Conductive 3d printing filament

All About Conductive PLA 3D Printing Filament: Materials, Properties, Definition

Resources3D Printing DesignAll About Conductive PLA 3D Printing Filament: Materials, Properties, Definition

Learn about conductive PLA 3D printing filament and how it's used in manufacturing.

By Team Xometry

September 19, 2022

8 min read

RECENT STORIES

TPR vs. PVC: Material Differences and Comparisons

December 23, 2022

6 min read

TPR vs. Latex: Material Differences and Comparisons

December 23, 2022

8 min read

Alloy Steel vs. Stainless Steel

December 23, 2022

8 min read

Conductive PLA (Polylactic Acid) is a 3D printing material specifically designed to transmit electric current. This property allows the manufacture of parts with integrated electrical circuits or anti-static enclosures for use with sensitive electronics. The first graphene-infused PLA filament was developed by Graphene 3D Lab in 2015. Graphene 3D Lab has since changed its name to G6 Materials.

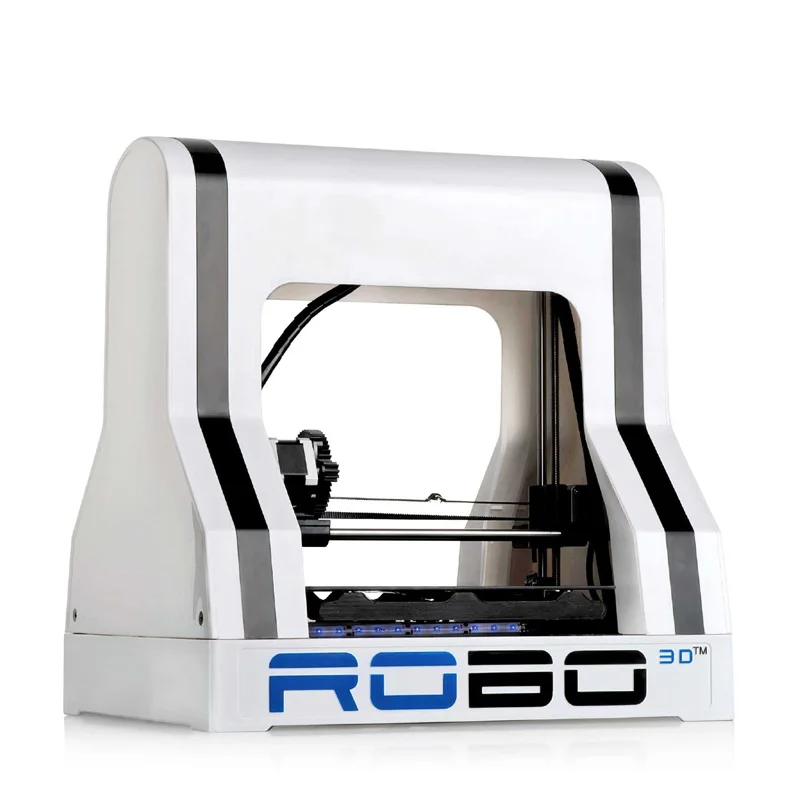

Conductive PLA is a low-cost way of powering low voltage (0 to 60 V) electronic devices while also maintaining some of the mechanical strength of PLA. The additives do, however, negatively affect the mechanical properties of the PLA to some degree. Printing with conductive PLA requires no special processes. The same settings that are used for standard PLA can be used for conductive PLA. A typical resistivity for conductive PLA is 0.6 Ω-cm. The main advantages of conductive PLA are its low cost and ease of use. Some typical applications are shown in Figure 1 below:

Slide 1 of 1

A variety of conductive PLA printed parts.

Image Credit: www.3dinsider.com/Types of 3D Printer Filaments

What is Conductive PLA 3D Printing?

Conductive PLA (Polylactic Acid) 3D printing filament refers to PLA filament that is able to transmit electrical current. Conductive PLA is one of the most popular conductive filaments due to its ease of use and relatively low cost. According to a recent study, conductive PLA shows promise in the development of sensors for use in wearable electronics.

Conductive PLA is one of the most popular conductive filaments due to its ease of use and relatively low cost. According to a recent study, conductive PLA shows promise in the development of sensors for use in wearable electronics.

What is the Composition of Conductive PLA Filament?

Conductive PLA 3D printing filament is made by mixing conductive additives into the PLA base polymer. These additives make standard PLA slightly conductive. Some of the common additives are listed below:

- Carbon Black: Carbon black is powdered carbon that is often used as a pigment. However, when a specific grade of carbon black is mixed in with PLA, the conductivity of the composite filament material is increased. Carbon black is the cheapest form of conductive PLA 3D printing filament.

- Graphene: Graphene is a planar sheet of carbon atoms arranged in a hexagonal pattern. The arrangement of the carbon atoms means that each atom has one free electron, which aids in the transmission of current.

- Metal-filled: Metal powder like copper or bronze can be mixed into the PLA to increase conductivity. Metal-filled PLA has some of the best conductivity ratings.

What are the Properties of Conductive PLA Filament?

Polylactic Acid (PLA) is one of the most popular 3D printing filaments due to its low cost and ease of use. PLA is a semicrystalline thermoplastic. Its partially ordered molecular structure gives it a distinct melting point, unlike amorphous polymers, which have no such distinct phase transition. Listed below are some common properties of conductive PLA 3D printing filament:

- The percentage of conductive PLA particles added to the base polymer is typically up to 80% by volume.

- The resistivity of the material on a part’s XY plane, i.e. parallel with the bed plate is typically up to 30 Ω-cm.

- The resistivity of the material along a parts’ Z axis, i.e. parallel with the bed plate is typically up to 115 Ω-cm.

- The maximum safe current that can be transferred through the conductive PLA is typically up to 100 mA.

The maximum safe voltage that can be applied across the PLA is typically up to 60 V.

The maximum safe voltage that can be applied across the PLA is typically up to 60 V. - The resistance of a 10 cm length of 1.75 mm diameter filament is typically between 2000 and 3000 Ω.

