Can a 3d printer print anything

Can 3D Printers Print Anything? – 3D Printerly

3D printing is a fairly modern technology which has had its capabilities questioned many times over the years. Many people wonder whether 3D printers can print absolutely anything so I’ve decided to make a post on it and try to answer it as good as I can.

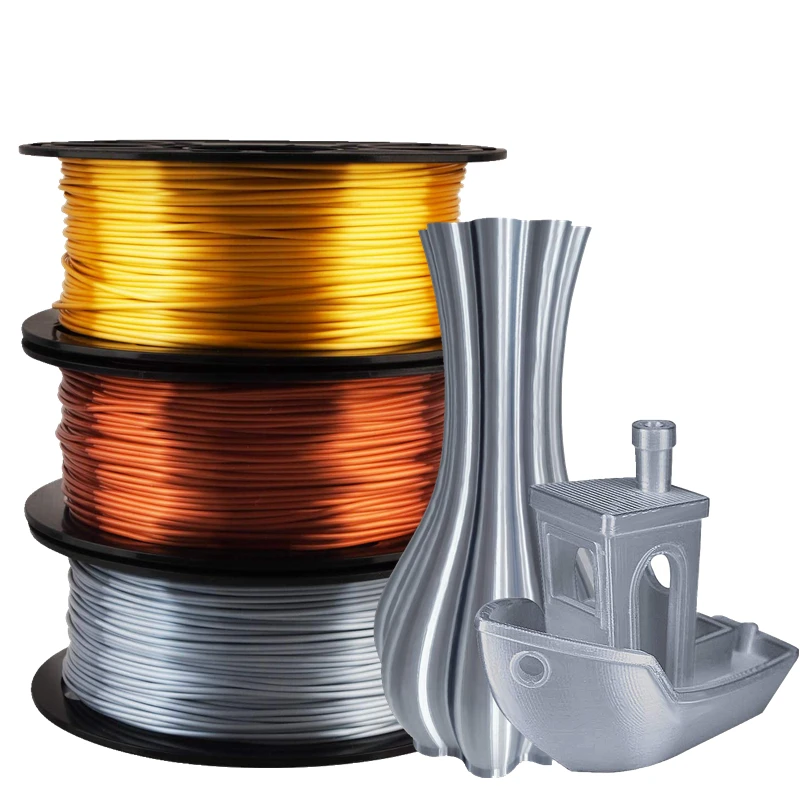

Can a 3D printer print anything? No, 3D printers can’t print anything in terms of materials and shapes. 3D printers require specific properties in materials to 3D print such as thermoplastics like PLA that soften when heated rather than burn. They can print almost any shape, structure and object with the right orientation and help of supports.

That’s the simple answer but I will go into more important details about what a 3D printer can print and its limitations.

What Can a 3D Printer Actually Print?

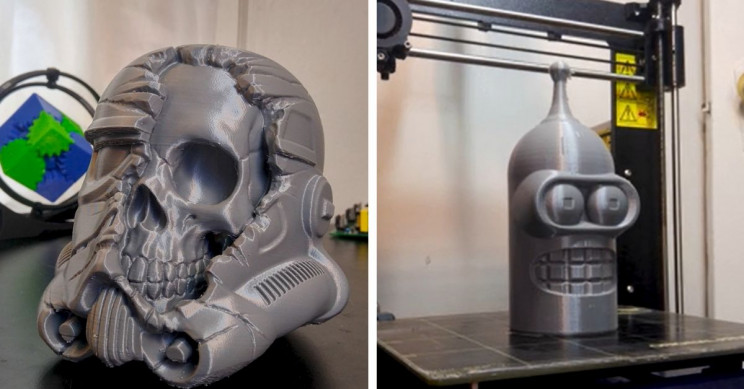

So generally, a 3D printer does a wonderful job at printing most objects in terms of their shapes and structures and there are several examples of 3D printers doing almost the impossible.

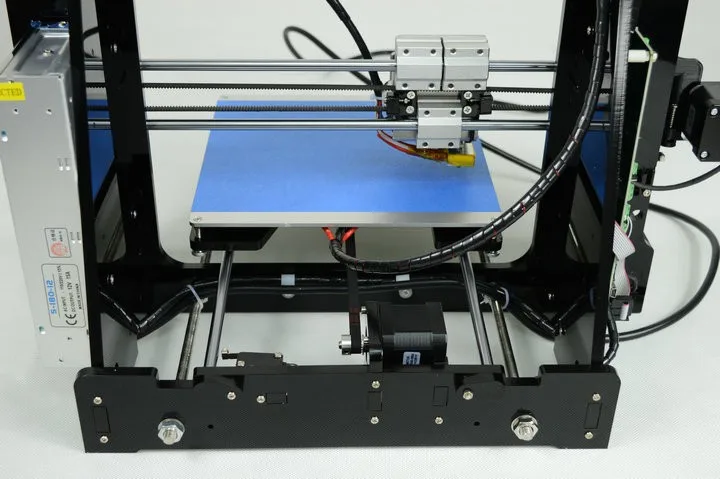

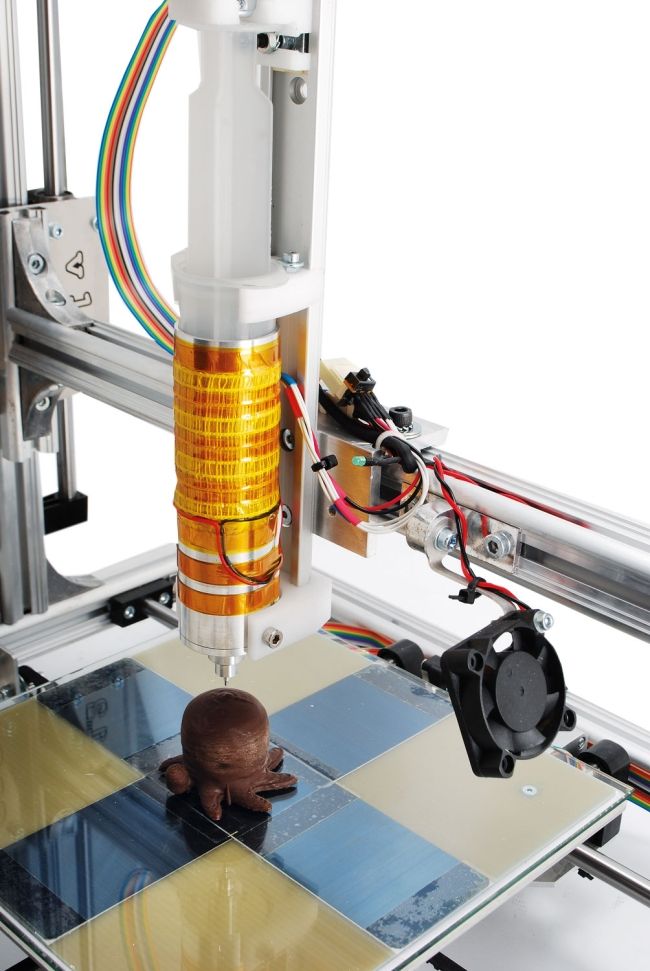

A 3D printer can print almost any shapes no matter how complex and detailed because it’s done in extremely fine layers and builds up an object from the bottom, up from the printing surface.

