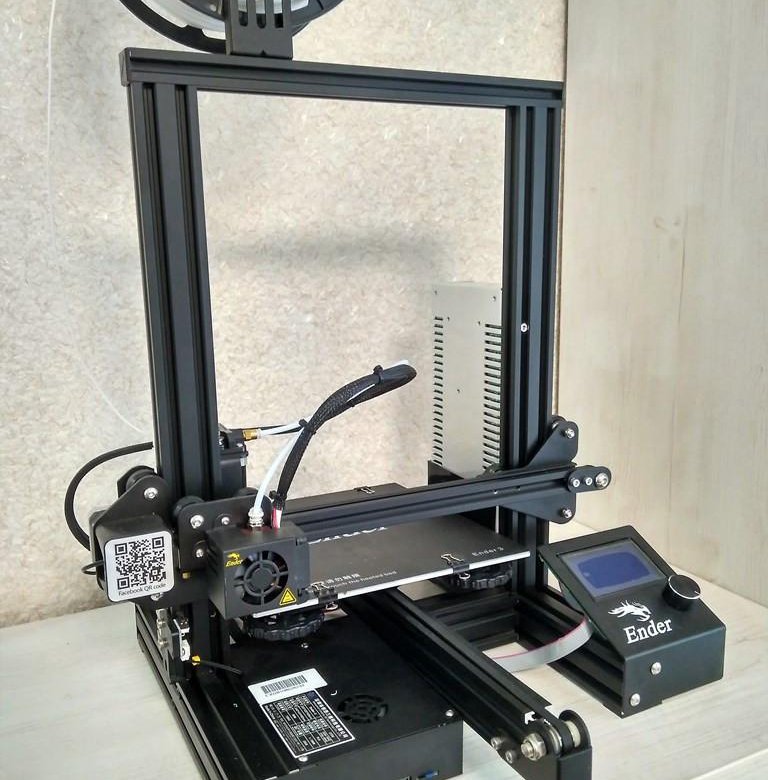

Bolt 3d printer

Bolt Pro | Professional 3D Printer

Bolt Pro FeaturesBUILT FOR OFFICE AND FACTORY FLOORS

BUILT FOR INDUSTRIAL 3D PRINTING

E3D HOTENDS AND EXTENSIVE FILAMENT OPTIONS

MINIMUM SETUP WITH OUR INTELLIGENT USER INTERFACE

LARGE INDUSTRIAL HEATED BED WITH BUILDTAK FLEXPLATE

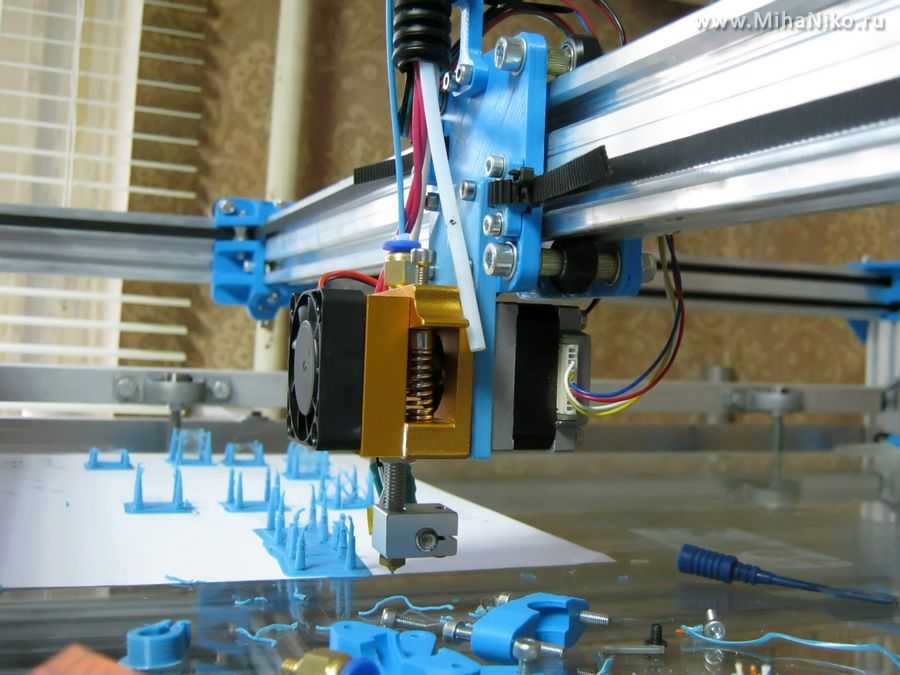

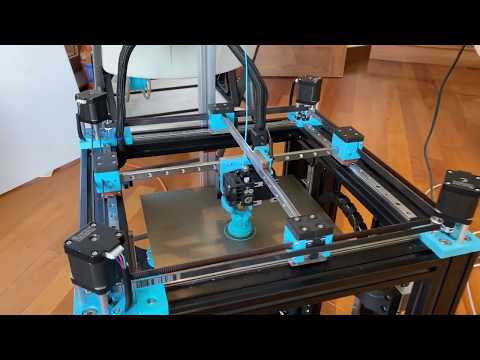

INDEPENDENT DUAL EXTRUDER 3D PRINTER

BUILT FOR OFFICE AND FACTORY FLOORS

The large enclosed build volume is equipped with a HEPA carbon filter that filters out 99.9% of any fumes that are produced when using certain filaments. This makes the Bolt Pro perfect for the office, education and any professional environments.

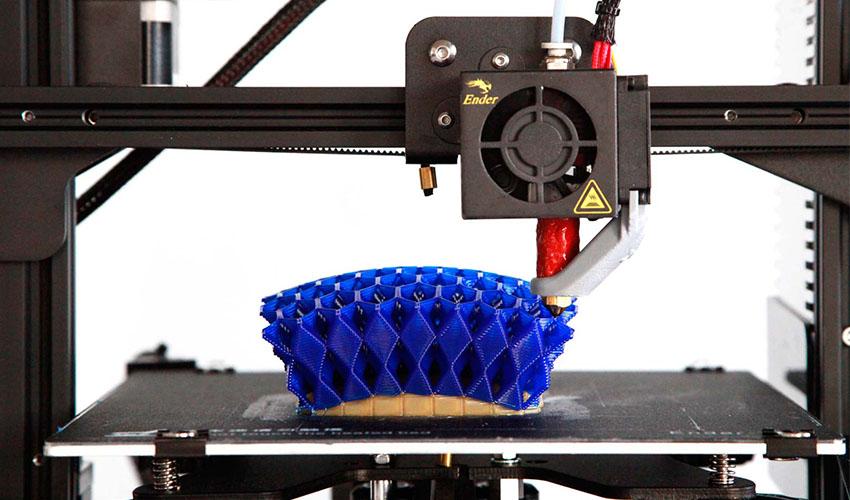

BUILT FOR INDUSTRIAL 3D PRINTING

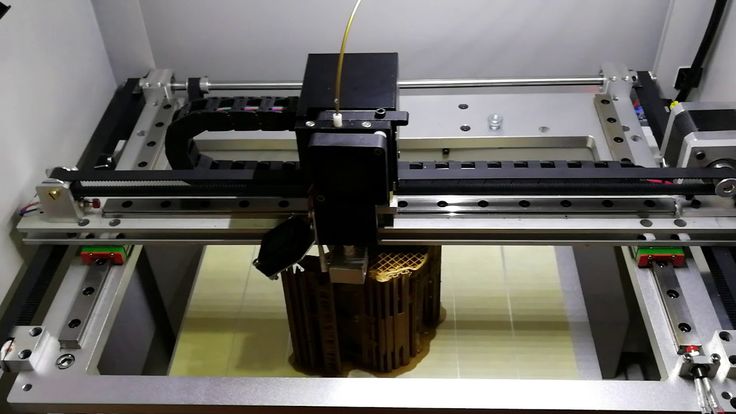

The Bolt Pro has a high-grade aluminium frame which sets it apart from many other printers in the market. The frame gives it great stability when printing ensuring lower printing issues that can arise during demanding projects. In addition to that, all our components are built with precision in mind, using high strength laser cut parts, extensive testing to create a machine that excels in demanding printing scenarios which gives the printer better longevity.

