3D printer safety enclosure

Best Safe and Functional Printer Cabinet

Fans of FDM 3D printing who wish to minimise or eliminate warping and shrinking can think of getting a 3D printer enclosure. Such a printer cabinet offers many advantages, but it does not suit everyone. Therefore, you must know all the pros and cons.

In this post, you will find a list of ideas for extra DIY safe and functional protection for your 3D prints and small or large 3D printer. Maybe you will decide to make one for yourself.

3D Printer Enclosure

While resin 3D printers are enclosed, FDM machines mainly comprise a frame and bed and have no printer cabinet.

Enthusiasts working with PLA at 60˚C (140°F) can run their Creality Ender 3, CR-10, Anet A8 and other devices without an additional box. However, those who are making figurines and projects of ABS at 105˚C (221°F) will benefit from a DIY 3D printer enclosure.

A 3D printer cabinet is a shell (box) that keeps the temperature in, protects the area from dust and models from warping. It plays an essential role in stabilising the “heat atmosphere” and helps the first layers stick well to the bed.

You do need a 3D printer enclosure if:

- You wish the temperature within the print area to be more stable when printing with ABS;

- You want to protect your FDM printer from dust;

- You need to organise your working space;

- You hope to reduce the 3D printing noise;

- You expect the 3D printer cabinet to low down the toxic fumes appearing while you are printing with ABS.

What you must decide:

- How much you can spend on a DIY 3D printer enclosure kit;

- You are ok with a cheap look, or you are concerned with the aesthetic look;

- Whether you need full access to your 3D printer or you would like to limit accessibility for your kids and pets.

When you have all the answers, you need to make a decision. Would you prefer a homemade DIY 3D printer enclosure or ready-to-buy accessory explicitly made for Creality Ender 3, CR-10, Anet A8 or a different machine?

Read also: Incredible Stuff You Can Make with a 3D Printer

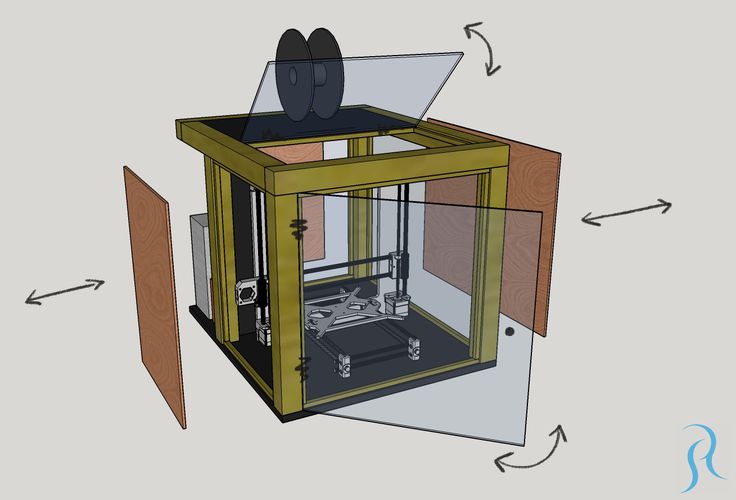

DIY 3D Printer Enclosure

It does not matter if you add good ventilation to your room and extraction system to exude the toxic fumes or not. You can always build your DIY 3D printer enclosure kit from household items and transform other products into such a box.

Decide if you want to place all components (filament spool, power supply, display, control boards) inside the 3D printer cabinet or outside. It is best to choose non-flammable material for DIY 3D printer enclosure instead of using ordinary boxes, polystyrene and other combustible materials. Besides, a smoke detector inside the box can help you prevent fire.

1. Cardstock Boxes

The simplest, fastest and cheapest DIY 3D printer enclosure is made of a shipping box. The big cardstock boxes can be found in numerous households and at post offices. You can go with a size bigger than your home machine with enough space for all the moving parts.

The big cardstock boxes can be found in numerous households and at post offices. You can go with a size bigger than your home machine with enough space for all the moving parts.

It is quick to cut “windows” and “doors” in your cardstock box and place it over the 3D printer. If you need to upgrade your machine or access it, all you have to do is remove your self-made cabinet.

Cardstock boxes turned into 3D printer enclosures by Reddit users Prashant Kumar and u/SkipopotamusPros: cheap (often 100% free), easy and fast to make.

Cons: flammable, extremely dangerous, requires a smoke detector and your control.

