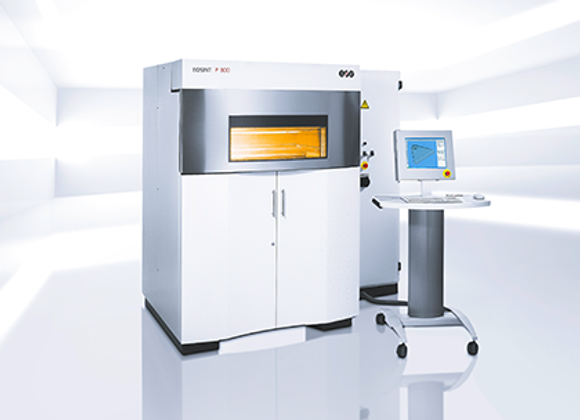

Eos printer 3d

Additive Manufacturing & 3D Printing Solutions

EOS is leading supplier for responsible manufacturing solutions via industrial 3D printing technology. With our innovative EOS 3D printers, we are leaders in technology and quality for high-end solutions in additive manufacturing (AM). Founded in 1989, we are pioneers in the field of metal 3D printing (DMLS) and providers of highly productive systems for additive manufacturing with plastics. Our portfolio also includes worldwide service and comprehensive consulting offers for additive manufacturing.

3D Printer for your Production

On Ariane program, we are combining our innovative strength with the expertise of EOS. Together, we work on the additive manufacturing of an injector head for a rocket engine. The results are impressive: Significant reduction in production time and 50 % lower costs.

Steffen Beyer

|

ArianeGroup

The enormous advantage of additive manufacturing is that we can always manufacture replacement parts that are as good as new, allowing us to keep our trains properly maintained for decades. We do not have to compromise on quality or performance. The cost is also lower than custom molds.

Florens Lichte

|

DB Fahrzeuginstandhaltung GmbH

With EOS’ industry-leading laser sintering 3D printing technology, Under Armour can deliver shoes to the marketplace in a meaningful way, creating truly amazing, desirable products which solve our customers’ needs in ways that could have never been imagined before. Together, our two organizations make a formidable pair.

Clay Dean

|

Under Armour

The 3D printed valve block has proven that additive manufacturing with EOS technology is feasible for building critical primary flight components.

Alexander Altmann

|

Liebherr-Aerospace Lindenberg

We believe EOS displays the maturity and the professionalism which we try to betray ourselves. We are not just a racing team, we are an engineering company. All our products, all our race cars are based on sound engineering decisions and we can see this reflected in EOS.

We are not just a racing team, we are an engineering company. All our products, all our race cars are based on sound engineering decisions and we can see this reflected in EOS.

Richard Brady

|

Williams Martini Racing

We’re only strong with our customers by our side and that’s why we focus on your success. Together with you, we are always working on topics of the future, further development of our additive manufacturing solutions, and the general answers that industrial 3D printing can provide to challenges from various industries, so that our technology can give you a truly competitive edge.

EOS is the right partner for manufacturing companies. We offer industry- and customer-specific solutions for complex challenges in industrial 3D printing. Our systems are robust and reliable, and they deliver consistent results even in the most demanding product environments. The components of our modularly structured portfolio of solutions are optimally coordinated with one another and can be combined according to your requirements. We help companies from a wide range of industries exploit the potential of 3D printing in the best possible way, for example in the medical, aerospace and tooling sectors, the industry, for lifestyle products, and in the automotive sector.

The components of our modularly structured portfolio of solutions are optimally coordinated with one another and can be combined according to your requirements. We help companies from a wide range of industries exploit the potential of 3D printing in the best possible way, for example in the medical, aerospace and tooling sectors, the industry, for lifestyle products, and in the automotive sector.

