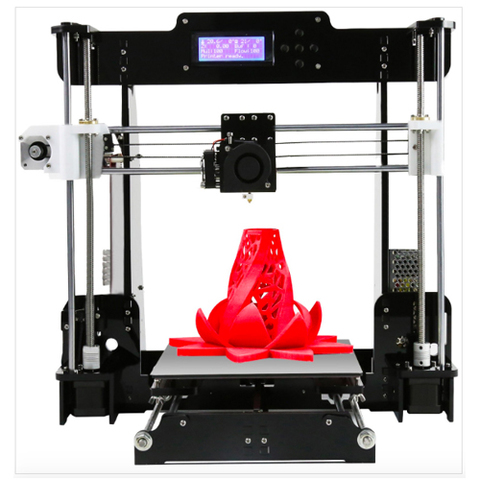

Bowden drive 3d printer

3D printer with Bowden extruders

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

Filters:

- Bowden Extruder

-

Creality Ender 5 Pro- High stability and precision

- Removable platform

- Large construction area

-

Creality Ender 6- Intelligent features

- Stable structure

- Low noise

-

Creality Ender 5 Plus- Large space

- Filament sensor

- Dual Z axis

-

FlashForge Adventurer 4- Flexible printing platform

- Quick-remove nozzle

- Integrated HD camera

-

Creality CR-10 Smart- WiFi connectivity + app

- Intelligent auto-leveling

- 4.

3" full-view touchscreen

-

Creality CR-6 Max- Intelligent auto-levelling

- Huge build space

- Reliable extruder

-

Anycubic Kobra Plus- Large build volume (LxWxH: 300 x 300 x 350 mm)

- LeviQ bed levelling

- Bowden dual gear extruder

-

Creality Ender 3 V2- New screen

- Resume function

- Quiet TMC2208 driver

-

Anycubic Vyper- Cortex-M3 CPU

- Automatic levelling

- Magnetic PEI platform

-

Creality Ender 3- Large space

- Heated print bed

- Easy construction

-

Creality Ender 7- 250 mm / s printing speed

- Core XY structure

- Minimalistic design

-

Creality Ender 3 Pro- More stable aluminium frame

- Easy removal of models

- Large build space

-

Creality Ender 2 Pro- Lightweight and portable

- Clip-on screen

- User-friendly design

-

Creality Ender 3 V2 Neo- Pre-assembled kit

- Automatic print bed leveling over 16 points

- Full metal Bowden extruder

-

FLSUN Q5- Ø 200 x 200 mm build volume

- Automatic leveling

- 32-bit mainboard with TMC2208 drivers

-

Creality CR-6 SE- Intelligent auto-levelling

- Modular hotend

- Reliable extruder

-

Anycubic Kobra Go- Practical design, large build volume

- Automatic 25-point levelling

- Spring steel magnetic build plate

-

Creality Ender 3 Neo- Automatic print bed levelling over 16 points

- Extremely quiet operation

- Full metal Bowden extruder

-

Artillery Hornet- Robust frame

- Cost-efficient

- Tempered glass platform

-

Creality CR-10 Max- Large space

- Easy assembly

- Easy operation

-

FLSUN Super Racer- 260 x 330 mm

- Capacitive colour touch screen

- High-speed 3D printing

-

Anycubic Kobra Max- LeviQ - Automatic Print Bed Leveling

- Large build volume (400 x 400 x 450 mm)

- Bowden extruder

-

Elegoo Neptune 3- Automatic print bed levelling

- Flexible PEI spring steel

- Modular construction

-

Creality CR-5 Pro High-Temp- 300 ° C max.

Nozzle temperature

Nozzle temperature

- Large, enclosed installation space

- Smart functions

- 300 ° C max.

All prices incl. VAT.

Direct-drive extruder vs. Bowden extruder - Guide

These are the differences

If you deal with 3D printers, you will sooner or later be confronted with the terms “direct drive extruder” and “bowden extruder”. Both extruder variants ensure that filament is fed into the printhead, but differ in the way the filament is pushed into the hotend. Both a direct extruder and a Bowden extruder have their advantages and disadvantages, which we would like to discuss in more detail below and thus make it easier for you to choose when buying.