Comparison of Conductive PLA Filament Properties

The properties of some common conductive PLA 3D printing filaments are listed in Table 1 below:

Table 1: Comparison of Different Brands of Conductive PLA

| Property | Protopasta Conductive PLA | Electrifi Conductive Filament | Black Magic 3D (Conductive Graphene PLA Filament) |

|---|---|---|---|

Property Resistivity (Ω-cm) | Protopasta Conductive PLA 30 | Electrifi Conductive Filament 0.006 | Black Magic 3D (Conductive Graphene PLA Filament) 0.6 |

What are the Limitations of 3D Printing with Conductive PLA?

Conductive PLA 3D printing filament is a popular choice for experimenting with electrical applications. However, there are some shortcomings that need to be understood prior to using the material. The key challenges to using conductive PLA filament are listed below:

However, there are some shortcomings that need to be understood prior to using the material. The key challenges to using conductive PLA filament are listed below:

- Conductive PLA is still not very conductive, despite its name. These materials offer a small amount of conductivity for special applications but are not meant to efficiently transfer electrical current. Nothing is better than a metal conductor like a copper wire.

- The addition of additives like carbon black, graphene, or metal powder will increase the brittleness of PLA. PLA is already classified as a brittle material, and conductive PLA will be even more susceptible to cracking when subjected to impact loading.

- Only low-voltage components can be powered through conductive PLA. This characteristic considerably limits the potential applications of the material.

- A part printed with electrically conductive PLA 3D printer filament will have lower conductivity along the z-axis due to the fact that the individual part layers are not as seamlessly bonded to each other as the material within a particular layer.

One big advantage of conductive PLA 3D printing filament is that it has ESD (Electrostatic Dissipative) properties. This property means that it does not allow a static charge to build up on its surface.

Why is Conductive PLA Used in 3D Printing?

Conductive PLA filament is mainly used for a range of low-voltage electrical applications, some of which are listed below:

- Conductive PLA 3D printing filament can be used to create parts that can transmit current through their structure without the need for electrical cabling. However, this application is limited to low-power applications like powering an LED light.

- Conductive PLA 3D printing filament can be used for electromagnetic and radio wave shielding to eliminate the interference of other signals on sensitive electronic equipment. This type of interference can produce erroneous readings which can skew scientific results.

- One of the best uses for conductive PLA is for capacitive sensors, i.

e., sensors that respond to touch. These are low-power applications that do not require high levels of conductivity.

e., sensors that respond to touch. These are low-power applications that do not require high levels of conductivity.

How to Use Conductive PLA in 3D Printing

Printing with conductive PLA (Polylactic Acid) 3D printing filament is generally as simple as printing with standard PLA, with a few special requirements. These requirements are listed below:

- Carbon-filled conductive PLA is very abrasive. Therefore, a hardened steel nozzle is recommended.

- Conductive PLA is very brittle. Therefore, it is important to ensure that the filament is guided to the nozzle as gently as possible. Any sharp bends will snap the filament.

What are the Best Configuration Settings for Conductive PLA 3D Printing?

The specific settings to use when printing with conductive PLA 3D printing filament depends on the filament brand. However, some general guidelines for printing with conductive PLA filament are listed in Table 2 below:

Table 2: Conductive PLA Printer Settings

| Printer Setting | Value |

|---|---|

Printer Setting Extruder/Nozzle temperature | Value 215 °C |

Printer Setting Bed temperature | Value 60 °C |

Printer Setting Print speed | Value 25 and 45 mm/s (10 mm/s for metal filled) |

Printer Setting Flow of filament | Value 2 and 3 mm3/s |

Printer Setting Extrusion Width | Value 0. |

What is the Best Conductive PLA 3D Print Speed?

Conductive PLA 3D printing filament tends to be brittle. The filament can easily snap during high-speed printing maneuvers. It is therefore recommended to print at speeds as low as 10 mm/s for more complex printing tasks. This lowered print speed may take longer, but it will ensure a successful print.

What is the Melting Temperature of Conductive PLA Filament?

Typical melting temperature of conductive PLA is between 230-250 °C, but still varies based on brand. The extruder temperatures of various conductive PLA (Polylactic Acid) 3D printing filaments are listed in Table 3 below:

Table 3: Recommended Extruder Temperatures for Typical Conductive PLA 3D Printing Filaments

| Filament Type | Conductive PLA Filament Extruder Temperature (°C) |

|---|---|

Filament Type Protopasta Conductive PLA | Conductive PLA Filament Extruder Temperature (°C) 215 |

Filament Type Electrifi Metal-Filled Conductive PLA | Conductive PLA Filament Extruder Temperature (°C) 130 to 160 |

Filament Type Black Magic 3D Conductive Graphene PLA | Conductive PLA Filament Extruder Temperature (°C) 220 |

Filament Type Amolen Conductive PLA | Conductive PLA Filament Extruder Temperature (°C) 220 to 250 |

Is a Heated Printing Bed Required When Printing with Conductive PLA?

No, a heating bed is not strictly required for printing conductive PLA. However, for larger parts, it may be required to prevent warping.

However, for larger parts, it may be required to prevent warping.

What is a Good Wall Thickness for 3D Printing Conductive PLA?

The optimal wall thickness for a conductive PLA part depends on how the product will be used. If it is used for an ESD (electrostatic discharge) enclosure, a thicker wall thickness may be required to improve structural integrity. This requirement is because conductive PLA is structurally weaker than standard PLA. However, in general, a wall thickness of 1 mm will be good enough for most applications.

What is a Good Wall Density for 3D Printing Conductive PLA?

The infill density for conductive PLA is best kept at 100%, meaning the part is completely solid. A solid structure will more effectively transmit current. It may be therefore beneficial to print the conductive parts of a design separately to save on material as conductive PLA is more expensive than standard PLA.

What is the Difference Between Conductive PLA and ABS in 3D Printing?

