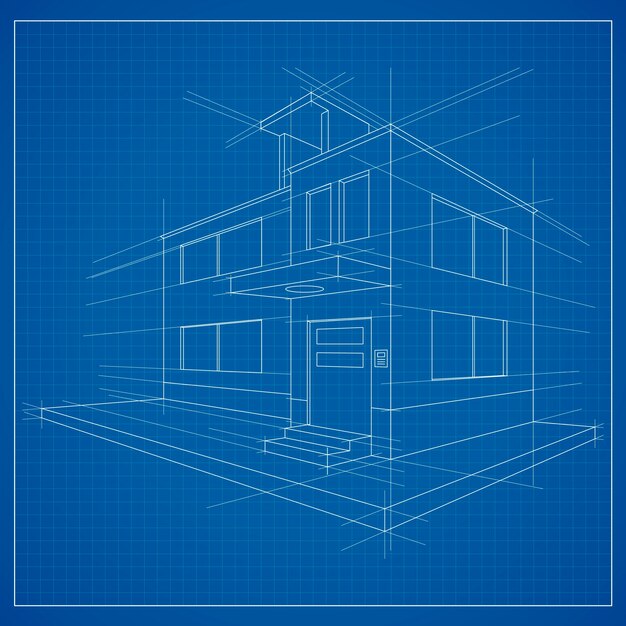

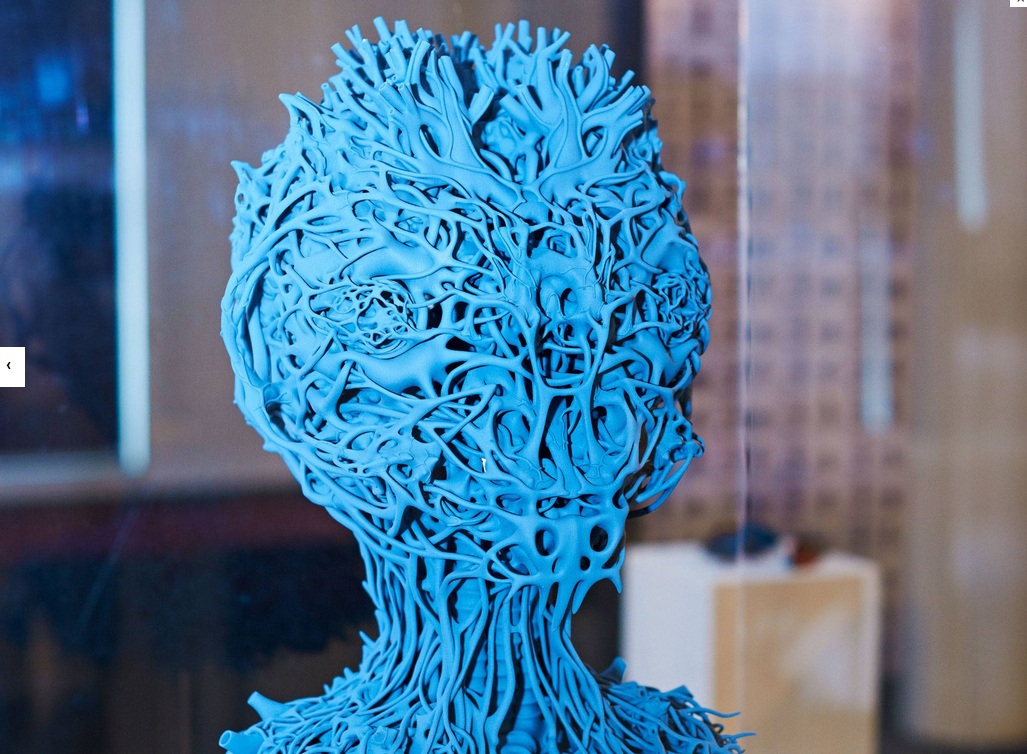

Blue print 3d

Blueprint 3D on the App Store

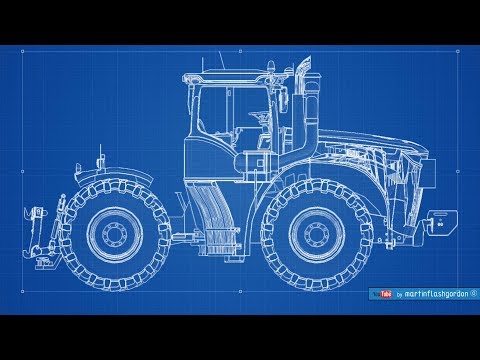

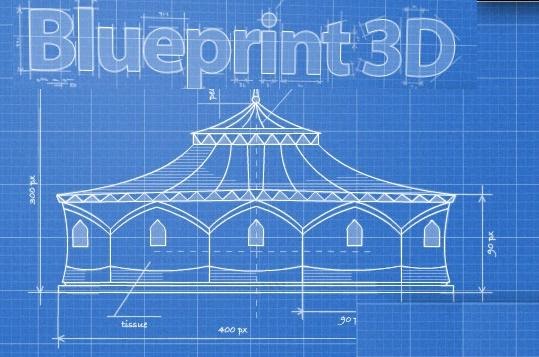

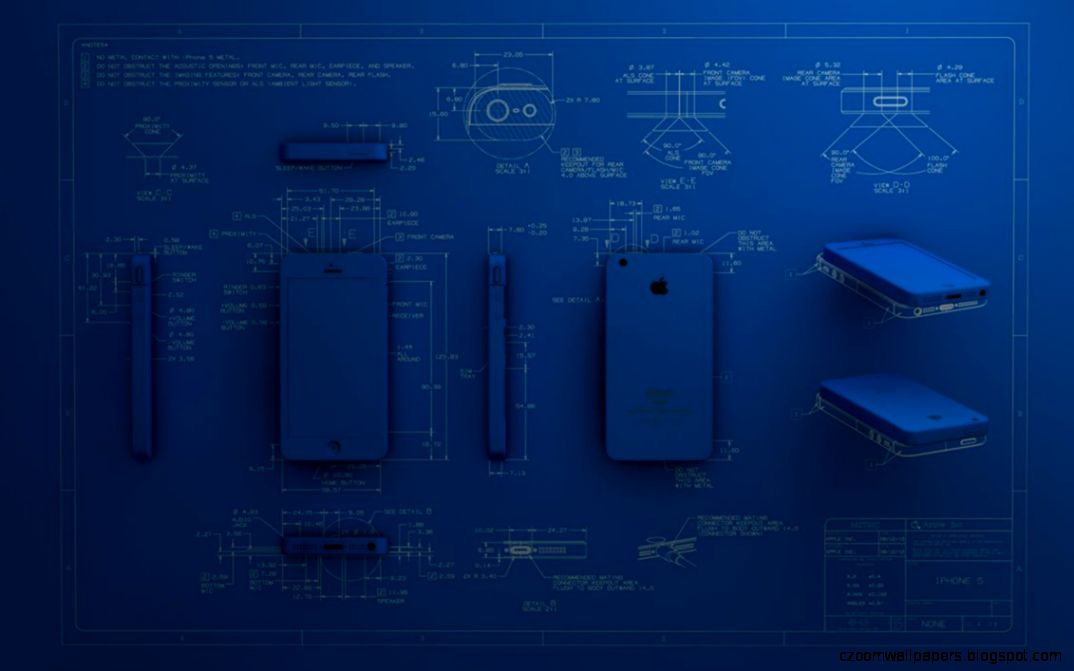

iPhone Screenshots

Description

AN ENTIRELY NEW GAMING EXPERIENCE

**USA TODAY: Rating: 4 stars (out of 4)

"In the crowded market of puzzle apps, Blueprint 3D HD shines for its uniqueness."

Magical 3D motion puzzle game

Never before seen gameplay

NEW: Create own 3-D puzzles

• OVER 300 LEVELS OF PURE AMAZEMENT!