2. Plastic Boxes

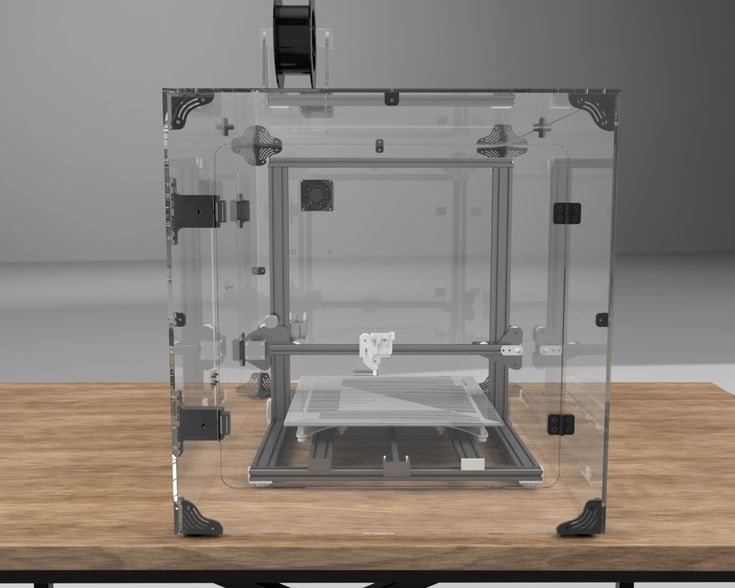

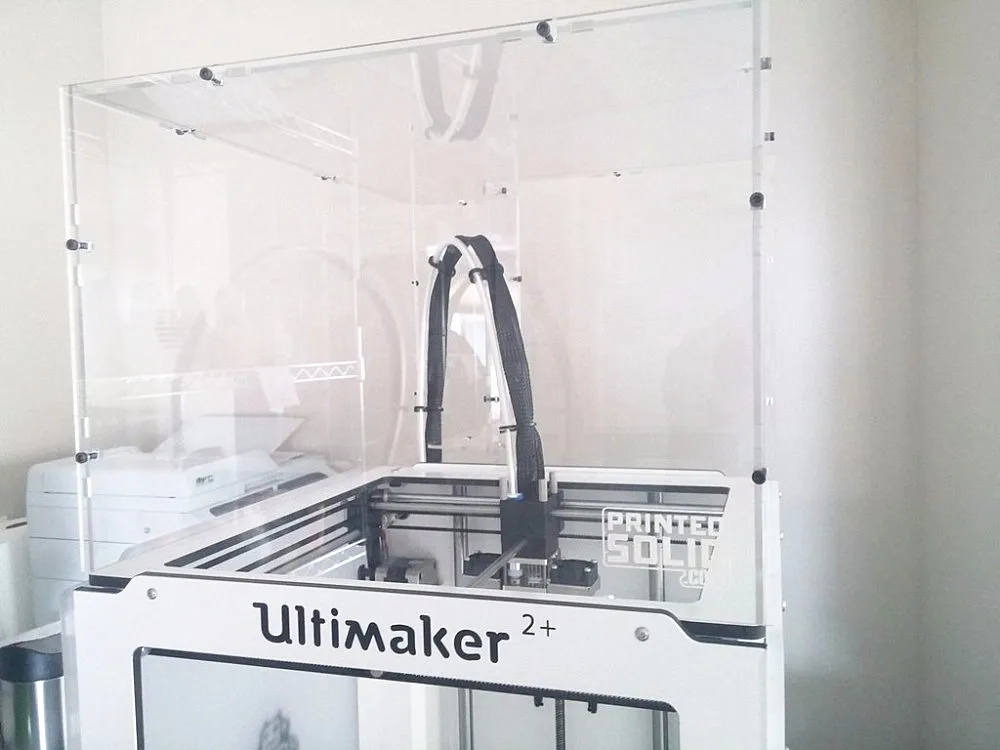

The market has many transparent plastic boxes, which you can turn into a DIY 3D printer enclosure. You will need your time, some skills and instructions (or your fantasy) to build such a 3D printer cabinet yourself. But the variety of containers makes it easy to find the right size and price.

Sometimes you will have to combine two or even three plastic boxes if you need a tall or super-wide enclosure. It might be necessary to cut windows, holes for cables, make doors that open and close, etc. Many enthusiasts use plexiglass which is a solid, transparent plastic made of polymethyl methacrylate because it is durable and not as fragile as glass.

It might be necessary to cut windows, holes for cables, make doors that open and close, etc. Many enthusiasts use plexiglass which is a solid, transparent plastic made of polymethyl methacrylate because it is durable and not as fragile as glass.

Pros: transparent walls that let you follow the 3D printing process, great custom opportunities to build your perfect printer cabinet.

Cons: the price can be high, time-consuming assembly or construction from scratch, flammable, dangerous, requires a smoke detector.

3. Photo Studio Shooting Tent

Portable and professional photo studio shoot tents and light boxes can become an excellent 3D printer enclosure, although they always cost money.

Such a box can play two roles. On the one hand, it can help to even the temperature inside the DIY 3D printer cabinet. On the other hand, you can use it to take professional-looking photos of your finished 3D prints.

Pros: no need to cut “windows” and “doors,” excellent illumination for the models inside your machine, opportunity to take stunning shots of your 3D prints.

Cons: can be expensive for big 3D printers, flammable, dangerous, requires a smoke detector.