E3D HOTENDS AND EXTENSIVE FILAMENT OPTIONS

Striving to offer our customers the best versatility in their 3D printing needs, the Bolt Pro comes with the best 3D printing hotends in the market. This means the Bolt Pro can print with most major filaments in the market. If users need to produce visual prototypes or functional engineering parts, the Bolt Pro can achieve it easily.

MINIMUM SETUP WITH OUR INTELLIGENT USER INTERFACE

The Bolt Pro has minimum setup requirements that makes it ready out of the box. Operating the Bolt Pro is easy and can be done using the 7” inch touch screen or your preferred personal device using wifi. Any device with network connectivity and a browser can log onto the Bolt Pro and will grant you control as well as visibility through the built-in webcam.

LARGE INDUSTRIAL HEATED BED WITH BUILDTAK FLEXPLATE

The Bolt Pro comes with a heated aluminum bed that is easily removable and it can heat prints up to 90°C. This ensures better heat distribution for hard to print materials that need better layer adhesion. In addition to that, the Bolt Pro includes a Buildtak Flexplate which makes the removal of parts very quick and easy without leading to damaging printed parts due to improper bed adhesion.

INDEPENDENT DUAL EXTRUDER 3D PRINTER

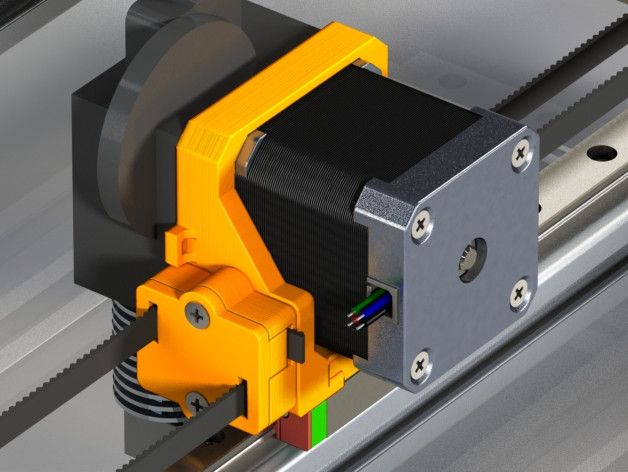

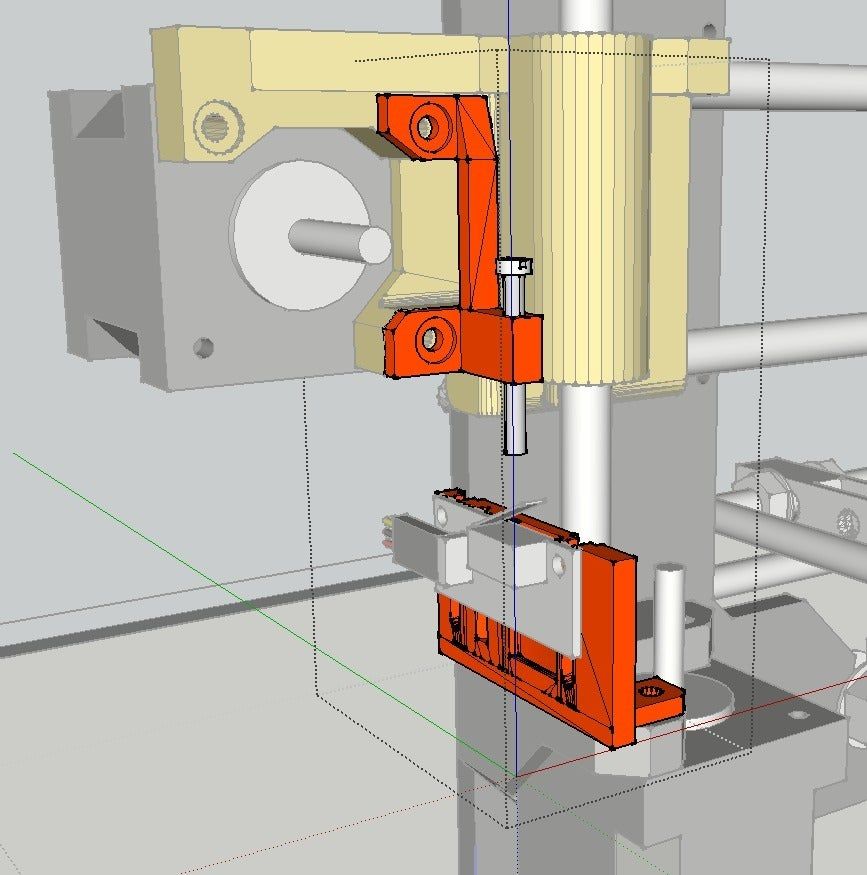

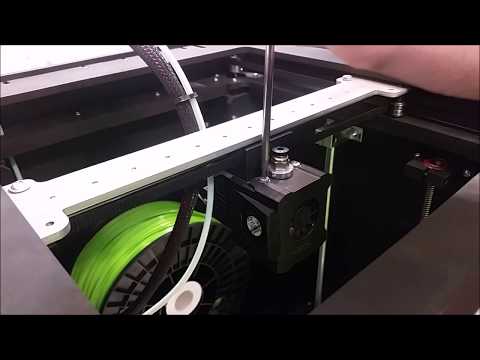

The Bolt Pro 3D printer is equipped with unique direct drive Independent Dual Extruders. This means that both extruders can move independent from each other for clean dual prints. The unique nozzles also give unique benefits like sync- or mirror-mode as well as swappable nozzles for a greater selection of filaments.

The Bolt Pro is a professional 3D printer, designed to offer precise and reliable functional 3D printing results. The Bolt Pro 3D printer can achieve this due to the focus in offering features that give full creative control to our users. These features include a dual extruder system (IDEX) that can print with two materials at once or clone 3D models, which cuts the lead time of a project by half. Additionally, featuring industrial build quality and E3D hot ends makes the Bolt Pro an excellent solution for your 3D printing needs. Designed for organisations, the Bolt Pro can run constantly, print with any 3D printing filament in the market and offers remote management features to ensure projects run effectively at all times. Leapfrog 3D Printers built the Bolt Pro 3D printer to give our users the optimal solution to convert their ideas into functional and tangible products.

These features include a dual extruder system (IDEX) that can print with two materials at once or clone 3D models, which cuts the lead time of a project by half. Additionally, featuring industrial build quality and E3D hot ends makes the Bolt Pro an excellent solution for your 3D printing needs. Designed for organisations, the Bolt Pro can run constantly, print with any 3D printing filament in the market and offers remote management features to ensure projects run effectively at all times. Leapfrog 3D Printers built the Bolt Pro 3D printer to give our users the optimal solution to convert their ideas into functional and tangible products.

