3D printer power usage

How Much Power Does a 3D Printer Use? – Clever Creations

Our site is reader-supported. When you buy via the affiliate links on this site, we will receive a commission at no cost to you. All opinions remain our own. Learn more

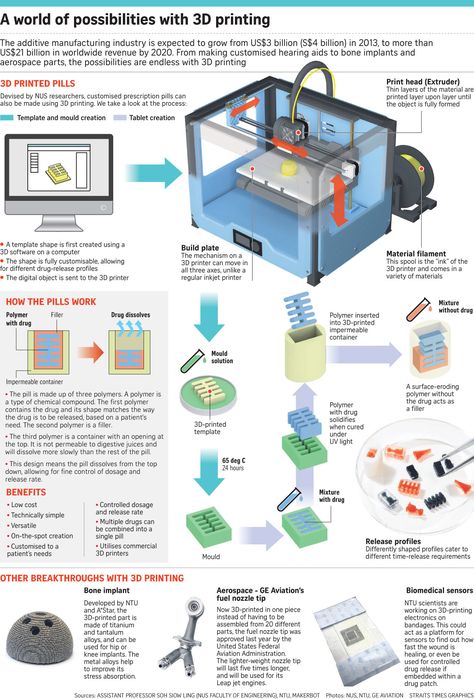

When deciding on whether 3D printing is the right hobby for you, it is important to take all 3D printing costs into account. Not only are there initial expenses you have to make, like filament and the device itself, but you also have to consider recurring costs.

One of the main operating expenses of a 3D printer is its power consumption. Without power, there won’t be any heating, motor movement and printing, so this cost is hard to avoid.

In this article, I will share how much electricity 3D printers typically use, how you can calculate the electricity cost and give you some tips on keeping energy usage of your 3D printer as low as possible.

3D printers come in many different shapes and sizes and this makes it impossible to give a single power consumption number that covers all models. There are simply too many variables (components) in play.

Luckily, there are several ways you can go about calculating the power consumption of a 3D printer. Some methods are easier than others, but like with many things, the more effort you put in, the better the results. Note that this article covers fused deposition modeling (FDM) 3D printers only.

Using the 3D printer power supply rating

All 3D printers have a power supply that converts high voltage AC (alternating current) to low voltage DC (direct current). This power supply has a maximum rating that it is unable to exceed. With that rating in mind, we can figure out the absolute maximum amount of electricity that a 3D printer can use.

For example, an Ender 3 V2 has a power supply that can supply 24V, 15A. To calculate its maximum power consumption, we use the formula Power = Current * Voltage to get 15A * 24V = 360 Watts.

The real electricity usage of a 3D printer is a bit more complicated, however. The number we just calculated is the absolute maximum amount of power the PSU (power supply unit) can supply, whereas in reality a 3D printer never requires the PSU to be at full load.

The number we just calculated is the absolute maximum amount of power the PSU (power supply unit) can supply, whereas in reality a 3D printer never requires the PSU to be at full load.

3D printer power supplies are usually picked with a safety margin in mind (they can provide more power than the 3D printer would ever need) and the printer’s individual components rarely all operate at full power at the same time either.

In the absence of a better calculation method, using the power supply rating is a good way to get an idea of the upper bound of a 3D printer’s power consumption. But to get a more precise number we need to dive a bit deeper.

Taking the individual components into account

A better way to determine how much electricity a 3D printer uses is to calculate it based on its components. The power of the hot end heater, number of stepper motors and whether or not the printer uses a heated bed are some factors that influence the printer’s total power consumption.

It is important to mention that these components do not run at a 100% power all the time. For example, heaters regularly toggle on/off depending on their current temperature. But looking at the typical power usage of these components can give a good idea of how much electricity a 3D printer uses on average.

Heated print bed

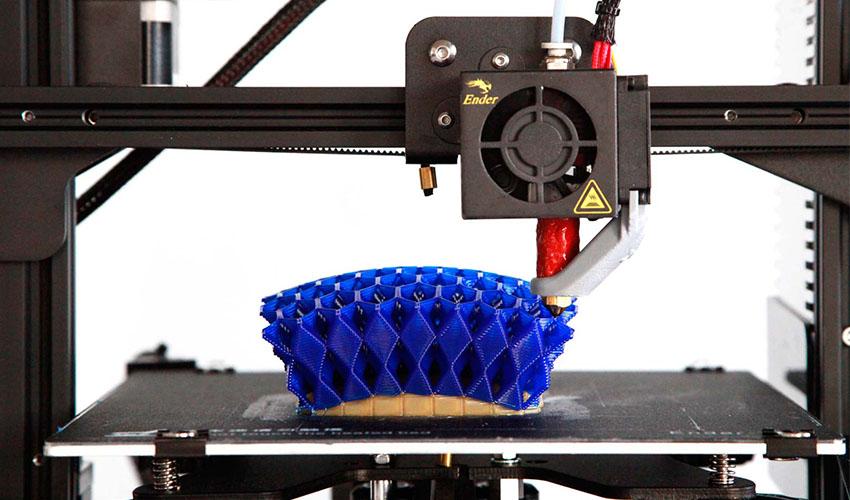

Heated beds are by far the most energy-hungry components in a 3D printer. Not all printers have one, but the ones that do, use significantly more power.

