3D printed car oak ridge

3D printing off to the races

Blog

ORNL, NASA showcase Shelby Cobra and advanced manufacturing at Talladega

Topic: Clean Energy

When race fans convene on Talladega, the legendary motor speedway in Alabama the last weekend in April, they’ll have the opportunity to view a classic sports car turned into a 3D printed laboratory on wheels. The Shelby Cobra, produced by the Department of Energy’s Manufacturing Demonstration Facility (MDF) and National Transportation Research Center at ORNL, will be part of Talladega’s fan zone, a highlight of racing festivities April 26-28.

Race fans will have the opportunity to talk to researchers about how the Cobra was produced and learn more about the role advanced manufacturing plays in transportation. The Cobra is appearing at Talladega in partnership with NASA’s Marshall Space Flight Center. NASA has a keen interest in 3D printing, having deployed a 3D printer aboard the International Space Station and successfully produced a printhead faceplate to investigate how additively manufactured materials perform in space. NASA has qualified 3D printing to aid in the application of the thermal protection system for the powerful deep space rocket, Space Launch System.

ORNL has collaborated with engineers from Marshall Space Flight Center in Huntsville, Alabama, and used neutrons to help understand the potential benefit of printed rocket engine components. The team studied residual stress in additively manufactured materials to qualify them for flight.

Advanced manufacturing is integral to our nation’s supply chain, impacting transportation, aerospace, and even deep space exploration. It’s exciting to see how rapidly additive manufacturing is changing and becoming a mainstream technology.

- Lonnie Love, Corporate Fellow and group leader for ORNL’s Manufacturing Systems Research

“We look forward to celebrating the achievements that have been made in 3D printing by showcasing the Shelby Cobra at Talladega,” said Lonnie Love, Corporate Fellow and group leader for ORNL’s Manufacturing Systems Research. “Advanced manufacturing is integral to our nation’s supply chain, impacting transportation, aerospace, and even deep space exploration. It’s exciting to see how rapidly additive manufacturing is changing and becoming a mainstream technology.”

“Advanced manufacturing is integral to our nation’s supply chain, impacting transportation, aerospace, and even deep space exploration. It’s exciting to see how rapidly additive manufacturing is changing and becoming a mainstream technology.”

The 3D printed Shelby Cobra, driven by ORNL Laboratory Director Thomas Zacharia at DOE’s Manufacturing Demonstration Facility at ORNL.

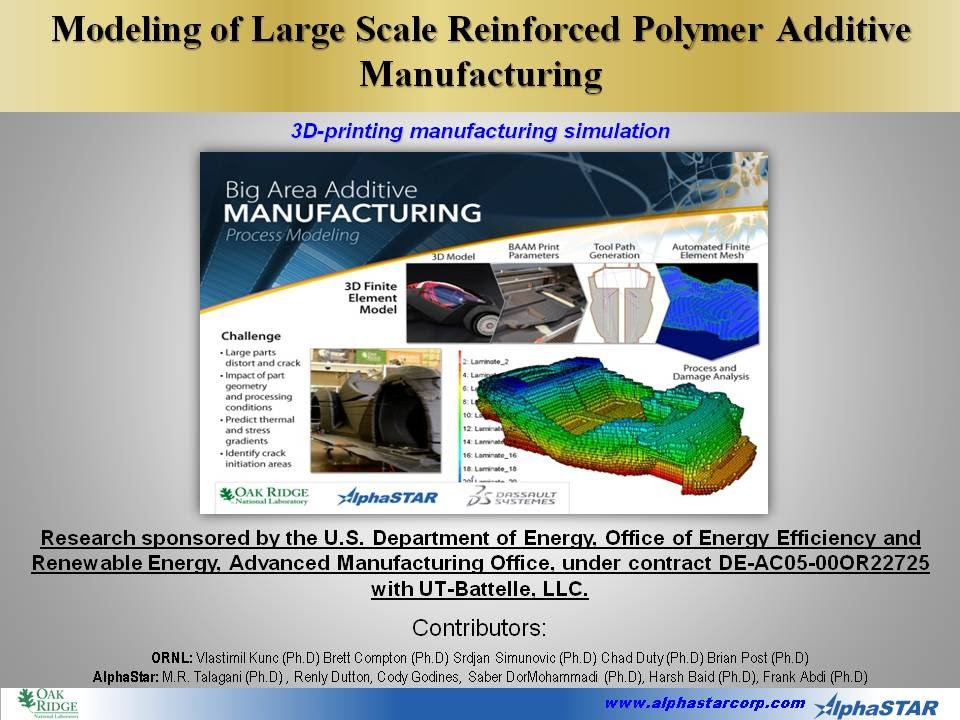

DOE debuted the Shelby Cobra in 2014. The car was the first large object 3D printed using the BAAM™ (Big Area Additive Manufacturing) system, a machine co-developed by ORNL and Cincinnati Incorporated, which produces lightweight composite parts without the need for tooling. The Cobra has a 3D printed chassis and an electric powertrain. Of the car's 1,400 pounds (635kg), roughly 500 pounds (227kg) was 3D printed out of a strong composite material that contains 20 percent carbon fiber.

Over the past few years, the Cobra has traveled around the world, appearing at international automotive and manufacturing shows in Europe and throughout the United States. However, this is the first time the car has appeared at a NASCAR speedway. While the Cobra won’t be on the track at Talladega, the vehicle has been driven by a racing legend, Bob Bondurant, who raced the Shelby Cobra in the 1960s. Bondurant visited ORNL in 2016 and took the 3D printed version for a spin.

However, this is the first time the car has appeared at a NASCAR speedway. While the Cobra won’t be on the track at Talladega, the vehicle has been driven by a racing legend, Bob Bondurant, who raced the Shelby Cobra in the 1960s. Bondurant visited ORNL in 2016 and took the 3D printed version for a spin.

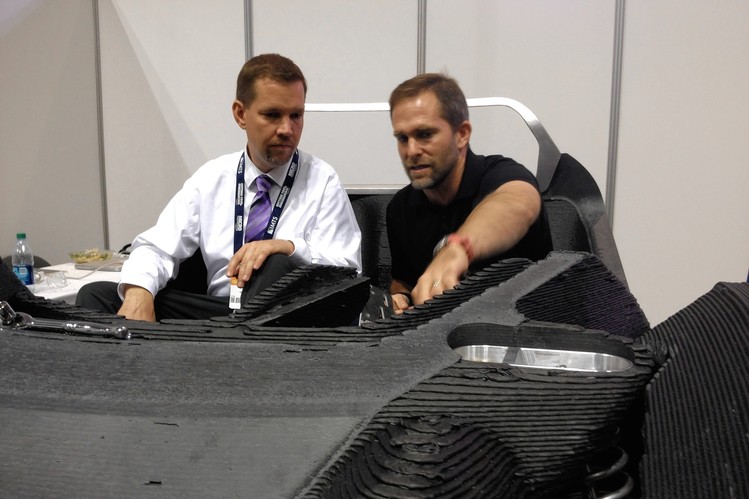

American racing legend Bob Bondurant visited the 3D printed version of the Shelby he raced in the 1960s.