- MULTI-MATERIAL PRINTING

- E3D HOTENDS ALLOWS PRINTING WITH MOST MAJOR FILAMENTS IN THE MARKET

- INDUSTRIAL GRADE BUILD FRAME FOR STABILITY

- INTELLIGENT USER INTERFACE WITH EASY WIRELESS CONTROL

- INDEPENDENT DUAL EXTRUSION SYSTEM FOR MIRROR-MODE PRINTING

- HEATED PRINT BED WITH BUILDTAK FLEXPLATE FOR EASY OBJECT REMOVAL

- SLICER SOFTWARE – SIMPLIFY3D

- QUICK START GUIDE

- LEAPFROG 3D PRINTERS USB KEY

Request a Sample

READ REVIEWS

Testimonials

Video Testimonial: FUJITSU aiming high with the Bolt Pro

‘We chose Leapfrog instead of other brands for two reasons.

Firstly, because it has an open environment that allowed us to use a variety of materials rather than limiting to just one. Secondly, because it has certain features that we didn’t find in other machines of its range.’

-

We use the Bolt Pro to create designs that were made with traditional technology like milling.

-

Creating

tooling for the production line. -

3D printing requires fewer parts, the cost is less and its much faster, additionally it has the

flexibility to test multiple concepts without increasing costs to the production lines, which is important. -

The

return on investment has been very fast, in about 6 months. -

We have noticed that our

flexibility and our speed to try new concepts has increased exponentially.

Luis De La Jara, Coordinator Mechanical Designers

Automotive Engineering Department Fujistu Spain

KLM and Leapfrog: a success story

-

We chose the Bolt Pro because of its rigidity and the option to print two parts simultaneously with the two heads.

Another advantage is the ability to print high-temperature materials. We have two Bolt Pro printers in our Engineering & Maintenance Department:

Another advantage is the ability to print high-temperature materials. We have two Bolt Pro printers in our Engineering & Maintenance Department: -

We also print prototypes of small aircraft cabin parts. These prototypes are actually tested on board by cabin crew. Final designs are mass produced by injection molding from certified materials.

-

The

dimensional accuracy of the prints is very good.

‘

I certainly recommend the Bolt Pro because of its rigidity, its large print bed and the two print heads which double the print speed once more similar parts are needed. I think the Leapfrog Bolt Pro is very suitable for engineering in prototyping and it can even produce a small series of plastic parts’.

Maarten Ottevanger, Process Engineer

KLM Engineering & Maintenance

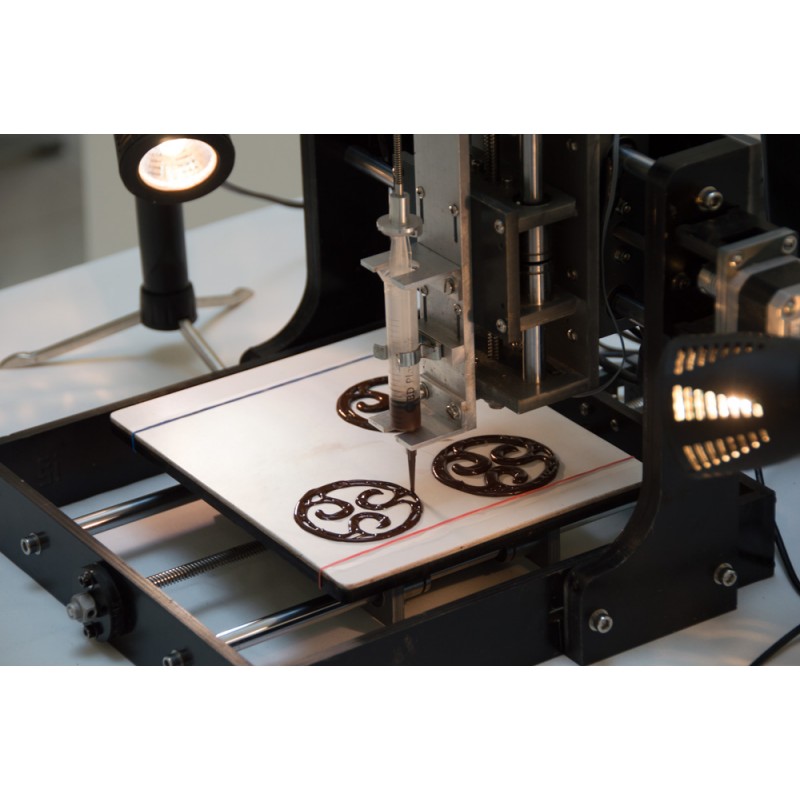

Benier: 3DP Food Production

What are we using the Leapfrog 3D Printers for?

At Benier we use the Leapfrog Bolt Pro to make among other items sealing caps, special washers and cover caps.

Why did we choose Leapfrog’s (Bolt Pro) 3D Printer?

Benier produces equipment for the bakery industry. The bolt pro can print with food approved materials which is a great advantage for us. Leapfrog advised us the Bolt Pro 3D printer also because of its large printing volume and its ease of use.

What is your overall experience with Leapfrog’s products and services?

After a demonstration at Leapfrog we received a demo version of the 3D printer to try out for several months. This great service and the right specifications for our products made our choice for Leapfrog and their Bolt Pro 3D printer easy.

Erik van Opstal – Managing Director Benier B.V.

Benier B.V. is a part of the Kaak group

What is Volkswagen using the Leapfrog 3D Printers for?

-

The Bolt was analyzed as the best machine for printing

flexible materials due to the direct drive system -

Relatively

large build volume, especially considering size vs. cost

cost -

2 Independent Dual Extruder system

IDEX since we assemble cars for both left and right driving sides, so this helps a lot for building mirror parts - Reliable – although we had our startup issues with this unit, support was good and we managed to correct issues. We believe the Leapfrog Bolt Pro is a very reliable machine for the way we use this equipment.

Summarizing, our engineers using the Leapfrog 3D printers are more than thrilled about the results and potential the Leapfrog printers have; your 3D printers are better from numerous points of view (printing materials, IDEX, build volume etc). At the same time, we also see room for improvements and are happy to share feedback for further development ideas.

Why Rollomatic chose the Bolt Pro to make Humanoid Robots

What are we using the Leapfrog 3D Printers for?

- Serial tool production for Humanoid Robots (grippers, feelers, etc.

)

) - One-off parts

- Customized prototypes

Would you recommend Leapfrog’s Bolt Pro and to who?

- Absolutely, we would highly recommend the Bolt

- Any company that wants to prototype and produce parts quickly without spending a lot of money on an SLS printer

What would you recommend as changes and added features for the Leapfrog Bolt 3D Printing solution?

- We would recommend looking into achieving a more evenly distributed heat distribution over the build platform

- Automate the bed levelling procedure

- Faster heating of the bed, maybe consider using 230VAC heated element with solid state relay?

- Linear rails for both axis and some guidance on the Z axis to prevent bed wobble.

- Exchangeable nozzle

- Nice to have for the user interface: Possibility to move axis manually, pre-heat button for the bed and extruder.