Conductive PLA and conductive ABS (acrylonitrile butadiene styrene) will both transmit electric current in a similar matter. However, conductive ABS will have better toughness than conductive PLA.

However, conductive ABS will have better toughness than conductive PLA.

Summary

This article presented conductive PLA 3D printing filament, explained what it is, and discussed all of the different factors to consider when using it. To learn more about conductive PLA 3D printing filament, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

Team Xometry

This article was written by various Xometry contributors. Xometry is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding, urethane casting, and more.

3D Print with Conductive Filaflex

Have you ever wanted to create something with your 3D printer that included electronic components? Perhaps sensors, conductive traces or shielding against radio frequency noise?

The FFF/FDM conductive filaments for 3D printing have been designed for users interested in combining 3D printing and electronics. Conductive assemblies that integrate switches, potentiometers, LEDs, capacitive touch sensors... All this and much more is possible thanks to them.

Specifically developed to enable 3D printing of electronically conductive components, conductive filaments are materials that are very easy to print and compatible with almost any FDM/FFF 3D printer on the market.

Applications

Its applications are many and varied, but the following stand out in particular:

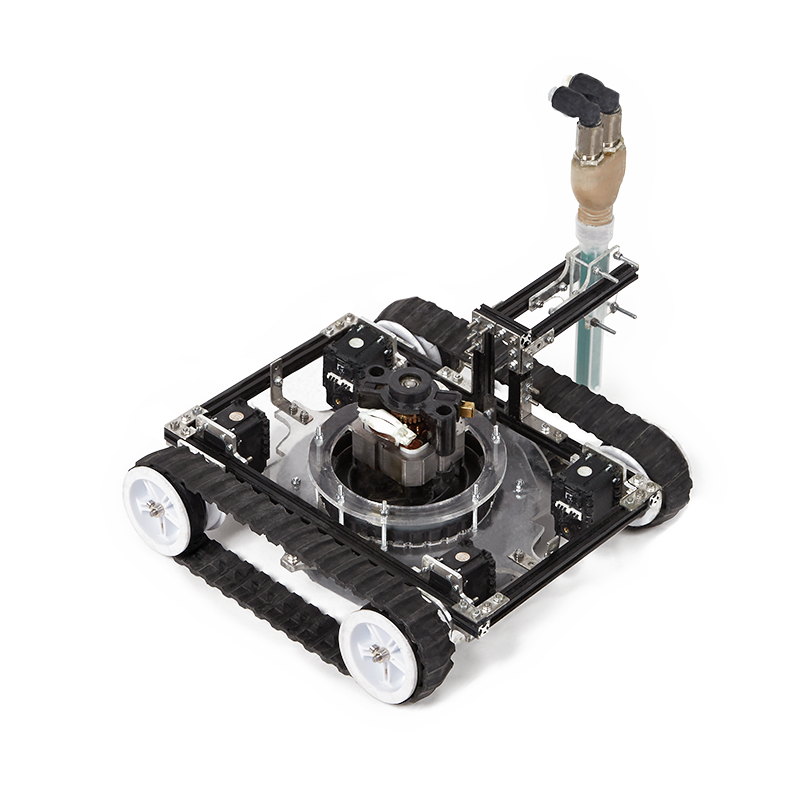

SensorsThe conductive filament can be used to create capacitive (touch) sensors used in a wide range of electronic products that are used in everyday life; It is an excellent material for the design of human interface devices (stylus pens for mobile phones and tablets).

Video 1: Pointer pencil. Source: Proto-Pasta.

Capacitive sensing sensors can also be used to measure proximity, position, humidity, liquid levels, and acceleration.

Conductive tracksAnother application of the conductive filament is in the creation of circuits conducting electricity for uses in electronics which, in the case of flexible conductive filaments, will also be applicable to flexible electronics.

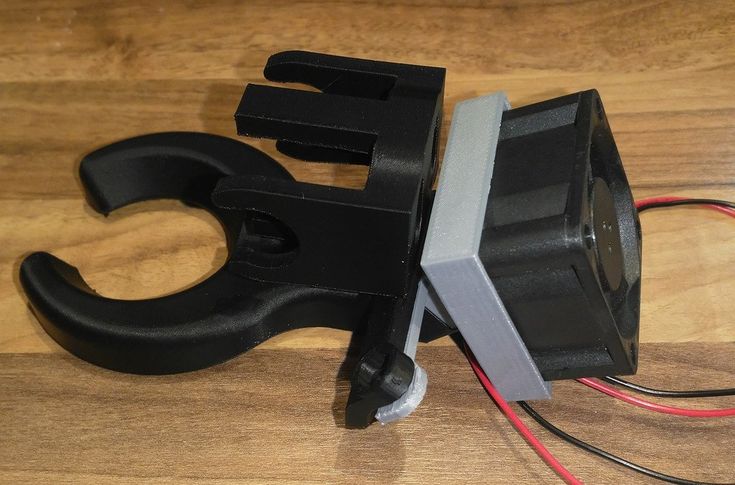

Image 1: Driving circuit. Source: Recreus.

Traditionally, in order to add conductive circuitry to their creations, 3D printing enthusiasts had to design parts with the necessary grooves to add copper wire after printing. With the conductive filament, the wiring can be printed simultaneously with the construction process of the piece.

With the conductive filament, the wiring can be printed simultaneously with the construction process of the piece.

The high conductivity offered by the conductive filament is not only excellent for 3D printed circuits and sensors, it is also useful for use against EMI (Electromagnetic Interference) and in very important RF (Radio Frequency) shielding applications in a wide range of applications. range of industries. EMI/RF shielding is used to block the electromagnetic field and radio frequency electromagnetic radiation within a space; It is important to use EMI and RF shielding in hospital, laboratory, or aerospace industry settings to protect against competing signals, as these can lead proprietary equipment to give false measurements. EMI/RF shielding accomplishes this by blocking AM, FM, TV, emergency services, and telephone signals. Conductive filament is ideal for designing RF/EMI shields used in highly custom items.