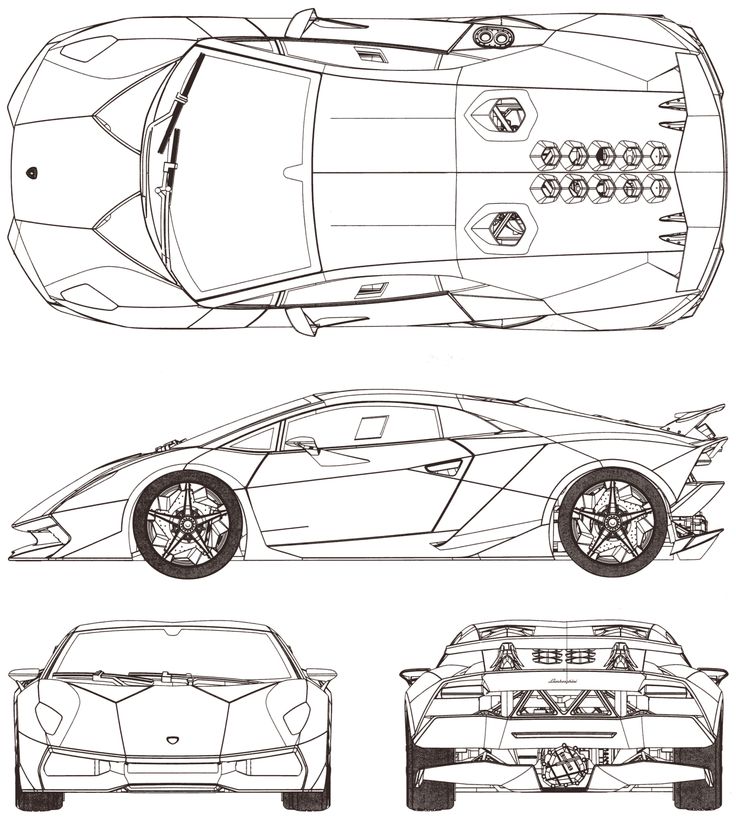

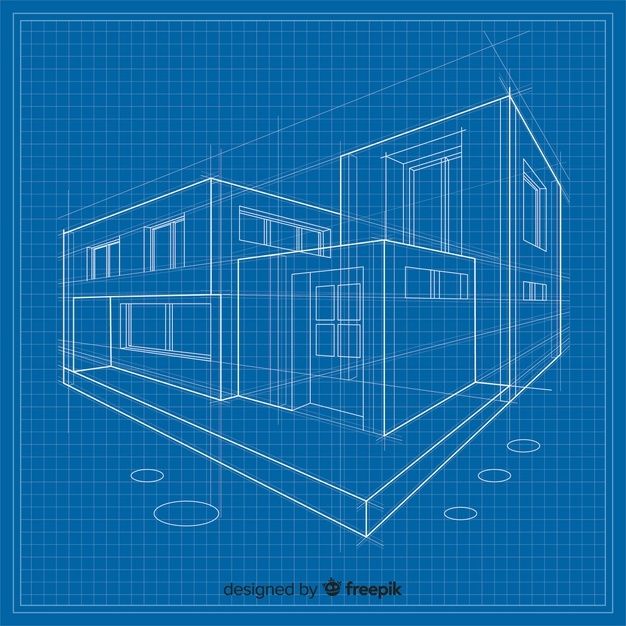

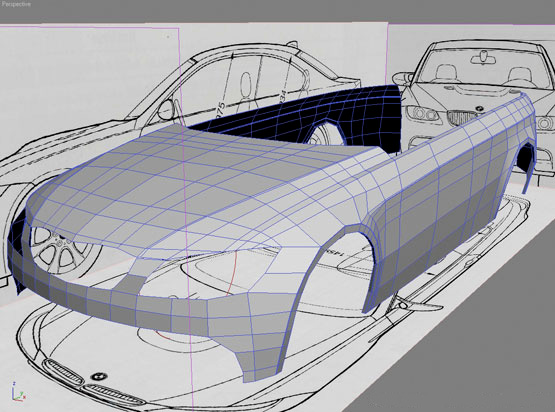

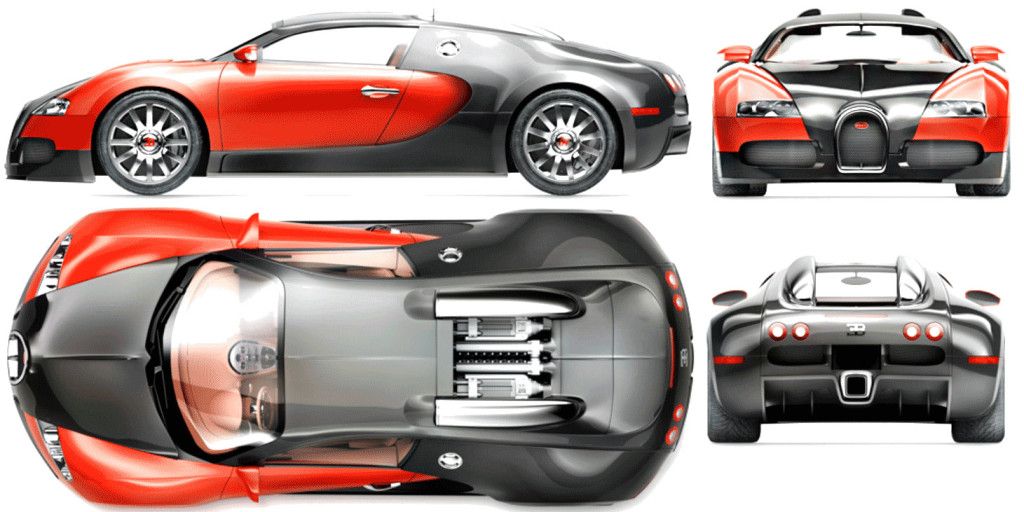

Each level begins with a mysterious clutter of seemingly chaotic dots and lines. Underneath all the chaos, however, lies a beautiful blueprint image waiting to be uncovered. It’s right there in front of you: Just drag your finger across the screen to rotate the figure, and all of a sudden you’ll notice that the lines start to make sense! Solve the puzzle by rotating the figure in all directions and on all planes until you hit the sweet spot. Once you’re there, the secret picture will reveal itself. Wait till you see this in action!

• 3-D Camera and Editor Feature

Take photos and easily convert them into amazing 3-D puzzles.

• INCLUDES 11 THEMES AND FREE UPDATES!

Reveal hundreds of artistic images and amaze your friends with the magic of this app. Select your picture challenge from the following themes:

• ORIGINAL SOUNDTRACK

Each theme comes with its own original music, but feel free switch to your favorite tracks in iTunes. Whatever your musical preference, this app is sure to deliver a delightfully artistic multimedia experience.

• TROPHY ROOM AND GAME CENTER

Earn trophies while you unlock new images, and add your prizes to your Blueprint 3D trophy room. Unlock GAME CENTER achievements and post the leading high score.

Feature Overview:

- Amazing 3D Motion Puzzle

- 3-D Camera and Editor

- Create new Levels

- More than 300 Levels

- 11 Theme Packs

- Smooth Graphics

- Retina Display Support

- Original Soundtrack

- Trophy Room

- Game Center Support

- Global High Scores

- Game Center Achievements

Version 2.0.1.3

This app has been updated by Apple to display the Apple Watch app icon.

Now supports iOS 11

Ratings and Reviews

5.3K Ratings

Unique and Original

