3D printer filament diameter

Does Filament Quality Really Matter? — 3D-Fuel

If you’re new to 3D Printing, you may wonder what all the specs listed with 3D filament are and why they matter. Well, each spec is there for a reason. And they are important. Let’s talk about a few of them now.

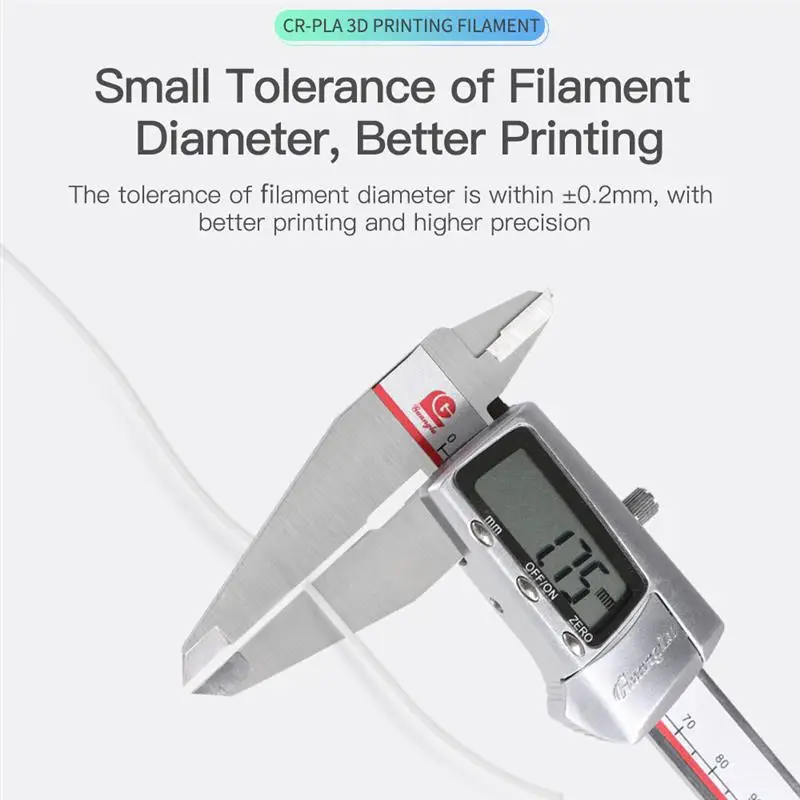

Filament Diameter

Diameter is the distance from one side of the filament to the other in a cross section. If you sliced a piece of filament into a tiny, thin slice, then measured it, you could get the diameter of that section. Most 3D printer filament comes in one of two standard diameter sizes: 1.75mm or 2.85mm (often referred to as 3.0mm). The size you use depends on the printer you use. Most printers use either one or the other. Once you’ve determined the size you use, you can go to the next level to see if the filament you’re buying is actually going to be that size.

Diameter Tolerance

When filament is described, you will usually find the tolerance level of the filament listed right along with it. It will be something like 1.75mm ±0.05mm. This last part, the Plus or Minus part, tell you how closely the manufacturer adheres to the size when they are making the product. ±0.05mm is pretty much an acceptable level and is generally considered the industry minimum for quality of the diameter of filament. Many manufacturers (Like 3DomFuel) will work toward making higher quality and tighter standards with their filament. In fact, our standard is closer to ±0.02mm. So, what does this mean? Well, if your filament has a tolerance level of 0.05mm, then that means the filament can vary as much as 0.05mm in either direction. Or to put it simply, the filament may be anywhere between 1.70mm and 1.80mm in size.

That doesn’t sound like much, does it? But in reality, that translates to a 5-6% difference in size. I know, that doesn’t sound like much either. But the reason it is important has to do with math. Yeah, yeah, you thought you’d never need math again… but 3D Printers use it constantly.

Why does this matter?

When a program (called a “slicer”) calculates how to print your item, it makes all the calculations based on a few assumptions. These assumptions are given to it by you in the settings. One of the numbers you give the slicer is the diameter of the filament you’re going to be using. It then uses that number to figure out how much, how fast, over how much area, and at what thickness to push filament out of the extruder nozzle. If the filament you’re using is not the same diameter as what the slicer is expecting, your print will not look as good as it should. In fact, it can lead to small holes, missing sections, too much filament in places, and other issues. So, it is important that the filament is as close to the spec as possible. If you tell your slicer it is 1.75mm, it needs to be as close to that as it can be.

Ovality

The other consideration for size in filament is the Ovality of the filament. In other words, does the filament look like a circle at every point? Or is it “squeezed” so that it is oval in shape? In the drawing above, you can see that the blue encircled area is not round, it’s oval. So, the ovality is off unless you have filament that is round like the outer black circle.