Since printing the Cobra, ORNL has used BAAM™ technology to 3D print a utility vehicle, excavator, submarine, and boat mold and has installed a second BAAM™ at the MDF that enables rapid development of bioderived materials including poplar, bamboo, flax and cellulosic fibers.

The Manufacturing Demonstration Facility at ORNL is supported by the Department of Energy’s Office of Energy Efficiency and Renewable Energy, Advanced Manufacturing Office. AMO supports early-stage research to advance innovation in U.:quality(80)/images.vogel.de/vogelonline/bdb/1440700/1440794/original.jpg) S. manufacturing and drive U.S. economic competitiveness and energy productivity.

S. manufacturing and drive U.S. economic competitiveness and energy productivity.

ORNL is managed by UT-Battelle for the Department of Energy's Office of Science, the single largest supporter of basic research in the physical sciences in the United States. DOE’s Office of Science is working to address some of the most pressing challenges of our time. For more information, please visit https://energy.gov/science.

Media Contact

Related News

3-D Printing/Advanced Manufacturing

3D Printed Shelby Cobra | Department of Energy

Description

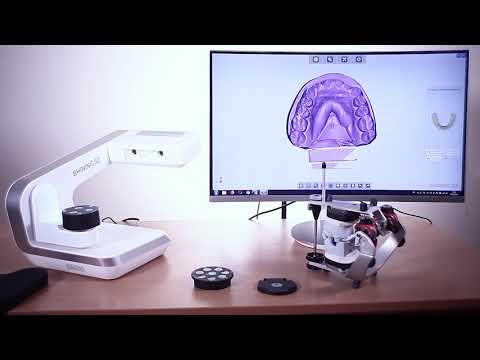

ORNL's newly printed 3D car will be showcased at the 2015 NAIAS in Detroit. This "laboratory on wheels" uses the Shelby Cobra design, celebrating the 50th anniversary of this model and honoring the first vehicle to be voted a national monument.

The Shelby was printed at the Department of Energy’s Manufacturing Demonstration Facility at ORNL using the BAAM (Big Area Additive Manufacturing) machine and is intended as a “plug-n-play” laboratory on wheels. The Shelby will allow research and development of integrated components to be tested and enhanced in real time, improving the use of sustainable, digital manufacturing solutions in the automotive industry.

The Shelby will allow research and development of integrated components to be tested and enhanced in real time, improving the use of sustainable, digital manufacturing solutions in the automotive industry.

Text Version

Below is the text version for the video 3D Printed Shelby Cobra:

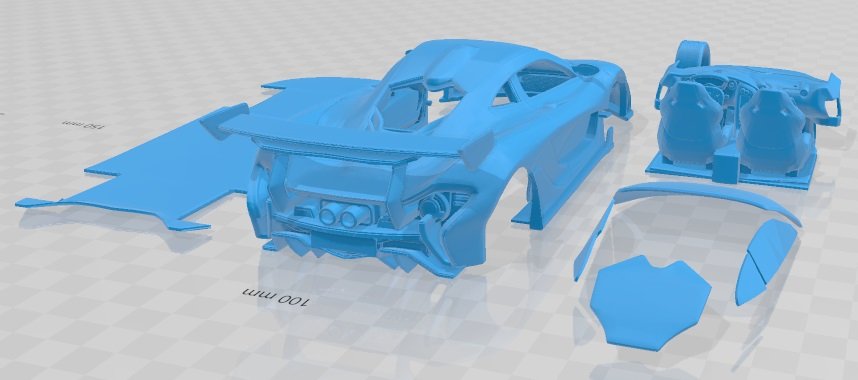

The video opens with a montage and time-lapse of 3D printing the car frame and parts, workers assembling the pieces, sanding and finishing the body, adding the motor and electronics, the motor, and displaying the final result: a Shelby Cobra in blue with white racing stripes.

LONNIE LOVE, PhD – Manufacturing Demonstration Facility: In a matter of six weeks to go from saying, “Hey, let’s print a car,” to actually having a working vehicle, which is unheard of. Six weeks is insane. What you’re going to see at the Detroit auto show is a car that’s going to shock people. It’s not going to look like a printed vehicle. It’s going to look like a real car. As a matter of fact it’s going to look like a real beautiful car.

On screen: Oak Ridge National Laboratory, Manufacturing Demonstration Facility

The Lab is not an auto manufacturer; we’re an auto innovator. We develop technologies that are going to go onto cars in 5 years, 10 years. Things like wireless charging, like lightweight power electronics, like new drivetrains.

On screen: video montage of testing apparatus for wireless charging, lightweight electronics in the vehicle, a vehicle on a drivetrain testing apparatus, and of the 3D printed cobra being assembled.

LOVE: So the reason that I believe that DOE’s Advanced Manufacturing Office got behind this was they saw that we didn’t just want to repeat what had already been done. We want to push the technology forward. So in a matter of six weeks not only have we developed a car, we’ve developed new technologies.

On screen: Caption that reads, "Energy Efficiency" and video of the car, in mid-production, being driven.

LOVE: Number 1, we quantified how much energy – how efficient this manufacturing process is. When you look at how much energy it takes to make a car, this is one of the most energy efficient ways to do it. It’s absolutely shocking.

When you look at how much energy it takes to make a car, this is one of the most energy efficient ways to do it. It’s absolutely shocking.

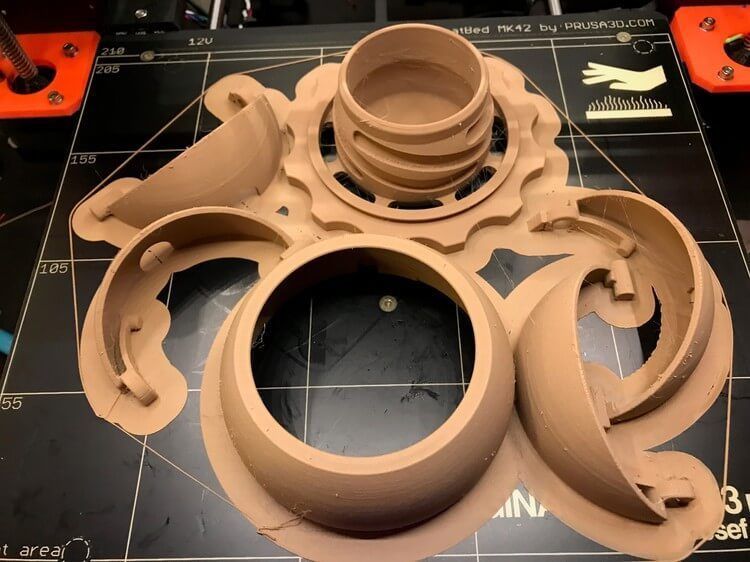

On screen: "Surface Finish" and video close-up of workers sanding, refining, bonding, and painting the surfaces of the 3D printed parts.