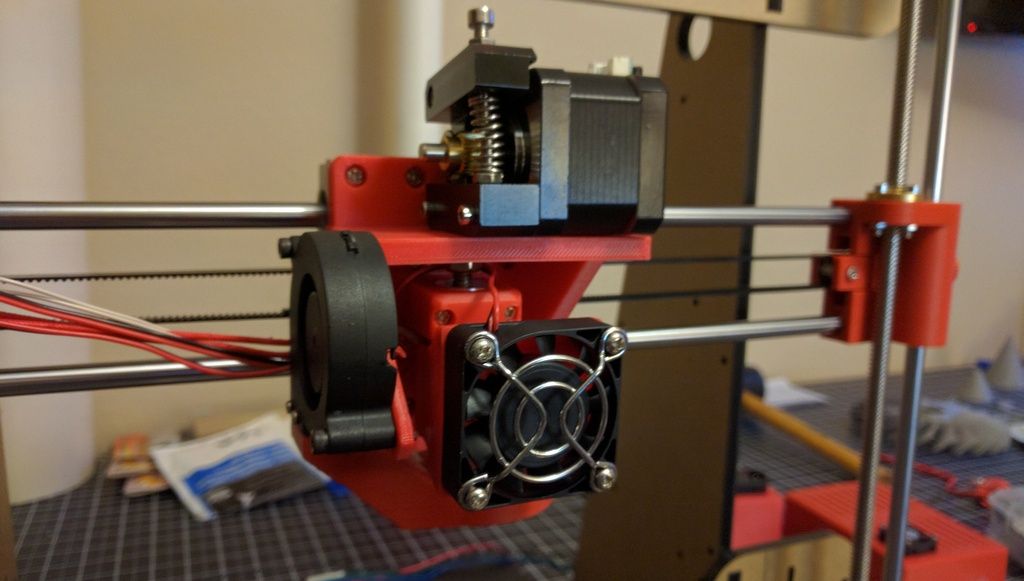

Direct extruderThe direct drive extruder (A) is installed with the hotend (C) and pushes the filament (B) directly into the nozzle (D). All filament processing components are therefore located in one place on the print head. This creates advantages and disadvantages that you should consider before buying a printer.

- Better extrusion

Since the extruder is located directly on the print head, the motor can simply push the filament through the nozzle.

- Faster retraction

Due to the proximity of the extruder and nozzle, the filament can be retracted quickly; in many cases, no retraction setting is necessary.

- Weaker, smaller motors are possible

Because of the short distance between extruder and nozzle, less torque is required from the motor to push the filament.

- Wider range of compatible filaments

Direct extruders are compatible with a wide range of filaments - they print reliably even with abrasive and flexible materials.

Disadvantages- More weight on the printhead

Since the extruder is mounted on the hotend, it has more weight. The increased weight has the following disadvantages:

The increased weight has the following disadvantages:

- More power requirement

- Increased wear on toothed belts and bearings

- Printing speed is reduced

- More complex maintenance

After the feed and the hotend are built directly together, maintenance such as cleaning the nozzle proves to be more difficult.