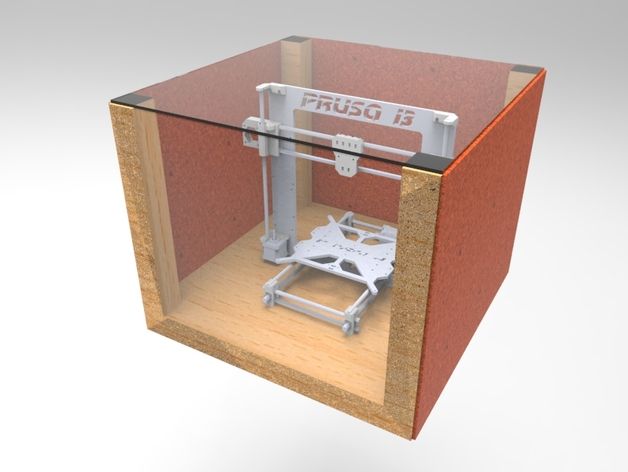

4. Used Furniture

Often, there is no need to buy boxes and search for a photo studio tent. You might have old wood furniture at your house, which you can transform from an ordinary closet into a perfect 3D printer enclosure. Of course, such work requires some time, equipment, might need money for refinishing and reassembling, additional parts, but the result could impress you.

Wooden cabinets have wooden doors, so you might want to replace the door with heat resistant glass. This way, you can see through and watch your 3D printer in action. Besides, it will be great if you can invest in fire retardant treatments for the wooden cabinet walls and roof.

Only look at this Star-Wars-inspired cabinet made by Reddit user BenaprScopian:

DIY 3D printer enclosure inspired by Star Wars. Maker: BenaprScopianIt is something you can make yourself too! And make sure to decorate your room with many fantastic 3D printing Star Wars models!

Pros: upcycling old closets can give a second life to your furniture, you can customise everything to your needs.

Cons: expensive, time-consuming, requires a smoke detector and fire retardant treatments.

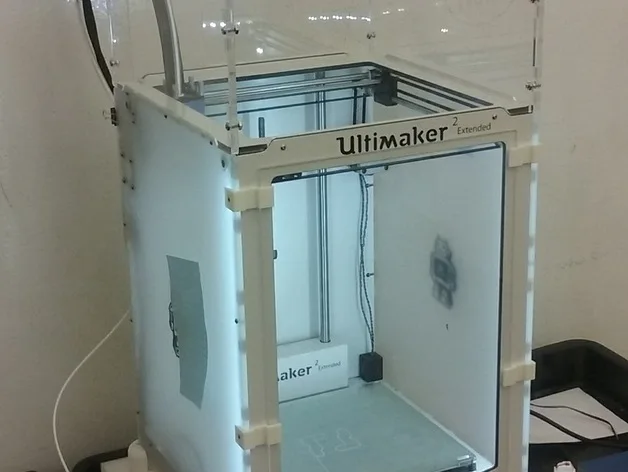

Ready-to-Buy 3D Printer Enclosure

Not every 3D printing enthusiast is willing to make a DIY 3D printer enclosure from cardstock, plastic boxes, IKEA Lack side tables, metal and glass or other materials. Some users are happier to get a factory accessory explicitly made for Creality CR-10, Ender 3, Anet A8, another machine.

Factories produce ready-to-buy enclosures for different 3D printers. Thus, even if you don’t have an enclosed machine, you can order a special box made of fireproof and dustproof material.

