3D printers in melbourne

3D Printing Service | 3D modeling, scanning, printing.

Contact us using the form below for your FREE quote

Note: Model formats can be sent as .stl or .obj

Instant Quote

Professional Service You Can Trust

We are serious about 3D Printing. Originating from a background in Mechanical Engineering with a professional knowledge base in additive manufacturing, your part will be optimized completely - including slicing options and custom support material to ensure it comes out right first time, every time.

Various Printing Methods

Various objects require different types of printing methods. At Kad3D we recognise this and now offer a range of printing options to suit your part/model/invention

FDM (Fused Deposition Modelling): Plastic is melted and deposited layer by layer.

Advantages: Gives strength to parts, usable, affordable, fast turnaround

Example Uses: Replacements parts, end products, engineered components,

SLS (Selectve Laser Sintering): Powder bonded layer by layer via a laser

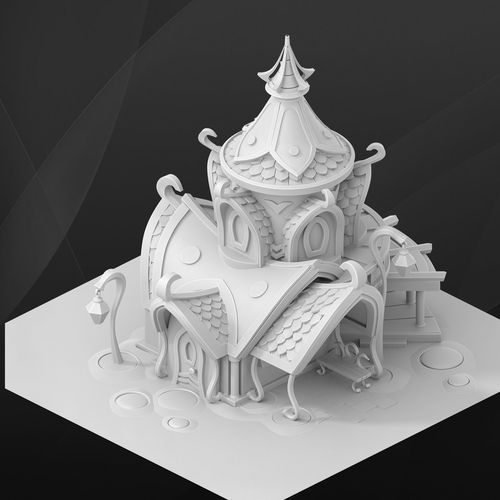

Advantages: Highly detailed static objects not under force

Example Uses: Architecture models, sculptures, figurines

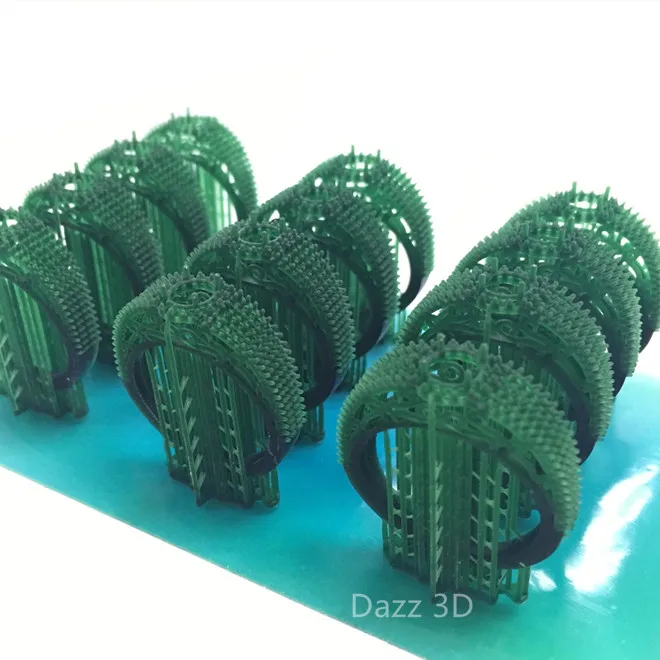

SLA (Stereolithography): Liquid resin cured via a laser and UV light

Advantages: Small and highly detailed intricate objects

Example Uses: Rings, jewellery, small figurines, highly detailed objects

Priority Printing

Time is valuable. We will strive to complete your model within the shortest amont of time possible.

Quality is our promise. If you are unhappy with your part or it falls out of tolerance, we will replace it.

Affordable

We can print your model or design for a fraction of the price as compared to other forms of manufacture.

If you're a student, take 20% off the entire printing service.

We can also repair the mesh of your model or give expert advice on the design to ensure it is capable of being 3D printed.

Lowest Shipping Costs Australia Wide

No matter where you are in Melbourne, if you can't personally pick up your model we will deliver it for a flat fee of $1 for registered post of $2 for express post

Professional

$1 Shipping

Quality

Guaranteed

Wide Range

Materials

Affordable

Quality Settings

We offer 3 quality options depending on your desired finish; high quality, standard quality and draft quality.

Since we quote based on time, you are now able to choose which print quality best suits your budget whether its a quick draft to check dimensions, a finished product to showcase or something in between.

Please note the default is set at 0.2mm (standard quality)

High Quality

0.1mm layer resolution

Printing Time: 3h 26m

Standard Quality (default)

0.2mm layer resolution

Printing Time: 1h 45m

Draft Quality

0.3mm layer resolution

Printing Time: 1h 11m

Printing Method FDM (plastics), SLS (powder), SLA (resin)

Material Options PLA (default), ABS, Nylon, Wood, Copper, Bronze, Rubber

Layer Resolution High (0.1mm), Standard (0.2mm), Draft (0.3mm)

Print Speed 80mm/s

Support Material Standard

Minimum Thickness 1.0mm

Maximum Build Dimensions 500mm x 500mm x 500mm (X,Y,Z)

Colour Please Specify

Specifics

Students, we understand the rush of uni and the strict time curfews those lecturers provide.

At Kad3D we're here to make your life that little bit easier by providing a fast turnaround time and a 15% discount* to all students.