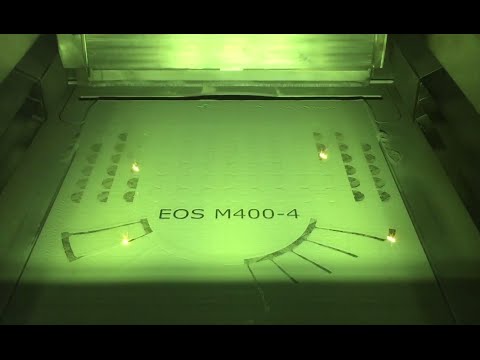

EOS EOS M 400 3D Printer

Properties

| Build Volume | 400 x 400 x 400 mm (15.8 x 15.8 x 15.8 in.) |

| Layer Resolution Low | 90 micron (0.0035 in.) |

| Layer Resolution High | 90 micron (0.0035 in.) |

| Brand | EOS |

| Machine type | 3D Printer |

| Technology | DMLS (Direct Metal Laser Sintering) |

| Materials | Stainless Steel 316L |

| Website | https://www. eos.info/systems_solutions/metal/systems_equipment/eos_m_400 eos.info/systems_solutions/metal/systems_equipment/eos_m_400 |

| Average Price | $750,000.00 |

Additive manufacturing system for the industrial production of high-quality large metal parts.

With a building volume of 400 x 400 x 400 mm, EOS M 400 allows the production of large metal parts on an industrial scale – directly from CAD data and with no need for tools.

Proven quality, high productivity

- Increased productivity due to 1 kW laser

- Reduced non-productive time due recoating from both sides

- Reduced filter costs due to new recirculating filter system with automated cleaning function

Modular platform

EOS M 400 consists of a Process Station and a Setup Station. This modular approach facilitates the easy integration of future innovations.

This modular approach facilitates the easy integration of future innovations.

Enhanced monitoring

Extensive monitoring features take quality management to a new level.

Sophisticated software

Job preparation and calculation is separated from the building process: the job file prepared at your desk is transmitted via the network; the system focusses entirely on building parts.

Improved usability

EOS M 400 supports the production of complex metal parts. Nonetheless, the system is extremely user-friendly. Quick and easy operation via a touchscreen.

Broad material portfolio

- EOS offers an increasing number of metal materials for the EOS M 400 system. With the corresponding ParameterSets, the system produces parts with standardized part property profiles (PPPs).

- The ParameterEditor enables you to modify parameters to meet your individual requirements.

3D printers EOS (Electro Optical Systems).

Industrial printers

Industrial printers Electro Optical Systems (EOS) is a German company considered one of the pioneers in the development of 3D technologies in general and additive manufacturing in particular. The brand was founded in 1989 and over almost 20 years of activity, the company has become a world leader in the production of SLS systems - selective laser sintering of metal powders used as a printing material on industrial EOS plants.

The SLS technology developed by the specialists of this brand is based on the use of a laser platform and a high power beam - today there are full-featured sintering systems for both powder metal alloy and plastic and even sand, which significantly expanded the range of applications for Electro Optical Systems printing machines.

The brand's industrial printers can solve various problems in such areas as the production of full-featured plastic parts for completing various products, the production of spare parts from thermoplastic materials, the sintering of polyamide materials, the production of parts and mold inserts from metal using tool and non-tool production methods.

The German company EOS (EOS) is considered the world leader in the field of 3D printing based on metal powder and plastic. By successfully applying the technology of laser sintering (SLS), using the equipment of this manufacturer, it is possible to obtain durable products that fully comply with the specified parameters. To guarantee high quality, the company supplies not only industrial 3D printers, but also all the necessary related materials for additive manufacturing.

Where and why you can use EOS 9 products0013

- To create a small-scale or piece object of complex geometric shape. Using 3D scanning, you can set the parameters of the future product.

- For the production of a prototype in the shortest possible time.

- For the production of parts by laser melting of metal powders. The result is solid and smooth 3D objects that do not need further processing.

All EOS equipment is professional, and finds its customers among the research centers of industrial organizations working in the field of aviation and space, mechanical engineering, medicine, dentistry and jewelry.

3DMALL offers EOS metal powder based 3D printers: PRECIOUS M 080, EOS M 100, EOS M 290, EOS M 400. The numbers in the model name indicate the printing area.