Number 2 is the surface finish. When you look at the parts as they come off of the printers, they’re relatively rough. And right now the body is out at a local company, True Design, and they’re for the first time starting to look at how do you really finish one of these printed bodies. They’ve really had to push the envelope on the chemistry of what paints, what bonding has to go on these materials to give you a really beautiful surface finish. So that was another thing that we’ve developed over the past six weeks is the processes to give you an extremely smooth surface finish not just for the Cobra but for the tools that can be used for the automotive manufacturing industry.

On screen: "Energy Absorption" and video displaying the 3D printed car mid-production.

Number 3 is the energy absorption. So can we design energy absorbing structures using additive we’ve never been able to do before.

On screen: "Speed" with fast-paced progression of images covering the entire process from 3D printing to final product.

And really to me number 4 the most important thing is just speed. The speed at which the national labs can work is absolutely amazing.

On screen: video montage of workers using a mold by laying down sheets of material, rolling on epoxy, and lifting the molded piece off the mold.

Another thing that we’re going to be highlighting and showing at the Detroit Auto Show is a mold. And typically these molds are made out of aluminum or steel. They’ll cost hundreds of thousands of dollars and take months to manufacture. And what we’ve shown is instead of taking months to manufacture, we’ve made a mold in about two days. Instead of costs of hundreds of thousands of dollars, it’s going to be thousands of dollars. It makes you just much more adept, much more nimble, and I think that you’ll see innovation just explode when this tool, these tools are in the hands of typical designers.

It makes you just much more adept, much more nimble, and I think that you’ll see innovation just explode when this tool, these tools are in the hands of typical designers.

On screen: video montage of production process of the 3D printed car, historical photos of sketches and clay models of prototype vehicles, and detailed view of the finished Shelby Cobra.

Are we going to be printing cars in the near future? And the answer is well I don’t know. Highly unlikely in the next in my lifetime we’re going to see mass production of printed vehicles, but the way we make prototype cars today is exactly the same way they made it thirty, forty years ago which is clay models. What we’re showing is we can go well beyond that now. You can go and print out a working prototype vehicle in weeks, in days and drive through the streets and look at people’s involvement, look at people’s excitement. You can test it for form, fit and function. So your ability to innovate quickly has radically changed. I think there’s a whole industry that can be built up around rapid innovation in transportation. And that again is revolutionary.

I think there’s a whole industry that can be built up around rapid innovation in transportation. And that again is revolutionary.

On screen: Logo of Oak Ridge National Lab; logo of U.S. Department of Energy

How long will it take to 3D print a car?

While there have been notable changes around 3D printing machines, it will be a long time before we enter the era of mass production. Most 3D printing projects are either prototypes or automotive parts. And despite significant advances in optimization, design, and sustainability, 3D printing technology is still not capable of printing an entire machine.

Photo. Custom car design (Source: Kristine Jayne Photography)

A car is a complex machine with hundreds of parts made from different materials. Therefore, for the purposes of this article, we will consider a car that has a fully 3D printed body, including most of its components and excluding basic functional elements such as wheels, chassis, and engine. With that in mind, let's look at a real world example of what to expect if you're going to "try it at home". Then we will briefly look at some of the factors that can affect print speed, and finally look at some interesting 3D printed machine projects to finally come to an answer to the question posed. nine0003

With that in mind, let's look at a real world example of what to expect if you're going to "try it at home". Then we will briefly look at some of the factors that can affect print speed, and finally look at some interesting 3D printed machine projects to finally come to an answer to the question posed. nine0003

On your own road

Photo. Dad printed a Lamborghini Aventador for his son (Source: Motor1.com)

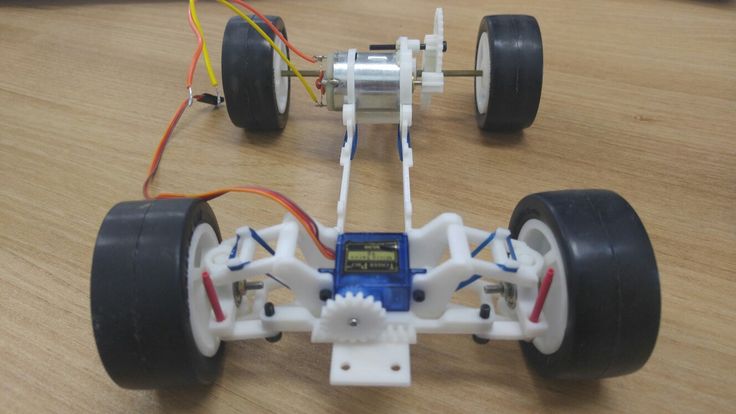

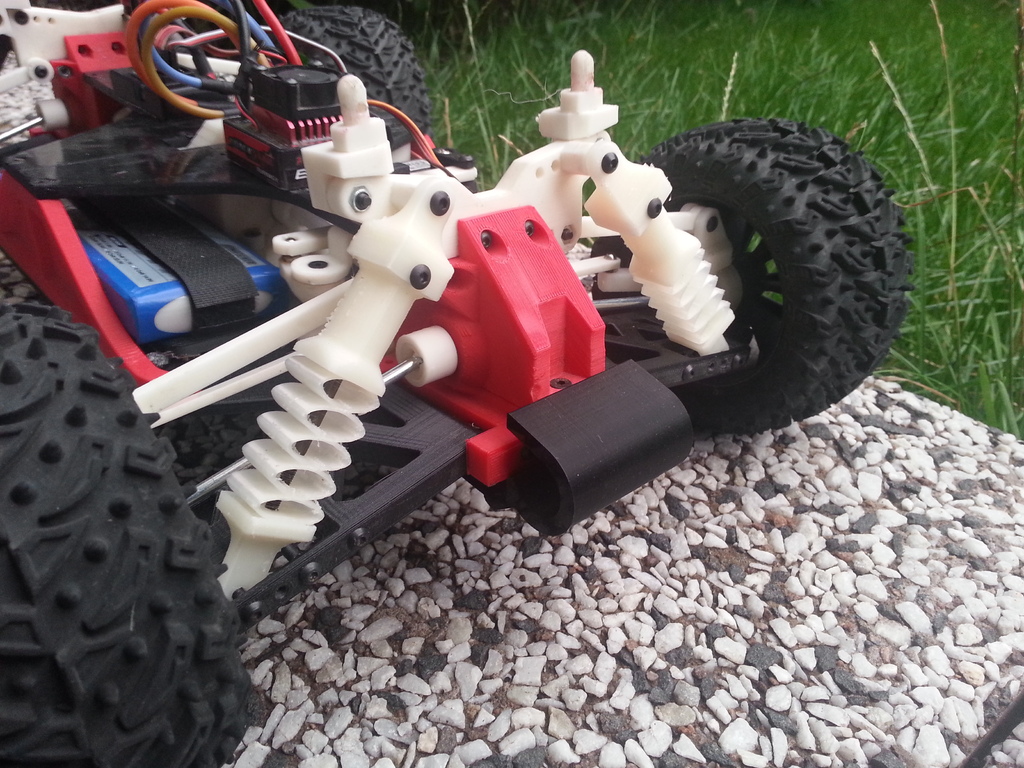

Sterling Backus wanted to create a project that could serve as an educational tool for STEM programs, and he made a copy of the Lamborghini Aventador after seeing his son drive such a machine in the Xbox video game. Mr. Backus called his $20,000 project "The Interceptor", hand-building the chassis and using a V8 engine to power the car. nine0003

First, Sterling found the panel layouts on an online forum and modified them for printing. For all his needs, Sterling used the Creality CR-10. He also admits that he has watched a sufficient number of informative videos on YouTube.