1. Upload your model below to view your instant quote

2. Use your student email

3. Use the discount code STUDENT to receive 15% off your order.

4. Pay for your order and let us do the rest

If you run into any problems, please contact us using the contact form below

Students

Instant Quote

Click on the link below for an instant quotation for 3D printing.

If you're having trouble with our online quote system, please use the contact form below.

Instant Quote

Please be patient, model analysis may take some time

IMPORTANT:

For interstate users we charge a flat rate of $1 for registered shipping and $2 for express

Professional

$1

Shipping

Quality

Guaranteed

Wide Range

Materials

Affordable

Free Model Repair

If you are unable to submit your model or you see an ERROR please repair your design by clicking the link below.

This service will save you time by taking care of the many common errors in 3D designs to create a model capable of 3D printing.

Contact Form

If you would like to order a large quantity, have any questions about your model or need further assitance, please use the contact form below

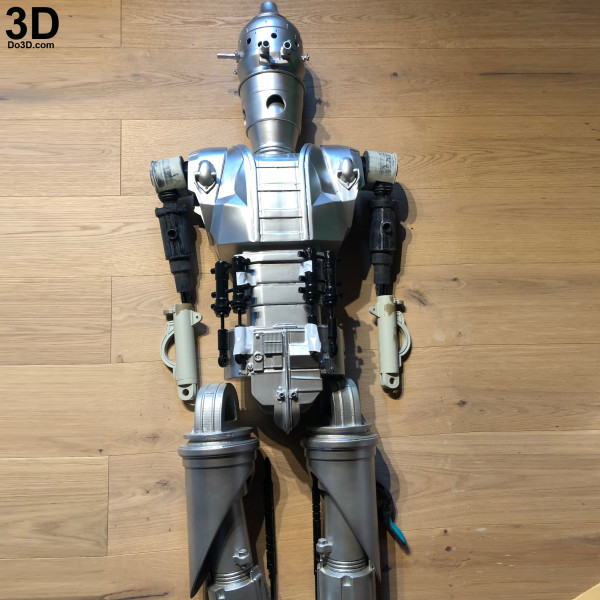

Unless specified, by submitting your file for printing you are allowing us to publish your work onto our social media accounts through the form of photographs uploaded to the KAD 3D Facebook and Instagram accounts. We will cite all work to the respective owners.

All uploads will be handled discretely with non-disclosure contracts available for innovative work.

Brisbane 3D Printing Service - FREE SHIPPING

3D Printing Masterclass

The idea of creating an object from thin air was fictional only to sc-fi movies and ideologists three decades ago. Now it’s real. 3D printing allows you to have your idea realized in a three-dimensional object through the process of additive manufacturing at an affordable price and in a short time frame. 3D objects are created by laying down thin layers of material in succession, one at a time until the object is completely built. The manufacturing industry is terming this technology as the “next industrial revolution” due to the many industries it can bring benefits into. One example being customized manufacturing on-demand by minimizing the need for ordinary industry processes, such as producing an object through an assembly line consisting of various small components. At Kad3D, we believe 3D printing is the future of manufacturing in Australia and every school, business or creative individual should have an understanding of this concept and how it works. Our values are quality, speed and customer satisfaction by providing 3D printing Brisbane services targeting all of Australia. Whether you need something 3D designed, 3D printed or looking to get into 3D printing, get in contact with us today and let us show you how we can help and the HUGE benefits this new industry brings to Australia.

3D objects are created by laying down thin layers of material in succession, one at a time until the object is completely built. The manufacturing industry is terming this technology as the “next industrial revolution” due to the many industries it can bring benefits into. One example being customized manufacturing on-demand by minimizing the need for ordinary industry processes, such as producing an object through an assembly line consisting of various small components. At Kad3D, we believe 3D printing is the future of manufacturing in Australia and every school, business or creative individual should have an understanding of this concept and how it works. Our values are quality, speed and customer satisfaction by providing 3D printing Brisbane services targeting all of Australia. Whether you need something 3D designed, 3D printed or looking to get into 3D printing, get in contact with us today and let us show you how we can help and the HUGE benefits this new industry brings to Australia.

1. Introduction

Typical forms of manufacturing are termed “subtractive” and require a solid piece of material to be cut away (mill, lathe, drill, cut) whilst 3D printing is termed “additive” in that material is added, layer by layer, until a part is created. 3D printing is the procedure by which a CAD (computer-aided design) model is used to create a three-dimensional model by laying down thin layers of material until an object is formed. Each layer represents a thin, flat cross-section of the specific CAD model adding up to make a 3D object.

2. Benefits

3D printing enables users to transform a thought/concept into reality in hours rather than weeks. Many industries have embraced 3D printing while innovative practices are emerging each day. Additive printing technology can provide numerous benefits both for individuals and businesses alike. Here are some of the most significant benefits that 3D printing provides:

Faster Production

3D printing is a lot faster than traditional manufacturing which includes injection moulds and subtractive production. That’s like comparing the speed of a sports car versus that of a horse. From a prototype to a final product, 3D printing tests ideas and designs quickly. Fast 3D printing allows for faster re-iterative testing and to provide the best fit for customers and consistent product evolution.

That’s like comparing the speed of a sports car versus that of a horse. From a prototype to a final product, 3D printing tests ideas and designs quickly. Fast 3D printing allows for faster re-iterative testing and to provide the best fit for customers and consistent product evolution.