The usual layer height that people use is 0.2mm but they can go as low as 0.05mm per layer, but this would take an extremely long time to print!

It means that even if there are curves, gaps or sharp edges, a 3D printer will print right through these obstacles.

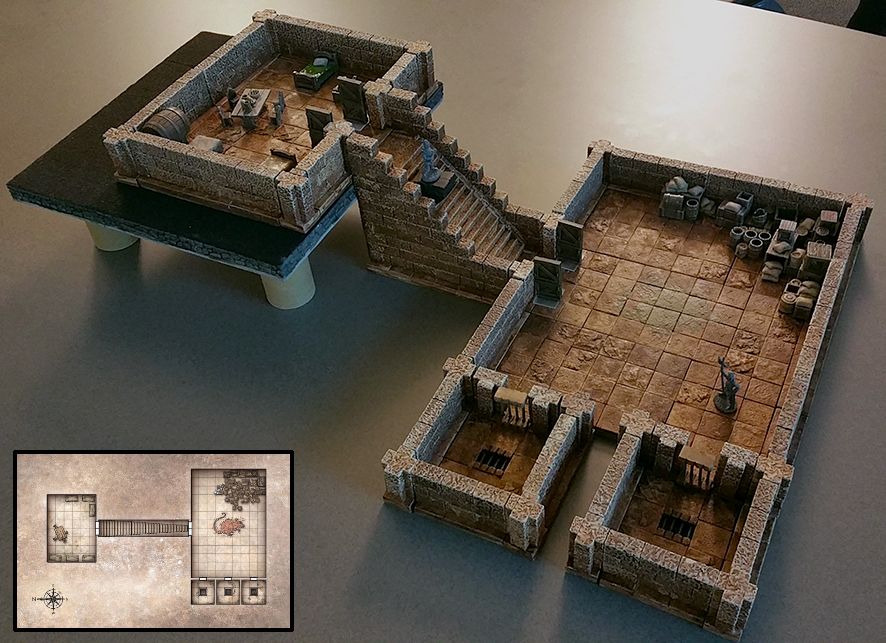

I’ve created a nice post on 51 Functional, Useful Objects Created with 3D Printing which showcases many examples of the beneficial objects you can create. Here’s a brief list of functional objects that 3D printers have created:

- A whole house

- The body of a vehicle

- An electric guitar

- Prototypes of all kinds

- Detailed action figures and characters

- Battery size converter to change those small AA batteries to C size

- A phone lockbox that you put your phone in and hide the key in another room!

- Tesla Cybertruck doorstop

- DSLR lens cap replacements

- Pet food dispenser if your pets usually eat too fast

- 3D printed heart valves

- Replacement coolant cap for your car

The list of items that people 3D print with are growing at insane rates each year, so we can only imagine the abilities and expansions we will see with 3D printing in the future.

3D printing is used in the automotive, medical, aerospace, home improvement, arts & design, cosplay, nerf gun, drone industries and tons more.

It’s the perfect hobby for a hobbyist because it can really expand into any hobby with a little bit of creativity and a can-do attitude. Imagine being a decorator and you find a hole behind a particular area where it’s hard to fill.

One individual actually 3D printed a wall cavity by 3D scanning it then inserting it into place and painting over it.

You might be thinking, what about shapes that hang over too far so it has no foundation underneath? You can’t just print in midair right?

Technically, no, but the advancement in 3D printing technology has created and made use of something called ‘supports’.

These are pretty self-explanatory and what they do is build a foundation underneath such objects to essentially support the object being printed. Once the object is finished and printed, the supports are then removed so it looks like nothing was ever there.

Once the object is finished and printed, the supports are then removed so it looks like nothing was ever there.

The possibilities of 3D printing really are endless.

The limitations of 3D printers have definitely been gradually decreasing over time.

Say, 10 years ago, a 3D printer had nowhere near the capabilities that it has today, from the materials that it can process to even the advancement in types of printing such as metals.

You have multiple technologies within 3D printing that aren’t held back by the same limitations as other technologies, so if you have a specific project, you can figure out what would work best for you.

Check the video out below that goes through some of the different 3D printing technologies.

What Are the Limitations of A 3D Printer?

Manufacturing Speed

Although 3D printing has the ability to create objects that traditional manufacturing methods would find extremely hard to create, it’s manufacturing speed per product does hold it back.

You can create customized, unique products that give huge benefits to an individual but being able to scale such items is a limitation of 3D printing.

That’s why it’s unlikely that 3D printing will be taking over the manufacturing industry any time soon, but this is a topic that is being looked at in the 3D printing industry. It did, however, take over the hearing aid industry in a very short space of time.

There are 3D printers out there that are extremely fast compared to how they used to be.

Below is a video that shows exactly that. They showcase a 3D printer which prints at 500mm per second which is exceptionally fast compared to your normal speeds of around 50mm per second.

There are types of printing which print in layers at a time rather than extruding every part of an object so speed can definitely be upgraded.

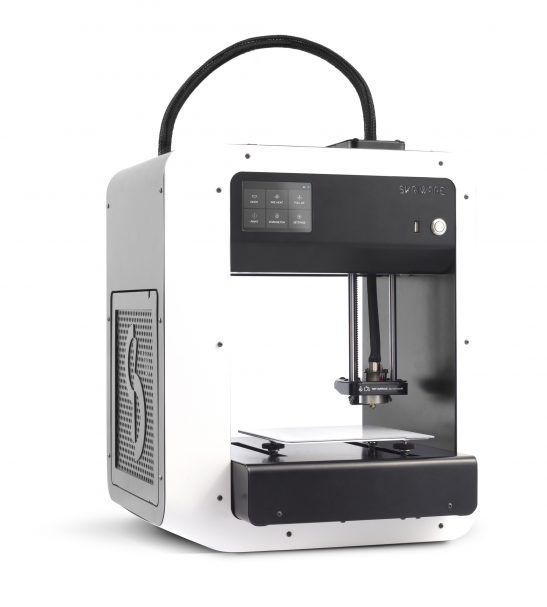

Can be Overwhelming for Beginners

It’s easy for individuals to get involved in 3D printing but there are many aspects that make it quite difficult. For 3D printing to really progress and develop into a common household product, it needs fewer steps and a simpler process for people to get started.