I love puzzle games, and I've never quite played something like this before. The learning curve is quite quick and before you know it, you can glance for a second and know right away how to twist the random lines around to unscramble the blueprint. That is, until the difficulty ramps up with each level. I played until my battery ran out, it was about half full when I downloaded it. I have not tried creating my own puzzle yet, but if it's as intuitive as the gameplay, I'm sure it will be fun as well. Five stars!

Amazing!

I love being able to take my own photo and then put it together.

I wish there were better instructions. Simple enough to figure out how to do it but I'm having trouble finding how to save it and download it. Also it changed from blue to b&w at one point but there was no reason why and I didn't see any options how to manually change it back. A bit disappointing to find out how limited it is before you are asked to pay.

All in all, this is a wondrously fun thing and I highly recommend it and I don't mind paying. I just wish it was more clear in the details and even more so as far as instructions. The tutorial is lacking.

Simply and elegantly awesome!

In love with this game! I couldn't figure out what to do at first but after watching the tutorial which was pretty quick, I understood what to do. I am addicted. It's like a digital jigsaw puzzle but the pieces are already on the board in 3 dimensions and you have to move it around the 3 dimensions until all the pieces fit together.

Such a BRILLIANT idea for a game. Stimulating the mind but not overly complicated so it keeps you interested and motivated at the same time. You don't have to be a nerd to play a mind game here. It's a visual game, I'm a very visually oriented student so I love it.

The developer, FDG Mobile Games, has not provided details about its privacy practices and handling of data to Apple. For more information, see the developer’s privacy policy.

No Details Provided

The developer will be required to provide privacy details when they submit their next app update.

Information

- Seller

- FDG Mobile Games GbR

- Size

- 100.4 MB

- Category

- Games

- Age Rating

- 4+

- Copyright

- © FDG Entertainment 2012-2018

- Price

- $0.