Better Quality

Traditional manufacturing methods can easily result in poor designs, and therefore poor quality prototypes due to human negligence or error. 3D printing allows the step-by-step assembly of the object via CAD, which guarantees enhanced designs and eventually better quality objects.

Cost-effectiveness

Labor costs play a huge role in determining the amount of money to be spent on developing a prototype. Labor costs are also very high with conventional subtractive manufacturing. You need experienced machine operators and technicians to handle the production. Also, you have to pay these laborers and use expensive machinery. With 3D printing, however, labor can be as little as one person issuing a print command.

Tangible Design and Product Testing

3D printing allows you to test and retest due to fast printing ability to reach a perfect design. With 3D printing, it is possible to experience the touch and feel of the product prototype to physically test it and find flaws in the design. If a problem is found, you can modify the CAD file and print out a new version by the next day.

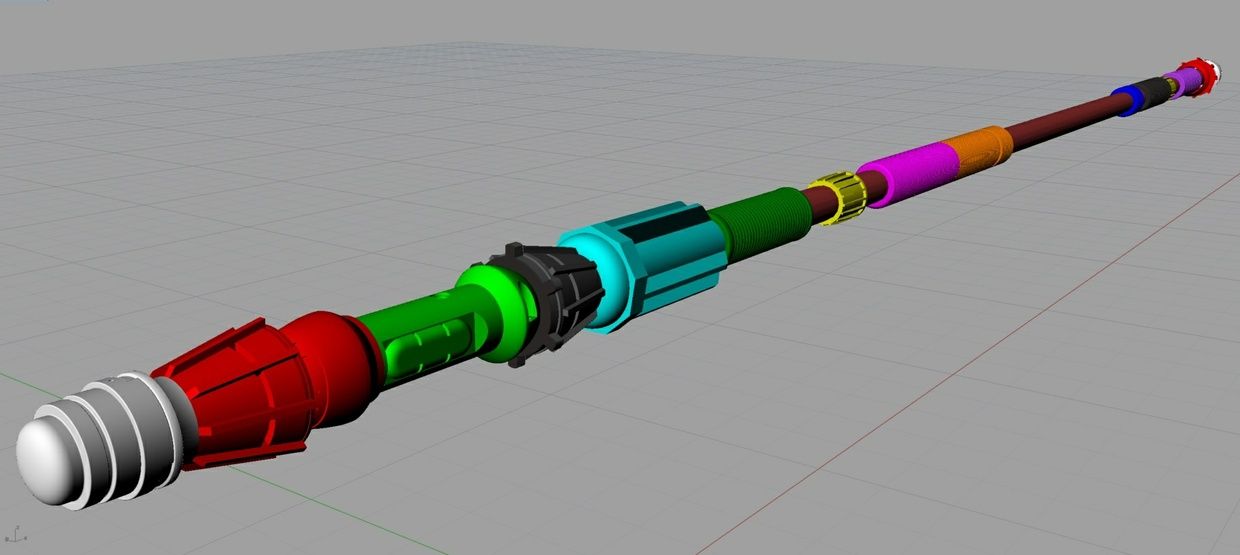

Creative Designs and Customization Freedom

Traditional manufacturing is good at creating millions of copies of the same thing Making each design unique with these techniques is extraordinarily hard.3D printing allows for endless personalization, which makes it much simpler to accommodate personal touches that are requested from customers. Users’ imagination is the only limitation.

Risk Reduction

When it comes to product manufacturing, a good designer knows that proper design verification is crucial before investing in an expensive molding tool. 3D printing technology enables product designers to verify product prototypes before starting on substantial manufacturing investments that can sometimes be disastrous.

Use of Miscellaneous Raw Materials

3D printing easily accommodates a diverse range of raw material including glass, metal, paper, ceramics, biomaterial, silver, etc.

Less Waste Production

Traditional manufacturing results in a lot of wasted resources. 3D printing only uses material that is needed to create a prototype part – no more, no less saving a company a lot of money.

Health & Safety:

Reduced health and safety risks if 3D printing can be used to produce assemblies that would otherwise need special equipment and precautions to be taken

Learning Environment:

Relatively a new technology in schools, 3D printing has the power to boost student engagement and interest.

Ultimately, though, it is a tool – much like a pottery kiln, a woodshop lathe, or a glue gun.

If it were possible for art students to simply download clay models and place them in the kiln, the learning would be very limited! A pottery kiln only has learning value in so far as it allows the student to end up with something tangible and creative from their design. What does 3D printing add that a pottery kiln, a woodshop lathe, or a stapler does not?

What does 3D printing add that a pottery kiln, a woodshop lathe, or a stapler does not?

3D printing takes a wholly abstract design (a 3D representation of an object in the form of a model) and makes it tangible very directly. Highly specialized handcrafting skills are removed from the process. The student need only learn the modelling process and understand a few constraints of the 3D printing process. This direct path from abstract to tangible also allows favors an iterative approach to prototyping. If the first print reveals a flaw or shortcoming in the design, the student can return to the 3D model and improve it before printing again.