Creality Ender 3 Enclosure

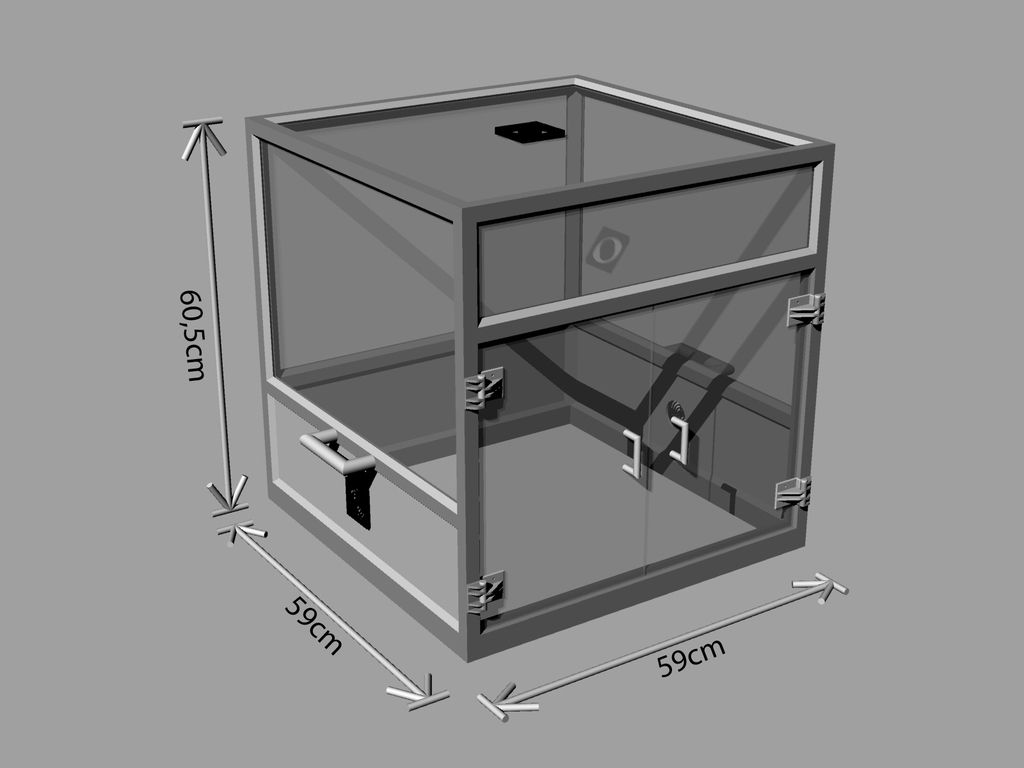

Suppose you wish to keep a constant temperature while your Creality Ender 3 or Ender 5 is running. Then, you could be interested in getting the official Ender 3 enclosure. The market has many offers, and you can find different sizes of this printer cabinet.

Ender 3 enclosure. Image: creality3dofficial.comAt about $80-$100, such an enclosure is often made of aluminium film and flame retardant material that will only melt in case of fire. The construction is light and easy to install. You can fold it for storage and enjoy the noise reduction effect when in use.

Creality CR-10 Enclosure

At about $60-$100, you can find a universal cabinet that suits many 3D printers, including Creality CR-10, CR-20 and others. Such CR-10 enclosure often offers pockets for tools, folding storage, dustproof and fireproof material (pure aluminium foil).

CR-10 enclosure. Images: creality.comWhen enclosed, your 3D printer will be secured within the folding box. Its purpose is to stabilise and preserve the temperature, improve the printing quality, protect your machine from dust.

Its purpose is to stabilise and preserve the temperature, improve the printing quality, protect your machine from dust.

Anet A8 Enclosure

While you can find ready-to-buy Creality CR-10, CR-20, Ender 5, Ender 3 enclosures, similar accessories are not offered for Anet A8 users. Still, you can get one of the folding cabinets designed for other machines sized to fit your particular 3D printer.

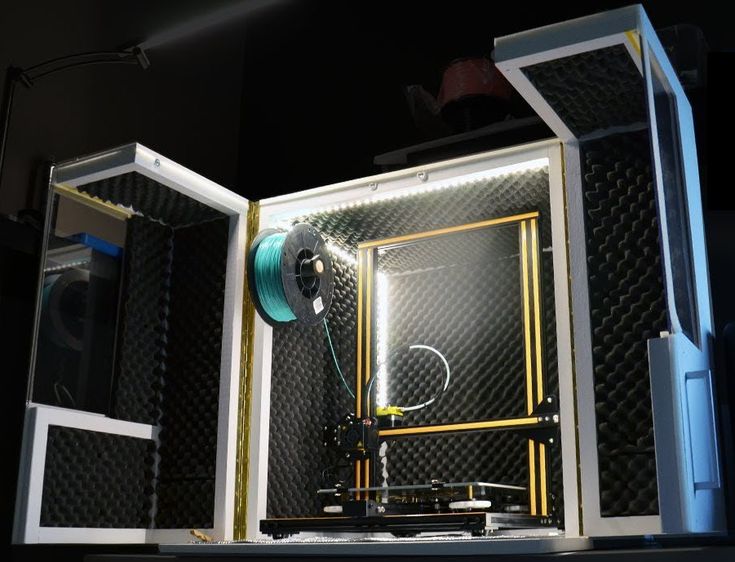

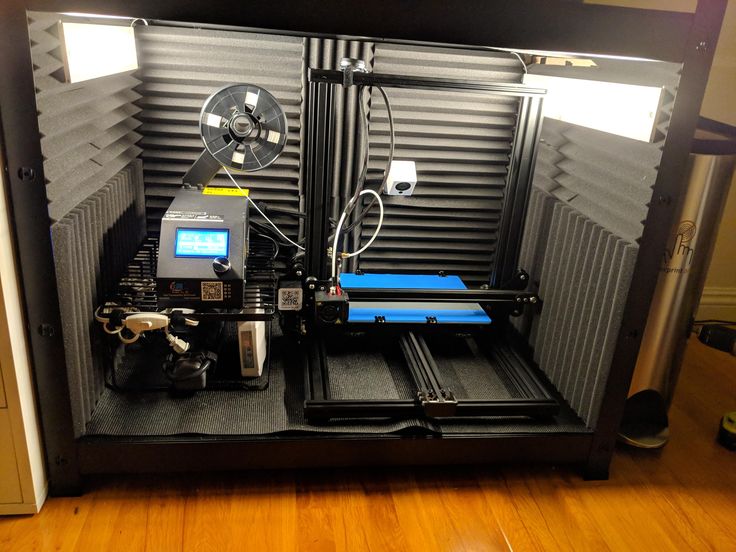

Also, there are many great tutorials and videos on how to make one on the internet. So, if you are searching for a nice Anet A8 3D printer enclosure, you might want to build it yourself just like Reddit users inhuman and u/ilcadm did.