Photo. The project is coming together (Source: All3DP)

This project attracted so much attention on the Internet and in the media that Lamborghini gave Mr. Backus a real Aventador. nine0003

Read on to find out some factors that anyone interested in 3D printing a car will need to take into account.

Factors affecting print time

SIZE AND GEOMETRY

Let's start simple: the larger the machine, the longer the print time, as the extruder has to create more layers. Also, if the details are complex, longer print times can of course be expected.

SPEED VS QUALITY

We are all aware of this compromise in 3D printing. Since the quality of the print is largely dependent on the layer height, thinner layers mean better quality but have longer print times. Layers are adjusted in your slicer and are typically between 100 and 500 microns.

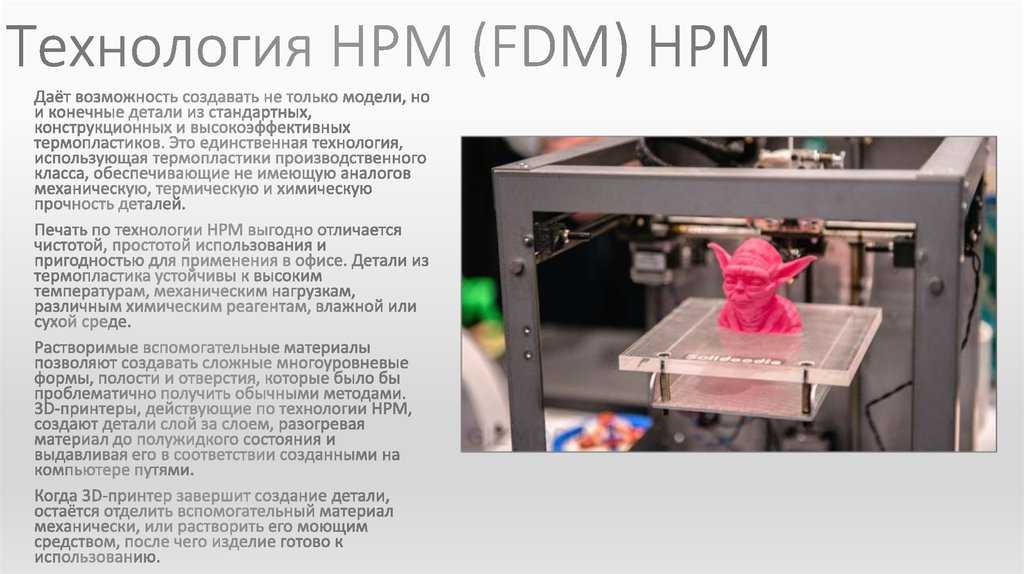

TECHNOLOGIES

Most of them will most likely use an FDM printer in cartesian or delta form. While both have their pros and cons, there is a general consensus that the delta versions are faster due to the smoothness of the movement. nine0003

While both have their pros and cons, there is a general consensus that the delta versions are faster due to the smoothness of the movement. nine0003

Vehicle #1: LSEV

Photo. LSEV is a promising 3D printed car (Source: Arch30)

The LSEV was supposed to be the first mass-produced car to be 3D printed. This car was expected to go on sale in late 2019 for $10,000, but we haven't received updates from the manufacturers yet.

The car is the result of a collaboration between 3D Polymaker and the Italian automaker XEV. It takes three days to 3D print all parts for the LSEV. nine0003

Unlike "regular" cars, which have more than 2,000 components, LSEVs only have 57. And with the help of large-format FDM technology and four different grades of TPU (thermoplastic polyurethane) and polyamide (commonly known as nylon), these two companies have been able to significantly reduce production costs.

- Manufacturers: Polymaker & XEV

- Used technology: FDM

- Print time: 3 days

Vehicle #2: Strati

Local Motors Strati 3D printing press with bright red seats (Source: Local Motors via Thingiverse)

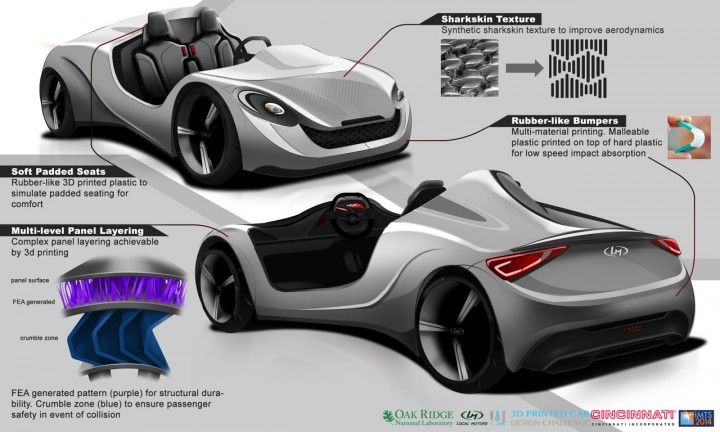

Strati was first displayed at the 2014 Chicago International Manufacturing Technology Show, which was attended by Local Motors , Oak Ridge National Laboratory (ORNL) and Cincinnati. It took 44 hours to 3D print the Strati, followed by three days of milling and assembly.

It took 44 hours to 3D print the Strati, followed by three days of milling and assembly.

Since then, ORNL has reduced print times to less than 24 hours and continues to do more research, hoping that a car can be printed in less than 10 hours. nine0003

Only the body of the Strati is 3D printed, not the mechanical components, but it's still a great showcase of the possibilities of 3D printing. The manufacturer claims that the Strati is the world's first 3D printed electric vehicle, and that 3D printing has been used for everything but "mechanically engaged" parts.