A heated bed helps prevent warping of 3D prints and improves adhesion of the first print layer. It is an essential feature to have when working with specialized or high-temperature filaments, even though it is a good feature to have for standard filaments as well.

Both the size of the heated bed and the temperature you raise it to, attribute to its power consumption. The bigger the bed, the more power it uses. Higher temperatures need more power as well.

A heated bed needs a lot of energy to get up to temperature, but it also needs energy to stay there. Ample heat escapes through its large surface area. To maintain a heated bed’s target temperature, its thermal energy needs to be continually replenished by converting electricity to heat.

Ample heat escapes through its large surface area. To maintain a heated bed’s target temperature, its thermal energy needs to be continually replenished by converting electricity to heat.

Typical wattages range from 120W for a small 20x20cm DC powered heated print bed, to 1000W or more for larger (≥30x30cm) AC powered beds. On popular printers like the Ender 3 Pro and Creality CR-10 you can find heated beds that draw around 200W.

On two equally sized heated beds with different wattages, the one with a higher wattage gets up to temperature quicker and can reach higher temperatures.

Further down in this article you can find some tips on how to reduce the energy usage of your heated bed and 3D printer.

Hot end heater

The hot end heater is responsible for melting our filament and tends to be the second-most energy consuming component in a 3D printer.

Just like a heated bed, the power consumption of a 3D printer hot end heater cartridge depends on the temperature that it needs to reach. That, in turn, depends on the feedrate and the type of filament you are printing. Filaments like PLA do not require much heat, whereas PEEK or PETG need significantly more.

That, in turn, depends on the feedrate and the type of filament you are printing. Filaments like PLA do not require much heat, whereas PEEK or PETG need significantly more.

Recommended:

The 10 Best PLA Filaments for 3D Printing

Pushing large amounts of plastic through a hotend, like on a Volcano hotend, increases power requirements. This is because more heat gets transferred from the heater block to the filament and needs to be replaced. Similarly, print cooling fans that are pointed directly at the hotend also increase the amount of power that a hotend draws.

Typical 3D printer hot end heaters are rated at 30-50 Watts. Anything higher than that comes with significant risks.

Stepper motors

The stepper motors in a 3D printer are responsible for extruding filament and for moving the extruder carriage. Sometimes they also move the bed.

A typical Cartesian or CoreXY 3D printer has four stepper motors (X-/Y-/Z-axis + extruder), but some printers come with more. These extra stepper motors are used for additional extruders or sometimes to drive the Z-axis with more control.

These extra stepper motors are used for additional extruders or sometimes to drive the Z-axis with more control.

Ordinary NEMA17 stepper motors use about 5-10 Watts each when active.

Control board

3D printer control boards are responsible for controlling all other electrical components. They instruct the stepper motors on how to move and turn heaters on or off depending on the current temperature of the temperature sensors.

Control board PCBs have large terminals that can handle a lot of power. Don’t be fooled by these, only a small portion of that power goes to the controller itself. The majority is for powering the aforementioned stepper motors and heaters. The control board simply points that power into the right direction with MOSFETs and transistors.

When isolating the controller, you will find that it only uses 5-15 Watts. Its power usage is highest when the 3D printer is printing and lowest when it is idle (not doing anything).

Other components

Aside from the main 3D printer components listed above, 3D printers can come with several smaller parts that use electricity.

- Fans are used for cooling prints, the hotend heatsink and the electronics. They do not use much power. Depending on their size, they use 1-2 Watts each.

- Some 3D printers come with LED strips, even though you can also install them yourself at a later point. LED strips use about 5-15 Watts per meter. High quality bright LED strips use more electricity than your typical AliExpress/eBay variant.

- LCD screens are a source of 3D printer power consumption as well. The energy usage of a small monochrome LCD is not worth mentioning, whereas something larger like a 7″ PanelDue touch screen still only uses 3-4 Watts at the most.

Adding it all together

For a typical budget 3D printer, say an Ender 3 or Creality CR-10 with a ~200 Watt heated bed, you would see the following power consumption numbers:

| 3D Printer State | Power Consumption |

|---|---|

| Off | 0 Watts |

| Sitting idle | 5-15 W |

Idle with motors engaged (e. g. after homing) g. after homing) | 20-40 W |

| Preheating after homing | 250-300 W |

| Printing | 50-150 W |

Once the heaters are up to temperature, they require less energy to keep them at that point. So during printing, electricity usage is significantly lower than when it is preheating.

Measuring electricity usage on a specific 3D printer

Of course, the above numbers are still all estimates. There are many different printer models out there and it is hard to say exactly what a 3D printer’s energy consumption is unless you specifically measure it. The target temperatures of the heaters, ambient temperature and stepper driver currents all can not be accounted for in these estimates.

The easiest way to measure 3D printer power consumption is to use a Kill-A-Watt electricity usage monitor. It precisely tracks the energy usage of the device that is plugged into it and even calculates the total electricity cost per day/month/year.