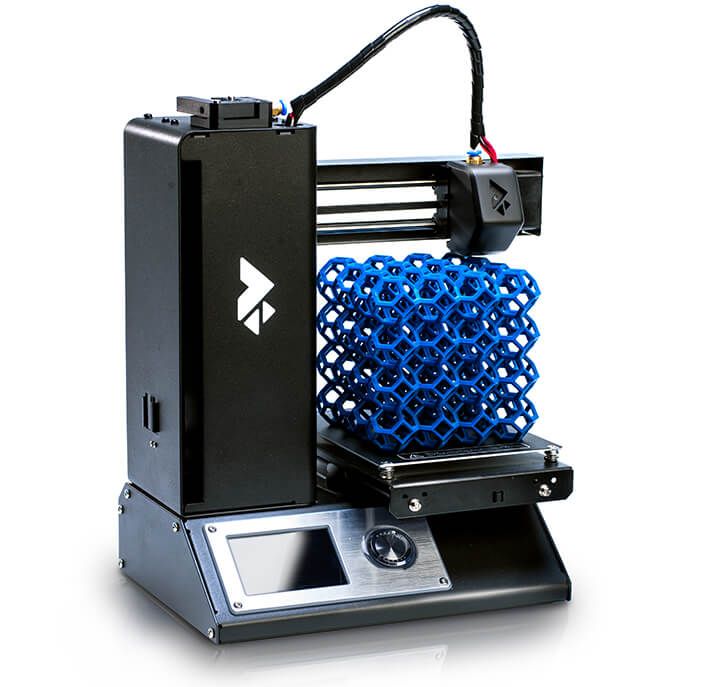

Many 3D printers are being made in a plug-and-play type of deal so this is certainly a problem being solved.

Other aspects such as designing your own prints can have quite the learning curve so when a complete beginner thinks about getting involved with 3D printing, they can get quite overwhelmed.

3D Scanner Applications

Rather than having to design, you have the choice to use a 3D scanner, with even smartphones giving 3D scanner options that you can make use of. The very accurate 3D scanners that are out there are pretty expensive so it’s definitely a deterrent for most people to try out.

I think in due time, as things progress, we will start to get cheap 3D scanners that work very well.

The great thing is that many people design things that are free for people to download and print directly. It saves you having to go through the creative process to make use of 3D printing.

Wrong Ideas of What 3D Printing Can Do

Sure, 3D printing can do tons of things that wouldn’t have been possible for the majority of people to begin to attempt, but people don’t know the real limitations.

As previously mentioned, the remarkable progress that manufacturers have made in the 3D printing space can only be applauded and I think they will continue to push through.

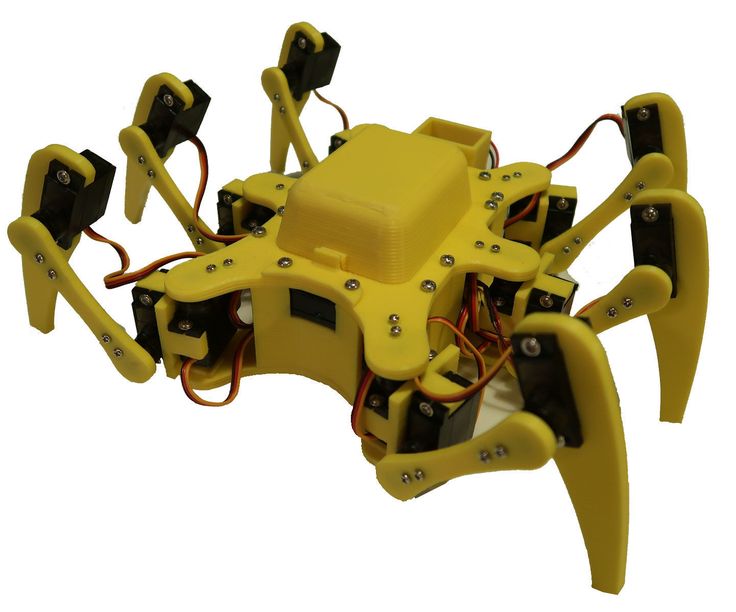

We cannot print objects outside the scope of what the actual material is extruded, so we can’t print electronic parts, wiring, motors, drivers etc. We can, however, print many of the parts which attach to these mechanical and electronic parts as a mount, holder or connector for these objects.

For example, many people out there have 3D printed prosthetic limbs, hearing aids, cosplay suits and accessories, DIY home modifications and much more.

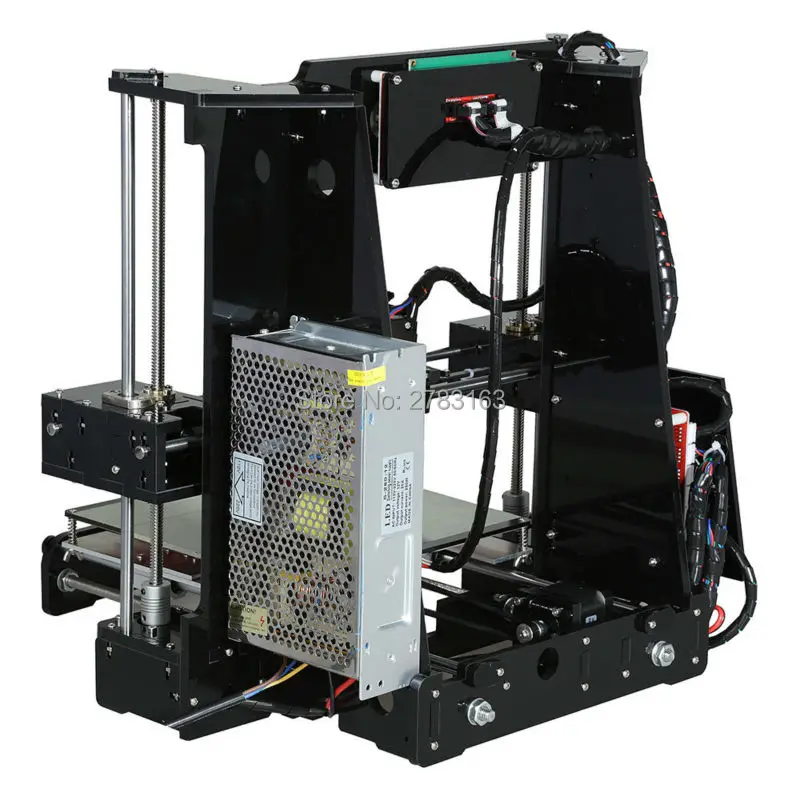

Can a 3D Printer Print Another 3D Printer?

The age-old question, if 3D printers are so remarkable, why don’t you just 3D printer another 3D printer right? Well, you might be pleasantly surprised at just how much a good quality 3D printer can do for you.

