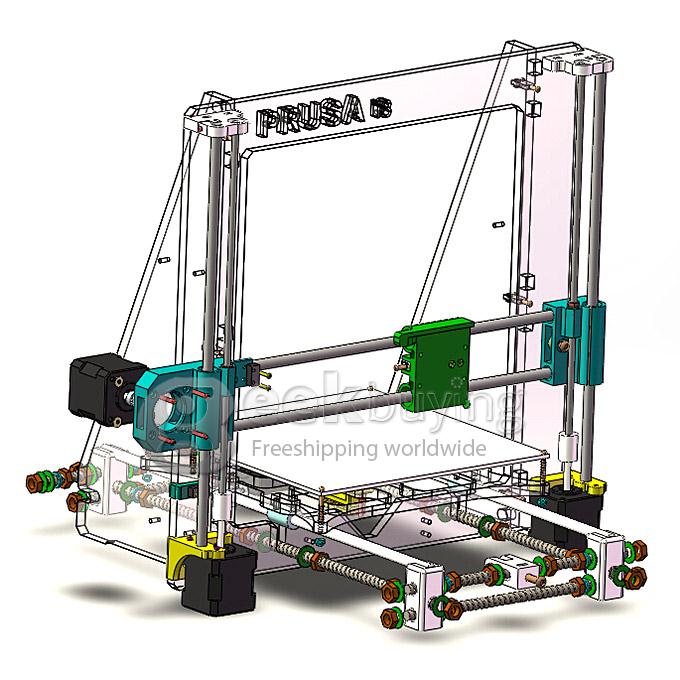

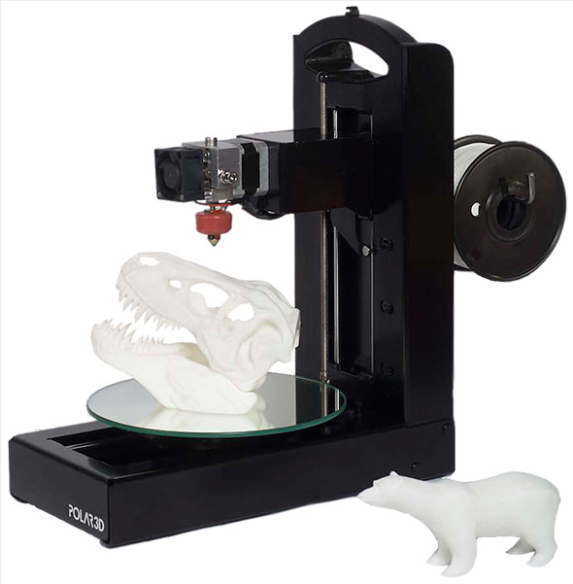

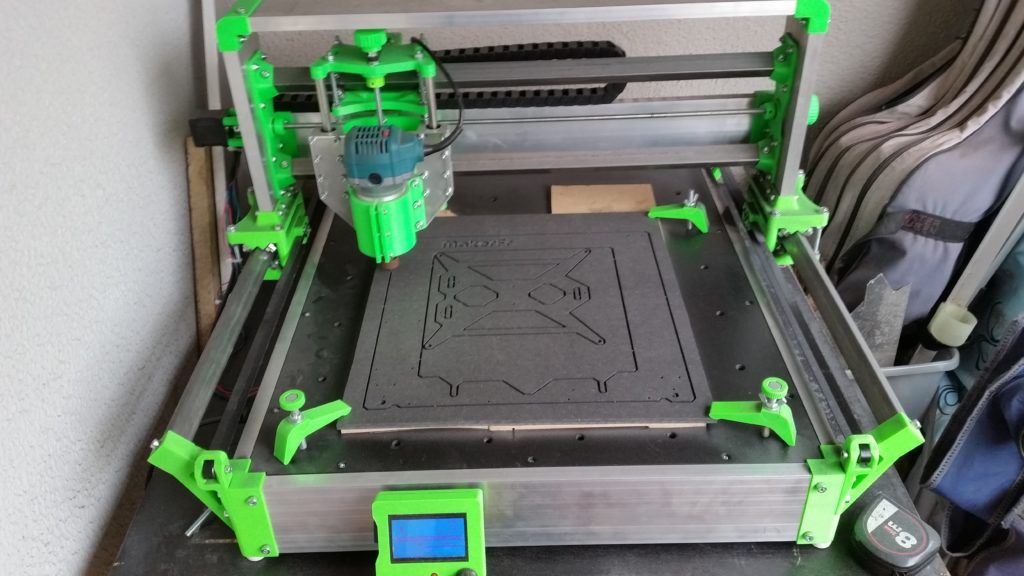

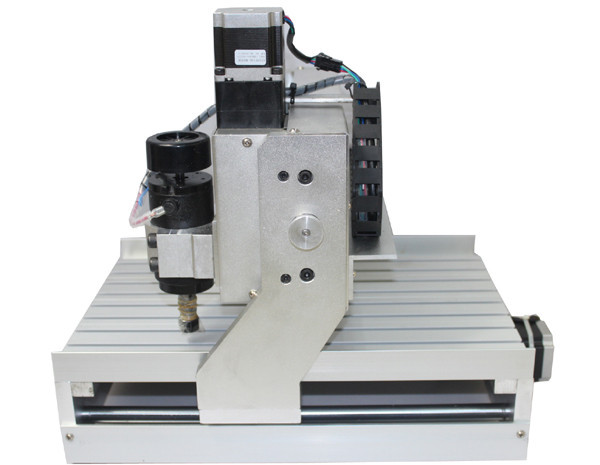

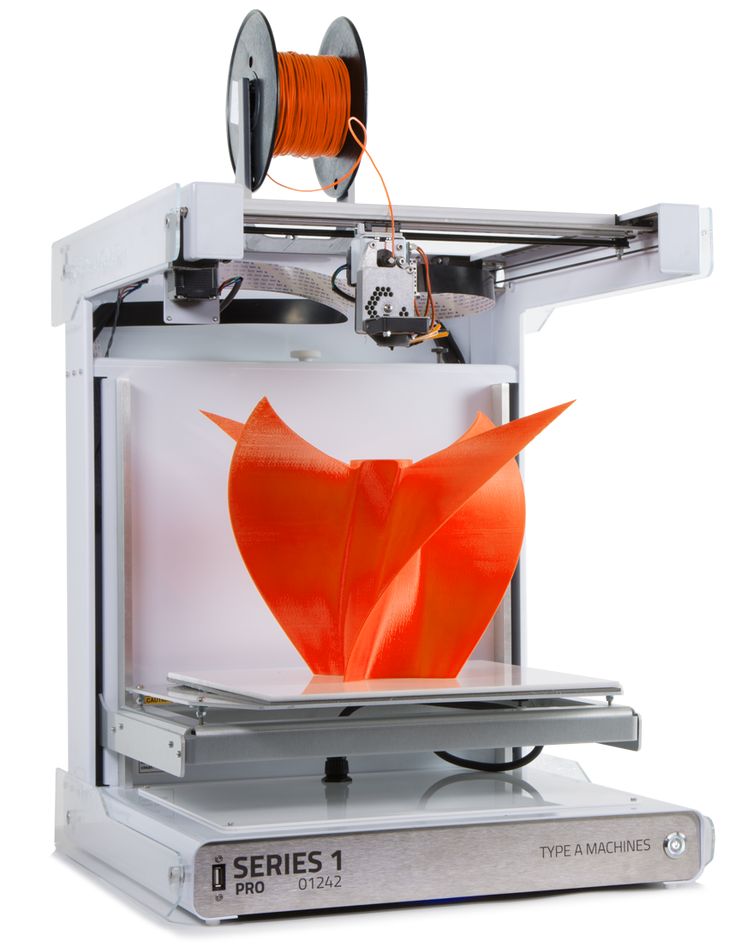

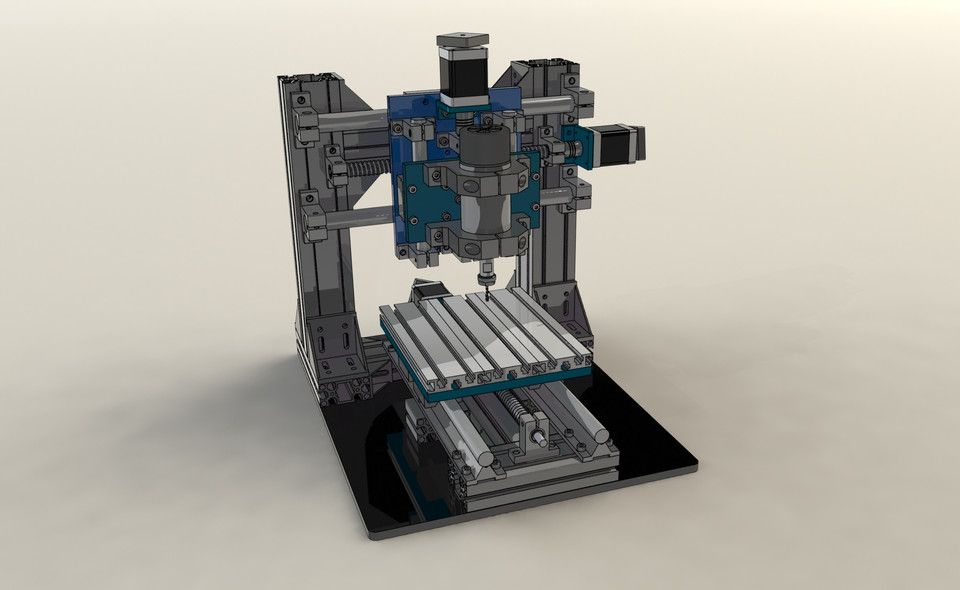

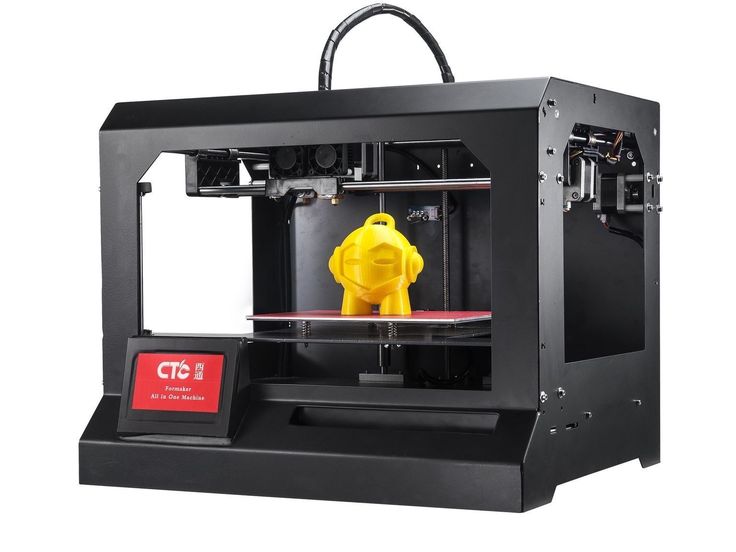

View gallery - 10 imagesIf you’re in the market for a personal fabrication machine, you probably already know that your budget might allow for a 3D printer or a CNC machine, but not both, and an additional 3D scanner would just be icing. However, all three are now available together on Indiegogo in the form of the FABtotum, one of the first hybrid fabrication machines in a quickly developing market.

However, all three are now available together on Indiegogo in the form of the FABtotum, one of the first hybrid fabrication machines in a quickly developing market.

I'll explain the name right off: in Latin, a factotum is a human servant responsible for many different things, literally doing and making everything.