In other words, does the filament look like a circle at every point? Or is it “squeezed” so that it is oval in shape? In the drawing above, you can see that the blue encircled area is not round, it’s oval. So, the ovality is off unless you have filament that is round like the outer black circle.

Ovality is important for more than one reason. First, the physics of the shape will tell you that a filament that is oval may have a hard time being pushed or pulled through your printer. Each printer has a motor that assists with pushing the filament through the nozzle. The motor is controlled by the instructions it gets from the software (the slicer). If it is oval, and the software says “Push”, but it can’t get a good grip on it. Then nothing happens. This can cause more inconsistencies in your print.

Additionally, ovality is also another indicator of poor diameter. The diameter could be off in both directions. Causing more issues with your print.

Most 3D manufacturers omit ovality in their specs. They just ignore it, or just don’t report it. 3D-Fuel not only reports it, we actually print the specs right on the box. Each spool is measured as it is produced. Hundreds of times a second we’re measuring the diameter and ovality of the filament as it passes through. These recordings are saved, then printed on a graph so that you can see the actual results of the spool you purchased. You get a report showing the diameter as the filament passed through, an average diameter, and the average or “mean” ovality.

They just ignore it, or just don’t report it. 3D-Fuel not only reports it, we actually print the specs right on the box. Each spool is measured as it is produced. Hundreds of times a second we’re measuring the diameter and ovality of the filament as it passes through. These recordings are saved, then printed on a graph so that you can see the actual results of the spool you purchased. You get a report showing the diameter as the filament passed through, an average diameter, and the average or “mean” ovality.

At 3D-Fuel, we are in a “continuous improvement mode” with all our production, all the time. We have continued to improve our results and feel we now produce the best filament available anywhere. Our filament now averages below ±0.02mm in diameter tolerance, and less than ±0.01 in ovality. Filament that is the right size prints better. Period.

Watch out!

When you’re selecting filament, it is easy to get caught up in pricing. Looking for the cheapest filament is normal. Most of us have gone through that, or are still doing it. But in the long run, it is the best filament that saves you money. Cheap filament can cause problems from bad prints to clogged equipment. Costing you time and money in lost prints and repair time or expenses.

Most of us have gone through that, or are still doing it. But in the long run, it is the best filament that saves you money. Cheap filament can cause problems from bad prints to clogged equipment. Costing you time and money in lost prints and repair time or expenses.

And when you see a spec on a 3D filament, how can you know it is correct? Filament made in the Far East is sold to people who sell it as their own brand and they never know if it actually meets the specs they have been told it does. Also, look how they quote the specs. Here are two specification listings:

Diameter Tolerance ±0.03

Diameter Tolerance averages ±0.02

Which is better? At first, you’d say the second one. But look closely. The first states that it is within 0.03mm all the time. The second says that they AVERAGE that. An average could include any size above or below that number as long as the average 0.02mm. So, it could be 0.15 to 0.001. The best way to know, is for the manufacturer to actually measure it and put it right on the box. That’s the best way to know you have high quality filament.

That’s the best way to know you have high quality filament.

Example of a 3D-Fuel box with printed actual specs

1.75 mm or 3 mm?