Tips for use

Designed for use with prints intended for room temperature operation and for use on low voltage, low current projects only (not to exceed 12 volts ), conductive filaments should be avoided for power supply exceeding 100mA.

Printing with conductive filaments (PLA) is almost as easy as printing with standard PLA. It is not necessary to have a 3D printer with a heated bed, although if you do have one, it is recommended to use the heated bed at 50-60º C since greater adhesion is obtained.

Possible contamination of the conductive filament with dirt from hands or dust from the environment should be avoided as much as possible, so it is recommended storage in a dry place and away from these and/or other particles. It is also recommended to wash your hands before and after use and treat it with gloves. The user should avoid prolonged exposure to moisture.

A nozzle is recommended for printing conductive filament of at least 0. 4 / 0.5 mm. The 3D printer nozzle should always be washed before and after using the filament to avoid printing complications. Conductive filament has a tendency to stick to brass nozzles so it is recommended to clean the external surface of the nozzle before printing with oil (technical or domestic) or lubricant to reduce build-up of the material on the outside of the nozzle during printing. You can also use plastic-repellent paint.

4 / 0.5 mm. The 3D printer nozzle should always be washed before and after using the filament to avoid printing complications. Conductive filament has a tendency to stick to brass nozzles so it is recommended to clean the external surface of the nozzle before printing with oil (technical or domestic) or lubricant to reduce build-up of the material on the outside of the nozzle during printing. You can also use plastic-repellent paint.

Image 2: Plastic repellent paint. Source: Sliceengineering.

The intrinsic properties of the conductive filament are such that it should not be left idle in the extruder of the 3D printer (while not printing) as it can expand and cause clogging of the nozzle ( clogging). Therefore, after printing, the filament should be removed as soon as possible from the extruder and use cleaning filament. cleaning.

Image 3: Cleaning filament. Source: Smart Materials.

It is also very important to print at the recommended temperature, since if you print at a lower temperature, the viscosity of the melt will not be optimal, so it will expand and clog the nozzle; and in case of printing it at a higher temperature, it will result in a partial degradation together with a substantial aggregation of nanomaterials also producing nozzle clogging.

In the event of a total obstruction of the nozzle, try to unclog it by heating the nozzle to 200ºC and try to remove the obstruction with a copper wire, or try to melt ABS or PLA (rigid filaments) to drag the material trapped, or soak it in acetone, etc. In case of not being able to solve the problem, it will be necessary to change the nozzle for a new one. To avoid this, all the advice mentioned above must be taken into account.

On the other hand, it is also very important to have the base of the 3D printer perfectly level, otherwise a significant amount of material will accumulate on the external surface of the nozzle, which when solidified will clog the flow of the melt. Therefore, the outer surface of the cooled mouthpiece should be cleaned with alcohol if this happens.

Conductive filaments on the market

Conductive PLA (Proto-Pasta): With a softening temperature similar to PLA, Proto-Pasta's conductive filament is more flexible, but has less adhesion between layers. Feasible to control any element through a 1Kohm resistor, it is ideal in low voltage circuits, digital keyboards that require low conductivity, arduino, touch sensors, robotics and electronics.

Feasible to control any element through a 1Kohm resistor, it is ideal in low voltage circuits, digital keyboards that require low conductivity, arduino, touch sensors, robotics and electronics.

Koltron G1 graphene filament (Addnorth): Doped with Aros Graphene, a graphene developed and patented by the company Graphmatech and with a matrix based on polyvinyldiene fluoride (PVDF), an advanced plastic that has excellent mechanical, chemical and thermal properties, the Koltron G1 filament has a volume resistivity of only 2 Ω-cm.

Filaflex Conductive (Recreus): Next, we will take a closer look at this filament.

Filaflex Conductive (Recreus)

The Conductive Filaflex is a flexible TPU elastic filament. With a 92A hardness, it reaches 100% elongation at break. After stretching it returns to its original shape, without deforming or breaking, presenting excellent mechanical properties. The Filaflex Conductive filament offers a volumetric resistivity of approximately 3. 9 Ω-cm, much higher than that of other conductive filaments.

9 Ω-cm, much higher than that of other conductive filaments.

From the manufacturer itself, we are offered a series of tips capable of solving any questions that may arise when printing with this filament:

- Hardened nozzle: It is not necessary to use it with the Filaflex Conductive filament. However, in case of intense use, it would be recommended to avoid excessively rapid wear of it.

- Security: Printing with Conductive Filaflex filament is totally safe and will not damage the printer, but to keep it in optimal conditions it is advisable to clean the nozzle very well when you finish printing with the filament. Thus, any type of rest that may have remained in the hotend will be eliminated. Using X after printing is an extra step that will also help with cleanup.

- Conductive material: For the filament to be conductive, Recreus informs that they use a special formulation that contains carbon black and it is this element that gives conductivity to the Filaflex Conductive filament.

- Flexibility: After printing with the filament, its characteristic elasticity is not lost. The resulting final piece will always be flexible and electrically conductive, keeping its other properties intact.

- Shore Hardness: It has a Shore hardness 92A, making it compatible for use in almost any printer (bowden included).

- Resistance: Filaflex Conductive has an electrical resistivity of approximately 3.9 Ω-cm, but to ensure compliance with its functions, the user must take into account that the resistance changes depending on the print. In addition, we must also consider the electrical resistance of the circuit and do not forget that the filament is designed for low current applications.

- Adhesion between layers: Due to its high carbon load, the heat will be dissipated very quickly and the adherence of the piece will be affected depending on its geometry. By adjusting some printing parameters (speed 20-25 mm/s, temperature 240-255 ºC, don't use layer fan) the user will be able to solve such rapid dissipation.

Video 2: Flexibility and conductivity with Filaflex Conductive. Source: Recreus.

In conclusion, conductive filaments are materials specifically designed to allow 3D printing of electronically conductive components using almost any FDM/FFF 3D printer available on the market, expanding the capabilities of additive manufacturing or 3D printing and allowing to shorten the path from development to commercial application.