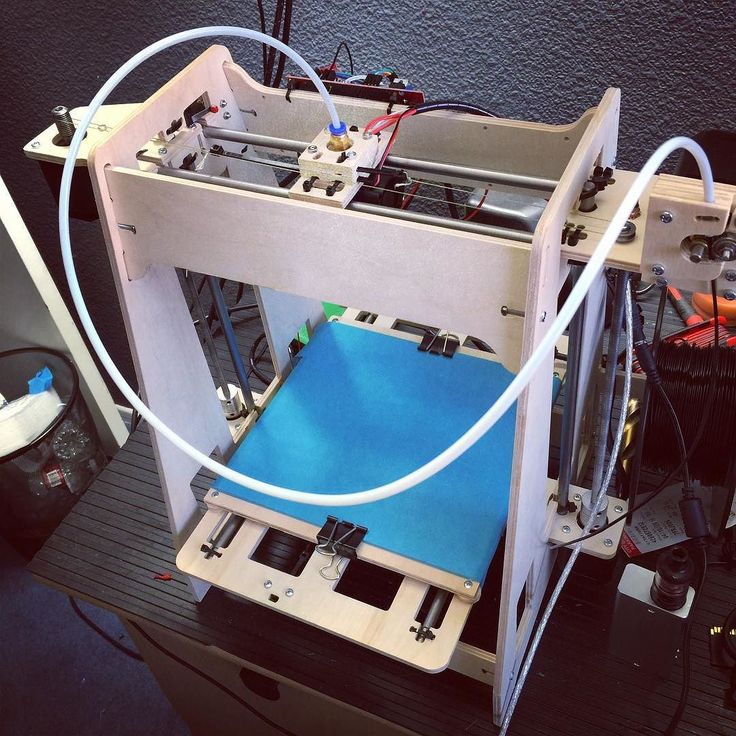

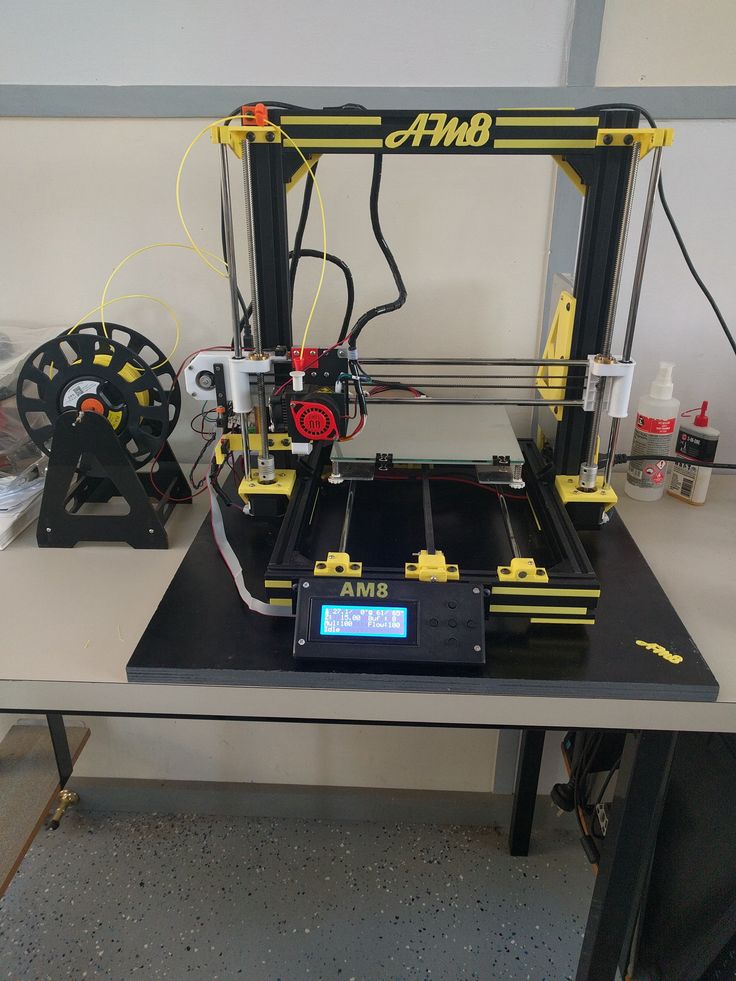

A well-known 3D printer company called RepRap set out to do exactly what you’re asking and they got pretty good at it.

Now because there are motors, drivers, power supply units and other objects that cannot be 3D printed, we won’t be able to completely 3D print a 3D printer, but we can basically do everything else.

RepRap started the first step towards 3D printing a 3D printer and many other creators have taken part and added to the wealth of knowledge to develop more efficient and easily replicated products that do the same thing.

Check out the video below for a great visual on exactly what I’m talking about.

There’s another popular 3D printed 3D printer called ‘Snappy’ which actually snaps together each part so you don’t need many external products to get it combined. We’ve come very far in the 3D printing journey and it’s still a relatively new technology.

We’ve come very far in the 3D printing journey and it’s still a relatively new technology.

Can You Print Paper Money with a 3D Printer?

You’re probably not the first person with this idea unfortunately! But no, a 3D printer cannot print paper money. What it can print similarly is something called a lithophane.

These are pretty cool objects that create 3D objects out of 2D ones. Many people use it to emboss photos and other cool designs onto a surface.

It works by printing the design and ‘thickness’ of a print to show different levels of shading which when light shines through, produces a nice clear image.

How Small of an Object Can a 3D Printer Print?

You might be quite surprised at just how small an object can be printed from a 3D printer. How about smaller than an ant’s forehead? That’s exactly what artist Jonty Hurwitz specializes in and does extremely effectively.

He created the world’s smallest sculpture called nano sculptures, made using 3D printed photosensitive material. When putting an object in comparison to it’s size, you’d find that it’s no wider than the width of a human hair and would resemble a spec of dust in the sunlight.

When putting an object in comparison to it’s size, you’d find that it’s no wider than the width of a human hair and would resemble a spec of dust in the sunlight.

The creation was made using a specialized version of 3D printing called Multiphoton Lithography, which was designed using Quantum Physics by using two photon absorption, really high-level stuff here. It just shows the strides that 3D printing can really go to when research and development is put into it.

You definitely wouldn’t be able to see these amazingly small prints with the naked eye, it would take a very strong microscope to make out the details as you can make out in the picture above.

Even a jewellers 400x magnification-powered microscope doesn’t have the facilities to do this. It took a 30-year specialist in human-cell studies to acquire a machine powerful enough to produce a detailed image.

Can A 3D Printer Print Something Bigger Than Itself?

A 3D printer can only print something within its build volume, but what you can do is print off parts which can be assembled to create one larger object. The same way a 3D printer can create another 3D printer.

The same way a 3D printer can create another 3D printer.

A printer that can produce many of its own parts is the RepRap snappy, which (as the name suggests) consists of plastic parts that – while they each fit within the build volume – snap together to make up the larger parts for the printer.