P3 International P4460 Kill A Watt EZ Electricity Usage Monitor , grey

Check PriceAlternatively, a Wi-Fi smart plug with energy monitoring lets you do the same thing but adds the ability of displaying its data remotely on your phone.

Kasa Smart HS100 WiFi Smart Plug, Classic 1-Pack, White

Check PriceCalculating the electricity

cost of your 3D printerAfter figuring out how much energy your 3D printer uses, you can calculate the electricity cost. In this calculation, there are three numbers that are relevant. The first is the energy usage (measured in Watts), the second is the price of electricity in your area and the last is the number of hours you run the printer.

Taking a 3D printer energy usage of 100 Watts while printing (a good estimate based on our earlier calculations) and an electricity price of $0.13 per kWh (the current US average) gives an hourly cost of 1.3 cents an hour (0.1 kWh * $0.13/kW = $0.013).

So for a print that takes two-and-a-half hours, you end up with a total electricity cost of 2. 5 * 1.3 = 3.25 cents. Not much.

5 * 1.3 = 3.25 cents. Not much.

Knowing the energy cost, you can calculate how much to charge for 3D prints if you decide to sell them. There are other costs involved as well, of course, like that of filament and wear and tear on the machine.

Comparing 3D printer power consumption to other devices

If all these numbers are a bit too abstract, it can be helpful to compare them to those of other appliances in and around your home. A bit of context typically makes energy consumption easier to understand.

| Appliance | Energy Usage |

|---|---|

| 46 Inch LED TV | 60-70 Watts |

| Incandescent light bulb | 60-100 W |

| 3D printer (while printing) | 50-150 W |

| Typical desktop computer | 100-450 W |

| Inverter air conditioner | 1300-1800 W |

| Space heater | 2000-5000 W |

As you can see in the table above, the power consumption of a typical 3D printer is not that much compared to other household appliances. And based on the calculations we did, you know that electricity costs are fairly negligible if you only run the printer for a couple hours a day.

And based on the calculations we did, you know that electricity costs are fairly negligible if you only run the printer for a couple hours a day.

It might be a different story if you have a beast of a 3D printer that runs 24/7, but for something like an Ender 3, the electricity cost is for most people nothing to worry about.

How to reduce the power consumption of your 3D printer

While ordinary 3D printers do not use much energy, it can still be a good idea to reduce power consumption as much as possible. Not only does this lower electricity costs further, but it also comes with secondary benefits such as reduced warm-up time.

Allow me to explain.

Most power consumption reduction methods are centered around keeping as much heat in the (components of the) 3D printer as possible. Less heat escaping means that more energy can be put towards raising the temperature. As a result, well-insulated components reach their target temperatures quicker and are able to reach higher temperatures.

These are the most common methods you can use to make your 3D printer more efficient.

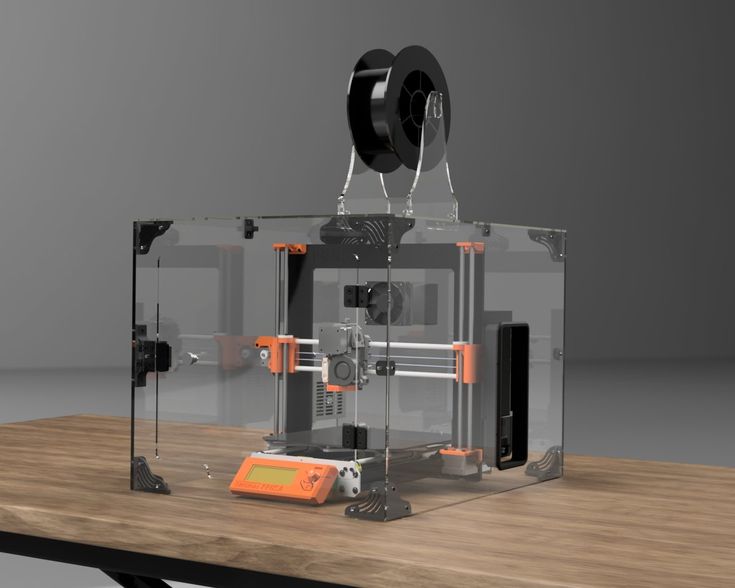

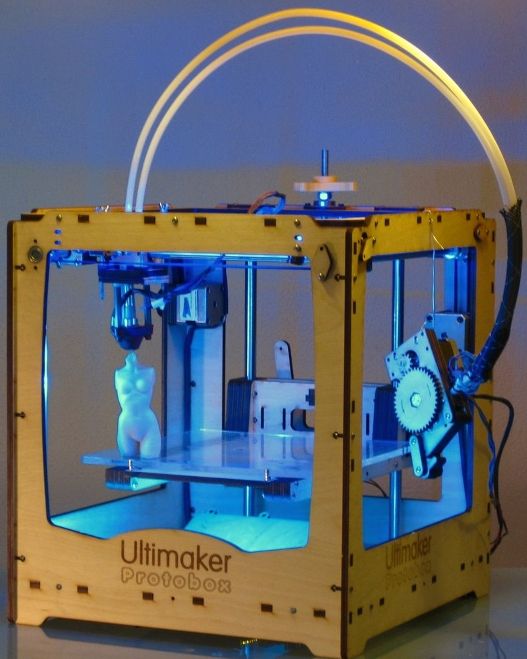

Adding an enclosure to your 3D printer

3D printer enclosures reduce energy usage by trapping heat inside, but they also provide additional benefits. For example, the heated chamber they create prevents warping of filaments (useful for ABS filament, for example), they keep potentially harmful 3D printing fumes inside, and they reduce the sound levels of your 3D printer.