5 Reasons Why Rolls Royce Chose Leapfrog’s 3D Printers

Rolls Royce was in the market for a new 3D printing solution so as to be able to expand their internal rapid prototyping capabilities. They looked at various machines We looked at a range of machines from cheap Chinese hobbyist machines all the way up to eye-watering expensive liquid polymer based printers but our deciding criteria were:

They looked at various machines We looked at a range of machines from cheap Chinese hobbyist machines all the way up to eye-watering expensive liquid polymer based printers but our deciding criteria were:

- Dual extrusion – soluble support material is very important for the types of models we will be printing, often involving large overhangs and intricate internal features.

- Full enclosure – Two reasons for this, first being to stop the curious/ignorant injuring themselves and the second is to provide an environment conducive to maximising print quality. The only area where the Leapfrog Bolt pro could be better is a heated enclosure but since this appears to be an ABS only issue and we’re getting such good results from PLA then this may not be an issue in the long run.

- Print quality – We had a few samples made up on the Leapfrog bolt and were pleased with the results

- Price – The cost was in the right ballpark to be able to make the business case for the leadership team.

Rez Manzoori – BEng(Hons) CEng MRAeS

Turbine Sub-System Integration

Mackay Hospital: Surgery simulation with Bolt Pro

Why did you choose the Bolt Pro 3D Printer?

- Large print volume allowing us to print large bones.

- High temp hot ends allow us to print with heat stable materials that can be sterilized

- Enclosed with HEPA filter allowed us to safely use in our office.

What are we using the Leapfrog 3D Printers for?

We are able to print fractured bones or bony deformities which gives the surgeons a tactile model to imprint the bony architecture in their memory. This makes surgery much easier and increases the surgeons understanding of the geometry. We can also use the models to trial implants so we know what will work best for fixing fractures.

What is your general impression of 3D Printing and the Leapfrog Bolt?

All surgeons using the models are very happy and see a great perceived benefit. Our prints have for the most part come out very well, and I myself (starting as a complete novice) have found the learning curve manageable and been impressed with how easy it was to get to the point of producing consistently good results.

Our prints have for the most part come out very well, and I myself (starting as a complete novice) have found the learning curve manageable and been impressed with how easy it was to get to the point of producing consistently good results.

Jonathan Davis, Orthopedic Surgeon

Crocs™ – Bolt Pro advantages for design.

-

The Bolt is fitted with a

large build volume. Large enough to create prototypes that can be tested for improvement. -

It also can

print many different types of materials, including flexible plastic. In general, 3D printing using flexible material can prove to be difficult, but the advanced Direct Drive of the Bolt controls the flow of the filament expertly through the nozzle.

For prototyping, to be able to develop new products quickly. Today we have many different models of Crocs footwear. This achievement has been by thinking of prototyping in a different way using Leapfrog’s Bolt 3D Printer.

Enthusiasm for the Bolt has started to become recognized outside of Crocs innovation department with our international colleagues. We recommend this machine for prototyping purposes in most professional environments.

Luca Faggin, Europe innovation manager Crocs™

3D printing helps surgeons plan, practice procedures

How 3D printing is used in surgery?

3D printing is having a major impact on medicine in a number of ways. This is mainly evident in Orthopedic Surgery where doctors use 3D printing to help treat patients musculoskeletal system. 3D scans are taken of patients and using that data, doctors print replica accurate bones of patients.

What are the models used for?

-

To view injuries more accurately to help plan surgery

-

Tactile feedback for doctors

-

Practice surgical procedures before full operation

-

To review treatment with accurate comparisons between the treatment time period

Dr Rudolph Venter, Division of Orthopaedic Surgery, Stellenbosch University

Specifications

Every little detail, yes, really everything

Precision

size

Speed

50 - 350

Layer height (micron)

64

Weight (kg)

100

Printing speed (mm/s)

DW/H: 8/10

Positioning precision (micron)

Aluminium

Body framework

6

Max. Flow Rate (mm3/s)

Flow Rate (mm3/s)

0.4

Nozzle diameter (mm)

723 x 831 x 801

Printer dxwxh (mm)

250

Travel speed (mm/s)

Precision

2

Number Extruders

Buildtak Flexplate System

Printbed

330 x 320 x 205

Single Extruder Build Volume (mm)

90°C

Print Bed Temperature

270/360°C

Nozzle Temperature

300 x 320 x 205

Dual Extruder Build Volume (mm)

Choose the right material for

Bolt proHIPS

Scaffold

PP

Carbon

Hybrid

Nylon

Flex

PETG

E-PLA

ABS

HIPS

HIPS is a filament that is used to both print objects and acts as support material during the construction of complex geometric objects with angles greater than 45 degrees. Acting as a support material, HIPS is easily removed when the completed object is submerged in D’Limonene where HIPS is soluble. The best material to pair HIPS with as support is ABS since they both have very similar mechanical properties. If used as a standard material, HIPS objects are very stiff and have good heat resistance.

Acting as a support material, HIPS is easily removed when the completed object is submerged in D’Limonene where HIPS is soluble. The best material to pair HIPS with as support is ABS since they both have very similar mechanical properties. If used as a standard material, HIPS objects are very stiff and have good heat resistance.

Printing tips

Heated Bed: Temperature affects HIPS when printing and you need to ensure better management for better printing results.

Scaffold

Scaffold Soluble Support Filament is used to print complex geometric parts. Objects that have angles greater than 45 degrees or overhangs require another material to keep the shape uniform, especially during the printing and cooling process.

Printing tips

Storage: Scaffold being soluble in water means it is highly hygroscopic and should be stored in a dry environment.

PP

PP (Polypropylene) is a light flexible material that offers a number of highly desired properties. It has high impact strength and bending abilities making it great for parts that require heavy use. In the consumer market, it is used for applications, such as packaging, stationary and more.

It has high impact strength and bending abilities making it great for parts that require heavy use. In the consumer market, it is used for applications, such as packaging, stationary and more.

Temperature: Printing with Polypropylene requires planning and careful temperature management to ensure successful prints. It is a material that is not as forgiving as E-PLA during the printing process.

Storage: Store the filament in dry areas since it absorbs moisture.

Carbon

Carbon filament is great for printing strong and durable parts. It is the perfect choice for mechanical parts, housing, shells or other protective casings. Carbon filament usually contains additional printing materials within its composition (ABS, PETG, NYLON etc.) depending on the product needed.

Printing tipsSteel Nozzles: Carbon filament is very abrasive and it is better to print with steel nozzles to reduce clogging.

Print Speed: To ensure better results, print carbon parts with a lower printing speed. This will ensure better results.

Hybrid

Leapfrog Hybrid (CPE) is a strong material that is easy to print with and has various properties that make it an ideal material for large objects or objects that are used for mechanical prototypes. In terms of durability, it is between ABS and PLA and produces objects that can withstand high temperatures.

Printing tipsTemperature: Printing with Hybrid requires correct print bed temperature settings and managment.

Nylon

Nylon is a well known and very tough filament that has a wide array of applications. It’ is slightly flexible giving it the ability to bend without breaking and has durability properties such as heat resistance and impact resistance. Compared to other materials, it is the most versatile due.

Printing tipsStorage: Nylon filament like some other filaments can absorb moisture from the air and can lead to printing issues.

Flex

Flex is a filament that uses a combination of plastic and rubber. The main benefit of Flex filament is the creation of flexible prints with elastic properties. When printing with Flex, the amount of infill can control the stiffness of your print. Flex printed with 100% infill will be quite rigid, whereas a 0% infill would create a rubber tube or even balloon-like print.