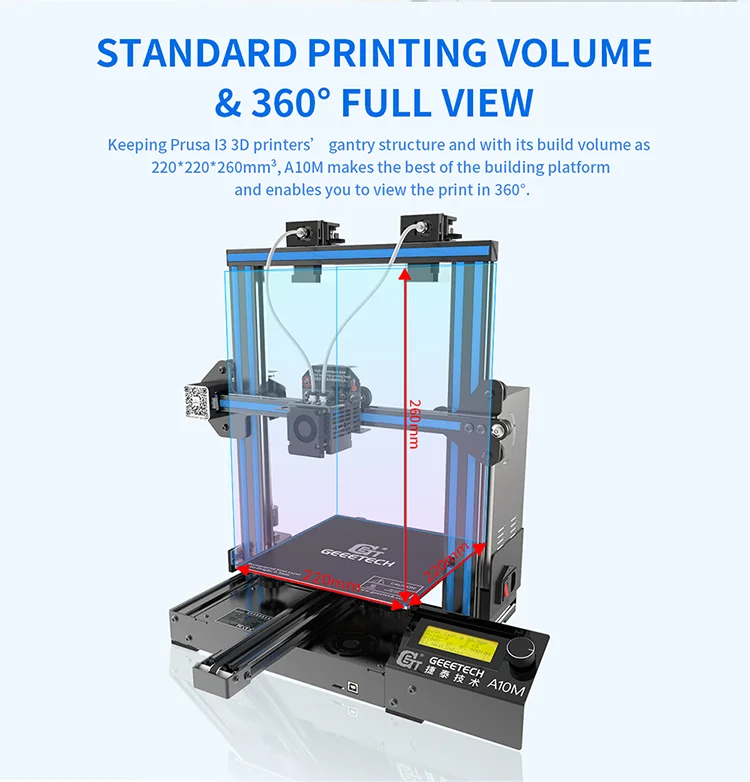

The following article tries to clarify the differences between the filaments of diameter 1.75 mm and 3 mm (3mm filament is the same diameter and 2.85 mm), a question that many users of 3D printing tend to have before acquiring a 3D printer.

Many professional and industrial 3D printers most use a Bowde System to reduce the moment of inertia, generated by the weight of the motors, on the axis of the HotEnd and thus have more printing precision) use 3 mm diameter filament.

One of the things that uses 3 mm and not 1.75 mm in this type of machines, is because the extruder motor has to work much less. Next we explain why:

If it is assumed that under theoretical conditions a 3D printer with pinion moves a filament with a radius R=10 mm, turning 10 turns with a filament of 1. 75 mm (for example PLA 1.75 mm) would displace 1511.29 mm³ of plastic volume. In order to move the same volume with a 3 mm filament (for example PLA 3 mm), the extruder pinion would only need 3.4 turns.

75 mm (for example PLA 1.75 mm) would displace 1511.29 mm³ of plastic volume. In order to move the same volume with a 3 mm filament (for example PLA 3 mm), the extruder pinion would only need 3.4 turns.

Now we do the previous operations in reverse order to obtain the turns that the same pinion of the motor of the extruder with a filament of 3mm must turn:

This reduction favors when making long-lasting 3D prints, since with the filament of 1.75mm the motors can get overheated by the rapid movements you need to do to push and retract the material, lose steps and ruin the entire piece that was to be printed. Another advantage of having less filament feed is that the pinion marks less amount of filament at the time of making the retractions.

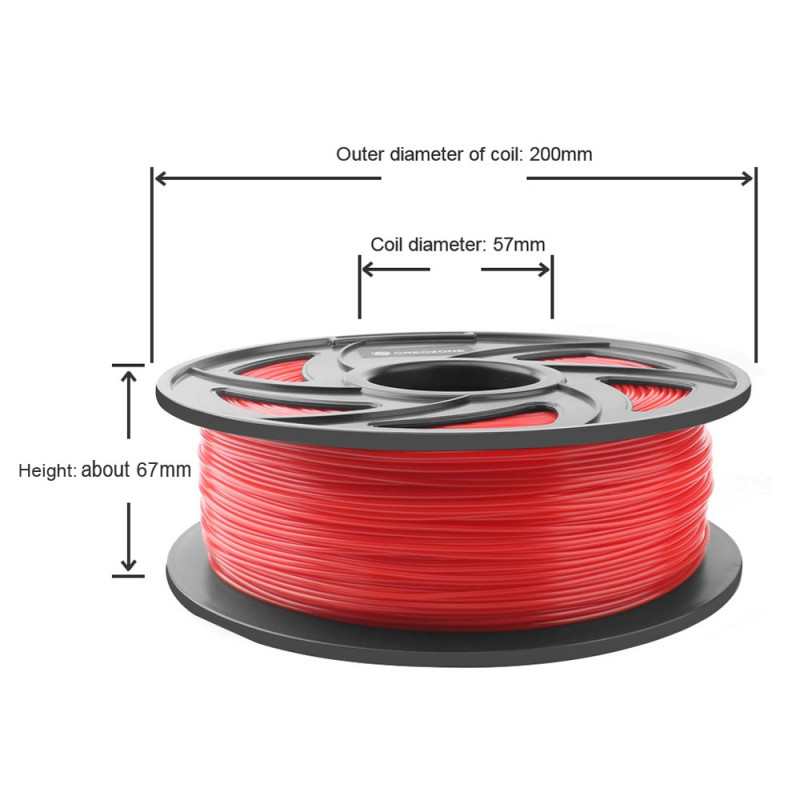

Image 1: The length difference marked by the extruder motor can be seen to extrude the same amount of volume for the 1.75 mm and 3 mm filamentWhen using flexible materials (Filaflex or TPU) or fragile (Lay-Woo3D) the 3mm filament has the advantage of being more resistant to bending than the same filament in 1. 75 mm. In addition, thanks to this resistance, the material remains more tense when winding it, which helps manufacturers to get coils with an almost perfect alignment and free of overlaps.