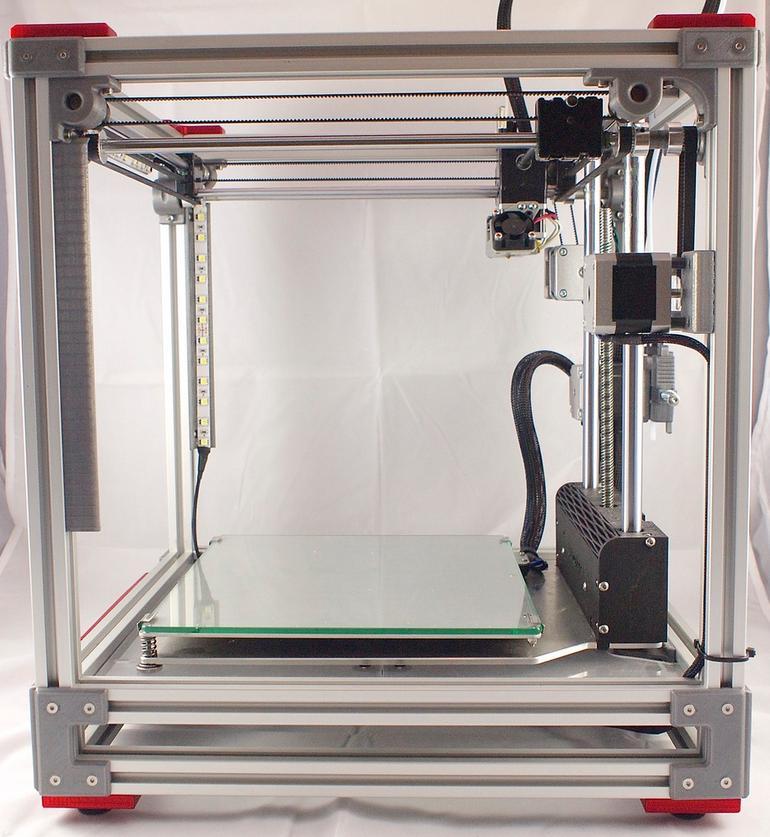

This FABtotum, however, is a shiny and neat 36-cm (14-inch) cube available in many color options. The maximum printing size is 210 x 240 x 240 mm (8.3 x 9.5 x 9.5 in), which is large proportionate to its overall footprint. Tools can be easily swapped out and the company will allow third-party tools and parts to be sold on its website – no proprietary spools of printing material to buy, or expensive upgrades.

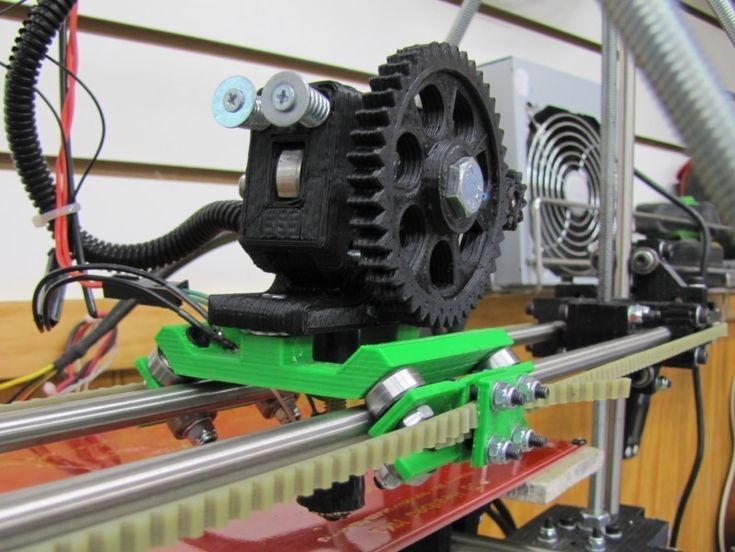

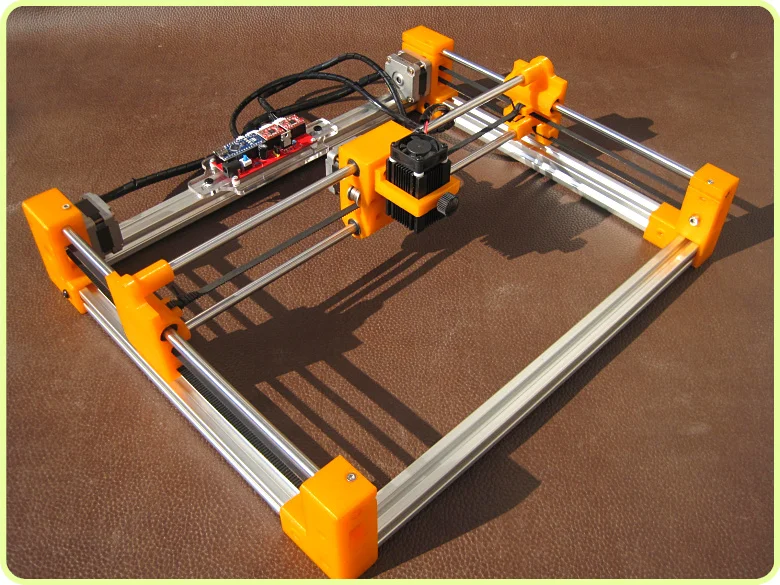

Additive printing with FABtotum allows for both quick prints and more polished prints with a Z-axis precision of 0.47 microns. Material options with the included CNC head only allow for lightweight materials up to thin aluminum and brass alloys, but users can swap in heads with stronger motors for other materials. The range of applications include milling, including circuit boards, 4-axis engraving, 2.5-D profiling, CNC pre-drilling, and 4-axis machining. The so-called 4th axis is a rotational axis, useful for lathing items or even creating fully 3D objects.

The range of applications include milling, including circuit boards, 4-axis engraving, 2.5-D profiling, CNC pre-drilling, and 4-axis machining. The so-called 4th axis is a rotational axis, useful for lathing items or even creating fully 3D objects.