Flex can be used for rubber wheels, mechanical grips or tough durable parts with superb shock absorption using 100% infill.

Print Speed: Use consistent flow rates and also smaller layer heights to ensure better interlayer adhesion.

Storage: Keep flexible filament dry and away from moisture.

PETG

Polyethylene Terephthalate is the most widely used plastic globally and is used to create various products like standard water bottles. PETG on the other hand is specifically designed for 3D printing applications and is considered the bridge in terms of mechanical properties between PLA and ABS. It offers strength, impact resistance and chemical resistance without having issues like warping.

It offers strength, impact resistance and chemical resistance without having issues like warping.

Having similar properties to PLA and ABS, PETG is a great filament for a number of applications that require more durability than PLA can offer, while being easier to print with than ABS.

Printing tipsPrint Speed: We recommend printing with lower than average print speed if the desire is to achieve better strength properties due to better layer adhesion.

Storage: Store the filament in dry areas since it absorbs moisture.

E-PLA

Leapfrog Engineering PLA (Polylactic Acid)is a biodegradable plastic that was formulated to provide greater durability than standard PLA without compromising on its eases of use when printing. PLA is the most popular filament used globally, offering great print quality with good dimensional accuracy and is used in many applications.

E-PLA is used in various settings mainly due to its ease of use compared to other filaments. It is the best filament to begin with for novice 3D printing users.

It is the best filament to begin with for novice 3D printing users.

Sunlight: Direct sunlight over long periods can degrade the quality of the printed object so store E-PLA parts inside.

Storage: Store the filament in dry areas since it absorbs moisture.

ABS

ABS (Acrylonitrile Butadiene Styrene) is a strong popular filament that is used widely for 3D printing parts. It has strong material properties which produce parts with high impact, high-temperature resistance. Having these qualities however does make it a little harder to print with than some other filaments, but our printers come with a heated bed that ensures the filament is constantly heated to ensure prints adhere to the bed and print to specifications.

Printing tipsTemperature: ABS is very sensitive to temperature fluctuations during the printing process. It often cracks or warps as different layers cool differently. To ensure this issue is mitigated, our printers come with an enclosure system and heated bed to produce better results.

It often cracks or warps as different layers cool differently. To ensure this issue is mitigated, our printers come with an enclosure system and heated bed to produce better results.

Sunlight: Direct sunlight over long periods can degrade the quality of the printed object so store ABS parts away from UV sources.

Leapfrog 3D Printers | Professional 3D Printers and Printing Materials

Oops...

Slider with alias homepage-refurbished-bolt-pro not found.

Discover our Bolt Pro 3D PrinterTestimonials

Video Testimonial: FUJITSU aiming high with the Bolt Pro

‘We chose Leapfrog instead of other brands for two reasons. Firstly, because it has an open environment that allowed us to use a variety of materials rather than limiting to just one. Secondly, because it has certain features that we didn’t find in other machines of its range.’

-

We use the Bolt Pro to create designs that were made with traditional technology like milling.

-

Creating

tooling for the production line. -

3D printing requires fewer parts, the cost is less and its much faster, additionally it has the

flexibility to test multiple concepts without increasing costs to the production lines, which is important. -

The

return on investment has been very fast, in about 6 months. -

We have noticed that our

flexibility and our speed to try new concepts has increased exponentially.

Luis De La Jara, Coordinator Mechanical Designers

Automotive Engineering Department Fujistu Spain

SEE VIDEO TESTIMONIAL

KLM and Leapfrog: a success story

-

We chose the Bolt Pro because of its rigidity and the option to print two parts simultaneously with the two heads. Another advantage is the ability to print

high-temperature materials. We have two Bolt Pro printers in our Engineering & Maintenance Department:

We have two Bolt Pro printers in our Engineering & Maintenance Department: -

We also print prototypes of small aircraft cabin parts. These prototypes are actually tested on board by cabin crew. Final designs are mass produced by injection molding from certified materials.

-

The

dimensional accuracy of the prints is very good.

‘

I certainly recommend the Bolt Pro because of its rigidity, its large print bed and the two print heads which double the print speed once more similar parts are needed. I think the Leapfrog Bolt Pro is very suitable for engineering in prototyping and it can even produce a small series of plastic parts’.

Maarten Ottevanger, Process Engineer

KLM Engineering & Maintenance

What is Volkswagen using the Leapfrog 3D Printers for?

-

The Bolt was analyzed as the best machine for printing

flexible materials due to the direct drive system -

Relatively

large build volume, especially considering size vs. cost

cost -

2 Independent Dual Extruder system

IDEX since we assemble cars for both left and right driving sides, so this helps a lot for building mirror parts - Reliable – although we had our startup issues with this unit, support was good and we managed to correct issues. We believe the Leapfrog Bolt Pro is a very reliable machine for the way we use this equipment.

Summarizing, our engineers using the Leapfrog 3D printers are more than thrilled about the results and potential the Leapfrog printers have; your 3D printers are better from numerous points of view (printing materials, IDEX, build volume etc). At the same time, we also see room for improvements and are happy to share feedback for further development ideas.

5 Reasons Why Rolls Royce Chose Leapfrog’s 3D Printers

Rolls Royce was in the market for a new 3D printing solution so as to be able to expand their internal rapid prototyping capabilities. They looked at various machines We looked at a range of machines from cheap Chinese hobbyist machines all the way up to eye-watering expensive liquid polymer based printers but our deciding criteria were:

They looked at various machines We looked at a range of machines from cheap Chinese hobbyist machines all the way up to eye-watering expensive liquid polymer based printers but our deciding criteria were:

- Dual extrusion – soluble support material is very important for the types of models we will be printing, often involving large overhangs and intricate internal features.

- Full enclosure – Two reasons for this, first being to stop the curious/ignorant injuring themselves and the second is to provide an environment conducive to maximising print quality. The only area where the Leapfrog Bolt pro could be better is a heated enclosure but since this appears to be an ABS only issue and we’re getting such good results from PLA then this may not be an issue in the long run.

- Print quality – We had a few samples made up on the Leapfrog bolt and were pleased with the results

- Price – The cost was in the right ballpark to be able to make the business case for the leadership team.

Rez Manzoori – BEng(Hons) CEng MRAeS

Turbine Sub-System Integration

Crocs™ – Bolt Pro advantages for design.

-

The Bolt is fitted with a

large build volume. Large enough to create prototypes that can be tested for improvement. -

It also can

print many different types of materials, including flexible plastic. In general, 3D printing using flexible material can prove to be difficult, but the advanced Direct Drive of the Bolt controls the flow of the filament expertly through the nozzle.

For prototyping, to be able to develop new products quickly. Today we have many different models of Crocs footwear. This achievement has been by thinking of prototyping in a different way using Leapfrog’s Bolt 3D Printer.

Enthusiasm for the Bolt has started to become recognized outside of Crocs innovation department with our international colleagues. We recommend this machine for prototyping purposes in most professional environments.

Luca Faggin, Europe innovation manager Crocs™

3D printing helps surgeons plan, practice procedures

How 3D printing is used in surgery?

3D printing is having a major impact on medicine in a number of ways. This is mainly evident in Orthopedic Surgery where doctors use 3D printing to help treat patients musculoskeletal system. 3D scans are taken of patients and using that data, doctors print replica accurate bones of patients.