75 mm. In addition, thanks to this resistance, the material remains more tense when winding it, which helps manufacturers to get coils with an almost perfect alignment and free of overlaps.

In the beginning, the filament was 3mm because of the ease of manufacturing it to that extent with an acceptable tolerance, but as technology has evolved, the large manufacturers of 3D printers have demanded the change to 2.85 mm (nº 4 inch) for being a standard measure in the world of industrial manufacturing, in which there are tools of this diameter and very accurate.

This change also favors the 3D printers with Bowden System, since these systems use PTFE tubes of 1/8" (3.175 mm) of inner diameter, so if a 3 mm filament with a tolerance of ± 0.05 is used (Beware of low quality filaments that may have areas of 3.2 mm) the material may slide very just through the PTFE tube, causing a high friction that will cause jumps in the extruder or even a total clog with low quality filaments that do not comply with the tolerance indicated by the manufacturer.

With the Direct System the filament is introduced in the HotEnd immediately and therefore this problem does not occur, regardless of the use of 2.85 mm or 3 mm. This measure of 3 mm is also favorable to use it with nozzle diameters larger than normal (0.8 mm, 1 mm, 1.2 mm or more) to be able to have a good control of material between the entrance and exit of the nozzle. As it is evident, with a nozzle of smaller diameter than usual (0.35 mm, 0.3 mm, 0.25 mm or less) the use of a 3 mm filament is an inconvenience to be forced to use a low extrusion speed, which can result in traces of material in the piece. In the previous case, the best option is to use a 1.75 mm filament that, in combination with small nozzle diameters, is possible to obtain very small and detailed models.

Image 2: Tumaker Voladora Bowden SystemImage 3: Direct System Mendel Max XLThis diameter of 1. 75 mm, having less resistance to bending, needs less pressure to be displaced by the extruder, which implies a simpler extruder design than for the 3 mm filament, simpler electronic components and can be used in any 3D printer with any type of extruder without great difficulty (not to be confused with any type of drive system).

75 mm, having less resistance to bending, needs less pressure to be displaced by the extruder, which implies a simpler extruder design than for the 3 mm filament, simpler electronic components and can be used in any 3D printer with any type of extruder without great difficulty (not to be confused with any type of drive system).

As a final conclusion to this article and taking into account that it is not a trivial matter, we can say that the 1.75 mm filament is more suitable for non-professional use, with desktop 3D printes where 3D prints are often made for many hours or days. And on the other hand, the 3 mm filament is more suitable for professional o industrial 3D printers where 3D prints of even days are usually made, with large output diameters.

Subscribe to our monthly newsletter and you will receive every month in your email the latest news and tips on 3D printing.

* By registering you accept our privacy policy.

What is the best plastic for 3D printing? Let's figure it out together!

Plastic for 3D printing

After purchasing your own FDM 3D printer, as well as in the course of choosing it, it becomes necessary to choose the right plastic for 3D printing. But how to do this if you are new to 3D printing and have little to no understanding of this issue? Plastic for printing on a 3D printer is in most cases the main component of successful product reproduction. Therefore, we will not save on knowledge, and will tell you how to choose the best plastic for 3D printing.

Types of plastic for a 3D printer

First of all, we need to consider the types of plastic for a 3D printer. Plastic for 3D printing, or filament, is produced in the form of a thin thread with a diameter of 1.75 mm and 3 mm. Most often, filaments with a thickness of 1.75 mm are used in the basic configuration, but some manufacturers of 3D printers provide the ability to install a 3 mm plastic feed system. Plastic for 3D printing has many varieties, among which the most common are ABS and PLA plastic.

Plastic for 3D printing has many varieties, among which the most common are ABS and PLA plastic.

Plastic for 3D printing: varieties

By popularity in the Ukrainian market, the following types of plastic for 3D printing can be distinguished:

- PLA (PLA) or polylactide. Organic and short lived. Suitable for 3D printing of decorative products, but not able to withstand high mechanical loads;

- ABS (ABS) or acrylonitrile butadiene styrene. It has a long life and excellent mechanical properties. Heat-resistant and used for industrial purposes. Shrinks on cooling. It is recommended to print in ventilated areas;

- PVA (PVA) or polyvinyl alcohol. A water-soluble material that is used as a support;

- Nylone (Nylon). An alternative to ABS plastic, suitable for many engineering structures. When printing with nylon, it is recommended to ventilate the room;

- HIPS (High Impact Polystyrene). In terms of physical properties, it is a cross between PLA and ABS.

May also emit toxic fumes when printed.