Anet A8 enclosure made by Reddit usersAn excellent 3D printer enclosure kit can improve life for hobbyists with FDM machines and protect your device from dust (when not in use). It also helps preserve constant temperature, improve the quality of 3D prints made of ABS filament and reduce the warping issues. You can DIY such a printer cabinet or purchase a ready-to-buy box. When you are happy with your 3D printed models, make sure to join Gambody 3D Printing Community on Facebook to share their photos.

When you are happy with your 3D printed models, make sure to join Gambody 3D Printing Community on Facebook to share their photos.

(Visited 7,315 times, 1 visits today)

Author

3D Printer Enclosure,Creality 3D Printing Enclosure,Ender 3/Ender 5 plus

Home Collections 3D Printer Enclosure: Safe, Quick and Easy installation$ USD

$ USD

21 Reviews Pricing Not Include Tax

Ship From

United StatesChinaUnited KingdomCzechAustraliaCanada

Apply to

For Ender 3 /3 Pro/3 V2For CR-10 Series/Ender 3 Max/Ender 5 Plus

Ship to

It is expected to arrive within and will cost $ USD to ship

This item can't be shipped to this Country/Region

Bundles

Quantity

28 Available

Add To Cart Buy It Now

Continue To Shopping View Cart

People who bought this item also bought

Small Warm Enclosure Size: 480mm×600mm×720mm

Applicable 3D Printer Specifications: Ender-2 Pro, Ender-3, Ender-3 Pro, Ender-3 V2, Ender-3 Neo, Ender-3 V2 Neo, CR-6 SE, Ender-7, CP-01, CR-20/Pro

Large Warm Enclosure Size: 750mm×700mm×900mm

Applicable 3D Printer Specification: Ender-3 S1, Ender-3 S1 Pro, Ender-3 S1 Plus, Ender-3 Max, Ender-3 Max Neo, Ender-5, Ender-5 Pro, Ender-5 Plus, Ender-5 S1, Ender-6, CR-10, CR-10S, CR-10 Mini, CR-10 V2/V3, CR-10S Pro/PRO V2, CR-10 Smart, CR-10 Smart Pro, CR-6 Max, CR-X 3D Printer

Worried that print quality coming from the open-framed Ender 3(Pro) or Ender 3 V2 and Ender 5 will be negatively affected by the external environment?

No need to fear, the 3D printer enclosure is here!

- Improve the overall printing experience - both for you and the machine itself.

- Easy to install, can be folded for efficient storage.

- Equipped with pockets to hold the necessary tools.

- You can easily access the printer by unzipping the front of the enclosure, which features a seethrough screen for full-time monitoring.

3D Printer Enclosure Advantage:

- Quick and easy installation: Folding storage, easy to carry, multi-faceted observation, reserved tool pockets. Economical 3D printing room!

- Constant Temperature: Keep a constant temperature printing environment, reduce the impact of printed products when low-- temperature weather, improve printing stability.

- Dustproof and good noise reduction: The interior uses Pure aluminum film and flame retardant appearance material. Technically, if in a fire, it will melt and not fire itself of the enclosure, and will not spread.

- Stable Structure: Equipped with a selection of Iron pipes, stable structure, and abundant space.

Constant Temperature

3D printer keeps a constant temperature printing environment, allowing for much more stable temperatures once the printer is operating.

Quick and Simple Installation

Quick and easy installation, folding storage, with reserved tool pockets, easy to carry(6.08lb), and multifaceted observation.

Safe to Use & Stable Structure

The interior uses pure aluminum film and flame retardant appearance material and will not fire itself of the enclosure and will not spread as well.

Customer Reviews

Customer Reviews

Based on 21 reviews

67%

(14)

19%

(4)

14%

(3)

Write A Review

Ask A Question

Reviews (21) Questions (0)$ USD

$ USD

ADD TO CART BUY IT NOW

Write a review

Ask a Question

What is support in 3D printing

Many users who are new to digital manufacturing or, more simply, 3D printing, do not understand some terminology, which causes them many questions. One such question is: “What is support and why is it needed?” But supports, along with other service elements, are used in the manufacture of most parts on a 3D printer.

One such question is: “What is support and why is it needed?” But supports, along with other service elements, are used in the manufacture of most parts on a 3D printer.