Manufacturers: Local Motors, ORNL and Cincinnati

- Technology used: FDM (BAAM)

- Print time: 24 hours (originally 44 hours)

Vehicle #3: Olli 2.0

Photo. Olli shuttle in action (Source: Local Motors)

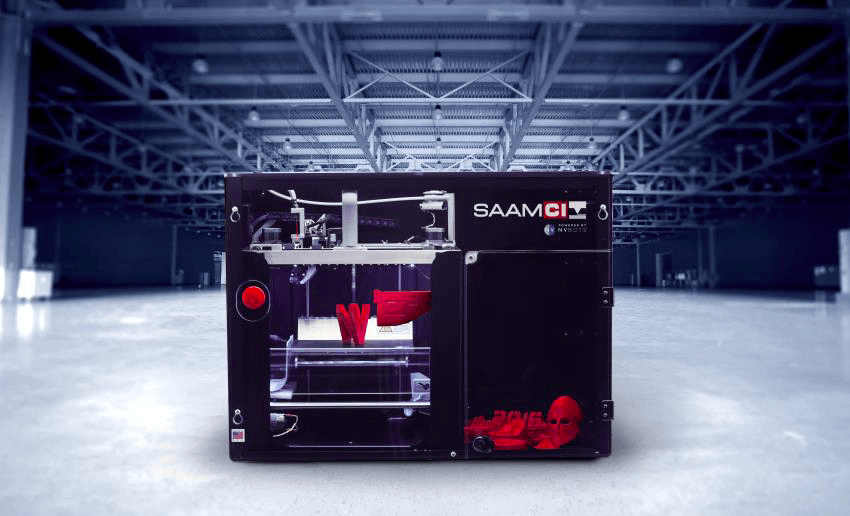

Local Motors, which first produced the Strati shuttle, later introduced the Olli, a 3D printed autonomous shuttle designed for high-speed transportation. The company used some of the largest 3D printers to manufacture most of Olli's components, including ORNL (BAAM) and Thermwood (LSAM).

The company used some of the largest 3D printers to manufacture most of Olli's components, including ORNL (BAAM) and Thermwood (LSAM).

Olli 1.0 debuted in 2016, followed by Olli 2.0 in 2019. Both share a lot of similarities and have Level 4 autonomous capabilities, which means they can drive a car on their own under certain conditions without any human assistance.

Unlike its predecessor, Olli 2.0 is 80% 3D printed, has a longer range per charge and comes with hub motors. Its user interface has also been significantly updated. nine0003

Since the introduction of this driverless electric bus, Local Motors has tested over 2,000 additive and printing material combinations. Olli 2.0 currently takes around 10 hours to print and assemble.

- Manufacturer: Local Motors

- Technology used: FDM (BAAM & LSAM)

- Print time: 10 hours

Vehicle #4: Shelby Cobra

Photo. Shelby Cobra 3D printed (Source: CincinnatiWeb via YouTube)

According to ORNL, the entire process of building the Shelby Cobra took six weeks. This included 24 hours of printing car parts, 8 hours of printing tool components, and 4 hours of bodywork.

This included 24 hours of printing car parts, 8 hours of printing tool components, and 4 hours of bodywork.

The machine was printed on a BAAM printer, allowing it to have strong, lightweight composite parts that are over one cubic meter in size. The 3D version of this classic car contains approximately 500 pounds of printed materials made from 20% carbon fiber. nine0003

- Manufacturer: ORNL

- Technology used: BAAM (FDM)

- Print time: 24 hours

Vehicle #5: The Urbee 2.0

Photo. The futuristic Urbee that never was (Source: Motor Lust)

This teardrop-shaped three-wheeler with two passengers was the brainchild of engineer Jim Core. He made the body using FDM technology and dreamed of a modern, environmentally friendly vehicle that would revolutionize movement. nine0003

Mr. Kor used the freedom of 3D printing design to combine several parts of this car into simple, one-piece shapes. Lightweight exterior design allows for minimal drag and fuel consumption. The car's plastic-and-metal exterior ended up being one piece, which, according to Mr. Cora, has a drag coefficient of just 0.15. Average modern vehicles have a drag coefficient between 0.25 and 0.3.

The car's plastic-and-metal exterior ended up being one piece, which, according to Mr. Cora, has a drag coefficient of just 0.15. Average modern vehicles have a drag coefficient between 0.25 and 0.3.

However, not all Urbee 2.0 was made using 3D plastic; important parts are still made of metal. The car is equipped with a 36-volt electric motor, which was used for most of its power, as well as an ethanol engine to increase speed. The Urbee 2.0 had a weight limit of less than 1200 pounds meaning it would technically be registered as a motorcycle and not a passenger car. nine0003

The Urbee was supposed to be the next big thing in urban transportation, but sadly we haven't heard much about it since it was first introduced in 2013.

- Manufacturers: Kor Ecologic & RedEye

- Used technology: FDM

- Print time: Approx. 100 days

How much time?

It's better to start small (Source: MacPlas)

Using the examples above as a guideline, we can offer a rough answer to the question: about 2 days. This is 48 hours to print the car body and its components, excluding post-processing that will need to be done in the finished car. nine0003

This is 48 hours to print the car body and its components, excluding post-processing that will need to be done in the finished car. nine0003

We also have to admit that 3D printing in general is getting faster and faster, and the same goes for our examples of 3D printed cars. Keep in mind that it took 44 hours for Strati to print in 2014, but this time has now been reduced to 24 hours, in the hope that it will be reduced to 10.

printing Urbee in 2003 took about 100 days. If we continue this trend, we can only guess that print times will decrease and you can probably print an entire machine in just a day. nine0003

(Lead image source: Siemens)

Source

-10, FDM Printer, LSEV, 3D Polymaker, TPU, Polyamide, Strati 3D, Local Motors, BAAM, Olli, Thermwood, LSAM, Shelby Cobr

A tale of how a toy frog helped make the leap to high tech.Part 2 Development and prospects

Beginning at Control Engineering Russia №4’17

The cherished dream of all developers of additive machines has always been metal. If not directly, then indirectly, one way or another, everything comes down to metal. And this is understandable. It is the metal part that is the “real” product, and not just a model, layout or “prototype” in varying degrees of approximation to the final product. Everyone wants a cherished end product with maximum added value. Machines that make metal parts are the pinnacle of engineering. The most advanced knowledge in metallurgy, laser technology, optics, electronics, control systems, measuring devices, mechanics, vacuum technology, etc. is concentrated here.

If not directly, then indirectly, one way or another, everything comes down to metal. And this is understandable. It is the metal part that is the “real” product, and not just a model, layout or “prototype” in varying degrees of approximation to the final product. Everyone wants a cherished end product with maximum added value. Machines that make metal parts are the pinnacle of engineering. The most advanced knowledge in metallurgy, laser technology, optics, electronics, control systems, measuring devices, mechanics, vacuum technology, etc. is concentrated here.