What are the models used for?

-

To view injuries more accurately to help plan surgery

-

Tactile feedback for doctors

-

Practice surgical procedures before full operation

-

To review treatment with accurate comparisons between the treatment time period

Dr Rudolph Venter, Division of Orthopaedic Surgery, Stellenbosch University

SEE VIDEO TESTIMONIAL

Trusted by

Professionals

Professionals around the world are using functional 3D printing to drastically improve their product development process in various ways. Most of the global leading companies in engineering, the automobile industry, robotics, architecture, and medical care have integrated 3D printing into their workflows to cut lead times and to bring back control of the process in-house. These range from prototyping parts before mass production, to producing functional parts that can demonstrate how a part will work. To help these companies, Leapfrog 3D Printers designs and produces a range of professional 3D printing solutions that aim to help our customers achieve results faster and produce the highest quality 3D printed parts.

Most of the global leading companies in engineering, the automobile industry, robotics, architecture, and medical care have integrated 3D printing into their workflows to cut lead times and to bring back control of the process in-house. These range from prototyping parts before mass production, to producing functional parts that can demonstrate how a part will work. To help these companies, Leapfrog 3D Printers designs and produces a range of professional 3D printing solutions that aim to help our customers achieve results faster and produce the highest quality 3D printed parts.

Trusted by

Professionals

Professionals around the world are using functional 3D printing to drastically improve their product development process in various ways. Most of the global leading companies in engineering, the automobile industry, robotics, architecture, and medical care have integrated 3D printing into their workflows to cut lead times and to bring back control of the process in-house. These range from prototyping parts before mass production, to producing functional parts that can demonstrate how a part will work. To help these companies, Leapfrog 3D Printers designs and produces a range of professional 3D printing solutions that aim to help our customers achieve results faster and produce the highest quality 3D printed parts.

These range from prototyping parts before mass production, to producing functional parts that can demonstrate how a part will work. To help these companies, Leapfrog 3D Printers designs and produces a range of professional 3D printing solutions that aim to help our customers achieve results faster and produce the highest quality 3D printed parts.

What the experts say

Make Magazine: Review on Bolt’s specs and 3D prints

"The Bolt is a powerful device with industrial mechanics and proved to be easy to use in the test. The dual extrusion mode works well, thanks to the enclosed installation space, the heat output of the extruders (up to 360 degrees Celsius) and the construction platform (up to 90 degrees Celsius), the machine is suitable for a wide range of materials"

Review by business.com: Xeed 3D printer

"With a wide choice of materials, very tight precision and a unique dual-extruder design, Leapfrog's Xeed 3D printer is a designer's dream come true. " Read more.

" Read more.

3dprintr.com: Reviewing the unique features of Bolt

A few weeks ago, I received the Leapfrog Bolt for intensive testing. Besides a lot of very positive things I have only a few minor points of criticism. What I enjoyed most were the two independent extruders, the air filter and the good print quality when printing with ABS and many other materials.

3DPrinting.com: In-depth review on the Bolt

"Definitely one of the best printers we’ve ever tested. The intuitive interface, massive build volume, closed print chamber and independent dual extruders make this printer a true workhorse that will bring your prints to the next level."

Previous Next

TRUSTED BY

Precision, Durability, Consistency

Discover your 3D printer

Xcel

Max print dimensions

550 x 500 x 2240 mm

Bolt Pro

Max print dimensions

300 x 320 x 205 mm

Xeed 2.

0

0Max print dimensions

280 x 220 x 230 mm

Find

Resellers- Buy your Bolt Pro 3D printer nearby

- The lowest shipping costs

- The quickest delivery

GermanyAustraliaBrazilChinaColombiaCzech RepublicEMEAFinlandFranceGermanyGreeceIndonesiaItalyKorea, Republic OfPhilippinesPortugalRomaniaRussian FederationSaudi ArabiaThailandTurkeyUnited Arab EmiratesUnited KingdomUnited States

Just3D

Germany

Visit websiteBFI 3D

Germany

Visit websiteSEE ALL RESELLERS

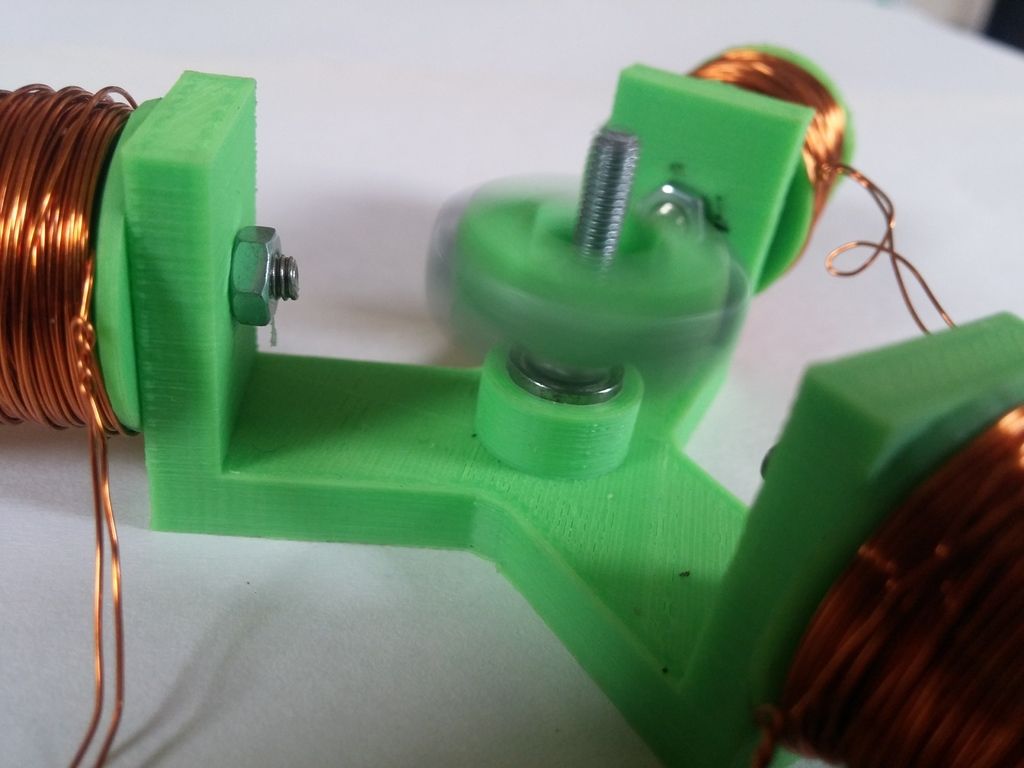

Wade Bolt Plastic Feed Extruder 1.

75 3mm CNC 3D Printer Wade Bolt Plastic Feed Extruder 1.75 3mm CNC 3D Printer

75 3mm CNC 3D Printer Wade Bolt Plastic Feed Extruder 1.75 3mm CNC 3D Printer Application status Lock the ring Write a sheet Rotate item Znizhki Articles

30

2419

Description

Plastic stitching bolt - Hobbed bolt M8 at 1.75, 3mm. A hobbed bolt with a toothed notch is used in the design of 3D printers. Yogo zavdannya - proshtovhuvat plastic thread in the extruder.

.