What many people do when printing whole costumes such as a full Iron Man suit or storm-trooper outfit, they will design the whole model then split the model within a slicer application which is where you

Any specific 3D printer will have a limited build volume so techniques have been devised to get around this limitation. You can 3D print objects that snap together, like the snappy 3D printer that is a whole 3D printer frame that snaps into place.

You can also create a print that requires screws to put together or actually 3D print the screws and threads yourself.

Can a 3D Printer Print Anything? – 3dprintscape.

com

comI’ve been tinkering with 3D printers for quite a while and a question I had back when I was a beginner was what can a 3d printer print? Based on my extensive experience and research here’s what I found.

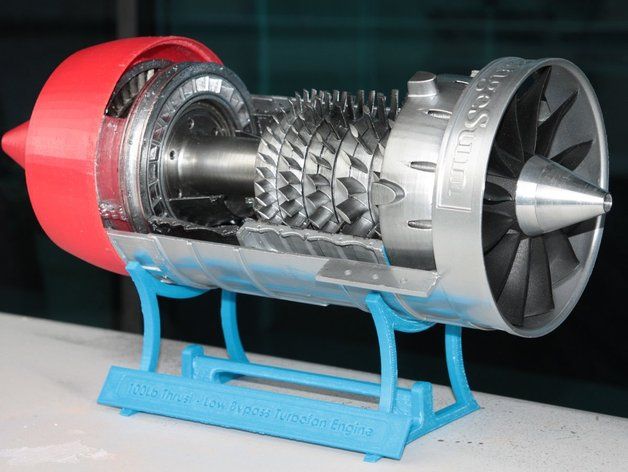

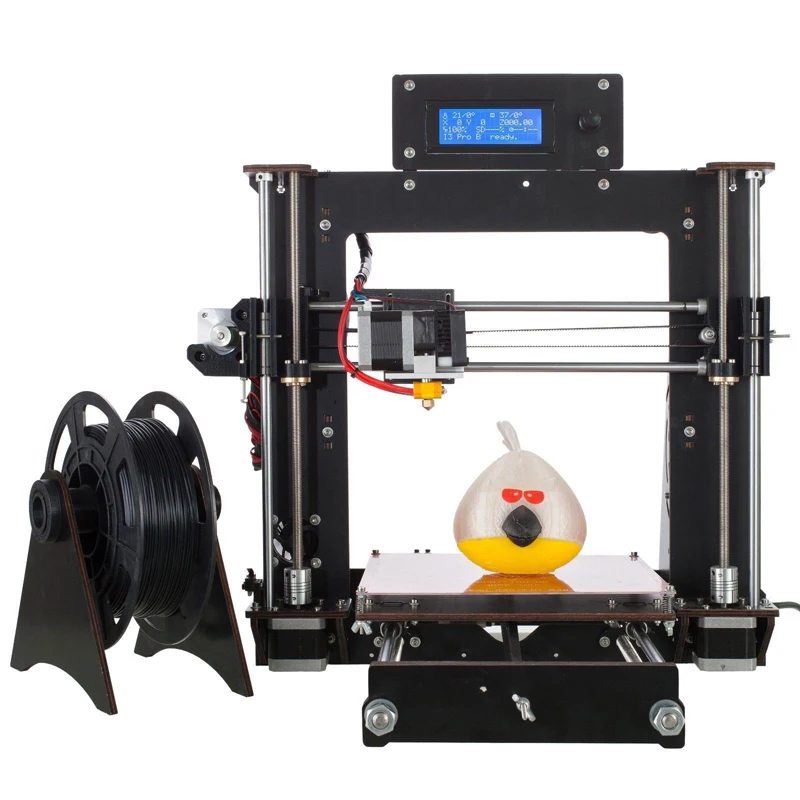

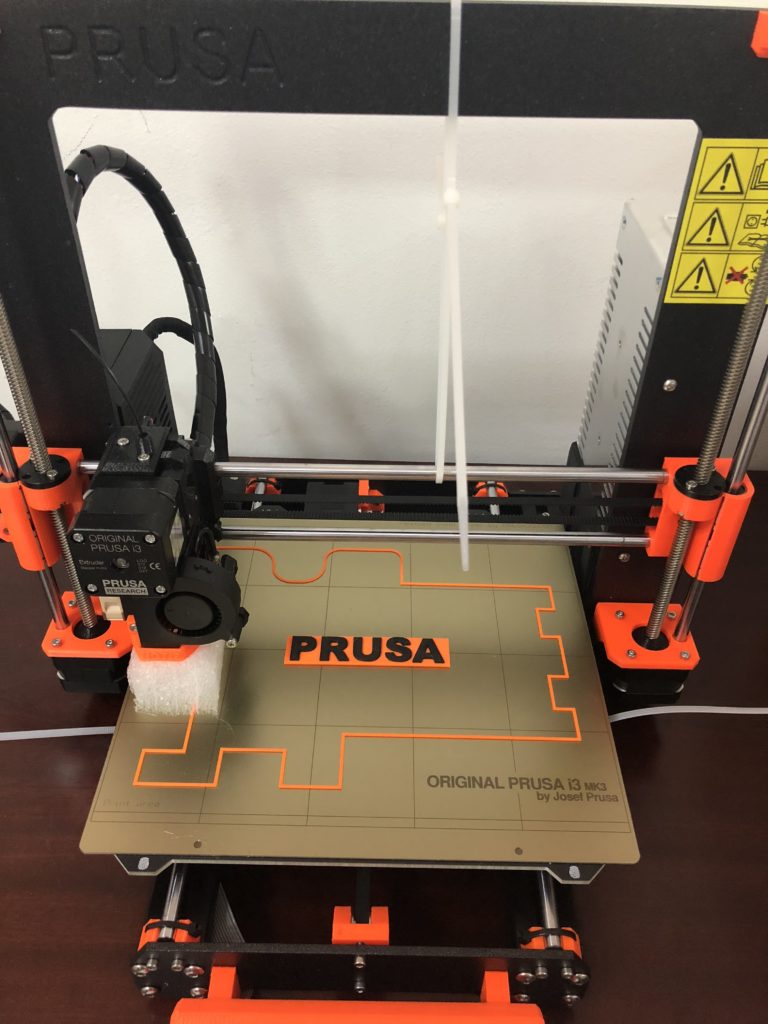

A 3D printer can print virtually anything. Hobbyist 3D printers will typically only print plastic, however, industrial 3D printers can print metal. Metal 3D printers can create metal objects with extreme precision. For example, they can make engine parts and circuit boards.

3D printers can also only print 3d objects that are as big as the 3D printer is. So, if you want to print something really large, you need to buy a much larger 3D printer. However, with that comes a much bigger price tag. A regular 3D printer that you’d use at home can print objects that are around 1 ft by 1 ft (30 cm x 30 cm) comfortably.