3. Types of 3D Printing

Over time, various 3D printing techniques have been developed to build 3D structures and objects. These processes have advantages and disadvantages depending on the application they are applied to. Following is a list of the most common technologies used in 3D printing today:

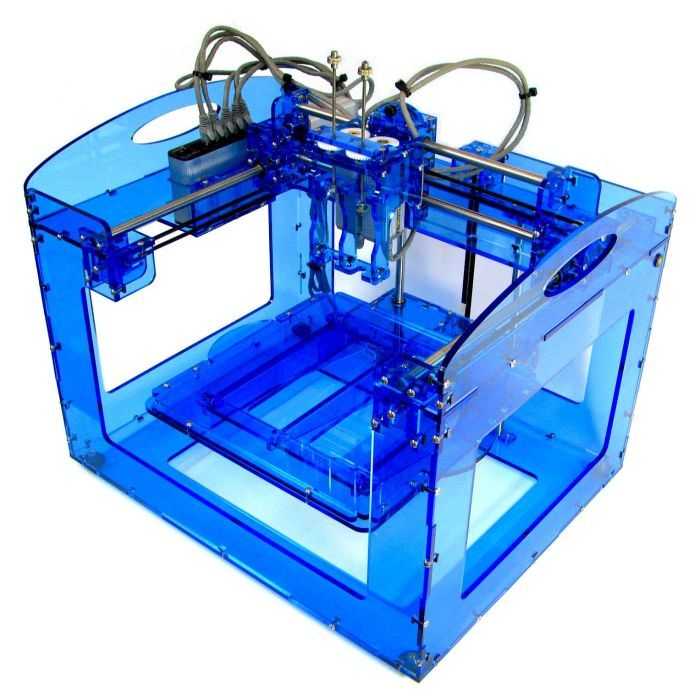

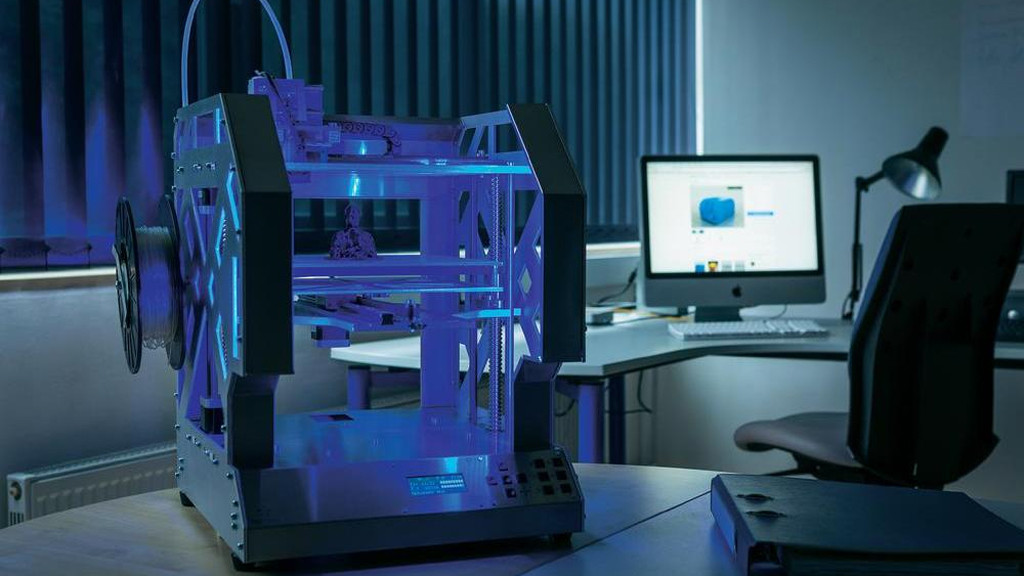

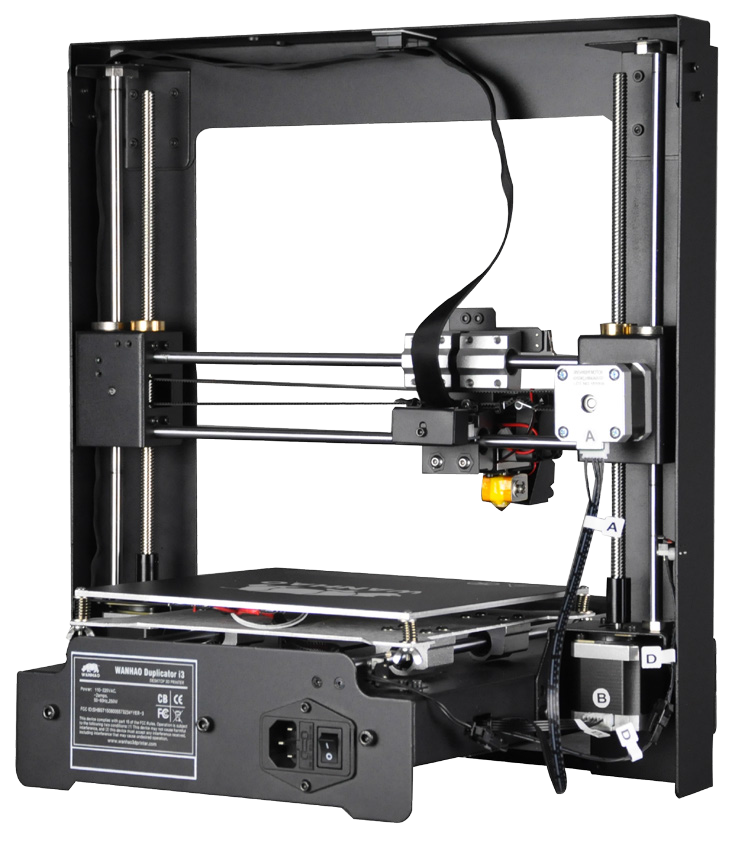

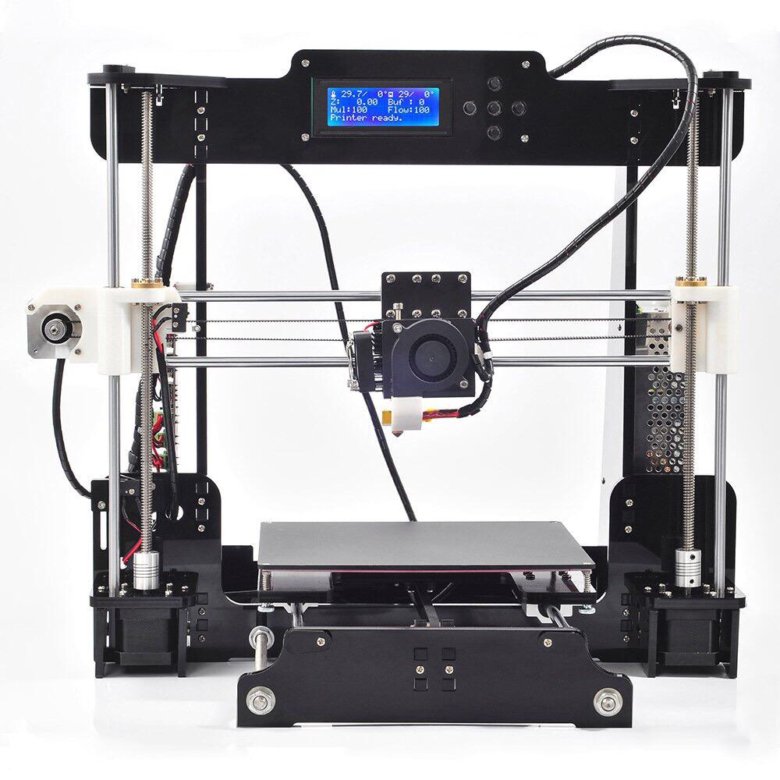

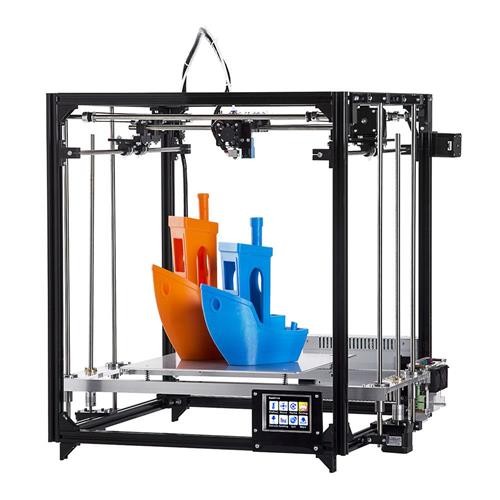

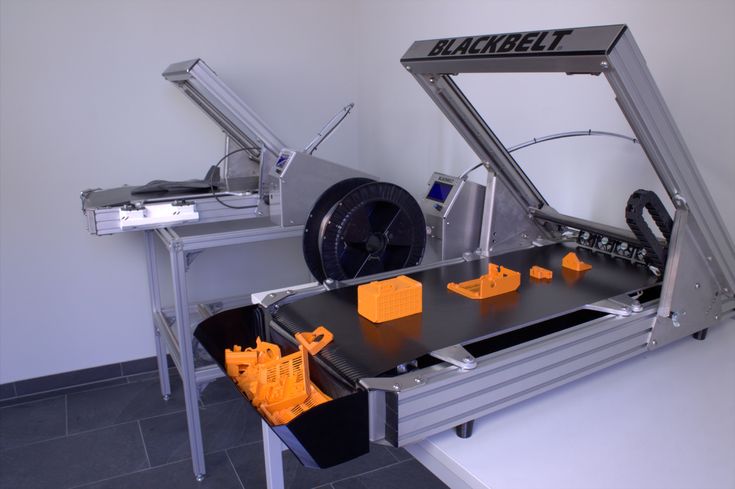

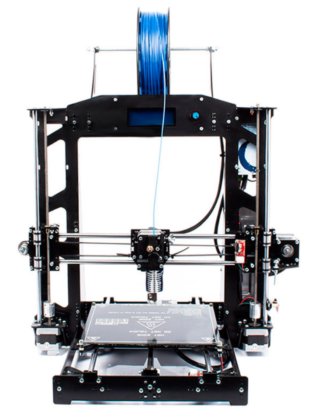

Fused Deposition Modelling (FDM)

FDM (Fused Deposition Modeling) is currently the most popular 3D printing technology and used in both affordable 3D printers and even 3D pens. 3D printers that use FDM Technology construct objects layer by layer from the very bottom up by heating and extruding thermoplastic filament. FDM is the only 3D printing technology that uses production-grade thermoplastics, so items printed have excellent mechanical, thermal and chemical attributes.

3D printers that use FDM Technology construct objects layer by layer from the very bottom up by heating and extruding thermoplastic filament. FDM is the only 3D printing technology that uses production-grade thermoplastics, so items printed have excellent mechanical, thermal and chemical attributes.