99

99

- Developer Website

- App Support

- Privacy Policy

Supports

More By This Developer

You Might Also Like

3D printing- creating a blueprint for the future of orthopedics: Current concept review and the road ahead!

1. U.S. Patent 4,575,330 ("Apparatus for production of three-dimensional objects by stereolithography").

2. U.S. Patent 5,121,329, June 9, 1989, "Apparatus and Method for Creating Three-Dimensional Objects" (A system and a method for building three-dimensional objects in a layer-by-layer manner via fused deposition modeling).

3. Long J., Gholizadeh H., Lu J., Bunt C., Seyfoddin A. Appl Fused Depos Model (FDM) Meth 3D Print Drug Deliv Curr Pharm Des. 2017;23(3):433–439. [Google Scholar]

Appl Fused Depos Model (FDM) Meth 3D Print Drug Deliv Curr Pharm Des. 2017;23(3):433–439. [Google Scholar]

4. Cooke M.N., Fisher J.P., Dean D., Rimnac C., Mikos A.G. Use of stereolithography to manufacture critical-sized 3D biodegradable scaffolds for bone ingrowth. J Biomed Mater Res B Appl Biomater. 2003 Feb 15;64(2):65–69. [PubMed] [Google Scholar]

5. Ibrahim D., Broilo T.L., Heitz C. Dimensional error of selective laser sintering, three-dimensional printing and PolyJet models in the reproduction of mandibular anatomy. J Cranio-Maxillo-Fac Surg. 2009 Apr;37(3):167–173. Epub 2008 Dec 3. [PubMed] [Google Scholar]

6. Nadgorny M., Ameli A. Functional polymers and nanocomposites for 3D printing of smart structures and devices. ACS Appl Mater Interfaces. 2018 May 16 [PubMed] [Google Scholar]

7. Sun W., Yan Y., Lin F., Spector M. Biomanufacturing: a US-China national science foundation-sponsored workshop. Tissue Eng. 2006 May;12(5):1169–1181. [PubMed] [Google Scholar]

8. Chua C.K., Yeong W.Y., An J. Special issue: NextGen materials for 3D printing. Materials (Basel) 2018 Apr 4;11(4) pii: E555. [PMC free article] [PubMed] [Google Scholar]

Chua C.K., Yeong W.Y., An J. Special issue: NextGen materials for 3D printing. Materials (Basel) 2018 Apr 4;11(4) pii: E555. [PMC free article] [PubMed] [Google Scholar]

9. Melican M.C., Zimmerman M.C., Dhillon M.S., Ponnambalam A.R., Curodeau A., Parsons J.R. Three-dimensional printing and porous metallic surfaces: a new orthopedic application. J Biomed Mater Res. 2001 May;55(2):194–202. [PubMed] [Google Scholar]

10. Bagaria V., Chaudhary K. A paradigm shift in surgical planning and simulation using 3Dgraphy: experience of first 50 surgeries done using 3D-printed biomodels. Injury. 2017 Nov 1;48(11):2501–2508. [PubMed] [Google Scholar]

11. Upex P., Jouffroy P., Riouallon G. Application of 3D printing for treating fractures of both columns of the acetabulum: benefit of pre-contouring plates on the mirrored healthy pelvis. Orthop Traumatol Surg Res. 2017 May;103(3):331–334. [PubMed] [Google Scholar]

12. Maini L., Sharma A., Jha S., Sharma A., Tiwari A. Three-dimensional printing and patient-specific pre-contoured plate: future of acetabulum fracture fixation? Eur J Trauma Emerg Surg. 2018 Apr;44(2):215–224. [PubMed] [Google Scholar]

2018 Apr;44(2):215–224. [PubMed] [Google Scholar]

13. Wang Y.C., Ma Y., Yu W.Z., Li Y.F., Liu Y.H. Application of the computer-assisted virtual reduction combined with 3D printing technique in acetabular fractures. Zhong Guo Gu Shang. 2017 Jul 25;30(7):627–632. [PubMed] [Google Scholar]

14. Zeng C.J., Huang W.H., Huang H.J., Wu Z.L. Laparoscopic acetabular fracture fixation after three-dimensional modelling and printing. Indian J Orthop. 2017 Sep-Oct;51(5):620–623. [PMC free article] [PubMed] [Google Scholar]