May also emit toxic fumes when printed.

Other questions and answers about 3D printers and 3D printing:

What is the best plastic for a 3D printer?

In fact, there are many more types of plastic for 3D printing. This can include flexible, fluorescent and luminescent filament, wood and metallized materials. But in practice, such consumables are rarely used and are needed for narrowly specific purposes. Metallized plastics are interesting in their own right, but they are at the initial stage of development and are inferior in performance to ordinary reinforced materials. “And what plastic is best for a 3D printer?” - you ask. You should choose based on specific goals. If you intend to print decorative elements that will not be subject to payload, you can look at PLA plastic. If your goal is to print gears, structural parts and other things, look at reinforced materials for 3D printing.

What plastic to print with?

Please note that not every printer supports the full range of 3D printing materials. Before buying a specific filament, check the specifications of your own device to avoid wasting money. The rest is up to you and your imagination. A huge range of colors and shades of plastic is available for sale, matte and glossy, semi- and fully transparent materials. Such a variety will allow you to make almost any product to your taste.

Before buying a specific filament, check the specifications of your own device to avoid wasting money. The rest is up to you and your imagination. A huge range of colors and shades of plastic is available for sale, matte and glossy, semi- and fully transparent materials. Such a variety will allow you to make almost any product to your taste.

Remember that if you need to buy plastic for 3D printing - 3DDevice store is at your service! We offer a wide range of different materials in all possible color options and are ready to provide advice when choosing a filament.

If you have additional questions that we have not covered, write to us by e-mail and we, if necessary, will add your questions! Best regards, 3DDevice team. We also provide 3D modeling, 3D scanning and 3D printing services. We work all over Ukraine! If you have any questions, please contact us in any way convenient for you. Contacts are listed here. We look forward to collaborating!

Back to Home

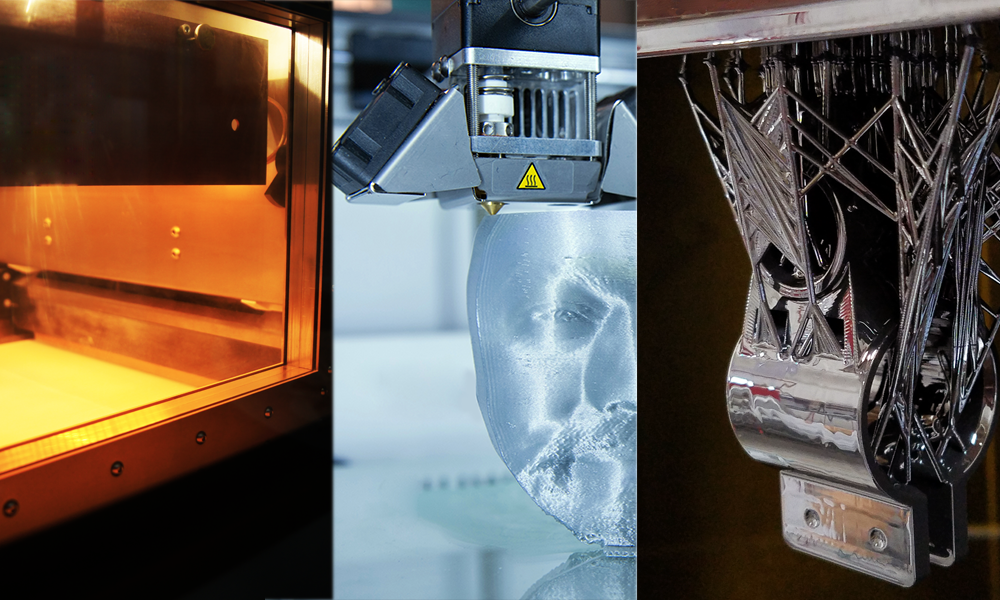

Review of the Best PETG Plastics for 3D Printing

3D printers can produce not only plastic toys and high-tech car parts, but also all sorts of exotic designs, from prosthetics to edibles. And with the best PETG materials, you will have durable and reliable 3D models. The low shrinkage makes this material an excellent choice for 3D printing with large, flat surfaces.

And with the best PETG materials, you will have durable and reliable 3D models. The low shrinkage makes this material an excellent choice for 3D printing with large, flat surfaces.

Moreover, with the rapid development of 3D technology, all different grades of PETG plastics are entering the market. And each of the manufacturing companies considers it their duty to report that it is their PETG plastic that is the best. It is not easy to stop at a really good product when there are so many manufacturers in stores. You will have to spend a lot of time going through all the available options in order to choose the best option. In this article, we will help you understand the question: "What kind of PETG plastic should I buy?".