Selective Laser Sintering (SLS)

During SLS, tiny particles of plastic, ceramic or glass are fused by heat from a high-power laser to form a solid, three-dimensional object. SLS is mostly used by manufactures instead of 3D amateurs at home as this technology requires using high-powered lasers, resulting in these printers being rather expensive.

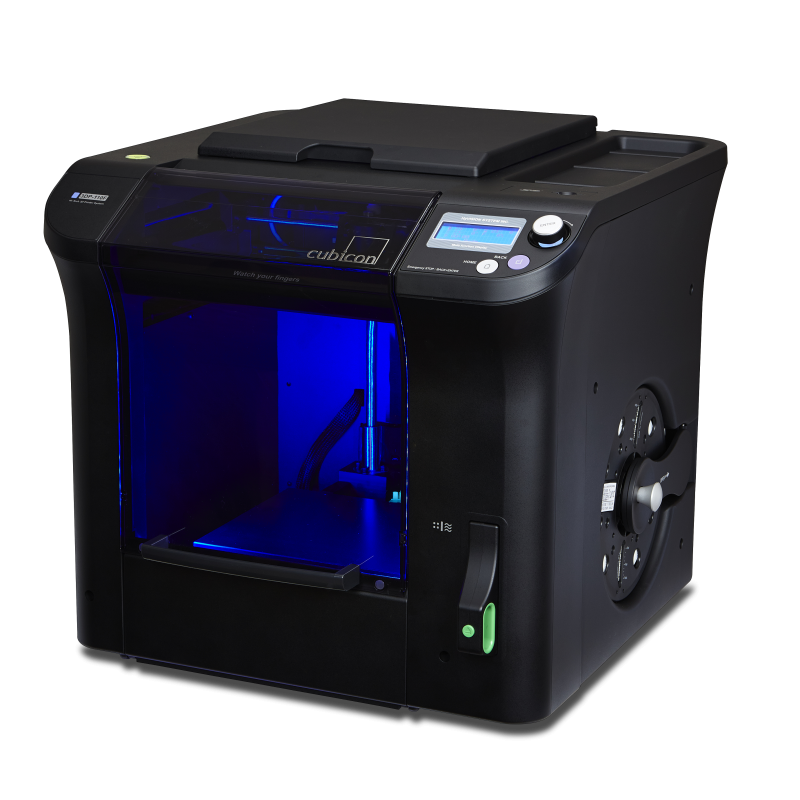

Stereolithography (SLA)

This process is the earliest one in the history of 3D printing, it is still in use today. It works by using a high-powered laser to harden liquid resin that is contained in a reservoir to create the desired 3D shape. SLA printing machines do not function like normal desktop printers that extrude some quantity of ink to the surface. SLA 3D printers operate with an excess of liquid plastic that after a while hardens and forms to a solid object.

SLA 3D printers operate with an excess of liquid plastic that after a while hardens and forms to a solid object.

PolyJet (JETTING)

A PolyJet 3D printer works similar to an inkjet printer. Instead of jetting drops of ink, the printer jets drops of photopolymer that solidifies when exposed to UV light. These layers accumulate on the build tray until the part is complete.

Metal Printing

Metal 3D printing is also becoming common now because of the extensive use of metal items. Metal 3D Printing is a laser-based technology that uses powdered metals. Similar to Laser Sintering, a high-powered laser selectively binds together particles on the powder bed while the machine distributes even layers of metallic powder.

4. Owning a 3D Printer

3D printing has the potential to be part of the solution to many personal and business challenges on a global scale. If done right, buying a 3D printing for your home can be a modest contribution to these efforts. Some of the reasons why consumers should consider buying a 3d printer are as follows:

Some of the reasons why consumers should consider buying a 3d printer are as follows:

Save Money

Users can save a lot of money by creating almost everything from smartphone cases to paper towel holders, reducing household expenses while adding a personal customized touch to their home.

Create Unique and Personalised Objects

3D printing can help users create unique accessories and customized gifts for their friends and family.

Quick Design Iterations

With a 3D printer, users don’t have to go through the waiting time for their products to arrive since they can almost build any personalized product.

Education

3D printing is very interesting for children as it proves very helpful in educating them. Children can practically see a product building which helps them grasp different manufacturing processes.

Environmentally Sustainable

This is probably the biggest advantage of 3D printing since it uses very little raw material and results in a minimal amount of wastes. In this way, 3D printing proves very beneficial for environmental sustainability.

In this way, 3D printing proves very beneficial for environmental sustainability.

5. 3D Printing Service Brisbane

At Kad3D we offer a hassle-free 3D printing service in Australia. Simply upload your 3D model through our quotation system, choose your material, quality, and choice of colour to receive your FREE INSTANT QUOTE. Also, we offer $7 shipping Australia wide for your order and guarantee to have it 3D printed fast, 3 days to be exact. If you need it in a hurry choose our fast 3D printing option (priority) and have it completed in 24 hours. Our services stretch Australia wide and we 3D print Sydney, Melbourne, Perth and Adelaide. If you require a 3D model to be designed, get in contact with us and we’ll help you realize your idea into a reality.

6. Glossary

ABS

Acrylonitrile butadiene styrene plastic is used in common products such as Lego.