15. Bagaria V., Deshpande S., Rasalkar D.D., Kuthe A., Paunipagar B.K. Use of rapid prototyping and three-dimensional reconstruction modeling in the management of complex fractures. Eur J Radiol. 2011 Dec;80(3):814–820. [PubMed] [Google Scholar]

16. Chen X., Chen X., Zhang G. Accurate fixation of plates and screws for the treatment of acetabular fractures using 3D-printed guiding templates: an experimental study. Injury. 2017 Jun;48(6):1147–1154. Epub 2017 Mar 7. [PubMed] [Google Scholar]

[PubMed] [Google Scholar]

17. Garg B., Gupta M., Singh M., Kalyanasundaram D. Outcome and safety analysis of 3D-printed patient-specific pedicle screw jigs for complex spinal deformities: a comparative study. Spine J. 2018 May 3 [PubMed] [Google Scholar]

18. Schwarzkopf R., Schnaser E., Nozaki T., Kaneko Y., Gillman M.J. Novel, patient-specific instruments for acetabular preparation and cup placement. Surg Technol Int. 2016 Oct 26:309–313. XXIX. [PubMed] [Google Scholar]

19. Li H., Qu X., Mao Y., Dai K., Zhu Z. Custom acetabular cages offer stable fixation and improved hip scores for revision THA with severe bone defects. Clin Orthop Relat Res. 2016 Mar;474(3):731–740. [PMC free article] [PubMed] [Google Scholar]

20. Mao Y., Xu C., Xu J. The use of customized cages in revision total hip arthroplasty for Paprosky type III acetabular bone defects. Int Orthop. 2015 Oct;39(10):2023–2030. [PubMed] [Google Scholar]

21. Wyatt M.C. Custom 3D-printed acetabular implants in hip surgery–innovative breakthrough or expensive bespoke upgrade? Hip Int. 2015 Jul-Aug;25(4):375–379. [PubMed] [Google Scholar]

2015 Jul-Aug;25(4):375–379. [PubMed] [Google Scholar]

22. You F., Eames B.F., Chen X. Application of extrusion-based hydrogel bioprinting for cartilage tissue engineering. Int J Mol Sci. 2017 Jul 23;18(7) pii: E1597. [PMC free article] [PubMed] [Google Scholar]

23. Levato R., Webb W.R., Otto I.A. The bio in the ink: cartilage regeneration with bioprintable hydrogels and articular cartilage-derived progenitor cells. Acta Biomater. 2017 Oct 1;61:41–53. [PMC free article] [PubMed] [Google Scholar]

24. Mouser V.H., Abbadessa A., Levato R. Development of a thermosensitive HAMA-containing bio-ink for the fabrication of composite cartilagerepair constructs. Biofabrication. 2017 Mar 23;9(1) 015026. [PMC free article] [PubMed] [Google Scholar]

25. Mouser V.H.M., Levato R., Bonassar L.J. Potential in the field of articular cartilage regeneration. Cartilage. 2017 Oct;8(4):327–340. [PMC free article] [PubMed] [Google Scholar]

26. Neufurth M., Wang X., Wang S. 3D printing of hybrid biomaterials for bone tissue engineering: Calcium-polyphosphate microparticles encapsulated by polycaprolactone. Acta Biomater. 2017 Dec;64:377–388. [PubMed] [Google Scholar]

Acta Biomater. 2017 Dec;64:377–388. [PubMed] [Google Scholar]

27. Park S.H., Choi Y.J., Moon S.W. Hree-dimensional bio-printed scaffold sleeves with mesenchymal stem cells for enhancement of tendon-to-bone healing in anterior cruciate ligament reconstruction using soft-tissue tendon graft. Arthroscopy. 2018 Jan;34(1):166–179. [PubMed] [Google Scholar]

Color 3D printing: some theory and practice

Technical

Subscribe to the author

Subscribe

Don't want

27

Briefly about RGB and CMYK color schemes. A little practice of mixing colors without a printer. We measure the color after mixing the plastics.