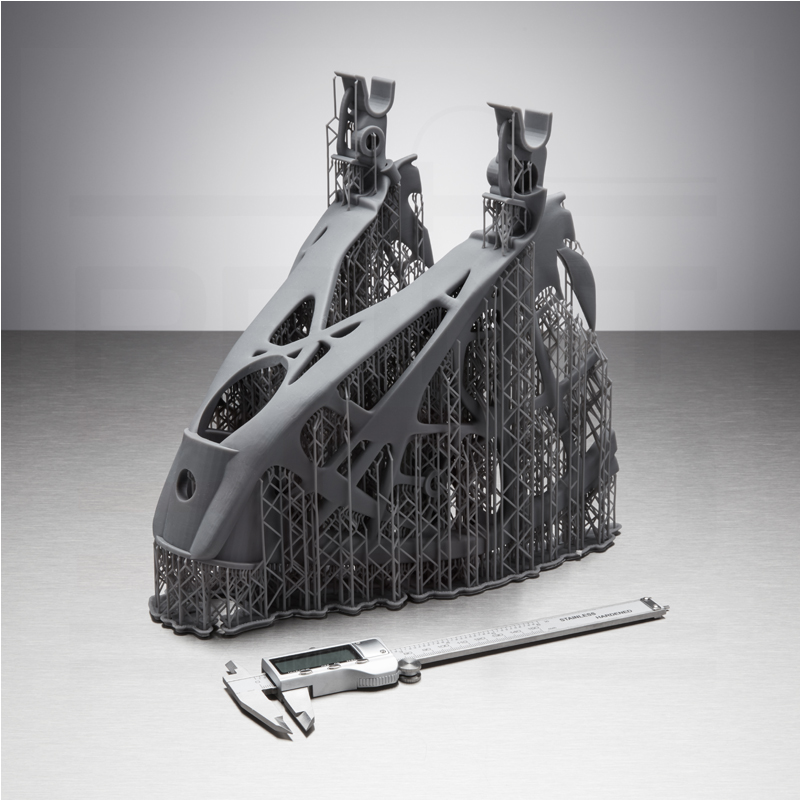

One of the first additive manufacturing technologies that made it possible to obtain a metal part immediately, without technological transitions, is selective laser sintering (English Selective Laser Sintering, SLS), sometimes called Direct Metal Laser Sintering (English Direct Metal Laser Sintering, DMLS). The formation of the finished product occurs by sintering any powdered material, which is subjected to melting under the influence of a laser beam. A uniform layer of initial powder is sprayed onto the printing platform, and with the help of laser radiation, it turns into a sintered, solid material. Then the movable base goes down to the thickness of one layer, and the operation is repeated again: applying the powder, sintering, lowering the base (Fig. 1). The melting process itself takes place in an environment without oxygen access, which avoids the oxidation of the resulting product. Over time, you end up with a hard, fused object buried in unused powder that can be easily scraped off. At first glance, this process resembles the technology of powder metallurgy, but it does not require complex equipment and therefore is a particularly advantageous solution for small batches of parts and products of complex shape. More complete information on this technology, or rather the entire set of "metal" technologies, is given in the NAMI publication [1] - we, as in the first part of this publication, will restrict ourselves to a review of what has already been achieved and what is possible.

A uniform layer of initial powder is sprayed onto the printing platform, and with the help of laser radiation, it turns into a sintered, solid material. Then the movable base goes down to the thickness of one layer, and the operation is repeated again: applying the powder, sintering, lowering the base (Fig. 1). The melting process itself takes place in an environment without oxygen access, which avoids the oxidation of the resulting product. Over time, you end up with a hard, fused object buried in unused powder that can be easily scraped off. At first glance, this process resembles the technology of powder metallurgy, but it does not require complex equipment and therefore is a particularly advantageous solution for small batches of parts and products of complex shape. More complete information on this technology, or rather the entire set of "metal" technologies, is given in the NAMI publication [1] - we, as in the first part of this publication, will restrict ourselves to a review of what has already been achieved and what is possible. nine0003

nine0003

Fig. 1. General functional principle of laser sintering technology

In fact, the powder is not melted - it is sintered, i.e. melted only on the surface to connect the layers. However, its complete melting is also possible, leading to the creation of more durable objects. This method is known as selective laser melting (eng. Selective Laser Melting, SLM), which will be discussed below.

Major patents expired in SLS in 2014, reducing equipment costs and allowing further improvements to the SLS process. Now the prices for industrial printers, on which molds for casting high-quality plastic parts are made using the SLS technology, start from ?100 thousand (hereinafter, the prices are given in accordance with [2]). nine0003

The problem with SLS technology is that more than 60% of the unused powder is usually wasted as its properties deteriorate after thermal shock. This impact occurs when fresh powder hits a freshly sintered area or is near the sintering zone. To reduce this loss, small objects can be printed in the hollow parts of larger objects. While this may take longer due to the need to efficiently sort and organize the component parts, the cost per print cycle can be reduced to a more reasonable level. nine0003

To reduce this loss, small objects can be printed in the hollow parts of larger objects. While this may take longer due to the need to efficiently sort and organize the component parts, the cost per print cycle can be reduced to a more reasonable level. nine0003

Printer manufacturer MarkForged has come up with another solution to this problem. It not only allows for efficient disposal of contaminated and spoiled powder, but also potentially maximizes part volume by combining the benefits of SLS and FDM printing. The object creation nozzle distributes the metal powder layer by layer, encased in a plastic binder. During the formation of the part, the intermediate structure is sintered. MarkForged's equipment allows the use of metals such as 6061 aluminum or Ti-6Al-4V titanium, making the company's technology suitable for joints that are subsequently welded onto tubes to create frame structures. MarkForged Metal X printer available for ?93,000 and is the most inexpensive laser sintering process equipment on the market.

Fig. 2. 3D printed titanium seat belt buckle is more expensive than the stamped version, but saves a lot of weight

In terms of materials, in 2014, EOS announced the creation of new metal materials for 3D printing, in particular EOS Titanium Ti64ELI titanium alloy . The abbreviation ELI stands for "ultra fine grain". This light alloy has high mechanical properties, is corrosion resistant, has a low specific gravity and is biocompatible. An example of a part printed from EOS Titanium Ti64ELI is shown in fig. 2.

EOS Titanium Ti64ELI can be machined, EDM, welded, micro shotblasted, polished and coated. And, importantly, the unclaimed powder of this material can be reused.