Technic characteristics

DIAMART: Can Vikoristovati for the Plastic Plastic Plastic Plastic DIAMM 3 mm

VIDSTAN Bolt head I to the ears0003

Thread: M8

Length: 65mm

Dodatkovo

| Country of registration of the brand | China |

| Product | China |

| Type | 3D printer |

Comments

0No comments yet.

Comment

| Registration is not obligatory for purchase! If you want to make a reservation, just add the goods you need to the cart, enter your details and click the "Make a reservation" button. We will call you at the next hour. Payment - transfer to the card-key account PB - online without commission by card to any bank (LiqPay) - unprepared transfer without VAT for 9 legal entities0003 - delivery by card upon delivery (only by New Post when ordered 100 UAH) - delivery via terminal in our shop Write us about it in the chat - button in the lower left corner of the screen. Delivery - Nova Poshta - Ukrposhta (only if prepaid) - samovivіz (you can also call kur.єra Glovo in Ivano-Frankіvsk) Direction of the product during the skin working day. In most cases, your request will be seen on the day of the application / payment or on the next day. Pickup by self-delivery can be picked up in our store, after the application we will call you and say, if the parcel for the booking is ready before you see it. Warranty and return - return for 14 days, if the goods are not returned - 6 months warranty for wet products |

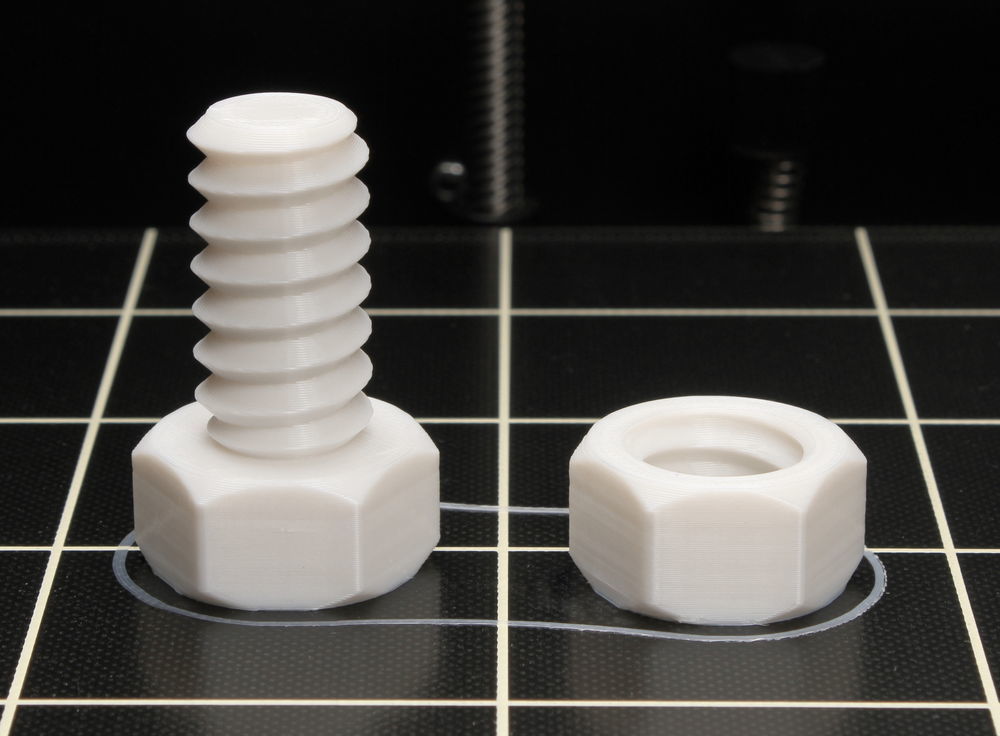

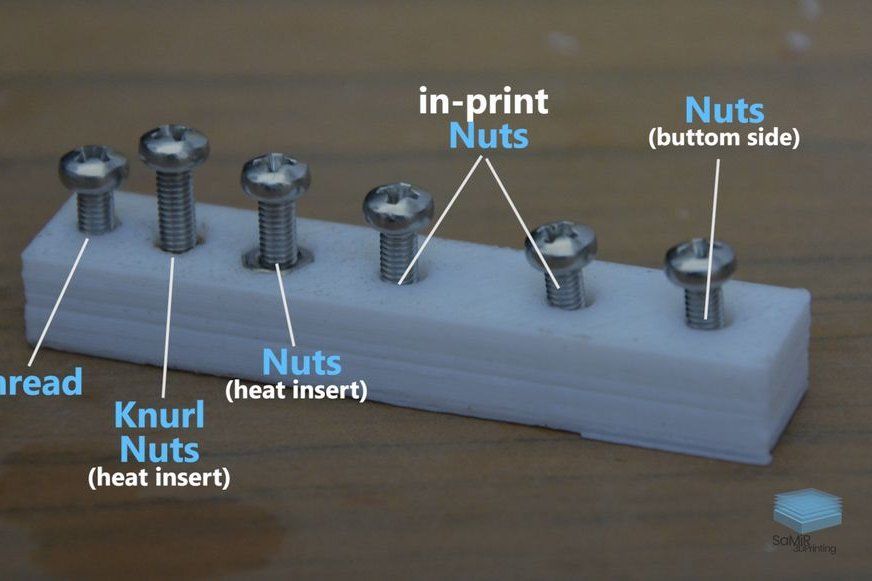

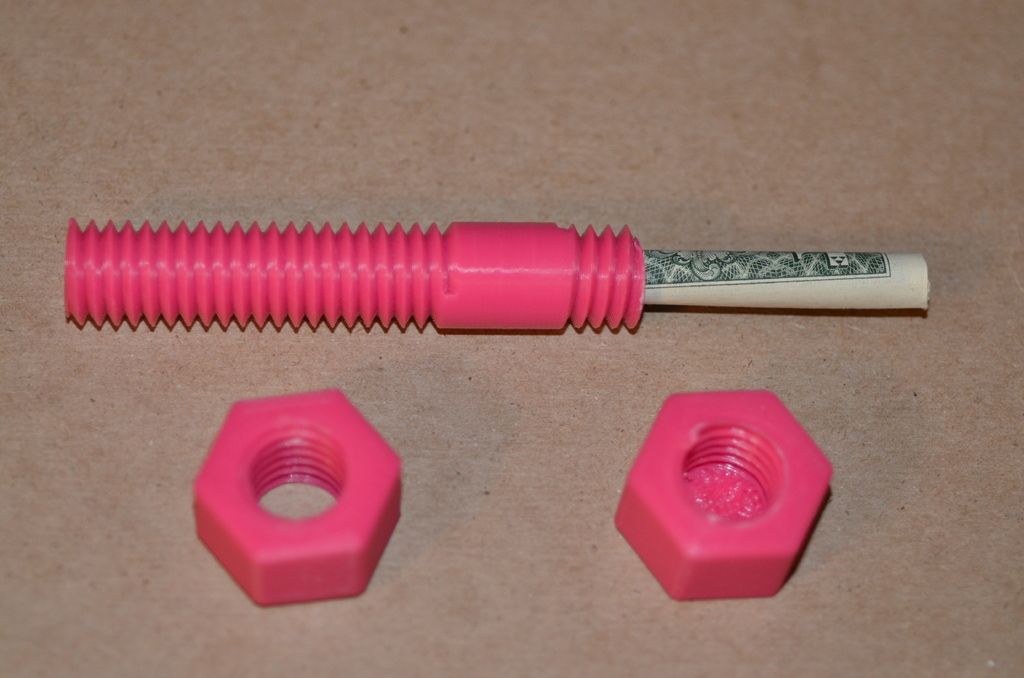

3D printing - threads and screws

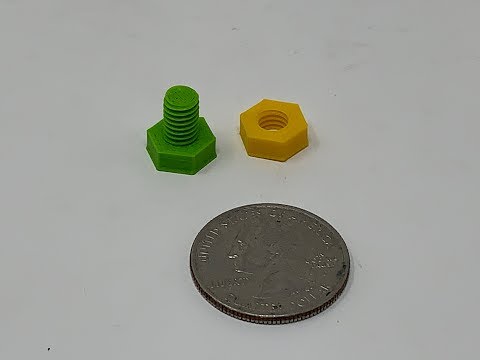

First things first: what is the difference between a screw and a thread?