In this article, I will explain what can be printed with a 3d printer, what materials can not be 3D printed with a 3D printer, whether you can print a phone, as well as, other helpful info about what the limits are to objects you can 3D print.

What can be printed with a 3D printer?

Some objects are very detailed and to create the design by hand using computer software would take a long time. But, how difficult is it to print anything on a 3d printer, and what exactly can be printed with a 3d printer?

You can virtually 3D print anything. The main limitation is how long it takes to create the 3D print design in a 3D printing software, how long it will take to print, and the size of the 3D printer you need.

However, there is now interesting technology that can create a 3D design based on photos of an object. And it takes dramatically less time.

Here’s a video showing the process of taking the photos, and creating the 3D print design:

But, waiting for the software to convert your images into a final 3D design can take many hours or days depending on how detailed it is.

Once it’s done though, you can export the file to your 3D printer for printing. Typically there’s some tidying work that needs to be done on it.

Although this method takes a lot less time than creating the design by hand, you do still need to take quite a lot of photos. Around 100 to 200 photos from lots of different angles will give you the best result.

Here’s a quick overview of the entire process of converting ANY object into a 3D print:

- Take 100 to 200 photos from lots of different angles

- Upload photos to software like Autodesk Remake (free version available)

- Use the software to convert the photos into a 3D print (does it in 1 click)

- Send the 3D print file to your 3D printer

- Print the file

Certain objects though are best printed in parts. As a simplified example, if you wanted to print a plastic skateboard, you would print the wheels separately from the axel. That way the wheel can spin.

When people talk about 3D printing they normally mean 3D printing at home as a hobby. However, steel manufacturing facilities will use 3D printers to print metal parts. For example, they can print parts used in a car engine, circuit boards for computers, and electronic parts for devices like toasters and kettles.

For example, they can print parts used in a car engine, circuit boards for computers, and electronic parts for devices like toasters and kettles.

What materials cannot be 3D printed and why?

As you may know, you can print plastic, and metal, however, what materials can you not print on a 3d printer?

Virtually all man-made materials can be 3D printed. However, some materials are extremely difficult and impractical to 3D print. Glass, for example, is not practical to 3D print because it has an extremely high melting point. Certain metals also have an extremely high boiling temperature and are thus impractical to 3D print.

A 3D printer is essentially a mechanical arm that is attached to a computer that can give it step-by-step instructions. Therefore, as long as a material is runny enough it can be printed using a 3D printer For example, there are also 3D printers that are designed to 3D print concrete.

Other materials won’t hold up when 3d printed because they are too soft or won’t go hard. Therefore, the sky is technically the limit when it comes to what material you can use in a 3D printer. However, a hobbyist type of 3D printer is typically only designed to work with plastics that have a specific formula. Which are commonly called 3D printer filaments.

Therefore, the sky is technically the limit when it comes to what material you can use in a 3D printer. However, a hobbyist type of 3D printer is typically only designed to work with plastics that have a specific formula. Which are commonly called 3D printer filaments.

Can a 3D printer print a phone?

A smartphone is an amazing device, and it has the power of a computer in a very compact size. I’ve often wondered how you would make a phone using a 3D printer and whether it can be done. Here’s what I found…

As a general rule, you can not 3D print a phone. However, you can 3D print a lot of the components for a phone. For example, you can 3D print the plastic exterior. 3D printers that can print metal are expensive and after you’ve printed the individual parts you still need to solder the parts together.

You can easily make an object that looks like a phone using a 3D printer. However, you couldn’t use it to make calls or send text messages.

3D printers that print metal are very expensive, and they cost around $50,000. After that, it needs to be set up, and you need to do special training, which requires the help of professionals that can be quite costly. And it isn’t really suited to a hobbyist 3D printer.

After that, it needs to be set up, and you need to do special training, which requires the help of professionals that can be quite costly. And it isn’t really suited to a hobbyist 3D printer.

What are the limits of 3D printing?

With 3D printing objects as a whole, I wanted to know whether there are any limitations to what you can create, and if so what are they?

The limits to 3D printing are:

- It takes more time to create bigger objects

- More intricate objects take more time to print

- You cannot print certain materials such as glass

- Size – to make a big object you need a big 3D printer

A 3D printer creates an object a very small amount at a time. So, a big object can often take a week to print. Also, with intricate objects, the nozzle has to make more back and forth movements. And as a result, it takes much more time to print an intricate object.

Other materials are impractical to print. Glass, for example, requires temperatures of around 1300 °F (700 °C) to begin to melt. Recent work by scientists to 3D print glass has been successful, but it is extremely difficult to create precise objects. And most designs are lop-sided and don’t look like the design at all (source: link).

Well, that about covers everything you need to know about whether you can 3D print anything.

Related Articles

- How to Print a File from Thingiverse (The Easy Way!)

- Create a Temperature Tower Using Cura – The Easy Way

- Cura Profiles

- Do 3D Printers Use a Lot of Power? (The Numbers Inside)

- Can You 3D Print Food?

Make sure you check out our YouTube channel, and if you would like any additional details or have any questions, please leave a comment below or join us on Discord. If you liked this article and want to read others click here.

We found out why 3D printing is dangerous. The main myths about technology

Vladislav Kochkurov General Director of the Center for Additive Technologies

The first product was 3D printed in 1983 - it was a small container in the form of a bowl. Now researchers are creating aircraft engines and rockets, jewelry, food, and even houses. Despite the fact that there is a lot of information about this area, many people still do not understand exactly how 3D printing works. Vladislav Kochkurov, General Director of the Center for Additive Technologies, talks about the misconceptions we face when talking about layer-by-layer creation of three-dimensional objects.

Now researchers are creating aircraft engines and rockets, jewelry, food, and even houses. Despite the fact that there is a lot of information about this area, many people still do not understand exactly how 3D printing works. Vladislav Kochkurov, General Director of the Center for Additive Technologies, talks about the misconceptions we face when talking about layer-by-layer creation of three-dimensional objects.

Read Hi-Tech in

Myth No. 1. 3D printing takes place with little or no human intervention

new product. One gets the false impression that the entire cycle of additive manufacturing consists only of the operation of equipment, and a person hardly participates in this - he only turns on a 3D printer and loads a polymer, metal powder or other material into it.

But the key role in building an object is played by its 3D model. It is a map on which the finished product will be built. The quality and characteristics of the future subject depend on its detailed study. Here, the participation of specialists with high competencies in the fields of design, technology and materials is needed.

Here, the participation of specialists with high competencies in the fields of design, technology and materials is needed.

In industrial production, the construction of a 3D model is carried out in AutoCAD computer-aided design systems. The design engineer, in accordance with the terms of reference and using various calculation methods, creates the geometry of the future product. Even if the 3D model already exists and does not need to be built from scratch, AutoCAD programs carry out its topological optimization - redesign for additive manufacturing.