A bit of theory

Many are already familiar with the RGB scheme - it consists of three components, each of which is responsible for a certain part of the visible spectrum (red, green and blue). This scheme is more applicable to radiation sources in the visible spectrum. Depending on the spectrum and its level of radiation, we perceive the total radiation in the form of some kind of color. For example, if the spectrum of all three ranges is present in the radiation, then we see white. If the spectrum contains only red and green, we perceive it as yellow. Everything is simple here. nine0003

Depending on the spectrum and its level of radiation, we perceive the total radiation in the form of some kind of color. For example, if the spectrum of all three ranges is present in the radiation, then we see white. If the spectrum contains only red and green, we perceive it as yellow. Everything is simple here. nine0003

Now CMYK (the picture is taken from the same site) - many people are also familiar with this scheme. Only this scheme is no longer applicable to radiation sources, but to objects that reflect or absorb a certain part of the visible spectrum. These objects are all that we see around us in the presence of lighting. And, as we see it, it depends on the lighting. What is the fundamental difference? Yes, the difference is just in the difference ... Components C yan, M agenta, Y ellow, K ey color (Blac K ) actually describe the color that is obtained when a certain part of the radiation spectrum is completely absorbed. Cyan is a color that has no red component in its spectrum, i. e. There is only blue and green part of the spectrum. Magenta - the green part of the spectrum is missing. Yellow - the blue part of the spectrum is missing. The surface from which light is reflected absorbs part of the radiation, which goes into heating the surface of the object (most of it). Therefore, a black object (absorbs all radiation) heats up more than a white object (reflects all radiation) under the same illumination. nine0003

e. There is only blue and green part of the spectrum. Magenta - the green part of the spectrum is missing. Yellow - the blue part of the spectrum is missing. The surface from which light is reflected absorbs part of the radiation, which goes into heating the surface of the object (most of it). Therefore, a black object (absorbs all radiation) heats up more than a white object (reflects all radiation) under the same illumination. nine0003

Colored plastic contains dyes that are responsible for the absorption of one or another part of the radiation spectrum. If you mix two plastics of different colors, you get a third color. If you mix plastics with dyes that absorb red, green and blue radiation, you get black (ideally).

A bit of practice

For mixing, you need plastic of different colors, cut into pieces of the same length, for a more convenient conversion of the percentage of a particular color. You also need a manual “mixer” - a soldering iron with a clean tip and temperature control is suitable here. Well, in order to “measure” the color, you need a spectrophotometer, which will show what part of the white spectrum is reflected from the surface. I have an X-Rite ColorMunki Photo and use it. nine0003

Well, in order to “measure” the color, you need a spectrophotometer, which will show what part of the white spectrum is reflected from the surface. I have an X-Rite ColorMunki Photo and use it. nine0003

I must say right away that for proper mixing you need the “correct” CMYK plastics, and I don’t have them, so I took them from the BestFilament PLA 3D pen kit.

To begin with, I chose colors close to CMYK and checked their color. It was necessary to check all the colors, but I did not see the point in checking the color that I did not need.

The result can be seen on the pictures:

Here I checked the mixing of white and black - the result is expected. The result is an almost even (R, G, B almost the same) gray color. nine0003

Yellow - in theory there should be only R (203) and G (179) components, but we see the presence of a blue (47) component.

It was supposed to be magenta, but in practice we observe the presence of a green (93) component.

I thought that cyan is blue, but after reading a little and understanding it, I realized that it should be blue-green. Taking the blue plastic, you can see a good absorption of the red component. It's almost blue-green, only twice as much blue as green. nine0003

Now I'm trying to mix different not true CMYK…

It's almost done - I got green color, mixing yellow and not cyan, but blue.

Here I added all the colors and a little black - I got almost gray. Too much blue.

I added less blue - I got almost pure gray.

I mixed blue and pink and got some kind of blue.

Conclusions

- Mixing turns out - you have to try (measure the color) different plastics and look for real CMYK. nine0070

- Plastic makers will need to tinker a bit to get pure CMYK.

- If you learn how to mix plastics in the printer, you will need only CMYK and white in order to get a model of any color.

Here, in fact, not every color can be obtained. Yes, and all sorts of transparent and luminous plastics will be mixed in different ways.

Here, in fact, not every color can be obtained. Yes, and all sorts of transparent and luminous plastics will be mixed in different ways. - Color printing requires color calibration, ie. you will need to create color profiles for each combination of CMYK plastics. At least for different manufacturers of plastics. nine0070

Subscribe to the author

Subscribe

Don't want

27

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them.

/cdn.vox-cdn.com/uploads/chorus_asset/file/24096810/AirBell_Shopify4_2048x.jpg)