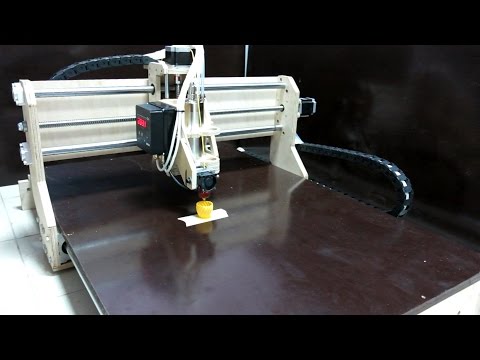

A range of products cut, milled, and printed with the FABtotum

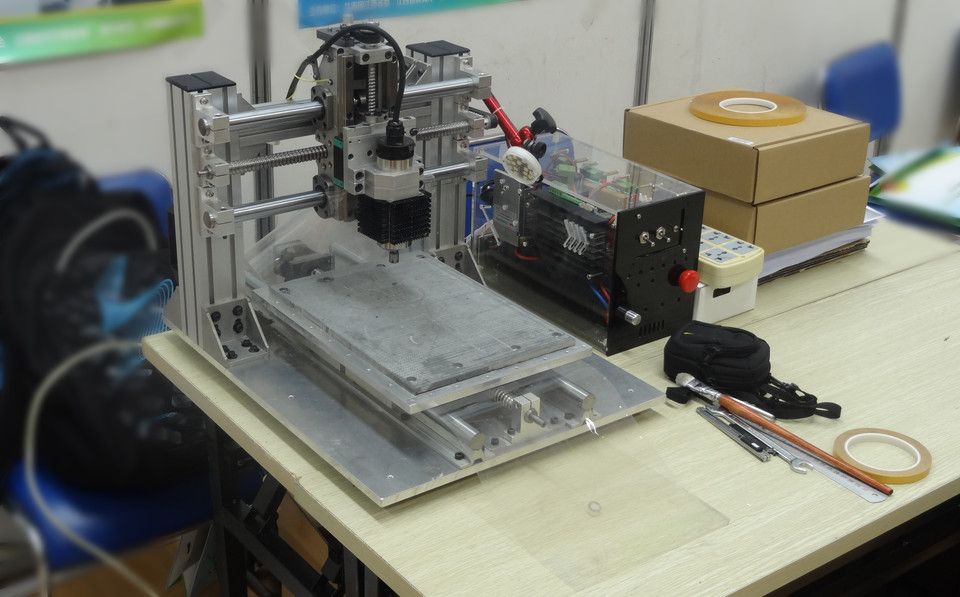

FABtotum’s scanning feature incorporates its 4th axis for touch probe digitization, useful for high accuracy scans, but it also has a laser for quicker scans. Between these two components, the company says that the machine can acquire objects that are smaller and more complex than many other 3D scanners.

Switching from printing to milling can be done easily, but even better is the dual head option allowing for alternate milling and printing without user intervention, adjusting the project, or having to swap parts. Marco Rizzuto explained the system in more detail over email, pointing out that while the system doesn’t allow for both heads to work simultaneously, this was done as a cost-balancing feature due to the expense of the extra parts, and will still be explored later.

Because FABtotum is being released open source, the schematics will be available online. But in addition to expressing interest in a hearty open-source community, the FABtotum also comes off as a valid option for those who don’t have the skills or interest to build their own machine. Buyers are promised replacement heads and two years of repairs. The company is open about design choices, constraints, the full list of specs (available on the Indiegogo page), and expected differences between the prototype machine and the shipped version.

The FABtotum is available for backing on Indiegogo until October 7, with delivery anticipated for May – if the funding goal is met. Pledge options include a fully-finished version for $1,099, a couple of flavors of DIY kits, and discount coupons for those who are interested but can’t commit to the full price now.

In the video below you can see the alpha prototype in action, set to dubstep.

Sources: FABtotum, Indiegogo via Shapeways

FABtotum Personal Fabricator - 2013 Indiegogo Campaign

View gallery - 10 imagesTechno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

CARIMA DENTAL 3D PRINTER

Delivery

In Moscow and Moscow Region within 3 days. To other regions by courier service at the expense of the recipient.

Payment

DEAR CLIENTS!

Due to the general economic situation and exchange rate instability , all prices on the website have the status "on request" .

We ask you to clarify the cost and availability of the ordered equipment from our managers by phone or on-line consultant.