Enclosures are fairly easy to construct. If you look online, you can find many tutorials that show you how to make an enclosure from IKEA furniture or simple wooden frames. Alternatively, you can just buy an aftermarket enclosure for your specific printer online.

Recommended:

9 Amazing DIY 3D Printer Enclosure Ideas

Even better would be to buy a fully enclosed 3D printer from the start, but these are more costly than your typical open-frame 3D printer with the same build volume. While the reduction in power consumption certainly won’t make up for this price difference, the other benefits of the enclosure might.

Recommended:

The 9 Best Enclosed 3D Printers

Insulating the heated bed

As you now know, a 3D printer’s heated print bed is responsible for the majority of the printer’s power consumption. Its large surface area allows for a lot of heat to escape to the surrounding air. Print cooling fans continuously blowing over its surface do not help either.

A good way to reduce the energy consumption of a heated bed is to cover its underside with a layer of insulation material. Good options are a self-adhesive aluminum insulation mat or a cork sheet. Both materials are capable of handling the highest temperatures that heated beds can reach.

You will find that afterwards the bed heats up a lot quicker than before. With less energy escaping to the surroundings, there is much more power available to get the bed up to temperature. Especially beds powered by DC current (from the 3D printer power supply) can benefit from this, as they tend to be underpowered.

Insulating the hot end

Hot end heating elements have an equally difficult job at staying at the right temperature. While they do not have a lot of surface area, they do need to continuously pump energy into filament and deal with cool air from print cooling fans drawing away heat.

Adding insulation is the best way to reduce energy usage of a hot end. There are several off-the-shelf products available that do this. You can find the most popular ones as silicone nozzle covers or silicone socks.

Reducing print time

Another way of reducing 3D printer power consumption is to simply reduce the amount of time that 3D prints take up. You can do this by increasing printing speed, reducing infill, using faster infill patterns or printing with thicker layers.

For example, while the hexagonal/honeycomb pattern is the strongest infill pattern, it also takes a long time to 3D print. Unless you specificially need its strength or aesthetics, it is often better to go for something simpler and faster to print.

These measures do come with sacrifices (decreased print quality, less strength in 3D prints), so setting these up is a matter of finding the right balance. If you want both a high printing speed and high quality prints, a CoreXY 3D printer can be a great option for you.

Conclusion

Ordinary 3D printers do not use much electricity, only about 50-150 Watts while printing. This is about the same as one or two incandescent light bulbs. There are many different 3D printers and print settings available, however, so for a more accurate number you need to make some calculations or measurements.

There are several methods you can go about calculating the electricity usage of a 3D printer. One of the quickest ways is to look at the power supply rating. This does not give you an accurate number, however, only an absolute maximum. For a more precise estimate, tallying the power consumption of all electrical components works better.

To figure out the exact amount of electricity a specific 3D printer uses, you need to use a device like a Kill-a-Watt or a Wi-Fi smart plug. These give you a 100% accurate measurement and remove any guesswork.

Once you know how much power your 3D printer uses, you can combine it with local price of electricity to figure out the hourly cost of running your printer.

If you want to lower a 3D printer’s power consumption, you can insulate its heat generating components to save on electricity. Enclosing the entire printer in an enclosure is a good solution too.

- US Average Energy Consumption

- Appliance Power Consumption

How Much Electric Power Does a 3D Printer Use? – 3D Printerly

Besides the cost of the 3D printer itself and the material to actually print out objects, there’s another thing creeps into people’s minds. Just how much electric is this thing using?!

It is a fair question. As fun as it is to 3D print our own objects, we want it to be as cost effective as possible. In this post I’m going to identify just how much power these 3D printers are using up and ways to manage it.

The average 3D printer with a hotend at 205°C and heated bed at 60°C draws an average power of 70 watts. For a 10-hour print, this would use 0.7kWh which is around 9 cents. The electric power your 3D printer uses depends mainly on the size of your printer and the temperature of the heated bed and nozzle.

There’s some more pretty useful information that you’ll want to know in the rest of this article, so keep on reading to get the proper knowledge on electricity with 3D printers.

If you are interested in seeing some of the best tools and accessories for your 3D printers, you can find them easily by clicking here (Amazon).

Determine Power Use by 3D Printer Specifications

Your 3D printer specifications for the power source and maximum/minimum power ratings are the answers you need so you know the limits of power consumption.