CAD

An abbreviation for the term Computer-Aided Design used to describe a 3D model developed using computer modeling software. Examples are Solidworks, Google SketchUp, Autodesk Rhino, etc.

Examples are Solidworks, Google SketchUp, Autodesk Rhino, etc.

extruding

In 3D modelling, the technique of “pulling” the face of a 2D shape upwards or outwards, so that it becomes a 3D prism.

FDM

Fused Deposition Modelling printers are the most common type of 3D printer in schools, due to their relative affordability. FDM printers melt plastic filament and lay the melted plastic row-by-row, layer-by-layer to build up an object.

g-code

The list of instructions for a 3D printer to print an object.

model

A digital 3D object before it is printed into a real object. The process of designing such an object on a computer or tablet is called modeling.

PLA

Polylactic acid plastic is a plant-based polyester. It is recommended for 3D printing in schools due to showing much lower particle emissions compared to ABS plastic.

SLA

Stereolithography. A 3D printing method whereby resin is cured using a UV light layer by layer until an object is formed. This is usually done upside down using a tank full of liquid resin.

This is usually done upside down using a tank full of liquid resin.

SLS

Selective Laser Sintering involves printers using a large bed of powder and a laser to solidify layers until a 3D model is formed in a bed of powder, typically nylon.

slicing

The process where 3D printing software analyses the geometry in a model and prepares a list of instructions for a 3D printer to print the object. The list of instructions is stored as a g-code.

Most consumer 3D printers ship with proprietary software that incorporates slicing just before printing.

.stl file

A computer file with the extension STL. Each STL file stores the 3D geometry for a model. It is by no means the only file format for storing 3D geometry, but it is very common in the 3D printing world.

tolerance

In engineering, extra space between two parts (eg. a shaft in a hole) to allow for different kinds of movement.

3d printers. Overview of achievements in 2013 / Sudo Null IT News

Prostheses for humans and animals, 3D printing of space structures, food and shoes, improved printing accuracy, new materials, new software.

A bunch of projects on crowdfunding platforms.

Well, pistols, where would we be without them.

China, Japan, Australia, USA, Netherlands, Africa and Haiti, 3D printing seems to be everywhere in the world.

In 2014, 3D printing will go into space.

(Review of achievements in 3D printing 2012 here)

We read what we achieved for 2013 under the cut ( 54 photos ).

January

The Chinese printed a 5 -meter whole spare part for the aircraft from Titan

more pictures

The laser 3D printer

Technology of selective laser sintering in the action of

Parts are smaller than

. 3d printed

Hackerspace BioCurious offers a do-it-yourself bioprinter based on HP 5150 inkje

(the first inscription where instead of ink is "E. coli")

coli")

The European Space Agency is conducting experiments to build a shelter on the moon using a 3D printer

one and a half ton building block

February

A team of scientists from Scotland, for the first time, using a 3D printer, print three-dimensional tissue from stem cells

Article PDF

3D printed Urbee 2 is ready for production

change the way we make most things in a different way”

In February, there was a buzz with 3doodler, a 3D pencil that can “draw in the air”.

In just a few hours, they raised over a million dollars on Kickstarter.

Articles on Habré about this:

With the 3Doodler pen, you can draw three-dimensional objects directly in the air

Our answer is 3doodler. Assembled in 20 minutes

3Doodler is in a hurry to you! (Bonus: clone review)

In November, the "pencil" was delivered to Russia - the first (and last) review

Scientists printed an artificial ear

original article

Nike presented the world's first boots printed on a 3D printer

4D printing. Self-transforming objects

Self-transforming objects

TED 4D Printing Video

March

The government of Singapore intends to invest $500 million in the development of the 3D printing industry.

3D printing makes it possible to create low-cost implants taking into account the anatomical features of patients

83-year-old inventor won $40,000 in a competition for his "do-it-yourself" extruder

April

Oxford University scientists say their 3D printer is capable of creating materials with some of the properties of living tissue0018

A 3D scanner capable of obtaining images from a distance of 1 km has been created

The Chinese government intends to invest $6.5M in the development of 3D printing technologies

GE prints fuel injectors for aircraft engines in two days

Printed ear capable of capturing radio frequencies

NASA awarded a $125K grant to develop a 3D food printer for astronauts who will fly into deep space

Saved life to the child, printing the trachea

NASA plans to send a 3D printer for the ISS in August 2014

The Japanese printed a carbon bunny the size of a

Chinese showed the largest detail for a combat aircraft, printed on 3D Printing Printing Printing Personnel 9000

June

British government invests £14. 7m in 3D printing projects

7m in 3D printing projects

'artificial bone' made from polymers 22 times stronger than composite component

Microsoft built support for 3D printers in Windows 8.1

A foot was printed for a wounded duck

July

MIT develops software that makes it easier to work with composite materials

British children will learn robotics and 3D printing from the age of 5

Telegraph article

August

3D printed rocket engine passed NASA test, which was the starting point for many innovations to reduce the cost of spare parts production

Melbourne scientists have proposed a technology that allows you to grow your own cartilage for the knee joint from stem cells using a 3D printer

MIT scientists have developed a lightweight structure, the smallest details of which can be 3D printed and assembled like a Lego constructor. The intended use is in the construction of aircraft, spacecraft, dams and bridges.