What to consider when choosing PETG filament for a 3D printer?

Stability, cost-effectiveness, durability, flexibility and reliability are among the important factors when choosing PETG plastic. This type of 3D printing material is different from other plastic filaments because its polymer chains can be easily rebuilt for later use. Chemical resistance allows it to act as a barrier when used with alcohol and solvents.

Chemical resistance allows it to act as a barrier when used with alcohol and solvents.

In terms of safety, this material is food safe and has been approved by the FDA.

Make sure you only buy the highest quality PETG thread from a trusted source, otherwise results may differ from photos of satisfied users online.

So let's move on to the top 10 PETG materials

OVERTURE PETG Filament 1.75mm with 3D Build Surface

Overture 3D PETG Filament is made and developed with an anti-clog patent to ensure you stable and smooth 3D printing. Before packaging in aluminum foil, 24 hours of complete drying is required. This protects the PETG material from moisture, which can destroy it. Each PETG spool comes with a 200 x 200mm 3D printable surface.

The large inner spool diameter ensures a smoother material feed during 3D printing. The manufacturing company has over eight years of experience in producing thousands of tons of 3D printing materials per month.

Overture can produce all types of top quality materials in high volume. This definitely adds to the reliability and cost effectiveness of Overture filament for most 3D printers including FlashForge, Monoprice, Ender 3 and Prusa MK2/MK3.

Duramic plastics are manufactured using high precision measurement and quality control systems. These manufacturing techniques ensure that the plastic diameter is accurate to a tolerance of ±0.05 mm on a 1.75 mm filament thread.

The color is even, without traces of other shades. It is produced using pure American raw materials without recycled secondary waste. Duramic PETG filament guarantees exceptional reliability and quality, providing all your wishes in terms of material quality at an adequate price for such quality.

There are additional goodies. For example, there is a scale on the bobbin that can be used to navigate in terms of the remaining current length of the filament and its weight. Naturally, this quality PETG plastic is odorless.

DPC :

- Ecological and without smell

- Provides stable and smooth 3D printing

- Exceptional quality and reliability

- Warranty of money back

Disadvantages :

- Brass nozzle may cause problems

AmazonBasics PETG 3D Printer 1.75mm Blue Filament

AmazonBasics PETG filament is one of those plastics that will allow you to turn your creative ideas into high-quality material realization. This PETG plastic has a diameter of 1.75mm and is designed for use with the most common 3D printer models. The spool has a built-in sensor that shows the approximate length and percentage of material remaining. In developing this material, the company focused on reducing the chance of jamming during 3D printing and improving first layer adhesion.

Filament comes with a resealable storage bag. In addition to PETG plastic, you can also find PLA and ABS plastics from the same manufacturer. Their quality is excellent too.

Their quality is excellent too.

This PETG plastic from Amazon comes with a one year warranty. There are not only blue, but also other colors.

Advantages :

- High strength

- Spool with built-in gauge

- Fits most standard 3D printers

- It is easy to use and reduces the probability of jamming

- Guarantee one year

- provides good grasping the first layer with a 3D printer table

Disocations :

- You can find bubbles on the printed 3D

- users, some users complain, that users complain that it complain. storage bag not resealable

OVERTURE 1.75mm Transparent PETG Filament

Overture transparent filament is made of high quality PETG plastic which combines the advantages of other materials such as good flow, high impact strength, low shrinkage, no smell and security. Each of these PETG coils has a quality surface for easy material glide.

This filament is manufactured and developed with an anti-clog patent to ensure stable and smooth 3D printing. You can store this PETG material for up to 24 hours without a vacuum bag and you won't experience the moisture problems associated with PETG.

This PETG material comes with a "self-adjusting" diameter measurement control system that ensures dimensional accuracy and feed stability and therefore 3D printing. The company has been producing plastics for 3D printers for about 8 years. Production volumes are thousands of tons of materials.

DPC :

- Size accuracy and the constant size of the thread along the entire length of the coil

- is supplied with vacuum aluminum foil for packaging

- is not embedded in the hollow and does not leave bubbles

SUNLU PETG Filament 1.75mm for FDM 3D Printer

SUNLU GT PETG filament for 3D printer is a high-quality polyethylene terephthalate filament with a wide range of applications, with the advantages of durability and ease of use. This material does not require heating of the table and provides rigidity, reliable adhesion to the table and a glossy surface. The recommended nozzle temperature is 235–245 °C (455–473 °F). SUNLU PETG plastic has a diameter of 1.75mm with a dimensional tolerance of ±0.02mm.