As an example, if a printer has a 30A 12V power source, it will have a maximum Watt of 360 (30*12=360), but the printer won’t always run at the upper limit. These maximums will kick in when heating up the necessary parts to start the printing process but will fall much lower as the printing is happening.

A great low-power 3D printer has to be the Ender 3 (Amazon), it’s an all-round popular machine that is perfect for beginners with quality that matches the most premium printers out there. You’ll see from the glowing reviews just how good it is!

Jason King from 3DPrintHQ used the MakerBot Replicator 2 printer and found that the energy costs were only $0.05 for a 5-hour print. 3D printing only used 50 watts per hour, which is comparable to an HP Laser Jet printer on stand-by, not even while printing or 1 use of your toaster.

Low Relative Cost of Power

When looking at the overall cost of 3D printing, power costs are something that is relatively very low and not something to worry about. Some printers will of course be more efficient than others, but not at such a point that it’s a big determining factor when choosing a printer over another.

Now there are slight differences in how much power a 3D printer is using depending on what the printer is actually doing. When the printer is preheating to the set temperature, if the print bed is relatively large it will use slightly more power than when printing.

The first real use of electric power when a 3D printer is turned on is the heating of the print bed, then comes in the nozzle is heated to the temperature for the specific material. While printing, you will get spikes in the power usage depending on if the heated platform is on to maintain the ideal temperature.

From what I’ve read around, it looks like the average 3D printer consumers as much electric as your standard fridge.

What Affects How Much Power is Used?

Strathprints done a test to compare the power consumption between four different 3D printers and confirmed a few things. The lower the layer thickness of the material, the longer a print will take therefore leading to a higher power consumption overall.

If you can speed up your prints you’ll be using less power overall so check out my post 8 Ways to Speed Up Your 3D Printer Without Losing Quality.

When the heating efficiency of a print bed or hot end is good, it will result in less power being used due to not having to constantly keep the temperatures hot as much.

The video below shows the wide differences in how much electricity a 3D printer will use when incorporating the heated bed.

A good idea to lower how much heating your bed has to do is to use an Ashata Heat Insulator Mat. It has great thermal conductivity and greatly reduces heat and cooling loss of your heated bed.

The MakerBot-Replicator 2X had a baseline of between 40-75 watts to power the controller and motor, but peaked to 180 watts when heat was needed. The hotter the necessary print bed temperature, the more frequent the 3D printer drew power shown by fluctuations in the watt meter used.

The test showed that there is quite a variance between the power consumption of 3D printers. So, it can be concluded that 3D printers don’t consume a similar level of power and it really does depend on many factors.

The set-up parameters of your 3D printer will have a pronounced influence on the overall power consumption. It is important to be familiar with the process of 3D printing so you can print high quality products at lower electricity levels.

If you want to take an extra step, get yourself an enclosure. A great one is the Sovol Warm Enclosure for Ender 3D Printers. It’s pretty pricey, but it will last you years and usually results in better prints.

How Do I Lower Electricity Costs With a 3D Printer?

- Use a smaller 3D printer

- Use 3D printing materials that don’t require a heated bed or high nozzle temperatures (PLA)

- Implement 3D printer settings that make 3D prints quicker

- Change to a larger nozzle so your prints don’t last as long

- Make sure you are 3D printing in a fairly warm environment

When it comes down to lowering power costs with your 3D printer, it boils down to finding ways that speed up your 3D prints and doesn’t require as much heating.

The simple things you can do to speed up prints is to use a bigger nozzle, use less infill, print less often, or printing more things at once rather than doing them separately.

Most of the electricity use comes from the heating elements, so focus on reducing the heat and you’ll be able to save more on power.

This isn’t usually a problem since the associated costs aren’t relatively high. You’re definitely going to be using more money on the filament itself than you ever would with the electricity.

How Much Power Does a 3D Printer Use?

How Much Electric Does an Ender 3 Use?

One Ender 3 user who had their 3D printer running for 4 hours only used around 0.5kWh (kilowatt-hour), which consisted of heating up twice (using 280 watts per). When you calculate this on a per hour basis, we can 0.12kWh per hour of using an Ender 3.

People like to know how much power would cost if their Ender 3 was running for a full day, so let’s take a 24-hour period.

24 * 0. 12kWh = 2.88kWh

The average cost of one kilowatt-hour across the US is 12 cents according to NPR, so a full 24 hours of running an Ender 3 would cost $0.35. If you ran your Ender 3 24 hours for the whole month, it would cost you around $11.

The Ender 3 has a 360W power supply (24V DC at 15A.

- Heated Bed – 220W

- 4 Stepper Motors – 16W

- Fans, Mainboard, LCD – 1-2W

After these parts, you should have a spare 60-70 Watts in spare capacity, which allows you to add extra things.

A basic set of 5050 LED lights connected to your 3D printer can be around 20W.

Can You Get Electric Shocks From a 3D Printer?

Now that you know 3D printers don’t actually use that much electricity, you might be wondering whether they are still capable of giving you electric shock. This is a valid question and the answer is pretty simple.

A 3D printer can give you electric shock if you don’t handle it properly, but with proper use, you will be safe from getting an electric shock.