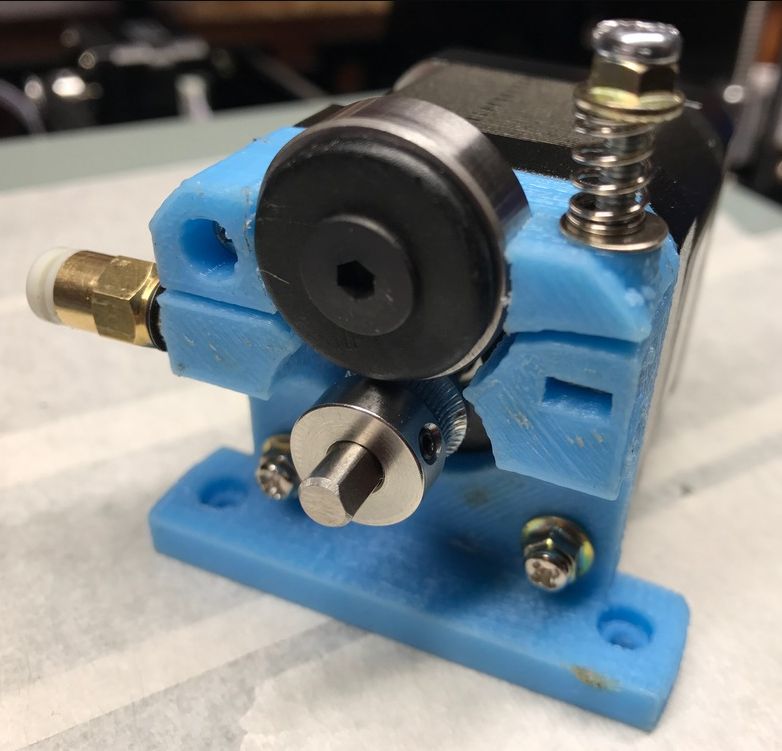

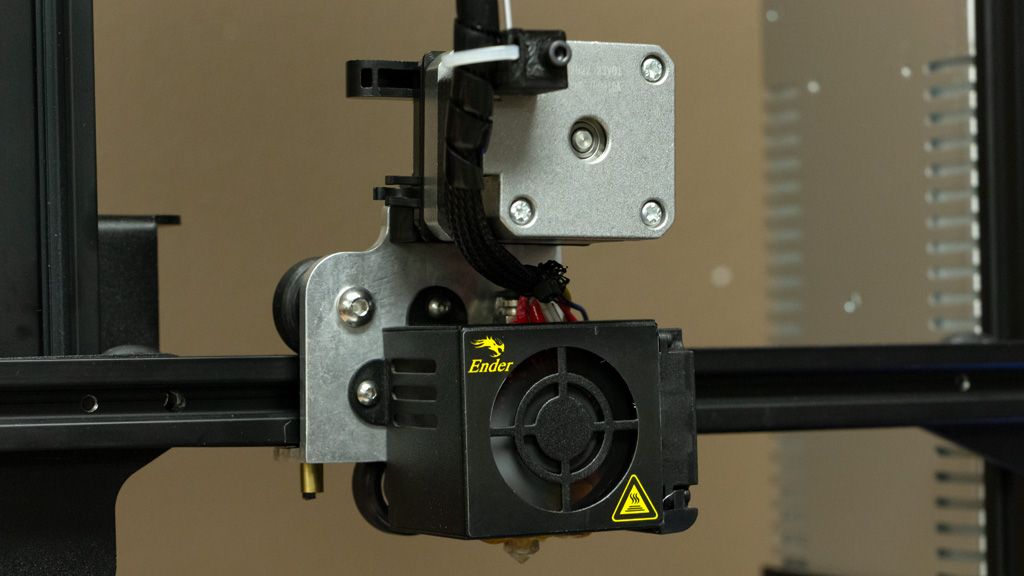

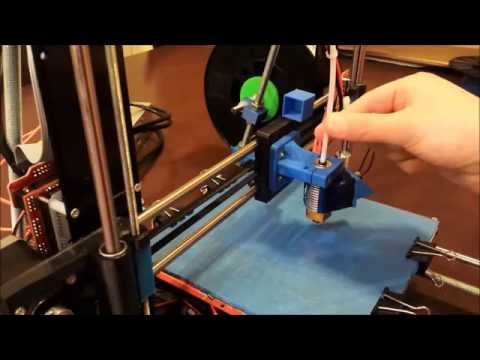

Bowden extruderUnlike the direct drive extruder, the Bowden extruder (A) is attached to the frame of the 3D printer and pushes the filament (B) through a long PTFE tube (Bowden tube) into the hotend (C).

Advantages- Less weight on the printhead / less moving mass

Since the printhead can work without additional weight, the following advantages result:

- Clean movements

- Increased printing speed

- Nice prints due to reduced vibration on the printhead

- More powerful motor needed

A Bowden extruder requires a more powerful motor with more torque to control the filament because it has to be pulled through the PTFE tube.

- Slower response time

Increased friction in the Bowden hose leads to a reduced reaction time. Bowden extruders require longer and faster retraction to avoid tension.

- Smaller range of compatible filaments

Flexible or abrasive filaments can wear out more in the Bowden hose and are processed more poorly than with the direct drive extruder due to the longer conveying path.

Conclusion - which extruder should you choose?Both extruder variants have their advantages and disadvantages. The biggest difference is clearly to be found in the processing of flexible filaments. If you want to print quickly and do not use flexible filament, you can use a Bowden extruder.

However, if you want to process flexible materials, a direct extruder is definitely recommended.