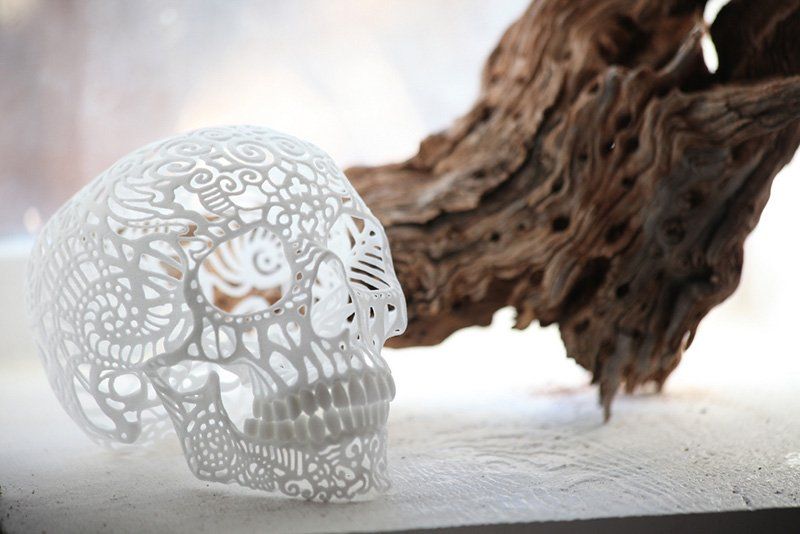

Using the most popular FDM 3D printing technology as an example, let's consider the main service elements. And so, when a 3D model is placed in the working chamber of the printer, several service elements are created around it: a border (can be replaced with a skirt, a substrate, or completely disabled), supports, and a casing. The photo below shows the model in the process of printing with service elements and the finished product, cleared of service elements. nine0003

Border is a thin layer of plastic that is created around the product on the heating plate. The border increases the area of attachment of the model to the table and does not allow it to come off under the action of shrinkage forces of the material and movements of the print head (extruder). With a border, 90% of products are printed. It may not be used on products with low heights and simple geometries that are guaranteed to be held firmly on the heating bed. In other cases, without a border in any way.

It may not be used on products with low heights and simple geometries that are guaranteed to be held firmly on the heating bed. In other cases, without a border in any way.

Supports are frame elements that are built under the overhanging parts of the product and serve to support them. Supports can be made from the same plastic as the main product or from another material such as soluble HIPS or PVA. More often, supports are built from the material of the product, as this speeds up and reduces the cost of the printing process. Supports made of HIPS or PVA tend to cost more than the product they are designed for. Printing a product that should be supported without supports will result in poor surface quality or even tear the product off the desktop. After all, printers with FDM printing technology cannot print in air, the plastic simply flows down from the extruder nozzle and is smeared over the product. An exception to the rule may be the printing of the so-called "bridges", which are built in the air, but these are specific elements, the printing of which requires fine tuning of the equipment and is not used in all models. nine0003

nine0003

Shroud is a protective plastic barrier that is built around the product on the 3D printer's heating bed. The casing protects the product from contact with cold air (less than +80 С°) in order to avoid abrupt cooling of the model and its warping due to a sharp shrinkage of the material. A casing is used on high models to improve the surface quality of the product, reduce the likelihood of the model breaking off the table and maintaining the geometric dimensions of parts subject to strong shrinkage. nine0003

After the end of the printing process, all service elements are mechanically removed from the product. This is done with a scalpel, drill (Dremel) or sandpaper. In most cases, the removal of the supports is included in the price of the product, but on some models, the removal of the supports is too long and painstaking, so an additional fee may be charged for the work.

There are other service elements created in the process of placing the model in the printer chamber, for example, towers for cleaning the extruder nozzle during two-color printing, and other elements. We talked about three main elements that are used in almost every print. You can read about other elements on the Internet if you are interested. nine0003

We talked about three main elements that are used in almost every print. You can read about other elements on the Internet if you are interested. nine0003

The items listed above are included in the scope of the product and therefore affect the cost of the final product. The percentage ratio of service elements to the volume of the model cannot be predicted in advance; it is calculated in the printer program. Therefore, the exact cost of manufacturing a product on a 3D printer can only be calculated by a specialist after placing the model in the printer chamber.