Do you want to receive articles like this in your email?

Subscribe to our monthly newsletter and you will receive every month in your email the latest news and tips on 3D printing.

* By registering you accept our privacy policy.

3D printed mesh fabric

Prologue

Hello everyone! I am developing "smart sequins" - electromechanical color-reproducing devices for designer clothes. Our team is passionate about the idea of creating clothes and accessories that can change their color at the request of the owner or depending on environmental conditions.

Our team is passionate about the idea of creating clothes and accessories that can change their color at the request of the owner or depending on environmental conditions.

In this article I want to talk about how we used 3D printing in our project, share our experience and tools. nine0008

3D printing on fabric

One of the tasks that I had to solve was to figure out how to make an elastic fabric out of plastic sequins, which in its properties would resemble textile materials. At the same time, it is necessary to provide for the possibility of easily creating electrical connections between the sequins.

There are quite a few articles and materials on making clothes on a 3D printer. Many different methods have already been invented, from creating hinges right in the printing process to printing with elastic plastics. nine0008

While looking for a solution, I came across this video. From it, I first learned about the method of printing on mesh fabric using a conventional FDM 3D printer.

The author himself claims that he spied the idea here: Shorey Designs.

The essence of the method is very simple. We create a 3D model of a fragment of the future canvas, then arrange a lot of fragments so that we get a whole canvas. We start the slicer and prepare the G-code. Before sending it to the printer, you need to insert a pause and raise the extruder before printing a certain layer. The printer will stop during operation. At this point, we cover the printed layers with a mesh cloth. We continue to print. Due to the presence of large holes in the fabric, the layers of plastic will interlock with each other, as in conventional printing, and the mesh fabric will be firmly integrated into the parts. nine0008

Modifying G-code

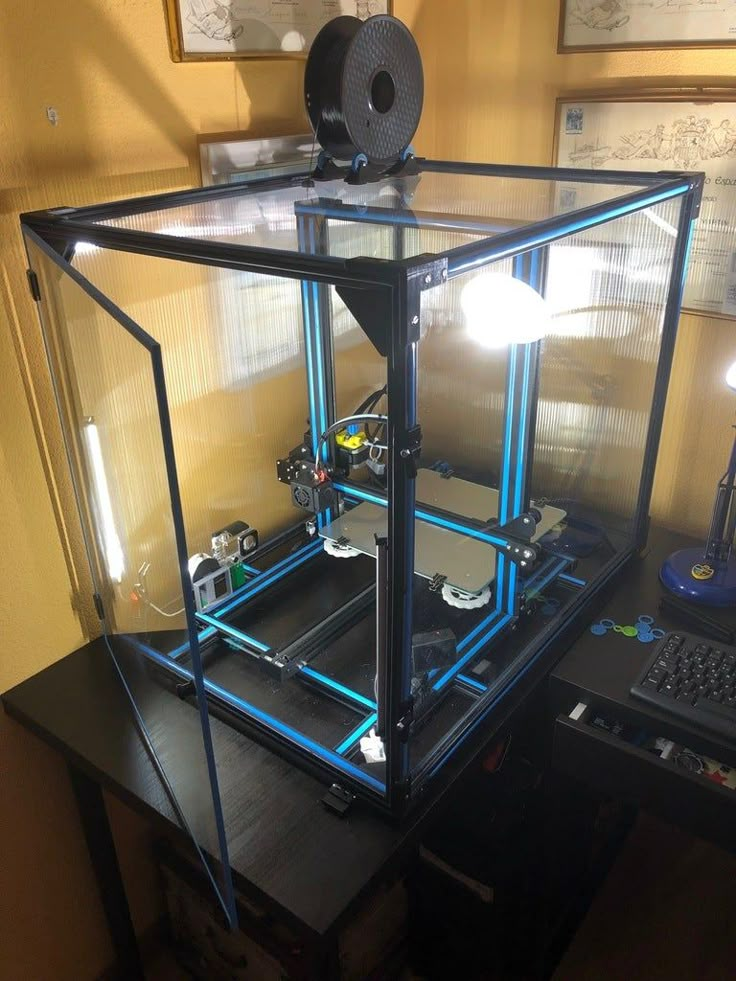

I use Cura version 3.2.1 as a slicer. 3D printer - homemade H-bot controlled by a board based on ATmega2560 (RAMPS 1.4) with Marlin firmware.

To pause the printer, there is an M25 command. Command for lifting in Z by 20mm: G0 Z20. It is noteworthy that the M25 must go before the ascent, otherwise the next command is processed first. Why this happens is a mystery to me, apparently somehow connected with the processing of commands by the printer. nine0008

It is noteworthy that the M25 must go before the ascent, otherwise the next command is processed first. Why this happens is a mystery to me, apparently somehow connected with the processing of commands by the printer. nine0008

Add commands to G-code:

Operation automation

Manually searching for the required line in the G-code file and inserting commands is not the most modern solution, I thought and wrote a simple program that allows you to open and view toolpaths.

For the convenience of viewing the layers, the “explode” command is provided, which allows you to visually increase the distance between the layers of the model. After pressing the "insert pause" button, the distance between the marked layer (red) and the previous one increases. This means that the print will be interrupted precisely between these layers. nine0008

To understand where one layer ends and the next begins, I used the comments that Cura kindly provides in its output files. The keyword ";LAYER:X" allows you to accurately find the boundaries of layers in a text file.

The keyword ";LAYER:X" allows you to accurately find the boundaries of layers in a text file.

Pressing the "write file" button allows you to save the modified G-code in the specified location.

Save the file to the SD card and bring it to the printer.

It's funny that only while preparing this article, I came across a video that tells how you can do the same using standard Cura tools ... But the process is already running, it's too late to slow down! nine0052 Here, starting at 7:30, it is described in detail how to do it. Well ... hurry up - learn how to parse G-code!