A screw is a fastener used to form a connection that can later be dismantled, while the thread is the main fastener of the screw. In this case, the thread is not only used for screws; they are also present on pipes, in linear drives, worm gears and many other devices.

In this case, the thread is not only used for screws; they are also present on pipes, in linear drives, worm gears and many other devices.

The common feature of all threads is the way they are formed. Each thread is a continuous spiral groove of a certain cross section, made on the outer or inner side of the cylindrical surface.

In most cases, the cross section or shape is triangular or trapezoidal. Triangular thread forms are primarily used for fasteners (screws), while trapezoidal thread forms, varieties of square threads, are used for power transmission and linear drives on lead screws. To keep things simple, this article only covers triangular shaped threads, but everything applies to both types.

A further level of categorization distinguishes metric threads from inch threads. The former are mainly used in Europe and Asia, while the latter are used in America and the UK. To the untrained eye, they look the same, but the difference exists in the shape of the triangle and the pitch of the spiral curve.

In this article, we will cover the basics of designing and 3D printing screws and threads.

Basic terms

There are a few terms and concepts that you should be familiar with before you start designing a thread.

External or internal thread : External or external thread exits the cylindrical surface. The female thread is cut on the inner cylindrical surface. For example, bolts have external threads, while nuts have internal threads.

Thread axis : a line passing through the center of the cylinder on which the thread is to be formed.

Base : the bottom of the groove around the body of the thread.

Comb : The highest point of the thread profile.

Large diameter : The diameter of a cylinder enclosing the top of an external thread or the base of an internal thread. This cylinder is concentric with the axis of the thread.

Minor Diameter : The diameter of a cylinder enclosing the root of a thread on an external thread or the crest of an internal thread. This cylinder is concentric to the thread axis and large diameter. The smaller diameter is also known as the drill diameter when handling internal threads.

This cylinder is concentric to the thread axis and large diameter. The smaller diameter is also known as the drill diameter when handling internal threads.

Pitch : distance between equivalent points on adjacent threads. For example, the distance between two adjacent crests of a triangular thread.

Metric thread: The "M" designation of a metric thread indicates the nominal outside diameter of the thread in millimeters. For example, an M5 thread has a nominal outer diameter of 5 mm. For external threads, the nominal outside diameter is equivalent to the major diameter. For internal threads, the nominal outside diameter can be determined by measuring the minor diameter and referring to the metric thread table.

Inch threads: Inch threads are designated using a number of standards, including the Uniform Thread Standard (UTS), which basically refers to standard thread sizes as numbers (eg #4). The two most important measurements in UTS are the major or minor diameter of external or internal threads, respectively, and threads per inch (TPI).

Thread Modeling

Let's look at the process of designing external and internal threads using Fusion 360, which provides a simplified threading feature.

Other CAD programs have tools of varying degrees of similarity. It is important to understand the basics presented in the previous section. With this knowledge, you will be able to use any available modeling tool for 3D modeling.

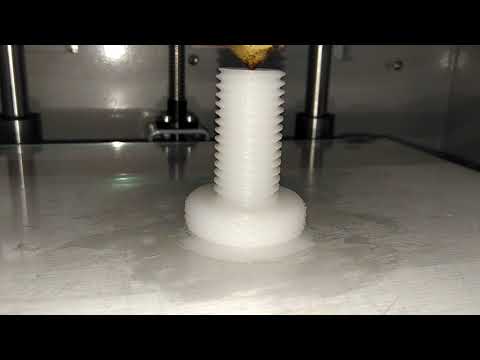

Let's start with the outer thread of the bolt.

External thread

- Draw a circle with a diameter equal to the largest diameter of the desired thread.

- Create a cylinder by extruding a circle to the desired thread length.

- Go to "Create" and select the "Thread" option.

- Select the newly created cylinder. Make sure "Modeled" is checked. Set the thread type and other thread options. Click OK.

That's it. You have an external thread! To make a good bolt out of it, you need to attach it to the head to your liking.

Now let's create a nut with an internal thread.

Internal thread

- Create a hexagon. For the purposes of this tutorial, just make sure it's larger than the carving you want to create.

- Press it out to the desired height.

- Make a hole in the center by selecting the "Hole" option from the "Create" menu. The hole diameter must match the largest thread diameter.

- Select the inner surface of the newly created hole, go to "Create" and select the "Thread" option.

- Don't forget to check the "Modeled" option. Set the thread size and other parameters. Click OK.

That's it. Your first carvings are ready for 3D printing!

Tips for 3D Printing Threaded Parts

This may seem like a simple task at first glance, but printing threads is not always easy, especially if you need small diameters.

Assume you are using a 0.4 mm nozzle and a 0.2 mm layer height. With this setting, the smallest pitch you can achieve during 3D printing is likely to be around 0.5mm (give or take 0. 1mm). This pitch is suitable for M3 threads and you should have no problem trying to print an internal thread on a relatively large part. This is because your threads will have enough time to cool while the nozzle is in a different location.

Things get interesting if you need an external thread, for example on a screw or bolt. In this case, the nozzle has nowhere else to go, which means that you will probably need additional cooling. Check your 3D printer before you decide to print a lot of thin external threads.

One of the most practical options before starting thread printing is the M10 3D Printed Thread Test. Thanks to this special 3D model, you will be able to check exactly what your 3D printer is capable of.

Settings when 3D printing parts with threads

Below are some general guidelines for setting up your 3D printer when printing threads.

- Make sure your 3D printer is properly calibrated. Extruder calibration is also important.

- Always try to print threads vertically. For best results, the thread axes should be perpendicular to your 3D printer table.

- Print without the calipers, or at least make sure they don't go inside the threads. Otherwise, removing them and maintaining functionality can be a real problem, especially with internal threads.

- If possible, use at least 4 vertical layers or vertical walls at least 2 mm thick. This will ensure the strength of the thread.

- Try to set the filling density to at least 25%.

- Layer height is an important parameter when 3D printing threads. For smooth operation, the layers should be as thin as possible. As a guideline, threads larger than M12 or 1/2" can be successfully printed at 0.2mm, while smaller threads should be printed at thinner layers.

Resume

Even if your first test fails, don't despair! Here are some final tips for 3D printing threads:

- Even if you manage to print beautiful external threads smaller than M6 (6mm in diameter), think twice before using it for heavy duty use.

In povіdomlennі vkazhіt lіnk on the active side of the same product in the Ukrainian online store and we look at the price.

In povіdomlennі vkazhіt lіnk on the active side of the same product in the Ukrainian online store and we look at the price.