One 3D printer user actually received an electric shock from the power supply, but it was through misuse. After setting up their 3D printer, they used an EU to UK adapter and set the voltage to 230V.

It would have been a better idea to purchase or get the seller to send them a UK plug rather than use an adapter. This could have happened due to poor grounding, because a small current can flow through the connections from the live wire.

Luckily it was just a harmless tingle/shock! You shouldn’t use electronics which are not grounded when they are supposed to be.

How Can I Measure My Actual Electricity Use?

When it comes to electricity use, there really isn’t a perfect measurement we can give you because there are many differences and variables. The best thing you can do to really know how much power you are using is to measure it yourself, rather than us guess for you.

You can purchase a power meter which has an in-built power usage monitor. High-end ones can even calculate the cost of your power usage, so it can easily answer your question.

There are plenty of electricity monitors out there, so I done some research and found one that works very well for most people.

The Poniie PN1500 Portable Electricity Monitor is going to be your best choice. Not only is it officially ‘Amazon’s Choice’ at time of writing, but it is the highest rated out of all the monitors at 4.8/5.

Here’s what’s good about this power monitor:

- Very easy to use, with access to different power parameters

- High-precision current sensor

- Backlight & memory with large digital numbers for easy viewing

- Ability to start detection at just 0.20W so you can monitor almost anything

- 1 full year warranty

You can easily monitor electrical use in real time and it has multiple uses which can allow you to save on future electricity bills. Whether you test other appliances like an old refrigerator or other power-wasting appliances.

Range Of Electricity Use For A 3D Printer

An example of the minimum and maximum levels of power a 3D printer can use is the MakerBot Replicator+, which according to the specs has between 100-240 volts and 0. 43-0.76 amps. To convert this, we simply need to multiply the lower ends and higher ends to get our limits.

100 volts * 0.43 amps = 43 watts

240 volts * 0.76 amps = 182.4 watts

So, the power can range anywhere between 43 and 182.4 watts.

From the watts, we convert this to kilowatts per hour (KwH) by dividing the watts by 1000 then multiplying the number of hours in use. For example, if you had a print that lasted 5 hours the calculation would be:

43 watts/1000 = 0.043 Kw * 5 hours = 0.215 KwH for the lower limit.

182.4 watts/1000 = 0.182 Kw * 5 = 0.912 KwH for the upper limit.

Just as an example, if we take the happy middle for these two power measurements, we’d have 0.56 KWh, costing you only 5-6c in electricity per hour. So now you have a bit of a gauge in just how much electric is used in 3D printing, which isn’t much at all but it can slowly build up over time.

Compared to the actual cost of the 3D printer, the filament materials and other tools and equipment the electric power required for 3D printers is something that you shouldn’t have to worry about.

When we’re talking about sizeable professional printers, then the power costs could be something to take into consideration, but for your standard domestic 3D printer it is very low cost.

If you love great quality 3D prints, you’ll love the AMX3d Pro Grade 3D Printer Tool Kit from Amazon. It is a staple set of 3D printing tools that gives you everything you need to remove, clean & finish your 3D prints.

It gives you the ability to:

- Easily clean your 3D prints – 25-piece kit with 13 knife blades and 3 handles, long tweezers, needle nose pliers, and glue stick.

- Simply remove 3D prints – stop damaging your 3D prints by using one of the 3 specialized removal tools.

- Perfectly finish your 3D prints – the 3-piece, 6-tool precision scraper/pick/knife blade combo can get into small crevices to get a great finish.

- Become a 3D printing pro!

For people struggling with various 3D printing issues, you might want have wanted more guidance towards getting ideal 3D printing results. I created a course that's available to get called Filament Printing 101: Beginner's Guide to Filament Printing that takes you through some of the best 3D printing practices early on, so you can avoid those beginner mistakes.

How much electricity does a 3D printer consume?

Author Kirill Sokolov Reading 8 min. 397 views Posted by

While 3D printing is certainly a fun hobby, there's no doubt that it can also get quite expensive. Apart from the cost of the printer and filaments, you could easily spend a few hundred dollars just to get started. Another recurring cost that we should not ignore is the cost of electricity consumed by a 3D printer.

Whether you're 3D printing for fun or business, the money you spend on electricity is what you need. keep in mind. How much electricity does a 3D printer use and what can you do to reduce your energy bills?

Table of Contents

- Step One: Check Your Printer's Power Rating

- What Factors Affect How Much Power 3D Printing Uses?

- Hot end heating

- Heating of the printed platform

- Heating losses

- Step engines

- Control board

- Comparison of energy consumption of various models of 3D printers

- Tips for reducing the costs of 3D printer

- 1.

Use the printer with the building

9 - 3. Print with high temperature fibers only when necessary

- Final Thoughts

Step One: Check Your Printer's Power Rating

Like any electrical device, your 3D printer must be rated. For example, a 3D printer that requires 30A 12V consumes up to 360W of power (power = current x voltage). This is a very high figure, but only because it is the maximum power that this particular 3D printer can draw.