Buying a 3D printer - What you should consider The new BIQU B1 - Competition for the Ender 3?

Techno Print 3D Company

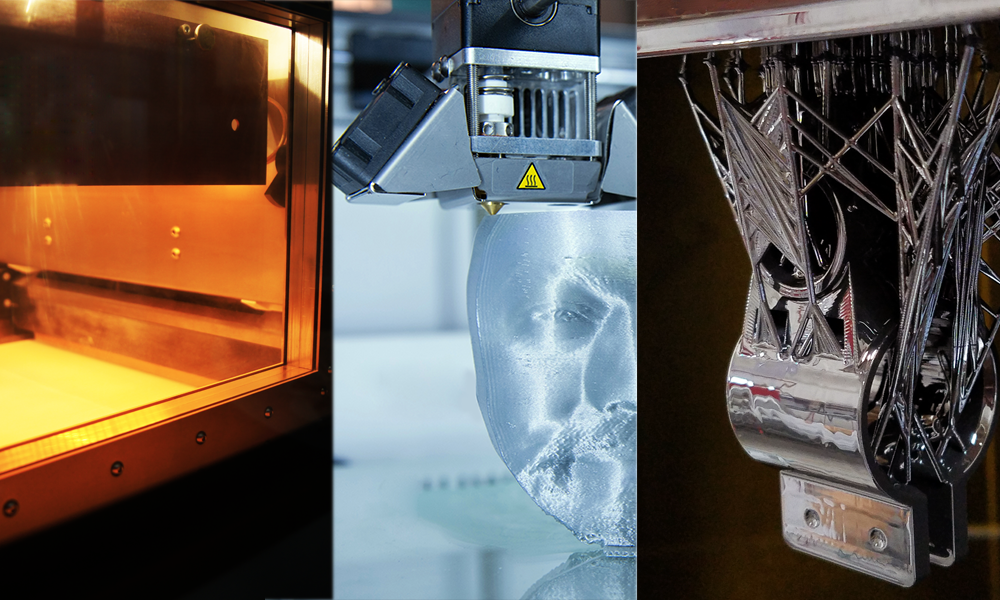

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

3D Printer Extruder - Complete Manual Heatle

Learn the basics of direct drive and Bowden extruders, hot and cold ends, nozzle sizes and materials, and find the best 3D printer cartridge for your needs.

The 3D printing process can be briefly described as follows: a filament of plastic material is fed into a heated metal block with a nozzle, where it is melted and extruded in a given form. This path is repeated, gradually building up until a solid three-dimensional object is formed.

The entire business task of handling the material, melting it and exiting for printing takes place in a block called 3D printer extruder .

In this article, we will look at the main sections of the 3D printer extruder, the options and advantages of different styles of extruders, popular models on the market, as well as cartridge heaters for 3D printers and other items.

What is an extruder

The 3D printer extruder is a set of parts that together process and move plastic filament.

Some consider the extruder to be just the motor and associated parts that push and pull the filament, others the entire assembly including the heated part that melts and deposits the filament.

For simplicity, this article treats the entire assembly as an extruder. To begin with, while explaining the key components of a 3D printer extruder, we will divide it into two elements: a cold zone and a hot zone.

Cold zone

As the name implies, the cold zone is exactly that - cold. It's The top part of the 3D printer's extruder system, into which the filament is fed and then passed into the hot zone to be melted and extruded onto the print platform.

It's The top part of the 3D printer's extruder system, into which the filament is fed and then passed into the hot zone to be melted and extruded onto the print platform.

The appearance and location of the cold zone on your 3D printer depends on whether it is a direct drive or Bowden drive extruder (both of which are detailed below).

There is no filament heating here. The cold zone consists of the extruder motor and gear train, which are usually mounted either on the printer frame or on the print head itself, depending on the type of extruder, and a PTFE tube to smoothly guide the filament into the hot end.

What happens in the cold zone?