Trying to print

Formation of the first layers. We print on glass. Heated table. Table temperature 60⁰С, printing temperature 220⁰С. The print material is PLA plastic. Layer height 0.2mm.

During the pause, place a piece of fabric and fix with magnets. Since the table is aluminum (paramagnetic), we put the magnets on the top and bottom sides of the table. Fixation is made in 4 places, in the corners of the part. This is quite enough. The main thing is not to place them too close to the print area, otherwise the magnets will stick to the print head. nine0008

Fixation is made in 4 places, in the corners of the part. This is quite enough. The main thing is not to place them too close to the print area, otherwise the magnets will stick to the print head. nine0008

After 40 minutes, this is the structure. The thickness of each 6 carbon element is 1mm. The gap between the elements is 2mm.

In this experiment, tulle was used as the backing fabric. It is a lightweight mesh fabric of medium stiffness, woven from polyester threads.

Experiments have also been made with mosquito net printing. In the hardware store, there were two types of them: fabric and fiberglass. Fabric mesh is softer than tulle, but has greater mechanical tensile strength, as well as less elasticity. The fiberglass mesh is harder than tulle, its mechanical strength is the highest of all participants in the experiment. nine0008

Hexagonal sequin printing on fiberglass mosquito net. The gap between the elements is 1mm. The matrix is very hard.Clearance is clearly not enough.

Round sequin printing on fiberglass mosquito net. The gap between the circles is 2mm. It has a lot of flexibility, but there is too much unfilled space between the sequins.

After several test prints, the fabric mesh was chosen. She formed the basis of the matrix of smart sequins. The resulting matrix can bend in all directions. nine0008

The video demonstrates the operation of the program, the printing process and the final result.

Conclusion

The method of printing on mesh fabric proved to be very good. This is an ideal solution for our task, because the fabric substrate allows us to weave conductive threads into it, which are used to provide electrical connection between the individual sequins of the matrix. Moreover, the formation of a “pattern” of conductors can be carried out at the preparatory stage. And the 3D printing itself is later. nine0008

And the 3D printing itself is later. nine0008

The strength of the resulting structure depends mainly on the strength of the substrate material. But the flexibility will also depend on the distance between the sequins, as well as their shape.

The developed program still needs to be improved. For example, you can finish the retract before lifting, allow the user to adjust the height of the extruder.

Link to the source code for the processing environment.

And also a link to the release with the .exe file of the program.

By the way, we recently launched our "smart sequins" on the crowdfunding platform. For those who want to get to know our work better, I will leave a link. nine0008

How to calculate the cost of printing on a 3D printer

For some ideas, 3D printing is the fastest and easiest solution. In some situations, purchasing your own 3D printer can be a good solution, but sometimes it is much more profitable and faster to order the necessary product from a company specializing in 3D printing. Yes, and many owners of a 3D printer are thinking about how to “monetize” their hobby, but how to correctly calculate their costs?

Yes, and many owners of a 3D printer are thinking about how to “monetize” their hobby, but how to correctly calculate their costs?

Despite the fact that it is customary to indicate the price per gram of working material, simply multiplying the weight of the model by the cost of 1 gram will be wrong. In addition to the cost of consumables, many more, at first glance, non-obvious costs are added to the price of the product.

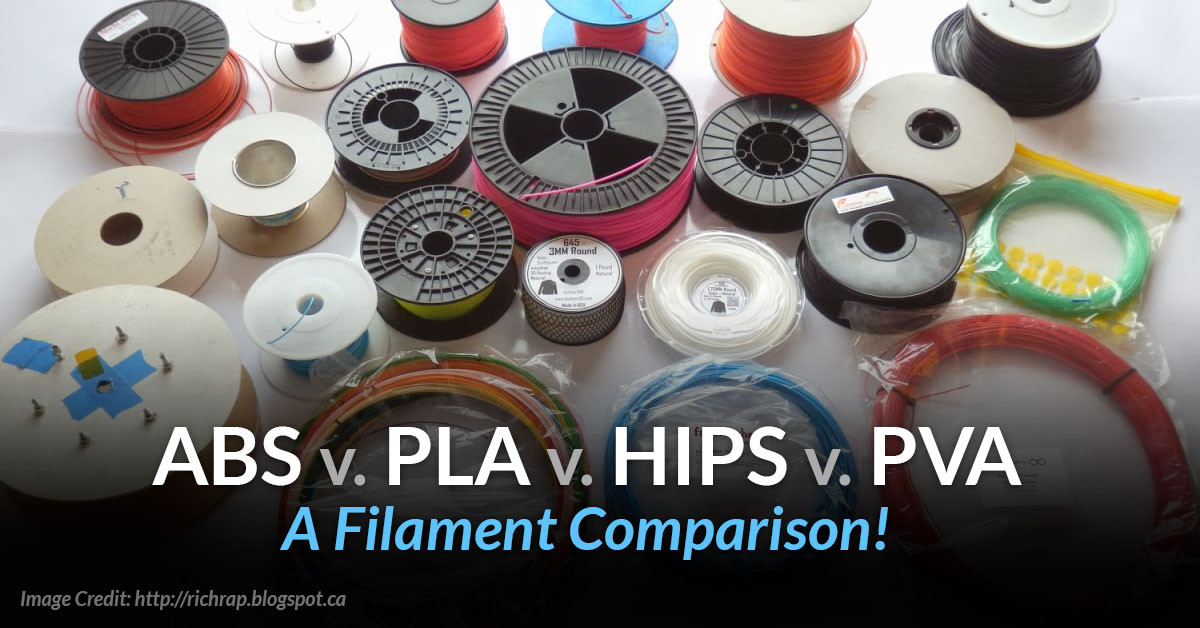

Each 3D printing technology uses its own consumables. Let's analyze the most popular and affordable of them.