The largest machine in this series is the EOS M 400. In just a few hours, it can create a large 3D model. The high speed of the press allows to use this device for mass production. Modular design allows you to improve the printer with the integration of new developments. To get a modern model for 3D modeling, you do not need to completely change the apparatus.

EOS PRECIOUS M 080 is designed for precious materials. It is very easy to make 3D prototyping with this model, because the machine works with a wide range of precious metals, is of high productivity and quality.

Any of the above EOS models can be ordered with delivery in Moscow and Russia. In stock and on order there are professional models and products for beginners from the world's leading manufacturers TEVO, Imprinta, Concept Laser, BQ, Mass Portal and many others.![]() All of them work on modern technologies FDM, FFF, SLA, DLP, PolyJet. Delivery within Moscow time is free, within the Russian Federation it depends on the total amount of the order.

All of them work on modern technologies FDM, FFF, SLA, DLP, PolyJet. Delivery within Moscow time is free, within the Russian Federation it depends on the total amount of the order.

EOS M 100 3D Printer - Scientific Equipment

The EOS M 100 is a professional machine specially designed for powder raw materials. The technology of directed, direct laser sintering of metal melting within a hermetically sealed chamber guarantees minimization of base material waste, which significantly affects the cost of products.

The high-power laser that comes with this device guarantees the best quality of detail, which is of great importance for the additive manufacturing of high-precision products for various purposes. The stability of production quality is guaranteed throughout the entire printing cycle, and the economic efficiency of industrial production of metal products is ideal for serial replication of highly complex elements.

Features:

- Best detail settings.

- High quality resolution.

- Efficiency.

- Economy.

- Easy to use.

Media Types:

The EOS M 100 industrial machine is considered to be a multi-purpose machine, as it works with almost all the most popular types of powder metals, which allows it to be used in various industries, including science and research.

EOS Cobalt-Chrome SP2 is a finely dispersed biocompatible powder alloy that guarantees the creation of the most durable and reliable parts of various configurations, including those with complex geometries. Applicable in dental medicine.

EOS 316L stainless steel is a high strength and corrosion resistant alloy used in a variety of industries such as jewelry, watch parts, medical and surgical instruments, prototyping and modeling in the aerospace and automotive industries.

EOS titanium Ti64 (currently under development, research stage) is a biologically compatible alloy with high strength, anti-corrosion properties and low density, used for the production of implants, as well as parts, spare parts and components for various equipment, requirements for the mechanical stability of which are elevated.

Applications EOS M 100:

The EOS M 100 works in direct powder metal sintering technology, which guarantees high performance and economical consumption of base materials.

Medicine - production of high quality biocompatible implants, surgical instruments, templates.

Industry - production of high-quality, high mechanical strength parts with complex geometry.

Manufacture of clocks, decorations, jewelery - the cultivation technology based on metal sintering guarantees high precision in the reproduction of the smallest details.

Interface/Software options:

The machine comes with original software EOS RP Tools/EOSPRINT, designed specifically to improve the parameters of work with powdered metal alloys. The system is equipped with a large number of pre-installed protocols and allows the user to adjust the previously set parameters during the production process, which is very convenient for both beginners and professionals. The platform allows you to use different strategies for processing metals, depending on their class, physical and chemical properties. The user-friendly, practical and intuitive Ethernet system is used as the connection interface.

The platform allows you to use different strategies for processing metals, depending on their class, physical and chemical properties. The user-friendly, practical and intuitive Ethernet system is used as the connection interface.

| CHARACTERISTICS | VALUE |

|---|---|

| Print Technology | DMLS |

| Media | Metal powder |

| Print area, mm | 100×95 |

| Layer thickness, mm | 0.04 |

| Laser power, W | 200 |

| Laser type | Yb-fiber laser |

| Construction, µm | x=100, y=95 |

| Operating systems | Windows |

| Supported file formats | STL |

| Display | Touch |

| Connection interface | Ethernet |

| Software | EOSPRINT/EOS RP Tools, CAMbridge, Magics RP |

| Body material | Plastic, metal |

| Power supply, V | 200-240 V, up to 1. |