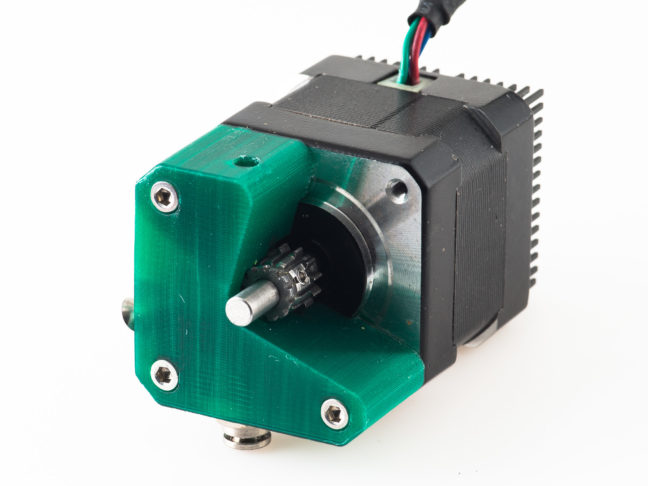

With the heatsink removed on this e3D Titan Aero, we can see the inner workings of the 3D printer's extruder.

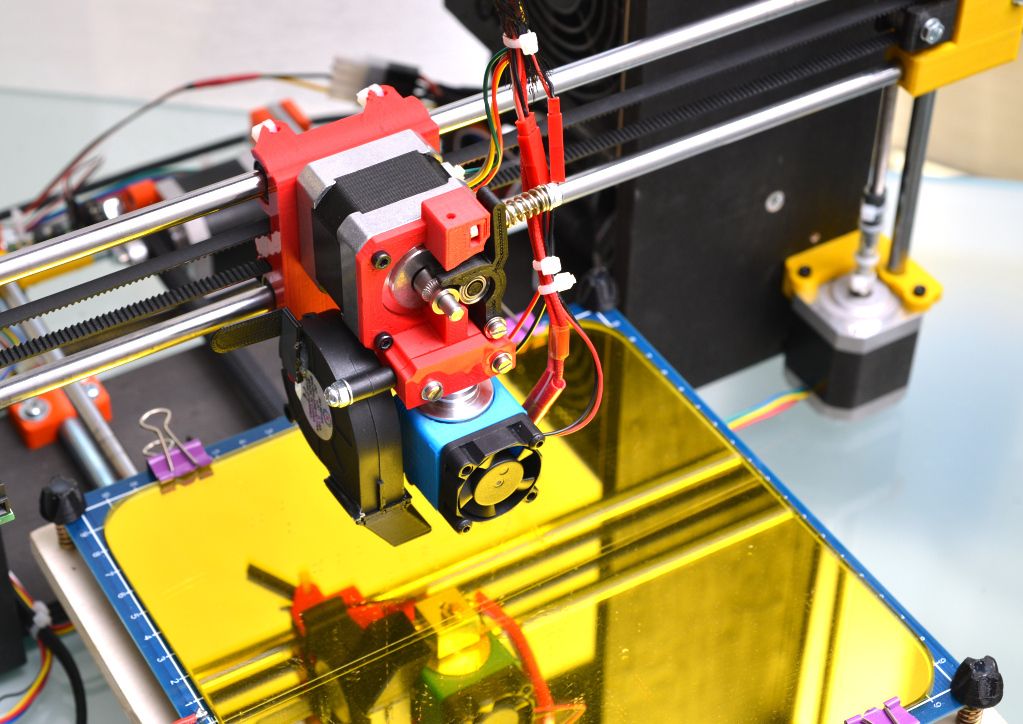

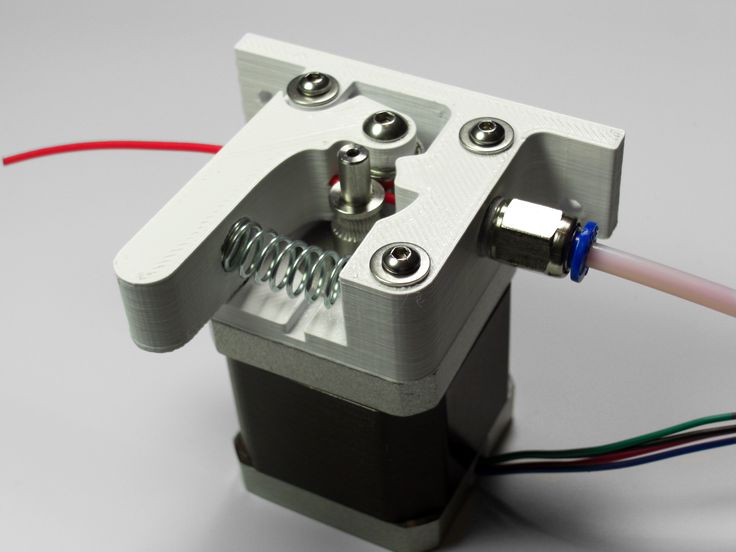

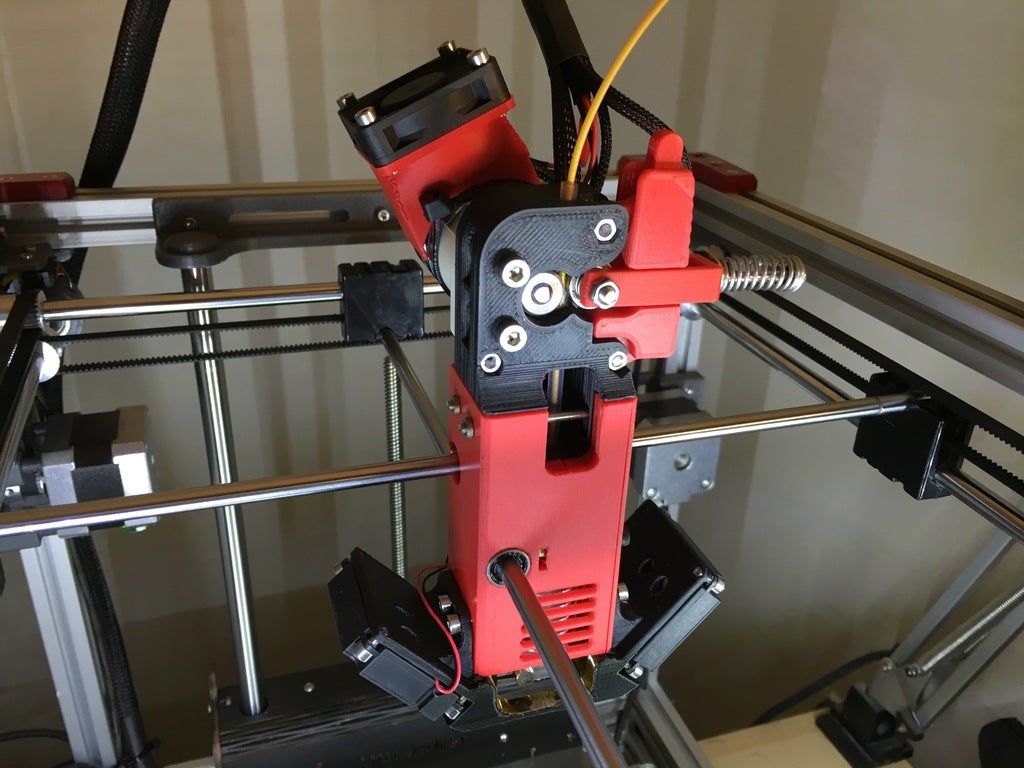

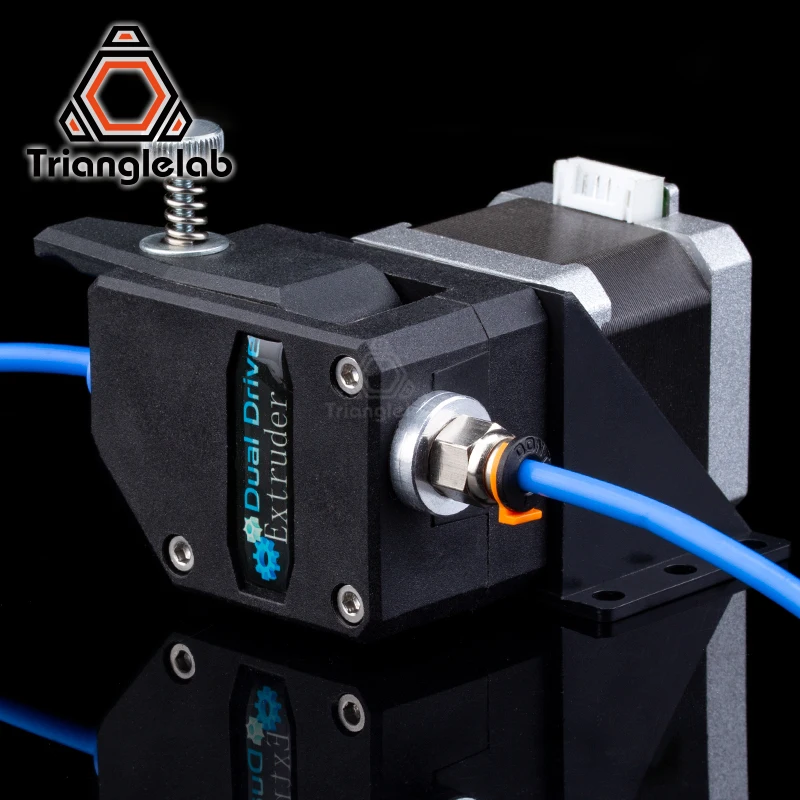

Essentially, the cold zone consists of a stepper motor, some form of gear, a toothed bolt or gear, a spring-loaded idler (usually a bearing of some kind) to hold the filament, and then a PTFE tube to guide the filament.

A humble stepper motor with a metal gear required for a 3D printer's extruder drives the filament extrusion in most if not all modern desktop 3D printers.

However, one stepper motor is not enough to feed the filament to the hot end. The parts attached to and operating the stepper motor drive shaft must physically grab the filament and push it on its way to the hot end.