This material does not require heating of the table and provides rigidity, reliable adhesion to the table and a glossy surface. The recommended nozzle temperature is 235–245 °C (455–473 °F). SUNLU PETG plastic has a diameter of 1.75mm with a dimensional tolerance of ±0.02mm.

This PETG material is produced with high precision and is suitable for most 3D pens and 3D printers. This plastic has a patent that describes a manufacturing procedure that reduces bubbles, nozzle clogging, and tangles, which guarantees stable and smooth 3D printing.

Reels with this PETG material undergo a full cycle of mechanical winding and strict manual testing, which guarantees accuracy and ease of feeding during 3D printing. SUNLU GT thread is completely dry in 24 hours. Like any other PETG plastic, this plastic is sensitive to moisture, so remember to always put it in an airtight bag after use. Large inner diameter spool design ensures smooth feeding during 3D printing.

DPC :

- Provides smooth and stable 3D printing

- The Bobin design is different, which provides ease of feeding during 3D printing

- A wide spectrum of use - from 3D printers to 3D handles

- Strong

- No notches to estimate material remaining

- No manufacturer's warranty

SUNLU PETG 3D Printer Filament With Dimensional Accuracy

This SUNLU PETG filament has a diameter of 1. 75mm and is perfect for 3D pens and 3D printers with a nozzle diameter of 1.75mm, such as Makerbot, Prusa, Geetech, Ante, Anycubic, 3D Hero and SUNLU. The recommended 3D printing temperature for SUNLU PETG plastic is 200-220°C and the bed temperature is 60-80°C. These recommended temperatures will help produce smoother 3D models that require minimal calibration. Problems with clogging of the nozzle and the need for further cleaning should also not arise.

75mm and is perfect for 3D pens and 3D printers with a nozzle diameter of 1.75mm, such as Makerbot, Prusa, Geetech, Ante, Anycubic, 3D Hero and SUNLU. The recommended 3D printing temperature for SUNLU PETG plastic is 200-220°C and the bed temperature is 60-80°C. These recommended temperatures will help produce smoother 3D models that require minimal calibration. Problems with clogging of the nozzle and the need for further cleaning should also not arise.

This PETG plastic makes it possible to obtain smooth 3D models and even a glossy surface with the right 3D print settings. The manufacturer has several patents that make it possible to maintain high quality 3D printing with low shrinkage. This PETG plastic stands out among others for its high hardness, good viscosity and absence of bubbles.

Supplied with a vacuum bag that makes it easy to store the reels in optimal conditions, away from dust and moisture. Like the others, this PETG filament is moisture sensitive. SUNLU offers a 100% lifetime warranty on this filament and they can replace the filament if any problem occurs.

DPC :

- It is characterized by high compatibility with different models of 3D printers and pens

- The result is smooth 3D models

- not scored 3D printer

- Forms the glossy surface 3D

- There is a long -term guarantee

- Essentially none, but for optimal 3D printing results, you will need to experiment with 3D printer nozzle and bed temperatures

YOYI 1.75mm 2.2lbs PETG Filament for 3D Printer

YOYI PETG 3D plastic in red color is usually imported from Europe and does not contain impurities, which ensures its high quality. In order to obtain a quality PETG plastic, strict procedures are followed during its production, guaranteeing the absence of bubbles, little or no smell, high accuracy of the thread diameter along its entire length and, therefore, achievement of the REACH standard.

This PETG plastic has a diameter of 1. 75 mm and a tolerance of ± 0.03 mm. It is designed with a tangle-free and clog-free patent, which guarantees you stable and smooth 3D printing. At optimal settings, there is minimal buckling.

75 mm and a tolerance of ± 0.03 mm. It is designed with a tangle-free and clog-free patent, which guarantees you stable and smooth 3D printing. At optimal settings, there is minimal buckling.

As a 3D filament manufacturing enterprise with many years of production experience, they can withstand all the strict requirements of 3D filaments and keep improving. The recommended printing temperatures for these PETG plastics are 250℃ - 275℃.

This PETG plastic is the best choice that guarantees you high quality 3D printing and is made from environmentally friendly materials that degrade gradually in the natural environment. If the quality of the plastic does not satisfy you, then YOYI offers a free return option within 30 days after purchase.

Advantages :

- Made from high quality and environmentally friendly raw materials.

- Ensures stable and smooth 3D printing

PETG materials from Prusa are characterized by very high strength and are guaranteed to meet the stated parameters of diameter accuracy and filament composition.

Again, you can use these PETG spools on any 3D printer if you are printing critical components that must meet high strength criteria. This plastic is practically not subject to deformation, has excellent adhesion of layers, including the first layer, which seizes with the table of your 3D printer.