Technologies available and key differences

Currently, a huge number of 3D devices have appeared, from small desktop ones that fit on the desktop to huge industrial machines. Among the most affordable, 2 technologies can be distinguished - FDM and photopolymer printers (LCD / DLP / SLA). nine0008

FDM 3D printing

Today, the most affordable 3D printing technology is FDM. A variety of materials and 3D printers allow FDM to be applied to a wide range of applications.

Schematic operation of the FDM printer

A large selection makes it easy to choose a 3D printer for a specific task or find a universal device.

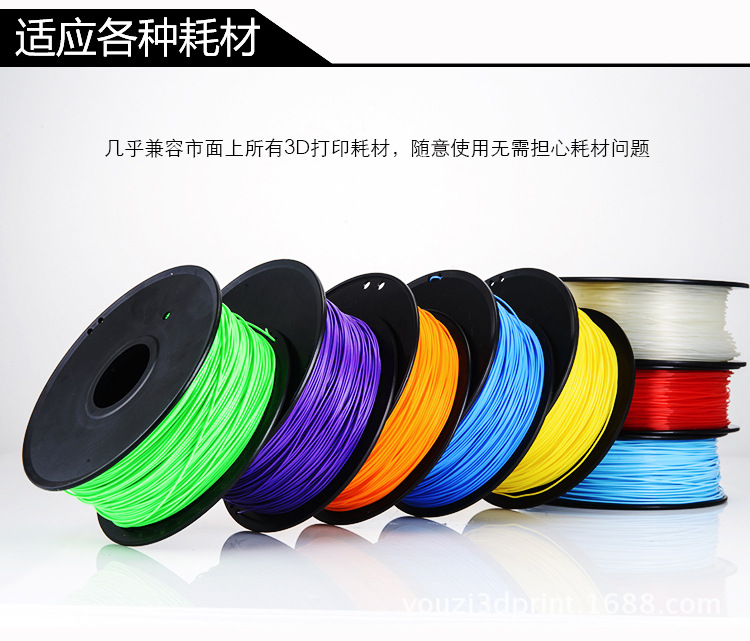

The material for printing is a plastic thread - filament. On the market you can find filament for various tasks, for every “taste” and budget. These can be very inexpensive ABS and PLA plastics or specific ones - conductive, burnable, etc. nine0008

Pros:

Cons:

Despite the fact that FDM allows you to print a wide range of plastics with different properties, the technology has some limitations. For example, it is impossible to obtain a perfectly smooth surface, to produce miniature and very thin elements, or to produce parts with very complex internal geometry with high accuracy.

Photopolymer printing

Photopolymer printers can work on one of 3 technologies - SLA, DLP or LCD. These devices will come to the rescue if you need to make a small but very detailed model with many small details. nine0008

nine0008

How photopolymer printers work

As a consumable material, a photopolymer resin hardened by UV radiation is used. Now there is a wide variety of photopolymer resins for every taste. From particularly strong and precise engineering or jewelry resins to soft flexes.

Pros:

-

High print precision

nine0161 -

Good surface quality

-

A wide variety of printers and consumables

Minuses:

Photopolymer printers have shown themselves well in a variety of industries that require a perfectly smooth surface and high accuracy. They are used in dentistry, the jewelry industry, for making miniature master models for casting, and much more. nine0008

Industrial printers

These are already industrial machines, which require a separate room and sometimes certain requirements for ventilation, etc. In this article, we will not analyze these devices in detail, but briefly consider the most popular technologies.

In this article, we will not analyze these devices in detail, but briefly consider the most popular technologies.

FDM

In addition to desktop devices using FDM technology, industrial printers that work on the same principle are common.

This category includes devices with a large print area (from 30x30x30 cm and more). For example, Raise Pro2 with a print area of 30x30x30 cm.

Raise Pro2

Or machines designed for printing with refractory materials (eg PEEK). Such 3D printers usually have an active thermal chamber, and the extruder can be heated above 400 degrees.

nine0051 CreatBot F160-PEEK for use with refractory plastics

Photopolymer printers

Industrial photopolymer devices usually have a much larger working area, compared to their "home" brothers. In addition, many processes have been optimized and automated for faster operation. On such printers, you can quickly and accurately produce a small batch of models, a large prototype or a master model. nine0008

On such printers, you can quickly and accurately produce a small batch of models, a large prototype or a master model. nine0008

Prismlab Large Area Industrial Resin Printer Family

3DP

3DP - Three-Dimensional Printing (translated as three-dimensional printing) is a logical continuation of conventional two-dimensional printers. Printing is done using nozzles that selectively apply a binder to the material (usually gypsum). A dye can be added to the binder and the model will be colored. nine0008

Colored plaster model

Since the plaster model is fragile, a similar principle is used for printing with metals. Only the finished product needs to be treated in an oven to remove the binder and improve strength. But despite the processing, such metal prints will still be inferior in strength to cast products.

MJM

This is a proprietary technology of 3D Systems. MJM is a mix of FDM, 3DP and sometimes SLA (depending on material chosen). Printing is done using a variety of small nozzles (from 96 to 488) located on the head of the machine. The accuracy and quality of the surface of models made in this way is in no way inferior to photopolymer printers.

MJM is a mix of FDM, 3DP and sometimes SLA (depending on material chosen). Printing is done using a variety of small nozzles (from 96 to 488) located on the head of the machine. The accuracy and quality of the surface of models made in this way is in no way inferior to photopolymer printers.

Models made with MJM technology

Such devices can work with photopolymer resins, wax or thermoplastics. You can combine several materials at once - for example, for complex models, you can use wax as a support. nine0008

SLM

SLM is the layer-by-layer sintering of metal powder using a powerful laser. There are several similar technologies - SHS/SLS. The principle of operation is the same, only a thermal print head is used instead of a laser beam.

SLM Turbine

As a material for printing, you can use powders of various metals - gold, stainless steel, aluminum, various alloys, etc. nine0008

nine0008

During printing, the working chamber is filled with an inert gas to prevent oxidation of metals. This allows printing even with titanium powder.