In this cutaway view of a 3D printer extruder, we see a metal gear and a plastic gear with a toothed shaft.

This usually uses a combination of toothed gears and toothed bolts or shafts (in the image above we see a metal gear and a plastic gear with a toothed shaft) serving as a pressure wheel along with a bearing or other rigid frictionless material.

Here we see a plastic lever with an integrated bearing, an extension spring and a plastic gear with a toothed shaft. Together they apply pressure to the filament and force it through the extruder.

Alternatively, there are versions of the cold end of the 3D printer extruder that use a slightly different arrangement of parts to feed the filament. Such deviations are often claimed to provide increased traction and yarn delivery.

Here we see both sides of the Prusa i3 Mk3 cold end, including the Bondtech extruder gear train.

As mentioned, there are varieties of 3D printer extruder that use these parts in slightly different layouts. Each has its pros and cons. Next, we will look at what is the difference between a direct drive 3D printer extruder and a Bowden 3D printer.

Direct drive extruders

The Direct Drive 3D Printer Extruder is different in that it places the extruder motor directly above the heating unit. This arrangement minimizes the travel distance of the filament to the hot end and can enable more reliable 3D printing of flexible filaments.

The advantage of using direct drive is more precise retraction control. Due to the location directly above the hot end, there is less distance between the clamp and the thread passing through the thermal barrier into the heating block. Consequently, the filament has less room to bend and deform under pressure.

Due to the location directly above the hot end, there is less distance between the clamp and the thread passing through the thermal barrier into the heating block. Consequently, the filament has less room to bend and deform under pressure.