There can be a very significant difference in power consumption if you print at high temperatures. , high speed settings or heated beds. However, between different models, you can expect printers with larger platforms to use more power, as well as printers that can print at higher temperatures.

What factors affect how much energy 3D printing consumes?

If you're interested in the exact amount of power your 3D printer requires, then the best way is to use a power consumption monitoring tool. These tools act as an interface between your 3D printer and an electrical outlet, giving you an accurate measurement of the volts, amps, and power your 3D printer draws. A good example is Kill A Watt Electricity Usage Monitor by P3.

It would be impossible to isolate any particular part of the 3D printing process and test how it affects the power consumption of the printer. Instead, we can sum up these factors and infer how much electricity they consume.

Heating at the hot end

One of the most energy intensive drain parts of a 3D printer is the hot end, specifically the part of the nozzle that melts the filament. How much energy this process consumes depends on the temperature you set as well as the type of filament you are working with. If you're working with a lot of high temperature fibers like nylon or ABS, then you're probably using a lot of electricity for just that part.

Print bed heating

The print bed temperature depends on the nozzle temperature. This is a measure that improves adhesion to the layer and prevents warping, which is one of the constant problems when working with high temperature fibers.

There are two factors to consider when evaluating the energy consumption of a heater. bed – temperature setting and bed size. The temperature also depends on the type of filament you are printing with. The size of the bed depends on your 3D printer. The larger the bed, the more energy will be required to maintain the set temperature.

Heat loss

3D printer components can reach temperatures above 200°C. They must also remain at this temperature, so any heat loss to the environment must be compensated by the heating element. This is another issue for high temperature 3D printing as a hotter nozzle and print bed will inevitably have higher heat loss. If there is a way to minimize heat loss, you can save a lot on your energy costs.

Stepper Motors

There are two important sets of stepper motors in one 3D printer: those that drive the extruder gears and those that drive the movement of the nozzle. While these motors are very small and draw little power, they also need to be constantly running for the hours needed to complete a single 3D printing project.

Control Board

The control board or "brain" of a 3D printer consists of several electrical components that help control the printer's temperature, nozzle placement, extruder gears, and various other trivial tasks. Despite the importance of this feature, the control board does not actually consume much power.

The conclusion that we can draw from this little exercise is that most of the energy consumed by a 3D printer goes towards heating the nozzle and the print bed. While not surprising, this fact also gives us insight into how we can reduce the power consumption of our 3D printing projects.

Comparison of power consumption of various 3D printer models

Since it is impossible to determine the exact power consumption of a 3D printer without specifying the model, we will look at how much power consumption of various 3D printer models and how this affects costs.

Let's start with the Monoprice Mini Delta, a very small and inexpensive Delta type device. A 3D printer that has proven to be quite popular among beginners. Among its distinguishing features are a small build platform and a print head driven by three stepper motors. The Monoprice Mini Delta reportedly only consumes up to 45W during bed and nozzle preheating. Power consumption during printing increases slightly to 60W, probably due to the action of the stepper motors.

To provide contrast, let's look at the power consumption of Flashforge Creator Pro. This is a much more expensive 3D printer with a larger print bed, a rigid metal frame, and a built-in housing. Preheating the large print bed required a staggering 300W of power, while the nozzle required slightly less than 280W. The case proved to be very useful in reducing heat loss and stabilizing the printer's power to 250W during printing.

The two 3D printers we referenced here give us a useful range for how much power models of varying complexity can consume, from 60W to 250W when printed. In terms of kWh, this range corresponds to 0.07–0.24 kWh.

This also allows us to compare the power consumption of 3D printers with other devices we have in the house. For example, a typical desktop computer consumes about 1.05 kWh, which is more than four times the power consumption of Flashforge Creator Pro.

Based on electricity tariff data from April 2020, the average US consumer pays 13.31 cents per kWh. This means that you will pay approximately 3.2 cents for every hour you use Flashforge Creator Pro. The numbers for the Monoprice Mini Delta are even more pleasantly surprising - you pay less than 1 cent for every hour of use.

These numbers are likely to come as a relief to 3D printing enthusiasts, especially those who leave their printers running for hours on end. While this isn't an excuse for wasting electricity, it's still nice to know that you haven't suffered much from your running costs just because you got into 3D printing.

Cost Saving Tips 3D Printer Power Consumption

Although you've come to terms with the fact that you're unlikely to add a huge amount to your energy bill just because you use a 3D printer, many of you probably we still appreciate any advice on how to reduce power consumption.

1. Use the Printer with the

Enclosure As our analysis of Flashforge Creator Pro has shown, having a platen enclosure can significantly reduce the power consumption of a 3D printer during the printing process. This becomes even more pronounced if you are printing with a filament that requires high temperatures for both the nozzle and the print bed. If you're using an inexpensive printer without a built-in case, you can simply make your own using a couple of plastic sheets and wood frames. There are many tutorials on the internet for DIY 3D printer cases.

2. Reduce print time

Time is a factor we haven't talked about much, but it's certainly one of the most important when determining how much power a 3D printer consumes. If you can reduce the print time of your project, you can significantly reduce your energy costs.