Models made by this method are in no way inferior, and sometimes even superior, to cast products. SLM allows you to produce models with complex internal geometry that cannot be produced by another method (casting or milling).

Cost of 3D printing

The cost of a model usually consists of several factors.

-

Equipment depreciation. The printer, like any machine, requires maintenance and periodic replacement of some parts. During operation, belts gradually stretch, bushings or linear bearings wear out. For example, when bushings or linear bearings are worn; shafts may wear out and need to be replaced.

Cost of materials

The main cost item for a 3D printer is, of course, the printed material.;

FDM (plastic filament)

Since FDM technology is by far the most common, the choice of filaments is very diverse.

-

Engineering plastics are usually nylon with various fillers added to improve the physical characteristics of the finished model. Special cost. plastics starts from 2000r per coil and above. It all depends on the manufacturer and filler (carbon fiber, fiberglass, etc.). nine0008

-

Decorative plastics are used to imitate various materials. Plastic can simply be unusually colored (luminous, transparent plastics) or a special filler is added to it (plastics with metal powder). The cost of decorative plastics starts from 1500 rubles per coil and more, depending on the filler.

A big advantage of FDM is the diverse choice of materials to work with. This allows, having one printer, to produce almost any product - from a child's toy to a complex engineering prototype. nine0008

Photopolymers (resin)

Photopolymer resin printing technology is becoming more and more accessible. There are many different resins.

-

The cost of ordinary colored resin starts from 2500 rubles per 0.5 kg (volume +/- 0.5 l). You can find a smaller volume of resin (250 gr) on sale. You can buy several different resins in small containers and find out in practice which one is best for a particular model. nine0008

-

Engineering resins are resins with increased strength. They can be used not only for printing decorative items, but also for making functional prototypes and models. The cost for 0.5 kg starts from 5900r and above.

-

Special resins - burnable, dental, soft flexes, etc. Depending on the resin, the price for 0.5 kg can start from 4800 rubles and more. It all depends on the characteristics of the resin. nine0008

Photopolymer resins have not yet reached such a variety as FDM filaments, but they are surely catching up. Although due to the fact that a liter of resin costs significantly more than a spool of filament, the cost of the product is much higher.

Print examples

FDM

Mag Pull for G3 magazines.

The model was downloaded for free from an open source (the file can be downloaded here). Printing with engineering carbon-filled plastic (price per spool from 4700 rubles). The weight of the model with support is about 25 grams. Post-processing was not needed. The cost of the finished model is 250 rubles. nine0116

Plastic fastener

The file was downloaded from an open source (can be downloaded here). Plastic - carbon-filled nylon (price per coil from 4700r). The weight of the finished product is about 20 grams. Print without post-processing. The total cost is 200 rubles.

Model watch

The model is modeled to order (the cost of modeling is from 1000 rubles). The product is printed on an industrial printer using soluble support. Print without post-processing. The cost of the finished product - from 700 rubles per piece (depends on the number of required products). nine0008

Print without post-processing. The cost of the finished product - from 700 rubles per piece (depends on the number of required products). nine0008

Traction prosthesis

The model is taken from an open source (you can download the modified version of the prosthesis here). The weight of the used material is about 600 gr, printed with ABS plastic (the cost of the coil is from 800 r). After printing, post-processing and assembly took place. The total cost of the product - from 3000 r (depends on the print material, support material, filling, etc.).

nine0008

Pedal layout

Production of a 3D model according to the drawing (from 1000 r). The weight of the finished model is about 200 gr. The product was printed with engineering carbon-filled plastic (the cost of the coil is from 4700 r). Post-processing was not needed. The cost of the finished product is about 3000 rubles.

Photopolymer printers

Model jaws for crowns

Files for printing were obtained using a 3D scanner and finalized in a 3D editor (the cost of scanning is from 3000 r, the cost of manual revision is from 1000 r). Printing on an industrial photopolymer printer. Post-processing is not needed. The cost of the finished product is from 80 r per gram.

Printing on an industrial photopolymer printer. Post-processing is not needed. The cost of the finished product is from 80 r per gram.

Burnout resin rings

The model is made to order. Printing on a desktop SLA printer with a burnable polymer. Post-processing is not needed. The cost of the finished product is 200 rubles per product. nine0008

Miniatures

The models were bought on the myminifactory website (the cost of the model is from $2). Made with a desktop DLP printer. Post-processing was not required. The cost of the finished figurine is from 70 r per gram.

Custom 3D printing

Many owners of 3D printers are thinking about monetizing their hobby. But you should understand that the price of 3D printing “for yourself” and the price of commercial printing are very different. nine0008

When starting to print to order, it is better to have several printers working on different technologies.

Cost of commercial 3D printing

In addition to the cost of the model, to the commercial production of products, you can add:

-

Modeling. Often the client needs not only to make a part, but to pre-model it. It can be a simple cogwheel that doesn't take long to model, or it can be a complex sculpture that takes more time to model than it does to make. nine0008

-

Model post-processing. This can be simply the removal of supports, with cleaning of the place of their contact with the product, or a complete processing cycle (puttying, surface grinding, painting, etc.).

It should be borne in mind that it is not always possible to print the model the first time. Sometimes it may take several attempts. And these are additional costs.

nine0056What is unprofitable to print

Despite the wide possibilities of 3D printing, there are models that are unprofitable to make on a 3D printer.

For such models, it is better to use other manufacturing methods.

Commercial print examples

Jewelry for further casting

Manufacture of promotional items and souvenirs

Piece miniatures or master model for further casting

3D printed model

Profitable to print on a 3D printer:

If the item is only sold as an assembly. For example, a small gear broke in the mechanism, but the mechanism is sold only “assembly”. It is much cheaper to make the desired gear on a 3D printer than to buy the entire mechanism. nine0008

A small batch of parts. Small batches, especially models with complex geometry, are more profitable to produce on a 3D printer than by casting or other methods.

Totals

If you need several models or a small project, sometimes it will be more expedient to outsource manufacturing.

Learn more

45 mm

45 mm