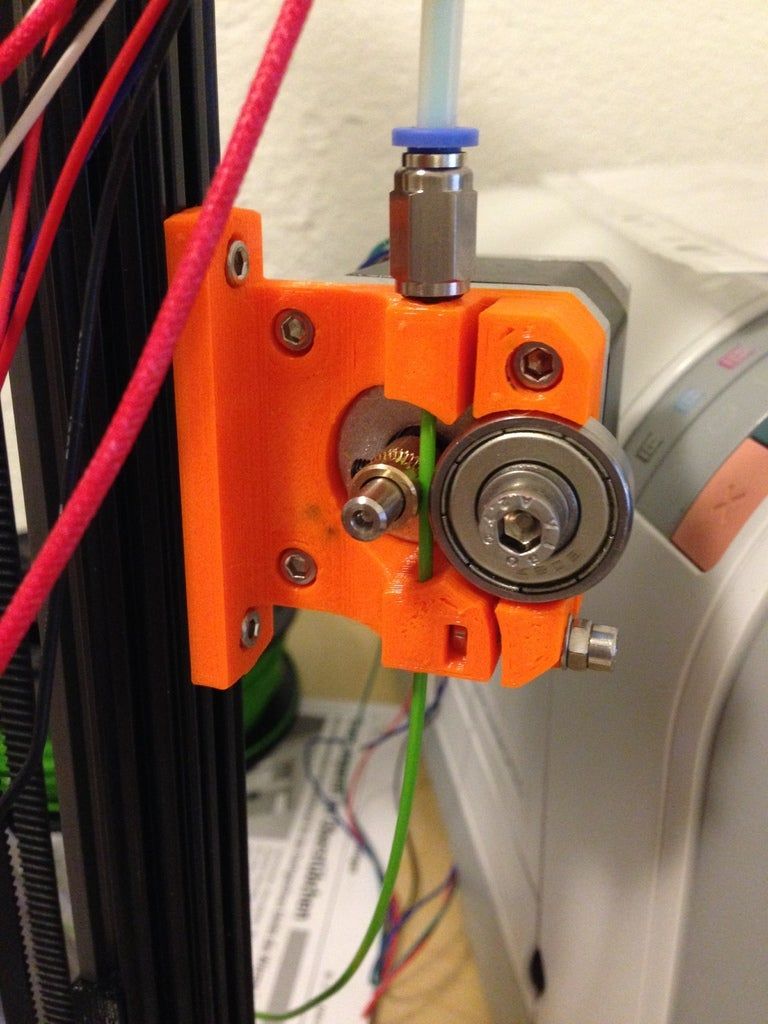

Bowden extruders

Bowden Style 3D Printer Extruder The does not mount directly on the top of the hotend like a direct drive 3D printer extruder, but the motor and gear assembly mounts on the frame of the printer. This gives this type of extruder an advantage over its head-mounted direct drive brother: speed.

By placing the mass of the 3D printer's extruder on the frame instead, the printhead is freed up to print at higher speeds without sacrificing print quality.

A side effect of placing the 3D printer's extruder this way is that the filament now has to travel a long way in a tube that's a fraction wider than it is. There should be enough room along the entire length of the tube for a slight bend in the thread. When pulling in the thread between strokes, this slack in the thread shortens the pull-in distance. Without correction (i.e., an increase in retraction), this results in a delay in relieving the pressure exerted on the hot end. In short, you can get confused if you don't change your retract settings.

When pulling in the thread between strokes, this slack in the thread shortens the pull-in distance. Without correction (i.e., an increase in retraction), this results in a delay in relieving the pressure exerted on the hot end. In short, you can get confused if you don't change your retract settings.

Heating block (Hotend)

Inside the knot, known as the hot end, the filament passes into a heated chamber where it changes from solid to liquid. Sounds simple, and mostly it is. Although there is a lot more to make the filament silky extrude onto the build plate.

What happens in the heating zone?

The E3D Titan Aero combines a heating block and an extruder in one compact unit. The hot end usually only has the central parts of this image: the heatsink (and fan), the heating element (micro cartridge heater), the heater block, the thermistor, and the nozzle.

A typical 3D printer hot end consists of a certain sequence of parts. There is a slight difference depending on whether you are using PTFE/PEEK or a full metal hot end. Here we explain the all-metal hot block.

There is a slight difference depending on whether you are using PTFE/PEEK or a full metal hot end. Here we explain the all-metal hot block.

First, it is a filament supply tube. In both a Bowden 3D printer extruder and a direct drive extruder, it will just be a PTFE tube coming from your cold filament feeder.

You can sometimes find direct drive 3D printer extruders where the filament runs straight into the print head.

On a Bowden 3D printer's extruder, this feed tube inserts the filament directly into the thermal barrier via a heatsink. The thermal barrier that is screwed into the heatsink is often a threaded stainless steel (or other non-conductive metal such as titanium) tube.

Split in two (note the two separate threads in the image below - longer for the heatsink, shorter for the heater block) and machined on the inside, the thermal break allows the filament to pass freely into the extrusion nozzle.

Clockwise from bottom left: steel thermal barrier, aluminum heating block and brass nozzle.

But since we're dealing with precision and a material that liquefies for rapid recooling, the 's temperature management is critical. The thermal barrier, in combination with the heat sink, maintains a certain limit at which the filament is exposed to high temperatures.

The top, which is actively cooled by a heatsink and dedicated fan, prevents heat from escaping from the hot end and weakening the filament before it is where it needs to be for extrusion. This unwanted phenomenon is known as thermal creep.

The lower part of the thermal barrier is located inside the heater block together with the cartridge heater, the temperature switch thermistor and the nozzle.

The heater block, usually made of aluminum, ensures a smooth transition of the filament from the open end of the thermal break tube to the nozzle.

The temperature to melt the filament has to come from somewhere, and this is where the cartridge heater comes into play.