Air pollution in 3D printing

Main page

Articles

Smoke from a 3D printer

Smoke from a 3D printer

Introduction How does a printer pollute the air How does a BOFA filter

What is 3D printing

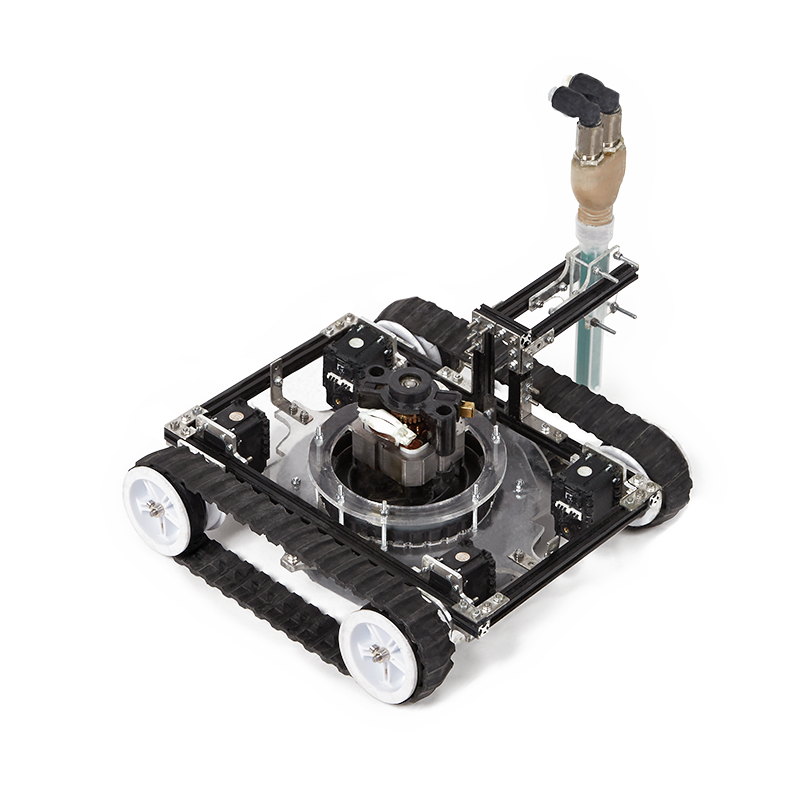

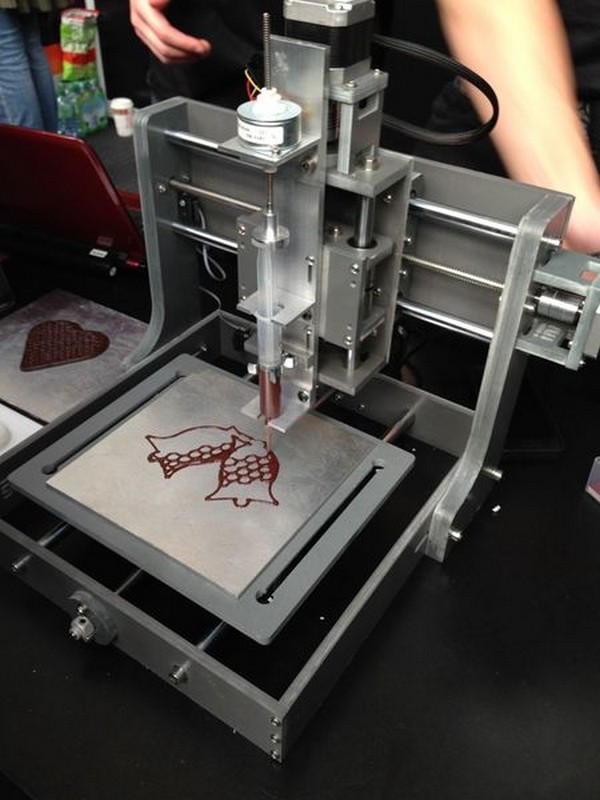

3D printing is also known as additive manufacturing. This means that the product is created by adding material in layers. The process is controlled by a coordinate XYZ robot with digital control. Printers work with plastic or metal. The material is fed to the deposition point in the form of wire or powder. The printer is melting the material. Then it connects to the previously applied base. nine0003

The process is controlled by a coordinate XYZ robot with digital control. Printers work with plastic or metal. The material is fed to the deposition point in the form of wire or powder. The printer is melting the material. Then it connects to the previously applied base. nine0003

A 3D printer will produce objects of complex shape. This favorably distinguishes the additive process from the subtractive one, when excess is removed from a large piece of material. Machining, laser processing, soldering or welding generate more contamination. And a lot of material is wasted. 3D printing does not consume a lot of extra material. It appears to be a clean process, but it still pollutes the air.

Anyone using 3D printing needs to be aware of the health risks. The 3D printer seems safe. But it can generate toxic fumes and hazardous substance particles. Technological processes that transform the material pollute the air in the workplace. This applies to cutting, engraving, thermal decomposition in a laser machine, soldering with a toxic flux, etc. Molten metals and polymers are no exception. nine0003

Molten metals and polymers are no exception. nine0003

Why is a 3D printer dangerous?

Ultrafine particles

Heating a substance causes the release of solid particles, droplets and vapors. They may be harmful if inhaled.

European scientists are gradually revealing the dangers of 3D printing to health. According to the 3D Printer Emission Report , plastic melting releases small nanoparticles of material into the air. They cannot be seen without special equipment. But that doesn't mean they are safe. nine0003

PLA plastic nanoparticles are used in pharmaceuticals as a means of delivering drugs to various organs, including the brain. Cosmetics use the same effect. Ultrafine particles penetrate the skin. By themselves, PLA particles are not toxic. But no one knows about the consequences of accumulation in human organs. Nanoparticles condense into relatively large formations. It is known for certain about the harmfulness of soot nanoparticles from automobile exhausts . They are associated with degenerative brain diseases, such as Alzheimer's disease. nine0003

ABS plastic is toxic when melted. Nanoscopic ABS particles are just as toxic. These particles are very small. During inhalation, they enter the brain through the olfactory nerve. They spread throughout the body through the bloodstream. Most organs can get rid of them naturally, but the brain and lungs become clogged for a long time.