This process aims to eliminate stress raisers and thin-walled features that can cause cracks or other damage during the printing process. Together with the 3D model, the location of technological supports is also designed - support structures needed for optimal positioning of the part on the platform, heat removal and reduction of the risk of deformation during the printing of the product. Printing is also preceded by the process of developing technological modes of construction, which is being worked on by a process engineer.

Together with the 3D model, the location of technological supports is also designed - support structures needed for optimal positioning of the part on the platform, heat removal and reduction of the risk of deformation during the printing of the product. Printing is also preceded by the process of developing technological modes of construction, which is being worked on by a process engineer.

Further, based on the prepared 3D model, the printer prints on its own, sometimes working for several days in a row. But before that, the equipment needs to be prepared - make sure that the build platform is level and all the mechanisms move as they should. Even the powder in the 3D printer is not just poured, but goes through the stages of incoming control and preparation.

Another mandatory stage in the production cycle of a product, where human participation is needed, is post-processing.

Myth #2: A finished product comes out of a 3D printer. Robotic installations in a matter of minutes create superhero costumes and print elements of spaceships. Technology, of course, is striving for this, but today all products removed from the printer need post-processing.

Technology, of course, is striving for this, but today all products removed from the printer need post-processing.

To relieve the internal stress that occurs during the printing process, the product undergoes alternating heating and cooling procedures. This way it achieves full mechanical properties. Then technological supports are cut off - they have already fulfilled their function. Removal of excess powder and surface treatment of the product are carried out using a sandblasting chamber. If it is necessary to achieve absolute smoothness of surfaces, then milling, turning, electrochemical and grinding machines are used. For plastic products, chemical post-treatment with acetone or other solvents is sometimes used.

Myth #3: You can 3D print anything

Innovations in the field of additive technologies appear every year and already surpass our imagination. Synthetic meat steaks, a human heart, and a whole house are already being printed. It seems that the possibilities of additive manufacturing are endless and a 3D printer can do anything. But now there are several limitations related to the size and material of the product - it is impossible to create very large and very small objects.

But now there are several limitations related to the size and material of the product - it is impossible to create very large and very small objects.

For example, the Center for Additive Technologies has an installation with a build chamber up to half a meter, the largest printer in Russia based on selective laser melting technology. Elements of Russian aircraft engines are already being “grown” there.

“Innovations in the field of additive technologies appear every year”The capabilities of polymer printers are much wider - one of them, listed in the Guinness Book of Records, can create objects up to 30 m long. In 2017, a monolithic boat was printed on it, weighing 2 tons and 7 m long. The smallest object printed on a 3D printer is a ship. Its length is 2-3 times less than the thickness of a human hair - only 30 micrometers (0.03 mm).

3D printers are already used to create even at home. A construction printer works by analogy with an FDMD printer that prints plastic products, but instead of polymeric materials, cement mixtures are used as “inks”. In size, such a mechanism is much larger. The world's largest 3D printed building has an area of 641 square meters. m. and is located in the UAE.

In size, such a mechanism is much larger. The world's largest 3D printed building has an area of 641 square meters. m. and is located in the UAE.

Other limitations in additive manufacturing are not related to the size of the 3D printer's build chamber, but to the material used. During the printing process, it is in a liquid or molten state, therefore, it should melt normally. Wood, fabric, or paper objects cannot yet be printed, as they will burn before the material can be melted. Although here you can find a loophole: if you mix crushed cellulose fibers with a water-based gel, and then freeze the object, gradually removing water from it, you will get products made of a material similar to wood.

Myth No. 4. Products printed on a 3D printer are of poorer quality

Visually, the 3D printing process looks like a layer-by-layer application of material. This may raise the question: how firmly are the layers interconnected?

3D printing can introduce several defects, so it is important to follow the workflow. A lot depends on the quality of the materials. In industrial production, all metal powders undergo input control, this process is regulated by standards. Even if the material is certified, it is very important to observe the conditions for proper storage: avoid moisture and dampness, place in a special package. If you do not check the condition of the nozzle, set the temperature or print speed incorrectly, misalignment of layers, overheating, or other defects may occur.

A lot depends on the quality of the materials. In industrial production, all metal powders undergo input control, this process is regulated by standards. Even if the material is certified, it is very important to observe the conditions for proper storage: avoid moisture and dampness, place in a special package. If you do not check the condition of the nozzle, set the temperature or print speed incorrectly, misalignment of layers, overheating, or other defects may occur.

If all conditions are met, then the product will not be inferior in properties, and often even surpass the analog made by traditional methods. If you compare two aluminum objects under a microscope, the printed product will have a denser structure.

“If all conditions are met, then the product will not be inferior in properties, and often even surpass the analog made by traditional methods”Myth #5. 3D printing is environmentally friendly

3D printing is considered to be environmentally friendly, as this type of production leaves little waste. In fact, this is a complex issue, in which there is no consensus yet.

In fact, this is a complex issue, in which there is no consensus yet.

3D printers use a lot of electricity and leave a large carbon footprint: the ATKINS project found that the production of a product using additive technologies emits approximately 7 times more CO emissions 2 than the production of casting.

But the use of additive technologies significantly reduces waste and the amount of materials used. CIM (material utilization factor) in the manufacture of casting does not exceed 40%, for additive technologies this figure approaches 100%. Additive technologies also help to reduce the weight of the final product. Reducing the weight of an aircraft by 100 kg can save up to 1.3 million tons of CO 9 throughout its entire life cycle0071 2 .

Read more:

An out-of-control Chinese rocket will soon fall back to Earth. What's going on

Scientists filmed a strange creature with tentacles that they thought was a flower

Marine archaeologists found the remains of a medieval shipwreck

How to 3D print anything (even if you don't have a 3D printer)

UNCACHED CONTENT

3D printers are amazing tools that allow you to create just about any physical object you can think of (or at least design in a 3D modeling program). One downside? They are stupidly expensive and you probably can't justify the cost . Luckily, you don't have to have your own to print your own content - there are plenty of services out there that will do it for you.

One downside? They are stupidly expensive and you probably can't justify the cost . Luckily, you don't have to have your own to print your own content - there are plenty of services out there that will do it for you.

RELATED: When should you buy 3D printers for home use?

There are plenty of reasons why you might want to 3D print something, but few justify owning one. You can print anything from custom GPS mount for your bike to Dungeons & Dragons Miniatures to wearable armor for your next Star Wars cosplay . However, unless you're going to print tons of documents on a regular basis, none of them are worth the hundreds you have to spend on a 3D printer (or the thousands you'll spend on a really good one).