DPCs :

- The production process is fully controlled, and the coils are tested before the sale of

- Strutary material with high heat resistance

- Universal use

- No guarantee from the manufacturer 9000. 1.75mm PETG Black Filament

- Combines the advantages of other materials from the current top

- Provides a smooth and stable 3D printing process

- 100% biodegradable

- No markings on the spool to estimate the remaining material

- No manufacturer's warranty

- Great combination of many 3D printing materials

- Eco-friendly material

- Compatible with any 3D printer

- Very high -quality results 3D print

- There is no control of the remaining thread on the coil

- There is no guarantee from the manufacturer

eSun PETG 3D Black Filament has a diameter of 1.75mm and a dimensional accuracy of +/- 0.05mm. This is an excellent material that combines the advantages of materials from other manufacturers. These include excellent glossy surface, good fluidity, high toughness, outstanding toughness, hydrophobicity, low shrinkage and no odor.

The black plastic is sold in 1kg spools and is easy to feed into your extruder. Naturally, like most of the high quality PETG plastics on this list, it comes vacuum-packed with a desiccant that protects the moisture-sensitive PETG material from moisture. The company provides a choice of 16 shades of colors.

The black plastic is sold in 1kg spools and is easy to feed into your extruder. Naturally, like most of the high quality PETG plastics on this list, it comes vacuum-packed with a desiccant that protects the moisture-sensitive PETG material from moisture. The company provides a choice of 16 shades of colors. The recommended extrusion/nozzle temperature is 240 - 255℃, printing speed 30~60mm/s, and travel speed 30~60mm/s. Note that eSun's PETG material requires a slower print speed than other PETG media.

Advantages :

Disadvantages :

HATCHBOX PETG 3D Printer Filament

This is one of the best filaments in the current list.

If you want to get the most out of PETG plastic 3D printing, this is definitely the option to try. These filaments are suitable for most 3D printers with a diameter of 1.75mm and an accuracy of +/- 0.03mm. HATCHBOX PETG is the perfect combination of flexibility and strength and is a great alternative to PLA or ABS. PETG plastics from this manufacturer have a combination of unique properties, such as rigidity, reliable adhesion and strength. A product printed on a 3D printer in compliance with the recommended 3D printing modes will have a glossy surface.

If you want to get the most out of PETG plastic 3D printing, this is definitely the option to try. These filaments are suitable for most 3D printers with a diameter of 1.75mm and an accuracy of +/- 0.03mm. HATCHBOX PETG is the perfect combination of flexibility and strength and is a great alternative to PLA or ABS. PETG plastics from this manufacturer have a combination of unique properties, such as rigidity, reliable adhesion and strength. A product printed on a 3D printer in compliance with the recommended 3D printing modes will have a glossy surface. It is environmentally friendly and does not require table heating. The recommended nozzle temperature is 230°C - 260°C, and the spool design makes it easy to dispense. HATCHBOX filament is vacuum packed and sealed with desiccant to keep its properties for a long period of time.

Benefits :

Disadvantages :

Frequent issues about Petg plastic

What is Petg plastic for 3D printer?

PETG plastic in the current context is the plastic filaments that are fed into the extruder of a 3D printer.

The filament is melted and extruded onto the print bed by an extruder to create physical 3D models. This is a very durable material that does not emit odor when 3D printed. PETG is more flexible than ABS or PLA. It is difficult to break and has very low shrinkage; hence, there is no deformation during 3D printing. It is worth noting that this is not a brittle plastic, but it is easier to scratch than ABS. It has good chemical resistance as well as water, acid and alkali resistance. Extremely durable material that allows you to get durable and reliable 3D models.

The filament is melted and extruded onto the print bed by an extruder to create physical 3D models. This is a very durable material that does not emit odor when 3D printed. PETG is more flexible than ABS or PLA. It is difficult to break and has very low shrinkage; hence, there is no deformation during 3D printing. It is worth noting that this is not a brittle plastic, but it is easier to scratch than ABS. It has good chemical resistance as well as water, acid and alkali resistance. Extremely durable material that allows you to get durable and reliable 3D models. What are the benefits of using PETG plastics for 3D printing?

PETG plastics combine many of the useful properties of PLA and ABS materials. PETG provides uninterrupted and stable 3D printing. Among the advantages of PETG plastics over PLA and ABS plastics are reduced shrinkage, warpage resistance, good layer adhesion, no smell during 3D printing, chemical resistance to alkalis and acids. Naturally, you will receive all these advantages only if you follow the recommendations for the temperature and high-speed modes of 3D printing, which are indicated by the manufacturer.

Learn more