There are several ways to achieve this goal, but there are two that are particularly effective: increasing print speed and printing with thicker layers. Obviously, this is not advice that can be taken in a vacuum. When making these adjustments, you need to consider other factors such as print temperature, filament type, and the quality level of the finished product..

3. Print with high temperature fibers only when necessary

Experimenting with different types of fiber materials is a natural part of 3D printing, but using those that require very high print temperatures can be quite expensive in the long run. . This requires not only more heat in the nozzle, but also a hotter print bed. The difference between 30 and 40°C may not seem like much, but every little thing counts – at least depending on which point of view you take.

Your 3D printer is unnecessary, then you can stick with low temperature fibers like PLA if you're printing just for fun. PLA not only saves energy but is also a more environmentally friendly choice due to its biodegradable nature.

Closing Thoughts

Consider how much power each of our electrical devices we consume on a regular basis is only part of being a responsible consumer. The same principle applies to 3D printers. As 3D printing is quickly becoming a hobby for more and more people, now is the perfect time to be more aware of how much power 3D printers use.

It's nice to know how energy efficient 3D printers are, especially when compared to the computers and TVs we usually have at home. However, this is no excuse for not making any effort to reduce the power consumption of our 3D printers. When used responsibly, we can reduce energy costs by fulfilling our responsibilities as responsible citizens.

Attention! Never leave 3D printers unattended. They can pose a fire safety hazard.

Creality Ender 3 printer power consumption?

Creality-ender-3 cost

Does anyone know how much power it takes to run a Creality Ender 3 3D Printer every day for a few hours? For example, what does he eat per hour? A rough estimate of energy consumption per hour would be good, then I can calculate how much it costs me. Can anyone help me?

@James Hanvey, 👍11

Talk

5 answers

▲ 5

If it's really important to you to know how much you spend on a particular print, it's best not to guess but to know how much energy you use. To this end, you can purchase a power meter that tracks your power consumption. With the right choice, it can even calculate the cost of energy consumption in one small package. This link, 10 Best Energy Monitors, should give you some ideas of what you might find, but I'm sure there are many more (NOTE: I'm not affiliated with the link provided... it was just a random file I found with a google search... Go go go google-fu!).

As 0scar pointed out in his comment, there are too many variables to try and guess what might be the power consumption of . If you're looking for a real answer, I believe that something like what I described above would be your best bet for getting a real answer. Everything else is more or less just guesswork.

, @ Pᴀᴜʟsᴛᴇʀ2

▲ 10

I am currently measuring the power consumption of my Ender 3. About 0.5 kWh of electricity was consumed in 4 hours of printing. With 2 heatings (about 280W each). Thus, on average, approximately 120 watts. Or 0.12 kWh per hour.

Assuming you print 12 hours a day, you use 1.5 kWh per day. This results in an electricity cost of 0.43 euros per day (0.3 euros/kWh).

If you use the printer for an average of 12 hours a day, you will consume about 525 kWh per year or 157 euros of electricity at 0.3 euros/kWh.

, @ Julian

▲ 9

Ender 3 has a 360W power supply. This is the maximum power that the printer can use. However, when properly designed, it should never reach such a level of consumption that it prevents premature failure of the power supply. It will use most of the energy during the initial warm-up, which is a relatively short amount of time. Then the average power consumption will drop significantly once per temperature. So, on average, 120 Wh per hour seems like a reasonable estimate.

So if you pay 11.4 cents per kWh (which is the nominal price in the US), then the cost of running something 24 hours a day is \$1 per watt per year. Thus, if you ran your printer all year round non-stop, it would cost $120 a year or $10 a month.

Since you live in New York, you are probably paying about 1.5 times more for electricity, or 17.1 cents per kWh. So you multiply the numbers above by 1.5, so you get \$15 per month. Plus, you don't use the printer 24 hours a day. Let's say you want to type an average of 8 hours a day. That's 1/3 of a day, so you divide your figure by 3 and you get $5 a month. You will hardly notice the difference in your electricity bill.

, @ Robert

▲ 0

The other answers include good estimates and show that the energy cost for a single printer is not very significant. If you use a lot of printers and want a specific answer, then it might be wise to get a power monitor (for continuous monitoring) or a clip-on multimeter.

With a clamp multimeter, you can attach it to the 3D printer's plug and read the consumed amplifiers. Assuming a single-phase 120VAC supply (typical for North America), the power consumption is 120VAC multiplied by the 3D printed amplifiers (P=VI) that you can read with a multimeter.

The intensifiers drawn by the 3D printer will vary throughout the print, but for longer prints you should be able to get good average intensifiers read during the middle layer of the print. Then the total energy cost of printing per day will be:

C = (V*I/1000)*t*E*n C, Total printer energy cost per day ($/day) V, AC voltage (V) I, Average current consumption during printing (Amps) t, operating time of printers per day (Hours/day) E, Energy costs from utilities ($/kWh) n, number of printers

, @ cambietech

▲ 0

Just order a Watt power monitor or similar and plug it into the wall, or better, a 3-pin extension cable, then plug your 3D printer into it and you'll get all the power details you need will be needed.