The world's first full-scale architectural installation Echoviren

September

Breakthrough technology - printing with dissimilar materials, both organic and inorganic materials: ceramics, metal, plastic and even biological cells

Developers from Disney introduced software that will allow you to create and print mechanical toys on a 3D printer

$100 3D printer - The Peachy Printer0003

Scientists from the Netherlands using a 3D scanner and 3D printer created reproductions of paintings by Rembrandt and Van Gogh

October

UK provides £500K grant to equip 60 schools with 3D printers

HP plans to enter the 3D printing market in mid-2014

Scientists have discovered that natural components (vitamin B2) can be used in the 3D printing process to create implants

Haiti has a 3D printer

Microsoft came up with a technology that can turn any smartphone into a 3D scanner

November

A program for encrypting 3D models was released

Gelatin bioink for printing organs

The world's first fully metal 3D printer 9008

Scientists printed 20 layers of liver tissue that lived for 40 days0003

Metal desktop 3D printer

Progress in the manufacture of lithium-ion batteries using 3D printers.

Batteries can now be smaller than a grain of sand and thinner than a human hair. They can be used in implants and insect robots.

December

$1,500 metal 3D printer

BioPen surgical 3D printer lets you “print” tissue during surgery

Epson President: "There is no big future for plastic 3D printing at home"

Total Z industrial 3D printers

FDM and SLS 3D printers, drying and post-processing equipment

About company

FDM 3D printers

Industrial 3D printers Total Z PRO series

450-PRO 950 PRO

Total Z High Performance LPRO Series 3D Printers

1000-PRO-LL

Total Z G3 Series Desktop 3D Printers

250-G3 250-G3 (2X) XL250-G3(2X)

Total Z G5 Series Desktop 3D Printers

G5

SLS 3D printers Total Z

SLS-250

Portal systems for 3D printing with granules

Total Z AnyForm FGF

Total Z machines for drying and post-processing

Total Z D5Vacuum drying chambers

Help prepare plastic for printing. Remove moisture from hygroscopic materials. Reduce the risk of plastic "boiling", extruder breakage, deterioration of the surface quality of the product.

Remove moisture from hygroscopic materials. Reduce the risk of plastic "boiling", extruder breakage, deterioration of the surface quality of the product.

Watch →

Total Z MPC-310Acetone baths

Equipment for chemical post-processing of finished objects. Helps to achieve a glossy and smooth product surface.

Watch →

Total Z UB-450; 500; 650; 950; 1200;Ultrasonic baths

Machines for physical and chemical post-processing of models. Remove the supporting plastic from the surface of finished products. They clean the material in places inaccessible for manual processing.

See 5 models →

Our capabilities

The equipment complies with Russian and international standards

Consumables for printers and equipment are always in stock

We participate in R&D, cooperate with research institutes

We work with defense enterprises and government customers

Operational warranty service

Departure and training on the territory of the customer

Implemented projects by industry

Aviation industry and special products

Supply of an industrial 3D printer for the project of the MS-21 passenger aircraft of Irkut Corporation.

Supply of high-temperature 3D equipment for the laboratory of additive technologies of VIAM.

Supply of a 3D printer for printing with experimental materials for the production of the Central Institute of Aviation Motors.

Shipbuilding

Selection of samples of engineering plastic for the project of printing body elements for a shipyard.

Auto industry

Supply of equipment for 3D prototyping to the plant of the AvtoVAZ group.

Rocket and space

Supply of the first production equipment for 3D printing to the Center for Additive Technologies of JSC RCC Progress.

Foundry

Fabrication of a matrix using FDM 3D printing for the production of piece metal parts that have been discontinued or to replace parts with a long delivery time.

Education

Production of a desktop 3D printer for schoolchildren and students in collaboration with a team of developers of teaching materials for classrooms.

Electronics

Implementation of 3D equipment at the Simvol East Kazakhstan region.

Prototyping of lighting equipment for the Pyaterochka grocery store chain.

Agroprom

Complex equipping of the research agro-engineering center with equipment.

Aviation industry and special products

Supply of an industrial 3D printer for the project of the MS-21 passenger aircraft of Irkut Corporation.

Supply of high-temperature 3D equipment for the laboratory of additive technologies of VIAM.

Supply of a 3D printer for printing with experimental materials for the production of the Central Institute of Aviation Motors.

Shipbuilding

Selection of samples of engineering plastic for the project of printing body elements for a shipyard.

Auto industry

Supply of equipment for 3D prototyping to the plant of the AvtoVAZ group.

Rocket and space

Supply of the first production equipment for 3D printing to the Center for Additive Technologies of JSC RCC Progress.

Foundry

Fabrication of a matrix using FDM 3D printing for the production of piece metal parts that have been discontinued or to replace parts with a long delivery time.

Education

Production of desktop 3D printers for schoolchildren and students in collaboration with a team of developers of teaching materials for classrooms.

Electronics

Implementation of 3D equipment at the Simvol East Kazakhstan region.

Prototyping of lighting equipment for the Pyaterochka grocery store chain.

Agroprom

Complex equipping of the research agro-engineering center with equipment.

Services

3D printing

Casting

Reverse engineering

prototyping

Upcoming Events

New models of Total Z industrial 3D printing systems in Moscow at the Interplastica exhibition

Interplastica is a key event for the plastics and rubber market, which annually brings together experts from all over the world at one business platform.