The mechanical properties of another printing method, SLM, are very close to those of the powder base material. This means that they can match the strength of cast or milled parts. The advantage of SLM technology is that it allows almost any shape to be printed, while cast parts usually require trade-offs due to metal casting features and machining limitations. But there is also a disadvantage: it is not possible to produce hollow closed parts with SLS/SLM technology, because then an opening must be provided to remove the remaining powder. nine0003

But there is also a disadvantage: it is not possible to produce hollow closed parts with SLS/SLM technology, because then an opening must be provided to remove the remaining powder. nine0003

Due to the respective properties of the base material as raw material and melt, the well-known aircraft manufacturer Airbus has decided to produce fasteners using SLM technology, which connect the cockpits to the main structure of the Airbus A350 XWB aircraft. The original fasteners were designed to withstand loads of 3400 kg with an actual load of 1700 kg. Parts made using SLM technology turned out to be 50% lighter, and during the test they broke only at a stress of 13,500 kg. Airbus does not disclose the level of costs that could be higher with SLM technology, but higher payloads or lower fuel consumption usually offset investments in lightweight aerospace structures. nine0003

In January 2017, Renault Trucks surprised its customers with an SLS version of the Renault Trucks DTI5 Euro 6 four-cylinder engine (fig. 3), which resulted in 120 kg, or 25%, lighter than its conventionally built engine. predecessor [3]. While both versions of the engine looked the same from the outside, their details, such as the rocker (rocker), clearly demonstrated how much the restrictions imposed by machining or casting processes can be discarded using SLS technology. nine0003

3), which resulted in 120 kg, or 25%, lighter than its conventionally built engine. predecessor [3]. While both versions of the engine looked the same from the outside, their details, such as the rocker (rocker), clearly demonstrated how much the restrictions imposed by machining or casting processes can be discarded using SLS technology. nine0003

Fig. 3. Version of Renault Trucks DTI5 Euro 6 four-cylinder engine made with SLS technology. Engine parts are printed in red. The picture on the right shows the old and the new (printed) valve rocker

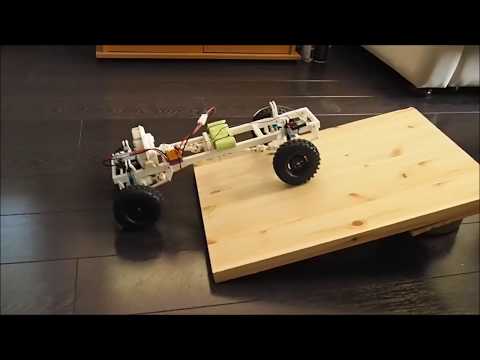

Another growing application for 3D printing is the production of tools. For example, FDM technology allows you to quickly create tools that require resistance to heavy loads. For example, Oak Ridge National Laboratory developed a cutting and drilling tool for the production of Boeing's 777X jet aircraft. Measuring over 5m long and 1.7m wide, this instrument has been listed in the Guinness Book of Records as the largest and strongest 3D piece. It takes just 30 hours to print, which compares favorably with conventional milling and finishing that took several months. nine0003

It takes just 30 hours to print, which compares favorably with conventional milling and finishing that took several months. nine0003

As for the technology of 3D printing of metal products, printers manufactured by InssTek Inc. successfully repair even military aircraft [4], in particular F-15K fighters, which are the main component of the South Korean air force. For this, DMT technology and the flagship Grand Teton 3D printer with a 5 kW ytterbium fiber laser are used (Fig. 4). The printer is capable of processing 2000×1000×1000 mm parts in 5/6 axes and repairs the turbine shell made of titanium alloy and the air seal made of cobalt alloy. The difficulty here lies not only in imprinting a new layer of metal, but also in achieving the same quality as the original metal. nine0003

Fig. Fig. 4. Grand Teton 3D printer (a) and control of the part restored on it (b)

Quality, reliability, safety and compliance with the specified technical characteristics of parts repaired using this technology were evaluated by the Korean Aerotechnology Research Institute (Korean Aero Technology Research Institute) and General Electric and InssTek. As a result, the manufacturer received a certificate and permission to use such parts without any prohibitions or restrictions. nine0003

As a result, the manufacturer received a certificate and permission to use such parts without any prohibitions or restrictions. nine0003

SLS and SLM technologies are also becoming increasingly popular in the medical field. For example, the manufacturer of orthopedic implants, Osteo Anchor, has already received awards and patents in connection with the development of a new surface texture for bone implants. 3D printing allowed them to create a serrated surface for cementless fixation of endoprostheses in arthroplasty, which better grips and better interacts with the bone. Implants are made as a single unit from the basic design, but custom variations can be easily made to give them greater biological similarity before printing. nine0003

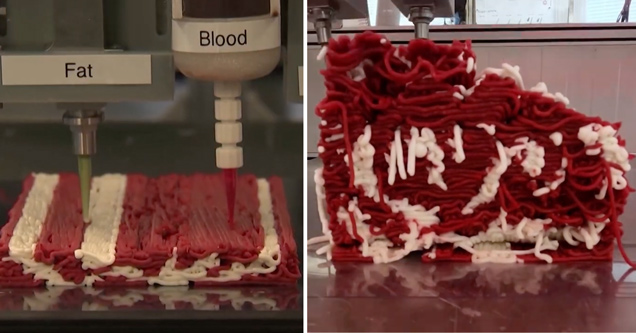

3D printing technology in the field of medicine related to living cells also promises truly incredible opportunities. In Israel, Nano Dimension, which is famous in the world of 3D printing for its pioneering technology for making complex electronic circuit boards, has entered into an agreement with biotech firm Accellta, which creates stem cell culture technologies. The purpose of the agreement is to conduct laboratory tests of a 3D bioprinter.

The purpose of the agreement is to conduct laboratory tests of a 3D bioprinter.

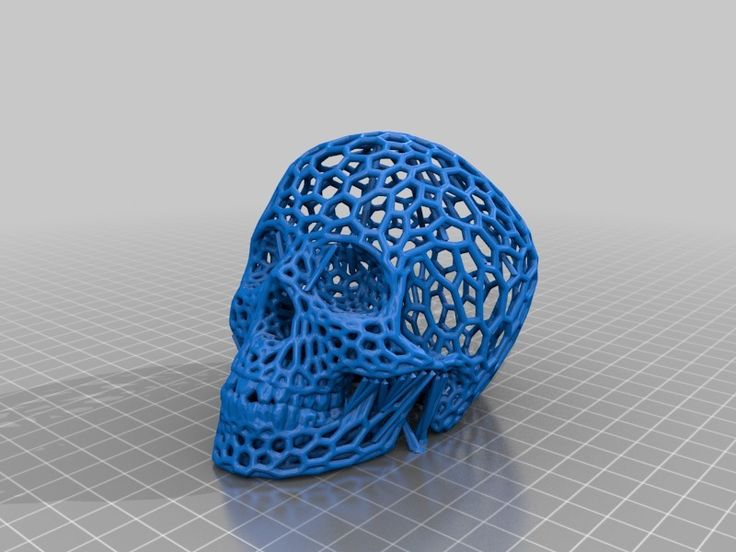

At the same time, bioengineers from the Wake Forest Institute for Regenerative Medicine (USA) have developed an unusual 3D printing technology that allows you to create full-fledged copies of individual bones, muscles and cartilage from stem cells. Until now, scientists have been able to print only very thin layers of living tissue (up to 200 microns) - otherwise the tissue began to die, since nutrients and oxygen cannot penetrate to such a depth without the presence of blood vessels. But in this case, they used a special polymer that allows them to lay the cells in layers and at the same time maintain a small gap between them. After printing, bioengineers place the organoid in a mouse, where it gradually “overgrows” with blood vessels, and the polymer decomposes, giving way to them. As a result, a full-fledged organ with the desired shape and all the necessary types of tissue appears at the site of the workpiece [5]. In addition, 3D models are already widely used for planning operations: a doctor can examine a complete three-dimensional copy of a patient's organ [6] (Fig. 5). nine0003