In fact, particles as small as 10-200nm easily enter the bloodstream through the lungs. Their toxic action differs from the original substance in the usual shapes and sizes. According to study by the Italian Institute of Health and Consumer Protection nanoparticles are deposited in the lungs in greater quantities than e-cigarette smoke.

Gases or vapors

Molten ABS gives off a particularly unpleasant odor. Other plastics including nylon, HIPS and HDPE emit the same toxic fumes but have less odor.

Polymer materials can vaporize some of their constituents. Dioctyl phthalate is often added to them for flexibility and mold resistance. During high heat or laser treatment, benzene is released in hazardous quantities. And while working with PVC, HCl aerosol condenses in the air. nine0003

The high temperature in the area of the printer head causes the air to expand. Vapors quickly spread in the work area along with plastic particles. Thermal degradation products of polymers are shown in the diagram below.

How does BOFA work?

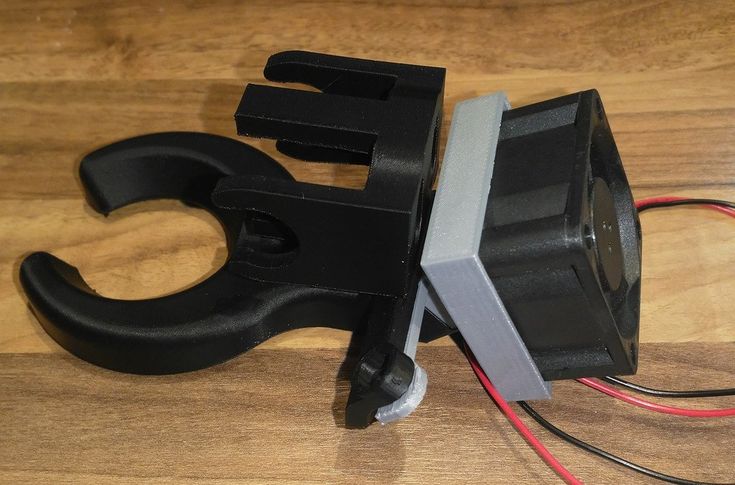

A smoke extractor is an extractor hood with filters placed in one device. She got her name at the time when she removed the smoke of a soldering iron or a laser engraver. But these same devices with special filters are also suitable for a three-dimensional printer. The smoke extractor block for the printer is not much different from the soldering block. nine0003

3D printing is sensitive to changes in air temperature. Therefore, he is afraid of drafts. If you are using a small open printer, then the polluted air can be removed with a conventional smoke extractor. In order not to disturb the climate in the printer, select the minimum air suction speed.

Therefore, he is afraid of drafts. If you are using a small open printer, then the polluted air can be removed with a conventional smoke extractor. In order not to disturb the climate in the printer, select the minimum air suction speed.

If your 3D printer model is closed, there is a protective cover, then you can install a cleaning curtain. During operation, while the printer window is closed, it can be turned off. But it will clean the outgoing air when you open the box to take out the finished product. nine0003

If your printer is large and completely enclosed, then it will most likely have built-in pipes for connecting the hood. They can be connected to a smoke extractor with large filters. It can operate continuously or turn on at the command of the printer. The fume extractor captures dirty air and returns it back to the printer so as not to change the air temperature during the printing process.

3-stage filtration

A complete smoke extractor is equipped with three filters. The first is the pre-filter. It does not let in coarse dust, so as not to clog the main fine filter with it. The fine filter is HEPA. Particles of all sizes, including aerosols and nanoparticles, settle on its fibers. The gas filter completes the cleaning. It consists of densely packed activated carbon granules with interlayers of fiberglass. Activated carbon traps VOCs and nanoparticles that HEPA missed. nine0003

The first is the pre-filter. It does not let in coarse dust, so as not to clog the main fine filter with it. The fine filter is HEPA. Particles of all sizes, including aerosols and nanoparticles, settle on its fibers. The gas filter completes the cleaning. It consists of densely packed activated carbon granules with interlayers of fiberglass. Activated carbon traps VOCs and nanoparticles that HEPA missed. nine0003

Smoke extractor against exhaust

The cheapest way to remove smoke is a duct fan and air ducts. Emission of polluted air through the window is prohibited by SanPin norms. And the smoke extractor has advantages.

- Good air purification from all kinds of solid particles and aerosols

- There will be no odors from melted plastic or metal in the room

- You will be sure that your health will not suffer

- The microclimate in the 3D printing machine will be stable

- Supply ventilation with heating or air conditioning is not needed, as for the hood in the window

Eliminate the harmful agent

The hood with filters will solve the problems with harmful emissions from 3D printing with polymers and metal powder.