To help people like you who want to print but don't want to spend a ton of money for the privilege, services are offered such as shapeways , Craftworks , Ponoko , as well as ZD Huvs made 3D printing accessible even if you don't have a printer. Some offer 3D model shops that you can print directly, or you can download models you made yourself or found online. Each service is slightly different, so we'll take a look at each and highlight the strengths and weaknesses of each.

Some offer 3D model shops that you can print directly, or you can download models you made yourself or found online. Each service is slightly different, so we'll take a look at each and highlight the strengths and weaknesses of each.

Shapeways lets you buy 3D prints in a variety of materials or upload your own

Shapeways is one of the largest and most versatile 3D printing stores in the world. The company has a sizable community of 3D modelers and designers who upload their creations for anyone to buy. You can go to Shapways Store find Jewelry , phone cases , Raspberry Pi Parts , desktop gaming accessories and much more. The designs you find are built to print flawlessly, and each design is inspected by Shapeways staff to ensure they are structurally sound. When making 3D printable models, extra care must be taken to ensure that the parts are thick enough not to break, and to avoid a host of other issues that most of us don't think about. Some Models like keychains and pendants are even customizable so you can add your name or personal message.

Some Models like keychains and pendants are even customizable so you can add your name or personal message.

You can also get prints in a wide variety of materials. If you've ever seen something 3D printed, chances are it's plastic. Shapeways offers prints in steel, bronze, brass, silver, gold, wax, porcelain, aluminum and several types of plastic. Of course, not all models are available in all materials. Some models print fine on plastic but will fall apart if they are made of metal or porcelain. Still, it's great to get a set stainless steel dice without buying a printer.

3D prints from Shapeways are made to order. Because the company uses industrial printers which can produce hundreds of models at the same time, the prices are relatively low compared to what you get. For simple plastic prints, you can spend only $10 for basic figures . Even some metal jewelry or trinkets can be from just $25 , although metal is clearly more expensive than plastic. As a rule, the larger the print, the more expensive it is. However, you will have to go for something quite large to compete on the cost of buying a 3D printer that can print at comparable quality.

As a rule, the larger the print, the more expensive it is. However, you will have to go for something quite large to compete on the cost of buying a 3D printer that can print at comparable quality.

If you can't find a model of something you need on Shapeways, you can upload your own. However, when you do this, things get more complicated. For example, you can find 3D models on sites like TurboSquid , but they are not necessarily intended for printing. Sites like Thingiverse offer 3D printable models, but they are not tested for printability. You may still find that the walls you uploaded are too thin or don't print properly. This is fine if you're used to 3D modeling on your own, but for hobbyists it can be a problem. To help deal with this problem, Shapeways offers a directory where you can hire a designer. Obviously, this will be more expensive than finding a ready-made print, but if you really need a professional's opinion, you can find it in the Shapeways community.

By the way, Shapeways' main advantage over the other services on this list is its community. Whether you're looking for a finished model or need help building something custom, you'll likely find someone to help. Shapeways also offers some of the best prices on single prints. Many 3D printing companies aim to print large volumes of products for small companies and are priced accordingly, making their services out of reach for the average person. Shapeways is one of the few that allows the average person to place a one-time order for a cheap trinket without emptying their wallet.

Craftworks also worth mentioning along with Shapeways as they have a very similar business model. Kraftwurx has wider choice of materials than Shapeways, but it doesn't have such a strong community. For 3D modellers, their tools are more clumsy. However, if you just want to find a model and print it right away, but can't find it on Shapeways, Kraftwurx is worth a look.

3D Hubs finds local printers that can make your project

Most people don't need to buy a 3D printer, but many people who drop thousands of dollars on a high quality 3D printer do so to start their business of selling prints to other people. 3D Hubs helps you find those people or small businesses near you who can do whatever you want. Although "next to" is a relative term. 3D Hubs will look for printers halfway across the country if needed to find a good printer, but that will likely be closer than ordering from a manufacturing facility in Europe.

The result of using 3D Hubs is that you can shop around. Some of the "hubs" (that's what each printer is called) on the site are nothing more than a seasoned enthusiast owning their own printer. Others are smaller companies with larger manufacturing facilities that can handle more complex requests. You can compare prices and services from dozens of different companies to see who can offer you the best price and quality printing.

The downside is that 3D Hubs by themselves don't provide much quality control. Unlike Shapeways, no one at 3D Hubs looks at your model to make sure it's ready to print and has no major flaws. The computer scans the file for basic errors, but no one steps in to make sure it works. The hub you hire to print should do the job, but the quality could hypothetically vary from one company to another. It's a bit like shopping on Etsy. You'll probably get a good product, but there is always a chance to get something junk.

Fortunately, if you receive a printout that you don't like, 3D Hubs offers a money-back guarantee. As long as you pay 3D Hubs when you place an order, the printer you hire will not receive that money until you receive your item and indicate that you like it. This is a pretty strong incentive for printers to make sure they get it right the first time.

You also won't get the same community from 3D Hubs that you'll find on sites like Shapeways and, to a lesser extent, Kraftwurx. However, you can view Thingiverse find a ton of ready-made models. When you find a model you like, you can use Thingiverse. Programs ” to send the model to 3D centers and find a printer in your area.

However, you can view Thingiverse find a ton of ready-made models. When you find a model you like, you can use Thingiverse. Programs ” to send the model to 3D centers and find a printer in your area.

The real strength of 3D Hubs is fast delivery times. Services like Shapeways and Kraftwurx make all their prints at just a few central locations and ship them all over the world. 3D Hubs, on the other hand, coordinates a network of hundreds of printing companies around the world. You can find a printer in your country or even your state that has a much lower workload and hopefully can get your order done faster than one of the larger services. Some printers even let you pick up your order if you live close enough. If you need a print urgently and want to support a local business, 3D Hubs is the place to be.

Get mass 3D printing (and laser cutting) from Sculpteo

If you are a designer or artist, there is nothing better than selling what you have made yourself. sculpteo is a 3D printing service that straddles the line between professional and consumer printing and is perfect for anyone just getting started. If you find a model on sites like Thingiverse that you want to print, you can upload it to Sculpteo and get comparable prices to sites like Shapeways. However, you can also order models in bulk.

sculpteo is a 3D printing service that straddles the line between professional and consumer printing and is perfect for anyone just getting started. If you find a model on sites like Thingiverse that you want to print, you can upload it to Sculpteo and get comparable prices to sites like Shapeways. However, you can also order models in bulk.

For a single print, Sculpteo works the same as Shapeways. You can upload the model, the program will run a few automatic checks to make sure there are no obvious errors, and then you will see how much it will cost to print. Sculpteo's prices are somewhat comparable to those of Shapeways, but they can be more expensive for certain materials or larger builds.

Where Sculpteo really shines is in mass print. Let's say you want to create a simple necklace or keychain, print a couple of dozen, color them in and sell them to your friends. You're not starting a Fortune 500 company or anything like that, but want to create something unique to make some extra money on the side.