In addition, 3D models are already widely used for planning operations: a doctor can examine a complete three-dimensional copy of a patient's organ [6] (Fig. 5). nine0003

Fig. 5. Happy and healthy five-year-old Mia Gonzales shows a 3D replica of her heart, printed on a 3D printer from Stratasys, which accurately showed doctors a heart defect At first, the use of 3D printing in this area seemed impractical, since the layer-by-layer printing of an optical material led to a loss of its optical characteristics. The problem was solved by LUXeXcel, which drew attention to large-format inkjet printers and their adaptation for printing optical materials [7]. For each optical design, a project is created using CAD and printed out by a printer. Thanks to this approach, the range of equipment and tools that could be required for its implementation (casting machines, diamond cutting and polishing machines, equipment for grinding ingredients) is reduced. In addition, it does not require additional purchase of any tool kits with the need for their constant modification or replenishment. The print quality problem has been solved by using inkjet printers and very fluid materials, resulting in high precision optics with smooth surfaces. At the same time, the design of the optics can be of arbitrary shape, with combinations of different textures and optical elements, and its adjustment to specific requirements makes it possible to go beyond the elliptical (oval) or concentric formation of the beam from the emitter. Fig. 6. Carclo free-form 3D printed optics The optics are formed by a jet of a transparent, ultraviolet-curing polymer, which is sprayed in droplets with a resolution of 1440 dpi or more. The material used is polymethyl methacrylate or polycarbonate. Drops harden under the influence of radiation from an ultraviolet lamp placed on a piezoelectric print head. The surface is smooth due to the introduced delay between the jet exit and the application of the UV light - this allows an optical quality surface without any grinding and polishing requirements. What's next? Industrial technology continues to evolve. For example, Made In Space has developed and successfully tested a 3D printer capable of printing in a low-gravity vacuum environment. According to company representatives, now 3D printing will be possible not only on board the ISS (International Space Station), but also in outer space. The new high-tech 3D printer, known as The Zero-Gravity, will be the first step in space-based industrial manufacturing: it can use approximately 30 different materials to create finished 3D shapes. The presence of a 3D printer is an effective solution that will significantly improve the conditions of stay on the ISS. Now astronauts will be able to print the necessary tools, parts and other items on their own. nine0003 Another space achievement will be the launch of a lunar rover, a lunar rover developed by the Google Lunar XPrize contributors from Germany, which is preparing to launch two rovers and visit the lunar module landing site of the Apollo 17 mission [8]. Fig. 7. A 3D printed aluminium-magnesium-silicon lunar rover wheel held by PTScientists founder Robert Boehme materials that change the shape of an object in response to changes in light, heat, water, air pressure, and other factors. To do this, 3D printing is combined with shape memory materials. The MIT Self-Assembly Lab is already working with 4D-printed self-assembly molds made of programmable carbon composites [10]. And at the Livermore National Laboratory. E. Lawrence (Eng. Lawrence Livermore National Laboratory, LLNL) has developed a new technology that allows you to create complex figures on the principle of origami. It must be understood that 3D printing does not work on its own - in addition to the printer, you will need related software and certain skills. But it opens up great opportunities that are unattainable using traditional technologies, and most importantly, it reduces the time from the inception of an idea to the completion of a project. If you did everything right, then the part, depending on the complexity, will be in your hands in a couple of hours or days. With a ready-made prototype, it is much easier to make and justify decisions. The field of 3D printing is currently dominated by SLS/SLM technology, which offers the designer almost complete freedom, allowing the final product to be lighter in weight and have better strength characteristics than conventional technologies. It is also now possible to print completely dissimilar materials. Due to the fact that 3D printing technology has literally burst into various areas of the industry, as can be seen even in this overview publication, one problem has arisen with their use. Its reason lies in the fact that these technologies did not come from industry, as is usually the case. They were born outside of it and only after being mastered by amateurs and university students entered various industries [9]. At first, we can say that this played a positive role, since it did not limit the search for optimal options for the implementation and use of 3D printing, but over time, this turned from an engine into a brake. Each manufacturer went his own way, which led to a lack of common standards and some anarchy. nine0003 The American National Standards Institute (ANSI) together with NAMII (National Additive Manufacturing Innovation Institute) undertook to solve the problem of standardization, which implies the harmonization and compatibility of 3D printing and processes on a global scale. This publication has examined a number of aspects and demonstrated the effectiveness of 3D printing technology. Nevertheless, new technologies always need a balanced approach with an assessment of an acceptable level of investment and total costs. Perhaps, based on the amount of work, it will be more profitable for someone not to organize their own 3D production, but to use the services of specialized companies or, with the accumulation of certain experience, rent the necessary equipment. The purpose of this article was to show the history of 3D printing technology, its applications and opportunities. We hope it has been achieved. nine0003 Literature  nine0003

nine0003  Today it is already possible to print microstructures or Fresnel lenses, focus on spot lighting, perform light scattering, and finally add color or print prismatic structures (Fig. 6). nine0003

Today it is already possible to print microstructures or Fresnel lenses, focus on spot lighting, perform light scattering, and finally add color or print prismatic structures (Fig. 6). nine0003  Four-fifths of the lunar rover and some elements of the landing platform, created by the private space company PTScientists (Eng. Part-Time Scientists - "part-time scientists"), are made by 3D printing, including aluminum-magnesium-silicon alloy using Audi technology ( Fig. 7). Not long to wait for this mission, Falcon 9 rocketalready pre-ordered, and its launch is expected within two to three years.

Four-fifths of the lunar rover and some elements of the landing platform, created by the private space company PTScientists (Eng. Part-Time Scientists - "part-time scientists"), are made by 3D printing, including aluminum-magnesium-silicon alloy using Audi technology ( Fig. 7). Not long to wait for this mission, Falcon 9 rocketalready pre-ordered, and its launch is expected within two to three years.  Researchers already have 3D printed structures that can fold, unfold, or expand and contract in size as a result of electricity or heat. nine0003

Researchers already have 3D printed structures that can fold, unfold, or expand and contract in size as a result of electricity or heat. nine0003  Multi-color printing has already become common. nine0003

Multi-color printing has already become common. nine0003  additive manufacturing, USA) [11]. To speed up the development of standards, last year they created two initiative groups. Solving this problem will contribute to the development of the additive manufacturing industry. nine0003

additive manufacturing, USA) [11]. To speed up the development of standards, last year they created two initiative groups. Solving this problem will contribute to the development of the additive manufacturing industry. nine0003

Learn more